display GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 99 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual92

Wheel

General tire balancing procedures

Clean out the accumulated dirt and debris from the inside of the rim.

Warning:

The gravel on the tread must be eliminated to avoid flying out and injuring the operator when

undergoing rotational balancing. This is also a good way to acquire better balance. First thoroughly

inspect the tire's damaged condition, then according to the balancing device manufacture's

recommendations, carry out the balancing operation.

Off-vehicle balancing

Most off-vehicle balancers are more accurate and convenient than on-vehicle rotational balancers. They are

also able to perform dynamic (two sided) balancing. Although it does not correct drum brake and brake disc

imbalance like on-vehicle balancing, it achieves the same effect based on its accuracy.

On-vehicle balancing

On-vehicle balancing is different based on equipment and tool manufacturer. Therefore, when performing

balancing operations, be sure to comply to each manufacturer's operating\

instructions.

Warning: Control the wheel rotation speed to make sure the speedometer stays within 55 km/h.

This restriction is necessary because when a driven wheel slides while the other one stays still, the

speedometer will display only half of the actual wheel speed. When a wheel is sliding, be extremely

careful, because sliding wheels can reach very high speeds. This may lead to the tire rubber peeling

or differential damage, which may cause serious personal injury, or damage to the vehicle.

Tire installation and removal

• Install or remove tires with a tire changer. When operating machinery, make sure to comply to the machine

manufacturers operation manual. Please do not change tires merely with manual hand tools or tire installation

crowbars. This will damage the tire chafer or the vehicle wheel's rim.

• Use a wire brush or coarse steel wool to clean off grease and old rubber, as well as light rust or corrosion from

the rim tire bead's tire chafer seat. Before tire installation or removal, first use the indicated tire lubricant to

thoroughly lube the tire chafer portions one time.

• After installing the tire, inflate it to the specified pressure and make\

sure the tire bead is properly seated.

Warning: Do not over-inflate the tire. If the tire bead severally expands and exceeds the safety limit,

it may burst and cause serious personal injury. While inflating, do not exceed the specified pressure.

If the specified pressure does not allow the tire bead to sit properly, deflate the tire, re-lubricate, and

then re-inflate.

Spare tire usage

• Spare tire standard inflation pressure: 420 kPa.

• Spare tire pressure measurements should be taken under normal temperatur\

e conditions.

• After inflating the spare tire, soapy water should be used to check if the air nozzles core is leaking air, then

lock on the air nozzle cap.

• The spare tire should always be kept in a useable state. Check the air p\

ressure at least once a month.

• When the spare tire's working limit, indicated by the remaining pattern's depth, reaches 1.6 mm (and its pat-

tern groove bottom protrudes to the same level), for your safety, please stop using the spare tire.

Caution:

• The "" symbol on the tire bead of the spare tire in-

dicates the set position of the wear index (shown on

the left).

• The spare tire's maximum driven speed is 80 km/h,

and maximum distance 200 km per trip.

• Each vehicle is allowed to use only one spare tire.

• The spare tire is only used as a temporary backup.

Please go to a professional service station immediately

to get the initial tire repaired or replaced.

Page 176 of 281

Downloaded from www.Manualslib.com manuals search engine 169Vehicle Body Electronic System

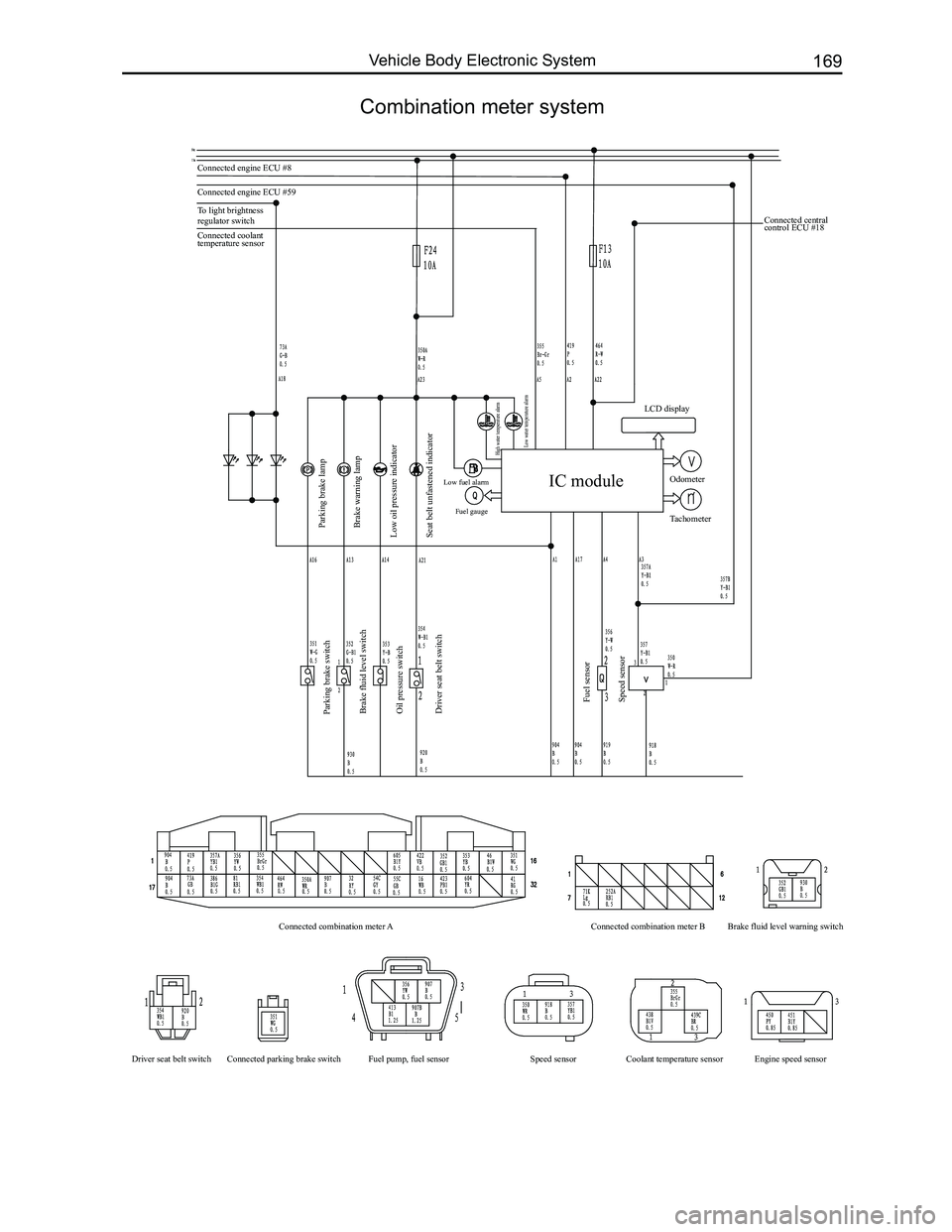

Combination meter system

Connected engine ECU #8

Connected engine ECU #59

To light brightness

regulator switch

Parking brake lamp

Parking brake switch

Brake fluid level switch

Oil pressure switch

Driver seat belt switch

Fuel sensor

Speed sensor

Connected combination meter A

Driver seat belt switch Connected parking brake switch Fuel pump, fuel sensor Coolant temperature sensor Engine speed sensor

Speed sensor Connected combination meter B

Brake fluid level warning switch

Brake warning lamp

Low oil pressure indicator

Seat belt unfastened indicator

Low fuel alarm Fuel gauge

High water temperature alarm

Low water temperature alarm

Connected coolant

temperature sensor Connected central

control ECU #18

IC module

LCD display

Odometer

Tachometer

Page 185 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual178

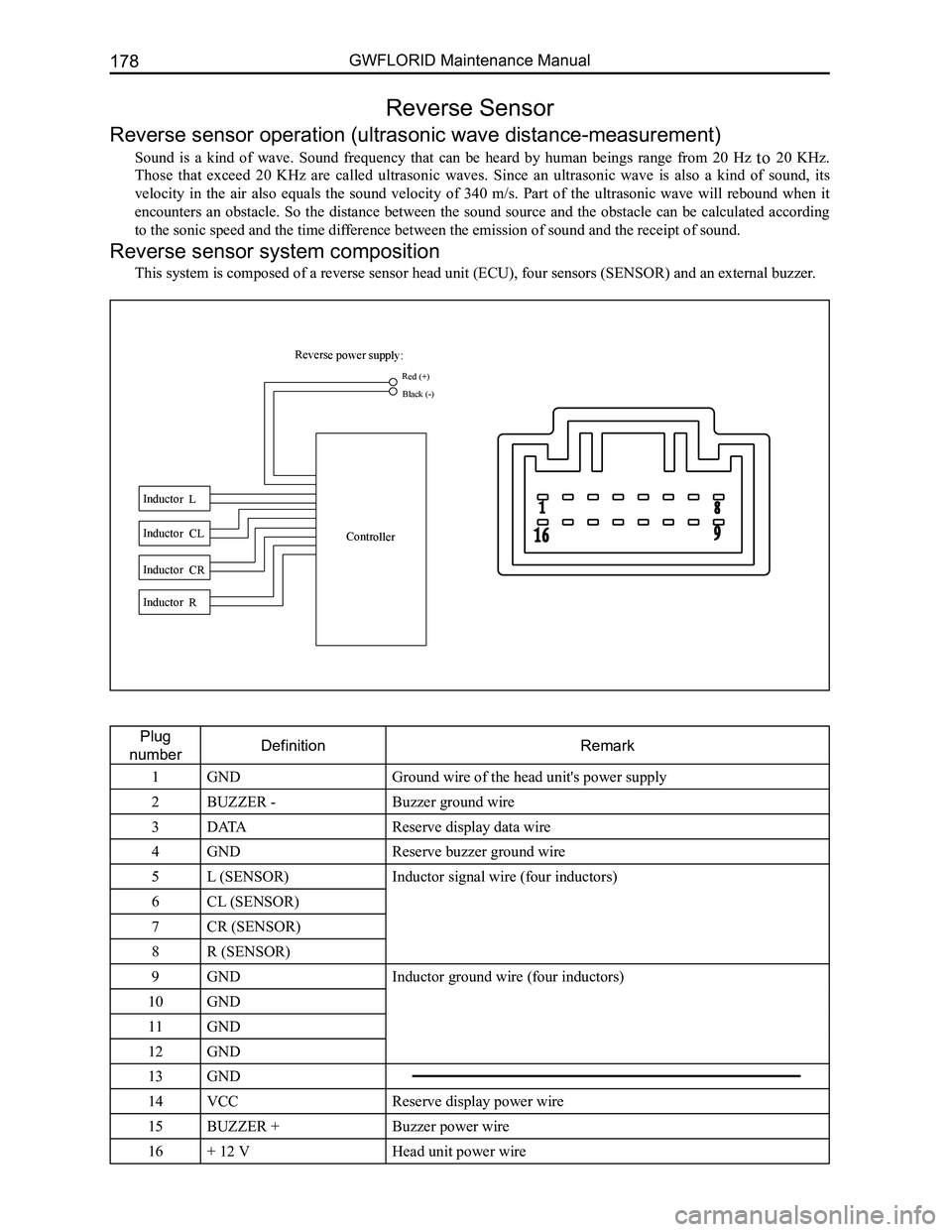

Reverse Sensor

Reverse sensor operation (ultrasonic wave distance-measurement)

Sound is a kind of wave. Sound frequency that can be heard by human beings range from 20 Hz to 20 KHz.

Those that exceed 20 KHz are called ultrasonic waves. Since an ultrasonic wave is also a kind of sound, its

velocity in the air also equals the sound velocity of 340 m/s. Part of the ultrasonic wave will rebound when it

encounters an obstacle. So the distance between the sound source and the obstacle can be calculated according

to the sonic speed and the time difference between the emission of sound and the receipt of sound.

Reverse sensor system composition

This system is composed of a reverse sensor head unit (ECU), four sensors (SENSOR) and an external buzzer.

Plug

numberDefinitionRemark

1GNDGround wire of the head unit's power supply

2BUZZER -Buzzer ground wire

3DATAReserve display data wire

4GNDReserve buzzer ground wire

5L (SENSOR)Inductor signal wire (four inductors)

6CL (SENSOR)

7CR (SENSOR)

8R (SENSOR)

9GNDInductor ground wire (four inductors)

10GND

11GND

12GND

13GND

14VCCReserve display power wire

15BUZZER +Buzzer power wire

16+ 12 VHead unit power wire

Reverse power supply:

Inductor L Inductor CL

Inductor CR Inductor R Controller

Red (+)

Black (-)

Page 186 of 281

Downloaded from www.Manualslib.com manuals search engine 179Electrical Accessories

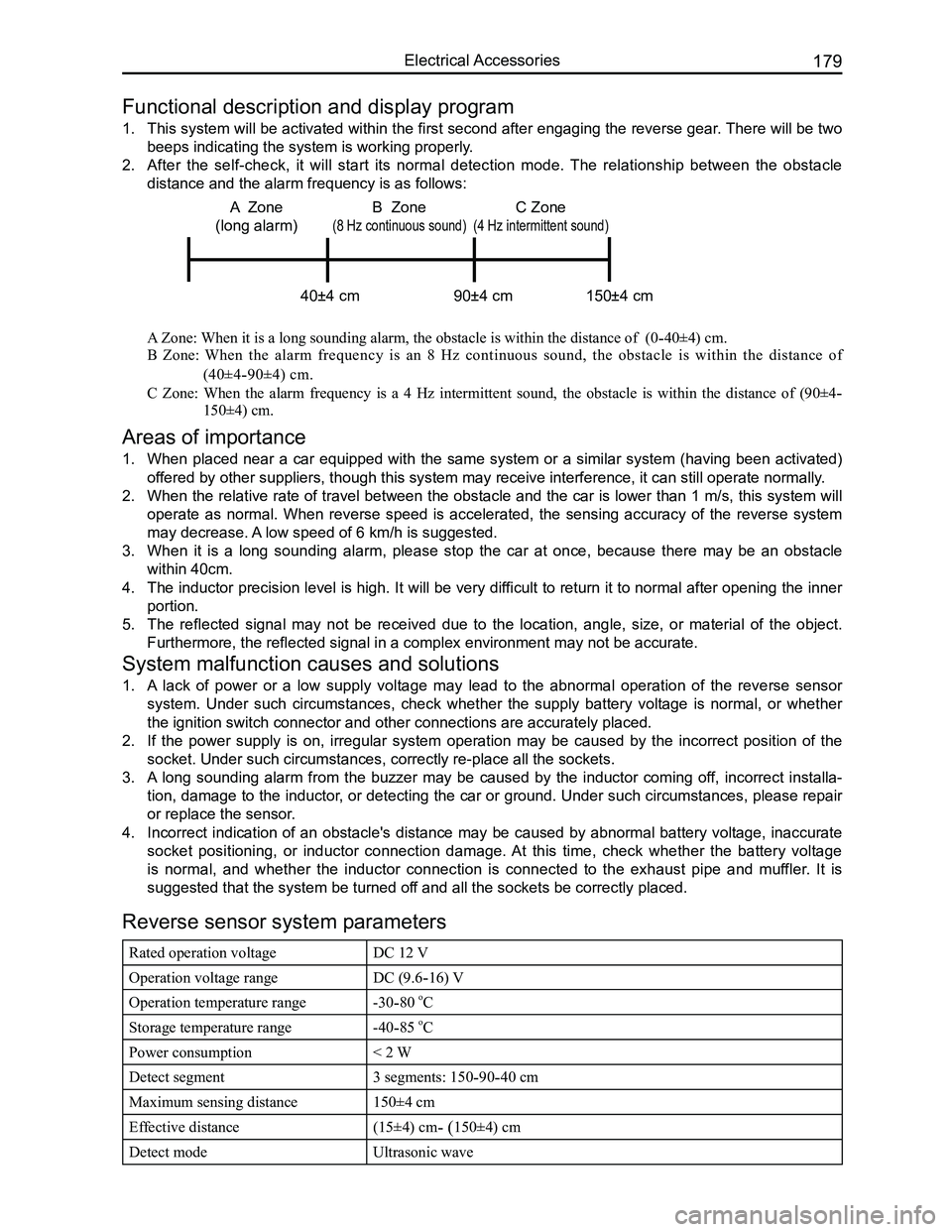

Functional description and display program

1. This system will be activated within the first second after engaging the reverse gear. There will be two

beeps indicating the system is working properly.

2. After the self-check, it will start its normal detection mode. The relationship between the obstacle

distance and the alarm frequency is as follows:

A Zone: When it is a long sounding alarm, the obstacle is within the distance of (0-40±4) cm.

B Zone: When the alarm frequency is an 8 Hz continuous sound, the obstacle is within the distance of

(40±4-90±4) cm.

C Zone: When the alarm frequency is a 4 Hz intermittent sound, the obstacle is within the distance of (90±4-

150±4) cm.

Areas of importance

1. When placed near a car equipped with the same system or a similar system (having been activated)

offered by other suppliers, though this system may receive interference, i\

t can still operate normally.

2. When the relative rate of travel between the obstacle and the car is lower than 1 m/s, this system will

operate as normal. When reverse speed is accelerated, the sensing accuracy of the reverse system

may decrease. A low speed of 6 km/h is suggested.

3. When it is a long sounding alarm, please stop the car at once, because there may be an obstacle

within 40cm.

4. The inductor precision level is high. It will be very difficult to return it to normal after opening the inner

portion.

5. The reflected signal may not be received due to the location, angle, size, or material of the object.

Furthermore, the reflected signal in a complex environment may not be ac\

curate.

System malfunction causes and solutions

1. A lack of power or a low supply voltage may lead to the abnormal operation of the reverse sensor

system. Under such circumstances, check whether the supply battery voltage is normal, or whether

the ignition switch connector and other connections are accurately place\

d.

2. If the power supply is on, irregular system operation may be caused by the incorrect position of the

socket. Under such circumstances, correctly re-place all the sockets.

3. A long sounding alarm from the buzzer may be caused by the inductor coming off, incorrect installa-

tion, damage to the inductor, or detecting the car or ground. Under such circumstances, please repair

or replace the sensor.

4. Incorrect indication of an obstacle's distance may be caused by abnormal battery voltage, inaccurate

socket positioning, or inductor connection damage. At this time, check whether the battery voltage

is normal, and whether the inductor connection is connected to the exhaust pipe and muffler. It is

suggested that the system be turned off and all the sockets be correctly placed.

Reverse sensor system parameters

Rated operation voltageDC 12 V

Operation voltage rangeDC (9.6-16) V

Operation temperature range-30-80 oC

Storage temperature range-40-85 oC

Power consumption< 2 W

Detect segment3 segments: 150-90-40 cm

Maximum sensing distance150±4 cm

Effective distance(15±4) cm- (150±4) cm

Detect modeUltrasonic wave

C Zone

(4 Hz intermittent sound)

40±4 cm 90±4 cm 150±4 cm

A Zone

(long alarm)

B Zone

(8 Hz continuous sound)

Page 198 of 281

Downloaded from www.Manualslib.com manuals search engine 191Electrical Accessories

4. Security system component replacement

When a failure appears in one of the immobilizer system components, this component must be replaced. After

the replacement, perform matching on the immobilizer system again.

Only changing the coil

There is no need to match the immobilizer system again.

Only changing the key (theft deterrent transponder assembly)

(a) Get the vehicle's PIN code from the code located inside the burglar-proof classified envelope

(b) Connect the scanner with the vehicle's diagnostic connection

(c) Insert the key into the ignition lock and turn it to the "ON" position

(d) Check whether the key is legal and matched. If it is illegal or already been matched, then it cannot be

matched again, but will have to be replaced

(e) Input the PIN code with the scanner

(f) Erase the damaged lost key's information

(g) Match the new key according to the scanner's prompt

(h) If it is necessary to match another key, insert the key, and after resetting the scanner, operate according to

steps c, d, e, and g.

Caution: Make sure the key is legal and hasn't been matched before learning the key. Otherwise, the

immobilizer system won’t successfully match or the scanner will display that it has been matched but

the electrojet's validation is not available.

Only replacing the theft deterrent controller assembly

(a) Get the vehicle's PIN code from the code inside the burglar-proof classified envelope

(b) Turn off the ignition switch, and replace with an unmatched new theft deterrent controller or reset the theft

deterrent controller

(c) Insert the key into the ignition lock and turn it to the ON position

(d) Input the PIN code with the scanner

(e) Match the theft deterrent controller assembly according to the scanner prompts

(f) Because the theft deterrent controller is new, there is no VIN and original key information stored in it. It

will need the VIN inputted and must be matched with the original key, otherwise the original key will not

work.

Caution:

(a) Replace the new alarm remote controller or reset the alarm remote controller, or the alarm re-

mote controller system matching can not be completed.

(b) Select "Read EMS to alarm remote controller", not "Read alarm remote controller to EMS", or it

will make the transponder inoperable.

Only replacing the engine ECU

(a) Get the vehicle's PIN code from the code inside the burglar-proof classified envelope

(b) Turn off the ignition switch, and replace with a new non-matched or reset ECU

(c) Insert the key into the ignition lock and turn it to the ON position

(d) Input the PIN code with the scanner

(e) Match the ECU according to the prompts on the scanner, and complete the ECU and theft deterrent

controller matching.

Caution:

(a) Make sure to replace it with a new or reset ECU, otherwise the immobilizer system matching can-

not be completed.

(b) Select the menu of "Read EMS to theft deterrent controller", but not "Read theft deterrent control-

ler to EMS", or it will make the transponder inoperable.

Replacing the theft deterrent controller and EMS controller at the same\

time

If both the theft deterrent controller and EMS controller need to be changed at the same time, then the transpon-

der that has been matched must also be replaced, otherwise the immobilizer system matching cannot be com-

pleted. The immobilizer system needs to be re-matched after being replace.

Matching after sales stage

Problems caused by lost keys or immobilizer system failures requires a duplicate key, replaced parts, etc. These

problems cannot be solved without re-matching the immobilizer system's parts. During the matching, input the

correct PIN code with scanner. Specific possible problems and matching methods the maintenance station may

encounter are as follows:

1. Match an empty key:

(a) Properly connect the engine ECU and the theft deterrent controller, and then insert the key to be matched,

and switch the ignition switch to the ON position

Page 201 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual194

Display characterMalfunctionSolutions

ERR3Disc is placed upside downEject the disc and reload

ERR4Incompatible disc file or formatCheck the disc format

ERR1

ERR1Disc structure errorEject the disc and replay

Trouble code

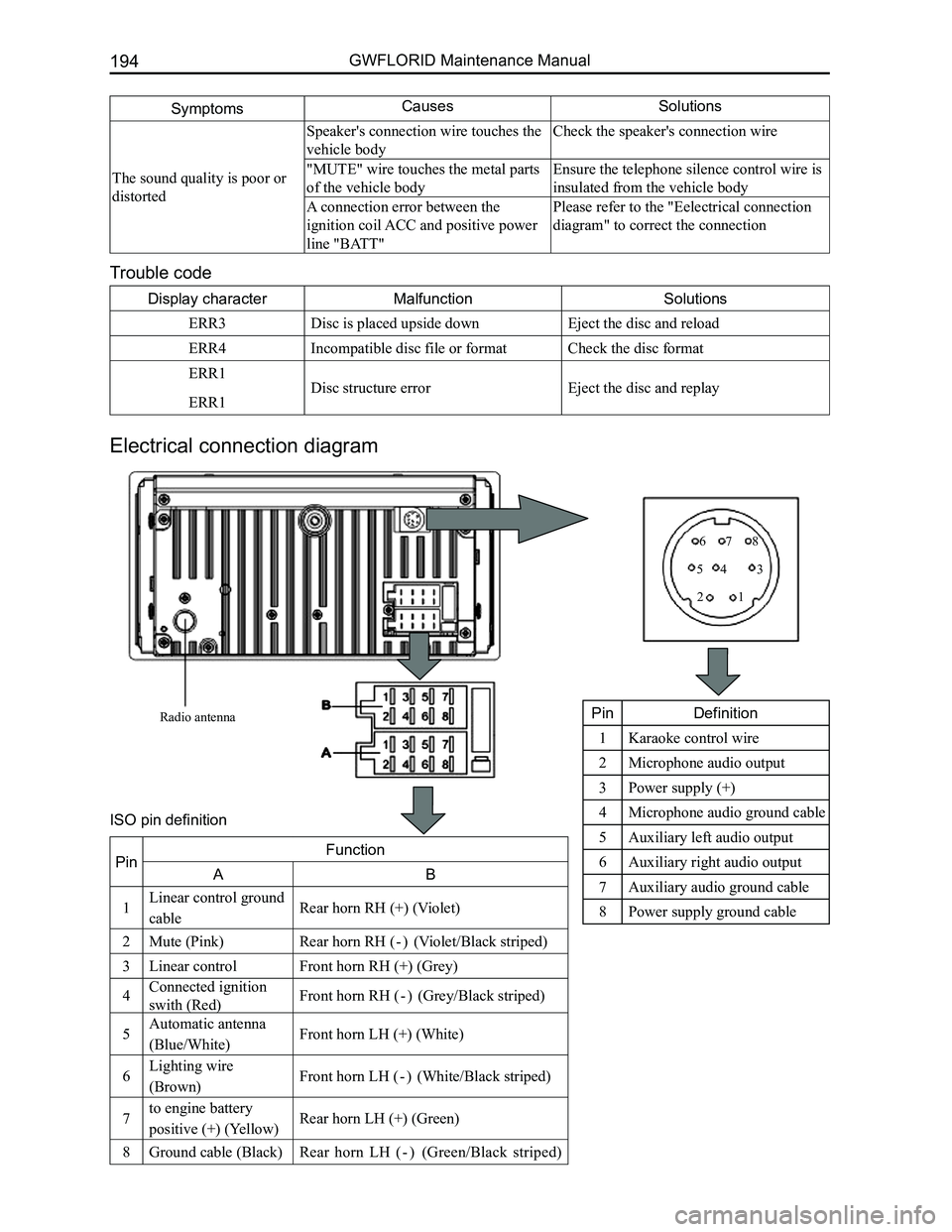

Electrical connection diagram

SymptomsCausesSolutions

The sound quality is poor or

distorted

Speaker's connection wire touches the

vehicle body

Check the speaker's connection wire

"MUTE" wire touches the metal parts

of the vehicle body

Ensure the telephone silence control wire is

insulated from the vehicle body

A connection error between the

ignition coil ACC and positive power

line "BATT"

Please refer to the "Eelectrical connection

diagram" to correct the connection

Radio antenna

12

345

678

PinDefinition

1Karaoke control wire

2Microphone audio output

3Power supply (+)

4Microphone audio ground cable

5Auxiliary left audio output

6Auxiliary right audio output

7Auxiliary audio ground cable

8Power supply ground cable

PinFunction

AB

1Linear control ground

cableRear horn RH (+) (Violet)

2Mute (Pink)Rear horn RH ( - ) (Violet/Black striped)

3Linear controlFront horn RH (+) (Grey)

4Connected ignition

swith (Red)Front horn RH ( - ) (Grey/Black striped)

5Automatic antenna

(Blue/White)Front horn LH (+) (White)

6Lighting wire

(Brown)Front horn LH ( - ) (White/Black striped)

7to engine battery

positive (+) (Yellow)Rear horn LH (+) (Green)

8Ground cable (Black)Rear horn LH ( - ) (Green/Black striped)

ISO pin definition

Page 204 of 281

Downloaded from www.Manualslib.com manuals search engine 197Electrical Accessories

Common faults and solutions

If the following faults occur while using this machine, please refer to \

the troubleshooting guide.

General problems

SymptomsCausesSolutions

Cannot start

Burnt fuseReplace with a new fuse of the same

specification

Vehicle supply battery fuse is burntReplace the vehicle supply battery fuse

Illegal operation and other factorsPress the reset button to reset the system

Remote controller doesn't

work

Remote controller battery is lowReplace the remote controller battery

Remote controller battery is reversely

installedProper battery installation

No sound or sound is too low

The volume of the head unit or the

connected component is too low

Raise the volume of the head unit or the

connected component

Speaker possibly damagedCheck the speaker

The sound balance settings lean to one

sideAdjust the sound balance

Speaker's connection wire touches the

vehicle body

Use insulated conductor to connect the

speaker and use insulating cement to cover

the exposed connections

Disc is not genuineUse a genuine disc

Speaker is incorrectly connectedPlease refer to the "Equipment connection

drawing" to correct the connection

The sound quality is poor or

distorted

Speaker's connection wire touches the

vehicle bodyCheck the speaker's connection wire

"MUTE" wire touches the metal parts of

the vehicle body

Ensure the telephone silence control wire

is insulated from the vehicle body

A connection error between ignition coil

ACC and positive power wire "BATT"

Please refer to the "equipment connection

drawing" to correct the connection

Common display characters and fault meaning

Display characterMalfunctionSolutions

No Disc

Disc is dirtyClean or replace the disc

The read side of the disc is inserted

upside-down

Insert the disc into the player with the

label side up

No disc in the playerInsert the disc

Bad disc

Disc is dirtyClean or replace the disc

The read side of the disc is reversely

inserted

Insert the disc into the player with the

label side up

Unknown disc Player cannot read discPlease use discs supported by this player

Region error The region code of this disc does not

match the region code for this player

Use discs that have a region code identical

to this player's

Page 205 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual198

TFT display screen common faults and solutions

SymptomsCausesSolutions

No image is shown on the

display screen, only a warning

image

Parking control wire "PRK SW" is not

properly connected

Please refer to the "Equipment connection

drawing" to correct the connection

Abnormal display status, like

pulsing lines, appear in the

image

The DVD output image format does not

match the display screen formatChange the screen format to automatic

Some non-genuine discs’ actual display

format do not match the labeled formatUse a genuine disc

Video wire is damaged Replace the video wire

Video wire connection error Please refer to the "Equipment connection

drawing" to correct the connection

Displayed characters are

messed up or displayed

incorrectly

Incorrect operation Shutoff and restart, or switch to another

source and then try again

SymptomsCausesSolutions

Poor lock channel effect

Automatic antenna fails to extend

Check if the radio reception automatic

a n t e n n a ' s c o n t r o l w i r e A N T. C O N T i s

properly connected. Please refer to the

"Equipment connection drawing"

Failure to connect the radio reception

antenna

P r o p e r l y c o n n e c t t h e r a d i o r e c e p t i o n

antenna. Please refer to the "Equipment

connection drawing"

Local search function is in the on-state Switch off the local search function, please

refer to the "Local search"

Radio reception failure and solution

DVD playing faults and solutions

SymptomsCausesSolutions

Cannot insert discThere is a disc in the playerEject the disc from the inside of the player

and insert a new one

Disc is unable to play

Disc is scratched and unable to be readReplace the disc

Disc is too dirty or wetClean the disc with a soft cloth

Laser head is dirtyClean the laser head with a laser head

cleaning disc

The disc is not supported by this playerCheck the disc type

Child lock grade too highChang the child lock settings

The read side of the disc is inserted

upside-down

Insert the disc into the player with its label

side up

The region code of the disc does not

match the region code of the player

Use discs that have a region code identical

to this player's

Subtitle does not displayThe disc does not contain a subtitle fileUse discs containing a subtitle file

Language or subtitle switch

does not work

The disc only has one type of language

or subtitle

Use discs containing multi-channel voice

or subtitle files

Multi-angle switch does not

work

The disc only has one visual angleUse discs that support multi-angle play

The section in play does not support

multi-angle

Select a section that supports multi-angle

play

Page 206 of 281

Downloaded from www.Manualslib.com manuals search engine 199Electrical Accessories

SymptomsCausesSolutions

Image is blurred and distortedThe disc is copy protected

The player is compatible with the copy

system, so if the disc is copy protected, it

may not be able to play, and is not a problem

with the player

PBC function has no effect

when playing a VCD discThe disc contains no PBC functionUse discs that support the PBC function

Repeat function and album/

time search are unavailablePBC is set to onTurn off the PBC function

SymptomsCausesSolutions

Cannot play MP3

Disc is scratched or dirty Clean the disc with soft cloth

Laser head is dirtyClean the laser head with a laser head

cleaning disc

The disc is not supported by this playerPlease use discs supported by this player

The read side of the disc is inserted

upside-down

Insert the disc into the player with its label

side up

The sound is not smooth when

playing MP3

The disc is too dirty or scratchedClean or replace the disc

Partial content is damagedReplace the disc

Bad record conditionRe-record the disc

Name of MP3 file is not

displayed normallyIrregular file nameDo not use Chinese names

MP3 playing faults and solution

Page 225 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual218

detection but also during the diagnostic detection cycle. However, if a short circuit on the power supply causes

a malfunction, and the low-end transistor is opened while malfunctioned, the low-end transistor can only be

detected when starting up detection, as to avoid faulty execution.

(b) Ignition voltage is provided by a pressure increase converter.

(c) Acceleration sensor performs self-detection when starting up detection.

(d) Allowed offset range of the acceleration sensor during a diagnostic cycle.

(e) Microcontroller includes AD converter, ROM, RAM, etc.

(f) Security sensor status.

Caution: There is a short-circuiting bar inside the squib circuit connector. When the connector is not

connected, the short circuit happens between the squib circuit's terminal (+) and terminal (-), as to

avoid faulty deployment caused by static electricity. When the connector is bad and the short-circuiting

bar is connected, the fault symptom may not be eliminated.

4. Clear the trouble code

When the X-431 diagnostic instrument receives the "Clear the trouble code" order sent through the serial inter-

face, the trouble code inside the ECU will be cleared. However, if an internal trouble code is recorded or has a

collision record, it will not carry out this order.

(a) Malfunction status display.

When the working voltage is supplied to the SRS-ECU through a battery, the SRS-ECU will light the warning

lamp to inspect the light bulbs. During the initialization stage, the warning lamp will remain on for 6-7 s, and

in order to inform the driver that the system has a malfunction, the warning lamp will continue to remain on

after the working voltage is supplied. If the history trouble code’s quantity is less than 16, the warning lamp

will remain lit for 6-7 s after turning the ignition on and then turn off automatically. If the history trouble code’s

quantity is 16 and the current malfunction appears, it will be recorded and the first history malfunction record

will be automatically removed.

(b) Malfunction indicator.

When the system has malfunctioned, the warning lamp will be always on.

A displayed or history malfunction can only be reset by service personnel. A SRS-ECU internal malfunction or

malfunction’s "collision record" cannot be reset. In this situation, the SRS-ECU mus\

t be replaced.

(c) Microcontroller - independent warning lamp is lit.

The controller has a self-diagnosis function. If the inner controller malfunctions, the warning lamp will always

be on.

(d) If the airbag warning lamp is always on, please inspect it according to the following steps.

The first step of inspecting any of the malfunctions is to detect the malfunction’s position with a scanner. Then

carry out the inspection using the corresponding part’s inspection method. If the scanning result is an internal

malfunction or having to do with airbag execution, the SRS-ECU can be di\

rectly replaced.