fuel filter GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 4 of 281

Downloaded from www.Manualslib.com manuals search engine Chapter One: Overview ........................................................................\

........................................1

How to Use This Manual ...................................................................................\

...........2

Identifying Number Location ..................................................................................\

......3

Comprehensive Repair Instructions .............................................................................4

General Repair Methods and Operations ....................................................................9

Chapter Two: Overall Parameters ........................................................................\

......................10

Basic Parameters of the Overall Vehicle ...................................................................11

Engine Technical Parameters ..................................................................................\

..12

Chassis’ Main Assembly Technical Parameters .........................................................13

Vehicle Structure Type and Parameters ....................................................................15

Air Conditioning System Structure and Parameters ..................................................16

Electrical System Structure and Parameters .............................................................16

Grade Specification and Filled Quantity of Each

Individual Functioning Component’s Working Agent ..................................................18

Torque Specifications for Key Operational Bolts ........................................................18

Vehicle Body’s Basic Calibration Measurements ......................................................22

Chapter Three: Fuel Supply and Exhaust System .....................................................................29

Fuel Supply System ...................................................................................\

................30

Components ..................................................................................\

..........................30

Fuel Tank Removal ..................................................................................\

................31

Fuel Pump and Charcoal Canister Removal ...........................................................31

Fuel Filter Removal ...................................................................................\

...............31

Fuel Filler Pipe Assembly Removal .........................................................................32

Exhaust System ...................................................................................\

......................33

Components ..................................................................................\

..........................33

Exhaust System Removal ...................................................................................\

.....34

Exhaust System Installation ...................................................................................\

..35

Chapter Four: Clutch Operational System........................................................................\

..........36

Areas of Importance ..................................................................................\

................37

Troubleshooting ..................................................................................\

.......................37

Clutch Operational System ..................................................................................\

......38

Components ..................................................................................\

..........................38

Clutch Master Cylinder Removal .............................................................................38

Clutch Master Cylinder Installation ..........................................................................40

Clutch Pedal Removal ..................................................................................\

...........40

Clutch Pedal Installation ..................................................................................\

........40

Clutch Pedal Examination and Adjustment ..............................................................41

CONTENTS

Page 20 of 281

Downloaded from www.Manualslib.com manuals search engine 13Overall Parameters

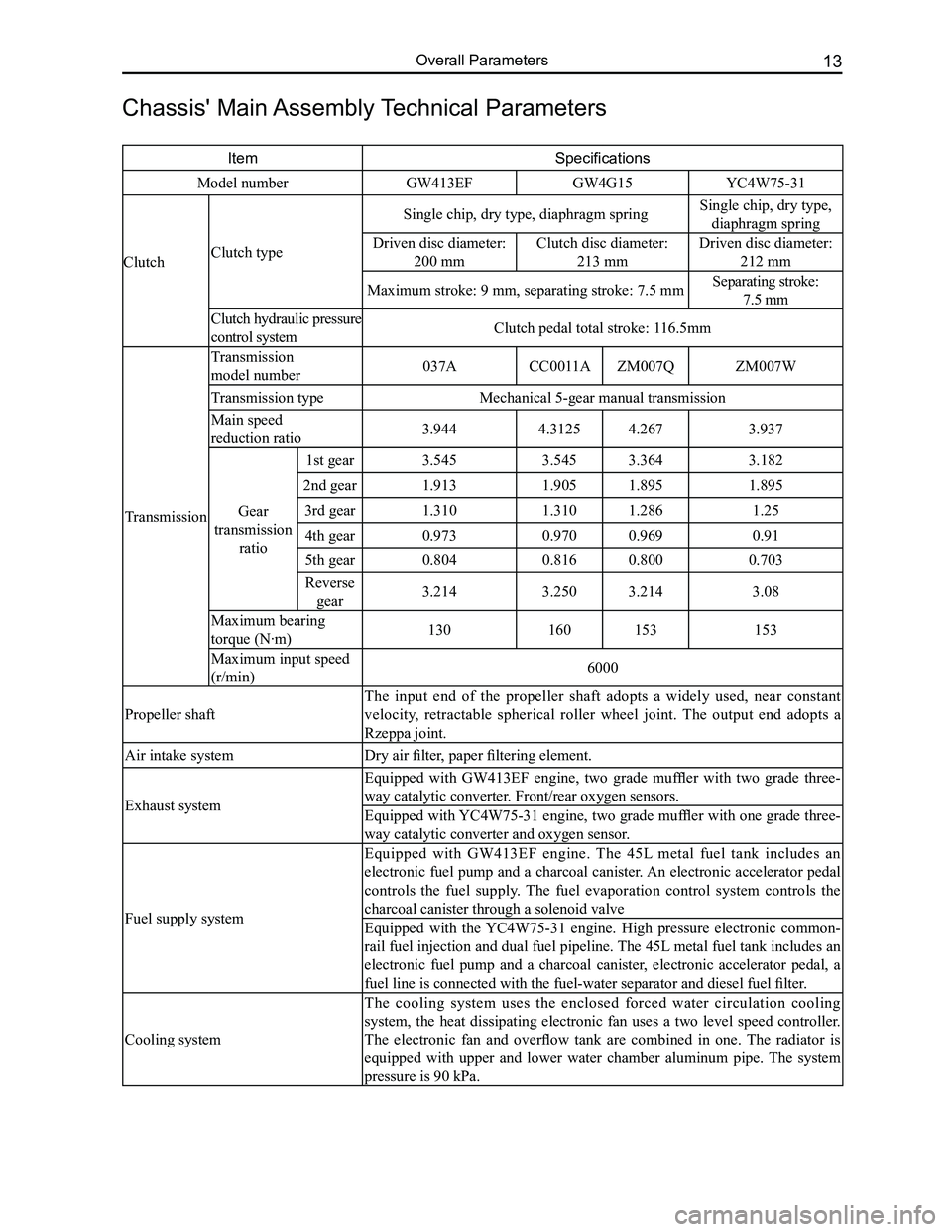

Chassis' Main Assembly Technical Parameters

ItemSpecifications

Model numberGW413EFGW4G15YC4W75-31

ClutchClutch type

Single chip, dry type, diaphragm springSingle chip, dry type,

diaphragm spring

Driven disc diameter:

200 mm

Clutch disc diameter:

213 mm

Driven disc diameter:

212 mm

Maximum stroke: 9 mm, separating stroke: 7.5 mmSeparating stroke:

7.5 mm

Clutch hydraulic pressure

control systemClutch pedal total stroke: 116.5mm

Transmission

Transmission

model number037ACC0011AZM007QZM007W

Transmission typeMechanical 5-gear manual transmission

Main speed

reduction ratio3.9444.31254.2673.937

Gear

transmission

ratio

1st gear3.5453.5453.3643.182

2nd gear1.9131.9051.8951.895

3rd gear1.3101.3101.2861.25

4th gear0.9730.9700.9690.91

5th gear0.8040.8160.8000.703

Reverse

gear3.2143.2503.2143.08

Maximum bearing

torque (N·m)130160153153

Maximum input speed

(r/min)6000

Propeller shaft

The input end of the propeller shaft adopts a widely used, near constant

velocity, retractable spherical roller wheel joint. The output end adopts a

Rzeppa joint.

Air intake systemDry air filter, paper filtering element.

Exhaust system

Equipped with GW413EF engine, two grade muffler with two grade three-

way catalytic converter. Front/rear oxygen sensors.

Equipped with YC4W75-31 engine, two grade muffler with one grade three-

way catalytic converter and oxygen sensor.

Fuel supply system

Equipped with GW413EF engine. The 45L metal fuel tank includes an

electronic fuel pump and a charcoal canister. An electronic accelerator pedal

controls the fuel supply. The fuel evaporation control system controls the

charcoal canister through a solenoid valve

Equipped with the YC4W75-31 engine. High pressure electronic common-

rail fuel injection and dual fuel pipeline. The 45L metal fuel tank includes an

electronic fuel pump and a charcoal canister, electronic accelerator pedal, a

fuel line is connected with the fuel-water separator and diesel fuel filter.

Cooling system

The cooling system uses the enclosed forced water circulation cooling

system, the heat dissipating electronic fan uses a two level speed controller.

The electronic fan and overflow tank are combined in one. The radiator is

equipped with upper and lower water chamber aluminum pipe. The system

pressure is 90 kPa.

Page 26 of 281

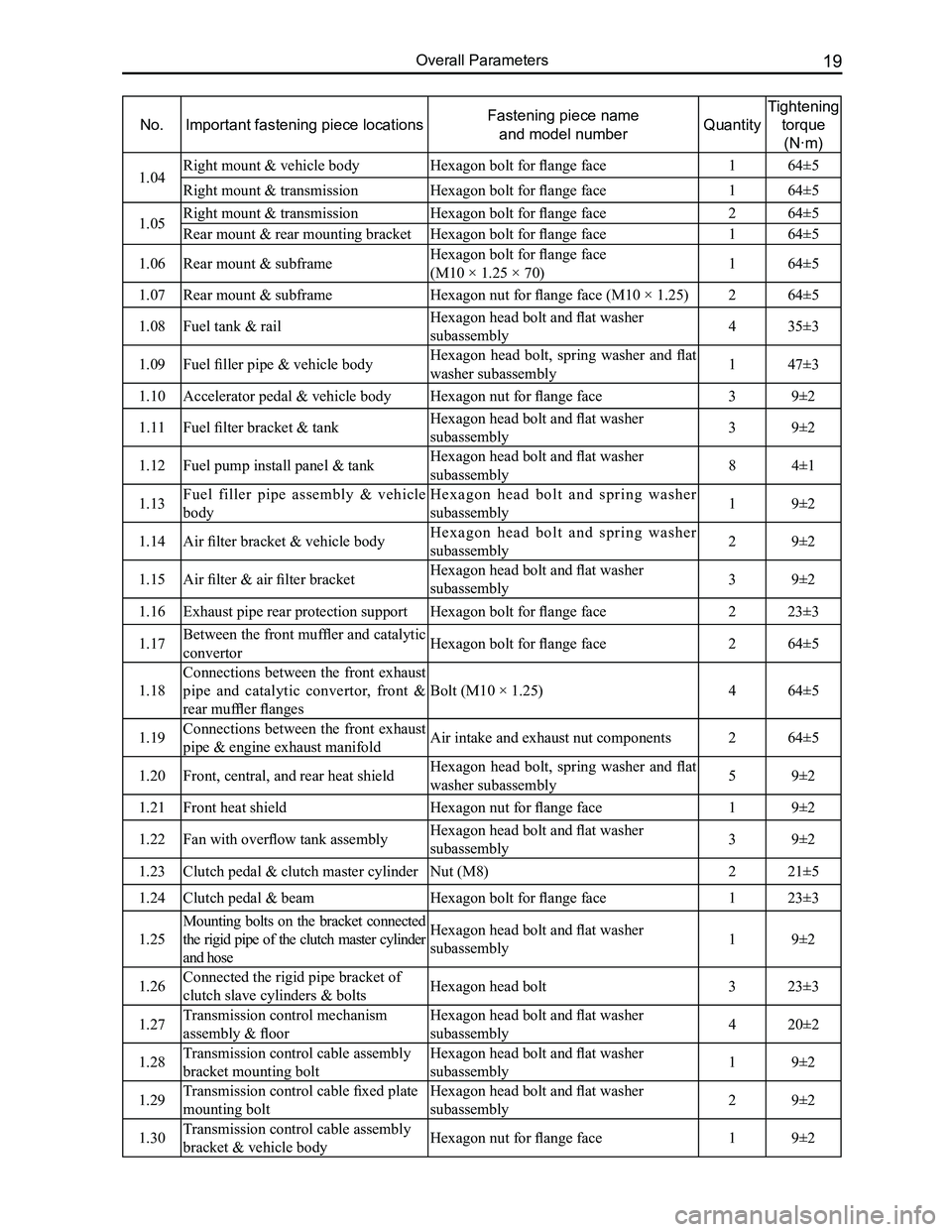

Downloaded from www.Manualslib.com manuals search engine 19Overall Parameters

No.Important fastening piece locationsFastening piece name

and model numberQuantity

Tightening

torque

(N·m)

1.04Right mount & vehicle bodyHexagon bolt for flange face164±5

Right mount & transmissionHexagon bolt for flange face 164±5

1.05Right mount & transmissionHexagon bolt for flange face 264±5

Rear mount & rear mounting bracketHexagon bolt for flange face 164±5

1.06Rear mount & subframeHexagon bolt for flange face

(M10 × 1.25 × 70)164±5

1.07Rear mount & subframeHexagon nut for flange face (M10 × 1.25)264±5

1.08Fuel tank & railHexagon head bolt and flat washer

subassembly435±3

1.09Fuel filler pipe & vehicle bodyHexagon head bolt, spring washer and flat

washer subassembly147±3

1.10Accelerator pedal & vehicle bodyHexagon nut for flange face39±2

1.11Fuel filter bracket & tankHexagon head bolt and flat washer

subassembly39±2

1.12Fuel pump install panel & tankHexagon head bolt and flat washer

subassembly84±1

1.13Fuel filler pipe assembly & vehicle

body

H e x a g o n h e a d b o l t a n d s p r i n g w a s h e r

subassembly19±2

1.14Air filter bracket & vehicle bodyH e x a g o n h e a d b o l t a n d s p r i n g w a s h e r

subassembly29±2

1.15Air filter & air filter bracketHexagon head bolt and flat washer

subassembly39±2

1.16Exhaust pipe rear protection supportHexagon bolt for flange face223±3

1.17Between the front muffler and catalytic

convertorHexagon bolt for flange face264±5

1.18

Connections between the front exhaust

pipe and catalytic convertor, front &

rear muffler flanges

Bolt (M10 × 1.25)464±5

1.19Connections between the front exhaust

pipe & engine exhaust manifoldAir intake and exhaust nut components264±5

1.20Front, central, and rear heat shieldHexagon head bolt, spring washer and flat

washer subassembly59±2

1.21Front heat shieldHexagon nut for flange face19±2

1.22Fan with overflow tank assemblyHexagon head bolt and flat washer

subassembly39±2

1.23Clutch pedal & clutch master cylinderNut (M8)221±5

1.24Clutch pedal & beamHexagon bolt for flange face123±3

1.25

Mounting bolts on the bracket connected

the rigid pipe of the clutch master cylinder

and hose

Hexagon head bolt and flat washer

subassembly19±2

1.26Connected the rigid pipe bracket of

clutch slave cylinders & boltsHexagon head bolt323±3

1.27Transmission control mechanism

assembly & floor

Hexagon head bolt and flat washer

subassembly420±2

1.28Transmission control cable assembly

bracket mounting bolt

Hexagon head bolt and flat washer

subassembly19±2

1.29Transmission control cable fixed plate

mounting bolt

Hexagon head bolt and flat washer

subassembly29±2

1.30Transmission control cable assembly

bracket & vehicle bodyHexagon nut for flange face19±2

Page 36 of 281

Downloaded from www.Manualslib.com manuals search engine 29Fuel Supply and Exhaust System

Fuel Supply and Exhaust System

Fuel Supply System............................................................30

Components .....................................................................30

Fuel Tank Removal ...........................................................31

Fuel Pump and Charcoal Canister Removal ....................31

Fuel Filter Removal ..........................................................31

Fuel Filler Pipe Assembly Removal ..................................32

Exhaust System..................................................................33

Components .....................................................................33

Exhaust System Removal ................................................34

Exhaust System Installation .............................................35

Page 37 of 281

Downloaded from www.Manualslib.com manuals search engine 30GWFLORID Maintenance Manual

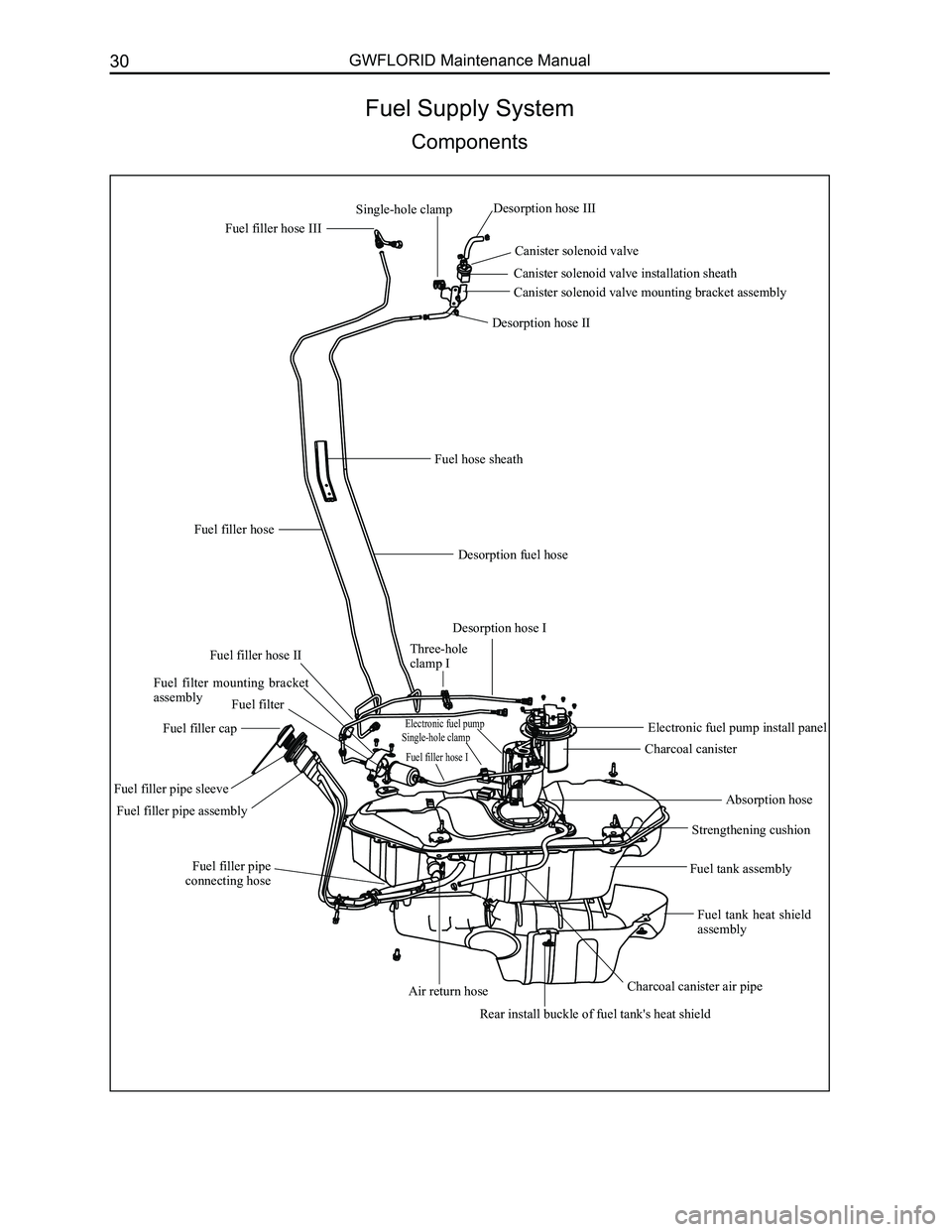

Fuel Supply System

Components

Fuel filler hose III

Canister solenoid valve

Canister solenoid valve installation sheath

Canister solenoid valve mounting bracket assembly

Fuel hose sheath

Desorption fuel hose

Fuel filler hose

Desorption hose I

Fuel filler hose IIThree-hole clamp I

Charcoal canister

Fuel tank assembly

Fuel tank heat shield assembly

Charcoal canister air pipeAir return hose

Fuel filler pipe assembly

Electronic fuel pumpSingle-hole clampElectronic fuel pump install panel

Strengthening cushion

Fuel filler pipe connecting hose

Absorption hoseFuel filler pipe sleeve

Single-hole clamp

Fuel filter

Rear install buckle of fuel tank's heat shield

Fuel filler cap

Fuel filler hose I

Desorption hose III

Desorption hose II

Fuel filter mounting bracket assembly

Page 38 of 281

Downloaded from www.Manualslib.com manuals search engine 31Fuel Supply and Exhaust System

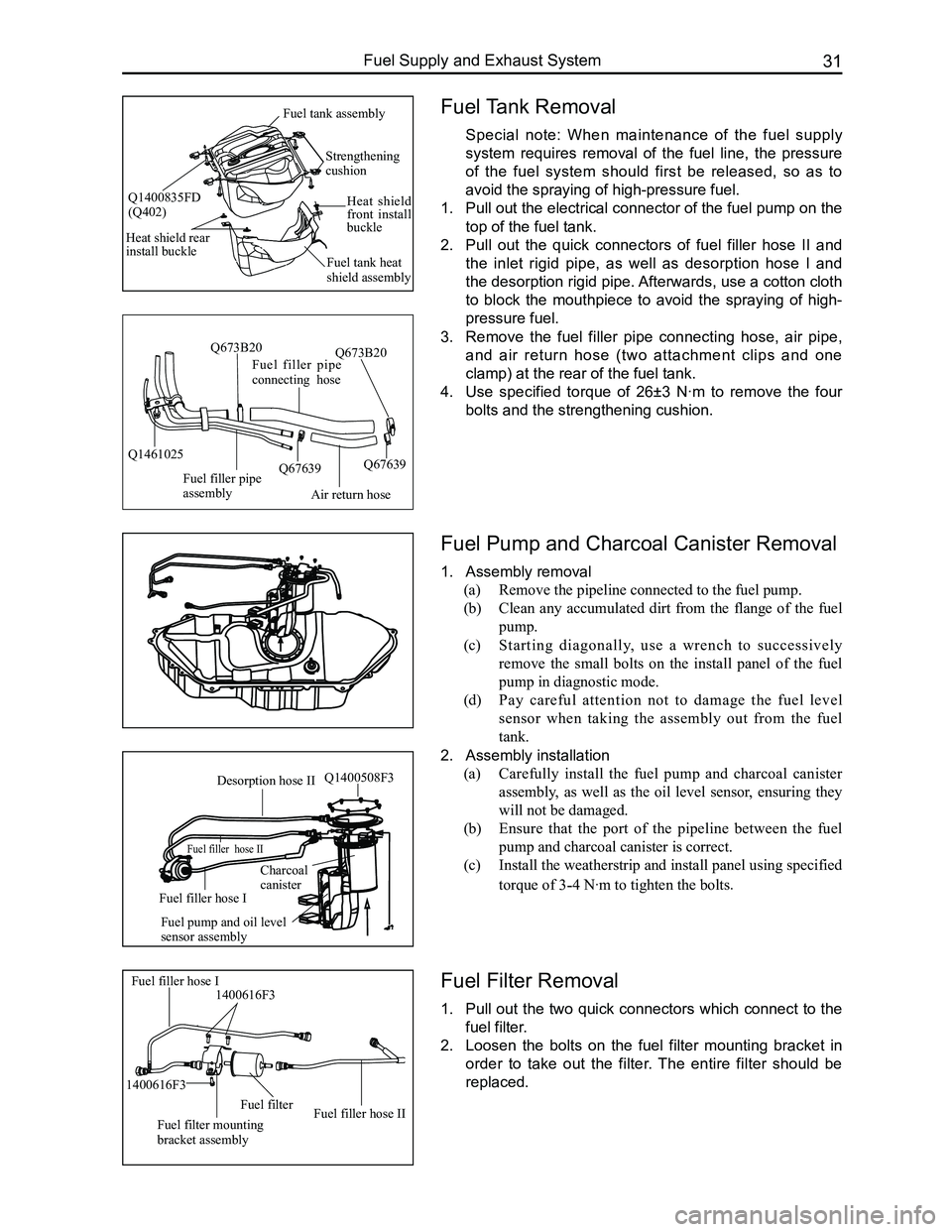

Fuel Tank Removal

Special note: When maintenance of the fuel supply

system requires removal of the fuel line, the pressure

of the fuel system should first be released, so as to

avoid the spraying of high-pressure fuel.

1. Pull out the electrical connector of the fuel pump on the

top of the fuel tank.

2. Pull out the quick connectors of fuel filler hose II and

the inlet rigid pipe, as well as desorption hose I and

the desorption rigid pipe. Afterwards, use a cotton cloth

to block the mouthpiece to avoid the spraying of high-

pressure fuel.

3. Remove the fuel filler pipe connecting hose, air pipe,

and air return hose (two attachment clips and one

clamp) at the rear of the fuel tank.

4. Use specified torque of 26±3 N·m to remove the four

bolts and the strengthening cushion.

Fuel Pump and Charcoal Canister Removal

1. Assembly removal

(a) Remove the pipeline connected to the fuel pump.

(b) Clean any accumulated dirt from the flange of the fuel

pump.

(c) Starting diagonally, use a wrench to successively

remove the small bolts on the install panel of the fuel

pump in diagnostic mode.

(d) Pay careful attention not to damage the fuel level

sensor when taking the assembly out from the fuel

tank.

2. Assembly installation

(a) Carefully install the fuel pump and charcoal canister

assembly, as well as the oil level sensor, ensuring they

will not be damaged.

(b) Ensure that the port of the pipeline between the fuel

pump and charcoal canister is correct.

(c) Install the weatherstrip and install panel using specified

torque of 3-4 N·m to tighten the bolts.

Fuel Filter Removal

1. Pull out the two quick connectors which connect to the

fuel filter.

2. Loosen the bolts on the fuel filter mounting bracket in

order to take out the filter. The entire filter should be

replaced.

Air return hose

Fuel filler pipe connecting hose

Fuel filler pipe assembly

Q1461025Q67639

Q673B20

Q67639

Q673B20

Fuel filler hose I1400616F3

Fuel filter mounting bracket assembly

Fuel filterFuel filler hose II

1400616F3

Desorption hose II

Fuel filler hose II

Fuel filler hose I

Charcoalcanister

Fuel pump and oil level sensor assembly

Q1400508F3

Strengthening cushion

Heat shield front install buckle

Fuel tank heat shield assembly

Heat shield rear install buckle

Fuel tank assembly

Q1400835FD(Q402)