transmission oil GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 51 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual44

Transmission's Proper Use and Care

1. Transmission's proper operation

1.1 Shift the gear gently, not excessively.

1.2 Do not start with high speed.

1.3 To avoid premature abrasion of the gear shift fork, do not rest your hand on the \

gear lever while driving.

2. Model number of the lubricant to be used:

GL-4 80W-90 (For China domestic model)

GL-4 75W-90 (For alpine region model)

GL-5 140 (For high-temperature region model)

Caution: Please only use the lubricant with model numbers specified by t\

he Great Wall Motor Co., Ltd.

Do not mix lubricants with different model numbers. Only fill with clean lubricant.

3. Areas of importance for new vehicle usage:

3.1 Before using a new vehicle, be sure to check the transmission and all exposed connectors and fastening

pieces, so as to avoid failure due to faulty installation or loose conne\

ctions.

3.2 Since the new vehicle is still in the run-in period, the transmission's lubricant should be replaced after 5000 km

distance.

4. Transmission three-level maintenance:

4.1 Transmission level-one maintenance: During the first level of maintenance, the liquid level of the lubricant

should be checked to ensure that it is up to the oil-filling mouth. Add more if insufficient. Excessive low

oil level can lead to ineffective lubrication, as well as burning of the bearings and gears. Excessive high oil

level, however, can overheat the transmission or cause oil to leak. In addition, during the first level of main-

tenance, the breather plug should be checked and cleaned. If the breather plug is clogged, internal pressure

will build up and oil will leak from the transmission.

4.2 Transmission level-two maintenance: The transmission's lubricant should be replaced the first time that the

vehicle undergoes the second level of maintenance. Clean the transmission with kerosene. The quality of the

lubricant should be inspected during the future second level of maintenance practises. The lubricant should

be replaced if diluted, gummy, or dirty.

4.3 Transmission level-three maintenance: During the third level of maintenance, it should be removed for in-

spection, cleaning, and oil changing.

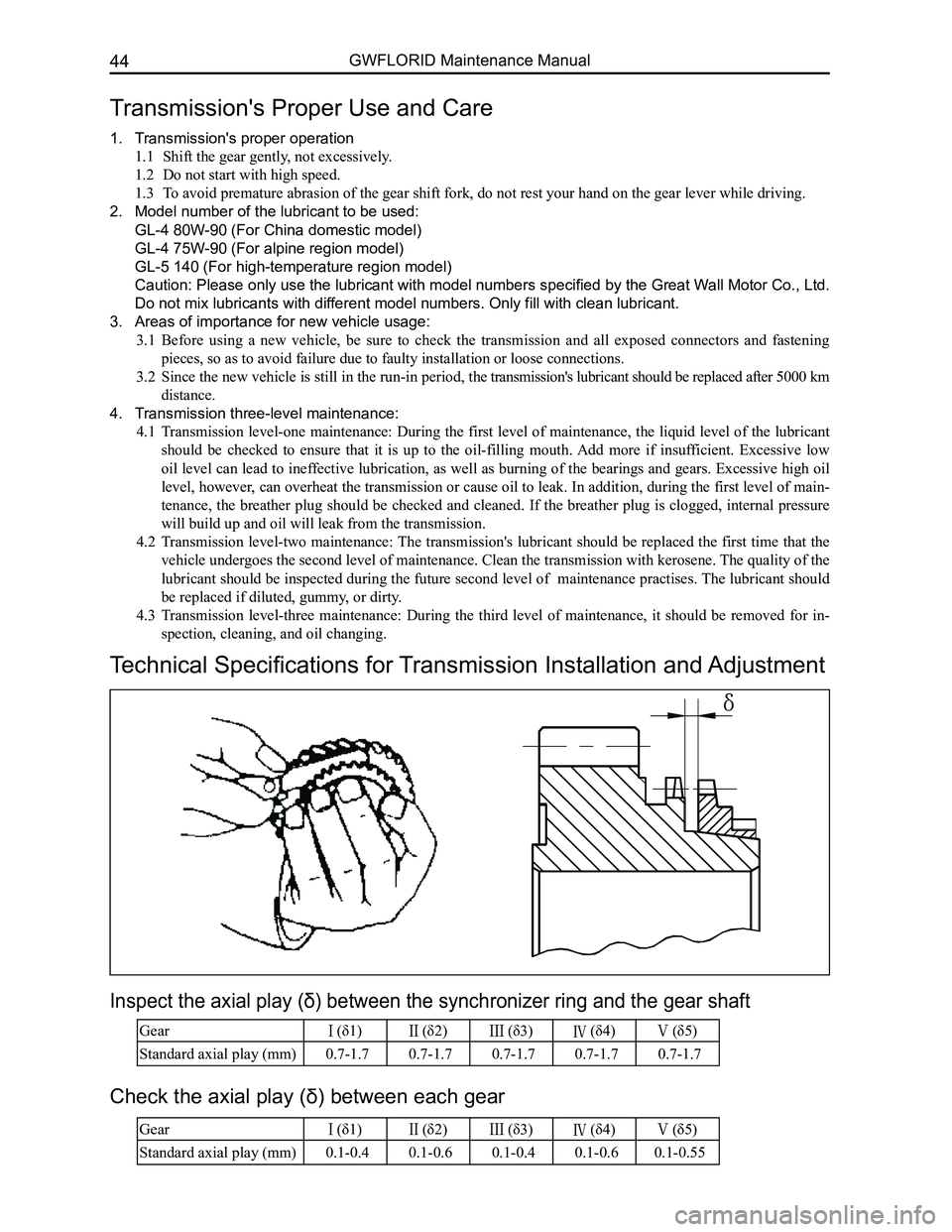

Technical Specifications for Transmission Installation and Adjustment

Inspect the axial play (δ) between the synchronizer ring and the gear shaft

Gear (δ1) (δ2) (δ3) (δ4) (δ5)

Standard axial play (mm)0.7-1.70.7-1.70.7-1.70.7-1.70.7-1.7

Gear (δ1) (δ2) (δ3) (δ4) (δ5)

Standard axial play (mm)0.1-0.40.1-0.60.1-0.40.1-0.60.1-0.55

Check the axial play (δ) between each gear

Page 52 of 281

Downloaded from www.Manualslib.com manuals search engine 45Transmission

Areas of Importance

Removal

During removal, all components should be gently handled to avoid knocking, especially the joint surface.

All components should be placed in the proper order to avoid misplacing \

and mistaking.

Installation

1. Clean all parts before installation (except rubber pieces and gaskets)\

.

2. All oil seals, shaft retainers, and elastic pins should not be reused.

3. All rubbing surfaces should be coated with lubricant, and the lips of all oil seals should be coated with

grease.

4. During installation of the bearings, do not use any kind of rolling element to transmit pressure, and

make sure not to tilt it.

5. During the installation of synchronizer components, the two sides of the spring piston's openings

should alternate.

6. When the transmission is operating under normal working conditions, there should be no lubricant

leakage from any of the parts.

Transportation and storage

1. When transporting a transmission, make sure the conditions are dustproof and rainproof, as well as

take proper care not to damage it due to jolting, shaking, removal, or i\

nstallation.

2. Transmission assembly should be stored in a ventilated, dustproof, and dr\

y place.

3. Users with special transportation or storage requirements should have another discussion to reach an

agreement on this matter in the supply contract.

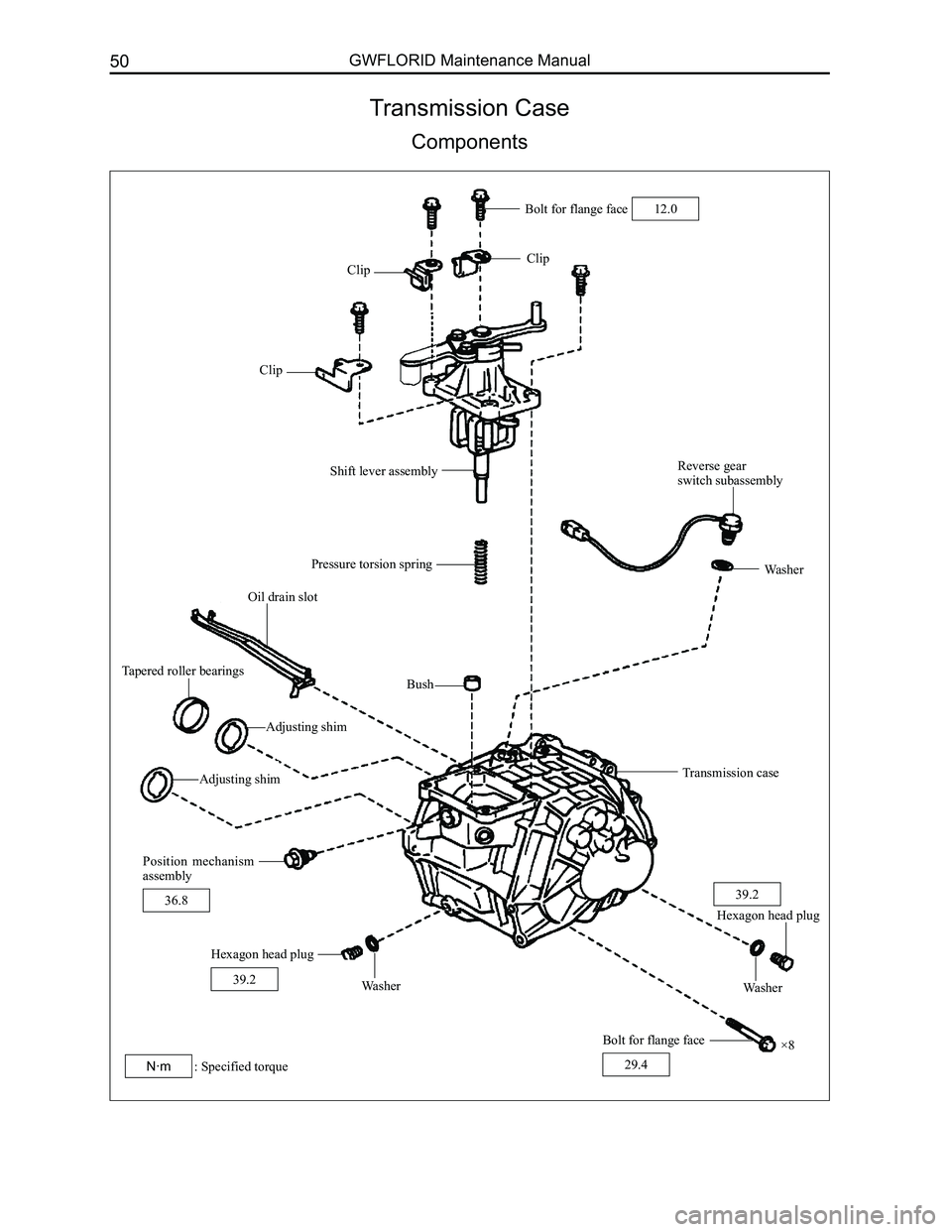

Use partsBolt codeSpecificationsQuantity

Tighten-

ing torque

(N·m)

Differential case × differential ring gear037-2303309M12 × 1.06123.6

C l u t c h h o u s i n g × r e v e r s e g e a r a r m

bracket subassembly037-1702073M8 × 1.25217.2

No. 1 gear shift fork shaft × No. 1 gear

shift fork037-1702056M6 × 0.75115.7

No. 2 gear shift fork shaft × No. 2 gear

shift fork037-1702056M6 × 0.75115.7

Transmission case × clutch housing037-1701012M8 × 1.251329.4

Transmission case × manipulation lid

subassembly037-1702051M8 × 1.25412.0

Transmission case × position mechanism

component037-1702042M18 × 1.5136.8

Transmission case × reverse gear idler

shaft × sealing ring037-1701404M8 × 1.25129.4

Transmission case × hexagon head plug037-1701016M18 × 1.5239.2

Transmission case × reverse gear switch

subassembly037-1701022M18 × 1.5140.2

Transmission case × cable bracket037-1701019M8 × 1.25411.3

Clutch housing × clutch slave cylinder

subassembly037-1601019M8 × 1.25211.3

Select lever assembly × gear shifting

block037-1702027M8 × 1.25138.0

Clutch housing × release fork support

nail037-1601011M10 × 1.25136.8

Counterweight component × shift lever

component037-1702030M8 × 1.25220.0

Release fork support nail129.4

Thread fastening piece tightening torque table

Page 54 of 281

Downloaded from www.Manualslib.com manuals search engine 47Transmission

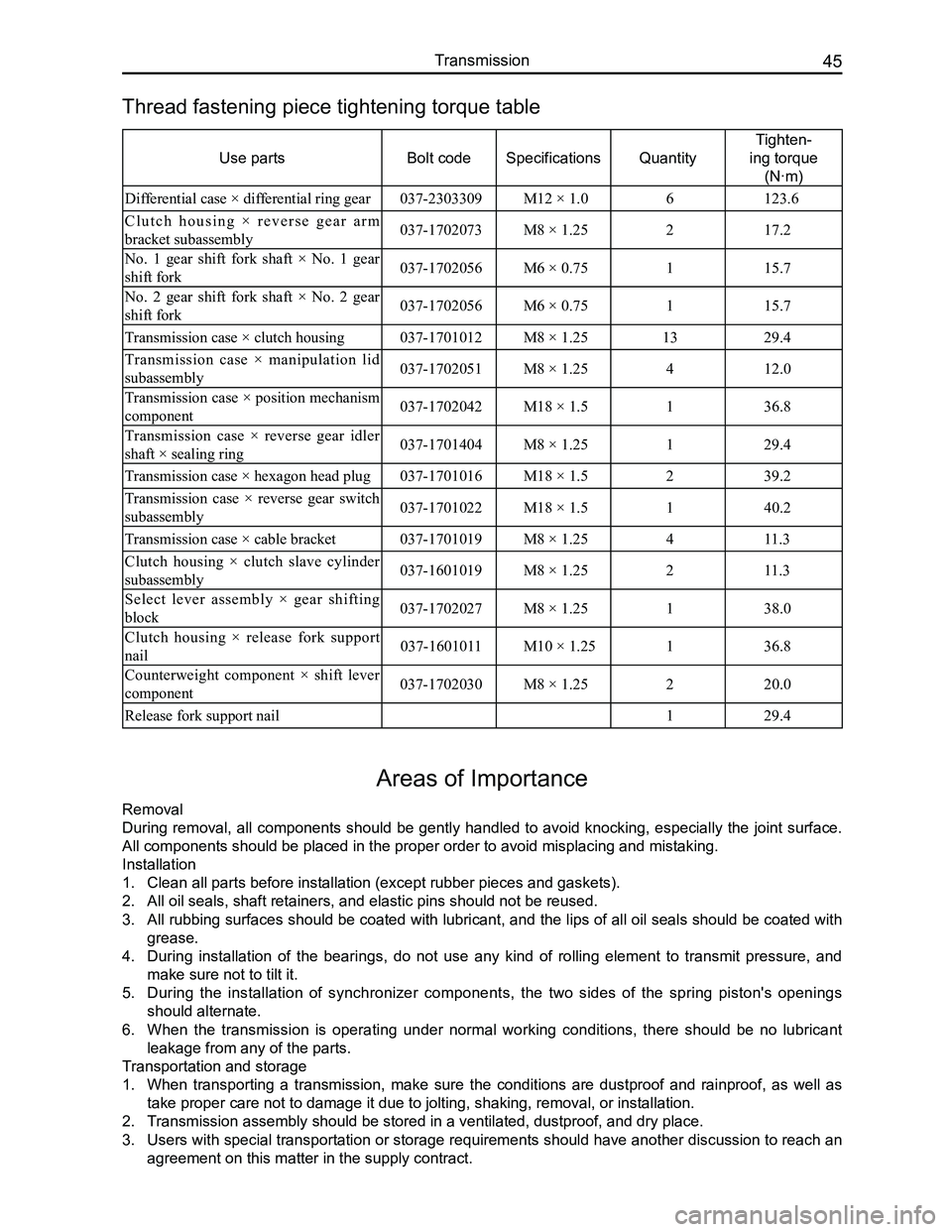

1. No. 2 gear sleeve 2. Shaft retainer 3. No. 2 Slider (3) 4. Spring expansion ring (2) 5. No. 2 gear hub 6. 3rd gear synchronizer ring 7. 3rd gear gear assembly 8. Needle bearing 9. With washer bolt 10. Clutch slave cylinder subassembly 11. Release fork protective cover 12. Release fork spring 13. Bolt for flange face (3) 14. Release fork 15. Clutch housing 16. Release fork support nail 17. Ball bearing 18. 2nd gear synchronizer ring 19. T oil seal 20. No. 1 gear sleeve 21. No. 1 Slider 22. 1st gear synchronizer ring 23. 1st gear gear components 24. Needle bearing 25. Release bearing subassembly 26. Tapered roller bearing 27. Guide nozzle 28. 2nd gear gear

assembly 29. No. 1 gear hub 30. Spring expansion ring (2) 31. Bolt for flange face (6) 32. Straight pin 33. Odometer driver 34. T oil seal 35. Tapered roller bearing 36. Adjusting shim (2) 37. Axle shaft gear (2) 38. Planetary gear (2) 39. Gasket (2) 40. Differential case 41. Planetary gear shaft 42. Differential ring gear 43. Bolt for flange face (8) 44. Tapered roller bearing 45. Adjusting shim 46. T oil seal 47. Shaft retainer 48. Retaining ring 49. Needle bearing 50. 3rd driven gear 51. Spacer 52. 4th driven gear 53. 5th driven gear 54. Shaft retainers 55. Tapered roller bearing 56. Adjusting shim 57. Output shaft 58. 5th gear gear assembly 59. Shaft retainer 60. Retaining ring 61. Spring expansion ring (2) 62. Needle bearing 63. Input shaft 64. Adjusting shim 65. Ball bearing 66. 3rd gear gear hub 67. 3rd gear Slider (3) 68. 3rd gear gear sleeve 69. 5th gear synchronizer ring 70. Steel ball 71. 5th gear thrust washer 72. Needle bearing 73. 4th gear components 74. Retaining ring 75. 4th gear synchronizer ring 76. Transmission case

037A Transmission Structural Schematics

1

2

34

567

9

8

10

111213

1415

1617181920

21

222324

25

26

27

2829

3031

32

33

343536

37

3839

4041

42

43

44

45

4647

48

49

50

51

52

53

54

55

59

56

57

58

60

61

62

63646566

6768

69

70

71

72

73

74

75

76

Page 57 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual50

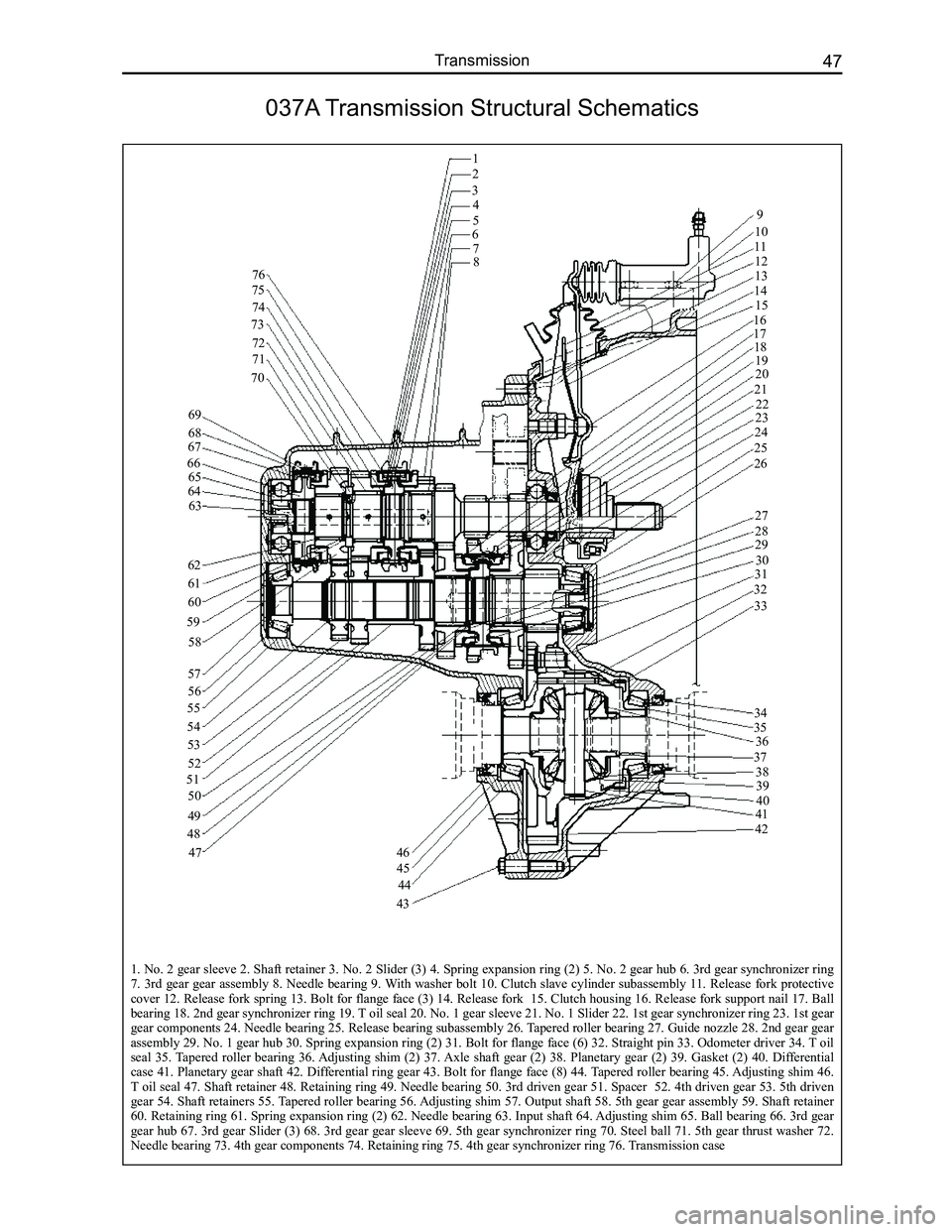

Transmission Case

Components

Clip

Shift lever assembly

Pressure torsion spring

Reverse gear switch subassembly

Washer

Bush

Oil drain slot

Tapered roller bearings

Adjusting shim

Transmission case

Clip

Clip

Adjusting shim

×8

WasherWasher

Hexagon head plug

39.2

Bolt for flange face12.0

: Specified torqueN·m

Hexagon head plug

39.2

Bolt for flange face

29.4

Position mechanism assembly

36.8

Page 62 of 281

Downloaded from www.Manualslib.com manuals search engine 55Transmission

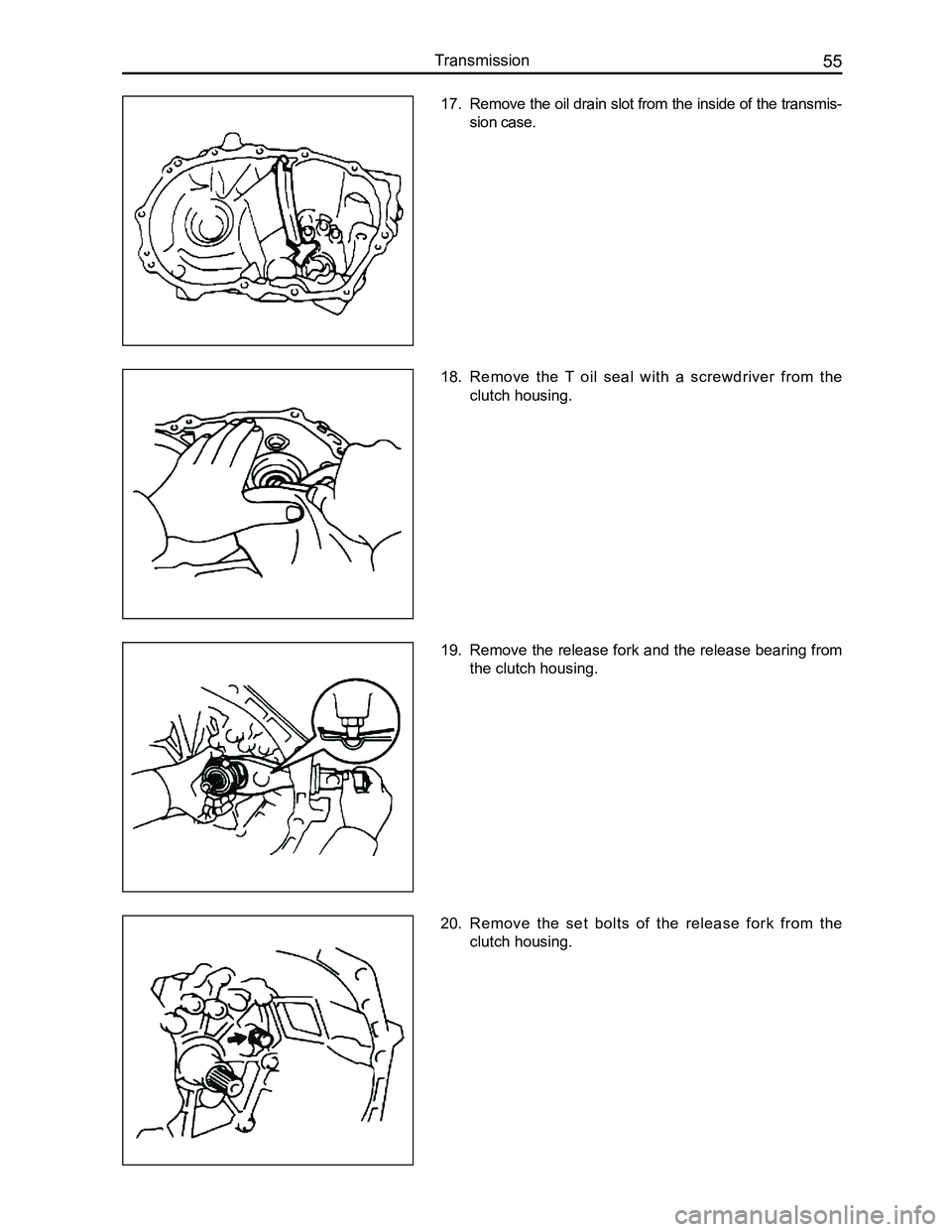

17. Remove the oil drain slot from the inside of the transmis-

sion case.

18. Remove the T oil seal with a screwdriver from the

clutch housing.

19. Remove the release fork and the release bearing from

the clutch housing.

20. Remove the set bolts of the release fork from the

clutch housing.

Page 74 of 281

Downloaded from www.Manualslib.com manuals search engine 67Transmission

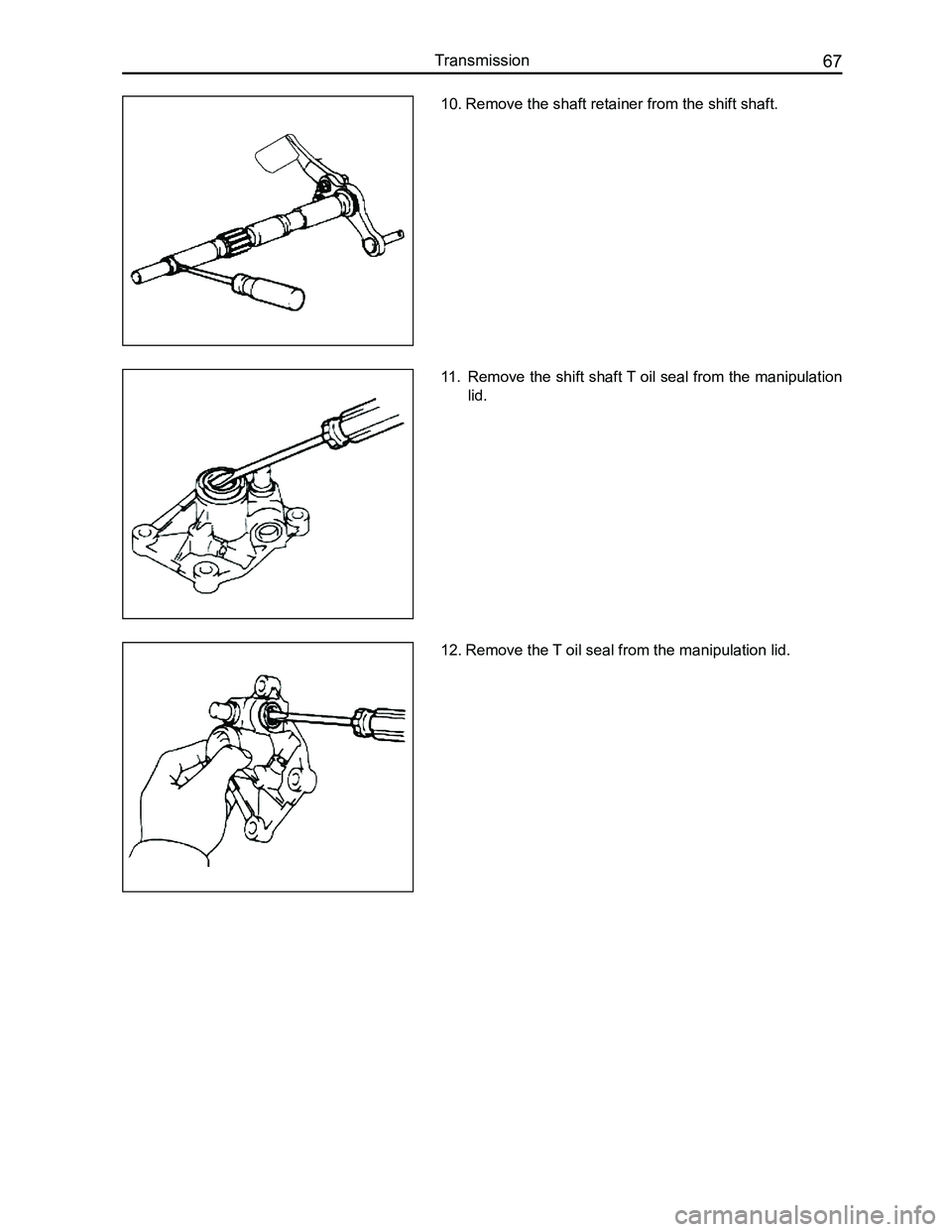

10. Remove the shaft retainer from the shift shaft.

11. Remove the shift shaft T oil seal from the manipulation

lid.

12. Remove the T oil seal from the manipulation lid.

Page 75 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual68

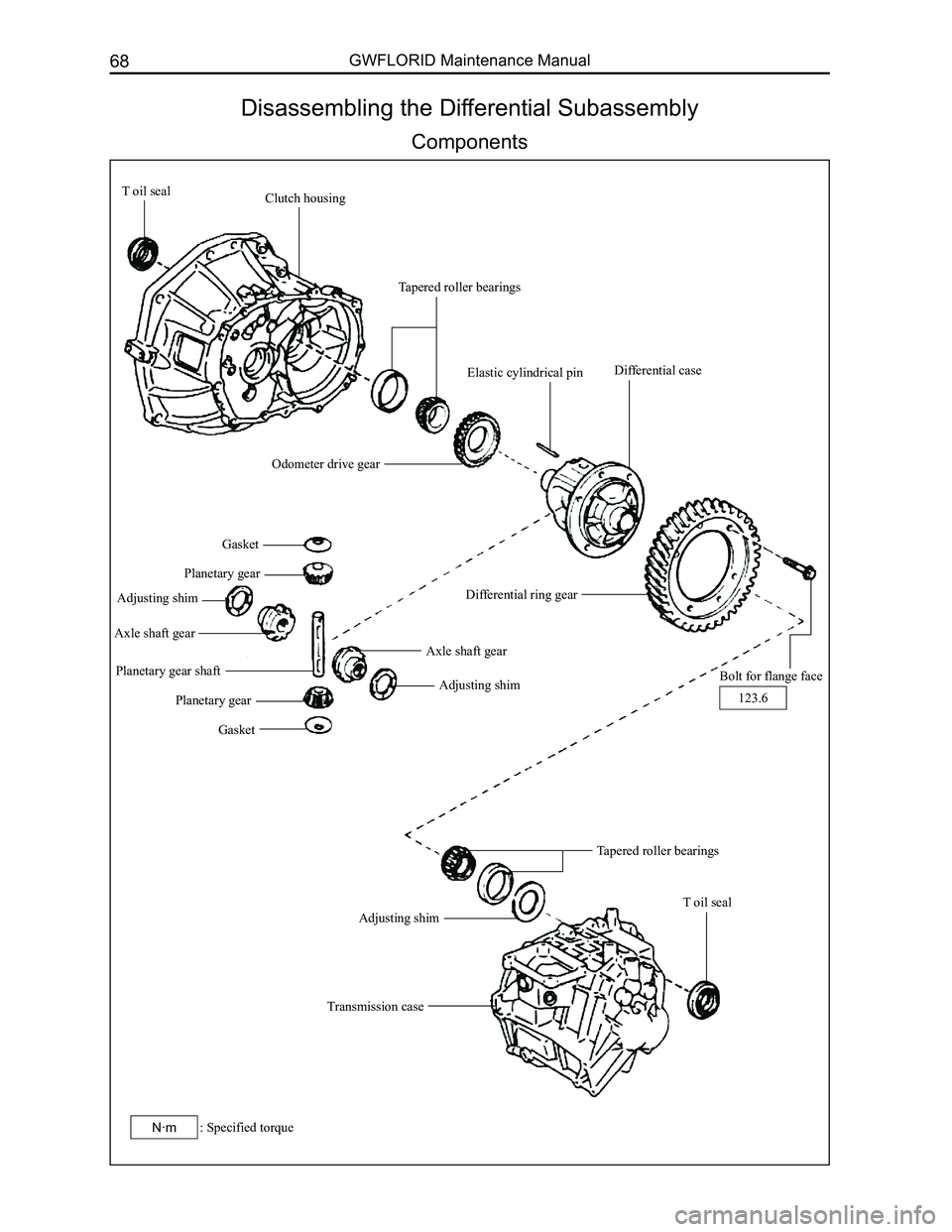

Disassembling the Differential Subassembly

Components

T oil sealClutch housing

Tapered roller bearings

Elastic cylindrical pin

Odometer drive gear

Differential case

Differential ring gear

Bolt for flange face

Gasket

Planetary gear

Adjusting shim

Axle shaft gear

Planetary gear shaft

Planetary gear

Gasket

Axle shaft gear

Adjusting shim

Tapered roller bearings

Transmission case

Adjusting shim

T oil seal

123.6

: Specified torqueN·m

Page 91 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual84

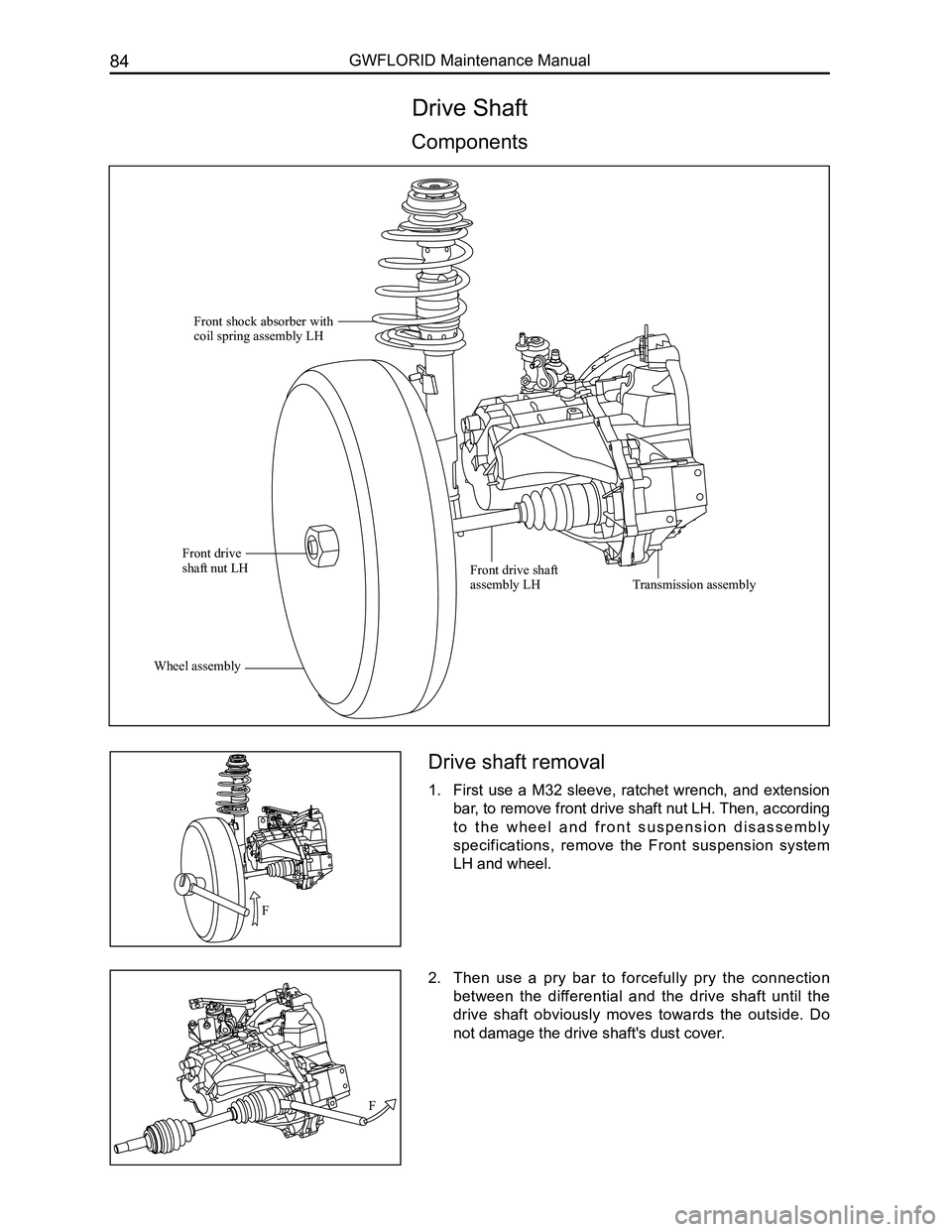

Drive Shaft

Components

Drive shaft removal

1. First use a M32 sleeve, ratchet wrench, and extension

bar, to remove front drive shaft nut LH. Then, according

t o t h e w h e e l a n d f r o n t s u s p e n s i o n d i s a s s e m b l y

specifications, remove the Front suspension system

LH and wheel.

2. Then use a pry bar to forcefully pry the connection

between the differential and the drive shaft until the

drive shaft obviously moves towards the outside. Do

not damage the drive shaft's dust cover.

Front shock absorber with coil spring assembly LH

Front drive shaft nut LH

Wheel assembly

Front drive shaft assembly LHTransmission assembly

F

F

Page 92 of 281

Downloaded from www.Manualslib.com manuals search engine 85Suspension System

Drive shaft installation

1. Insert the drive shaft.

First, align the inner end of the drive shaft and differential

spline. Keep the drive shaft axes and the differential axes

bases uniform, then hammer towards the direction of the

differential drive shaft's outer end until a clear and sharp

clicking sound is heard. Here, the drive shaft and the

transmission should have a clearance of about 1 mm.

2. According to the front suspension and wheel assembly

installation specifications, properly install the front

shock absorber with coil spring assembly LH and

wheel.

3. Use an M32 sleeve, ratchet wrench, and extension bar

to tighten front drive shaft nut LH.

Tightening torque: 225±20 N·m

F

F

Page 193 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual186

Immobilizer System

Immobilizer system composition

This vehicle's engine immobilizer system consists of a theft deterrent ECU assembly, a theft deterrent coil as-

sembly, and two theft deterrent converter assemblies. The theft deterrent coil assembly is put on the head of

ignition lock cylinder, with the other end connected to the theft deterrent ECU assembly. The two theft deterrent

converter assemblies are separately installed inside the plastic handles\

of the two keys.

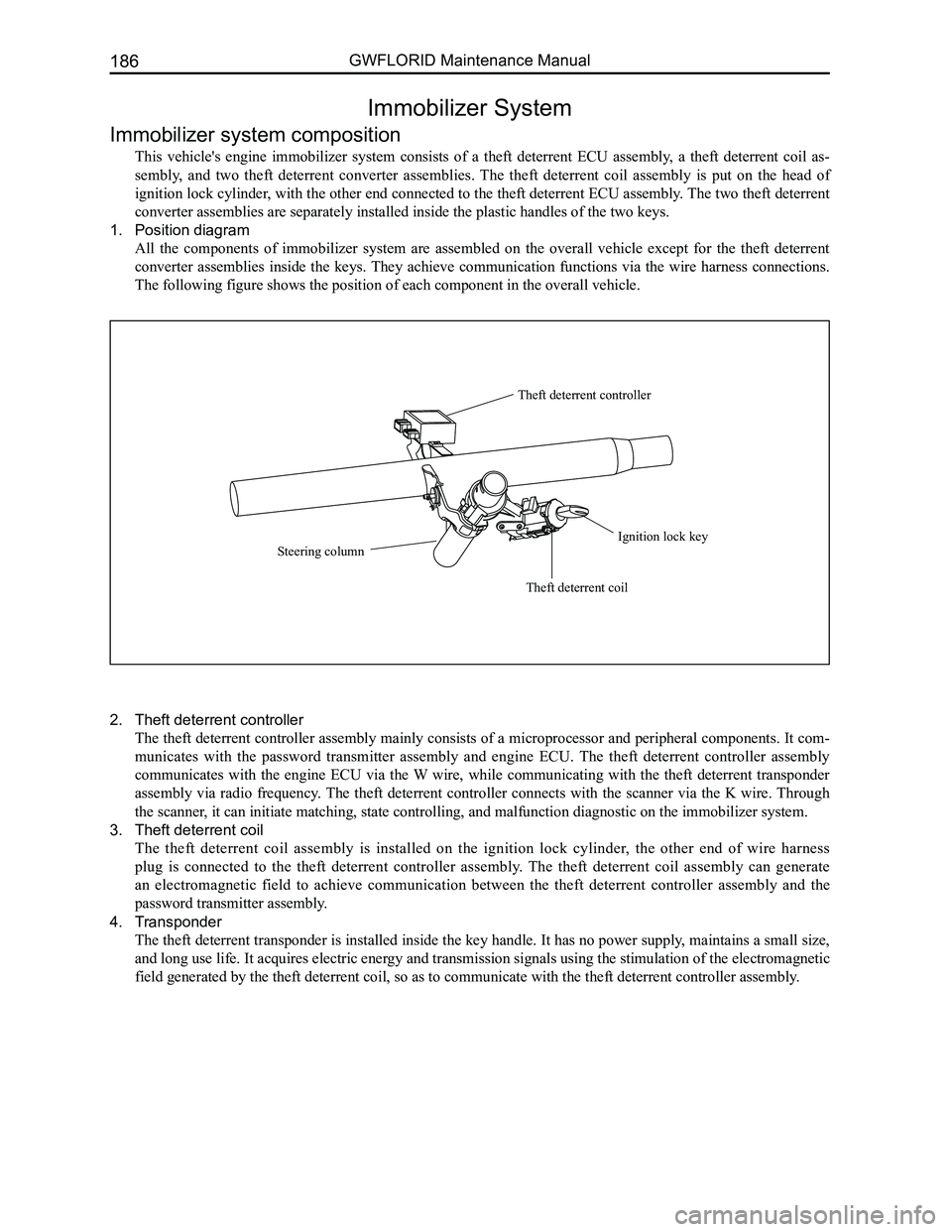

1. Position diagram

All the components of immobilizer system are assembled on the overall vehicle except for the theft deterrent

converter assemblies inside the keys. They achieve communication functions via the wire harness connections.

The following figure shows the position of each component in the overall\

vehicle.

Theft deterrent controller

Ignition lock key

Theft deterrent coil

Steering column

2. Theft deterrent controller

The theft deterrent controller assembly mainly consists of a microprocessor and peripheral components. It com-

municates with the password transmitter assembly and engine ECU. The theft deterrent controller assembly

communicates with the engine ECU via the W wire, while communicating with the theft deterrent transponder

assembly via radio frequency. The theft deterrent controller connects with the scanner via the K wire. Through

the scanner, it can initiate matching, state controlling, and malfunction diagnosti\

c on the immobilizer system.

3. Theft deterrent coil

The theft deterrent coil assembly is installed on the ignition lock cylinder, the other end of wire harness

plug is connected to the theft deterrent controller assembly. The theft deterrent coil assembly can generate

an electromagnetic field to achieve communication between the theft deterrent controller assembly and the

password transmitter assembly.

4. Transponder

The theft deterrent transponder is installed inside the key handle. It has no power supply, maintains a small size,

and long use life. It acquires electric energy and transmission signals using the stimulation of the electromagnetic

field generated by the theft deterrent coil, so as to communicate with t\

he theft deterrent controller assembly.