transmission GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 167 of 425

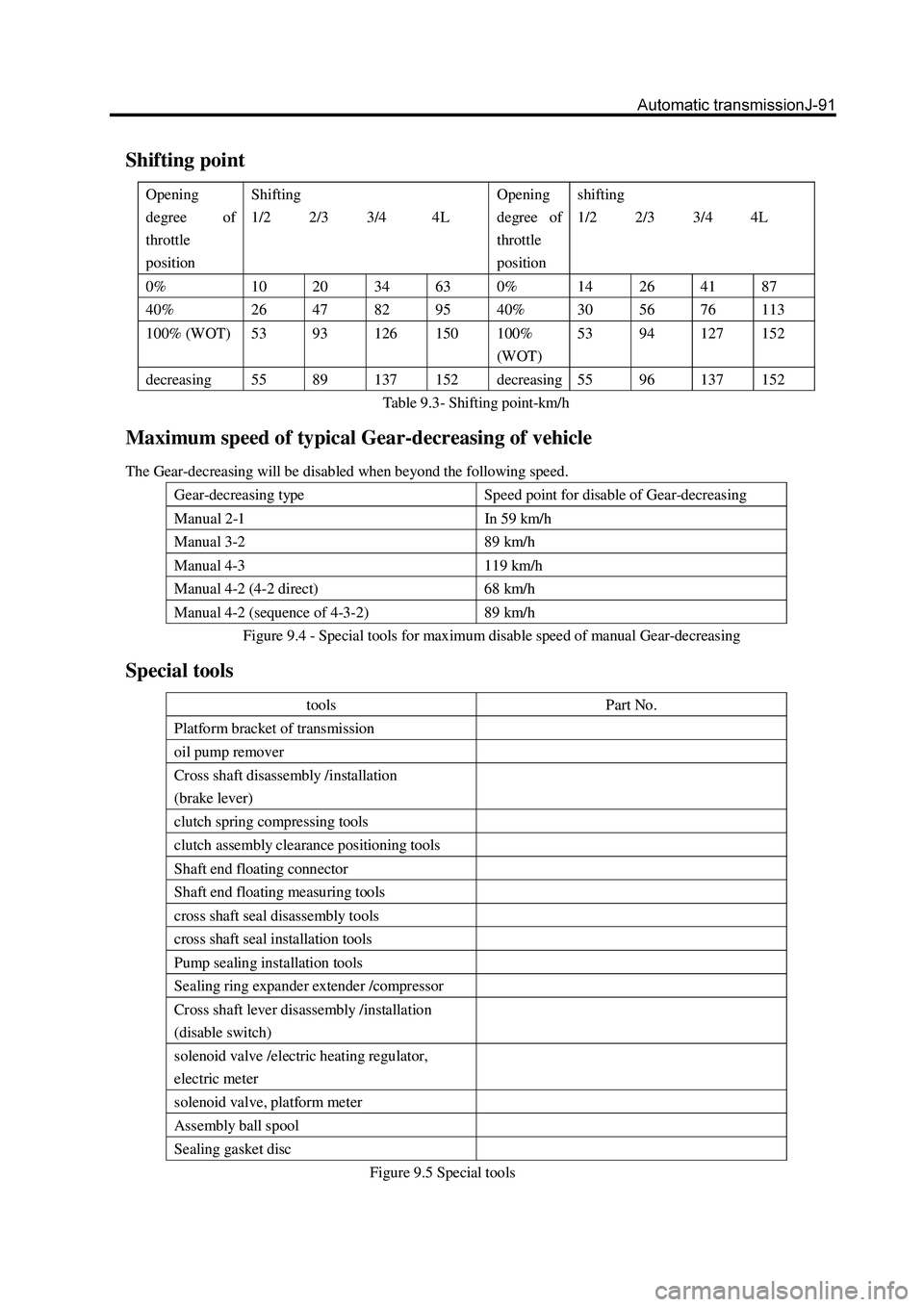

Shifting point

Opening

degree of

throttle

position Shifting

1/2 2/3 3/4 4L Opening

degree of

throttle

position shifting

1/2 2/3 3/4 4L

0% 10 20 34 63 0% 14 26 41 87

40% 26 47 82 95 40% 30 56 76 113

100% (WOT) 53 93 126 150 100%

(WOT) 53

94 127 152

decreasing 55 89 137 152 decreasing 55 96 137 152

Table 9.3- Shifting point-km/h

Maximum speed of typical Gear-decreasing of vehicle

The Gear-decreasing will be disabled when beyond the following speed.

Gear-decreasing type Speed point for disable of Gear-decreasing

Manual 2-1 In 59 km/h

Manual 3-2 89 km/h

Manual 4-3 119 km/h

Manual 4-2 (4-2 direct) 68 km/h

Manual 4-2 (sequence of 4-3-2) 89 km/h

Figure 9.4 - Special tools for maximum disable speed of manual Gear-decreasing

Special tools

tools Part No.

Platform bracket of transmission

oil pump remover

Cross shaft disassembly /installation

(brake lever)

clutch spring compressing tools

clutch assembly clearance positioning tools

Shaft end floating connector

Shaft end floating measuring tools

cross shaft seal disassembly tools

cross shaft seal installation tools

Pump sealing installation tools

Sealing ring expander extender /compressor

Cross shaft lever disassembly /installation

(disable switch)

solenoid valve /electric heating regulator,

electric meter

solenoid valve, platform meter

Assembly ball spool

Sealing gasket disc

Figure 9.5 Special tools

Page 170 of 425

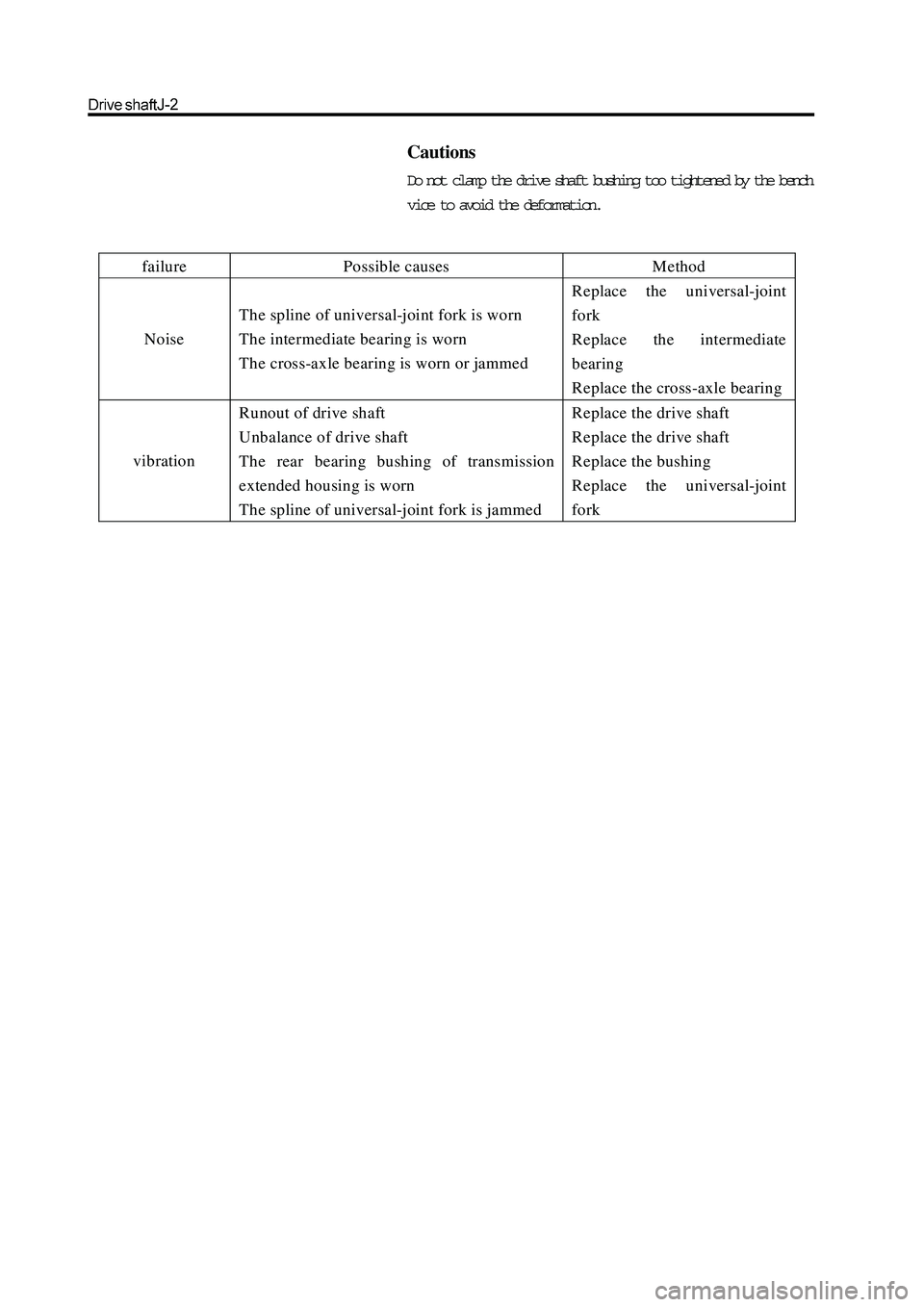

Cautions

Do not clamp the drive shaft bushing too tightened by the bench

vice to avoid the deformation.

failure Possible causes Method

Noise The spline of universal-joint fork is worn

The intermediate bearing is worn

The cross-axle bearing is worn or jammed Replace the universal-joint

fork

Replace the intermediate

bearing

Replace the cross-axle bearing

vibration Runout of drive shaft

Unbalance of drive shaft

The rear bearing bushing of transmission

extended housing is worn

The spline of universal-joint fork is jammed Replace the drive shaft

Replace the drive shaft

Replace the bushing

Replace the universal-joint

fork

Page 172 of 425

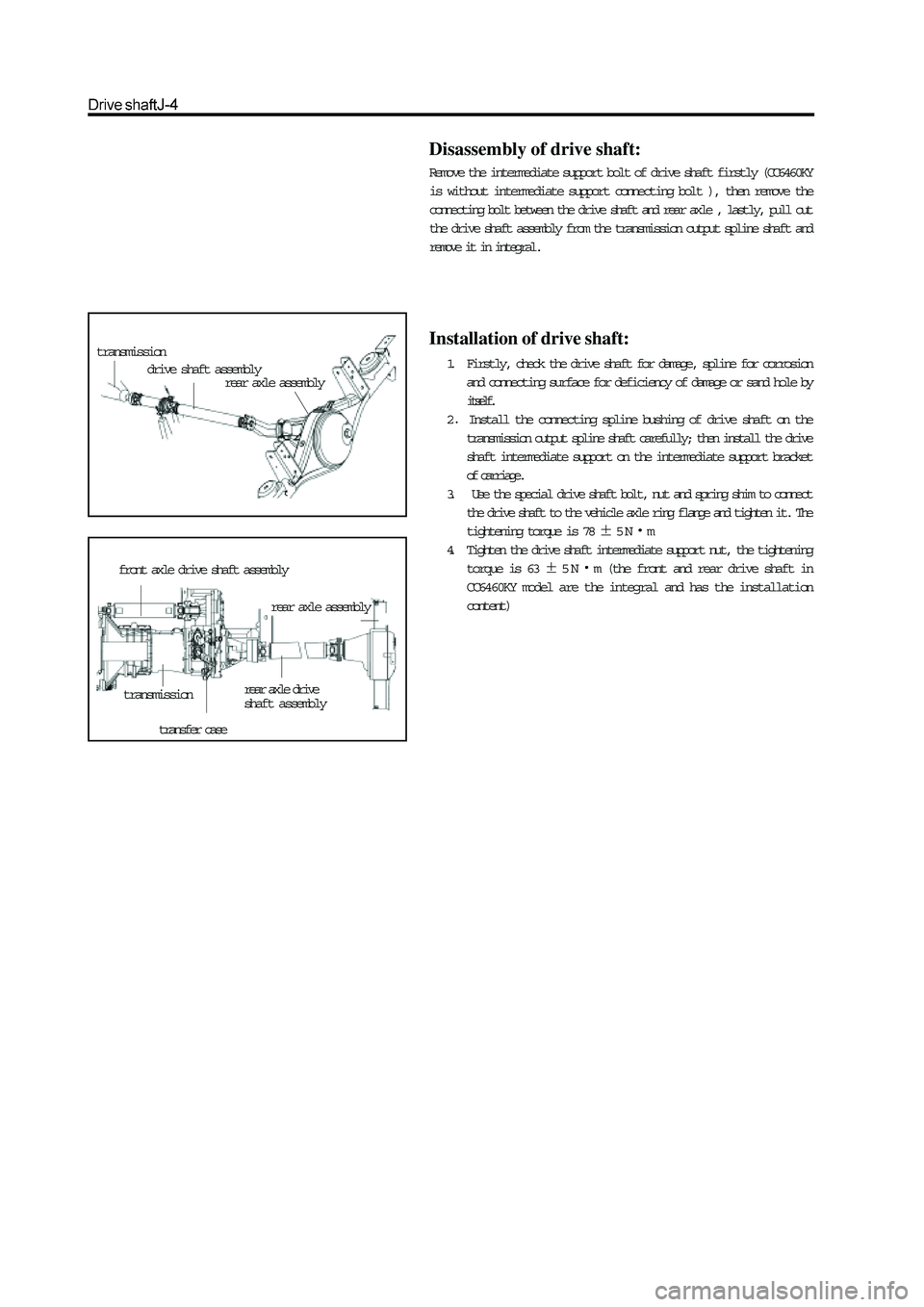

transmission

drive shaft assemblyrear axle assembly

front axle drive shaft assembly

transmissionrear axle drive

shaft assembly

transfer case

rear axle assembly

Disassembly of drive shaft:

Remove the intermediate support bolt of drive shaft firstly (CC6460KY

is without intermediate support connecting bolt ), then remove the

connecting bolt between the drive shaft and rear axle , lastly, pull out

the drive shaft assembly from the transmission output spline shaft and

remove it in integral.

Installation of drive shaft:

1. Firstly, check the drive shaft for damage, spline for corrosion

and connecting surface for deficiency of damage or sand hole by

itself.

2

Install the connecting spline bushing of drive shaft on the

transmission output spline shaft carefully; then install the drive

shaft intermediate support on the intermediate support bracket

of carriage.

3. Use the special drive shaft bolt, nut and spring shim to connect

the drive shaft to the vehicle axle ring flange and tighten it. The

tightening torque is 78

5Nm

4. Tighten the drive shaft intermediate support nut, the tightening

torque is 63

5Nm (the front and rear drive shaft in

CC6460KY model are the integral and has the installation

content)

Page 377 of 425

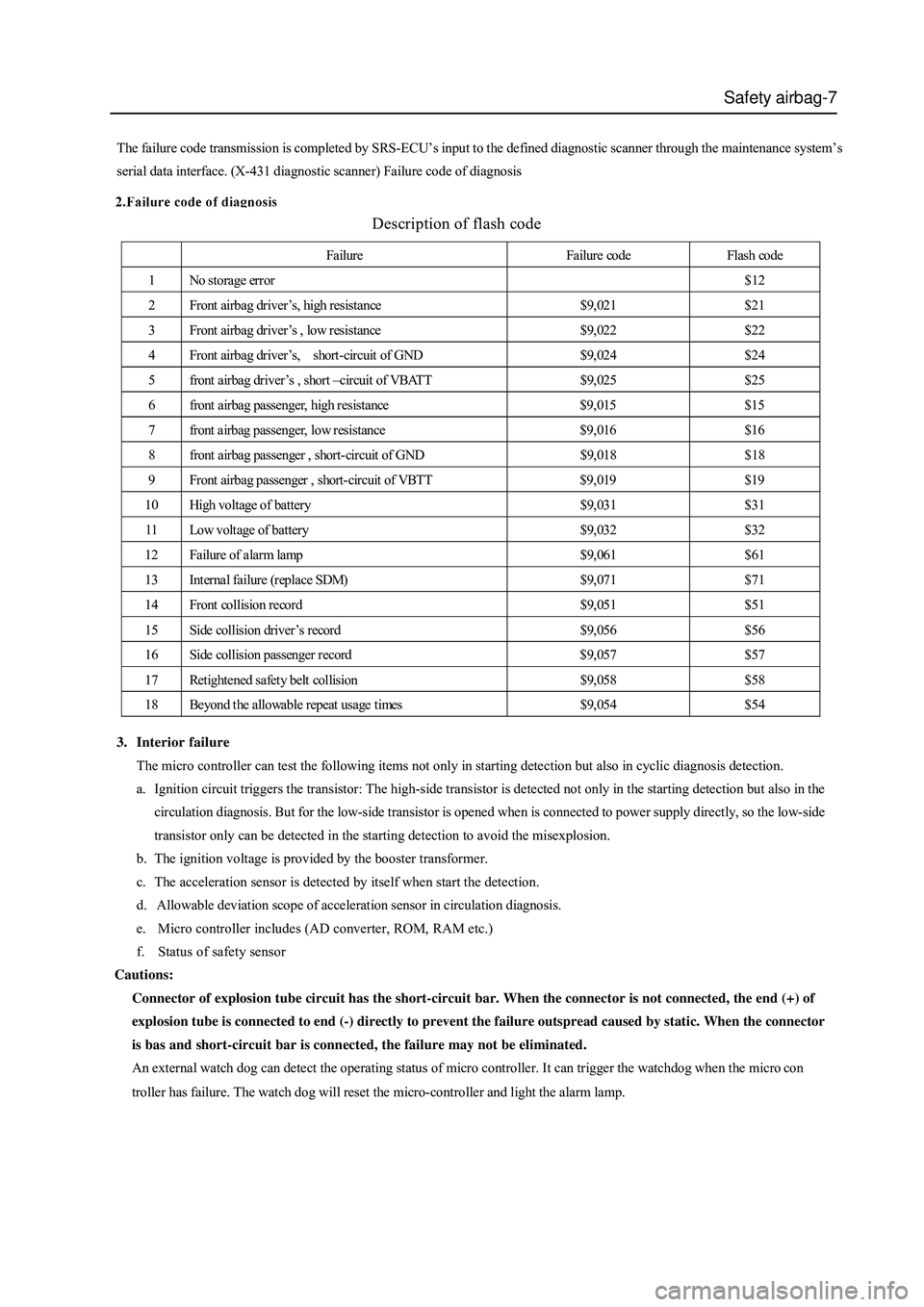

Safety airbag-7

Description of flash code

The failure code transmission is completed by SRS-ECU’s input to the defined diagnostic scanner through the maintenance system’s

serial data interface. (X-431 diagnostic scanner) Failure code of diagnosis

Failure Failure code Flash code

1 No storage error $12

2 Front airbag driver’s, high resistance $9,021 $21

3 Front airbag driver’s , low resistance $9,022 $22

4 Front airbag driver ’s, short-circuit of GND $9,024 $24

5 front airbag driver ’s , short –circuit of VBATT $9,025 $25

6 front airbag passenger, high resistance $9,015 $15

7 front airbag passenger, low resistance $9,016 $16

8 front airbag passenger , short-circuit of GND $9,018 $18

9 Front airbag passenger , short-circuit of VBTT $9,019 $19

10 High voltage of battery $9,031 $31

11 Low voltage of battery $9,032 $32

12 Failure of alarm lamp $9,061 $61

13 Internal failure (replace SDM) $9,071 $71

14 Front collision record $9,051 $51

15 Side collision driver’s record $9,056 $56

16 Side collision passenger record $9,057 $57

17 Retightened safety belt collision $9,058 $58

18 Beyond the allowable repeat usage times $9,054 $54

3. Interior failure

The micro controller can test the following items not only in starting detection but also in cyclic diagnosis detection.

a. Ignition circuit triggers the transistor: The high-side transistor is detected not only in the starting detection but also in the

circulation diagnosis. But for the low-side transistor is opened when is connected to power supply directly, so the low-side

transistor only can be detected in the starting detection to avoid the misexplosion.

b. The ignition voltage is provided by the booster transformer.

c. The acceleration sensor is detected by itself when start the detection.

d. Allowable deviation scope of acceleration sensor in circulation diagnosis.

e. Micro controller includes (AD converter, ROM, RAM etc.)

f. Status of safety sensor

Cautions:

Connector of explosion tube circuit has the short-circuit bar. When the connector is not connected, the end (+) of

explosion tube is connected to end (-) directly to prevent the failure outspread caused by static. When the connector

is bas and short-circuit bar is connected, the failure may not be eliminated.

An external watch dog can detect the operating status of micro controller. It can trigger the watchdog when the micro con

troller has failure. The watch dog will reset the micro-controller and light the alarm lamp.

Page 410 of 425

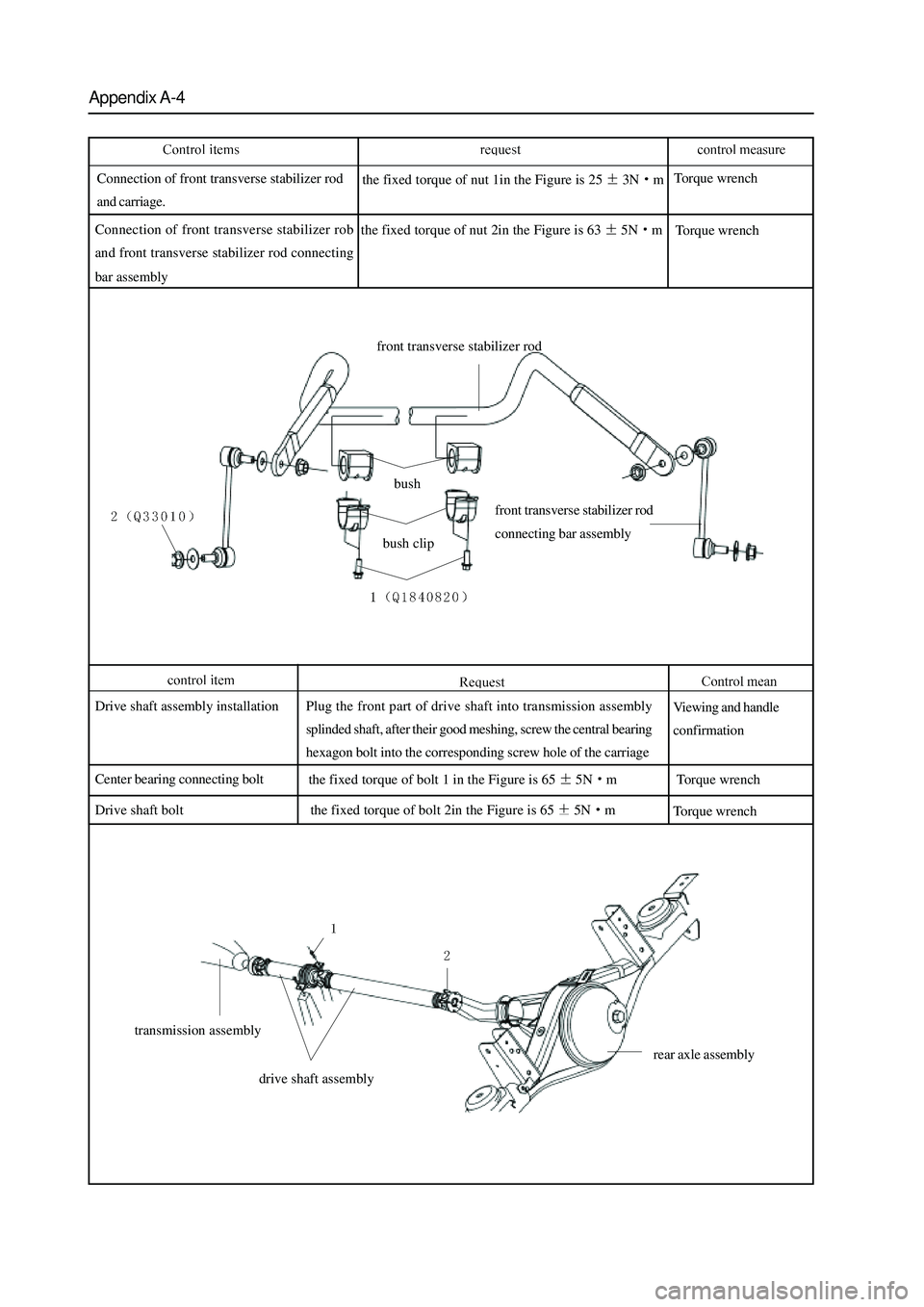

Appendix A-4

Connection of front transverse stabilizer rod

and carriage.the fixed torque of nut 1in the Figure is 253Nm

the fixed torque of nut 2in the Figure is 63

5Nm Connection of front transverse stabilizer rob

and front transverse stabilizer rod connecting

bar assemblyTorque wrench

Torque wrench

transmission assembly

drive shaft assemblyrear axle assembly

Drive shaft assembly installationPlug the front part of drive shaft into transmission assembly

splinded shaft, after their good meshing, screw the central bearing

hexagon bolt into the corresponding screw hole of the carriage

Center bearing connecting bolt

the fixed torque of bolt 1 in the Figure is 65

5Nm

Drive shaft bolt

the fixed torque of bolt 2in the Figure is 65

5Nm

Torque wrenchTorque wrench Viewing and handle

confirmation

front transverse stabilizer rod

bush

bush clipfront transverse stabilizer rod

connecting bar assembly

Page 411 of 425

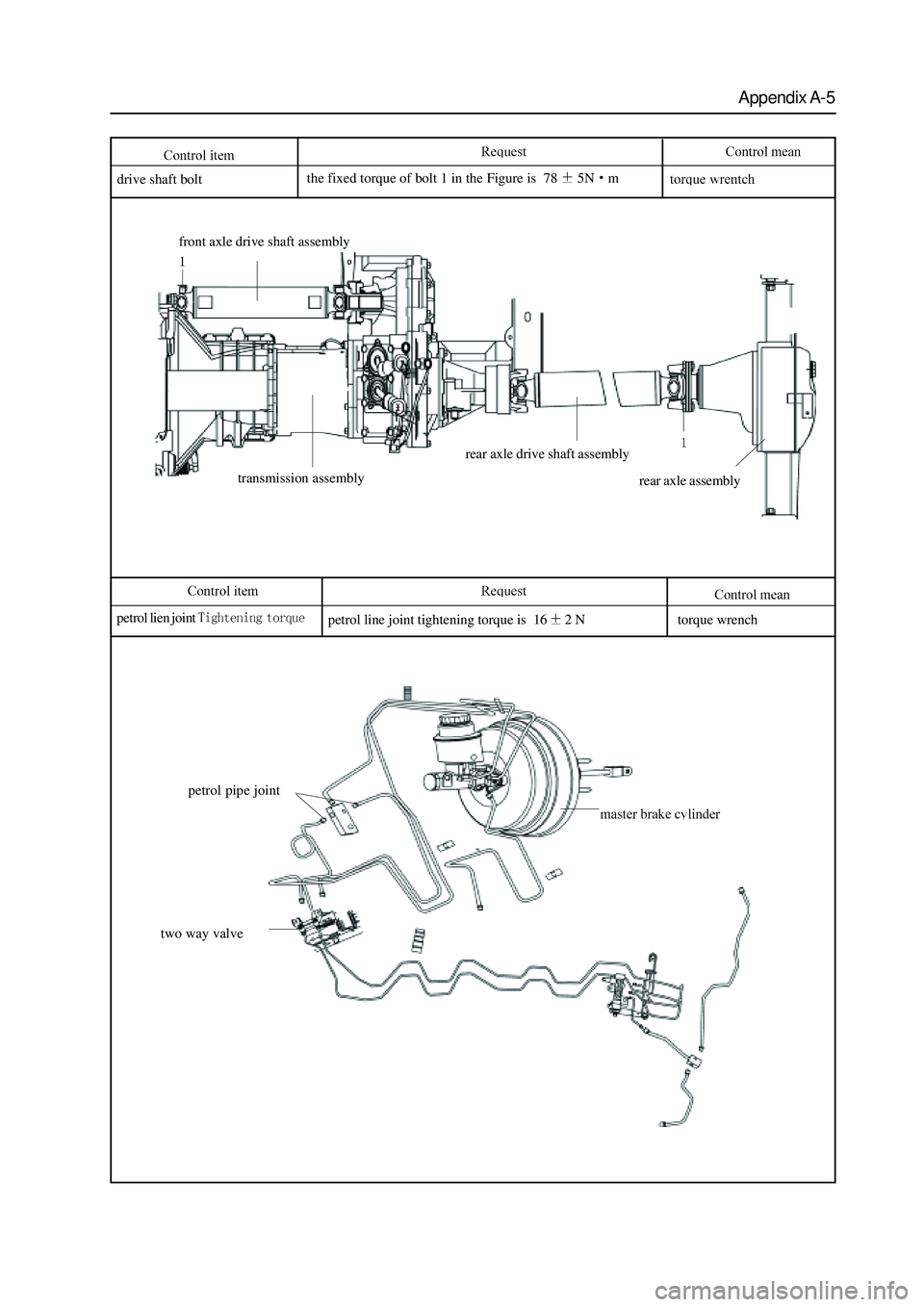

Appendix A-5

drive shaft boltthe fixed torque of bolt 1 in the Figure is 785Nm

front axle drive shaft assembly

transmission assemblyrear axle drive shaft assembly

rear axle assembly

petrol lien joint

petrol line joint tightening torque is 162 N torque wrench

petrol pipe joint

two way valve

Page 417 of 425

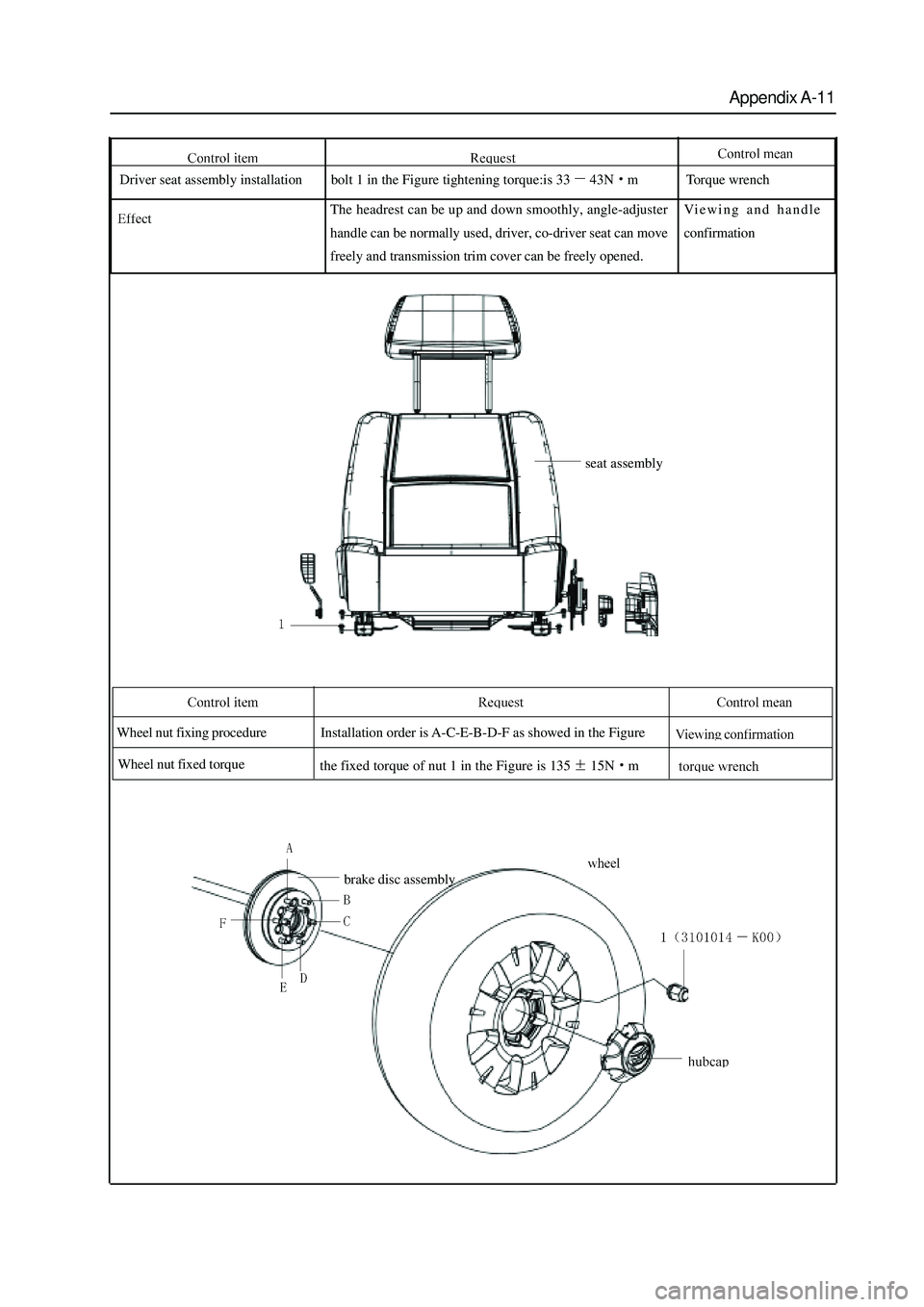

Appendix A-11

Driver seat assembly installationbolt 1 in the Figure tightening torque:is 3343Nm

Wheel nut fixing procedure

Wheel nut fixed torqueInstallation order is A-C-E-B-D-F as showed in the Figure

Torque wrench

Viewing and handle

confirmation The headrest can be up and down smoothly, angle-adjuster

handle can be normally used, driver, co-driver seat can move

freely and transmission trim cover can be freely opened.

seat assembly

the fixed torque of nut 1 in the Figure is 135

15Nm

brake disc assembly

Page 418 of 425

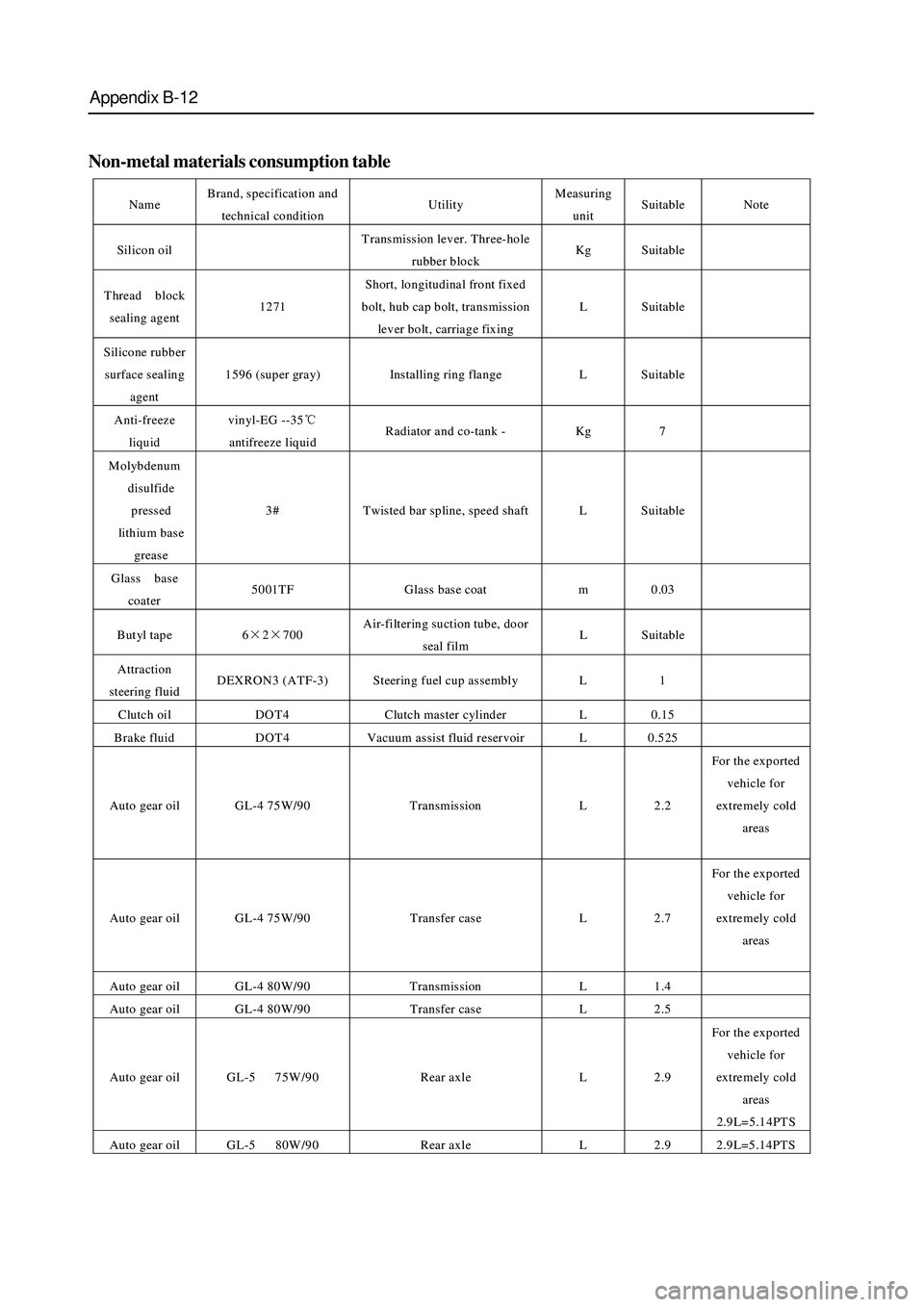

Appendix B-12

Non-metal materials consumption table

Name Brand, specification and

technical condition Utility Measuring

unit Suitable Note

Silicon oil Transmission lever. Three-hole

rubber block Kg Suitable

Thread block

sealing agent 1271 Short, longitudinal front fixed

bolt, hub cap bolt, transmission

lever bolt, carriage fixing L Suitable

Silicone rubber

surface sealing

agent 1596 (super gray) Installing ring flange L Suitable

Anti-freeze

liquid vinyl-EG --35℃

antifreeze liquid Radiator and co-tank - Kg 7

Molybdenum

disulfide

pressed

lithium base

grease 3# Twisted bar spline, speed shaft L Suitable

Glass base

coat er 5001TF Glass base coat m 0.03

Butyl tape 6×2×700 Air-filtering suction tube, door

seal film L Suitable

Attraction

steering fluid DEXRON3 (ATF-3) Steering fuel cup assembly L 1

Clutch oil DOT4 Clutch master cylinder L 0.15

Brake fluid DOT4 Vacuum assist fluid reservoir L 0.525

Auto gear oil GL-4 75W/90 Transmission L 2.2 For the exported

vehicle for

extremely cold

areas

Auto gear oil GL-4 75W/90 Transfer case L 2.7 For the exported

vehicle for

extremely cold

areas

Auto gear oil GL-4 80W/90 Transmission L 1.4

Auto gear oil GL-4 80W/90 Transfer case L 2.5

Auto gear oil GL-5 75W/90 Rear axle L 2.9 For the exported

vehicle for

extremely cold

areas

2.9L=5.14PTS

Auto gear oil GL-5 80W/90 Rear axle L 2.9 2.9L=5.14PTS

Page 419 of 425

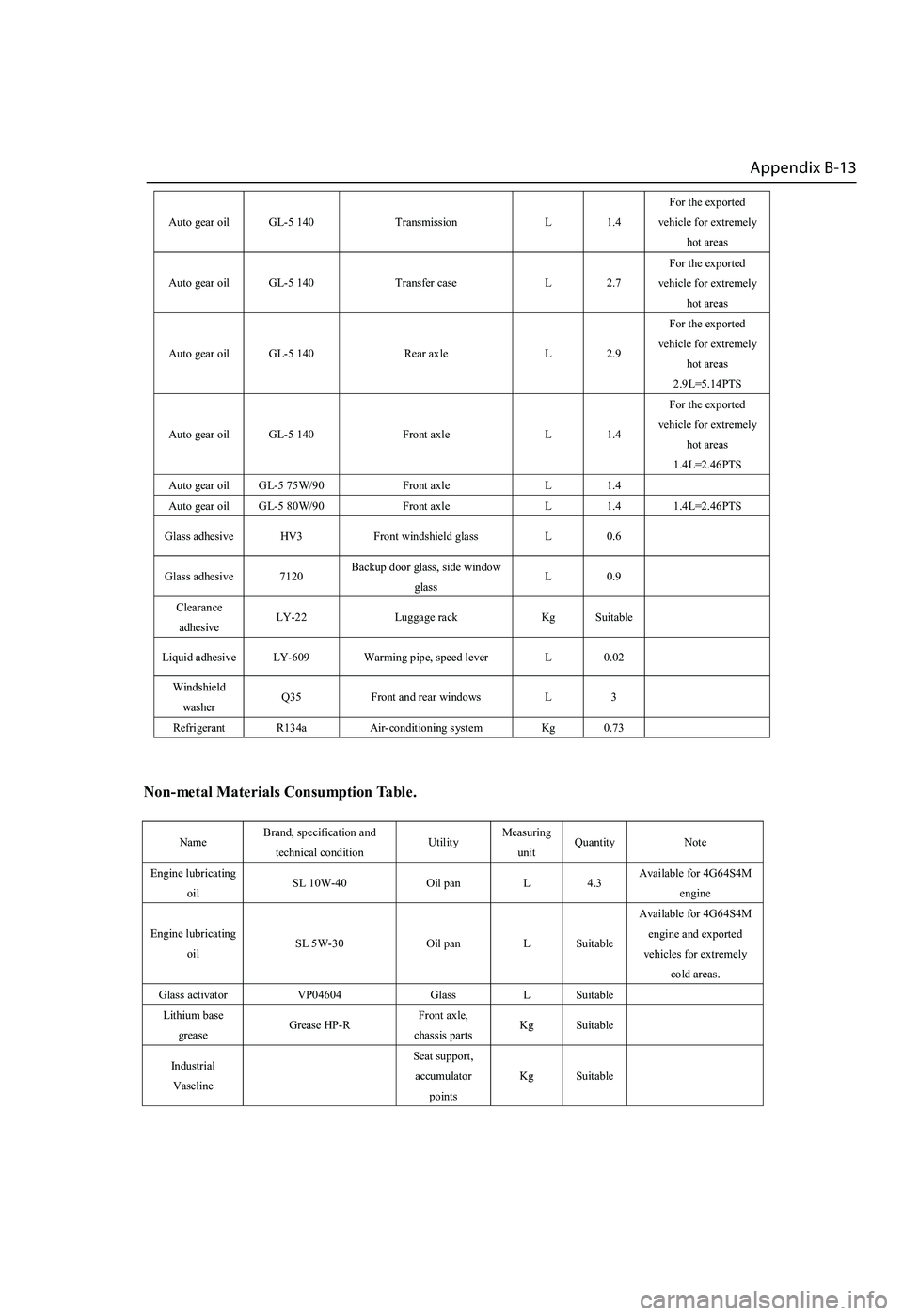

Appendix B-13

Auto gear oil GL-5 140 Transmission L 1.4

For the exported

vehicle for extremely

hot areas

Auto gear oil GL-5 140 Transfer case L 2.7

For the exported

vehicle for extremely

hot areas

Auto gear oil GL-5 140 Rear axle L 2.9

For the exported

vehicle for extremely

hot areas

2.9L=5.14PTS

Auto gear oil GL-5 140 Front axle L 1.4

For the exported

vehicle for extremely

hot areas

1.4L=2.46PTS

Auto gear oil GL-5 75W/90 Front axle L 1.4

Auto gear oil GL-5 80W/90 Front axle L 1.4 1.4L=2.46PTS

Glass adhesive HV3 Front windshield glass L 0.6

Glass adhesive 7120 Backup door glass, side window

glass L 0.9

Clearance

adhesive LY-22 Luggage rack Kg Suitable

Liquid adhesive LY-609 Warming pipe, speed lever L 0.02

Windshield

washer Q35 Front and rear windows L 3

Refrigerant R134a Air-conditioning system Kg 0.73

Non-metal Materials Consumption Table.

Name Brand, specification and

technical condition Utility Measuring

unit Quantity Note

Engine lubricating

oil SL 10W-40 Oil pan L 4.3 Available for 4G64S4M

engine

Engine lubricating

oil SL 5W-30 Oil pan L Suitable

Available for 4G64S4M

engine and exported

vehicles for extremely

cold areas.

Glass activator VP04604 Glass L Suitable

Lithium base

grease Grease HP-R Front axle,

chassis parts Kg Suitable

Industrial

Vaseline

Seat support,

accumulator

points

Kg Suitable

Page 423 of 425

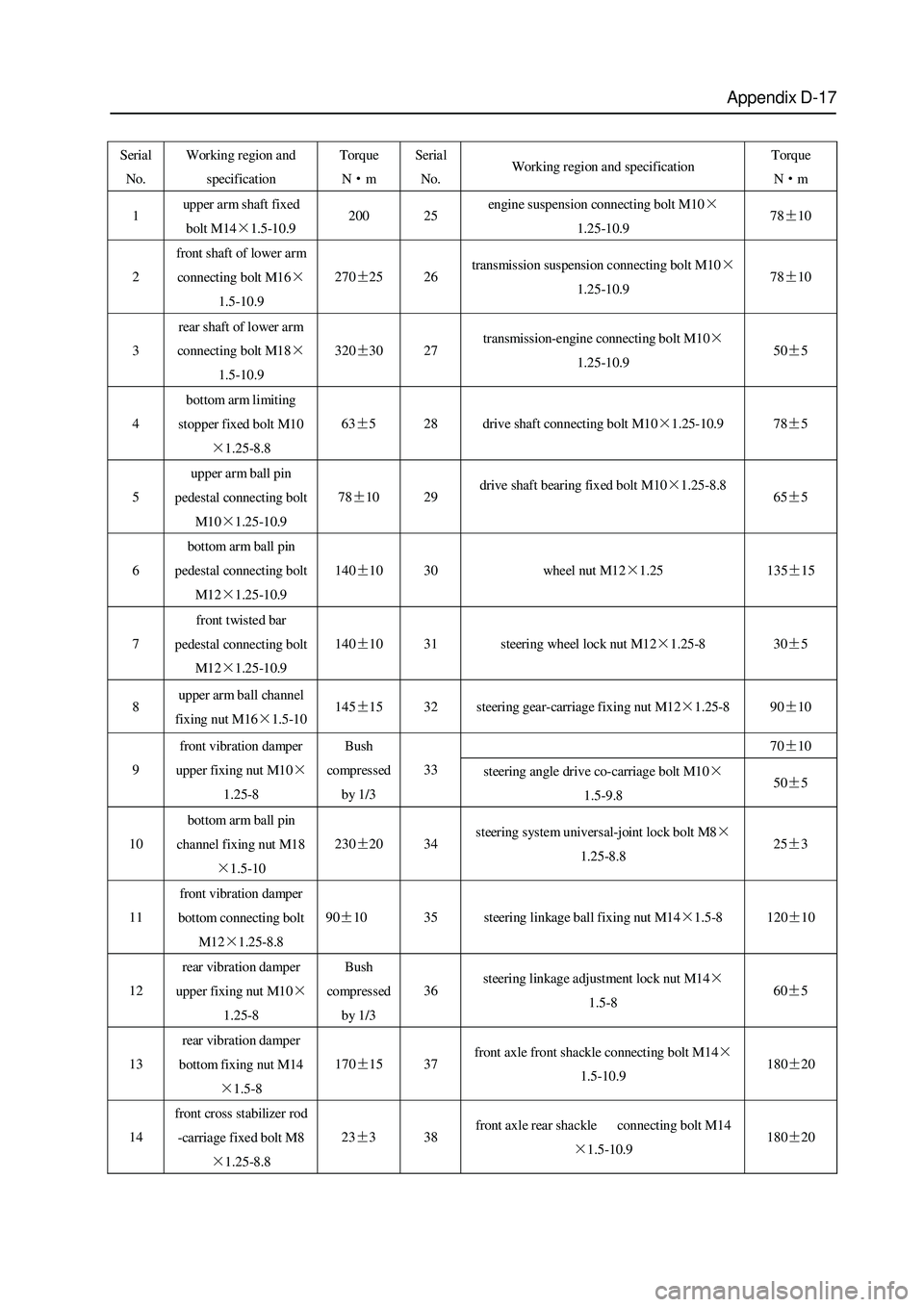

Appendix D-17

Serial

No. Working region and

specification Torque

N·m Serial

No. Working region and specification Torque

N·m

1 upper arm shaft fixed

bolt M14×1.5-10.9 200 25 engine suspension connecting bolt M10×

1.25-10.9 78±10

2 front shaft of lower arm

connecting bolt M16×

1.5-10.9 270±25 26 transmission suspension connecting bolt M10×

1.25-10.9 78±10

3 rear shaft of lower arm

connecting bolt M18×

1.5-10.9 320±30 27 transmission-engine connecting bolt M10×

1.25-10.9 50±5

4 b ottom ar m l imit ing

stopper fixed bolt M10

×1.25-8.8 63±5 28 drive shaft connecting bolt M10×1.25-10.9 78±5

5 upper arm ball pin

pedestal connecting bolt

M10×1.25-10.9 78±10 29 drive shaft bearing fixed bolt M10×1.25-8.8

65±5

6 bottom ar m ball p in

pedestal connecting bolt

M12×1.25-10.9 140±10 30 wheel nut M12×1.25 135±15

7 front twisted bar

pedestal connecting bolt

M12×1.25-10.9 140±10 31 steering wheel lock nut M12×1.25-8 30±5

8 upper arm ball channel

fixing nut M16×1.5-10 145±15 32 steering gear-carriage fixing nut M12×1.25-8 90±10

70±10

9 front vibration damper

upper fixing nut M10×

1.25-8 Bush

co mpr es sed

by 1/3 33

steering angle drive co-carriage bolt M10×

1.5-9.8 50±5

10 bottom ar m ball p in

channel fixing nut M18

×1.5-10 230±20 34 steering system universal-joint lock bolt M8×

1.25-8.8 25±3

11 front vibration damper

bottom connecting bolt

M12×1.25-8.8 90±10 35 steering linkage ball fixing nut M14×1.5-8 120±10

12 rear vibration damper

upper fixing nut M10×

1.25-8 Bush

co mpr es sed

by 1/3 36 steering linkage adjustment lock nut M14×

1.5-8 60±5

13 rear vibration damper

bottom fixing nut M14

×1.5-8 170±15 37 front axle front shackle connecting bolt M14×

1.5-10.9 180±20

14 front cross stabilizer rod

-carriage fixed bolt M8

×1.25-8.8 23±3 38 front axle rear shackle connecting bolt M14

×1.5-10.9 180±20