transmission GREAT WALL HOVER 2006 Service Manual PDF

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 124 of 425

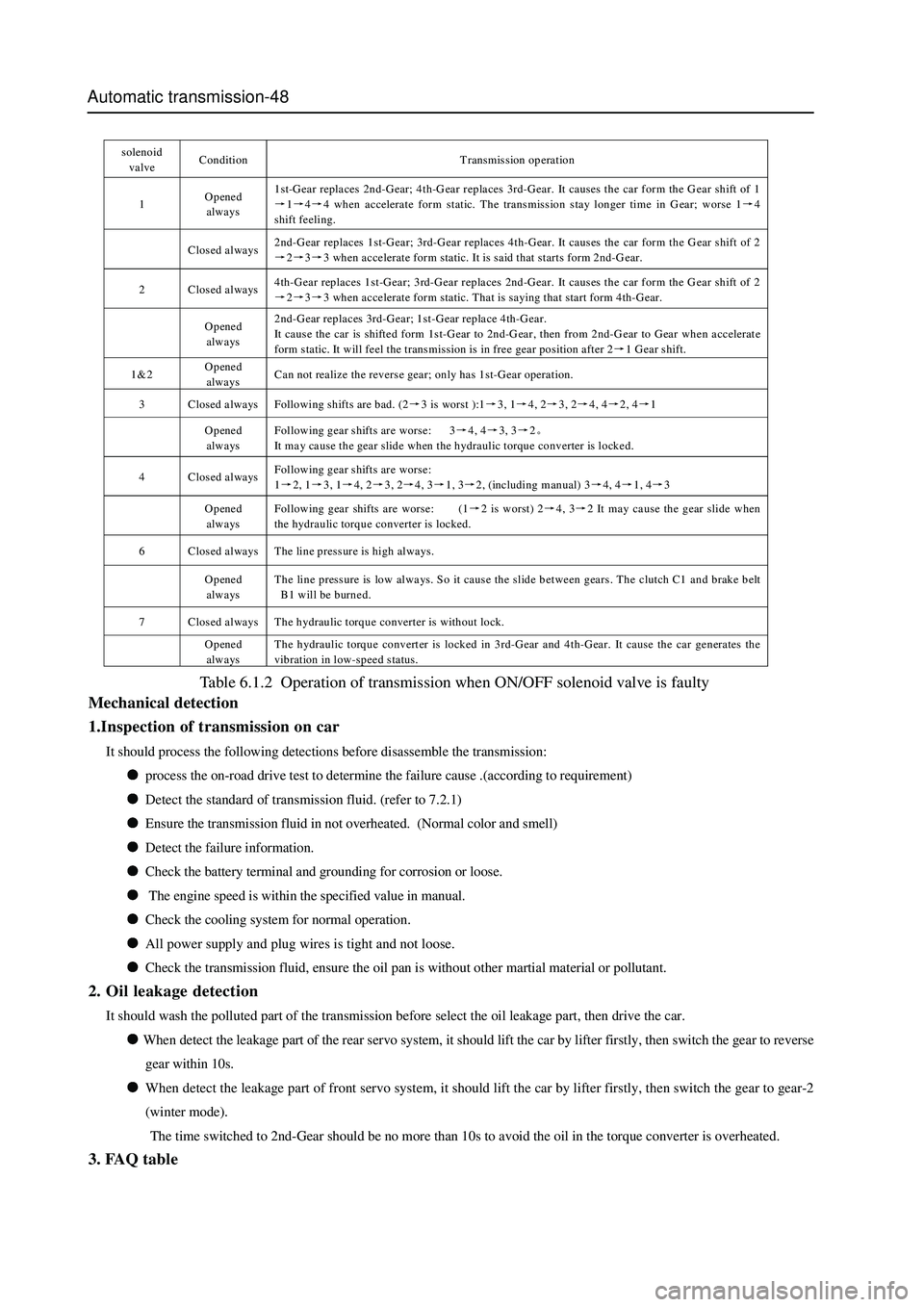

Automatic transmission-48

s oleno id

valve Condition Transmission operation

1 Opened

always 1st-Gear replaces 2nd-Gear; 4th-Gear replaces 3rd-Gear. It causes the car form the G ear shift of 1

→1→4→4 when accelerate form static. The transmission stay longer time in Gear; worse 1→4

shift feeling.

Closed always 2nd-Gear replaces 1st-Gear; 3rd-Gear replaces 4th-Gear. It causes the car form the G ear shift of 2

→2→3→3 when accelerate form static. It is said that starts form 2nd-Gear.

2 Closed always 4th-Gear replaces 1st-Gear; 3rd-Gear replaces 2nd-Gear. It causes the car form the G ear shift of 2

→2→3→3 when accelerate form static. That is saying that start form 4th-Gear.

Opened

always 2nd-Gear replaces 3rd-Gear; 1st-Gear replace 4th-Gear.

It cause the car is shifted form 1st-Gear to 2nd-Gear, then from 2nd-G ear to Gear when accelerate

form static. It will feel the transmission is in free gear position after 2→1 Gear shift.

1&2 Opened

always Can not realize the reverse gear; only has 1st-Gear operation.

3 Closed always Following shifts are bad. (2→3 is worst ):1→3, 1→4, 2→3, 2→4, 4→2, 4→1

Opened

always Following gear shifts are worse: 3→4, 4→3, 3→2。

It may cause the gear slide when the hydraulic torque converter is locked.

4 Closed always Following gear shifts are worse:

1→2, 1→3, 1→4, 2→3, 2→4, 3→1, 3→2, (including manual) 3→4, 4→1, 4→3

Opened

always Following gear shifts are worse: (1→2 is worst) 2→4, 3→2 It may cause the gear slide when

the hydraulic torque converter is locked.

6 Closed always The line pressure is high always.

Opened

always The line pressure is low always. So it cause the slide between gears. The clutch C1 and brake belt

B1 will be burned.

7 Closed always The hydraulic torque converter is without lock.

Opened

always The hydraulic torque converter is locked in 3rd-Gear and 4th-Gear. It cause the car generates the

vibration in low-speed status.

Table 6.1.2 Operation of transmission when ON/OFF solenoid valve is faulty

Mechanical detection

1.Inspection of transmission on car

It should process the following detections before disassemble the transmission:

process the on-road drive test to determine the failure cause .(according to requirement)

Detect the standard of transmission fluid. (refer to 7.2.1)

Ensure the transmission fluid in not overheated. (Normal color and smell)

Detect the failure information.

Check the battery terminal and grounding for corrosion or loose.

The engine speed is within the specified value in manual.

Check the cooling system for normal operation.

All power supply and plug wires is tight and not loose.

Check the transmission fluid, ensure the oil pan is without other martial material or pollutant.

2. Oil leakage detection

It should wash the polluted part of the transmission before select the oil leakage part, then drive the car.

When detect the leakage part of the rear servo system, it should lift the car by lifter firstly, then switch the gear to reverse

gear within 10s.

When detect the leakage part of front servo system, it should lift the car by lifter firstly, then switch the gear to gear-2

(winter mode).

The time switched to 2nd-Gear should be no more than 10s to avoid the oil in the torque converter is overheated.

3. FAQ table

Page 125 of 425

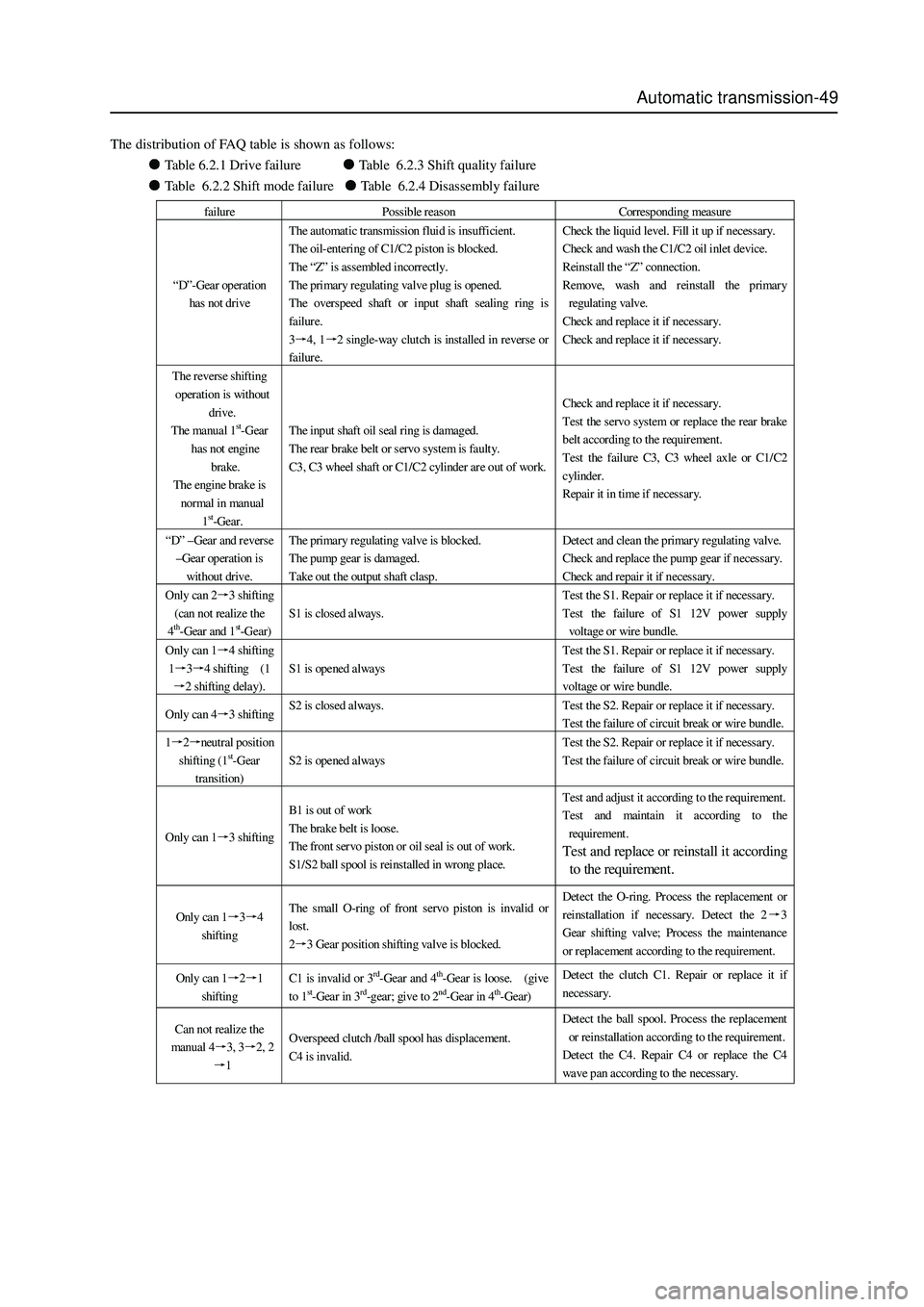

Automatic transmission-49

The distribution of FAQ table is shown as follows:

Table 6.2.1 Drive failure Table 6.2.3 Shift quality failure

Table 6.2.2 Shift mode failure Table 6.2.4 Disassembly failure

failure Possible reason Corresponding measure

“D”-Gear operation

has not drive The automatic transmission fluid is insufficient.

The oil-entering of C1/C2 piston is blocked.

The “Z” is assembled incorrectly.

The primary regulating valve plug is opened.

The overspeed shaft or input shaft sealing ring is

failure.

3→4, 1→2 single-way clut ch is installed in revers e or

failure. Check the liquid level. Fill it up if necessary.

Check and wash the C1/C2 oil inlet device.

Reinstall the “Z” connection.

Remove, wash and reinstall the primary

regulating valve.

Check and replace it if necessary.

Check and replace it if necessary.

The reverse shifting

operation is without

drive.

The manual 1

st-Gear

has not engine

brake.

The engine brake is

normal in manual

1

st-Gear. The input shaft oil seal ring is damaged.

The rear brake belt or servo system is faulty.

C3, C3 wheel shaft or C1/C2 cylinder are out of work. Check and replace it if necessary.

Test the servo system or replace the rear brake

belt according to the requirement.

Test the failure C3, C3 wheel axle or C1/C2

cylinder.

Repair it in time if necessary.

“D” –Gear and reverse

–Gear operation is

without drive. The primary regulating valve is blocked.

The pump gear is damaged.

Take out the output shaft clasp. Det ect and clean the primary regulating valve.

Check and replace the pump gear if necessary.

Check and repair it if necessary.

Only can 2→3 shifting

(can not realize the

4

th-Gear and 1st-Gear) S1 is closed always. Test the S1. Repair or replace it if necessary.

Test the failure of S1 12V power supply

voltage or wire bundle.

Only can 1→4 shifting

1→3→4 shifting (1

→2 shifting delay). S1 is opened always Test the S1. Repair or replace it if necessary.

Test the failure of S1 12V power supply

voltage or wire bundle.

Only can 4→3 shifting S2 is closed always.

Test the S2. Repair or replace it if necessary.

Test the failure of circuit break or wire bundle.

1→2→neutral position

shifting (1st-Gear

transition) S2 is opened always Test the S2. Repair or replace it if necessary.

Test the failure of circuit break or wire bundle.

Only can 1→3 shifting B1 is out of work

The brake belt is loose.

The front servo piston or oil s eal is out of work.

S1/S2 ball spool is reinstalled in wrong place. Test and adjust it according to the requirement.

Test and maintain it according to the

requirement. Test and replace or reinstall it according

to the requirement.

Only can 1→3→4

shifting The small O-ring of front s ervo piston is invalid or

lost.

2→3 Gear position shifting valve is blocked. Det ect the O-ring. Process the replacement or

reinstallation if necessary. Detect the 2→3

Gear shifting valve; Process the maintenance

or replacement according to the requirement.

Only can 1→2→1

shifting C1 is invalid or 3rd-Gear and 4th-Gear is loose. (give

to 1st-Gear in 3rd-gear; give to 2nd-Gear in 4th-Gear) Det ect the clutch C1. Repair or replace it if

necessary.

Can not realize the

man ual 4→3, 3→2, 2

→1 Overspeed clutch /ball spool has displacement.

C4 is invalid. Detect the ball spool. Process the replacement

or reinstallation according to the requirement.

Det ect the C4. Repair C4 or r eplace the C4

wave pan according to the necessary.

Page 126 of 425

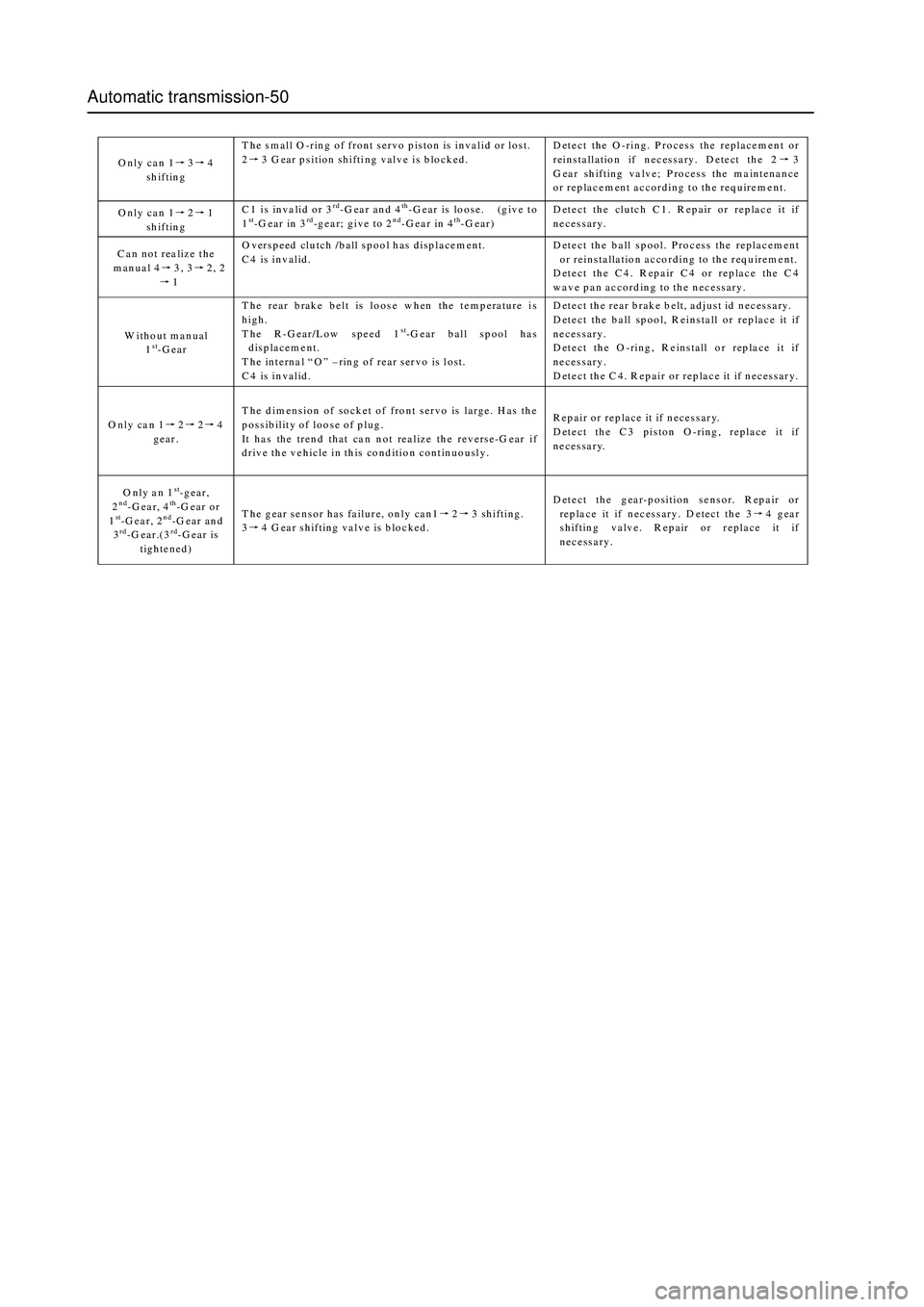

Automatic transmission-50

Only can 1→3→4

shifting The sm all O -ring of front servo piston is invalid or lost.

2→3 G ear psition shifting valve is blocked. D etect the O -ring. P rocess the replacem ent or

reinstallatio n if n ecessary. D etect th e 2→3

G ear shifting valve; Process the maintenance

or replacem ent according to the requirem ent.

Only can 1→2→1

shifting C1 is invalid or 3rd-G ear and 4th- G ea r is lo o s e . (g iv e t o

1st-G ear in 3rd-gear; give to 2nd-G ear in 4th-G ear) D etect th e clutch C 1 . R ep air or rep la ce it if

necessary.

Can not realize the

manual 4→3, 3→2, 2

→1 O verspeed clutch /ball spool has displacem ent.

C4 is invalid. D etect the ball spool. Process the replacem ent

or reinstallation according to the req uirem ent.

D etect the C4. R epair C4 or replace the C 4

wave pan according to the necessary.

W itho ut m an ual

1st-G ear The rear brake belt is loose when the tem perature is

high.

The R -G ear/Low speed 1

st-G ear ball spool has

displacem ent.

The internal “O ” –ring of rear servo is lost.

C4 is invalid. D etect the rear brake b elt, adjust id necessary.

D et e ct t h e b a ll sp o o l, R ein s ta ll o r r ep la c e it if

necessary.

D etect the O -ring, R einstall or replace it if

necessary.

D et e ct th e C 4 . R ep a ir o r r ep la c e it if n e c ess a r y.

Only can 1→2→2→4

gear. The dim ension of socket of front servo is large. H as the

possibility of loose of plug.

It has the trend that ca n n ot realize th e reverse-G ear if

drive the vehicle in this condition continuously. Repair or replace it if necessary.

Detect the C3 piston O -ring, replace it if

necessary.

Only an 1st-gear,

2nd-G ear, 4th-G ear or

1st-G ear, 2nd-G ear an d

3rd-G ear.(3rd-G ear is

tightened) The gear sensor has failure, only can1→2→3 shifting.

3→4 Gear shifting valve is blocked. D etect the gear-position sensor. R epair or

replace it if necessary. D etect the 3→4 gear

shiftin g va lv e. R ep air or r ep la ce it if

necessary.

Page 127 of 425

Automatic transmission-51

Table 6.2.3Shifting quality failure

Bad 1→2 Gear

shifting quality The throttle position sensor has failure.

T he brake b elt is adjusted incorrectly.

The front servo piston O-ring is damaged.

The variable pressure solenoid valve (S5) is damaged or

has failure.

S1, S4 has the failure.

The brake belt combination regulating valve (BAR) has

the failur e.

The front servo release spring is installed incorrectly. Detect the resistance, replace the sensor if

necessary.

Detect and replace the rake belt if necessary.

Detect and r epla ce the O -ring if necessary.

Detect, repair or repla ce the S5 if necessary.

Detect, repair or repla ce the S1, S4 if

necessary.

Detect, repair or repla ce the B AR if

necessary.

Detect and repair it if necessary.

Bad 2→3 Gear

shifting quality B1brake belt release valve is blocked.

S3, S2 has the failure.

The clutch combination regulating valve has failure.

The clutch combination oil feed ball spool is lost or

damaged.

The input shaft oil seal is damaged.

C1 piston O-ring is damaged.

C1 piston oil feed ball spool is damaged. Detect the blow-off valve. Replace or

maintain it if necessary.

Detect the S3, S2.Replace or maintain it if

necessary.

Detect the r egulating valve. R eplace or

maintain it if necessary.

Detect the ball spool .Reinstall or replace it if

necessary.

Detect the sealing ring. Reinstall or replace it

if necessary.

Detect the O -ring .R einstall or replace it if

necessary.

Detect the ball spool .Reinstall or replace it if

necessary.

Bad 3→4 Gear

shifting quality S1, S4 has failure.

B1brake belt release valve is blocked.

T he brake b elt is adjusted incorrectly.

The front servo piston O-ring is damaged.

The variable pressure solenoid valve (S5) is damaged or

has failure.

The brake belt combination regulating valve has failure. Detect the S1, S4.R einstall or replace it if

necessary.

Detect the blow-off valve. Replace or repair

it if necessary.

Detect the brake belt. Adjust it if necessary.

Detect the O -ring .R eplace or maintain it if

necessary.

Detect the S5.R epla ce or maintain it if

necessary.

Detect the r egulating valve. R eplace or

maintain it if necessary.

The engine has

the

extinguishing

co nd itio n

when select

the automatic

gear or R-gear. The torque converter clutch control valve is blocked or

solenoid valve 7 has failure. Detect and clean the torque converter clutch

valve (CCCV)

Has unstable

vibration

co nd itio n. S7 has the failure. Process the necessary detection, maintenance

and replacement according to the

requirem ent.

Page 128 of 425

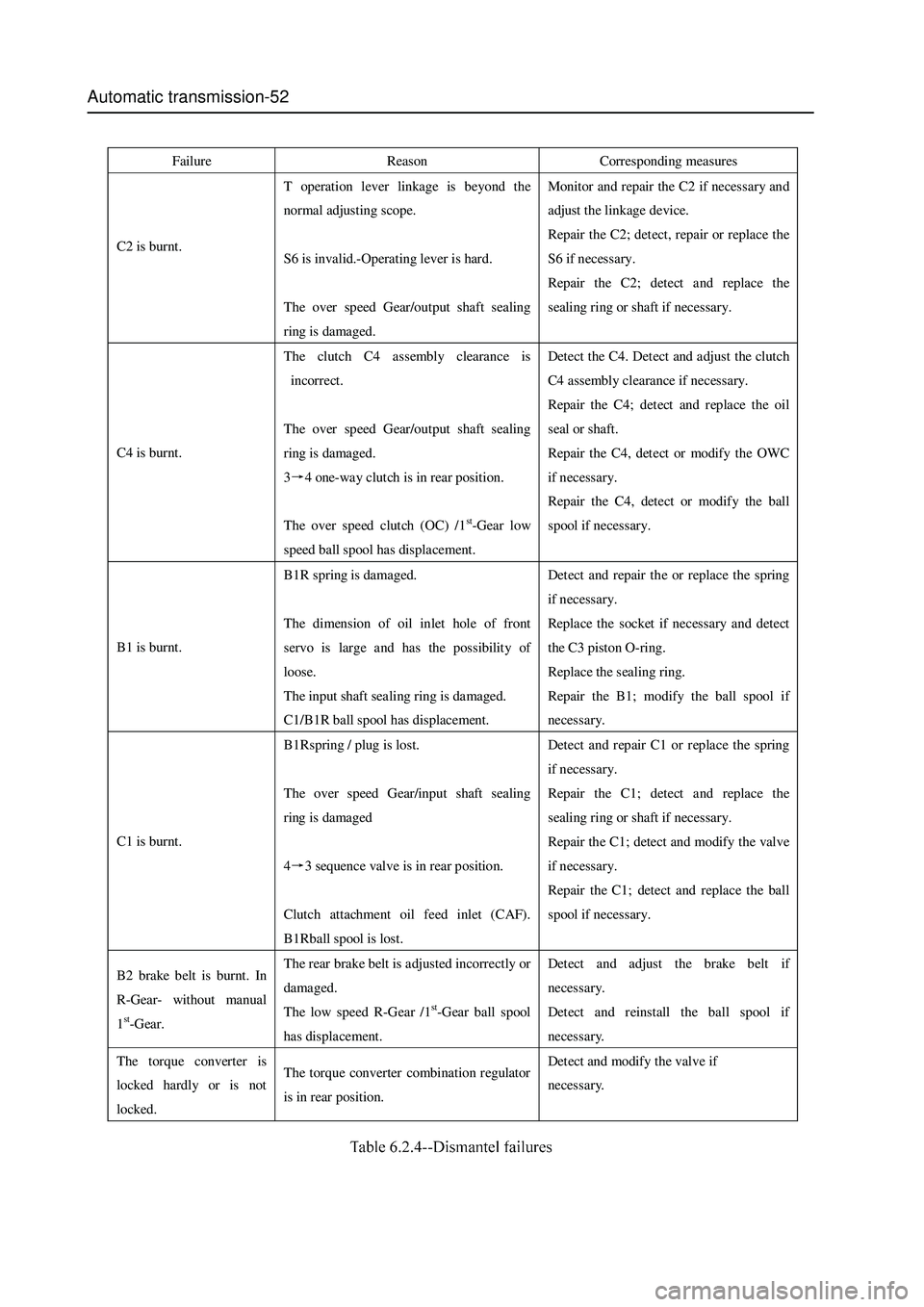

Automatic transmission-52

Failure Reason Corresponding measures

C2 is burnt.

T operation lever linkage is beyond the

normal adjusting scope.

S6 is invalid.-Operating lever is hard.

The over speed Gear/output shaft sealing

ring is damaged. Monitor and repair the C2 if necessary and

adjust the linkage device.

Repair the C2; detect, repair or replace the

S6 if necessary.

Repair the C2; detect and replace the

sealing ring or shaft if necessary.

C4 is burnt. The clutch C4 assembly clearance is

incorrect.

The over speed Gear/output shaft sealing

ring is damaged.

3→4 one-way clutch is in rear position.

The over speed clutch (OC) /1

st-Gear low

speed ball spool has displacement. Detect the C4. Det ect and adjust the clutch

C4 assembly clearance if necessary.

Repair the C4; detect and replace the oil

seal or shaft.

Repair the C4, detect or modify the OWC

if necessary.

Repair the C4, detect or modify the ball

spool if necessary.

B1 is burnt. B1R spring is damaged.

The dimension of oil inlet hole of front

servo is large and has the possibility of

loose.

The input shaft sealing ring is damaged.

C1/B1R ball spool has displacement. Detect and repair the or replace the spring

if necessary.

Replace the socket if necessary and detect

the C3 piston O-ring.

Replace the sealing ring.

Repair the B1; modify the ball spool if

necessary.

C1 is burnt. B1Rspring / plug is lost.

The over speed Gear/input shaft sealing

ring is damaged

4→3 sequence valve is in rear position.

Clutch attachment oil feed inlet (CAF).

B1Rball spool is lost. Detect and repair C1 or replace the spring

if necessary.

Repair the C1; detect and replace the

sealing ring or shaft if necessary.

Repair the C1; detect and modify the valve

if necessary.

Repair the C1; detect and replace the ball

spool if necessary.

B2 brake belt is burnt. In

R-Gear- without manual

1

st-Gear. The rear brake belt is adjusted incorrectly or

damaged.

The low speed R-Gear /1

st-Gear ball spool

has displacement. Detect and adjust the brake belt if

necessary.

Detect and reinstall the ball spool if

necessary.

The torque converter is

locked hardly or is not

locked. The torque converter combination regulator

is in rear position. Detect and modify the valve if

necessary.

Page 129 of 425

Adjustment

Hydraulic system

Following parts is the detailed description for self-detection procedure pointed to the condition occurred in chapter

6. including the condition indicated the failure, to point the problem existed in the hydraulic system.

It should select the proper procedure from the following primary detection when adjust the transmission.

Detection process of transmission fluid

Detect the manual linkage adjusting system(refer to factory manual of car)

Detect the engine idle speed

Anchoring test (beyond the scope of the maintenance manual)

On-road test (beyond the scope of the maintenance manual)

Detection procedure of transmission fluid level

1. General

The process is used to detect the level of vehicle transmission fluid. It will cause the failure or delay of transmission shifting if

the level is low than required value and the vehicle does not reach the drive temperature.

Firstly, process the transmission diagnosis information detection for vehicle (refer to chapter 6). If found the failure of sensor,

then it maybe caused by transmission fluid level is less than specified value.

It should detect whether has the abnormal delay and Gear-position condition when select the forward or reverse-gear by driving

the vehicle. One feature of oil level less than normal value is that the vehicle has the gear-position delay and lack condition when

the vehicle is in steering. The previous problem will occur when the transmission fluid temperature is low.

When the oil temperature is medium and vehicle speed failure is recorded, the gear-position lose condition

will not occurs any longer, it means that needs to fill the transmission with the transmission fluid.

2. Detection of transmission fluid level

When fill up or replace the transmission fluid, it must use the Castrol TQ95 automatic transmission fluid (ATF) or other

permissive oil. It will damage the performance and service life of transmission if use the unpermissive transmission fluid.

Please ensure the transmission fluid level is correct. The transmission also can be damaged if the transmission fluid level is

incorrect.

The setting procedure of transmission fluid level is shown as follows:

Caution:

When the transmission is in operating temperature, the hot transmission fluid may flow out form the

housing if remove the filling plug.

a. If the vehicle is in operating temperature, allow two hours time for cooling before add the transmission fluid, but

it must not more than 4 hours (this will make the transmission locate in the correct temperature range). When the

temperature is overheating, the transmission fluid level will higher than the plug port. Removal of plug will cause

the transmission fluid flows out from the oil filling port, then cause the low level of transmission fluid.

b. The gear-position of transmission is in parking-Gear (P-Gear), shut off the engine.

c. Lifting the vehicle (or parking above the trench).

d. Clean the around of plug when remove it. Then remove and clean the plug and check the O-ring for damage. Install

the oil filling pump in the oil filling hole.

e. Lower the vehicle; the oil filling pump will be connected to the vehicle at this time. Fill the transmission with the

oil partially. Then start the vehicle in P-Gear to rotate the engine in idle speed. Step down the foot brake, pull the

shifting lever in each gear-position in circulation and add the transmission fluid until the action of each gear-

position can be sensed.

f. Shut down the engine; lift the vehicle; ensure the vehicle is always in horizontal.

g. Remove the filling plug 3 minutes after the engine is shut off, but must not be no more than1 hour. At this time, the

correct level position should be in the bottom of oil filling hole. If does not reach the liquid level position, then fill

with few transmission fluid to make it reach the correct level.

h. Replace the transmission; clean the residual transmission fluid on the transmission and

vehicle.

i. Tighten the transmission plug to the specified torque of 30

35Nm.

Page 130 of 425

3. Oil filling of service after sales

Set the liquid level position correctly; the procedure is shown as follows:

a. Shut down the engine; place the gear-position in the P-Gear.

b . Lift the vehicle (or place it above the trench).

c. Clean the around of plug before remove it. Remove the oil plug and check the O-ring for damage, finally connect the oil filling

pump to the oil filling hole.

d. Lower the vehicle and oil filling pump to the ground; fill with the transmission fluid partially. The general oil filling amount

is shown as follows:

If in the status of transmission hydraulic torque converter is empty: 8.0 L

If in the status of transmission hydraulic torque converter is full: 3.8 L

e. When start the vehicle in P-Gear, rotate the engine in idle speed. Step down the foot brake, pull the shifting lever in each gear-

position in circulation and add the transmission fluid until the action of each gear-position can be sensed.

f. Then fill with 0.5L transmission fluid (ATF) additionally.

g. Shut off the engine, lift the vehicle; take off the pump and replace the plug. Ensure the plug is tightened according to the

specification.

h. Then pull the vehicle throttle position for slight opening to make the vehicle runs for 3.5

4.5km; the rotary speed of engine

is no more than 2500r/min; then the transmission fluid temperature will in the scope of 50

60.

i. The engine is in idle-speed; pull the hand brake to make the shifting lever circuits in each gear-position horizontal status.

k. Remove the filling plug 3 minutes after the engine is shut off, but must be no more than1 hour. At this time, the correct

level position should be in the bottom of oil filling hole. If does not reach the liquid level position, then fill with few

transmission fluid (ATF) to meet the requirement.

l. Reinsert the transmission fluid plug, remove the residual transmission fluid around the vehicle and transmission; tighten the

plug to the specified torque.

4. Replace the ATF

Please notice that the color of TQ95 automatic transmission oil will be faded in the normal operation of transmission; it will be

turn into the deep brown or even in black. It will not affect the performance of ATF. It means that the fading of transmission

fluid not always means to replace the transmission fluid.

If the transmission temperature is raised, the ATF will be burnt. In this condition, ATF will change into black and with special

sulfur smell. The smell of the ATF means the oil is burnt.

If the ATF is burnt, it will cause the damage of transmission (the clutch assembly is damaged at least).At this time, it should

disassembly the transmission and process the necessary detection.

Electronic calibration

1. Idle-speed calibration

The idle-speed calibration is introduced in detail in the vehicle factory manual.

2 Calibration of position of throttle position

If the throttle position information stored in TCU is lost or not in application scope. It can be reestablished according to the

following program as the diagnosis error information.

a. Check whether the engine idle speed is in required range.

b. In the status of shutting off of air-condition, make the engine is in “D” –Gear for 60s,then the reference point with opening

degree of 0

of throttle position is reset in TCU.

Shut off the engine; switch on the ignition device, step the accelerator pedal to bottom for 60s, then the reference point with opening

degree of 100

of throttle position is reset in TCU.

3. Clear of throttle position

The clear process set by learning throttle position is necessary for M88 transmission TCU.

4. Car code

For M88 transmission, the car code is unnecessary.

Page 131 of 425

Figure 8.1 Removal of typical pump

Disassembly /assembly

Cautions for assembly

It should notice the following items before reassemble the transmission system:

1. Ensure the cooler pipeline is washed and all chip is removed when replace the transmission. It can

be realized by using the compressed air to enter into the rear cooler pipeline to remove the oil and

all foreign material in the front cooler.

2. It should check the cooler after the transmission is installed. Ensure the front and rear cooler

pipeline is connected to the proper container. Rotate the vehicle in P-Gear in idle-speed, measure

the flow rate within 15s.

3. The flow within 15s should be more than 1L.

4. It should avoid any water entering into the transmission. This will cause the transmission fluid to

generate the foam or make the transmission fluid flows out form the respirator.

5. Ensure that two grounding wires in vehicle (one end to battery, one end to vehicle) are connected

before the installation of the anode of battery.

6. If the power control module and transmission control unit is exchanged, then calibrate the pro-

gram refer to related throttle position in Part

Removal

1. Transmission

Caution:

It should remove the gear-position sensor before wash the transmission in solvent or hot abluent.

When need to remove the transmission from the vehicle, it should drainage the transmission fluid,

and use the special removal tools.

The removal of the transmission should be processed in module method, the details of removal of each module is described

in following section in detail. Refer to details of special tools listed in table 9.10 and 9.6 when remove it.

The technician needs a set of quality tools when inspect the transmission, especially for dual hexagon spanner of model

30, 40, 50 and 8mm, 10mm, 12mm.

It should abide by the following procedure when disassemble the transmission:

a. Remove the shell of torque converter and torque converter.

b. Place the transmission on the saddle platform.

c. Remove the oil pan and oil pan sealing.

d. Remove the filter retainer of each valve and remove the filter.

e. Remove the wire on solenoid valve, place it in side.

f. Remove the protection screw in the valve and remove the valve from the main housing (remove the model Z connecting bar).

g. Remove the front servo circlip, cover and piston.

Caution:

The plastic servo block on used for piston return spring.

h. Remove the flange shaft fork, then remove the transmission housing (2WD and Chairman).

Use the 8mm hexagon wrench to move the pump to the housing bolt.

Page 132 of 425

Caution:

Do not take out the central support by knocking the output shaft , otherwise, it will damage the surface of thrust bearing

permanently

o. Remove the central support, 1-2 one-way clutch and planetary gear block.

p. Use the T40 special tools to remove the parking lever cum disc.

q. Remove the rear brake belt support and rear brake belt.

r. Remove the output shaft assembly.

2. Transmission case

It should follow the following procedure when remove the transmission:

a. Use the tools to take out the fixed pin from one side of cross shaft gear sensor (2WD and 4WD mode).

b. Remove the gear sensor from the case. Use the special tools to take out the cross shaft seal.

c. Take out the circlip from the cross shaft. Pull up the cross shaft and take out the drive pin from the sector gear-position

selection plate.

d. Use the tools, press down the cross-shaft pin and take out the shaft , reset spring and bolt from the housing. Refer to Figure

8.3.

Figure 8.3 Installation and disassembly of cross-axle pinFigure 8.2 central support retainer

i. Use the pump remover to remove the pump, refer to Figure 8.1.

g. Remove the input shaft , front clutch cylinder and overspeed –Gear shaft as an integral. Take it out from the front of housing.

k. Remove the clutch C3 cylinder and central gear .

l. Remove the brake belt support and brake belt.

m. Use the 50 special tools to remove two central support connecting bolts.

n. Remove the central support retainer, refer to Figure 8.2.

Page 137 of 425

Caution:

Some valves are pulled by the spring and may fall down form the valve.

m. Press down the plug of 4-3 sequence valve and take out the locking nut disc.

n. Take out the plug, valve and spring.

o. Press down the solenoid valve 5 gate. Remove the fixed pin, valve and spring.

Caution:

The valve is pulled by the spring and may fall down form the valve.

p . Press down the line pressure blow-off valve , then remove the fixed pin, disc (if proper) spring and valve.

q. Take out the roller pin and remove the spring and ball spool detection valve adjacent BAR.

Assembly

The transmission is assembled in the method of module. The detailed assembly process of each module is described in the

following chapter in detail.

Refer to Table 8.1 (end of section 8.3) for the description of used torque specification. The Table 9.10 in section 9.6 describes

the necessary special tools for assembly.

The technician also needs to select the quality Torx tools, especially for the two-screw socket wrench with code of 40, 50,

8mm,10mm and 12mm to detect the transmission completely.

1.Transmission

Caution:

Ensure the BIR retainer is proper for the case (otherwise, the valve will damage the separation disk).

Ensure the E clip is installed on the cross shaft.

Ensure all parts of parking machine can operate normally.

The assembly procedure of transmission is shown as follows:

a. Place the upper transmission on the platform upwardly and place it on the transmission bracket.

b. Install all accessories, bolts and bleed devices. Paint the sealant on the sealing place. Tighten all components according

to the specification. Ensure the cleanness of all bleed devices. Ensure the rear oil filling nozzle of housing is correct and

without blocking material. Refer to Figure 8.19.

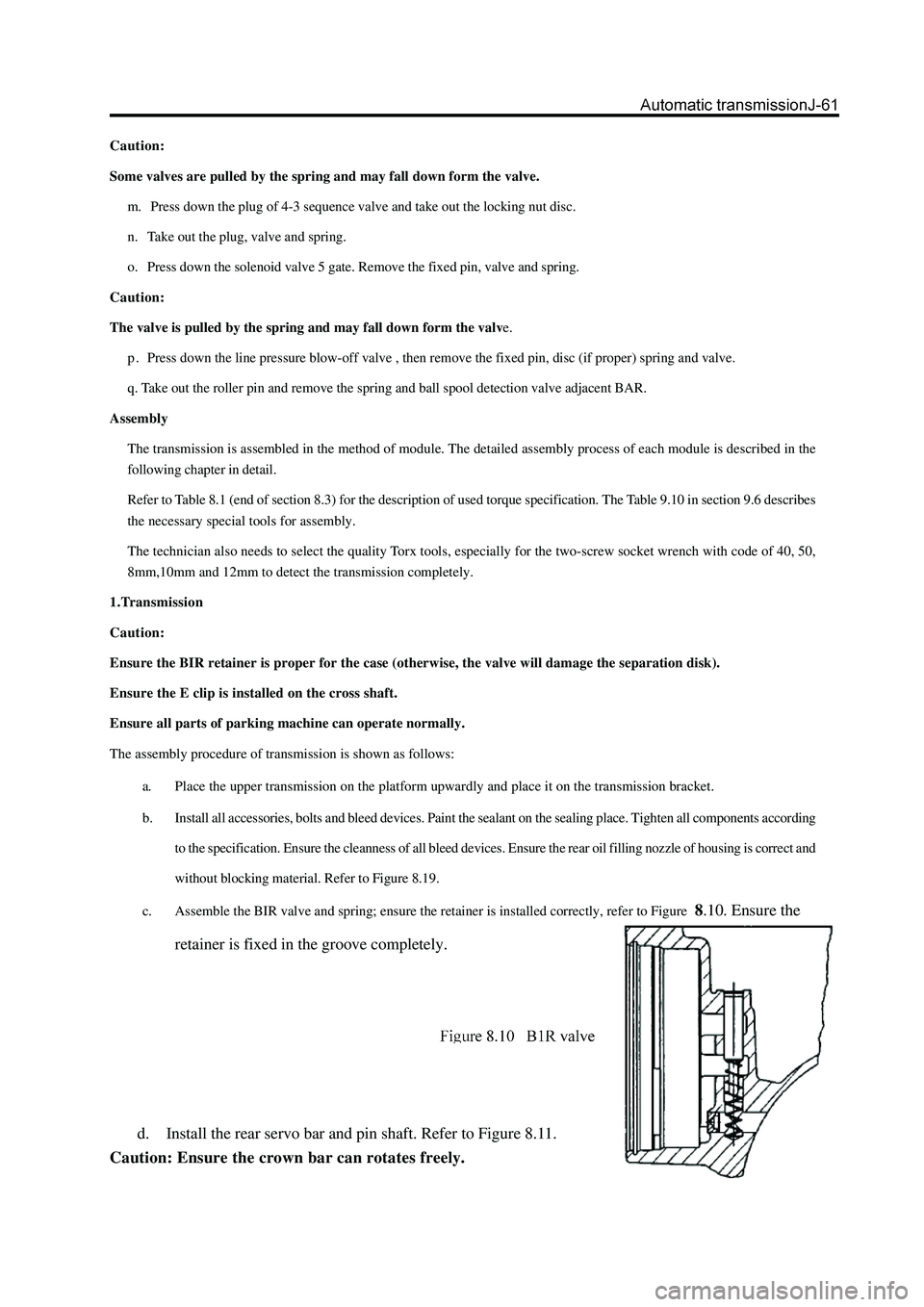

c. Assemble the BIR valve and spring; ensure the retainer is installed correctly, refer to Figure

8.10. Ensure the

retainer is fixed in the groove completely.

d. Install the rear servo bar and pin shaft. Refer to Figure 8.11.

Caution: Ensure the crown bar can rotates freely.