torque GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 366 of 425

CD Player and Air Conditioning System-13

1 .CC6460K air conditioning system is designed with SD7V16 compressor, whose refrigeration oil type as

specified is SP-10P AG; hence application of other type of refrigeration oil may damage the parts and compo

nents of the compressor. When the

air conditioning system goes through maintenance and replacement of

parts, it should be added with new refrigeration oil, whose volume is listed as follows: the evaporator and

condenser: 30ml; the drier: 20ml; the pipeline: 10ml.

Addition of refrigeration oil can be available with two methods: The direct addition and the vacuum suction

2 .D irect addition method

a. remove the oil filler plug and fill with the specified SP-10P AG refrigeration oil.

b. observe through the hole of oil filter plug and rotate front plate of clutch to make the piston connecting rod right positio n in the

center of the hole of oil filter plug.

c. insert the dipstick along the right side of piston connecting rod till the top of dipstick touches the case of the compresso

r

d. pull out the dipstick and examine the graduations (grooves) of refrigeration oil, the readings shall be within the range of 4-6

scales

.

e. screw firmly the oil filter plug with the fastening torque of 14.7± 4.9N

.m

3. Vacuum suction method:

Firstly pump out the refrigerating system to the vacuum of 0.2x105Pa, and then fill with the specified 0.2x10 5 Pa refrigeration oil;

the detailed steps are as follows:

a. switch off the high-pressure manual valve and the auxiliary valve.

b. dismantle the high-pressure side hose from the manifold pressure gauge and insert it into the oil cu

p

c. open the auxiliary valve and have the refrigeration oil sucked into the refrigerating system from the oil cup.

d. when the refrigeration oil in the oil cup is almost pumped out to the vacuum, then immediately turn off the auxiliary valve

to

prevent the air from being sucked into the system

.

e. secure the hose adapter at high-pressure side to the manifold pressure gauge, start the vacuum pump and turn on the high-

pressure manual valve, then turn on the auxiliary valve to pump the system to the vacuum state of 0.2x10

5Pa, keep such state

for 15mins so as to discharge out the air flowing into the system along with the oil.

V ol ume of Refrigeration Oil Addition and its Methods

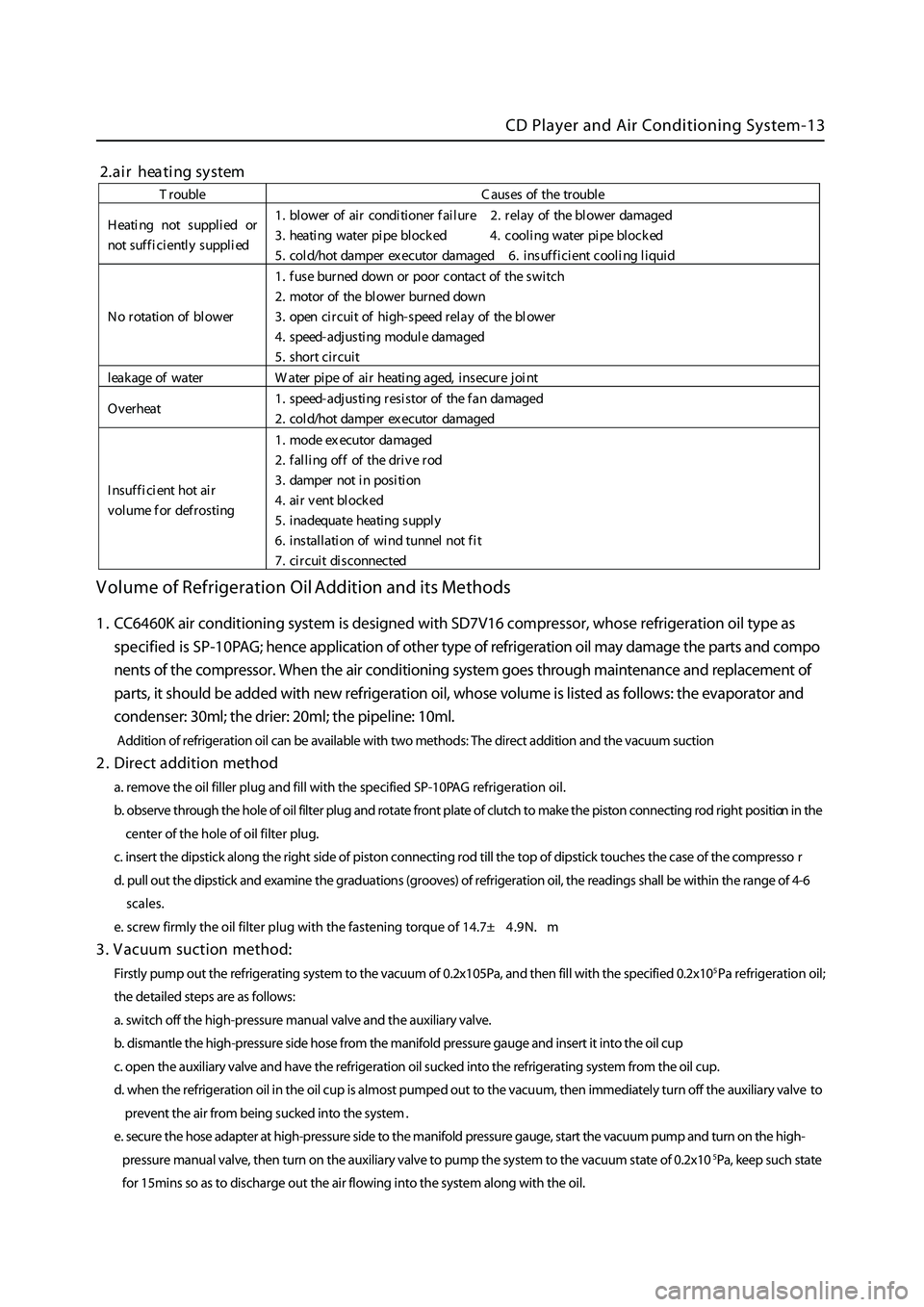

2.ai r h eating system

T r oubl e Cau ses o f the trouble

H e ati n g n otsuppl i ed or

no t s

uf f i cientl y suppl i ed 1.

blow erof air c ondition erf ai l u re 2.relay o f the blow erdamage

d

3. heati n g w ater pipe bloc k e d 4 . coo ling water p i pe b lock ed

5. col d/h ot damp erexecutor damage d 6. ins

uf f i cien t c oo ling l iqu id

N o rotation ofblow er 1.

f use burned

down orpoor contac t o f the switch

2. mo tor o f the blowe r burne d d ow

n

3. op en circ uit o f h igh- sp eed relay o f the blow er

4. speed-ad j usti n g m odule d am aged

5. short c ircu it

leak age o f w ater W ater p ipe o f ai rhe ati n g a ged, inse cu re j oi nt

O v erhe at 1.

speed-ad j usti n g r esi sto r o f the f an d am aged

2. col d/h ot damp erexecutor damaged

I nsu f f i cien t h otair

vo lume f or d efro stin

g 1.

mode executor dama ge

d

2. f al li n g o f fof the d riv e ro

d

3. damp ernot in p osi ti o

n

4. air v ent b l ock ed

5. inad equa te heatin g s

upply

6. inst

alla tion ofwind tunn elno t fi t

7. circ uit d i sco nn ecte

d

Page 370 of 425

CD Player and Air Conditioning System-17

Daily Maintenance of Air Conditioning System

In order to ensure normal operation of air conditioning system, maintenance and care services shall be frequently performed for the

air conditioning system. The daily maintenance of air conditioning system is illustrated as follows:

1. Inspect, wash and clean the condenser of air conditioning system, requiring that radiator pins are clean and there is no dirt

between the pins. After the car runs in the rain or on the muddy road, the fan of the condenser should be inspected to find

whether it bears the earth, sand, stone and etc, and remove them if any.

2. Check the quantity of the working media of the refrigerating system; when the compressor set works normally, observe the

liquid viewing glass, under the normal circumstance, there shall be not air bubbles in the glass.

3. Inspect the drive belt. The belt between the compressor and the engine should be tensioned.

4. Check if there is any abnormal noise or odor in the air conditioning system.

5. Check if the temperature difference between the air inlet and outlet of the compressor is normal.

6. Check if the hose of the refrigerating system is in an apparent good condition and connections of all joints are secure.

7. Check if the pipeline of the refrigerating system collides with other parts and components, and if there is any oil leakage trace

left at each joint.

8. Check if the circuit connection of the refrigerating system is secure and if there is an occurrence of short circuit and falling off

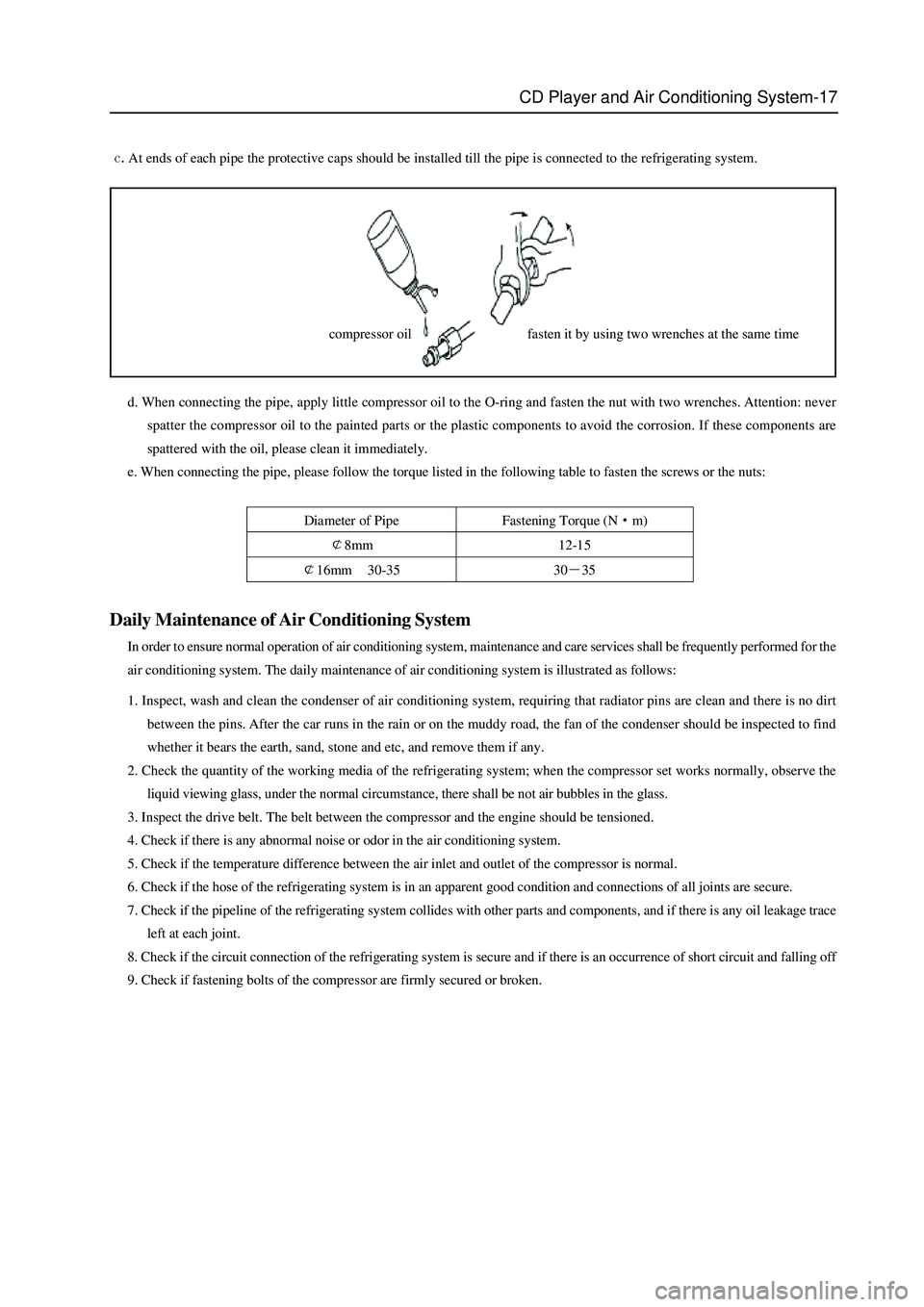

9. Check if fastening bolts of the compressor are firmly secured or broken. d. When connecting the pipe, apply little compressor oil to the O-ring and fasten the nut with two wrenches. Attention: never

spatter the compressor oil to the painted parts or the plastic components to avoid the corrosion. If these components are

spattered with the oil, please clean it immediately.

e. When connecting the pipe, please follow the torque listed in the following table to fasten the screws or the nuts:

Diameter of Pipe Fastening Torque (N·m)

¢8mm 12-15

¢16mm 30-35 30-35

At ends of each pipe the protective caps should be installed till the pipe is connected to the refrigerating system.

compressor oil fasten it by using two wrenches at the same time

Page 406 of 425

Appendix-1

A important parts assurance and request.........................................1

B non-metal materials consumption table.......................................12

C Special tools.............................................................................14

D important working regions and tightening torque

important working region............................................................17

E Electric wiring diagram ..............................................................18

Appendix

Page 407 of 425

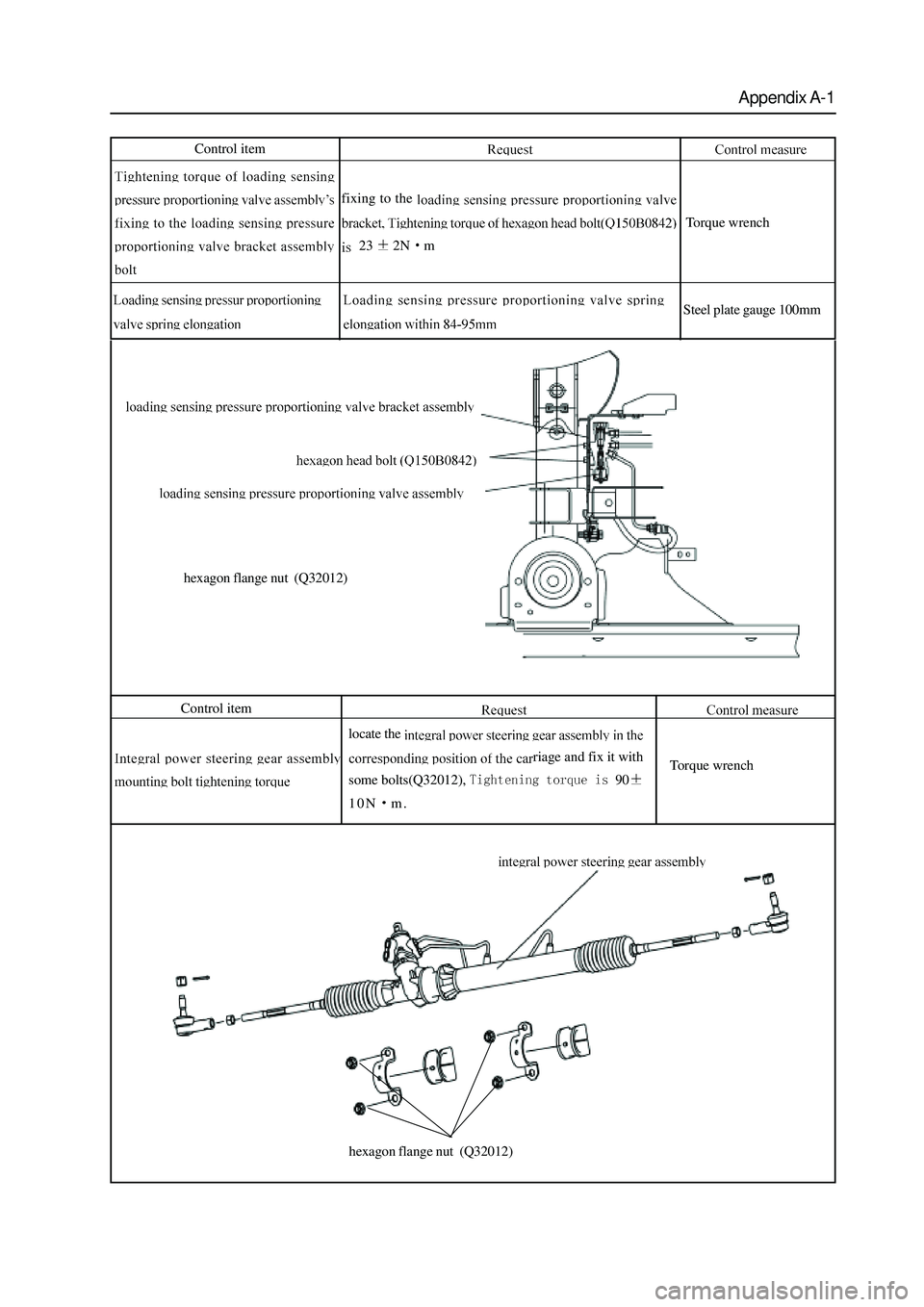

Appendix A-1

Control item

fixing to the

232NmTorque wrench

Steel plate gauge 100mm

hexagon flange nut (Q32012)

hexagon flange nut (Q32012)

Control item

locate the

riage and fix it with

some bolts(Q32012),

90

10Nm.Torque wrench

Page 408 of 425

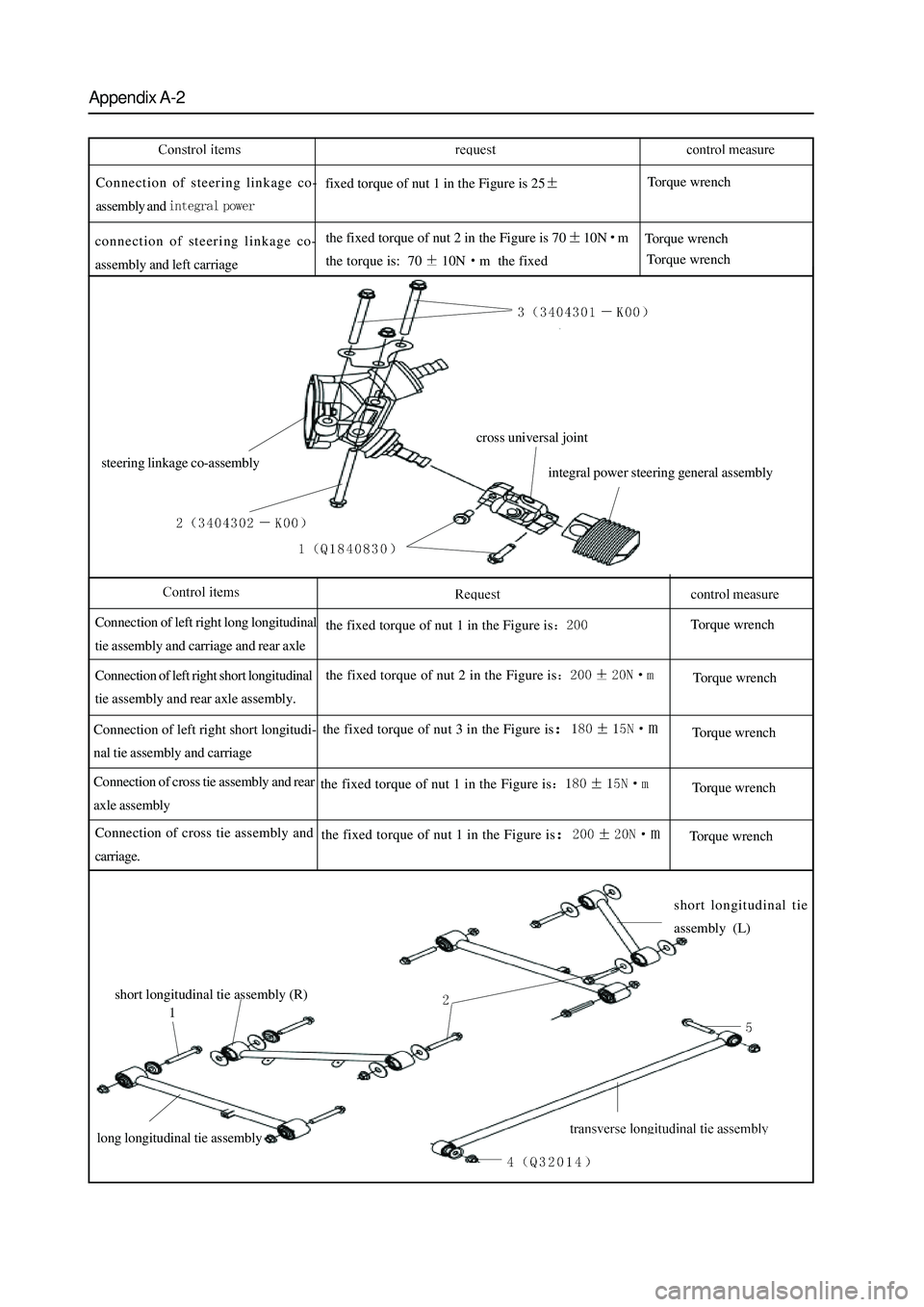

Appendix A-2

the fixed torque of nut 2 in the Figure is 7010Nm

the torque is: 70

10Nm the fixed

Connection of steering linkage co-

assembly and fixed torque of nut 1 in the Figure is 25Torque wrench

connection of steering linkage co-

assembly and left carriageTorque wrench

Torque wrench

Connection of left right long longitudinal

tie assembly and carriage and rear axle the fixed torque of nut 1 in the Figure isTorque wrench

the fixed torque of nut 2 in the Figure isTorque wrench

Connection of left right short longitudi-

nal tie assembly and carriagethe fixed torque of nut 3 in the Figure is

Torque wrench

Connection of cross tie assembly and rear

axle assemblythe fixed torque of nut 1 in the Figure isTorque wrench

the fixed torque of nut 1 in the Figure isTorque wrench

steering linkage co-assemblycross universal joint

integral power steering general assembly

Connection of left right short longitudinal

tie assembly and rear axle assembly.

Connection of cross tie assembly and

carriage.

short longitudinal tie assembly (R)

long longitudinal tie assemblyshort longitudinal tie

assembly (L)

Page 409 of 425

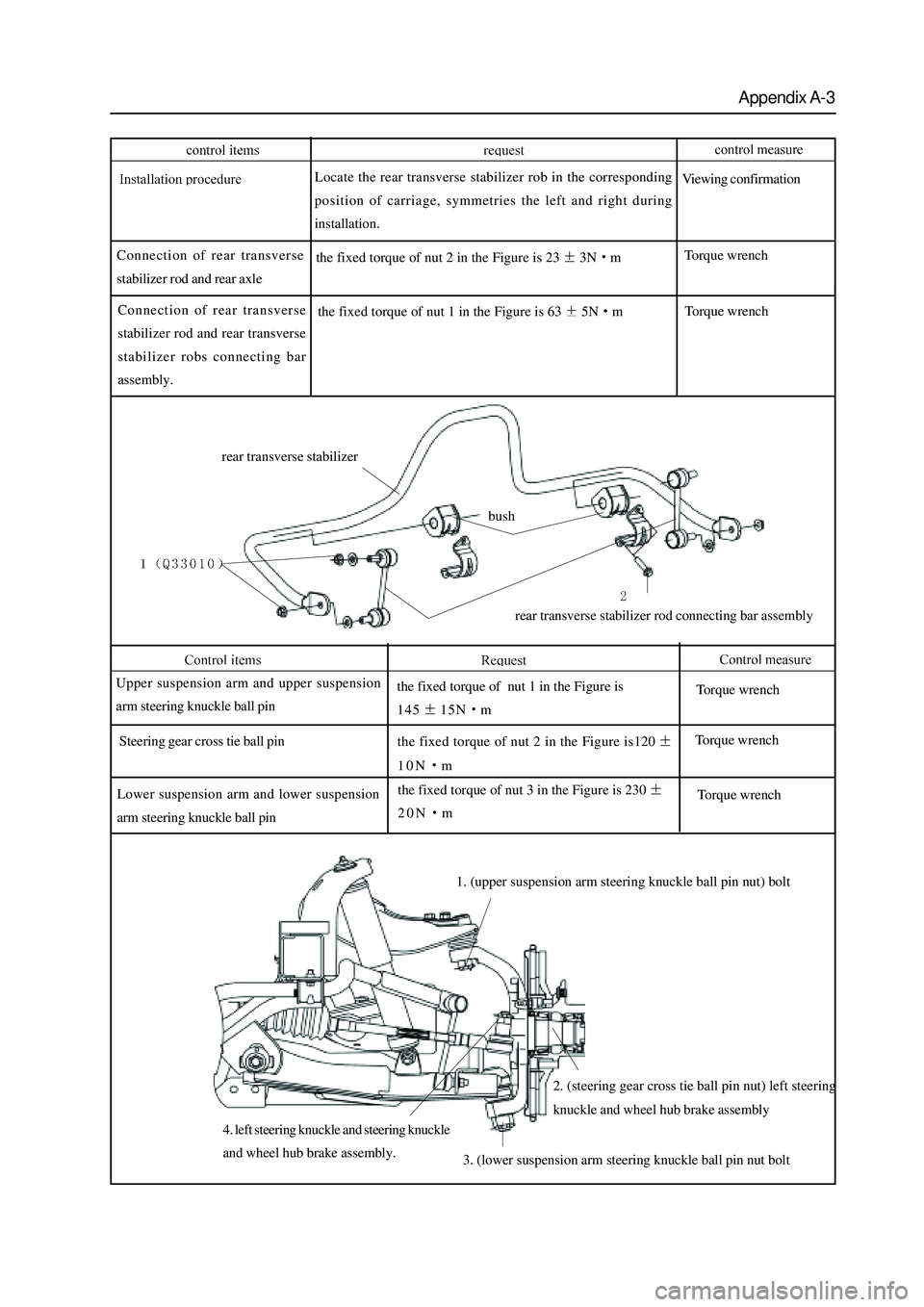

Appendix A-3

1. (upper suspension arm steering knuckle ball pin nut) bolt

Locate the rear transverse stabilizer rob in the corresponding

position of carriage, symmetries the left and right during

installation.

Connection of rear transverse

stabilizer rod and rear axleViewing confirmation

the fixed torque of nut 2 in the Figure is 23

3NmTorque wrench

Connection of rear transverse

stabilizer rod and rear transverse

stabilizer robs connecting bar

assembly.the fixed torque of nut 1 in the Figure is 63

5NmTorque wrench

rear transverse stabilizer

rear transverse stabilizer rod connecting bar assembly bush

Upper suspension arm and upper suspension

arm steering knuckle ball pin

Steering gear cross tie ball pin

Lower suspension arm and lower suspension

arm steering knuckle ball pinthe fixed torque of nut 1 in the Figure is

145

15Nm

the fixed torque of nut 2 in the Figure is120

10Nm

the fixed torque of nut 3 in the Figure is 230

20Nm

Torque wrench

Torque wrench

Torque wrench

2. (steering gear cross tie ball pin nut) left steering

knuckle and wheel hub brake assembly

3. (lower suspension arm steering knuckle ball pin nut bolt 4. left steering knuckle and steering knuckle

and wheel hub brake assembly.

Page 410 of 425

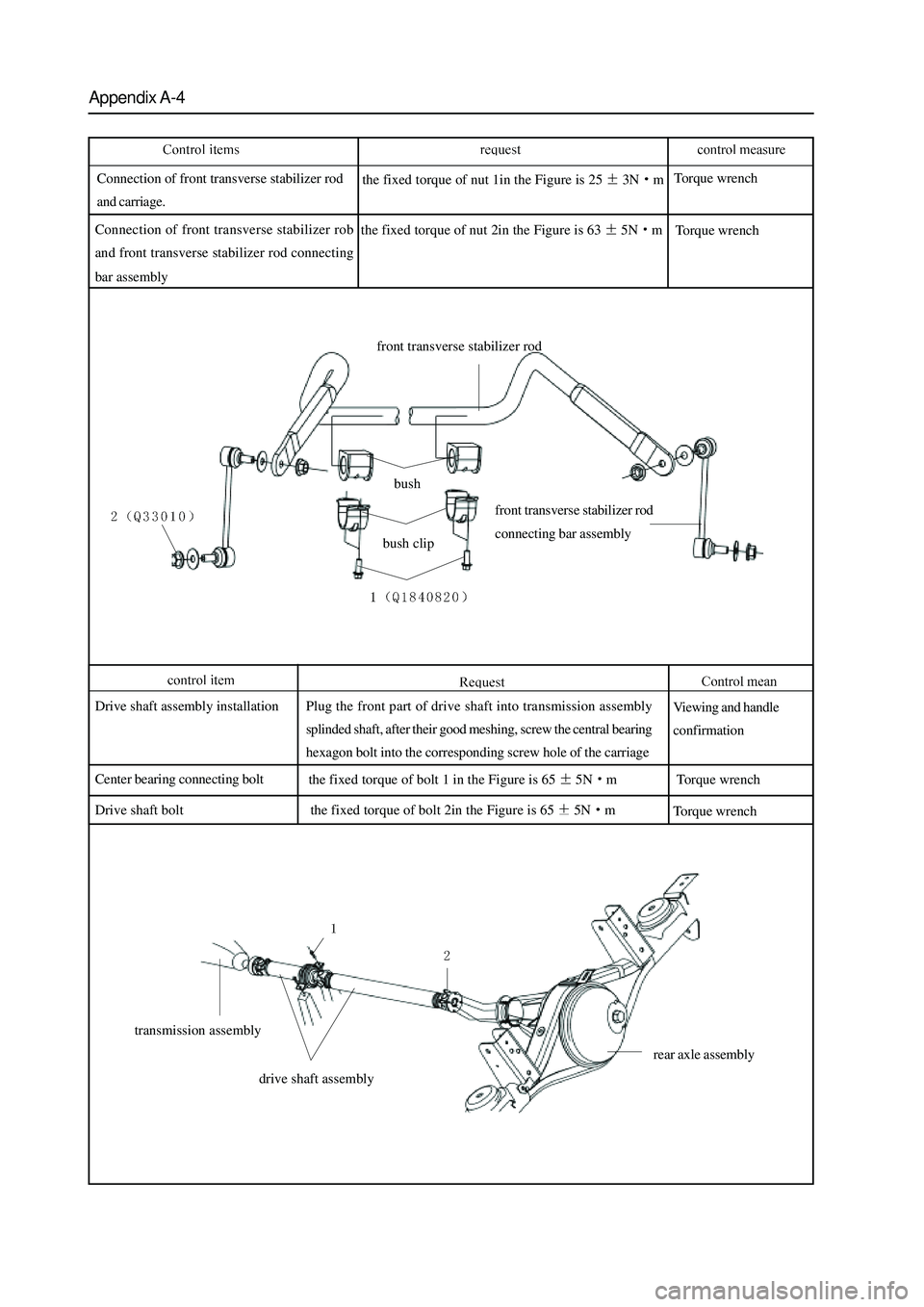

Appendix A-4

Connection of front transverse stabilizer rod

and carriage.the fixed torque of nut 1in the Figure is 253Nm

the fixed torque of nut 2in the Figure is 63

5Nm Connection of front transverse stabilizer rob

and front transverse stabilizer rod connecting

bar assemblyTorque wrench

Torque wrench

transmission assembly

drive shaft assemblyrear axle assembly

Drive shaft assembly installationPlug the front part of drive shaft into transmission assembly

splinded shaft, after their good meshing, screw the central bearing

hexagon bolt into the corresponding screw hole of the carriage

Center bearing connecting bolt

the fixed torque of bolt 1 in the Figure is 65

5Nm

Drive shaft bolt

the fixed torque of bolt 2in the Figure is 65

5Nm

Torque wrenchTorque wrench Viewing and handle

confirmation

front transverse stabilizer rod

bush

bush clipfront transverse stabilizer rod

connecting bar assembly

Page 411 of 425

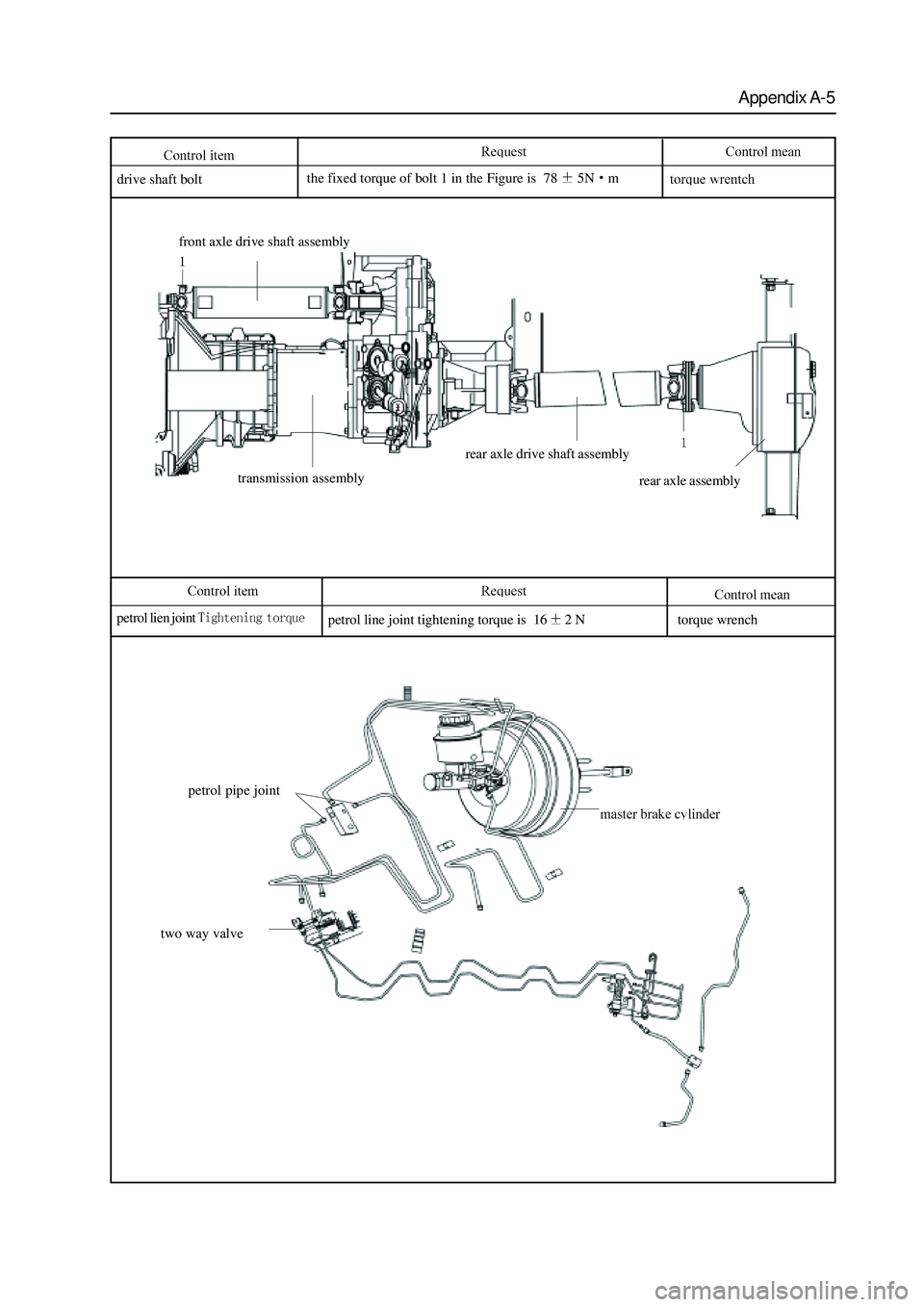

Appendix A-5

drive shaft boltthe fixed torque of bolt 1 in the Figure is 785Nm

front axle drive shaft assembly

transmission assemblyrear axle drive shaft assembly

rear axle assembly

petrol lien joint

petrol line joint tightening torque is 162 N torque wrench

petrol pipe joint

two way valve

Page 412 of 425

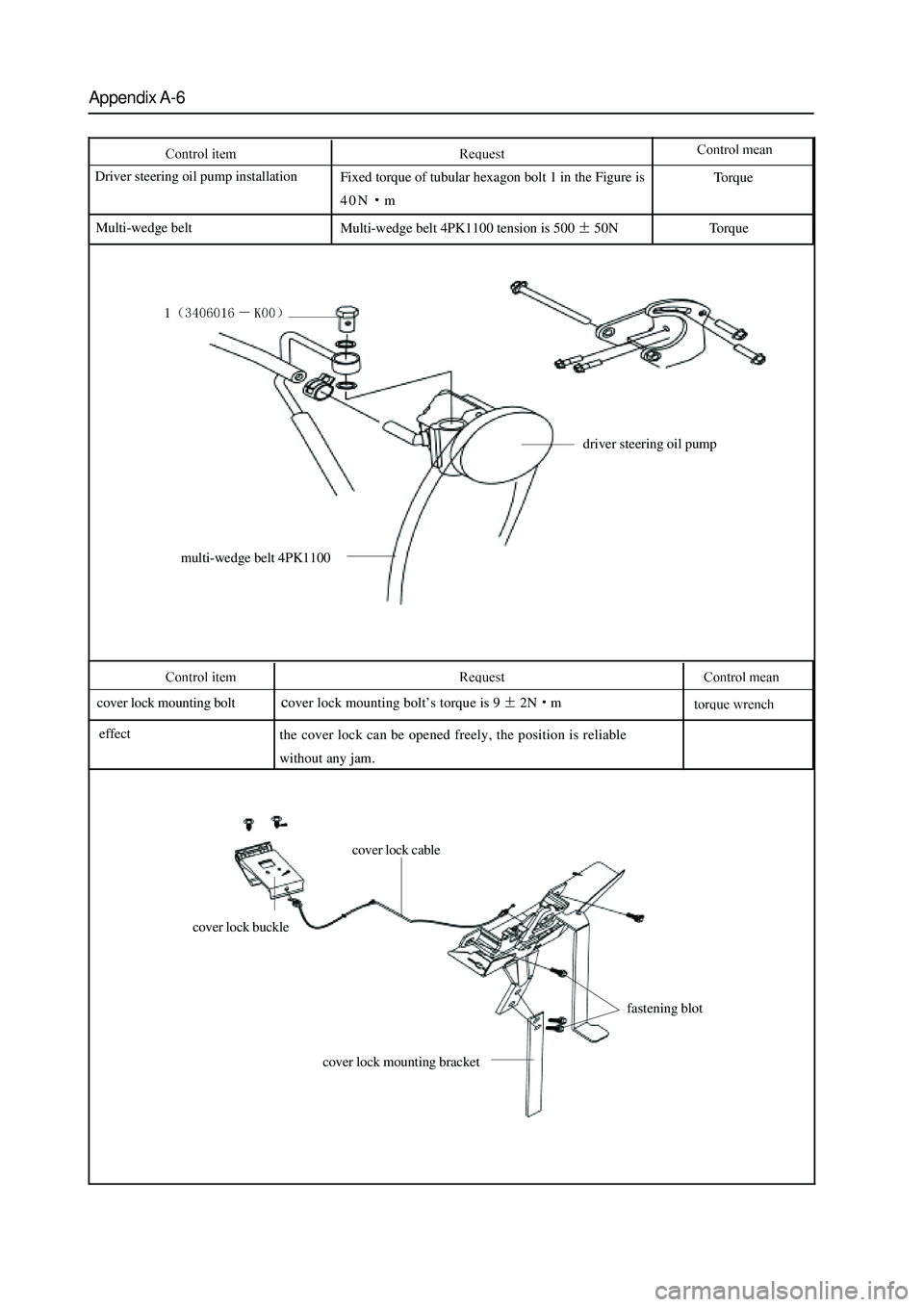

Appendix A-6

Driver steering oil pump installation

Fixed torque of tubular hexagon bolt 1 in the Figure is

40N

m

Multi-wedge belt

Multi-wedge belt 4PK1100 tension is 500

50NTorque

Torque

multi-wedge belt 4PK1100driver steering oil pump

cover lock mounting bolt

effect

cover lock mounting bolt’s torque is 92Nm

the cover lock can be opened freely, the position is reliable

without any jam.

cover lock cable

cover lock buckle

fastening blot

cover lock mounting bracket

Page 413 of 425

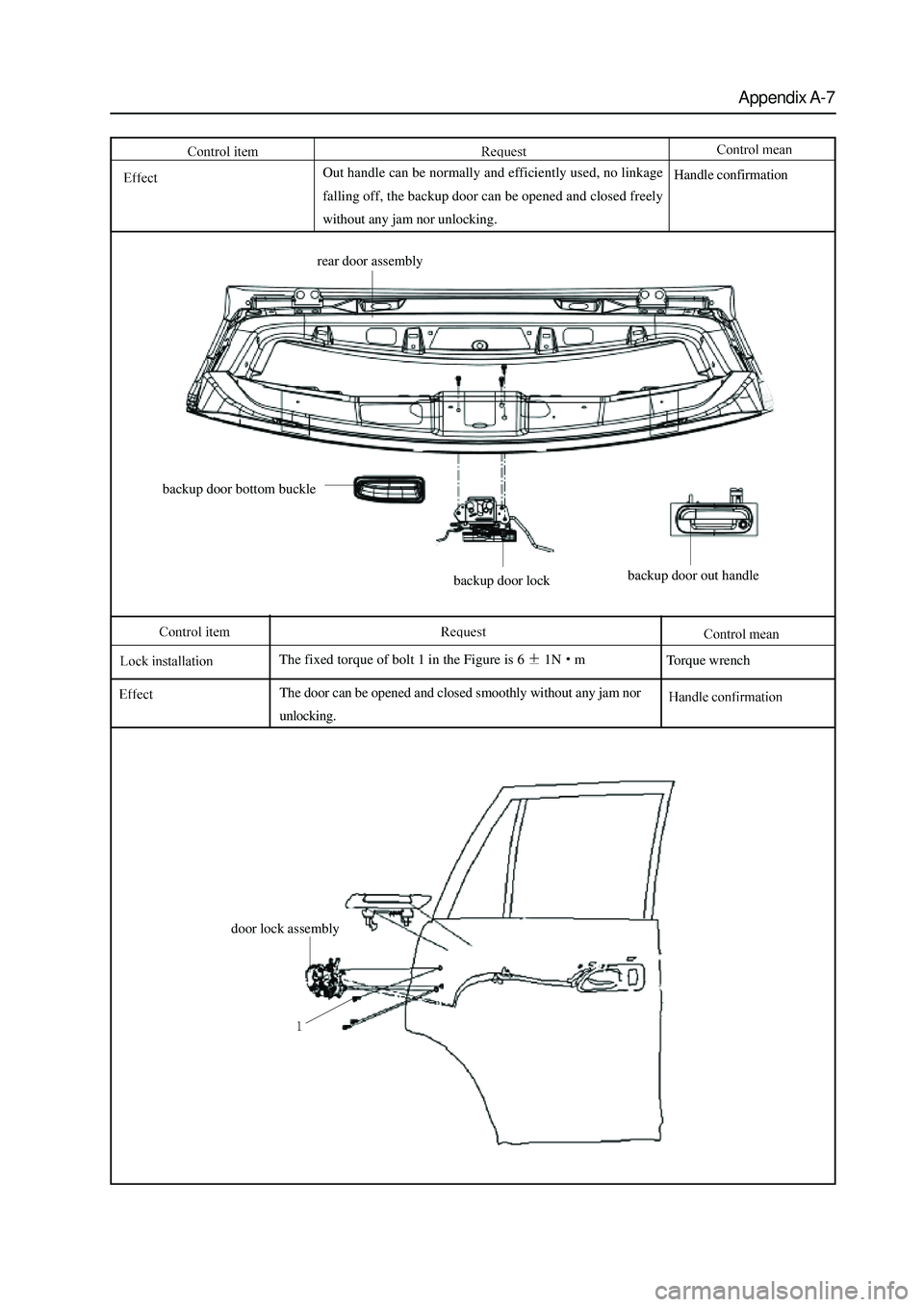

Appendix A-7

The fixed torque of bolt 1 in the Figure is 61Nm

Out handle can be normally and efficiently used, no linkage

falling off, the backup door can be opened and closed freely

without any jam nor unlocking.Handle confirmation

rear door assembly

backup door bottom buckle

backup door lockbackup door out handle

The door can be opened and closed smoothly without any jam nor

unlocking.Torque wrench

door lock assembly