clutch GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 9 of 425

Preface

Table of Contents

Instruction How to use the manual

Chapter 1 Overview of the entire car (parameters)

Chapter 2 Fuel supply system and exhaust air system

Chapter 3 Clutch

Chapter 4 Transmission

Chapter 5 Automatic transmission

Chapter 6 Driving shaft

Chapter 7 Suspension and vehicle axle

Chapter 8 Brake (ABS)

Chapter 9 Steering

Chapter 10 Car body electric appliance

Chapter 11 CD player and air-conditioning system

Chapter 12 Safety airbag

Annex:

Important components guarantee and requirement

List of non-metal material consumption

Special tools

D Important working components and tightening torque

E Electric wiring diagram

Page 10 of 425

Overview of the entire car-1

Chapter 1

Overview of the entire car

Basic parameter....................................................... 2

Engine..................................................................... 4

Air inlet system........................................................ 5

Exhaust air system................................................... 5

Fuel supply system................................................... 5

Cooling system........................................................ 5

Clutch..................................................................... 5

Transmission............................................................ 6

Drive shaft............................................................... 6

Front shaft/axle........................................................ 6

Rear axle................................................................. 6

Wheel tyre............................................................... 6

Suspension.............................................................. 7

Frame..................................................................... 7

Steering system........................................................ 7

Brake system........................................................... 8

Car body................................................................. 9

Electrical system.................................................... 10

Air-conditioning system …………………..............12

Page 14 of 425

Overview of the entire car-5

The friction, disc, single-diaphragm spring clutch, hydraulic control mechanism. The external diameter of friction disc D=225mm,

internal diameter d=150mm, material is F810.

Adjustment of clutch pedal:

1. Measure the height of clutch pedal (from pedal pad surface to floor) and free stroke of clutch pedal (fork bar pin clearance).

Standard height of clutch pedal: flush with the brake pedal, free stroke of clutch pedal is 5-15mm;

2. Readjust the free stroke of pedal after adjust the height of pedal; rotate the push bar to the standard value, then fix the bolt

and nut;

3. If the free stroke of clutch pedal is not within standard value, it should rotate the adjusting bolt to standard value, then fix

the bolt and nut. Do not move the push bar to main cylinder when adjust the free stroke of pedal;

4. If the free stroke of clutch pedal and clearance between the clutch pedal and floor when the clutch is disengaged de not

consist with the standard, this may by caused by the air in hydraulic system and failure of main cylinder or clutch. It can

discharge the air of system or dissemble and inspect the main cylinder or clutch.

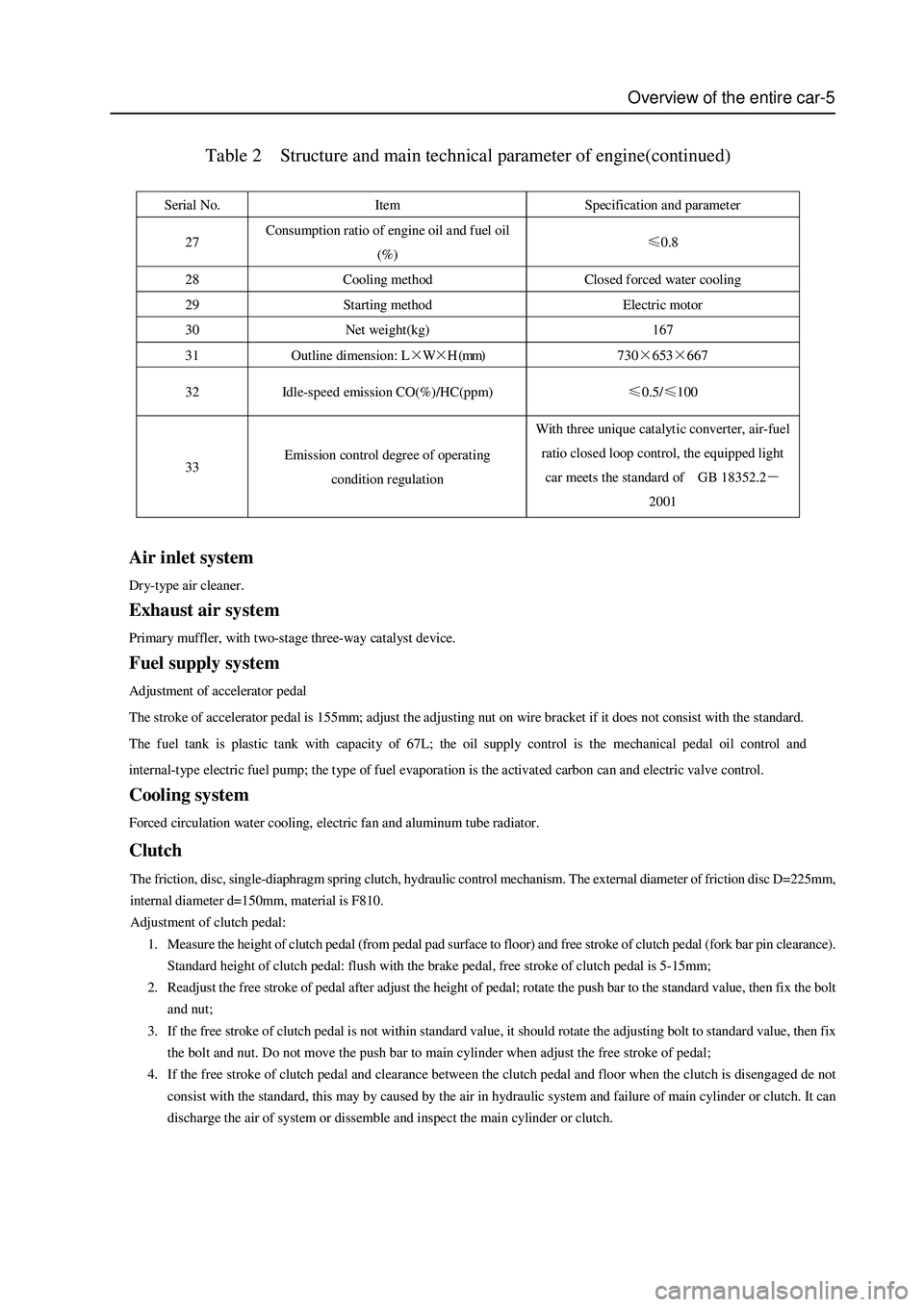

Table 2 Structure and main technical parameter of engine(continued)

Serial No. Item Specification and parameter

27 Consumption ratio of engine oil and fuel oil

(%) ≤0.8

28 Cooling method Closed forced water cooling

29 Starting method Electric motor

30 Net weight(kg) 167

31 Outline dimension: L×W×H (mm) 730×653×667

32 Idle-speed emission CO(%)/HC(ppm) ≤0.5/≤100

33 Emission control degree of operating

condition regulation With three unique catalytic converter, air-fuel

ratio closed loop control, the equipped light

car meets the standard of GB 18352.2-

2001

Air inlet system

Dry-type air cleaner.

Exhaust air system

Primary muffler, with two-stage three-way catalyst device.

Fuel supply system

Adjustment of accelerator pedal

The stroke of accelerator pedal is 155mm; adjust the adjusting nut on wire bracket if it does not consist with the standard.

The fuel tank is plastic tank with capacity of 67L; the oil supply control is the mechanical pedal oil control and

internal-type electric fuel pump; the type of fuel evaporation is the activated carbon can and electric valve control.

Cooling system

Forced circulation water cooling, electric fan and aluminum tube radiator.

Clutch

Page 31 of 425

Clutch-1

Chapter 3

Clutch

Troubleshooting........................................................................2

Inspection and adjustment of clutch pedal..................................3

Bleed air of clutch.....................................................................3

Disassembly of clutch master cylinder and clutch cylinder ..........5

Cautions for installation of clutch operation device.....................5

Disassembly of clutch assembly.................................................6

Inspection of clutch component.................................................7

Installation of clutch..................................................................9

Page 32 of 425

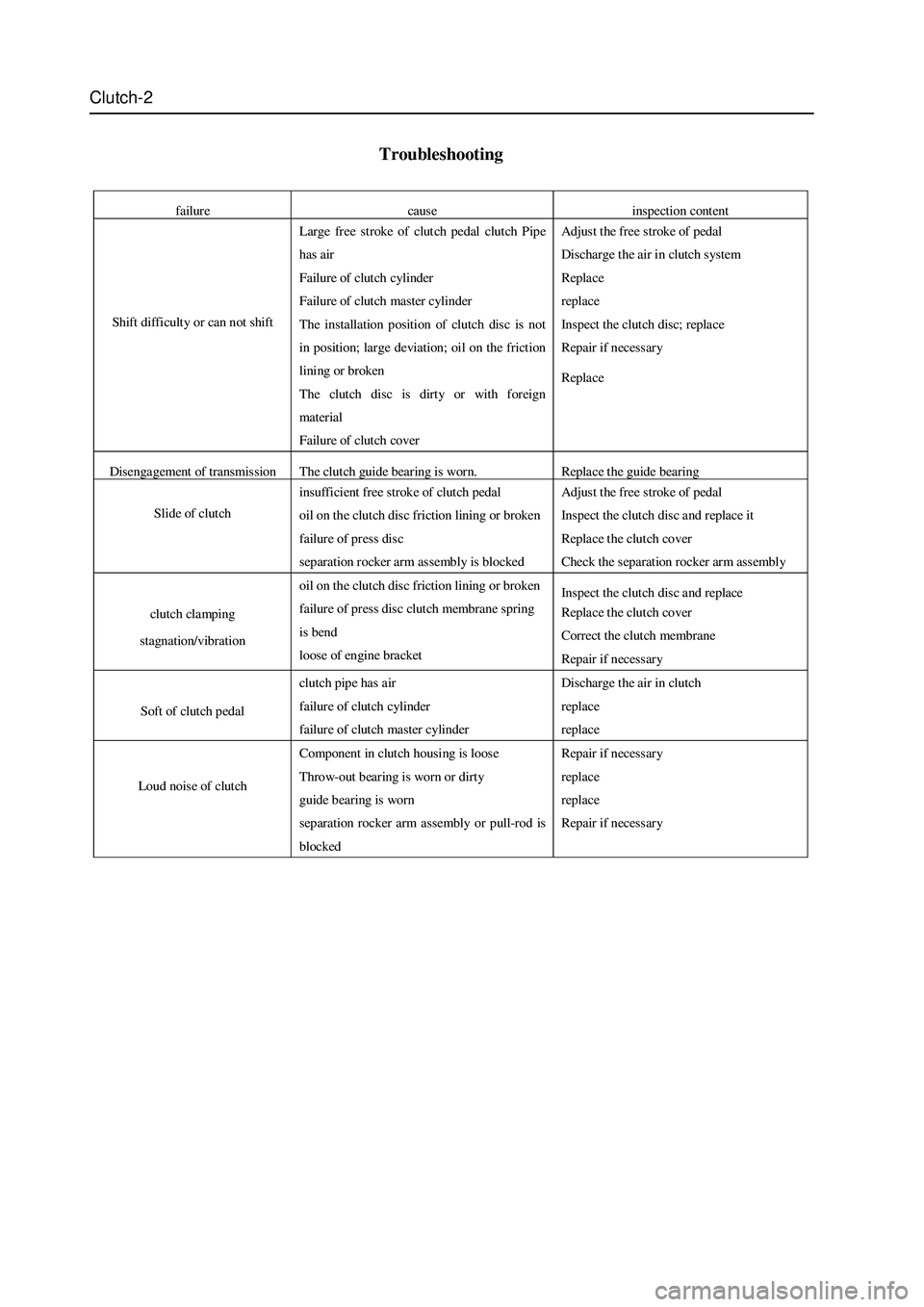

Clutch-2

Troubleshooting

failure cause inspection content

Shift difficulty or can not shift

Large free stroke of clut ch pedal clutch Pipe

has air

Failure of clutch cylinder

Failure of clutch master cylinder

The installation position of clutch disc is not

in position; large deviation; oil on the friction

lining or broken

The clutch disc is dirty or with foreign

material

Failure of clutch cover Adjust the free stroke of pedal

Discharge the air in clutch system

Replace

replace

Inspect the clutch disc; replace

Repair if necessary

Replace

Disengagement of transmission The clutch guide bearing is worn. Replace the guide bearing

Slide of clut ch

insufficient free stroke of clutch pedal

oil on the clutch disc friction lining or broken

failure of press disc

separation rocker arm assembly is blocked Adjust the free stroke of pedal

Inspect the clutch disc and replace it

Replace the clut ch cover

Check the separation rocker arm assembly

clutch clamping

stagnation/vibration oil on the clutch disc friction lining or broken

failure of press disc clutch membrane spring

is bend

loose of engine bracket Inspect the clutch disc and replace

Replace the clut ch cover

Correct the clutch membrane

Repair if necessary

Soft of clutch pedal clutch pip e has air

failure of clutch cylinder

failure of clutch master cylinder Discharge the air in clutch

replace

replace

Loud noise of clut ch

Component in clutch housing is loose

Throw-out bearing is worn or dirty

guide bearing is worn

separation rocker arm assembly or pull-rod is

blocked Repair if necessary

replace

replace

Repair if necessary

Page 33 of 425

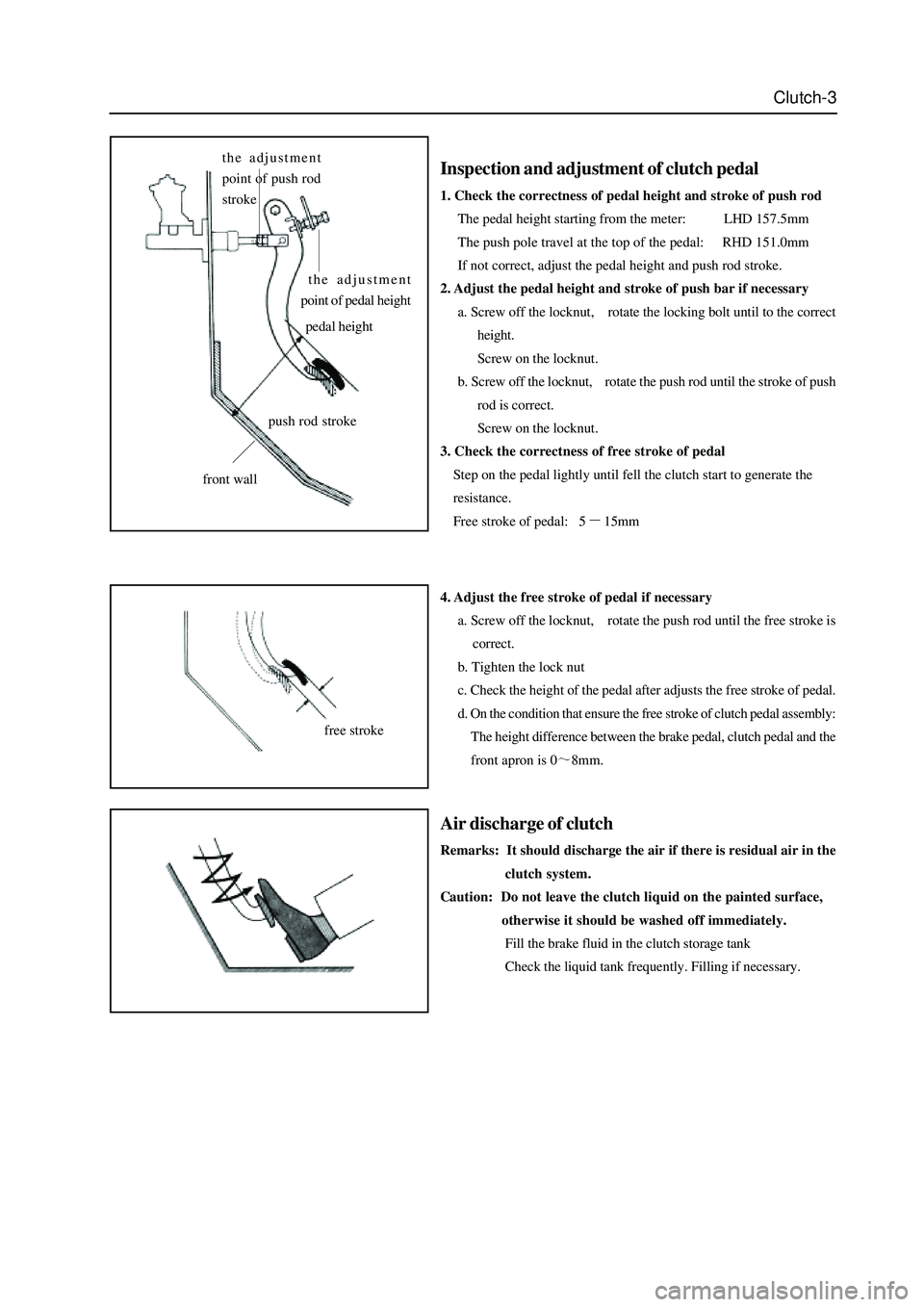

Clutch-3

Inspection and adjustment of clutch pedal

1. Check the correctness of pedal height and stroke of push rod

The pedal height starting from the meter: LHD 157.5mm

The push pole travel at the top of the pedal: RHD 151.0mm

If not correct, adjust the pedal height and push rod stroke.

2. Adjust the pedal height and stroke of push bar if necessary

a. Screw off the locknut, rotate the locking bolt until to the correct

height.

Screw on the locknut.

b. Screw off the locknut, rotate the push rod until the stroke of push

rod is correct.

Screw on the locknut.

3. Check the correctness of free stroke of pedal

Step on the pedal lightly until fell the clutch start to generate the

resistance.

Free stroke of pedal: 5

15mm

4. Adjust the free stroke of pedal if necessary

a. Screw off the locknut, rotate the push rod until the free stroke is

correct.

b. Tighten the lock nut

c. Check the height of the pedal after adjusts the free stroke of pedal.

d. On the condition that ensure the free stroke of clutch pedal assembly:

The height difference between the brake pedal, clutch pedal and the

front apron is 0

8mm.

Air discharge of clutch

Remarks: It should discharge the air if there is residual air in the

clutch system.

Caution: Do not leave the clutch liquid on the painted surface,

otherwise it should be washed off immediately.

Fill the brake fluid in the clutch storage tank

Check the liquid tank frequently. Filling if necessary.

the adjustment

point of push rod

stroke

the adjustment

point of pedal height

pedal height

front wall

free stroke

push rod stroke

Page 34 of 425

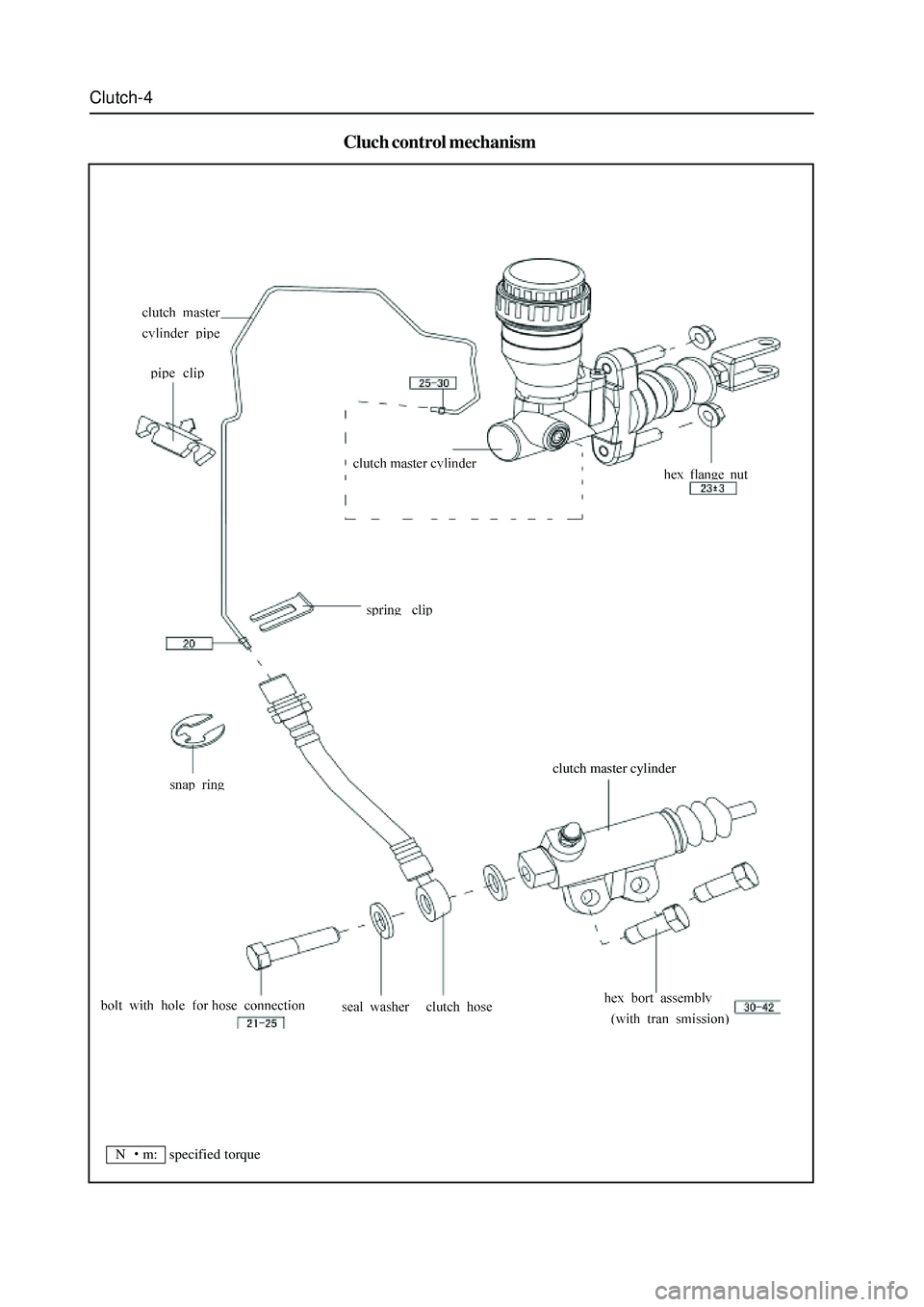

Clutch-4

Cluch control mechanism

clutch master cylinder

N

m: specified torque

Page 35 of 425

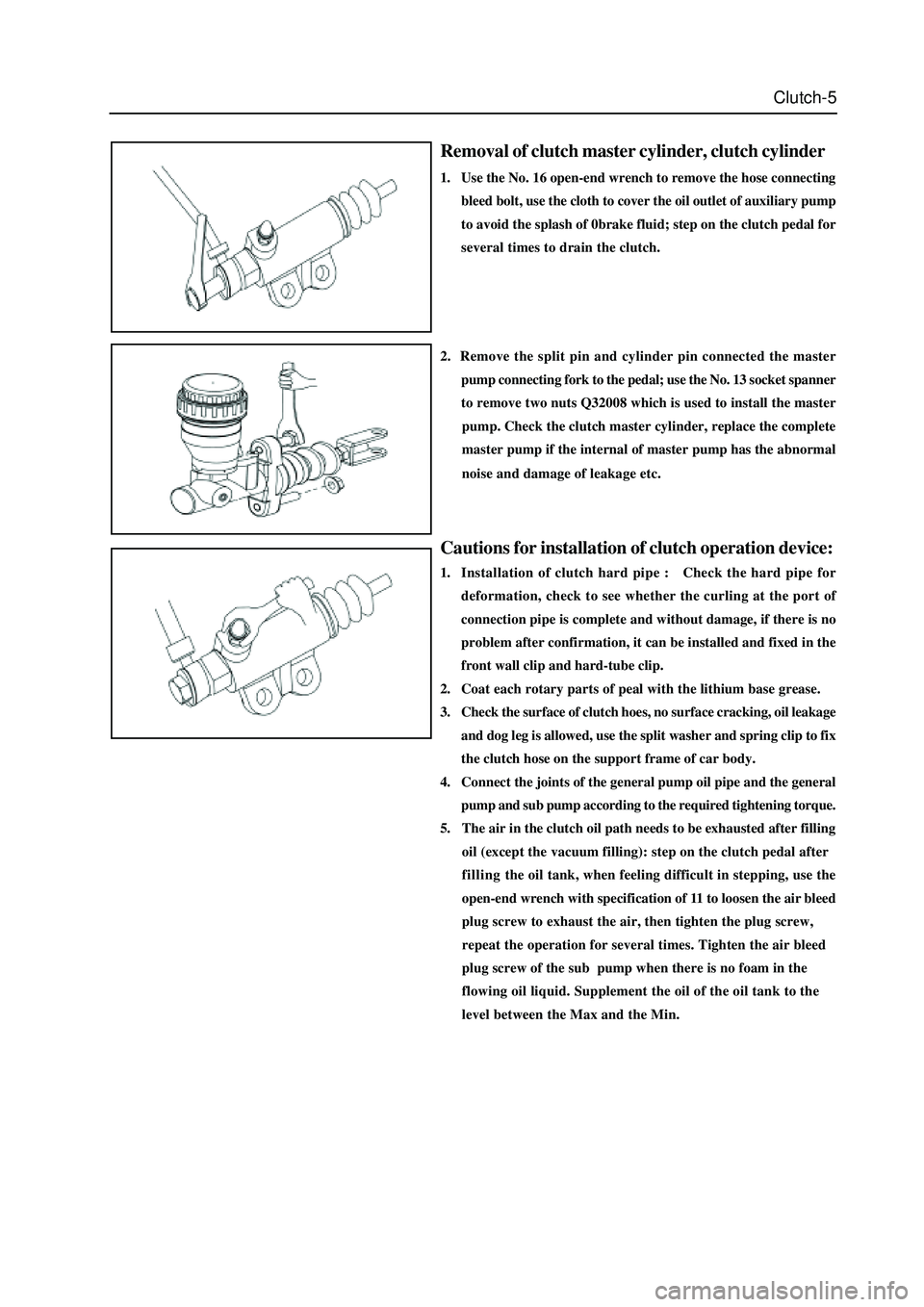

Clutch-5

Removal of clutch master cylinder, clutch cylinder

1. Use the No. 16 open-end wrench to remove the hose connecting

bleed bolt, use the cloth to cover the oil outlet of auxiliary pump

to avoid the splash of 0brake fluid; step on the clutch pedal for

several times to drain the clutch.

Cautions for installation of clutch operation device:

1. Installation of clutch hard pipe : Check the hard pipe for

deformation, check to see whether the curling at the port of

connection pipe is complete and without damage, if there is no

problem after confirmation, it can be installed and fixed in the

front wall clip and hard-tube clip.

2. Coat each rotary parts of peal with the lithium base grease.

3. Check the surface of clutch hoes, no surface cracking, oil leakage

and dog leg is allowed, use the split washer and spring clip to fix

the clutch hose on the support frame of car body.

4. Connect the joints of the general pump oil pipe and the general

2. Remove the split pin and cylinder pin connected the master

pump connecting fork to the pedal; use the No. 13 socket spanner

to remove two nuts Q32008 which is used to install the master

pump. Check the clutch master cylinder, replace the complete

master pump if the internal of master pump has the abnormal

noise and damage of leakage etc.

pump and sub pump according to the required tightening torque.

5. The air in the clutch oil path needs to be exhausted after filling

oil (except the vacuum filling): step on the clutch pedal after

fillingthe oil tank, when feeling difficult in stepping, use the

open-end wrench with specification of 11 to loosen the air bleed

plug screw to exhaust the air, then tighten the plug screw,

repeat the operation for several times. Tighten the air bleed

plug screw of the sub pump when there is no foam in the

flowing oil liquid. Supplement the oil of the oil tank to the

level between the Max and the Min.

Page 36 of 425

Clutch-6

Clutch

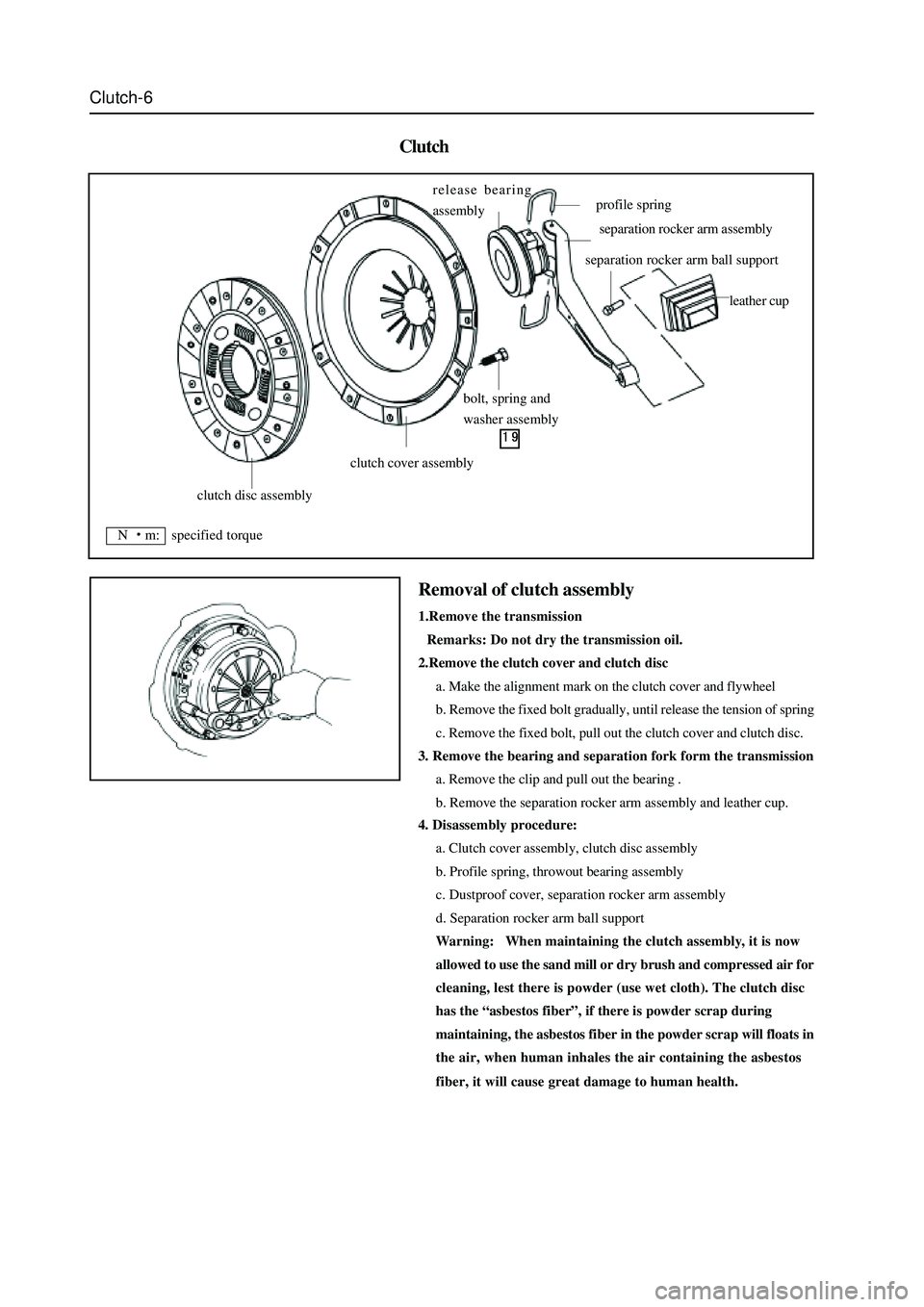

4. Disassembly procedure:

a. Clutch cover assembly, clutch disc assembly

b. Profile spring, throwout bearing assembly

c. Dustproof cover, separation rocker arm assembly

d. Separation rocker arm ball support

Warning: When maintaining the clutch assembly, it is now

allowed to use the sand mill or dry brush and compressed air for

cleaning, lest there is powder (use wet cloth). The clutch disc

has the “asbestos fiber”, if there is powder scrap during

maintaining, the asbestos fiber in the powder scrap will floats in

the air, when human inhales the air containing the asbestos

fiber, it will cause great damage to human health.

Removal of clutch assembly

1.Remove the transmission

Remarks: Do not dry the transmission oil.

2.Remove the clutch cover and clutch disc

a. Make the alignment mark on the clutch cover and flywheel

b. Remove the fixed bolt gradually, until release the tension of spring

c. Remove the fixed bolt, pull out the clutch cover and clutch disc.

3. Remove the bearing and separation fork form the transmission

a. Remove the clip and pull out the bearing .

b. Remove the separation rocker arm assembly and leather cup.

clutch disc assembly

clutch cover assembly

bolt, spring and

washer assembly release bearing

assembly

profile spring

separation rocker arm assembly

separation rocker arm ball support

leather cup

N m: specified torque

Page 37 of 425

Clutch-7

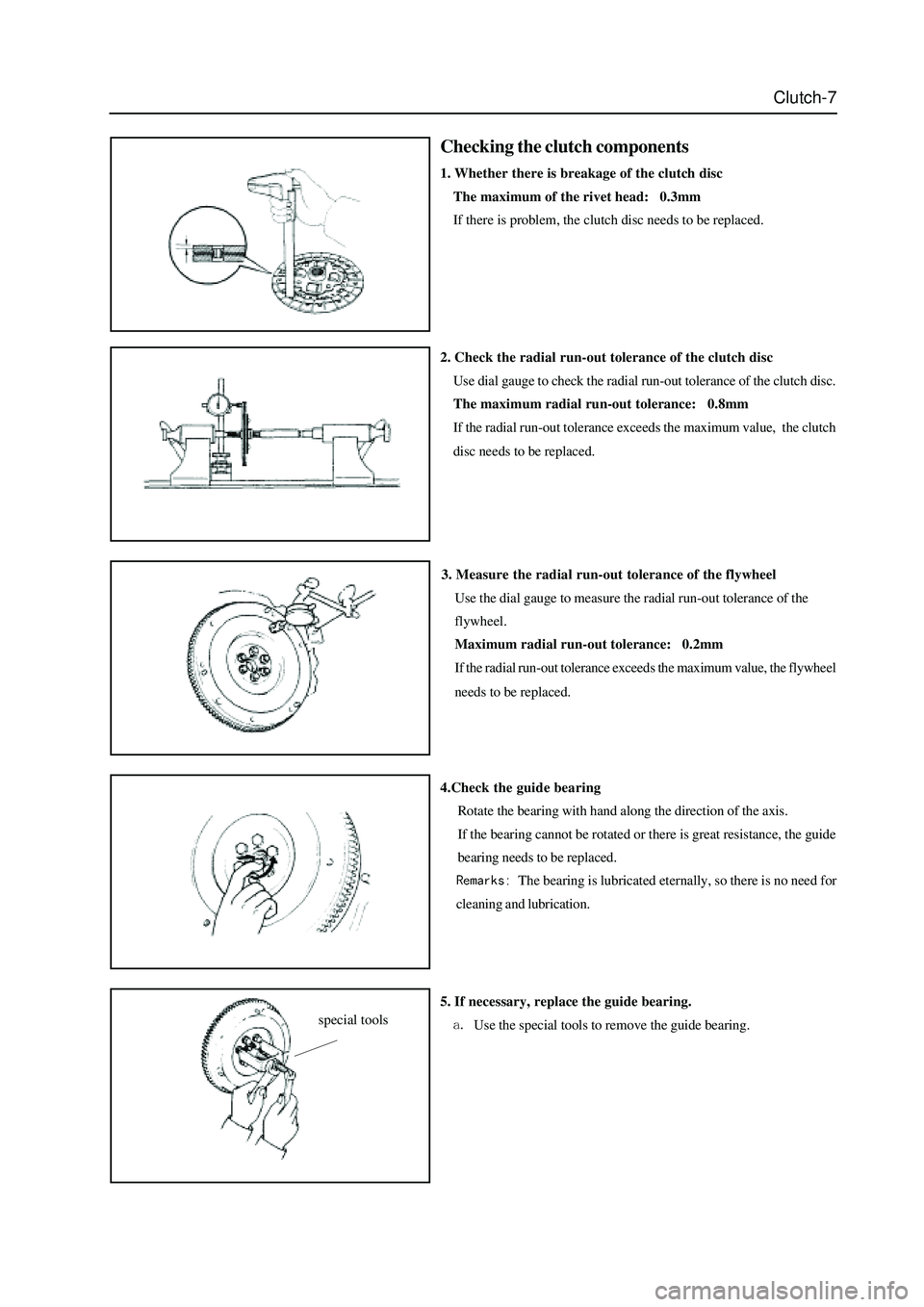

Checking the clutch components

1. Whether there is breakage of the clutch disc

The maximum of the rivet head: 0.3mm

If there is problem, the clutch disc needs to be replaced.

3. Measure the radial run-out tolerance of the flywheel

Use the dial gauge to measure the radial run-out tolerance of the

flywheel.

Maximum radial run-out tolerance: 0.2mm

If the radial run-out tolerance exceeds the maximum value, the flywheel

needs to be replaced.

4.Check the guide bearing

Rotate the bearing with hand along the direction of the axis.

If the bearing cannot be rotated or there is great resistance, the guide

bearing needs to be replaced.

The bearing is lubricated eternally, so there is no need for

cleaning and lubrication. 2. Check the radial run-out tolerance of the clutch disc

Use dial gauge to check the radial run-out tolerance of the clutch disc.

The maximum radial run-out tolerance: 0.8mm

If the radial run-out tolerance exceeds the maximum value, the clutch

disc needs to be replaced.

5. If necessary, replace the guide bearing.

Use the special tools to remove the guide bearing.special tools