lock GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 28 of 425

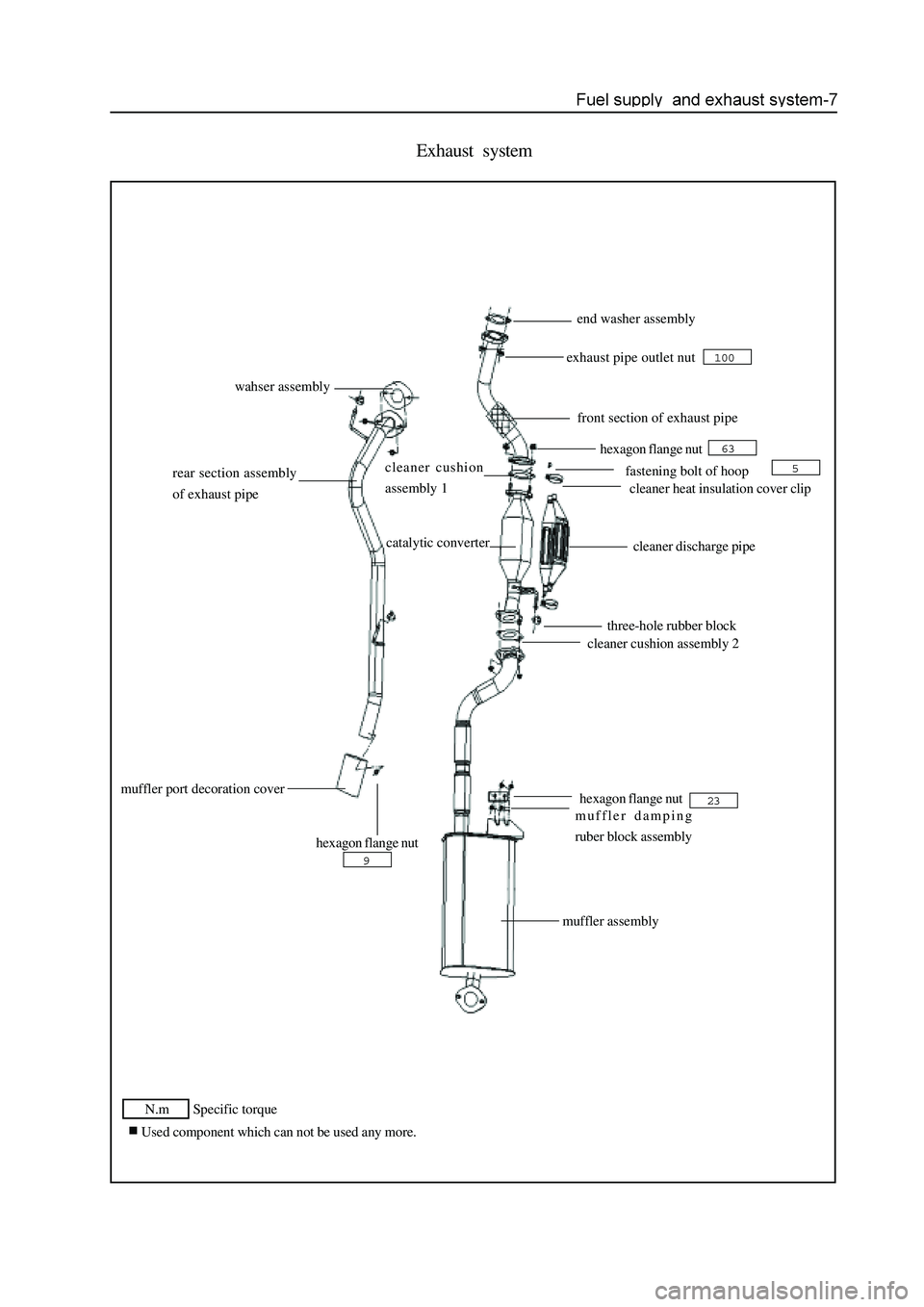

Exhaust system

N.m Specific torque

Used component which can not be used any more.

end washer assembly

exhaust pipe outlet nut

front section of exhaust pipe

hexagon flange nut

cleaner cushion

assembly 1

fastening bolt of hoop

cleaner heat insulation cover clip

cleaner discharge pipe catalytic converter

three-hole rubber block

cleaner cushion assembly 2

hexagon flange nut

muffler assembly

muffler port decoration cover

hexagon flange nut

rear section assembly

of exhaust pipe

wahser assembly

100

9

63

5

23muffler damping

ruber block assembly

Page 29 of 425

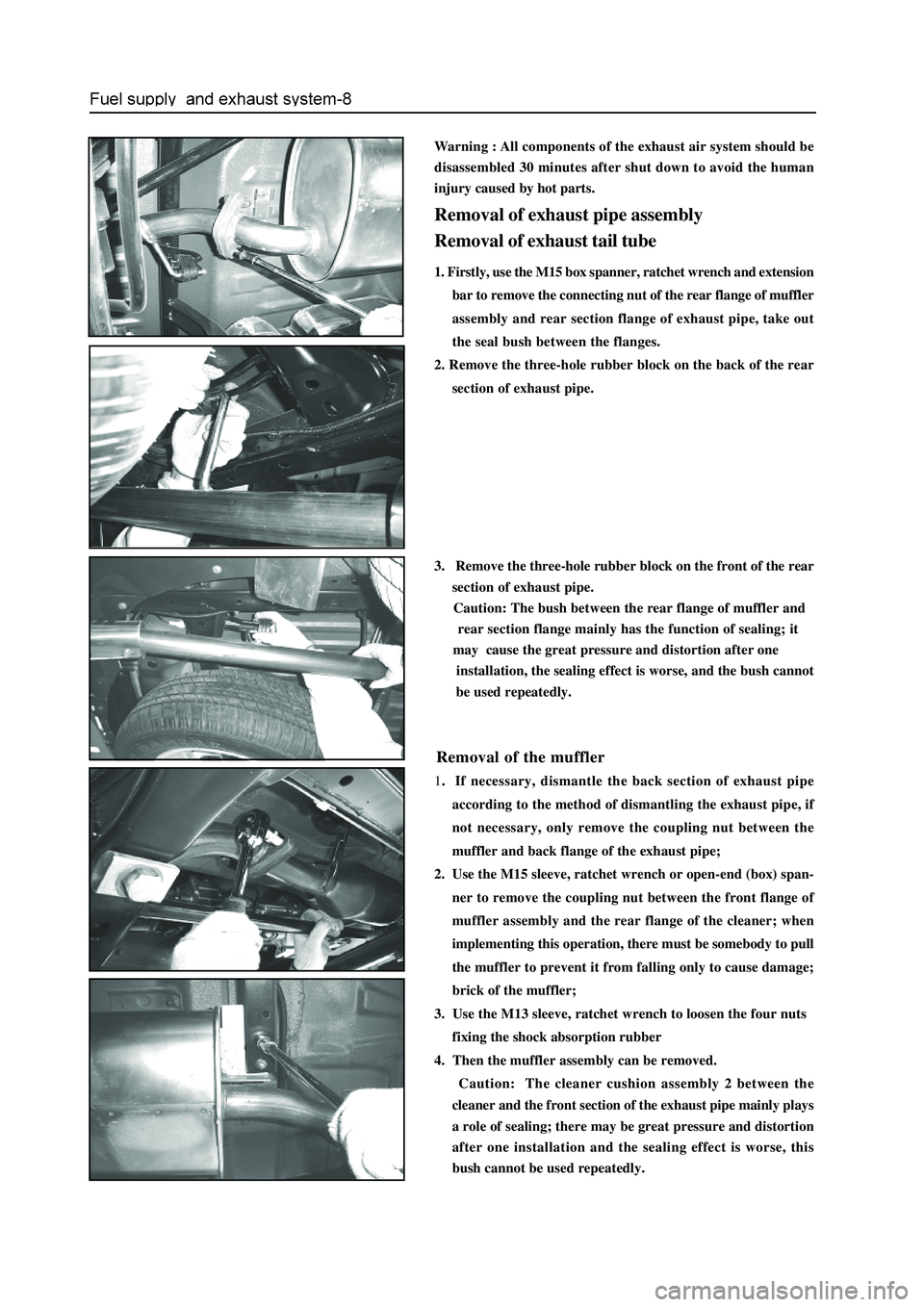

Warning : All components of the exhaust air system should be

disassembled 30 minutes after shut down to avoid the human

injury caused by hot parts.

Removal of exhaust pipe assembly

Removal of exhaust tail tube

1. Firstly, use the M15 box spanner, ratchet wrench and extension

bar to remove the connecting nut of the rear flange of muffler

assembly and rear section flange of exhaust pipe, take out

the seal bush between the flanges.

2. Remove the three-hole rubber block on the back of the rear

section of exhaust pipe.

3. Remove the three-hole rubber block on the front of the rear

section of exhaust pipe.

Caution: The bush between the rear flange of muffler and

rear section flange mainly has the function of sealing; it

may cause the great pressure and distortion after one

installation, the sealing effect is worse, and the bush cannot

be used repeatedly.

Removal of the muffler

1. If necessary, dismantle the back section of exhaust pipe

according to the method of dismantling the exhaust pipe, if

not necessary, only remove the coupling nut between the

muffler and back flange of the exhaust pipe;

2. Use the M15 sleeve, ratchet wrench or open-end (box) span-

ner to remove the coupling nut between the front flange of

muffler assembly and the rear flange of the cleaner; when

implementing this operation, there must be somebody to pull

the muffler to prevent it from falling only to cause damage;

brick of the muffler;

3. Use the M13 sleeve, ratchet wrench to loosen the four nuts

fixing the shock absorption rubber

4. Then the muffler assembly can be removed.

Caution: The cleaner cushion assembly 2 between the

cleaner and the front section of the exhaust pipe mainly plays

a role of sealing; there may be great pressure and distortion

after one installation and the sealing effect is worse, this

bush cannot be used repeatedly.

Page 32 of 425

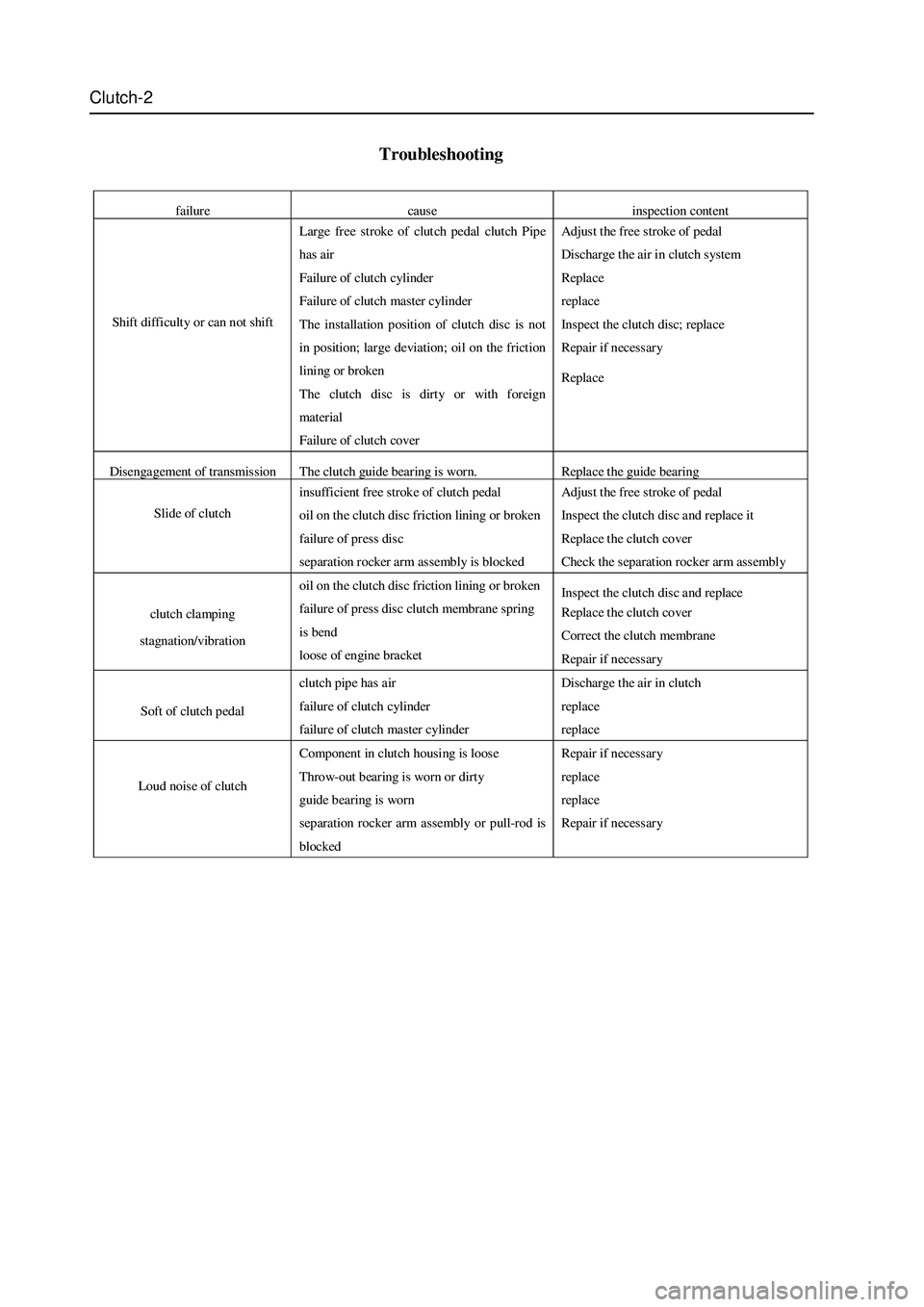

Clutch-2

Troubleshooting

failure cause inspection content

Shift difficulty or can not shift

Large free stroke of clut ch pedal clutch Pipe

has air

Failure of clutch cylinder

Failure of clutch master cylinder

The installation position of clutch disc is not

in position; large deviation; oil on the friction

lining or broken

The clutch disc is dirty or with foreign

material

Failure of clutch cover Adjust the free stroke of pedal

Discharge the air in clutch system

Replace

replace

Inspect the clutch disc; replace

Repair if necessary

Replace

Disengagement of transmission The clutch guide bearing is worn. Replace the guide bearing

Slide of clut ch

insufficient free stroke of clutch pedal

oil on the clutch disc friction lining or broken

failure of press disc

separation rocker arm assembly is blocked Adjust the free stroke of pedal

Inspect the clutch disc and replace it

Replace the clut ch cover

Check the separation rocker arm assembly

clutch clamping

stagnation/vibration oil on the clutch disc friction lining or broken

failure of press disc clutch membrane spring

is bend

loose of engine bracket Inspect the clutch disc and replace

Replace the clut ch cover

Correct the clutch membrane

Repair if necessary

Soft of clutch pedal clutch pip e has air

failure of clutch cylinder

failure of clutch master cylinder Discharge the air in clutch

replace

replace

Loud noise of clut ch

Component in clutch housing is loose

Throw-out bearing is worn or dirty

guide bearing is worn

separation rocker arm assembly or pull-rod is

blocked Repair if necessary

replace

replace

Repair if necessary

Page 33 of 425

Clutch-3

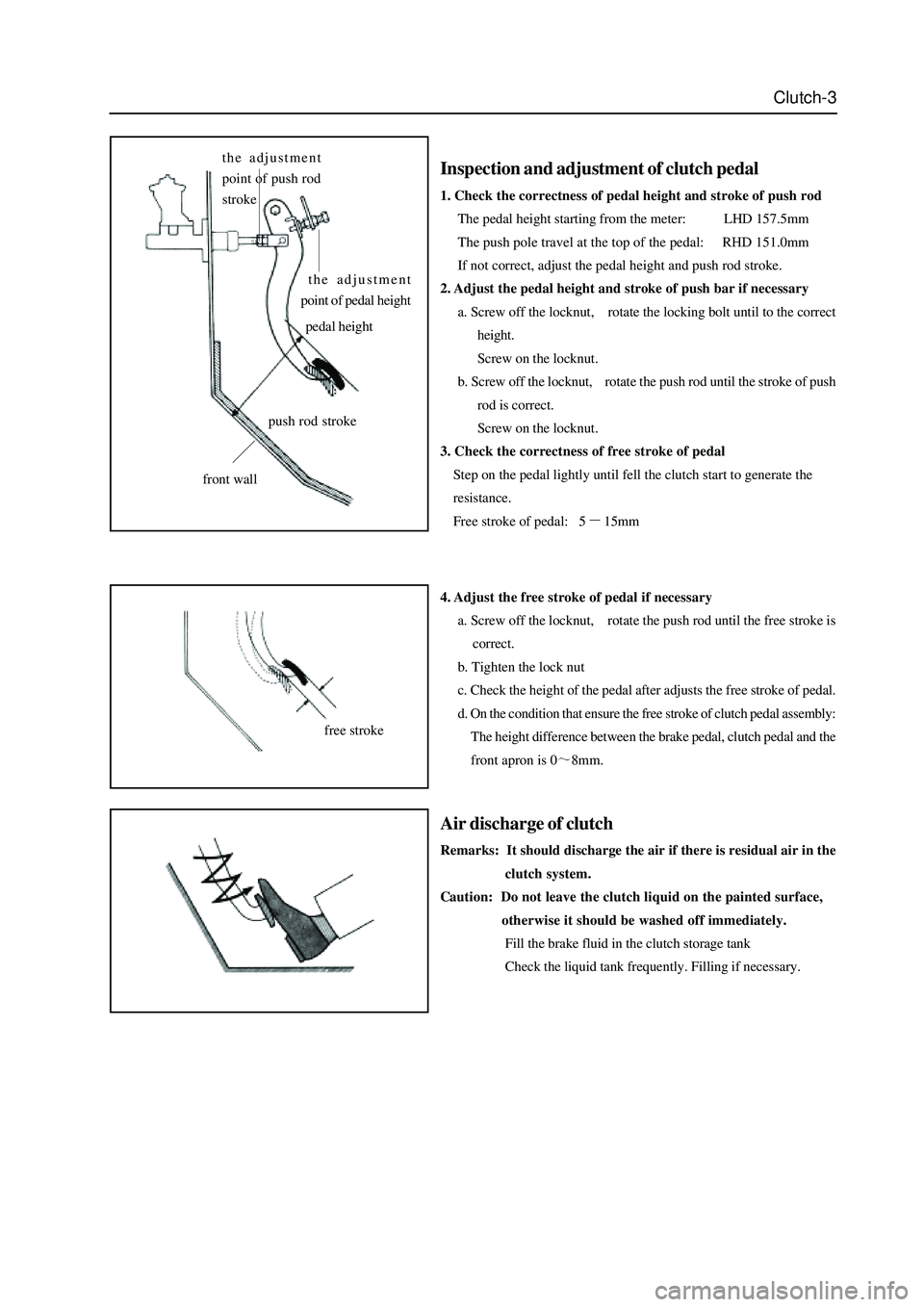

Inspection and adjustment of clutch pedal

1. Check the correctness of pedal height and stroke of push rod

The pedal height starting from the meter: LHD 157.5mm

The push pole travel at the top of the pedal: RHD 151.0mm

If not correct, adjust the pedal height and push rod stroke.

2. Adjust the pedal height and stroke of push bar if necessary

a. Screw off the locknut, rotate the locking bolt until to the correct

height.

Screw on the locknut.

b. Screw off the locknut, rotate the push rod until the stroke of push

rod is correct.

Screw on the locknut.

3. Check the correctness of free stroke of pedal

Step on the pedal lightly until fell the clutch start to generate the

resistance.

Free stroke of pedal: 5

15mm

4. Adjust the free stroke of pedal if necessary

a. Screw off the locknut, rotate the push rod until the free stroke is

correct.

b. Tighten the lock nut

c. Check the height of the pedal after adjusts the free stroke of pedal.

d. On the condition that ensure the free stroke of clutch pedal assembly:

The height difference between the brake pedal, clutch pedal and the

front apron is 0

8mm.

Air discharge of clutch

Remarks: It should discharge the air if there is residual air in the

clutch system.

Caution: Do not leave the clutch liquid on the painted surface,

otherwise it should be washed off immediately.

Fill the brake fluid in the clutch storage tank

Check the liquid tank frequently. Filling if necessary.

the adjustment

point of push rod

stroke

the adjustment

point of pedal height

pedal height

front wall

free stroke

push rod stroke

Page 42 of 425

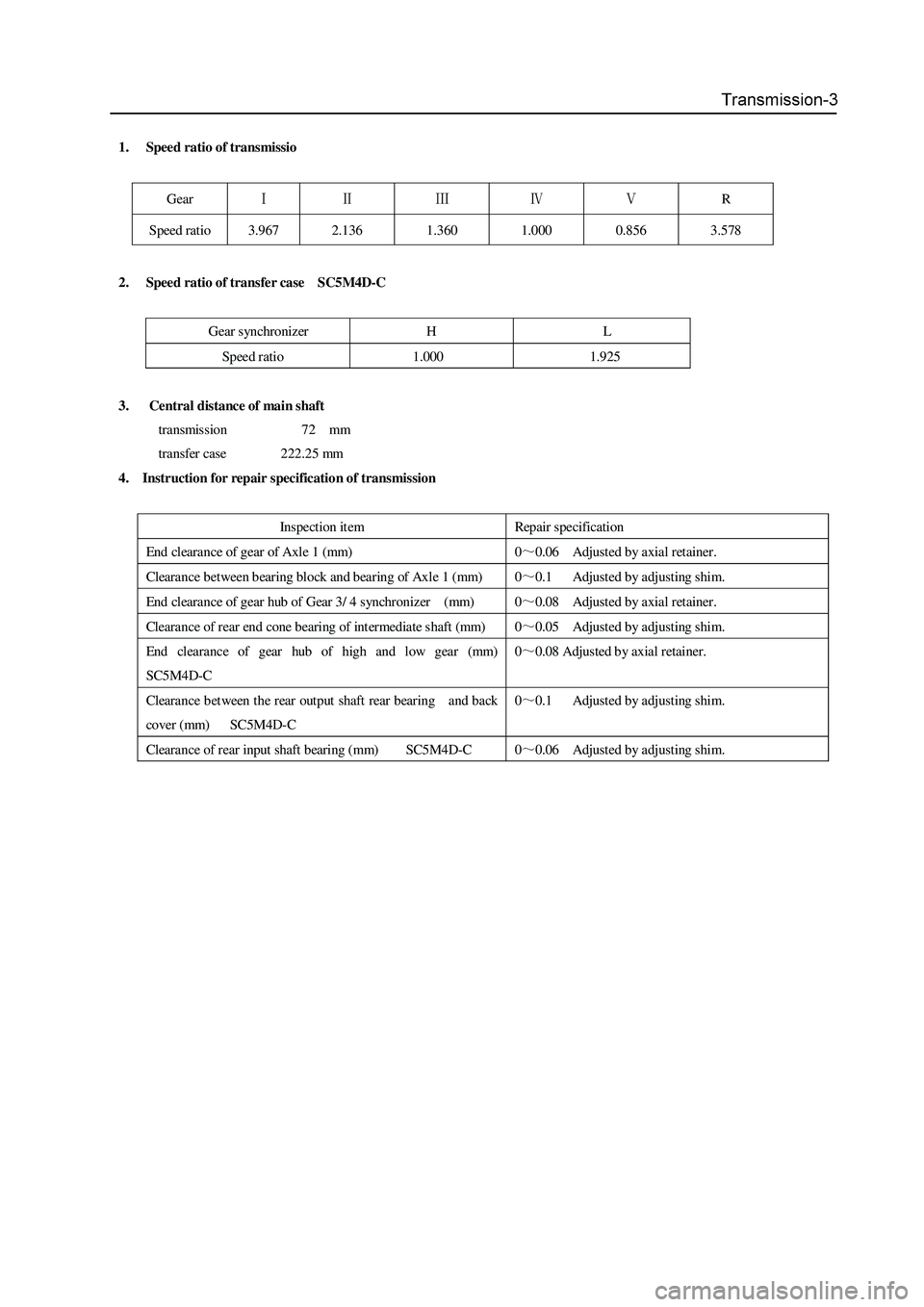

1. Speed ratio of transmissio

Gear Ⅰ Ⅱ Ⅲ Ⅳ Ⅴ R

Speed ratio 3.967 2.136 1.360 1.000 0.856 3.578

2. Speed ratio of transfer case SC5M4D-C

Gear synchronizer H L

Speed ratio 1.000 1.925

3. Central distance of main shaft

transmission 72 mm

transfer case 222.25 mm

4. Instruction for repair specification of transmission

Inspection item Repair specification

End clearance of gear of Axle 1 (mm) 0~0.06 Adjusted by axial retainer.

Clearance b etween b earing block and bearing of Axle 1 (mm) 0~0.1 Adjusted by adjusting shim.

End clearance of gear hub of Gear 3/ 4 synchronizer (mm) 0~0.08 Adjusted by axial retainer.

Clearance of rear end cone b earing of int ermediate s haft (mm) 0~0.05 Adjusted by adjusting shim.

End clearance of gear hub of high and low gear (mm)

SC5M4D-C 0~0.08 Adjusted by axial retainer.

Clearance between the rear output shaft rear bearing and back

cover (mm) SC5M4D-C 0~0.1 Adjusted by adjusting shim.

Clearance of rear input shaft bearing (mm) SC5M4D-C 0~0.06 Adjusted by adjusting shim.

Page 44 of 425

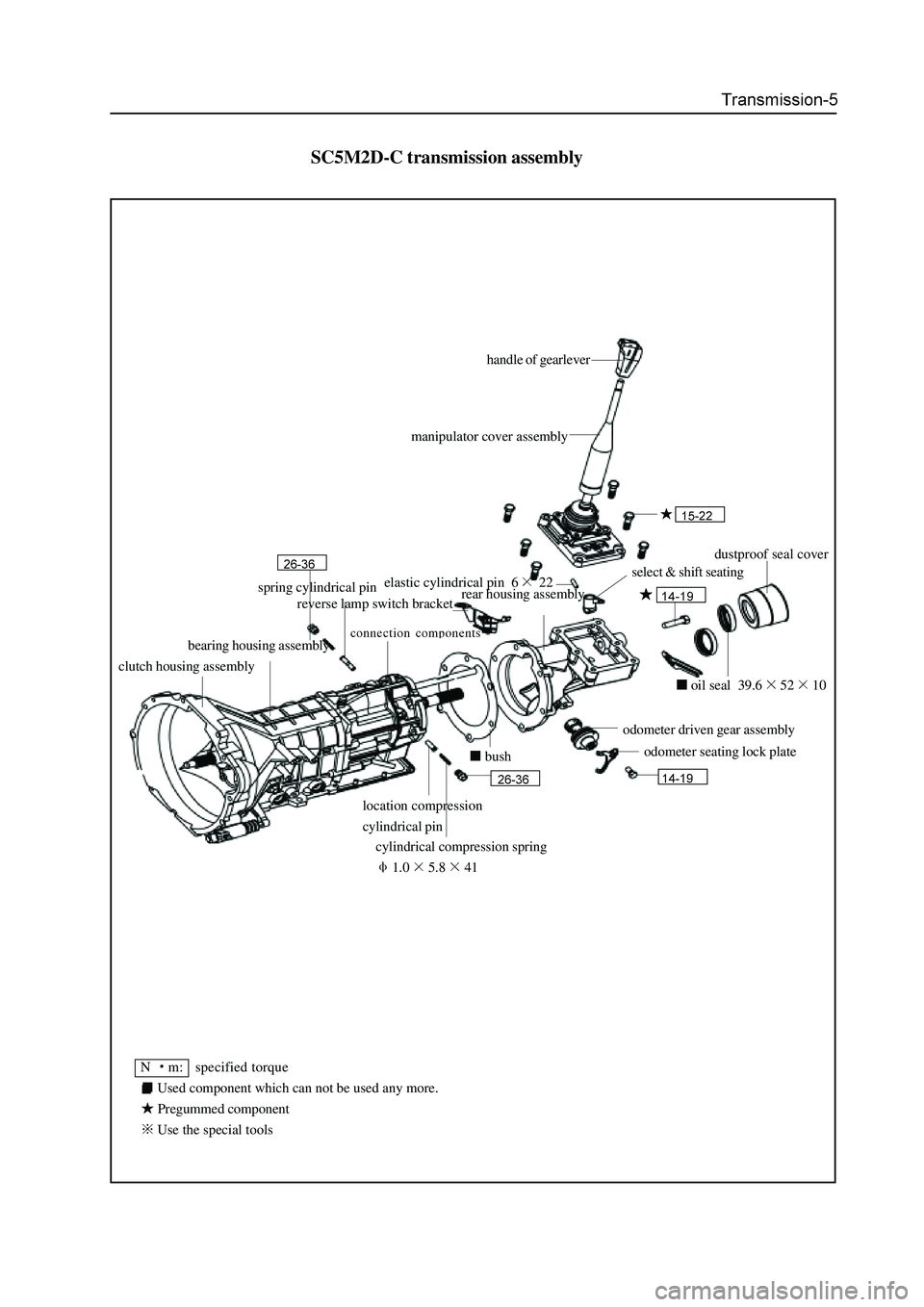

SC5M2D-C transmission assembly

handle of gearlever

dustproof seal cover

oil seal 39.65210

odometer driven gear assembly

odometer seating lock plate

cylindrical compression spring

1.05.841

bush

select & shift seating

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special toolsmanipulator cover assembly

elastic cylindrical pin 6

22

rear housing assembly spring cylindrical pin

reverse lamp switch bracket

bearing housing assembly

clutch housing assembly

location compression

cylindrical pin

Page 45 of 425

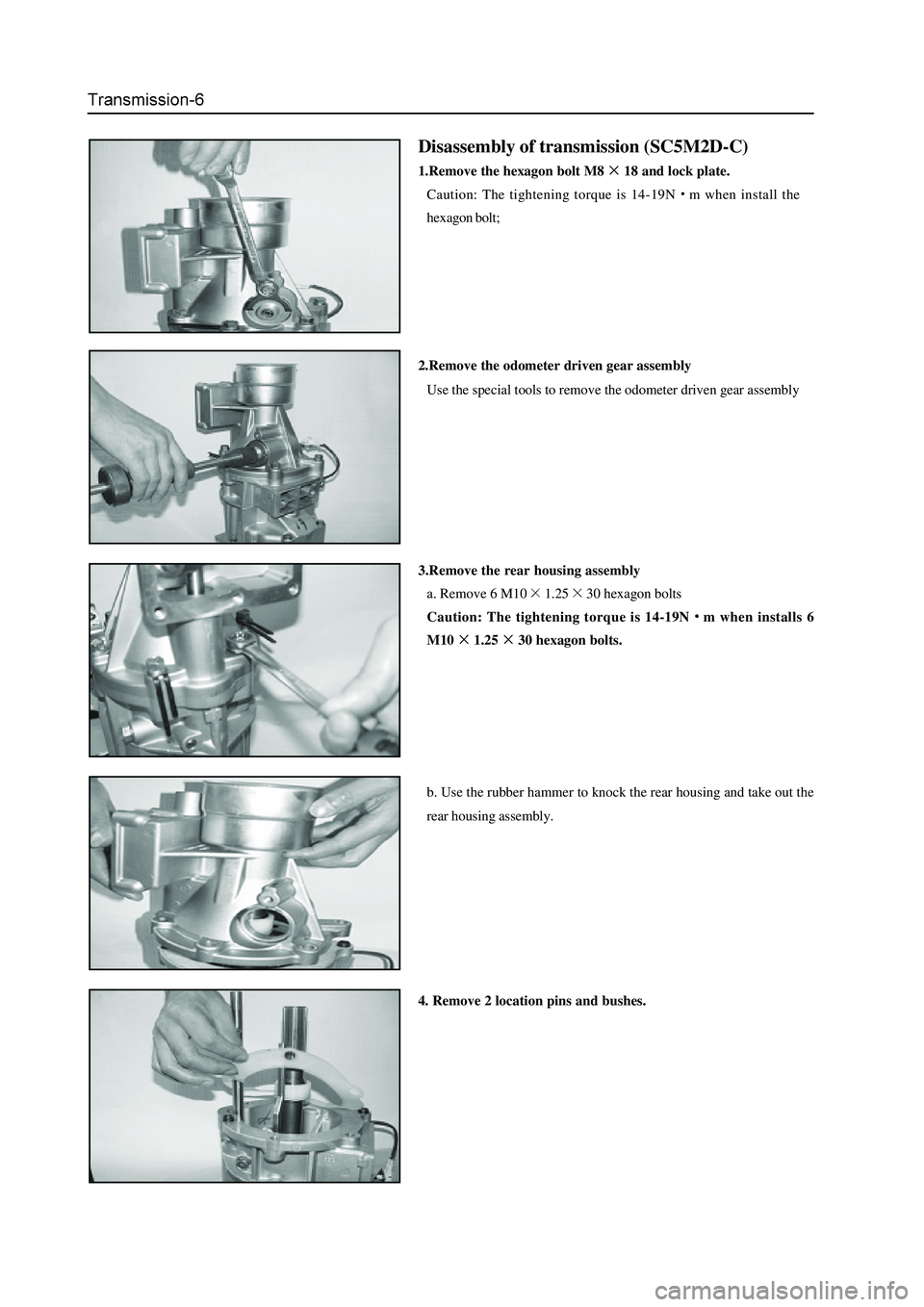

Disassembly of transmission (SC5M2D-C)

1.Remove the hexagon bolt M818 and lock plate.

Caution: The tightening torque is 14-19N

m when install the

hexagon bolt;

2.Remove the odometer driven gear assembly

Use the special tools to remove the odometer driven gear assembly

3.Remove the rear housing assembly

a. Remove 6 M10

1.2530 hexagon bolts

Caution: The tightening torque is 14-19N

m when installs 6

M10

1.2530 hexagon bolts.

b. Use the rubber hammer to knock the rear housing and take out the

rear housing assembly.

4. Remove 2 location pins and bushes.

Page 46 of 425

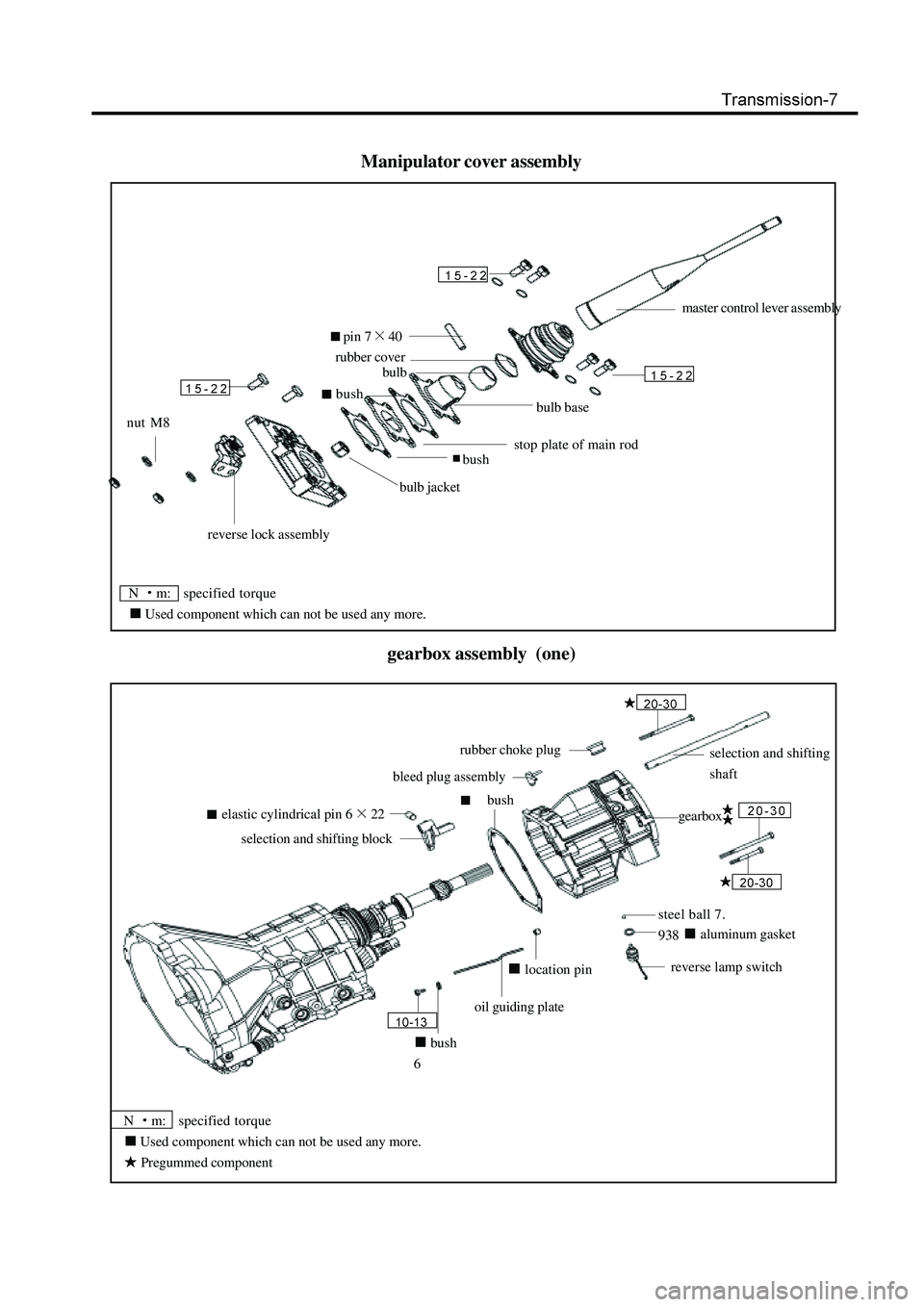

Manipulator cover assembly

gearbox assembly (one)

reverse lock assembly nut M8

bulbrubber cover

pin 740

master control lever assembly

bulb basebush

stop plate of main rodbush

bulb jacket

N m: specified torque

Used component which can not be used any more.

Pregummed component N

m: specified torque

Used component which can not be used any more.

bush

6

oil guiding plate

location pin

steel ball 7.

938

aluminum gasket

reverse lamp switch

gearbox

selection and shifting

shaft rubber choke plug

bleed plug assembly

bush

selection and shifting block

elastic cylindrical pin 622

Page 47 of 425

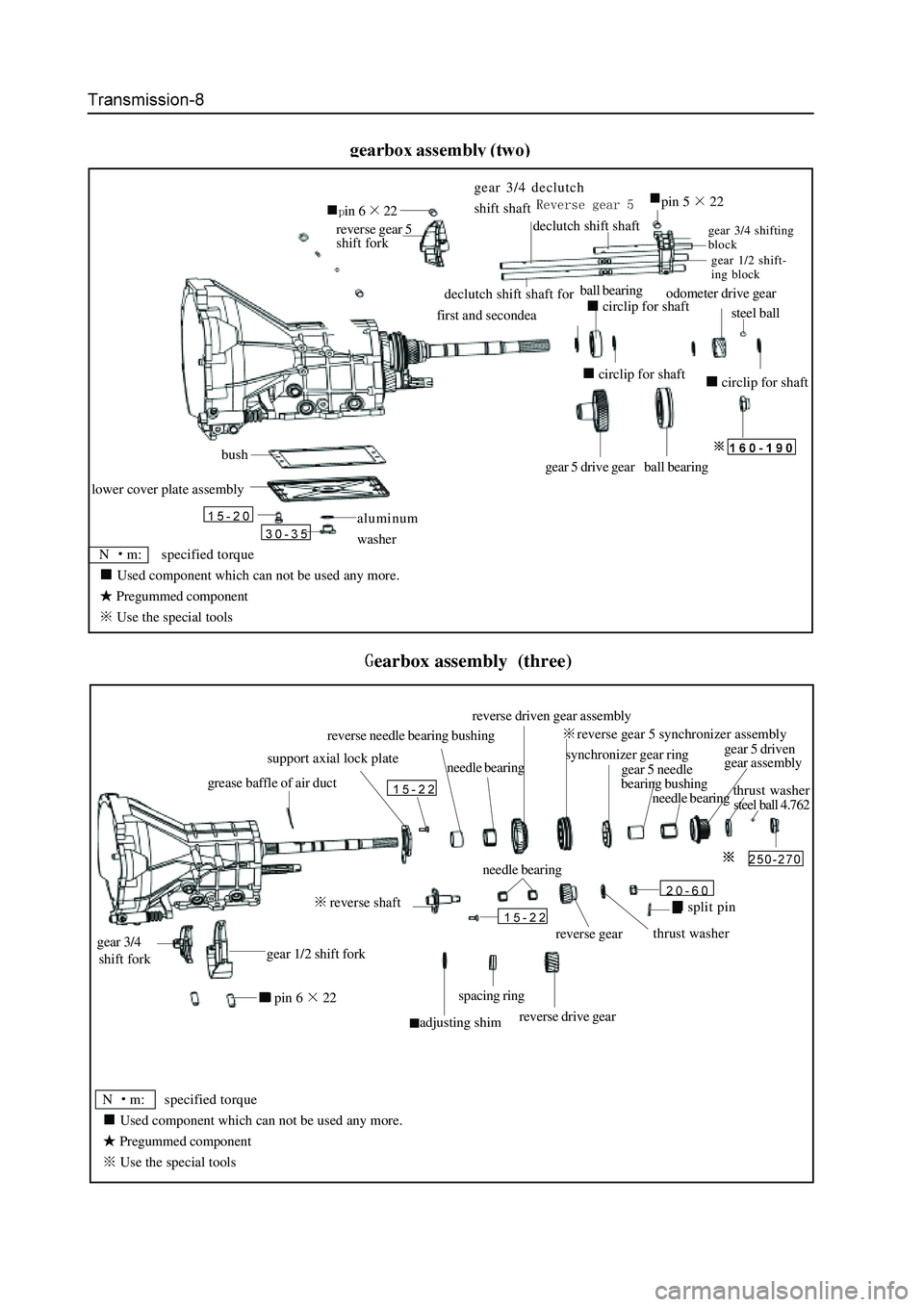

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special tools

aluminum

washer

lower cover plate assembly

bushgear 5 drive gear ball bearing

circlip for shaft

steel ball

odometer drive gear

circlip for shaft

ball bearing

circlip for shaft

reverse gear 5

shift fork

in 622

declutch shift shaft for

first and secondea

gear 3/4 declutch

shift shaft

declutch shift shaft

pin 522

gear 1/2 shift-

ing block

gear 3/4 shifting

block

earbox assembly (three)

steel ball 4.762

pin 622

gear 1/2 shift fork

adjusting shim

spacing ring

reverse drive gear

reverse shaft

needle bearing

reverse gear thrust washer

split pin

grease baffle of air duct

support axial lock plate

reverse needle bearing bushing

needle bearing

thrust washer

gear 5 needle

bearing bushingsynchronizer gear ring

reverse gear 5 synchronizer assembly

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special tools

gear 3/4

shift forkreverse driven gear assembly

needle bearinggear 5 driven

gear assembly

Page 50 of 425

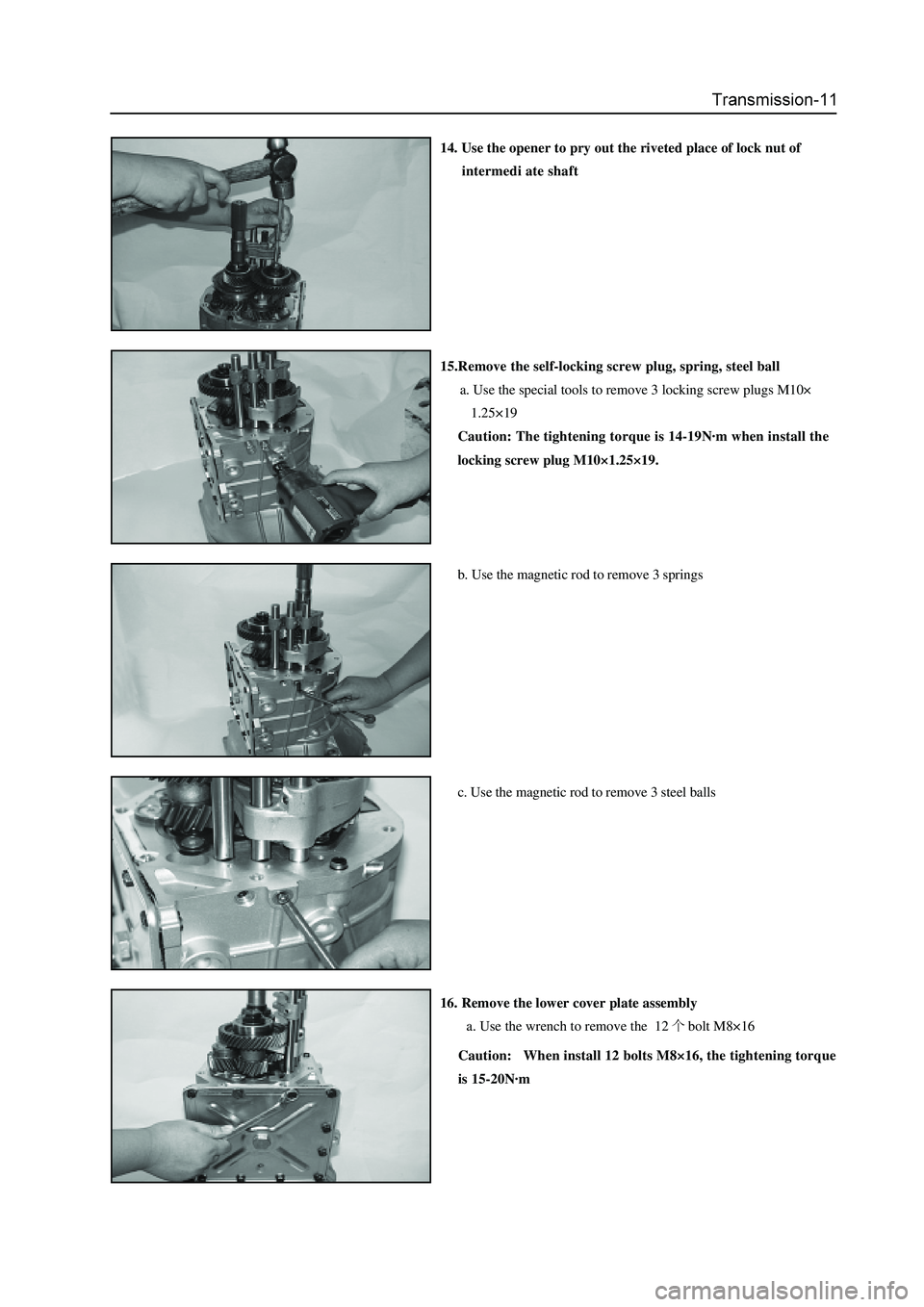

14. Use the opener to pry out the riveted place of lock nut of

intermedi ate shaft

15.Remove the self-locking screw plug, spring, steel ball

a. Use the special tools to remove 3 locking screw plugs M10×

1.25×19

Caution: The tightening torque is 14-19N·m when install the

locking screw plug M10×1.25×19.

b. Use the magnetic rod to remove 3 springs

c. Use the magnetic rod to remove 3 steel balls

Caution: When install 12 bolts M8×16, the tightening torque

is 15-20N·m

16. Remove the lower cover plate assembly

a. Use the wrench to remove the 12

bolt M8×16