lock GREAT WALL HOVER 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 52 of 425

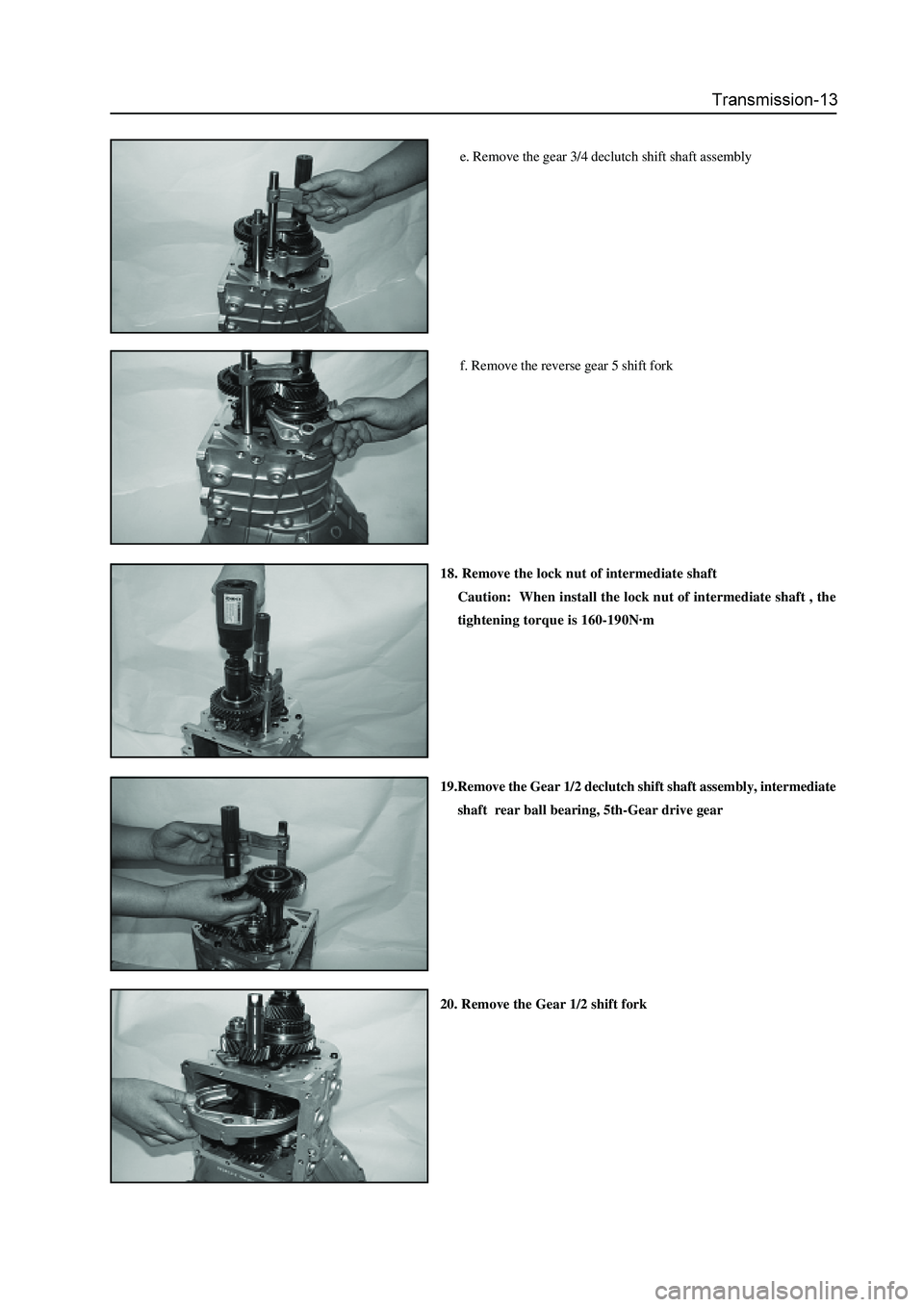

e. Remove the gear 3/4 declutch shift shaft assembly

f. Remove the reverse gear 5 shift fork

18. Remove the lock nut of intermediate shaft

Caution: When install the lock nut of intermediate shaft , the

tightening torque is 160-190N·m

19.Remove the Gear 1/2 declutch shift shaft assembly, intermediate

shaft rear ball bearing, 5th-Gear drive gear

20. Remove the Gear 1/2 shift fork

Page 53 of 425

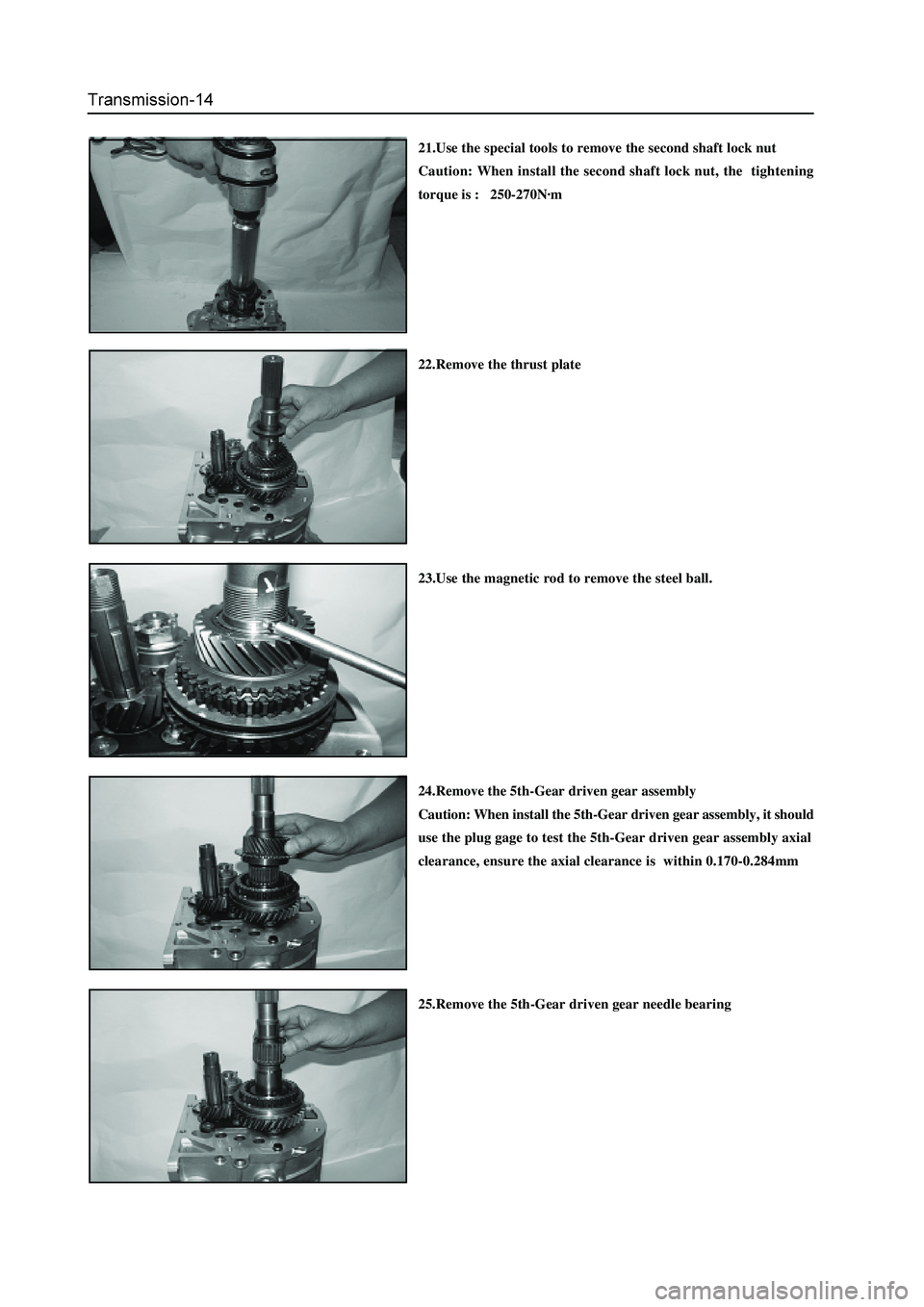

21.Use the special tools to remove the second shaft lock nut

Caution: When install the second shaft lock nut, the tightening

torque is : 250-270N·m

22.Remove the thrust plate

23.Use the magnetic rod to remove the steel ball.

24.Remove the 5th-Gear driven gear assembly

Caution: When install the 5th-Gear driven gear assembly, it should

use the plug gage to test the 5th-Gear driven gear assembly axial

clearance, ensure the axial clearance is within 0.170-0.284mm

25.Remove the 5th-Gear driven gear needle bearing

Page 54 of 425

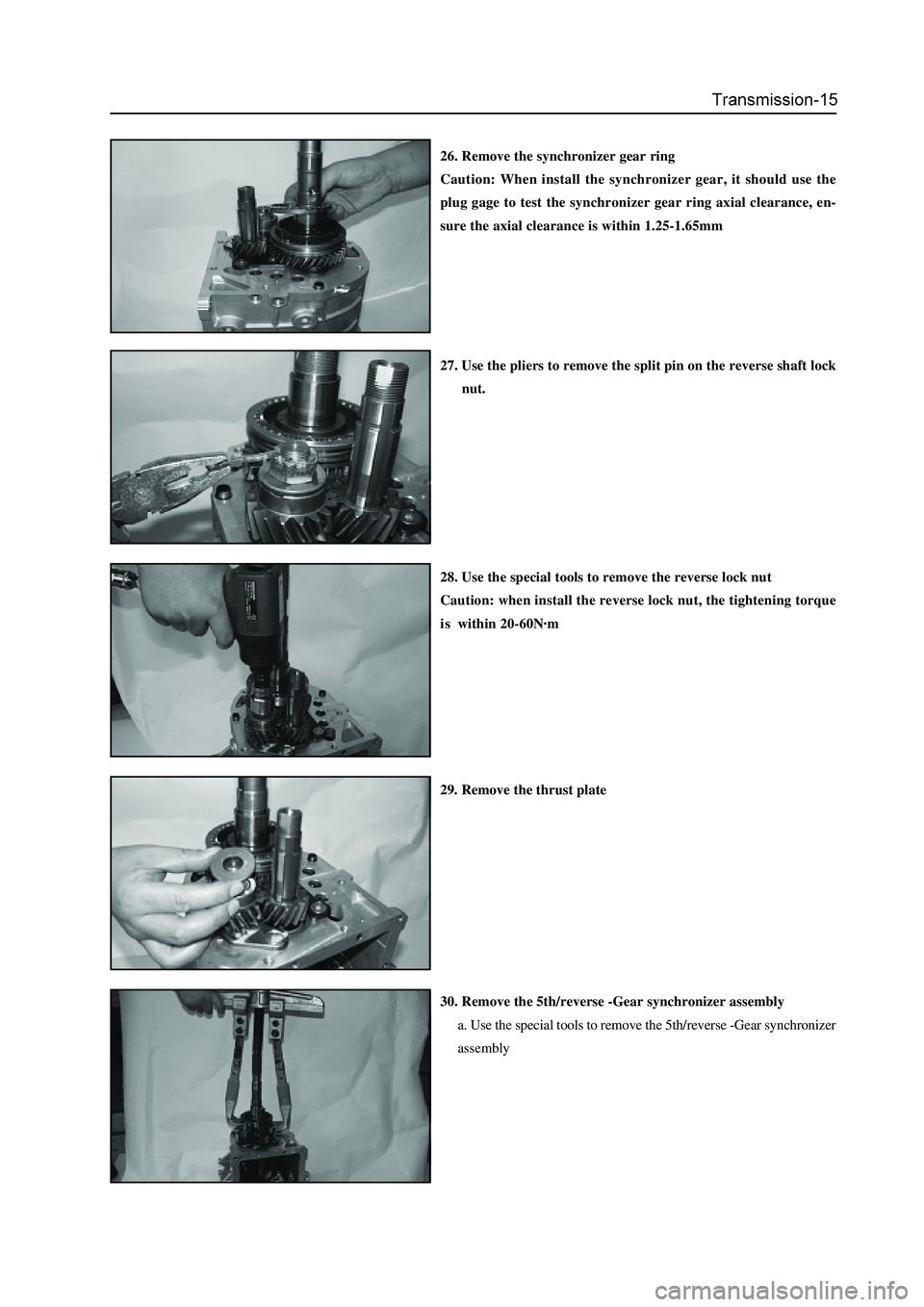

27. Use the pliers to remove the split pin on the reverse shaft lock

nut.

28. Use the special tools to remove the reverse lock nut

Caution: when install the reverse lock nut, the tightening torque

i s within 20-60N·m

29. Remove the thrust plate

30. Remove the 5th/reverse -Gear synchronizer assembly

a. Use the special tools to remove the 5th/reverse -Gear synchronizer

assembly 26. Remove the synchronizer gear ring

Caution: When install the synchronizer gear, it should use the

plug gage to test the synchronizer gear ring axial clearance, en-

sure the axial clearance is within 1.25-1.65mm

Page 56 of 425

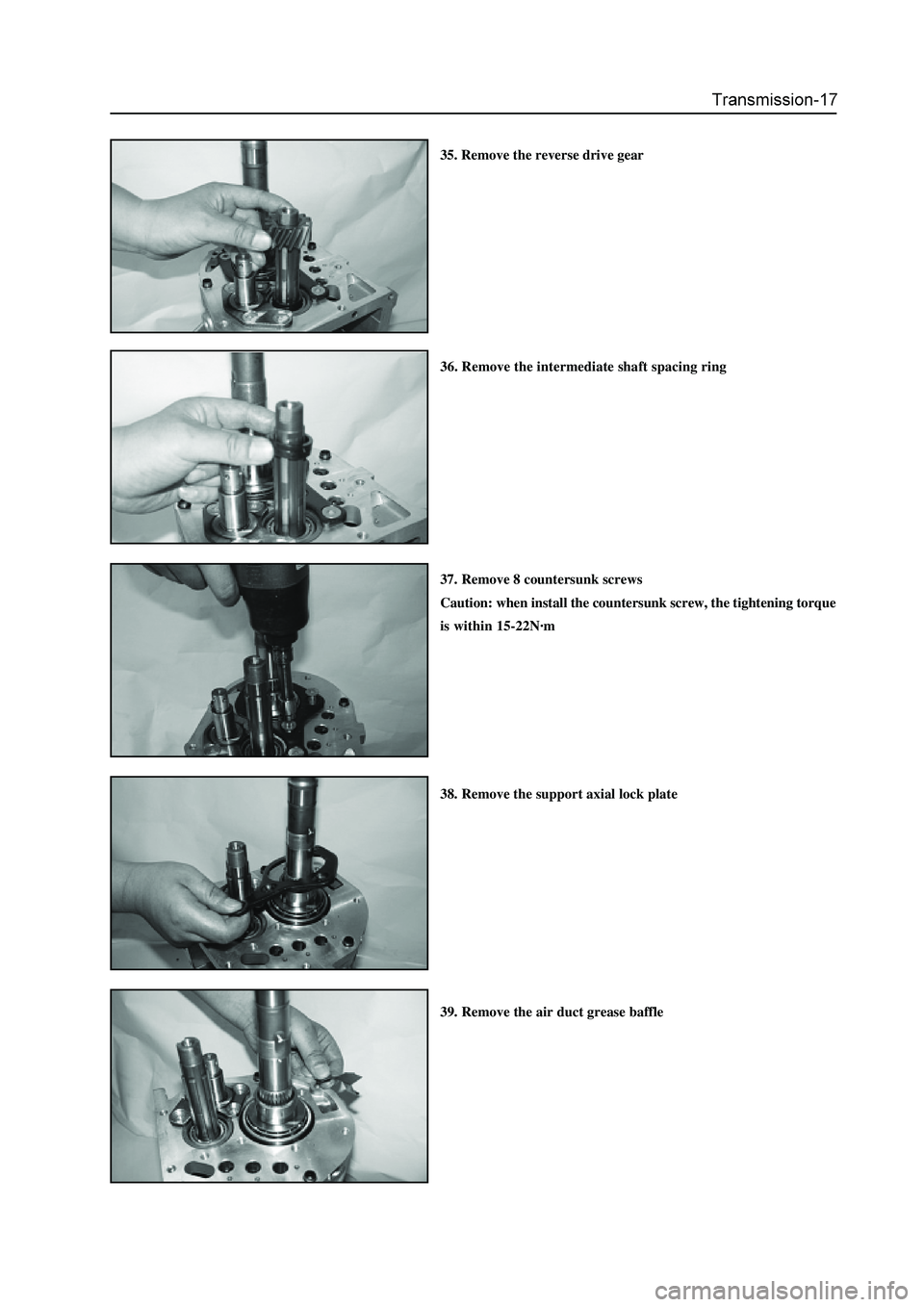

35. Remove the reverse drive gear

36. Remove the intermediate shaft spacing ring

37. Remove 8 countersunk screws

Caution: when install the countersunk screw, the tightening torque

is within 15-22N·m

38. Remove the support axial lock plate

39. Remove the air duct grease baffle

Page 57 of 425

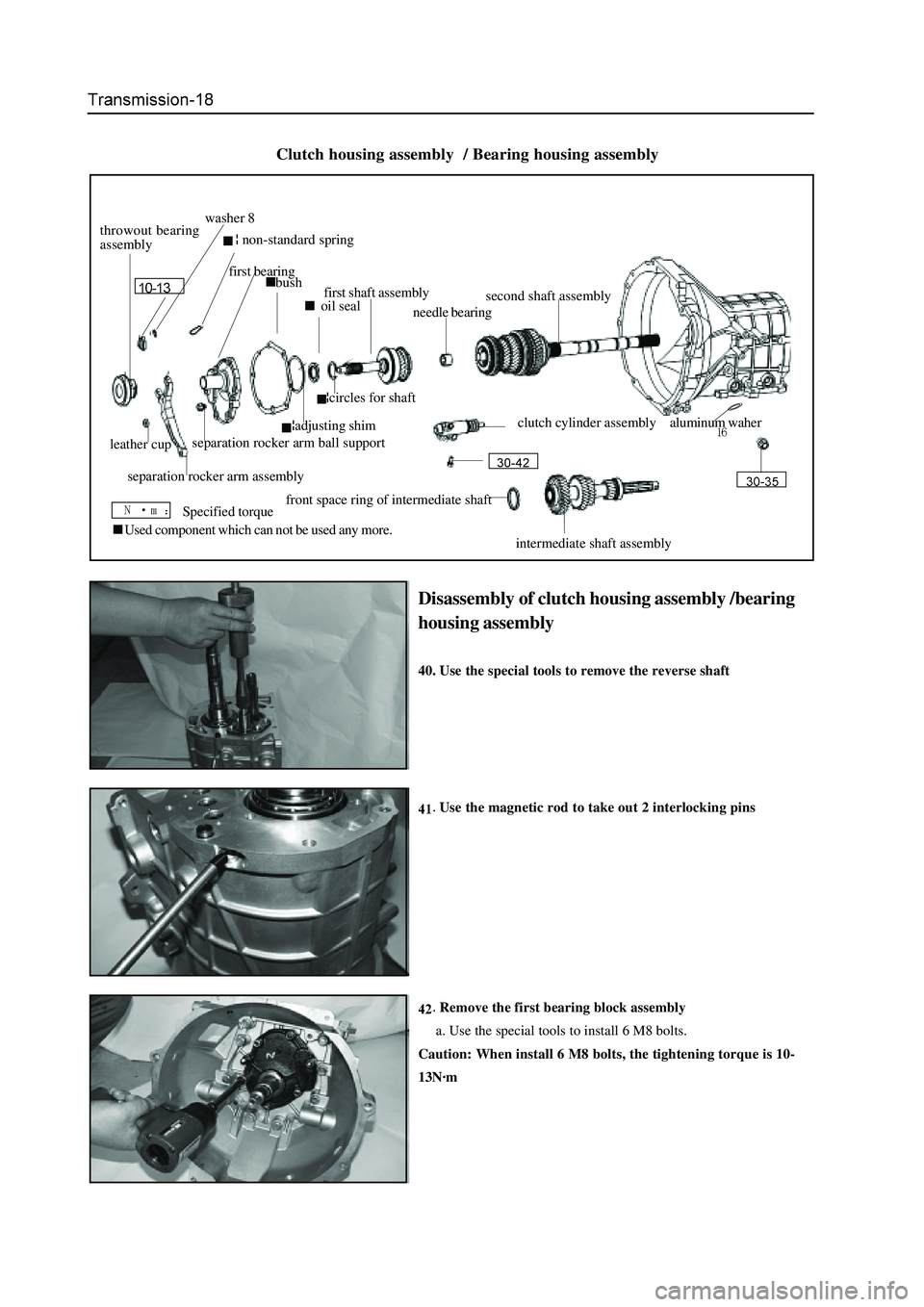

Disassembly of clutch housing assembly /bearing

housing assembly

40. Use the special tools to remove the reverse shaft

Use the magnetic rod to take out 2 interlocking pins

Remove the first bearing block assembly

a. Use the special tools to install 6 M8 bolts.

Caution: When install 6 M8 bolts, the tightening torque is 10-

13N·m

Clutch housing assembly / Bearing housing assembly

bush

oil seal

Used component which can not be used any more.

throwout bearing

assembly washer 8

¦ non-standard spring

first bearing

first shaft assembly

needle bearingsecond shaft assembly

¦circles for shaft

¦adjusting shim

leather cup

separation rocker arm assembly separation rocker arm ball supportclutch cylinder assembly

front space ring of intermediate shaft

intermediate shaft assembly aluminum waher

Specified torque

Page 58 of 425

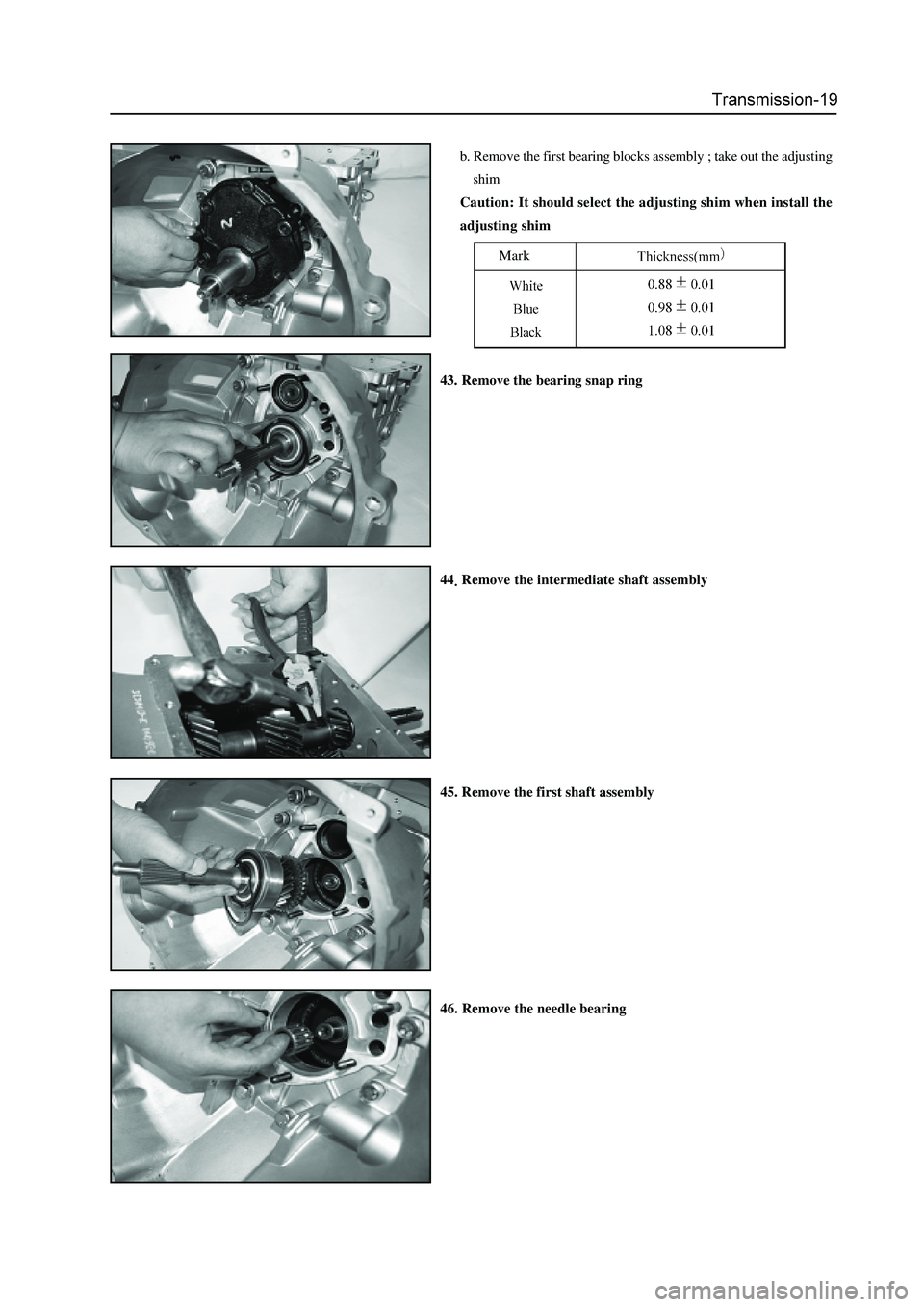

b. Remove the first bearing blocks assembly ; take out the adjusting

shim

Caution: It should select the adjusting shim when install the

adjusting shim

43. Remove the bearing snap ring

44

Remove the intermediate shaft assembly

45. Remove the first shaft assembly

46. Remove the needle bearing

Mark

Page 66 of 425

Transmission-27

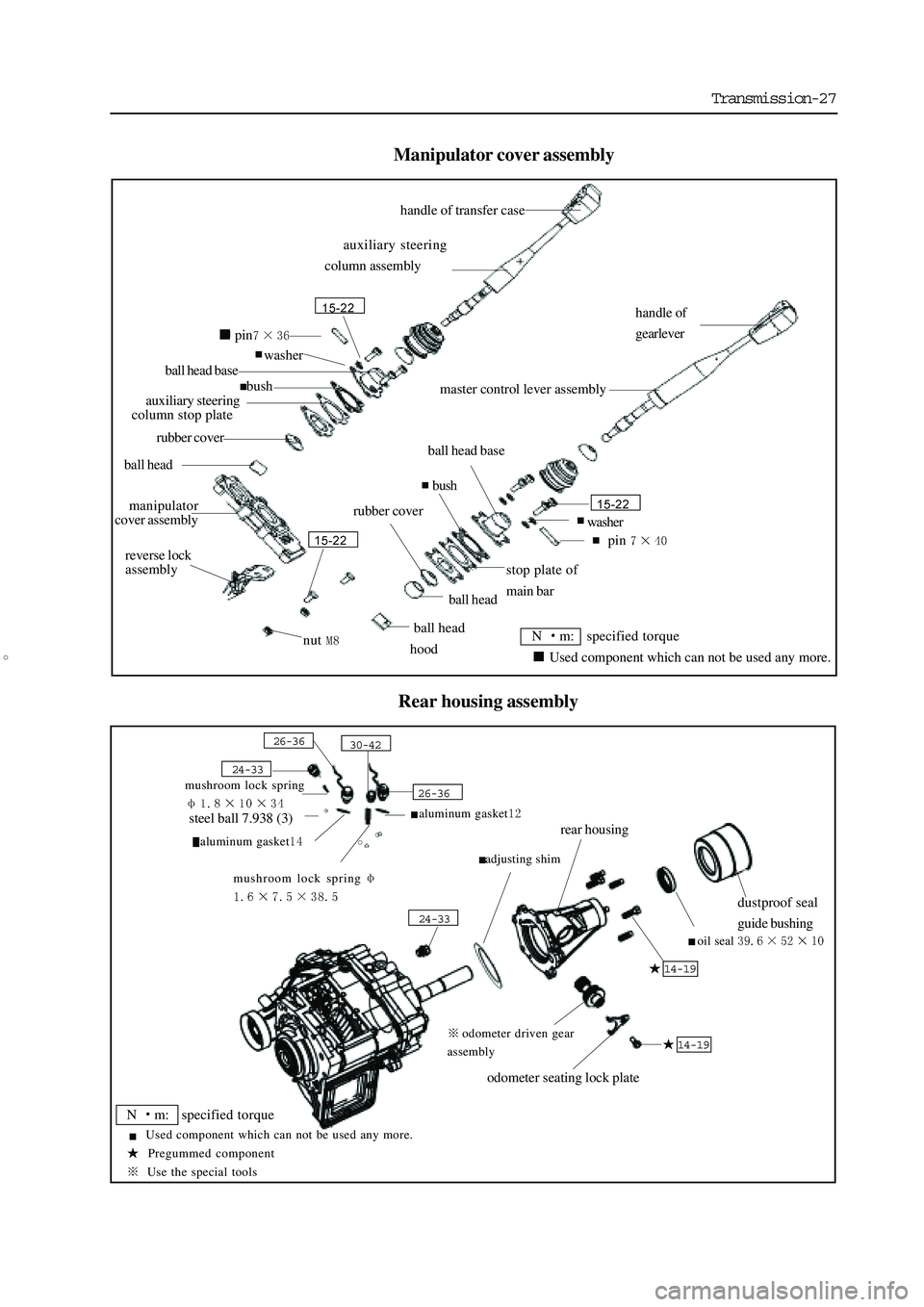

Manipulator cover assembly

Rear housing assembly

nut

reverse lock

assembly

manipulator

cover assembly

ball head

rubber cover

auxiliary steering

column stop platebush

ball head basewasher

pin

auxiliary steering

column assembly

handle of transfer case

ball head

hood

ball head

rubber cover

stop plate of

main bar

bush

ball head base

pin

washer

master control lever assembly

handle of

gearlever

N m: specified torque

Used component which can not be used any more.

odometer driven gear

assembly

odometer seating lock plate

14-19

14-19

oil seal

dustproof seal

guide bushing

rear housing

adjusting shim

24-33

26-36

aluminum gasket

mushroom lock spring

aluminum gasket

24-33

mushroom lock spring

26-3630-42

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special tools

steel ball 7.938 (3)

Page 67 of 425

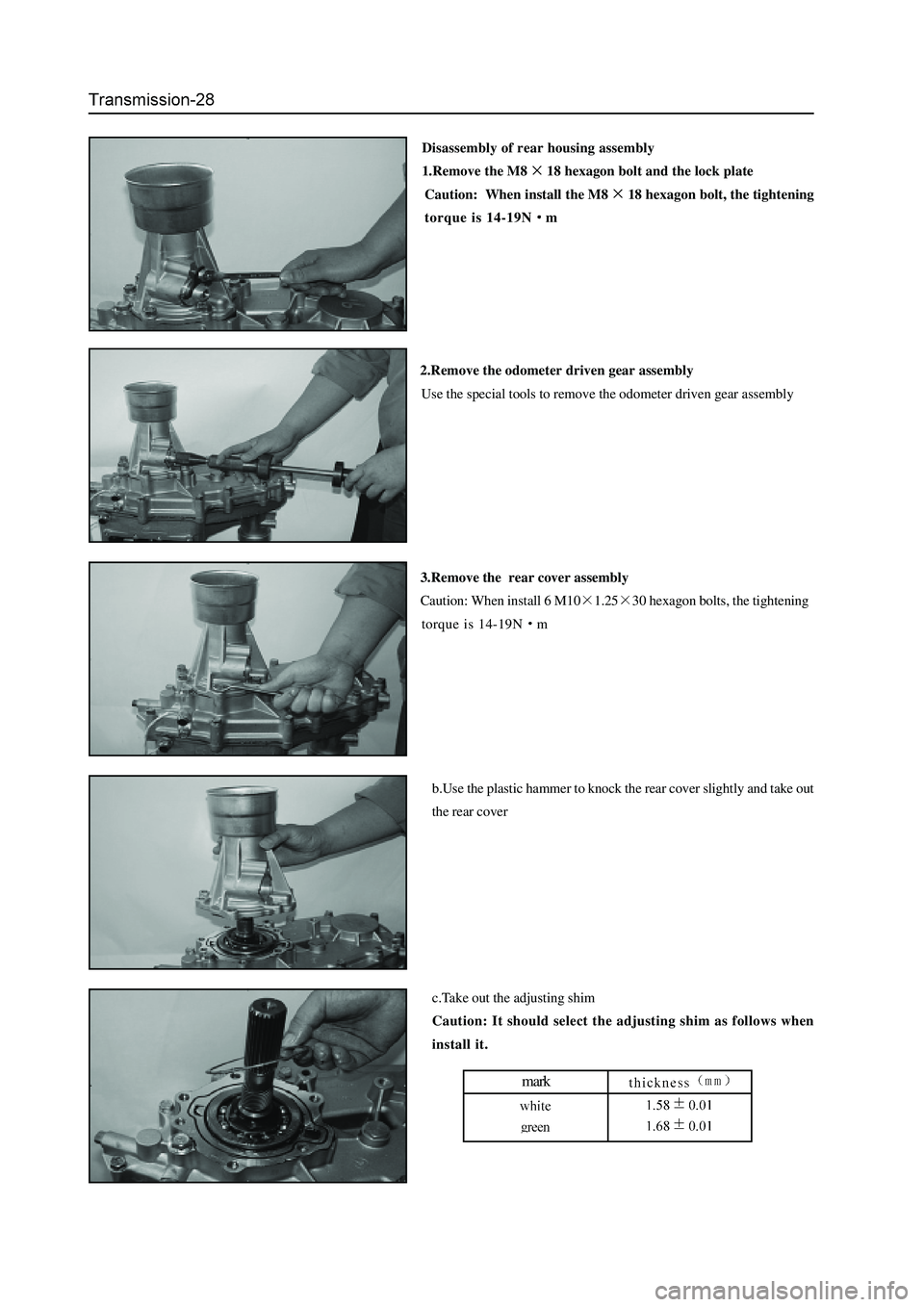

Disassembly of rear housing assembly

1.Remove the M8

18 hexagon bolt and the lock plate

Caution: When install the M8

18 hexagon bolt, the tightening

torque is 14-19N

m

2.Remove the odometer driven gear assembly

Use the special tools to remove the odometer driven gear assembly

3.Remove the rear cover assembly

Caution: When install 6 M10

1.2530 hexagon bolts, the tightening

torque is 14-19N

m

b.Use the plastic hammer to knock the rear cover slightly and take out

the rear cover

c.Take out the adjusting shim

Caution: It should select the adjusting shim as follows when

install it.

mark

Page 68 of 425

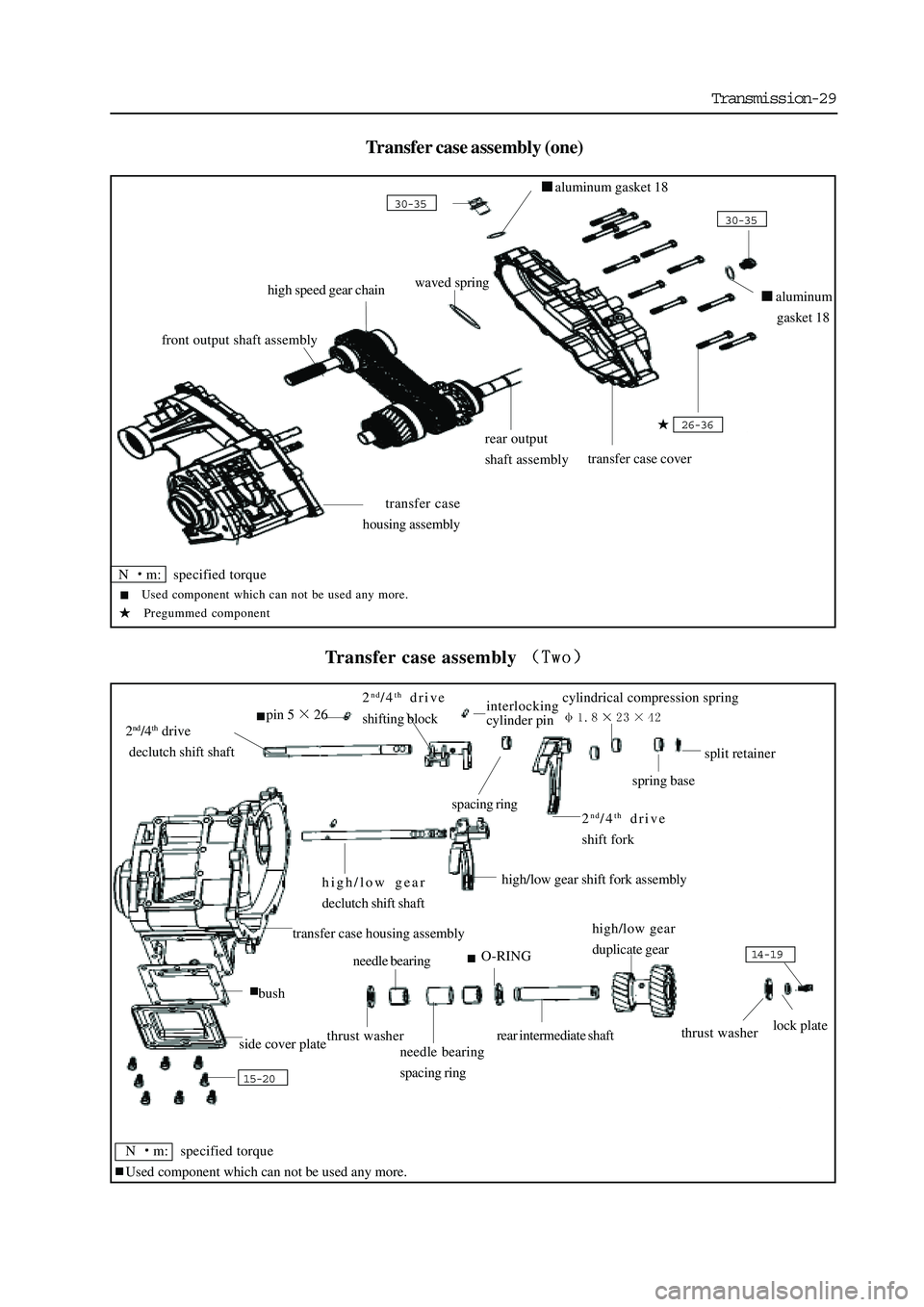

Transmission-29

Transfer case assembly (one)

Transfer case assembly

transfer case

housing assembly

rear output

shaft assembly

transfer case cover

26-36

30-35

aluminum gasket 18

30-35

waved springhigh speed gear chain

front output shaft assembly

15-20

side cover plate

bush

thrust washer

needle bearing

needle bearing

spacing ring

O-RING

rear intermediate shaft

high/low gear

duplicate gear

thrust washerlock plate

14-19

high/low gear

declutch shift shaft high/low gear shift fork assembly

2nd/4th drive

declutch shift shaft

pin 526

2nd/4th drive

shifting blockinterlocking

cylinder pin

spacing ring2nd/4th drive

shift fork

cylindrical compression spring

spring base

split retainer

aluminum

gasket 18

N

m: specified torque

Used component which can not be used any more.

Pregummed component

transfer case housing assembly

N

m: specified torque

Used component which can not be used any more.

Page 69 of 425

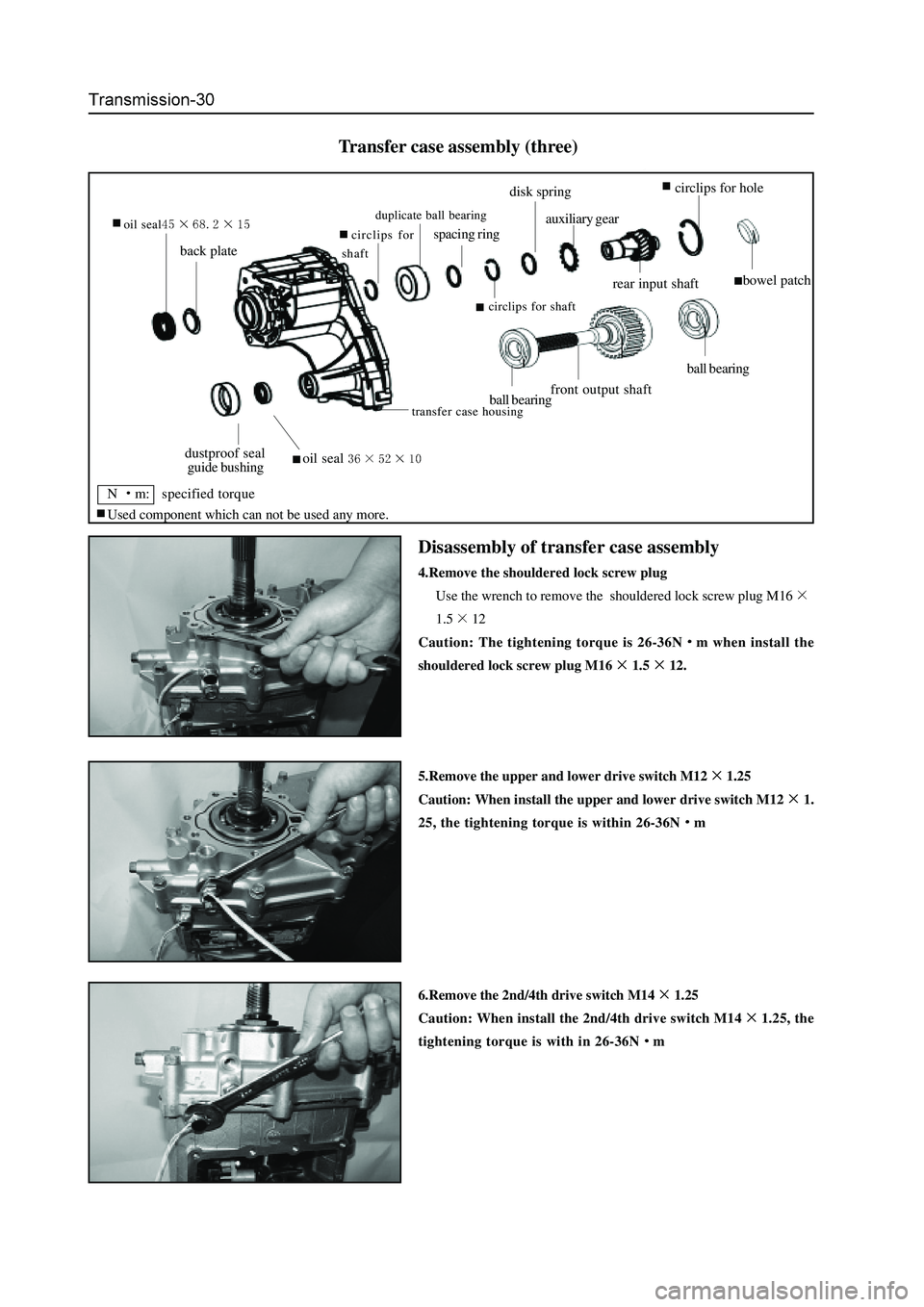

dustproof seal

guide bushingoil seal

transfer case housingball bearingfront output shaft

ball bearing

bowel patch

circlips for hole

rear input shaft

auxiliary gear

disk spring

circlips for shaft

spacing ring

duplicate ball bearing

circlips for

shaft oil seal

back plate

Transfer case assembly (three)

Disassembly of transfer case assembly

4.Remove the shouldered lock screw plug

Use the wrench to remove the shouldered lock screw plug M16

1.512

Caution: The tightening torque is 26-36N

m when install the

shouldered lock screw plug M16

1.512.

5.Remove the upper and lower drive switch M12

1.25

Caution: When install the upper and lower drive switch M12

1.

25, the tightening torque is within 26-36N

m

6.Remove the 2nd/4th drive switch M14

1.25

Caution: When install the 2nd/4th drive switch M14

1.25, the

tightening torque is with in 26-36N

m

N m: specified torque

Used component which can not be used any more.