torque GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 35 of 425

Clutch-5

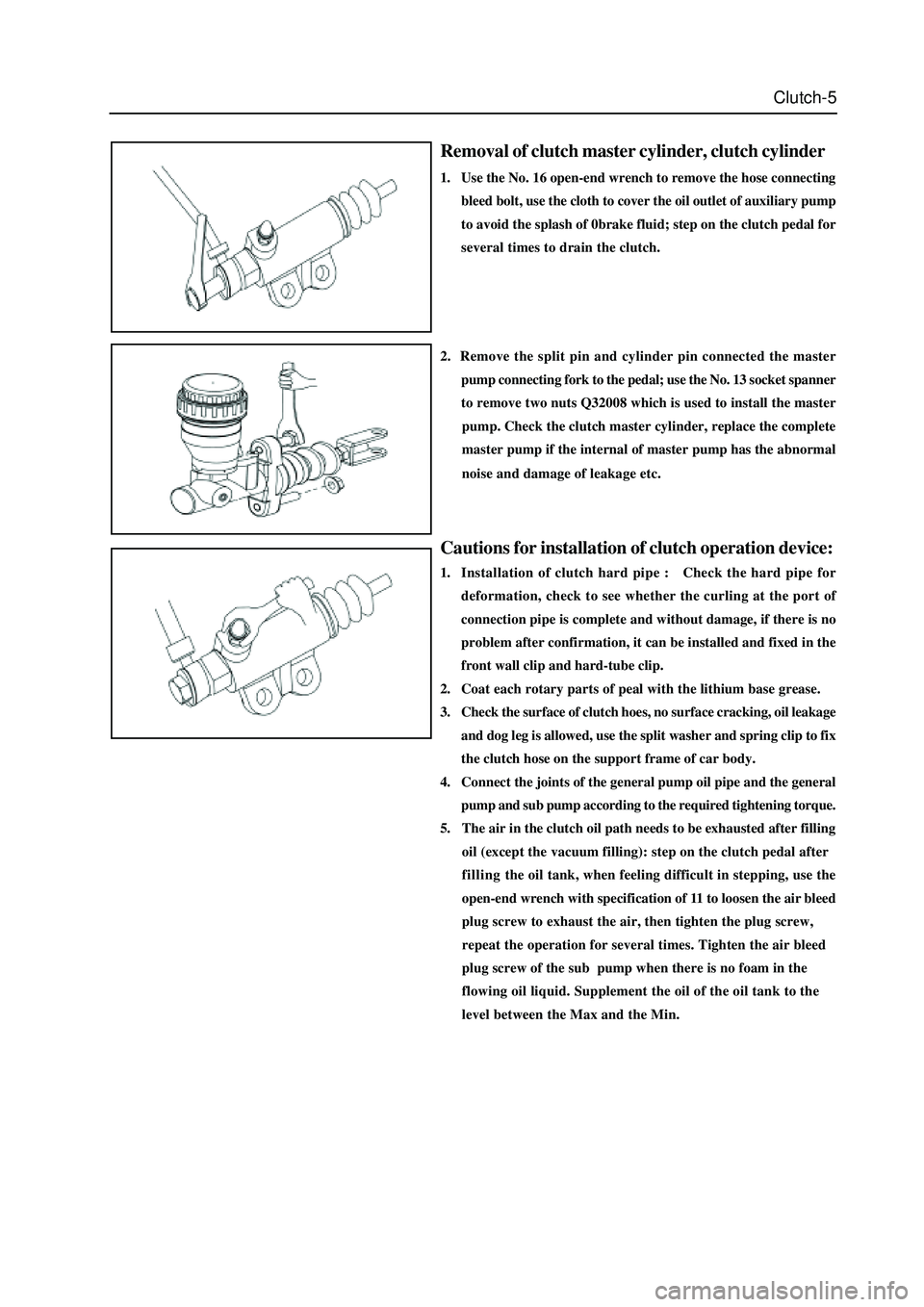

Removal of clutch master cylinder, clutch cylinder

1. Use the No. 16 open-end wrench to remove the hose connecting

bleed bolt, use the cloth to cover the oil outlet of auxiliary pump

to avoid the splash of 0brake fluid; step on the clutch pedal for

several times to drain the clutch.

Cautions for installation of clutch operation device:

1. Installation of clutch hard pipe : Check the hard pipe for

deformation, check to see whether the curling at the port of

connection pipe is complete and without damage, if there is no

problem after confirmation, it can be installed and fixed in the

front wall clip and hard-tube clip.

2. Coat each rotary parts of peal with the lithium base grease.

3. Check the surface of clutch hoes, no surface cracking, oil leakage

and dog leg is allowed, use the split washer and spring clip to fix

the clutch hose on the support frame of car body.

4. Connect the joints of the general pump oil pipe and the general

2. Remove the split pin and cylinder pin connected the master

pump connecting fork to the pedal; use the No. 13 socket spanner

to remove two nuts Q32008 which is used to install the master

pump. Check the clutch master cylinder, replace the complete

master pump if the internal of master pump has the abnormal

noise and damage of leakage etc.

pump and sub pump according to the required tightening torque.

5. The air in the clutch oil path needs to be exhausted after filling

oil (except the vacuum filling): step on the clutch pedal after

fillingthe oil tank, when feeling difficult in stepping, use the

open-end wrench with specification of 11 to loosen the air bleed

plug screw to exhaust the air, then tighten the plug screw,

repeat the operation for several times. Tighten the air bleed

plug screw of the sub pump when there is no foam in the

flowing oil liquid. Supplement the oil of the oil tank to the

level between the Max and the Min.

Page 36 of 425

Clutch-6

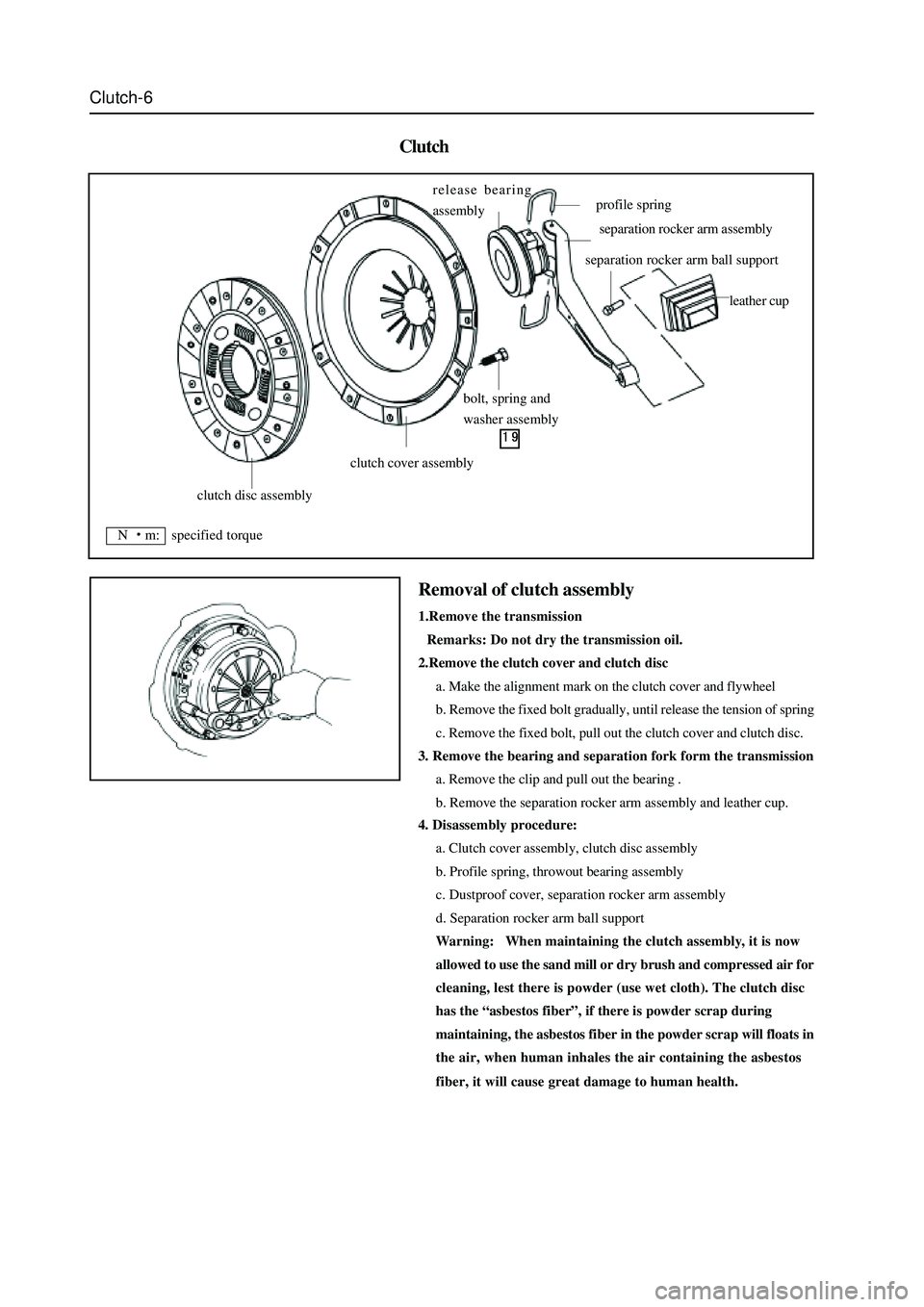

Clutch

4. Disassembly procedure:

a. Clutch cover assembly, clutch disc assembly

b. Profile spring, throwout bearing assembly

c. Dustproof cover, separation rocker arm assembly

d. Separation rocker arm ball support

Warning: When maintaining the clutch assembly, it is now

allowed to use the sand mill or dry brush and compressed air for

cleaning, lest there is powder (use wet cloth). The clutch disc

has the “asbestos fiber”, if there is powder scrap during

maintaining, the asbestos fiber in the powder scrap will floats in

the air, when human inhales the air containing the asbestos

fiber, it will cause great damage to human health.

Removal of clutch assembly

1.Remove the transmission

Remarks: Do not dry the transmission oil.

2.Remove the clutch cover and clutch disc

a. Make the alignment mark on the clutch cover and flywheel

b. Remove the fixed bolt gradually, until release the tension of spring

c. Remove the fixed bolt, pull out the clutch cover and clutch disc.

3. Remove the bearing and separation fork form the transmission

a. Remove the clip and pull out the bearing .

b. Remove the separation rocker arm assembly and leather cup.

clutch disc assembly

clutch cover assembly

bolt, spring and

washer assembly release bearing

assembly

profile spring

separation rocker arm assembly

separation rocker arm ball support

leather cup

N m: specified torque

Page 43 of 425

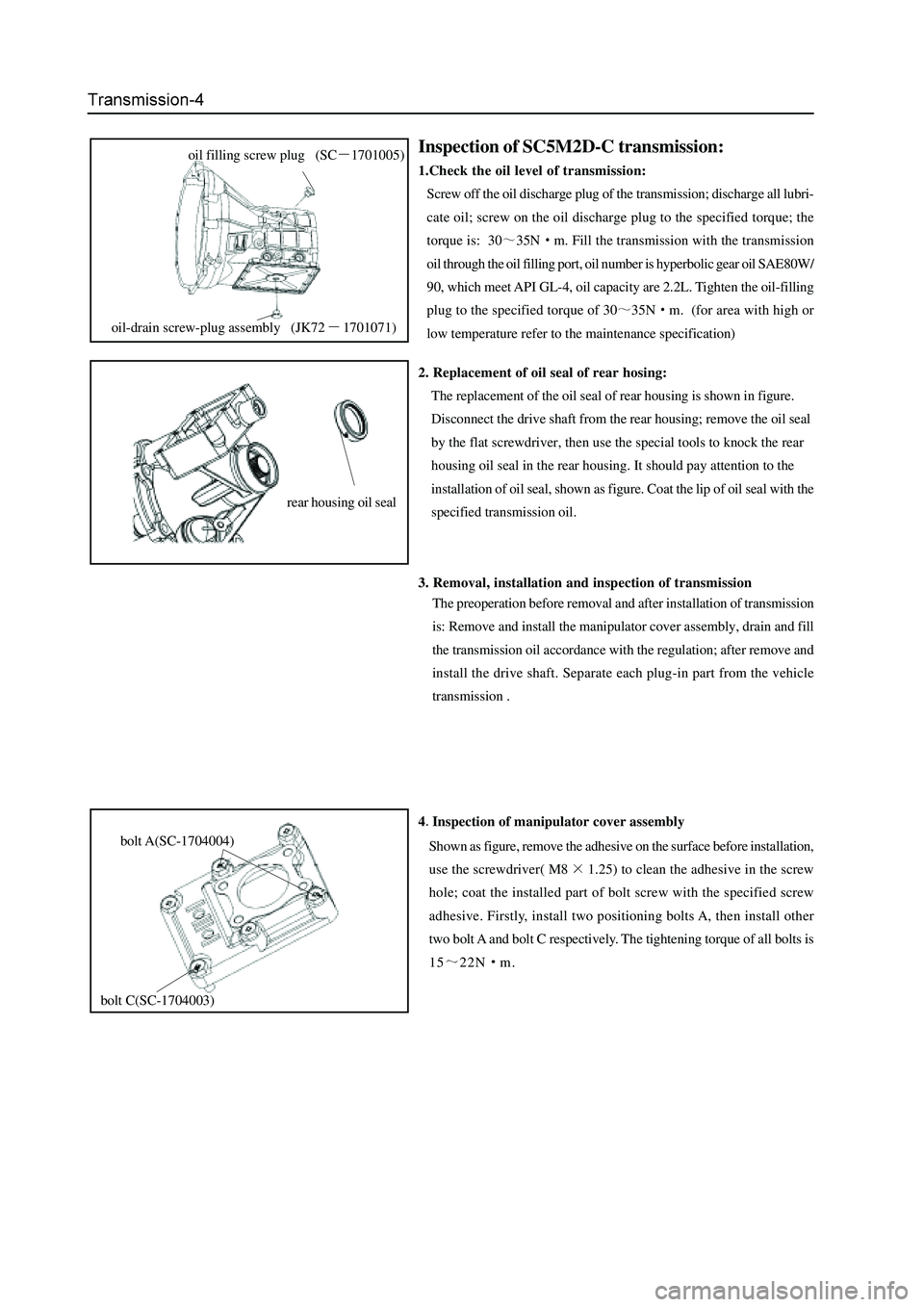

Inspection of SC5M2D-C transmission:

1.Check the oil level of transmission:

Screw off the oil discharge plug of the transmission; discharge all lubri-

cate oil; screw on the oil discharge plug to the specified torque; the

torque is: 30

35Nm. Fill the transmission with the transmission

oil through the oil filling port, oil number is hyperbolic gear oil SAE80W/

90, which meet API GL-4, oil capacity are 2.2L. Tighten the oil-filling

plug to the specified torque of 30

35Nm. (for area with high or

low temperature refer to the maintenance specification)

2. Replacement of oil seal of rear hosing:

The replacement of the oil seal of rear housing is shown in figure.

Disconnect the drive shaft from the rear housing; remove the oil seal

by the flat screwdriver, then use the special tools to knock the rear

housing oil seal in the rear housing. It should pay attention to the

installation of oil seal, shown as figure. Coat the lip of oil seal with the

specified transmission oil.

3. Removal, installation and inspection of transmission

The preoperation before removal and after installation of transmission

is: Remove and install the manipulator cover assembly, drain and fill

the transmission oil accordance with the regulation; after remove and

install the drive shaft. Separate each plug-in part from the vehicle

transmission .

4

Inspection of manipulator cover assembly

Shown as figure, remove the adhesive on the surface before installation,

use the screwdriver( M8

1.25) to clean the adhesive in the screw

hole; coat the installed part of bolt screw with the specified screw

adhesive. Firstly, install two positioning bolts A, then install other

two bolt A and bolt C respectively. The tightening torque of all bolts is

15

22Nm.

oil filling screw plug (SC1701005)

oil-drain screw-plug assembly (JK721701071)

rear housing oil seal

bolt C(SC-1704003)bolt A(SC-1704004)

Page 44 of 425

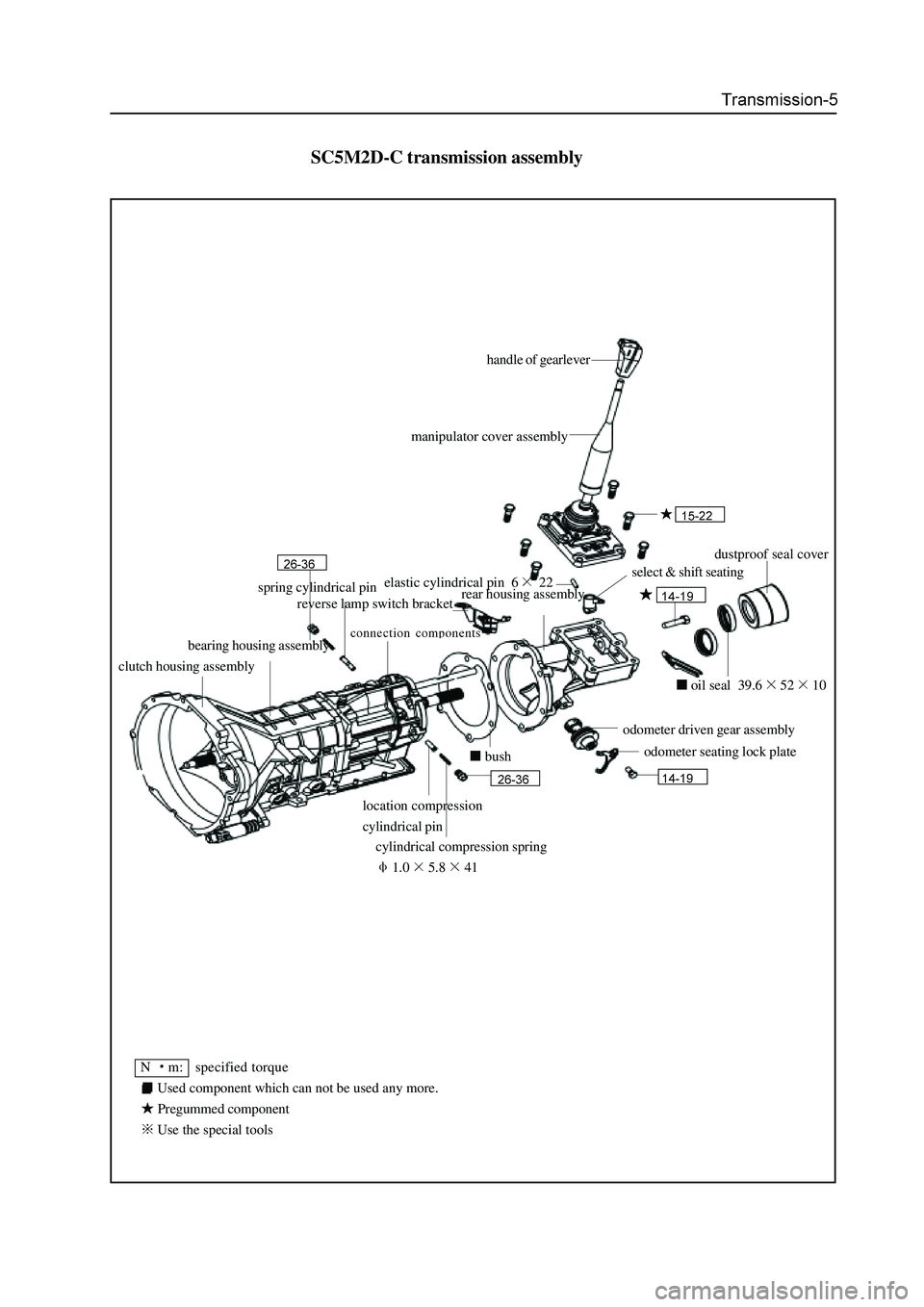

SC5M2D-C transmission assembly

handle of gearlever

dustproof seal cover

oil seal 39.65210

odometer driven gear assembly

odometer seating lock plate

cylindrical compression spring

1.05.841

bush

select & shift seating

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special toolsmanipulator cover assembly

elastic cylindrical pin 6

22

rear housing assembly spring cylindrical pin

reverse lamp switch bracket

bearing housing assembly

clutch housing assembly

location compression

cylindrical pin

Page 45 of 425

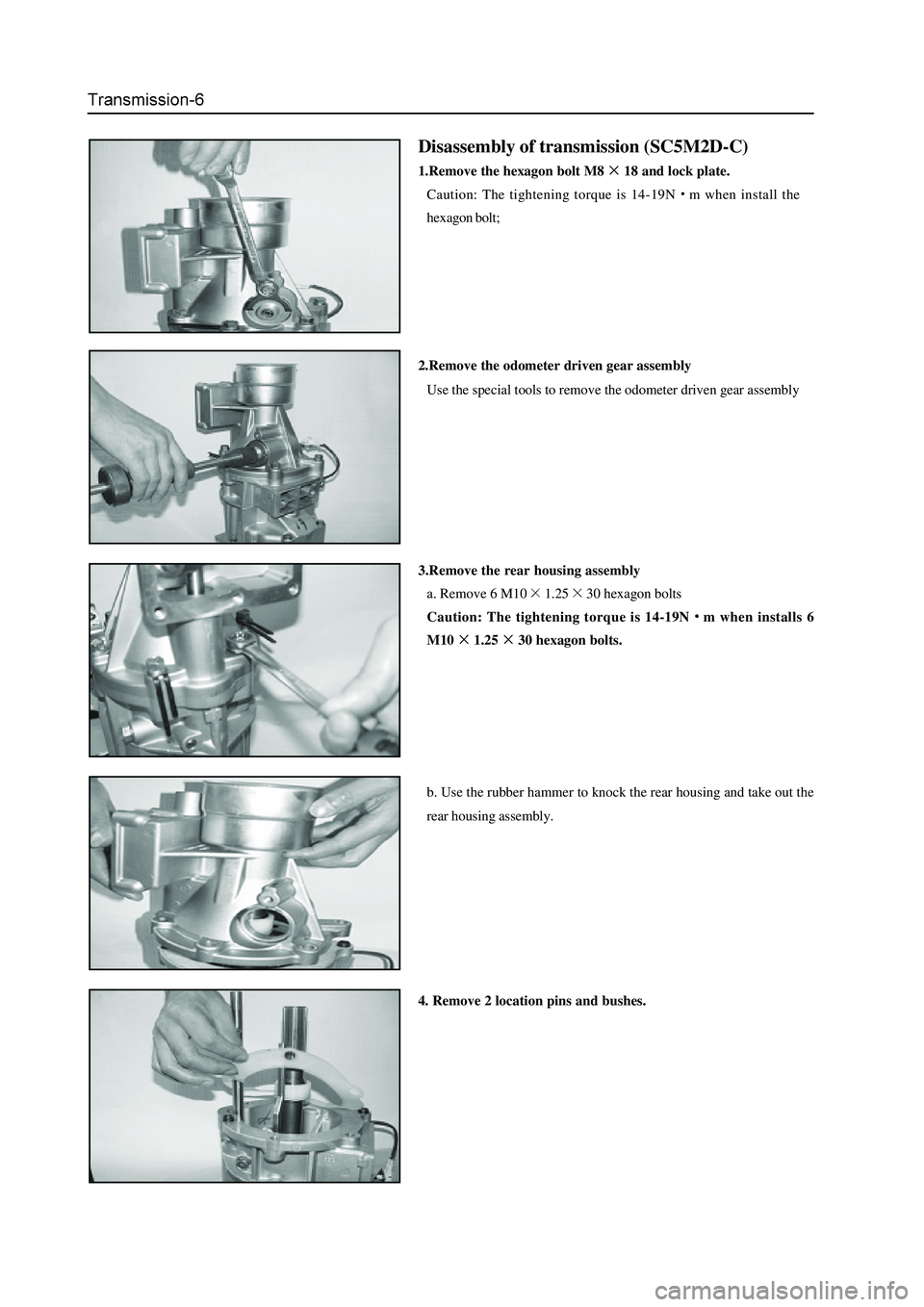

Disassembly of transmission (SC5M2D-C)

1.Remove the hexagon bolt M818 and lock plate.

Caution: The tightening torque is 14-19N

m when install the

hexagon bolt;

2.Remove the odometer driven gear assembly

Use the special tools to remove the odometer driven gear assembly

3.Remove the rear housing assembly

a. Remove 6 M10

1.2530 hexagon bolts

Caution: The tightening torque is 14-19N

m when installs 6

M10

1.2530 hexagon bolts.

b. Use the rubber hammer to knock the rear housing and take out the

rear housing assembly.

4. Remove 2 location pins and bushes.

Page 46 of 425

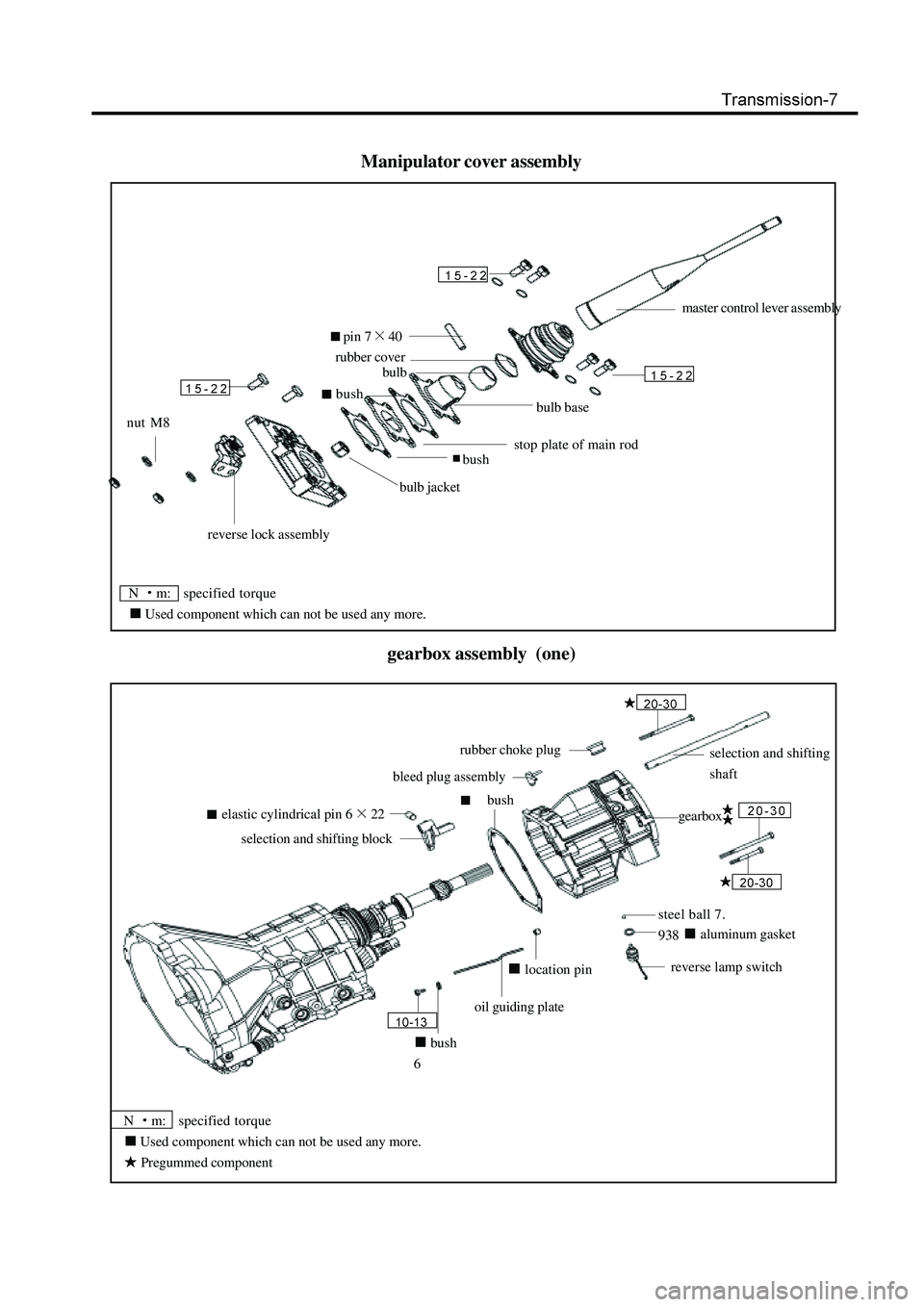

Manipulator cover assembly

gearbox assembly (one)

reverse lock assembly nut M8

bulbrubber cover

pin 740

master control lever assembly

bulb basebush

stop plate of main rodbush

bulb jacket

N m: specified torque

Used component which can not be used any more.

Pregummed component N

m: specified torque

Used component which can not be used any more.

bush

6

oil guiding plate

location pin

steel ball 7.

938

aluminum gasket

reverse lamp switch

gearbox

selection and shifting

shaft rubber choke plug

bleed plug assembly

bush

selection and shifting block

elastic cylindrical pin 622

Page 47 of 425

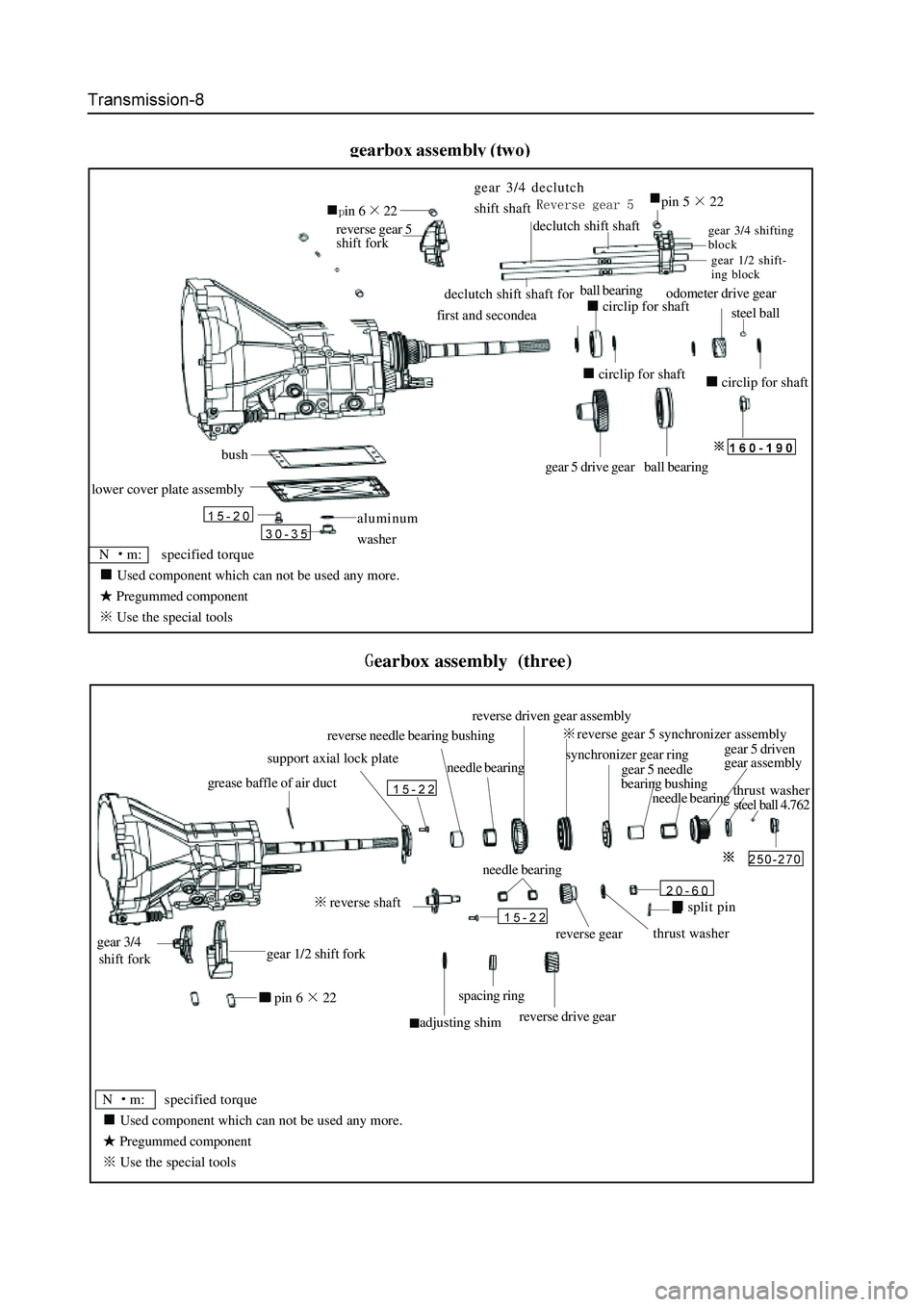

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special tools

aluminum

washer

lower cover plate assembly

bushgear 5 drive gear ball bearing

circlip for shaft

steel ball

odometer drive gear

circlip for shaft

ball bearing

circlip for shaft

reverse gear 5

shift fork

in 622

declutch shift shaft for

first and secondea

gear 3/4 declutch

shift shaft

declutch shift shaft

pin 522

gear 1/2 shift-

ing block

gear 3/4 shifting

block

earbox assembly (three)

steel ball 4.762

pin 622

gear 1/2 shift fork

adjusting shim

spacing ring

reverse drive gear

reverse shaft

needle bearing

reverse gear thrust washer

split pin

grease baffle of air duct

support axial lock plate

reverse needle bearing bushing

needle bearing

thrust washer

gear 5 needle

bearing bushingsynchronizer gear ring

reverse gear 5 synchronizer assembly

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special tools

gear 3/4

shift forkreverse driven gear assembly

needle bearinggear 5 driven

gear assembly

Page 48 of 425

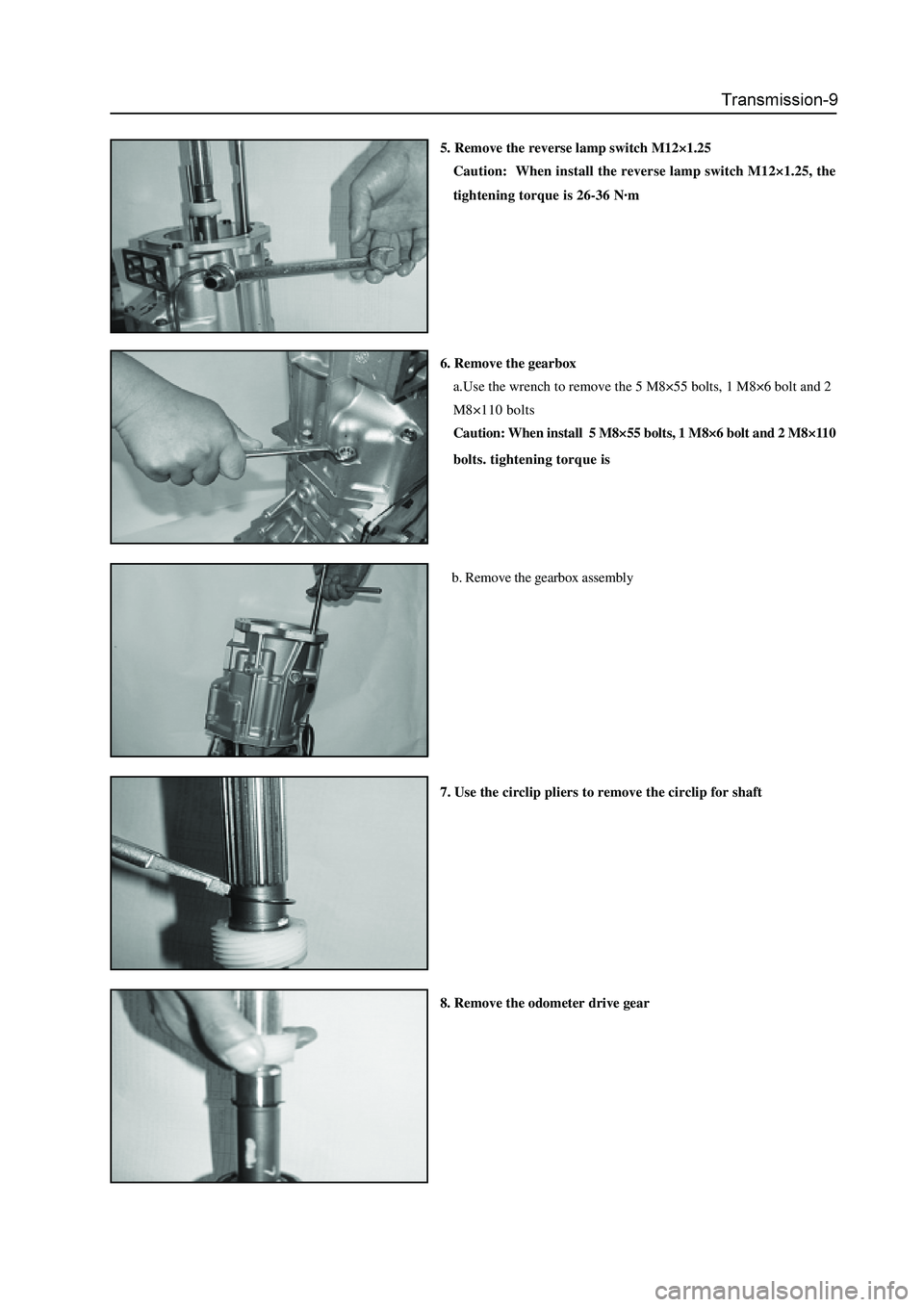

5. Remove the reverse lamp switch M12×1.25

Caution: When install the reverse lamp switch M12×1.25, the

tightening torque is 26-36 N·m

6. Remove the gearbox

a.Use the wrench to remove the 5 M8×55 bolts, 1 M8×6 bolt and 2

M8×110 bolts

Caution: When install 5 M8×55 bolts, 1 M8×6 bolt and 2 M8×110

bolts. tightening torque is

b. Remove the gearbox assembly

7. Use the circlip pliers to remove the circlip for shaft

8. Remove the odometer drive gear

Page 50 of 425

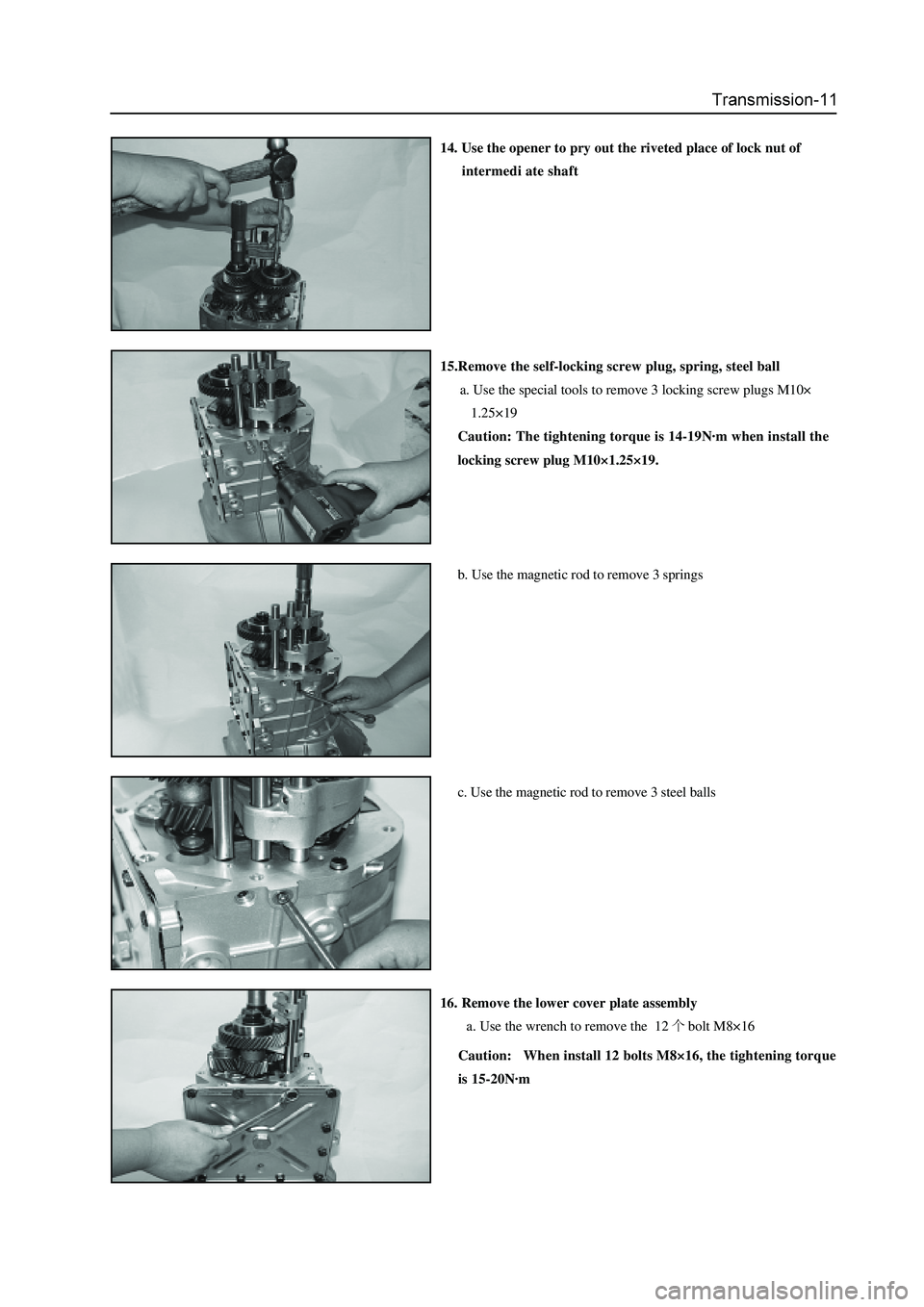

14. Use the opener to pry out the riveted place of lock nut of

intermedi ate shaft

15.Remove the self-locking screw plug, spring, steel ball

a. Use the special tools to remove 3 locking screw plugs M10×

1.25×19

Caution: The tightening torque is 14-19N·m when install the

locking screw plug M10×1.25×19.

b. Use the magnetic rod to remove 3 springs

c. Use the magnetic rod to remove 3 steel balls

Caution: When install 12 bolts M8×16, the tightening torque

is 15-20N·m

16. Remove the lower cover plate assembly

a. Use the wrench to remove the 12

bolt M8×16

Page 52 of 425

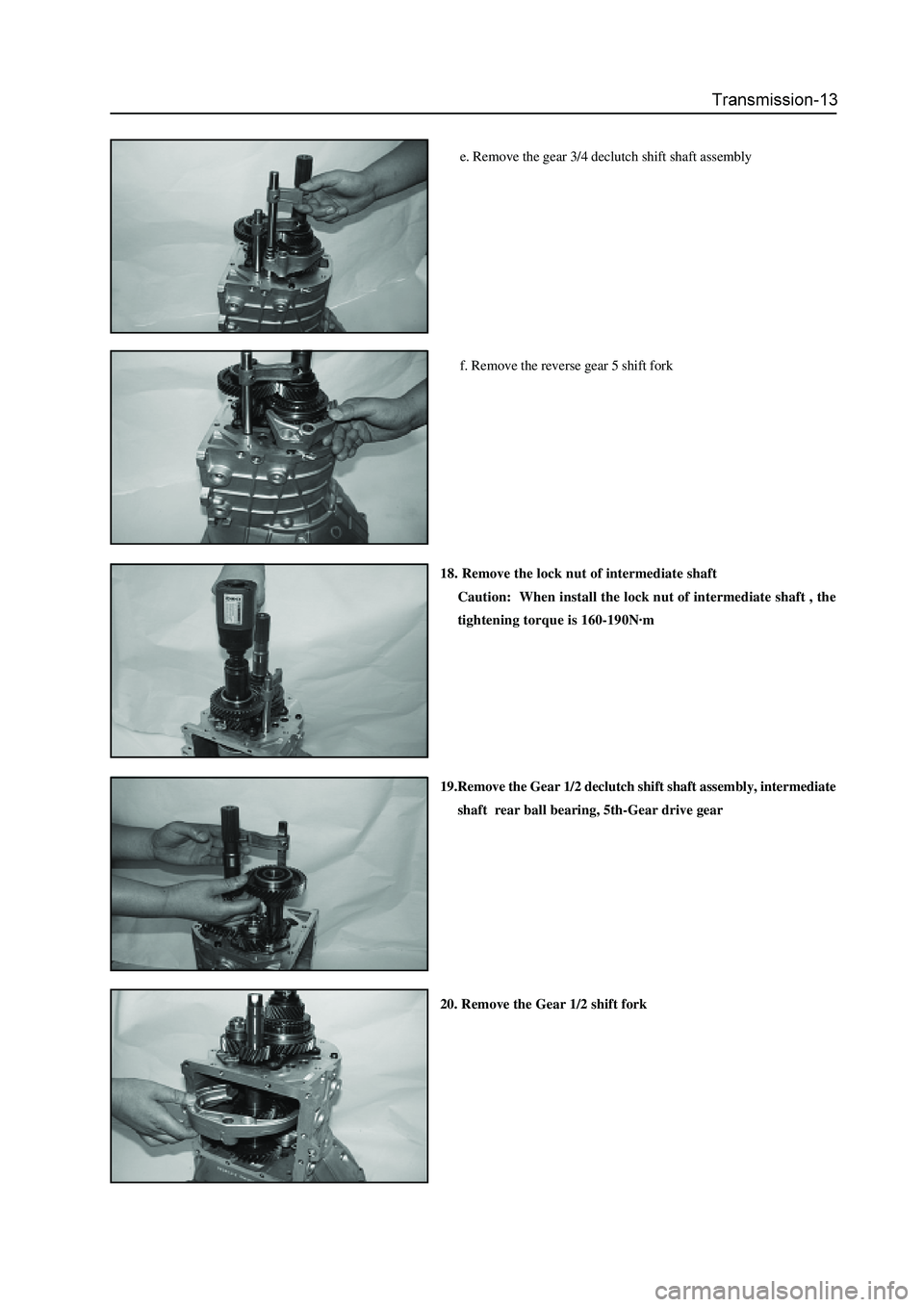

e. Remove the gear 3/4 declutch shift shaft assembly

f. Remove the reverse gear 5 shift fork

18. Remove the lock nut of intermediate shaft

Caution: When install the lock nut of intermediate shaft , the

tightening torque is 160-190N·m

19.Remove the Gear 1/2 declutch shift shaft assembly, intermediate

shaft rear ball bearing, 5th-Gear drive gear

20. Remove the Gear 1/2 shift fork