transmission GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 43 of 425

Inspection of SC5M2D-C transmission:

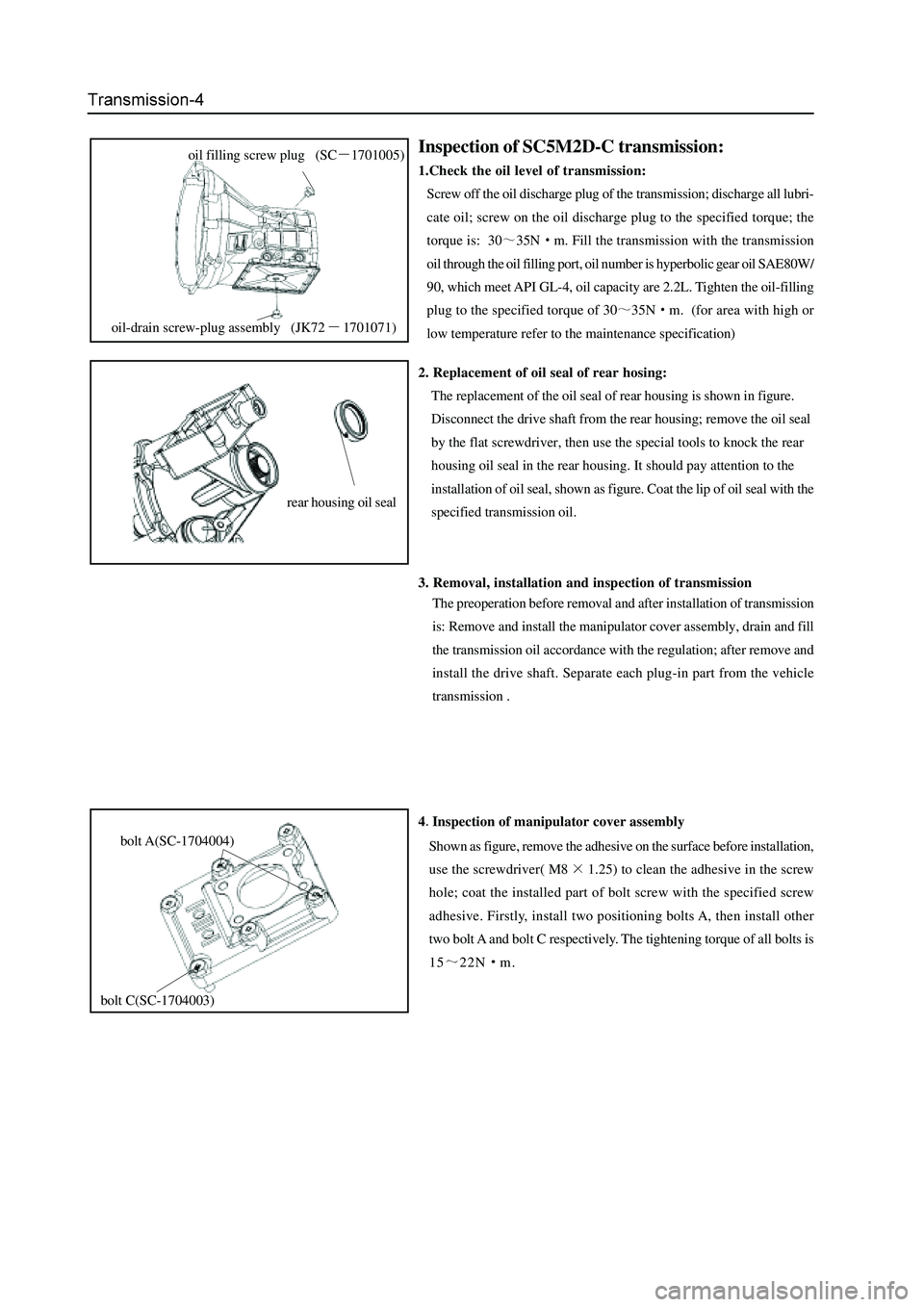

1.Check the oil level of transmission:

Screw off the oil discharge plug of the transmission; discharge all lubri-

cate oil; screw on the oil discharge plug to the specified torque; the

torque is: 30

35Nm. Fill the transmission with the transmission

oil through the oil filling port, oil number is hyperbolic gear oil SAE80W/

90, which meet API GL-4, oil capacity are 2.2L. Tighten the oil-filling

plug to the specified torque of 30

35Nm. (for area with high or

low temperature refer to the maintenance specification)

2. Replacement of oil seal of rear hosing:

The replacement of the oil seal of rear housing is shown in figure.

Disconnect the drive shaft from the rear housing; remove the oil seal

by the flat screwdriver, then use the special tools to knock the rear

housing oil seal in the rear housing. It should pay attention to the

installation of oil seal, shown as figure. Coat the lip of oil seal with the

specified transmission oil.

3. Removal, installation and inspection of transmission

The preoperation before removal and after installation of transmission

is: Remove and install the manipulator cover assembly, drain and fill

the transmission oil accordance with the regulation; after remove and

install the drive shaft. Separate each plug-in part from the vehicle

transmission .

4

Inspection of manipulator cover assembly

Shown as figure, remove the adhesive on the surface before installation,

use the screwdriver( M8

1.25) to clean the adhesive in the screw

hole; coat the installed part of bolt screw with the specified screw

adhesive. Firstly, install two positioning bolts A, then install other

two bolt A and bolt C respectively. The tightening torque of all bolts is

15

22Nm.

oil filling screw plug (SC1701005)

oil-drain screw-plug assembly (JK721701071)

rear housing oil seal

bolt C(SC-1704003)bolt A(SC-1704004)

Page 44 of 425

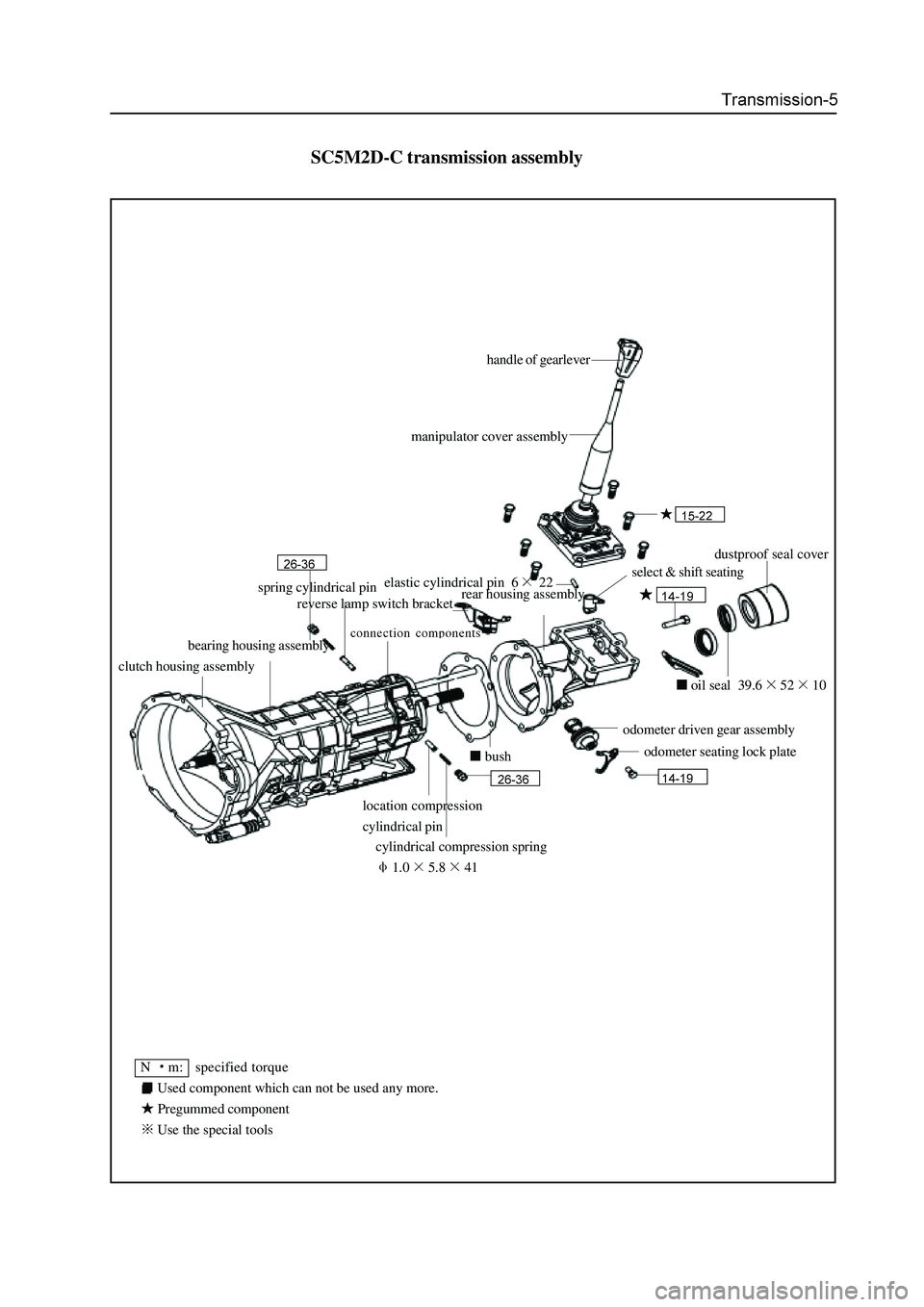

SC5M2D-C transmission assembly

handle of gearlever

dustproof seal cover

oil seal 39.65210

odometer driven gear assembly

odometer seating lock plate

cylindrical compression spring

1.05.841

bush

select & shift seating

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special toolsmanipulator cover assembly

elastic cylindrical pin 6

22

rear housing assembly spring cylindrical pin

reverse lamp switch bracket

bearing housing assembly

clutch housing assembly

location compression

cylindrical pin

Page 45 of 425

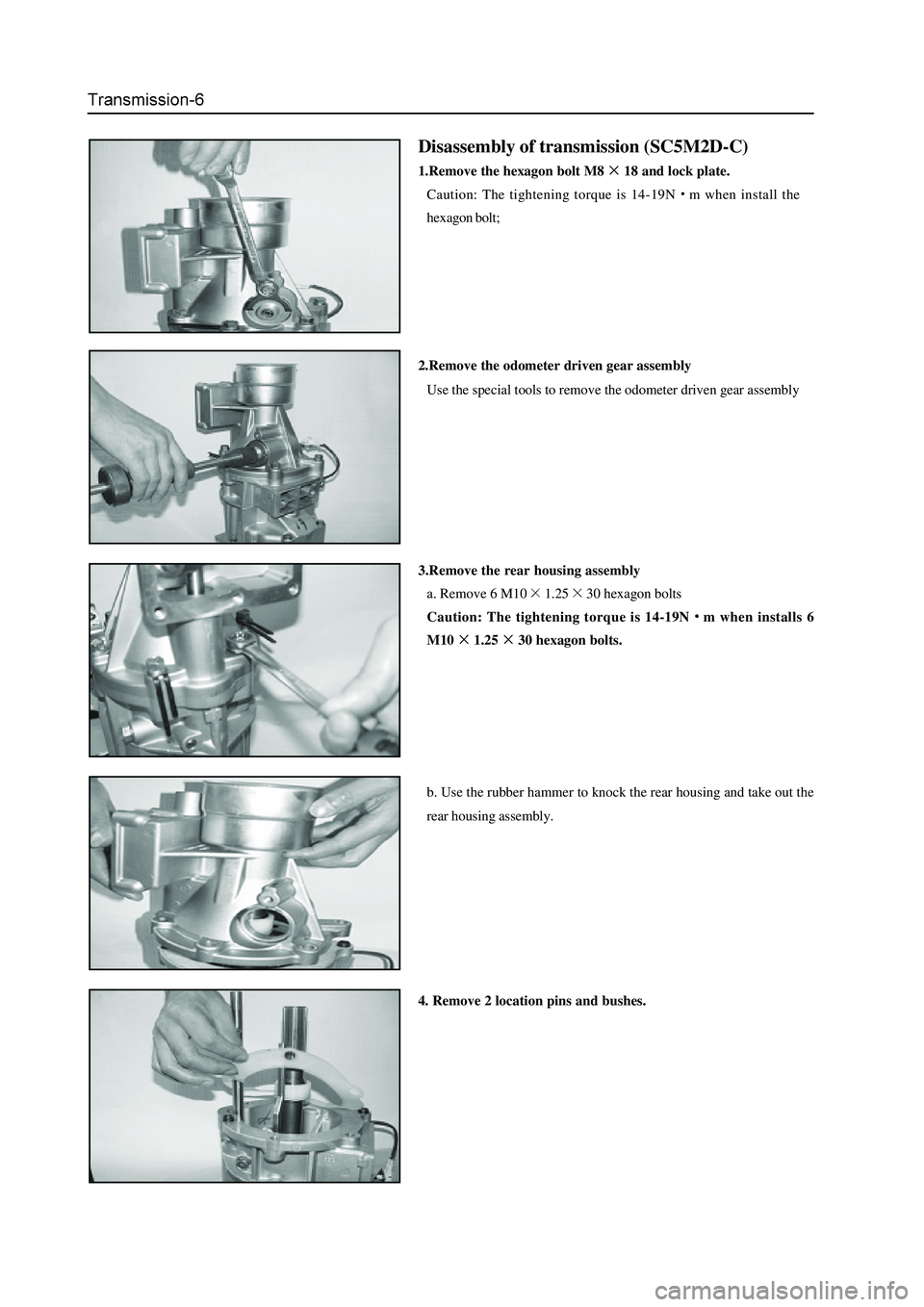

Disassembly of transmission (SC5M2D-C)

1.Remove the hexagon bolt M818 and lock plate.

Caution: The tightening torque is 14-19N

m when install the

hexagon bolt;

2.Remove the odometer driven gear assembly

Use the special tools to remove the odometer driven gear assembly

3.Remove the rear housing assembly

a. Remove 6 M10

1.2530 hexagon bolts

Caution: The tightening torque is 14-19N

m when installs 6

M10

1.2530 hexagon bolts.

b. Use the rubber hammer to knock the rear housing and take out the

rear housing assembly.

4. Remove 2 location pins and bushes.

Page 62 of 425

Transmission-23

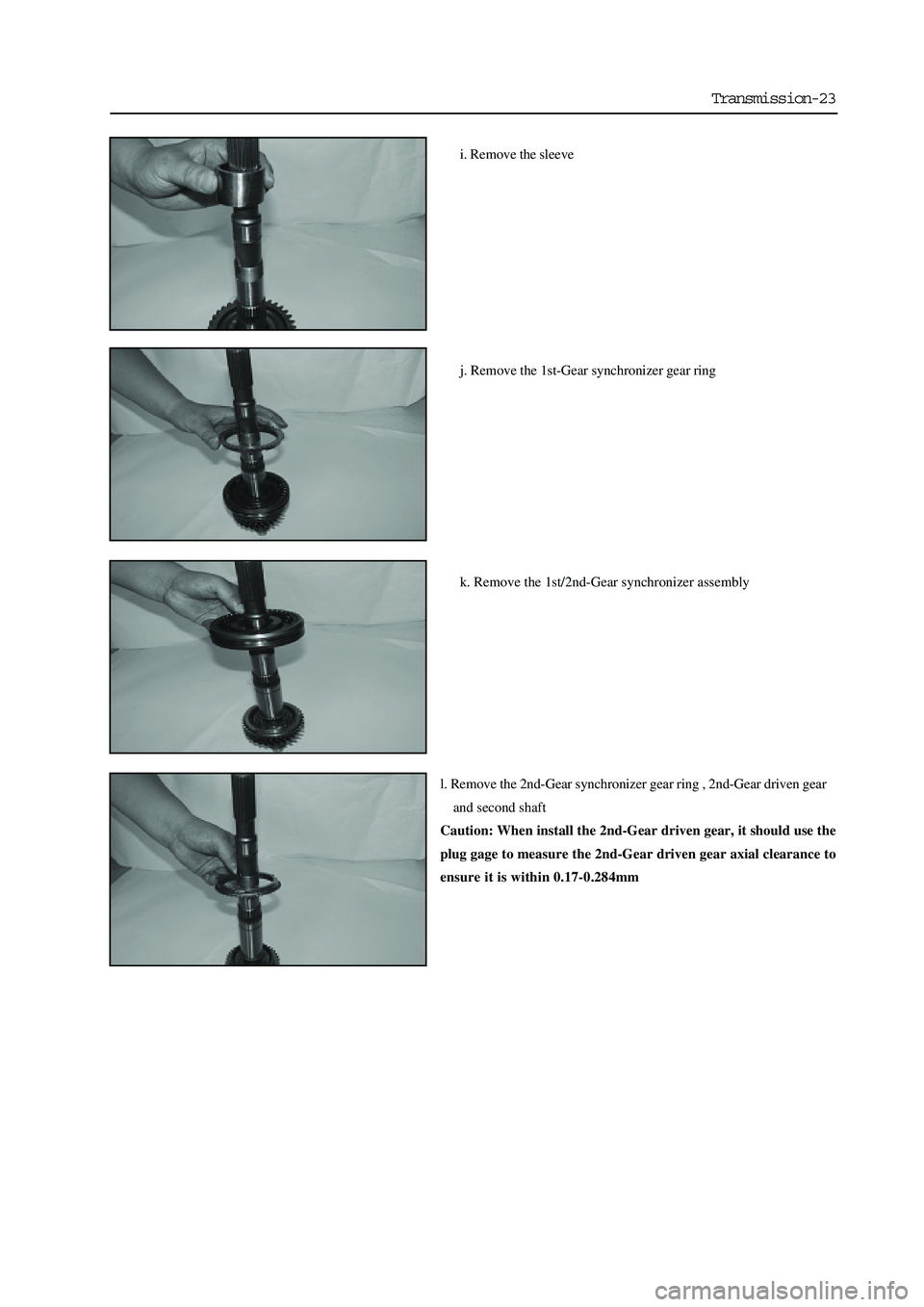

i. Remove the sleeve

j. Remove the 1st-Gear synchronizer gear ring

k. Remove the 1st/2nd-Gear synchronizer assembly

l. Remove the 2nd-Gear synchronizer gear ring , 2nd-Gear driven gear

and second shaft

Caution: When install the 2nd-Gear driven gear, it should use the

plug gage to measure the 2nd-Gear driven gear axial clearance to

ensure it is within 0.17-0.284mm

Page 63 of 425

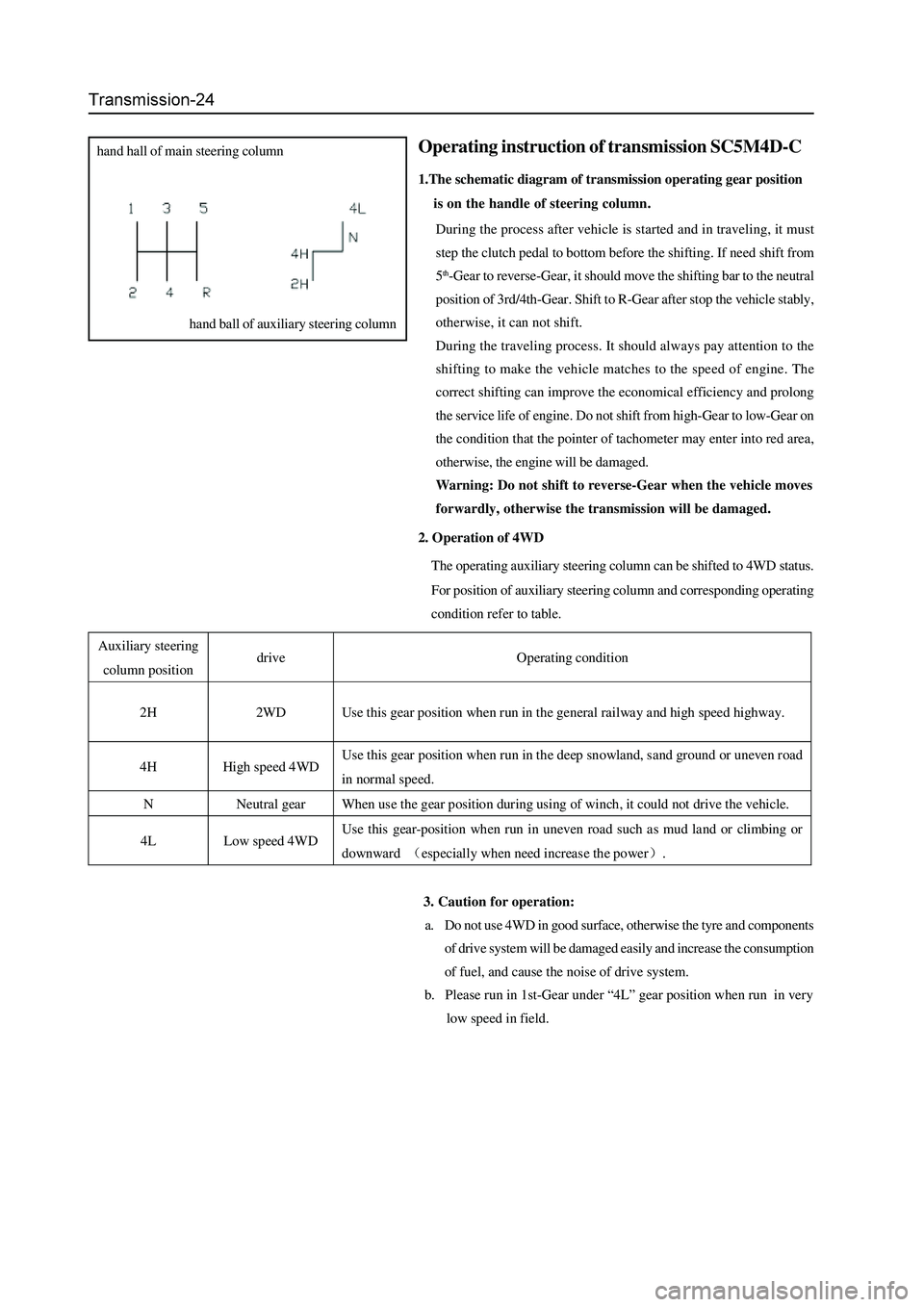

2. Operation of 4WD

The operating auxiliary steering column can be shifted to 4WD status.

For position of auxiliary steering column and corresponding operating

condition refer to table.

3. Caution for operation:

a. Do not use 4WD in good surface, otherwise the tyre and components

of drive system will be damaged easily and increase the consumption

of fuel, and cause the noise of drive system.

b. Please run in 1st-Gear under “4L” gear position when run in very

low speed in field.

Operating instruction of transmission SC5M4D-C

1.The schematic diagram of transmission operating gear position

is on the handle of steering column.

During the process after vehicle is started and in traveling, it must

step the clutch pedal to bottom before the shifting. If need shift from

5

th-Gear to reverse-Gear, it should move the shifting bar to the neutral

position of 3rd/4th-Gear. Shift to R-Gear after stop the vehicle stably,

otherwise, it can not shift.

During the traveling process. It should always pay attention to the

shifting to make the vehicle matches to the speed of engine. The

correct shifting can improve the economical efficiency and prolong

the service life of engine. Do not shift from high-Gear to low-Gear on

the condition that the pointer of tachometer may enter into red area,

otherwise, the engine will be damaged.

Warning: Do not shift to reverse-Gear when the vehicle moves

forwardly, otherwise the transmission will be damaged.

hand hall of main steering column

hand ball of auxiliary steering column

Auxiliary steering

column position drive Operating condition

2H 2WD Use this gear position when run in the general railway and high speed highway.

4H High speed 4WD Use this gear position when run in the deep snowland, sand ground or uneven road

in normal speed.

N Neutral gear When use the gear position during using of winch, it could not drive the vehicle.

4L Low speed 4WD Use this gear-position when run in uneven road such as mud land or climbing or

downward (especially when need increas e the power).

Page 64 of 425

Transmission-25

2.Replacement of oil-seal of transfer case

The replacement of transfer case oil seal is shown as figure. Disconnect

the drive shaft from the transfer case, use the flat head screwer to

remove the oil seal

Caution: Do not damage the housing hole during the disassembly.

Then use the special tools to knock the transfer case oil seal into

the transfer case. It should pay attention to the installation dire

tion of oil seal. The oil seal is flush with the port of transfer case.

Shown as figure. Coat the lip of oil seal with the specified general

synthetic gear oil.

3. Disassembly and check of transmission

The preoperation before the removal and after installation of

transmission is : When remove and install the manipulator cover

assembly, drain and fill with the specified transmission and transfer

case lubrication oil. When remove and install the front and rear drive

shaft, separate each plug-in part of transmission from the vehicle.

Inspection of manipulator cover assembly:

The bolt dimension is different for different installation position. Do not

confuse it during the installation. It should install the fixing bolt A firstly.

The tightening torque of bolt A and B bolt is 15

22Nm.

installation position of fastening blot

bolt

bolt bolt

Repair of transmission SC5M4D-C

1. Inspection of oil level of transmission and transfer case:

Screw off the oil drainage screw plug of main box and transfer case;

drain all lubrication oil, tighten the oil drain plug to specified torque.

The torque is: 30

35Nm. Fill the main box and transfer case with

the transmission oil through the oil filling port. The number is hyperbolic

gear oil SAE80W/90, comply with API GL-4. The oil quantities are

main box : 2.2 L, transfer case : 2.7 L. (for high and low temperature

environment refer to maintenance specification). Tighten the oil filling

screw plug to specified torque. The torque is: 30

35Nm.

front output shaft oil

seal (SC

1802504)

rear output shaft oil seal

(SC

1802323)

transmission

transfer case

oil filling screw plug

oil-drain screw-plug assembly

(JK72

1701070) oil filling screw plug

Page 65 of 425

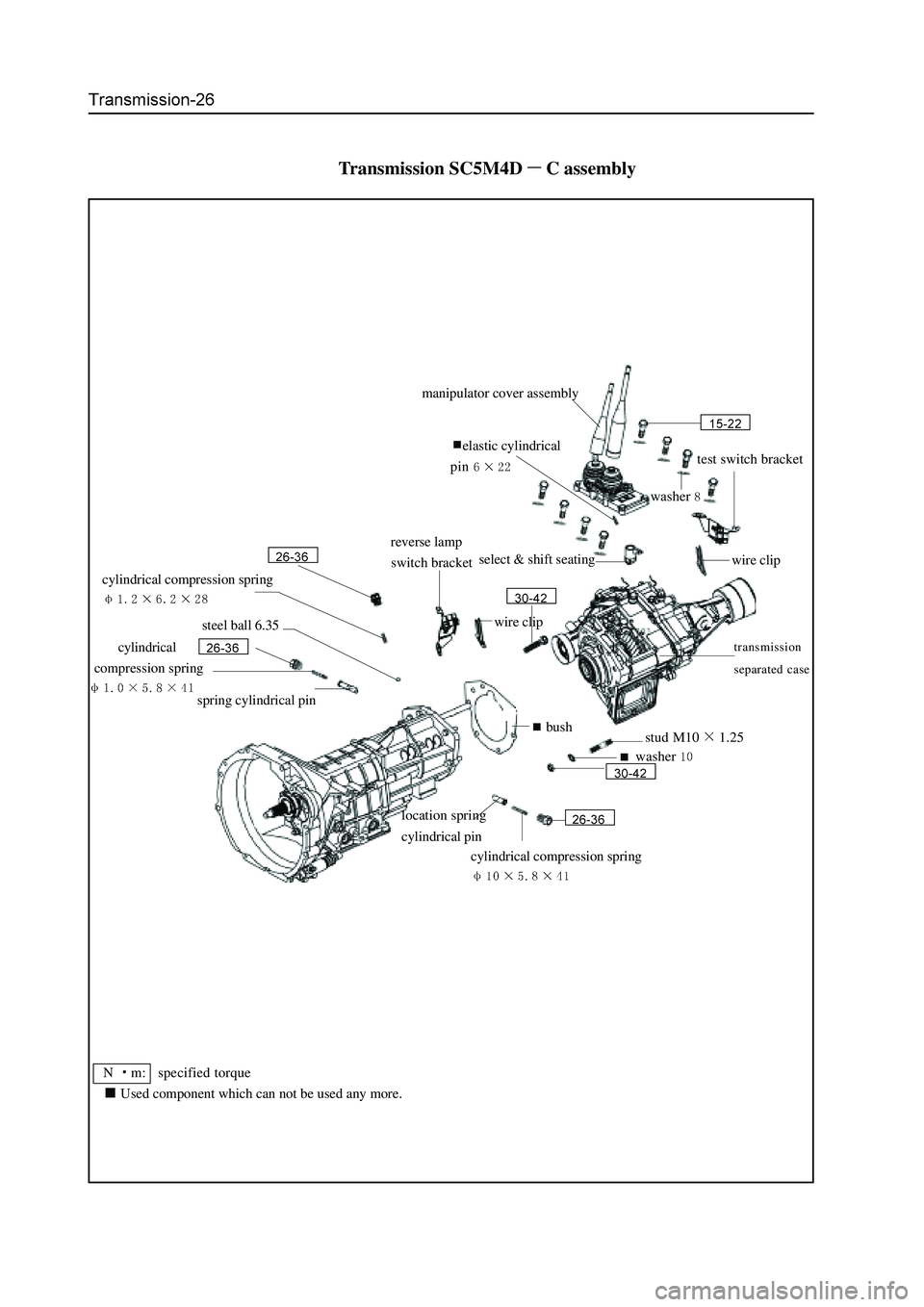

Transmission SC5M4DC assembly

N m: specified torque

Used component which can not be used any more.

transmission

separated case

spring cylindrical pin

cylindrical

compression spring

steel ball 6.35 cylindrical compression spring

reverse lamp

switch bracket

wire clip

elastic cylindrical

pin

manipulator cover assembly

washer

test switch bracket

select & shift seating

washer

location spring

cylindrical pin

cylindrical compression spring

bush

wire clip

stud M101.25

Page 66 of 425

Transmission-27

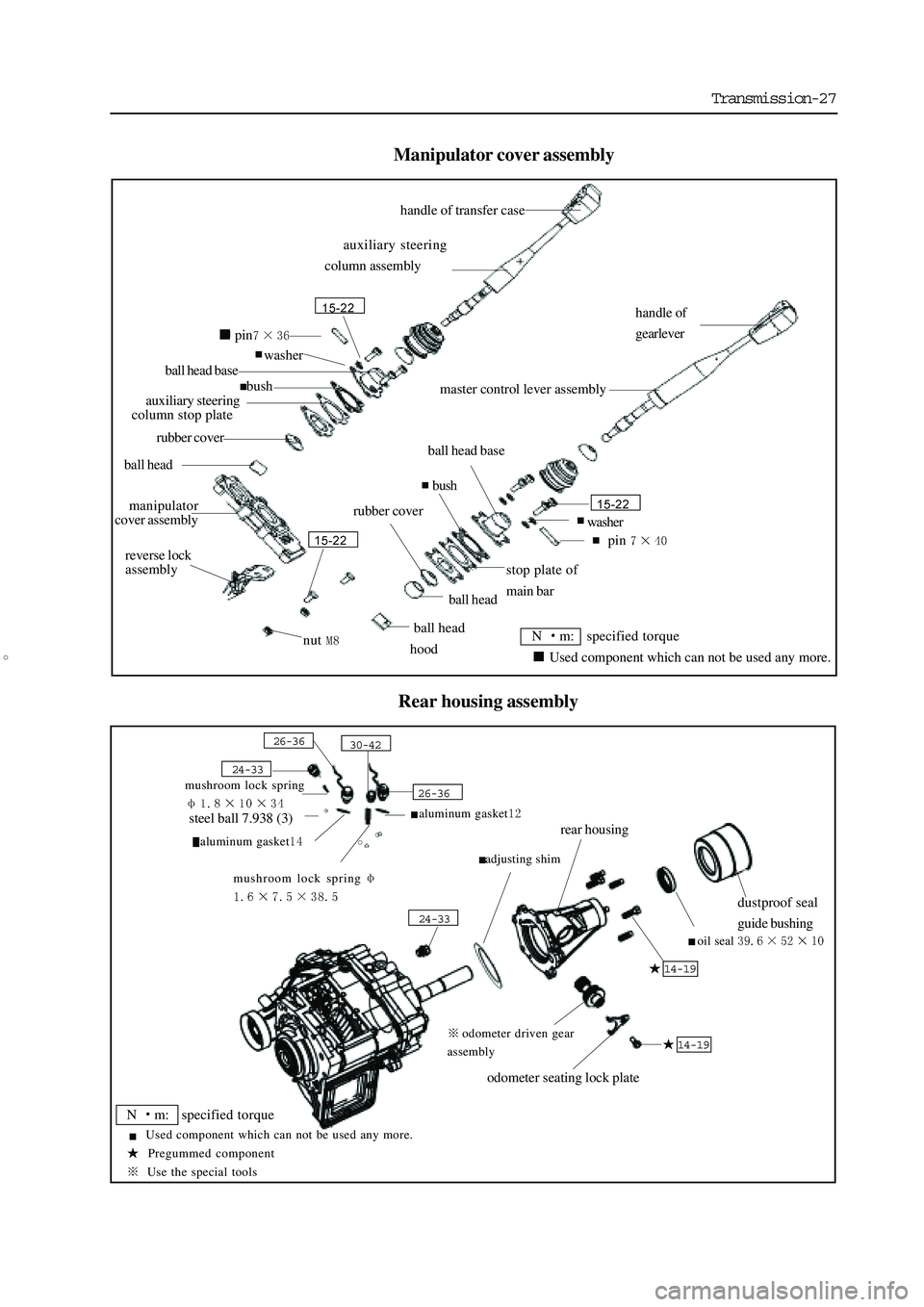

Manipulator cover assembly

Rear housing assembly

nut

reverse lock

assembly

manipulator

cover assembly

ball head

rubber cover

auxiliary steering

column stop platebush

ball head basewasher

pin

auxiliary steering

column assembly

handle of transfer case

ball head

hood

ball head

rubber cover

stop plate of

main bar

bush

ball head base

pin

washer

master control lever assembly

handle of

gearlever

N m: specified torque

Used component which can not be used any more.

odometer driven gear

assembly

odometer seating lock plate

14-19

14-19

oil seal

dustproof seal

guide bushing

rear housing

adjusting shim

24-33

26-36

aluminum gasket

mushroom lock spring

aluminum gasket

24-33

mushroom lock spring

26-3630-42

N m: specified torque

Used component which can not be used any more.

Pregummed component

Use the special tools

steel ball 7.938 (3)

Page 68 of 425

Transmission-29

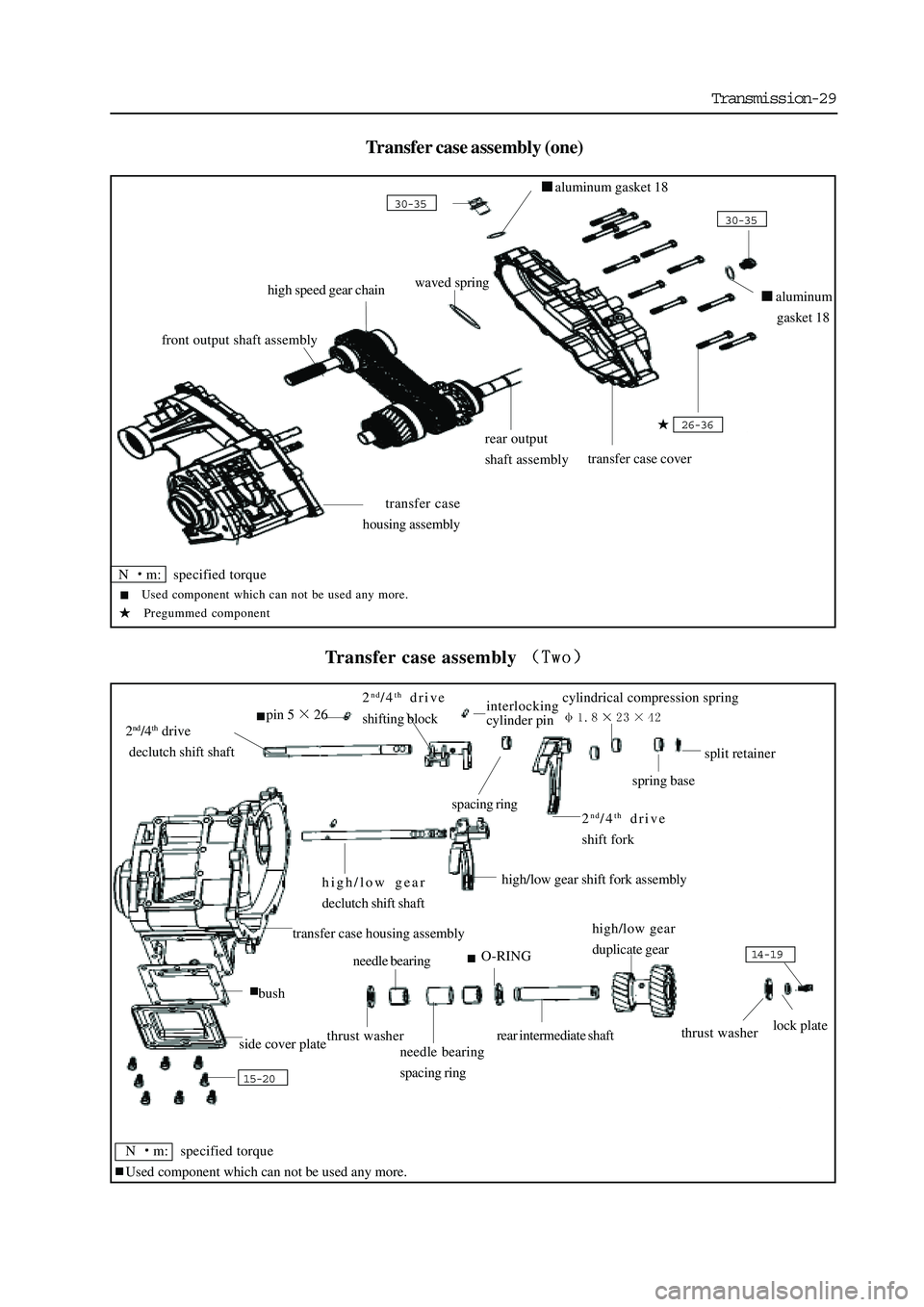

Transfer case assembly (one)

Transfer case assembly

transfer case

housing assembly

rear output

shaft assembly

transfer case cover

26-36

30-35

aluminum gasket 18

30-35

waved springhigh speed gear chain

front output shaft assembly

15-20

side cover plate

bush

thrust washer

needle bearing

needle bearing

spacing ring

O-RING

rear intermediate shaft

high/low gear

duplicate gear

thrust washerlock plate

14-19

high/low gear

declutch shift shaft high/low gear shift fork assembly

2nd/4th drive

declutch shift shaft

pin 526

2nd/4th drive

shifting blockinterlocking

cylinder pin

spacing ring2nd/4th drive

shift fork

cylindrical compression spring

spring base

split retainer

aluminum

gasket 18

N

m: specified torque

Used component which can not be used any more.

Pregummed component

transfer case housing assembly

N

m: specified torque

Used component which can not be used any more.

Page 70 of 425

Transmission-31

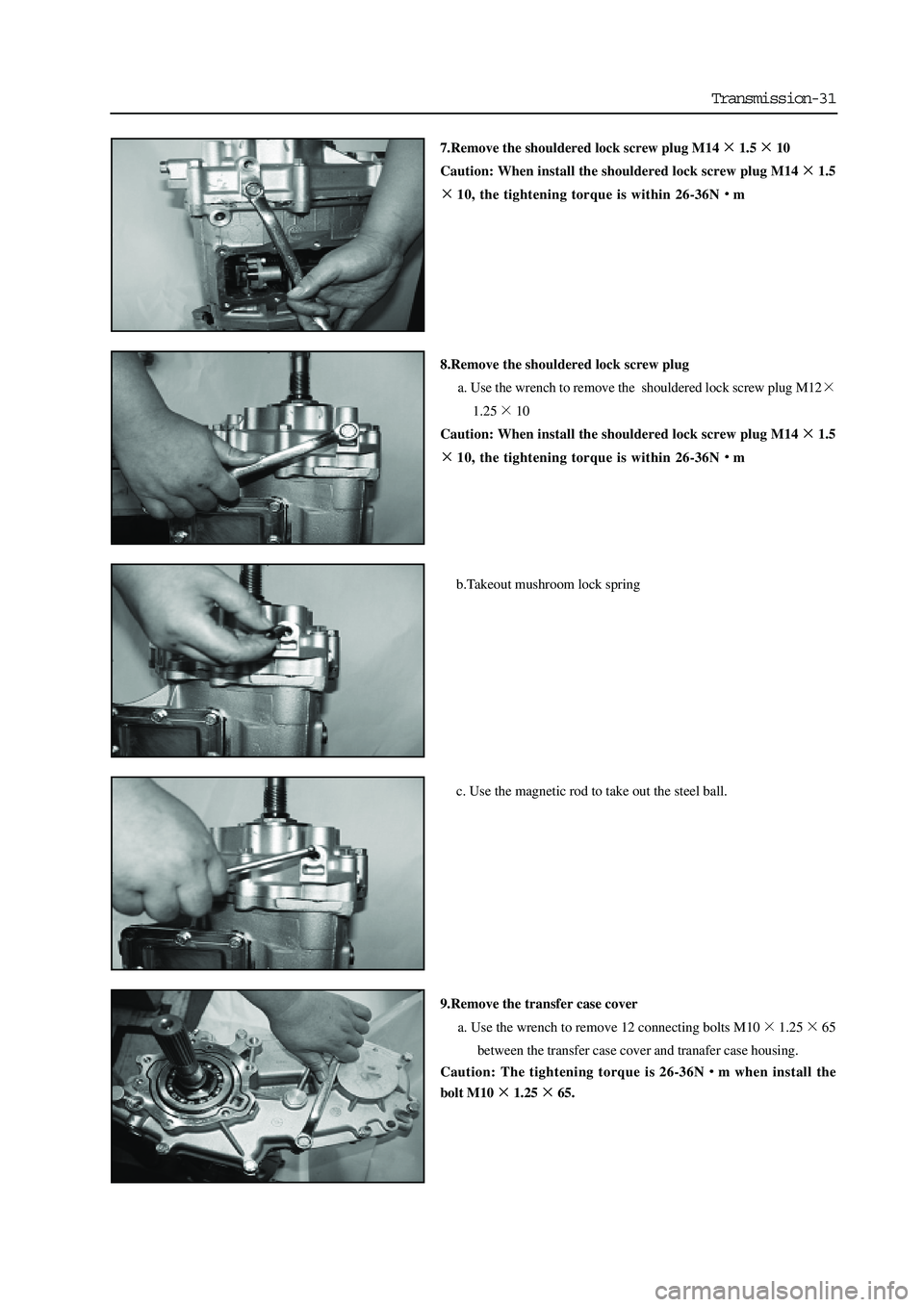

7.Remove the shouldered lock screw plug M141.510

Caution: When install the shouldered lock screw plug M14

1.5

10, the tightening torque is within 26-36Nm

8.Remove the shouldered lock screw plug

a. Use the wrench to remove the shouldered lock screw plug M12

1.2510

Caution: When install the shouldered lock screw plug M14

1.5

10, the tightening torque is within 26-36Nm

b.Takeout mushroom lock spring

c. Use the magnetic rod to take out the steel ball.

9.Remove the transfer case cover

a. Use the wrench to remove 12 connecting bolts M10

1.2565

between the transfer case cover and tranafer case housing.

Caution: The tightening torque is 26-36N

m when install the

bolt M10

1.2565.