clock GREAT WALL HOVER 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 382 of 425

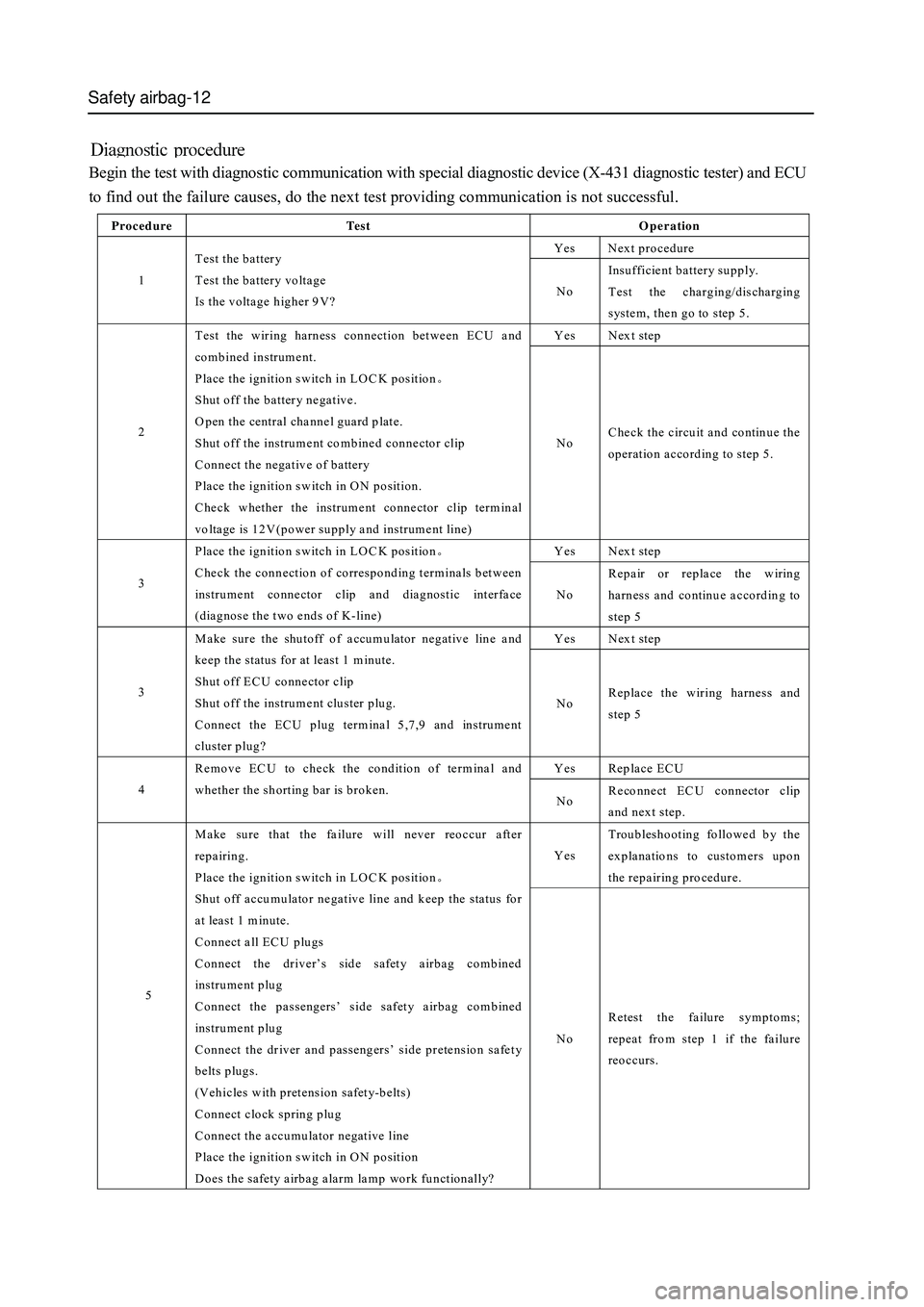

Safety airbag-12

Begin the test with diagnostic communication with special diagnostic device (X-431 diagnostic tester) and ECU

to find out the failure causes, do the next test providing communication is not successful.

Procedure Te s t Operation

Yes Next procedure

1 Test the battery

Test the battery voltage

Is the voltage higher 9V? No Insufficient battery supply.

Test the charging/discharging

system, then go to step 5.

Yes Next step

2 Test the wiring harness connection between ECU and

combined instrument.

Place the ignition switch in LO C K position。

Shut off the battery negative.

O pen the central channel guard plate.

Shut off the instrument combined connector clip

Connect the negative of battery

Place the ignition switch in ON position.

Check whether the instrument connector clip terminal

voltage is 12V(power supply and instrument line) No Check the circuit and continue the

operation according to step 5.

Yes Next step

3 Place the ignition switch in LO C K position。

Check the connection of corresponding terminals between

instrument connector clip and diagnostic interface

(diagnose the two ends of K-line) No Repair or replace the wiring

harness and continue according to

step 5

Yes Next step

3 Make sure the shutoff of accumulator negative line and

keep the status for at least 1 minute.

Shut off ECU connector clip

Shut off the instrument cluster plug.

Connect the ECU plug terminal 5,7,9 and instrument

cluster plug? No Replace the wiring harness and

step 5

Yes Replace ECU

4 Remove EC U to check the condition of term inal and

whether the shorting bar is broken.

No Reconnect EC U connector clip

and next step.

Yes Troubleshooting followed by the

explanations to customers upon

the repair ing pro ced ur e.

5

Make sure that the failure will never reoccur after

repairing.

Place the ignition switch in LO C K position。

Shut off accumulator negative line and keep the status for

at least 1 m in ute.

Connect all ECU plugs

Connect the driver’s side safety airbag combined

instrum ent p lug

Connect the passengers’ side safety airbag combined

instrum ent p lug

Connect the driver and passengers’ side pretension safety

belts plugs.

(Vehicles with pretension safety-b elts)

Connect clock spring plug

Connect the accumulator negative line

Place the ignition switch in ON position

Does the safety airbag alarm lamp work functionally? No Retest the failure symptoms;

repeat from step 1 if the failure

reoccurs.

Page 384 of 425

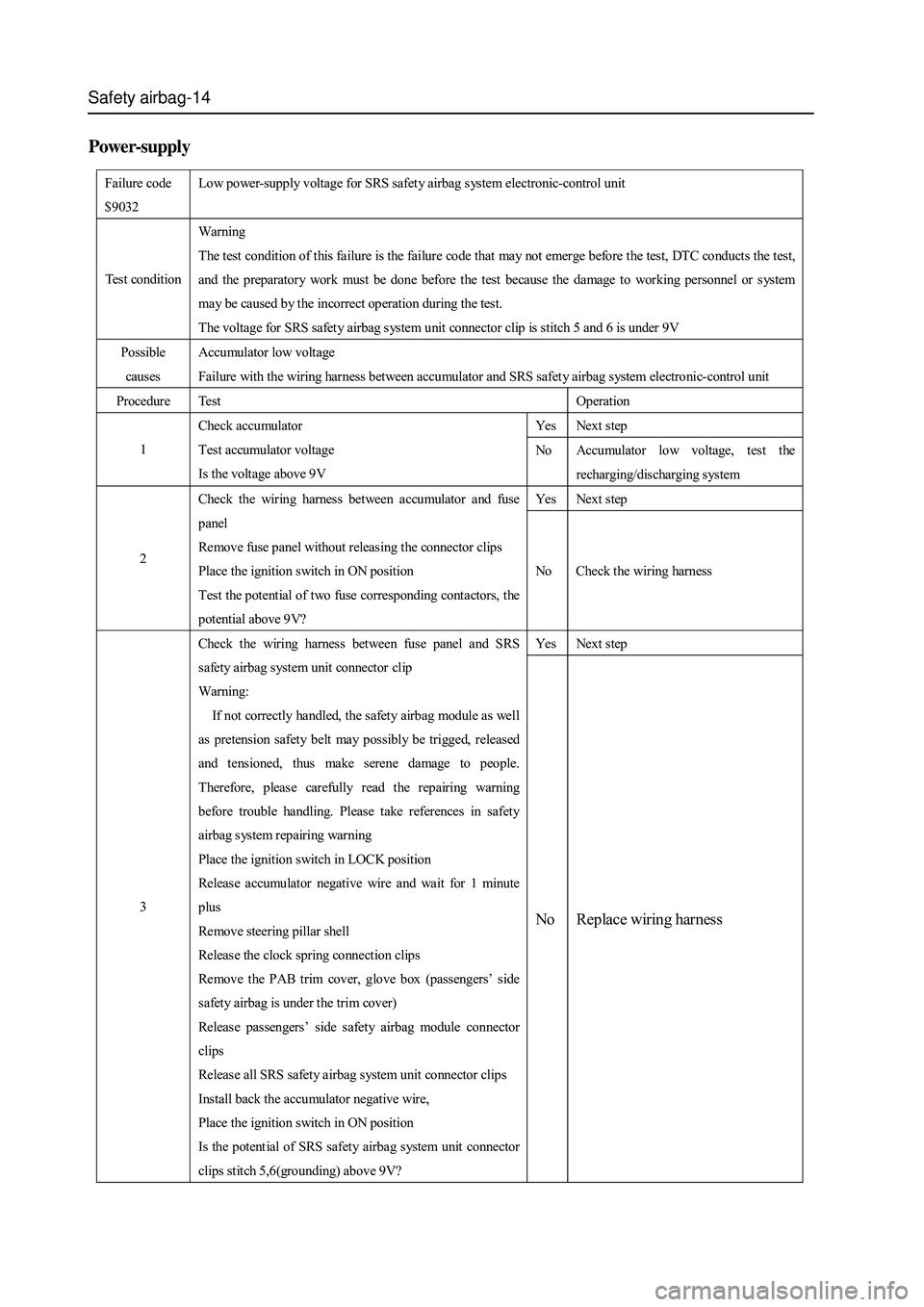

Safety airbag-14

Power-supply

Failure code

$9032 Low power-supply voltage for SRS safety airbag system electronic-control unit

Test condition Warning

The test condition of this failure is the failure code that may not emerge before the test, DTC conducts the test,

and the preparatory work must be done before the test because the damage to working personnel or system

may be caused by the incorrect op eration during the test.

The voltage for SRS safety airbag system unit connector clip is stitch 5 and 6 is under 9V

Possible

caus es Accumulator low voltage

Failure with the wiring harness between accumulator and SRS safety airbag system electronic-control unit

Procedure Test Operation

Yes Next step

1 Check accumulator

Test accumulator voltage

Is the voltage above 9V No Accumulator low voltage, test the

recharging/discharging system

Yes Next step

2 Check the wiring harness between accumulator and fuse

panel

Remove fuse panel without releasing the connector clips

Place the ignition switch in ON position

Test the potential of two fuse corresponding contactors, the

potential above 9V? No Check the wiring harness

Yes Next step

3 Check the wiring harness between fuse panel and SRS

safety airbag system unit connector clip

Warning:

If not correctly handled, the safety airbag module as well

as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people.

Ther efor e, pleas e carefully r ead the r epairing warning

before trouble handling. Please take references in safety

airbag system repairing warning

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute

plus

Remove steering pillar shell

Release the clock spring connection clips

Remove the PAB trim cover, glove box (passengers’ side

safety airbag is under the trim cover)

Release passengers’ side safety airbag module connector

clips

Release all SRS safety airbag system unit connector clips

Install back the accumulator negative wire,

Place the ignition switch in ON position

Is the potential of SRS safety airbag system unit connector

clips stitch 5,6(grounding) above 9V? No Replace wiring harness

Page 385 of 425

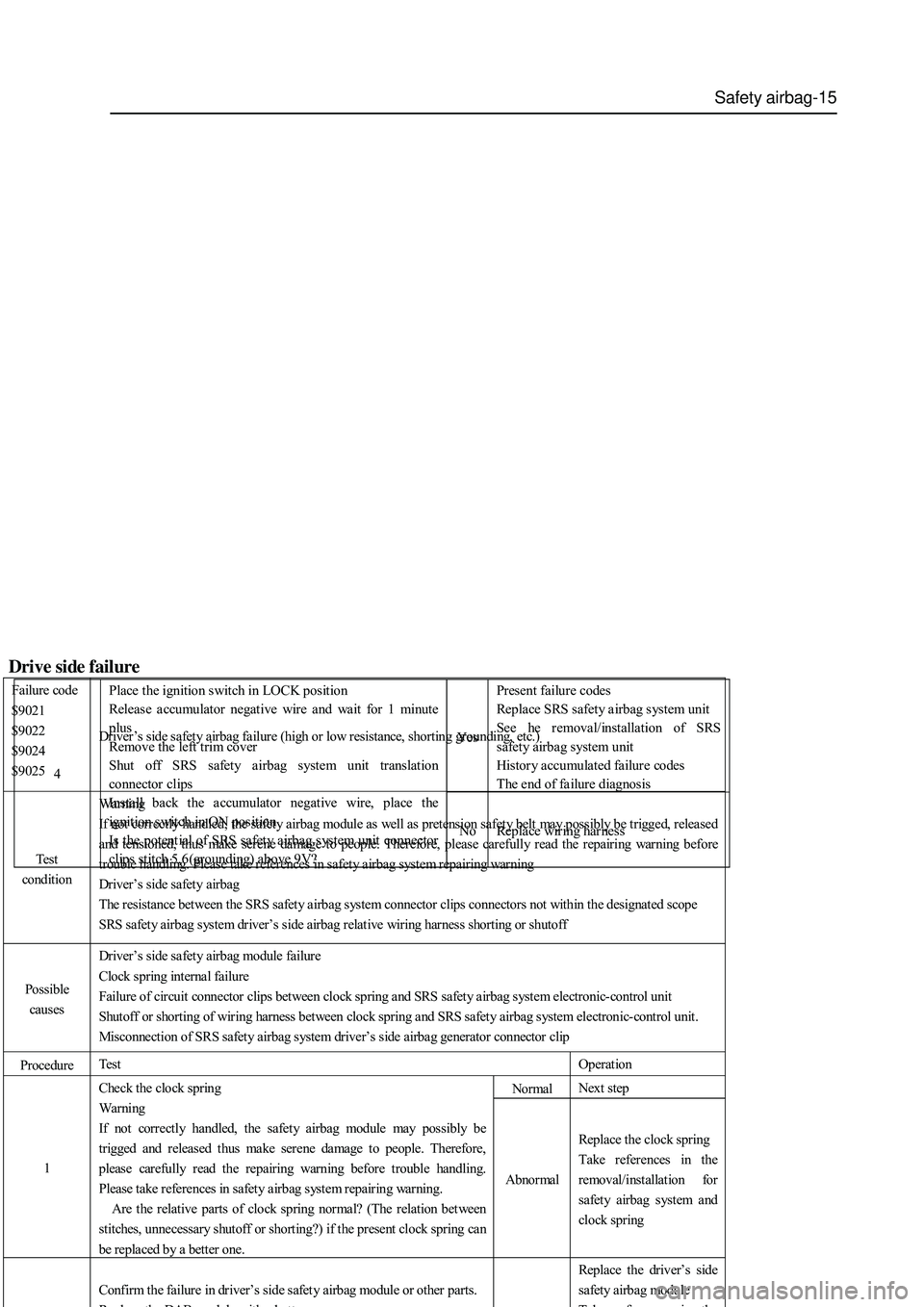

Safety airbag-15

Yes Present failure codes

Replace SRS safety airbag system unit

See he removal/installation of SRS

safety airbag system unit

History accumulated failure codes

The end of failure diagnosis

4 Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute

plus

Remove the left trim cover

Shut off SRS safety airbag system unit translation

connector clips

Install back the accumulator negative wire, place the

ignition switch in ON position

Is the potential of SRS safety airbag system unit connector

clips stitch 5,6(grounding) above 9V? No Replace wiring harness

Drive side failure

Failure code

$9021

$9022

$9024

$9025 Driver ’s side safety airbag failure (high or low resistance, shorting grounding, etc.)

Tes t

condition Warni ng

If not correctly handled, the safety airbag module as well as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people. Therefore, please carefully read the repairing warning before

trouble handling. Please take references in safety airbag system repairing warning

Driver’s side safety airbag

The resistance between the SRS safety airbag system connector clips connectors not within the designated scope

SRS safet y airbag system driver’s side airbag relative wiring harness shorting or shutoff

Possible

caus es Driver’s side safety airbag module failure

Clock spring internal failure

Failure of circuit connector clips between clock spring and SRS safety airbag system electronic-control unit

Shutoff or shorting of wiring harness between clock spring and SRS safety airbag system electronic-control unit.

Misconnection of SRS safety airbag system driver’s side airbag generator connector clip

Procedure Tes t Operation

Normal Next step

1 Check the clock spring

Warni ng

If not correctly handled, the safety airbag module may possibly be

trigged and released thus make serene damage to people. Therefore,

please carefully read the repairing warning before trouble handling.

Please take references in safety airbag system repairing warning.

Are the relative parts of clock spring normal? (The relation bet ween

stitches, unnecessary shutoff or shorting?) if the pr esent clock spring ca n

be replaced by a better one. Abnormal Replace the clock spring

Take references in the

removal/installation for

safety airbag system and

clock spring

Replace the driver’s side

safety airbag module

Tk f i th

Confirm the failure in driver’s side safety airbag module or other parts.

Rl thDAB dl ithbtt

Page 386 of 425

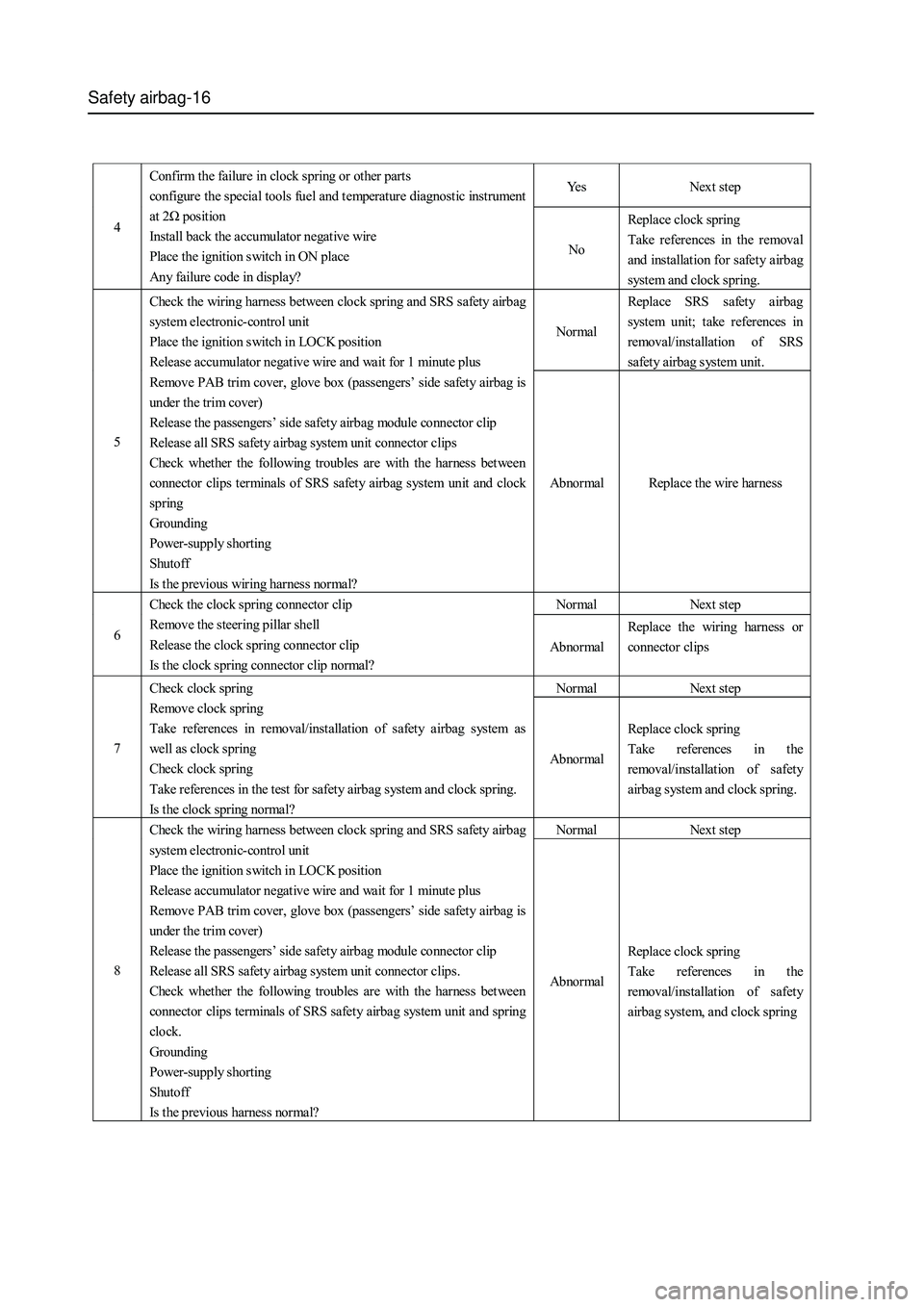

Safety airbag-16

Yes Next step

4 Confirm the failure in clock spring or other parts

configure the special tools fuel and t emperature diagnostic instrument

at 2Ω position

Install back the accumulator negative wire

Place the ignition switch in ON place

Any failure code in display? No Replace clock spring

Take references in the removal

and installation for safety airbag

system and clock spring.

Nor mal Replace SRS safety airbag

system unit; take references in

removal/installation of SRS

safety airbag system unit.

5 Check the wiring harness between clock spring and SRS safety airbag

system electronic-control unit

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute plus

Remove PAB trim cover, glove box (passengers’ side safety airbag is

under the trim cover)

Release the passengers’ side safety airbag module connector clip

Release all SRS safety airbag system unit connector clips

Check whether the following troubles are with the harness between

connector clips terminals of SRS safety airbag system unit and clock

spring

Grounding

Power-supply shorting

Shutoff

Is the previous wiring harness normal? Abnormal Replace the wire harness

Nor mal Next step

6 Check the clock spring connector clip

Remove the steering pillar shell

Release the clock spring connector clip

Is the clock spring connector clip normal? Abnormal Replace the wiring harness or

connector clips

Nor mal Next step

7 Check clock spring

Remove clock spring

Take references in removal/installation of safet y airbag system as

well as clock spring

Check clock spring

Take references in the test for safety airbag system and clock spring.

Is the clock spring normal? Abnormal Replace clock spring

Take references in the

removal/installation of safety

airbag system and clock spring.

Nor mal Next step

8 Check the wiring harness between clock spring and SRS safety airbag

system electronic-control unit

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute plus

Remove PAB trim cover, glove box (passengers’ side safety airbag is

under the trim cover)

Release the passengers’ side safety airbag module connector clip

Release all SRS safety airbag system unit connector clips.

Check whether the following troubles are with the harness between

connector clips terminals of SRS safety airbag system unit and spring

clock.

Grounding

Power-supply shorting

Shutoff

Is the previous harness normal? Abnormal Replace clock spring

Take references in the

removal/installation of safety

airbag system, and clock spring

Page 388 of 425

Safety airbag-18

Impact-vehicle diagnosis

Test SRS-ECU diagnostic signals

1. Connect the (X-431 diagnostic test’s) diagnostic joint

2. Read the diagnostic results with X-431 diagnostic tester

Repairing procedure

1.When safety airbag is released.

The following parts should be replaced with new ones

a. Passengers’ side safety airbag module

b. SRS-ECU

c. Driver’s side safety airbag module

2 Check the following parts; replace them with new ones providing something wrong with them.

a. Clock spring

b. Steering-wheel, steering column, bottom steering shaft module

3.Driver’s side safety airbag module’s installation status towards the steering wheel.

a. Check whether abnormal knocking is with the steering wheel, its activity is in good condition and its clearance is normal.

b. Check whether the wiring harness joint is broken and its terminal is deformed.

Caution: Due to the impact, the diagnostic instrument cannot communicate with SRS-ECU when accumulator is lack of

power, in this case, check and maintain the instrument panel wiring harness or utilize the extension power supply.

Page 389 of 425

Safety airbag-19

1. Check whether depression, crack or deformation is with the SRS-ECU bracket.

2. Check whether the joint is broken and terminal is deformed

3. Check SRS-ECU bracket’s installation status

a. Check whether depression, crack or deformation is with the shroud

b. Check whether the joint is broken, terminal is deformed and wiring harness is meshed.

c. Check whether depression, crack or deformation is with the gas generator shield.

d. Make sure the direction of the arrow is straightforward

4. Check the installation status of safety airbag module.

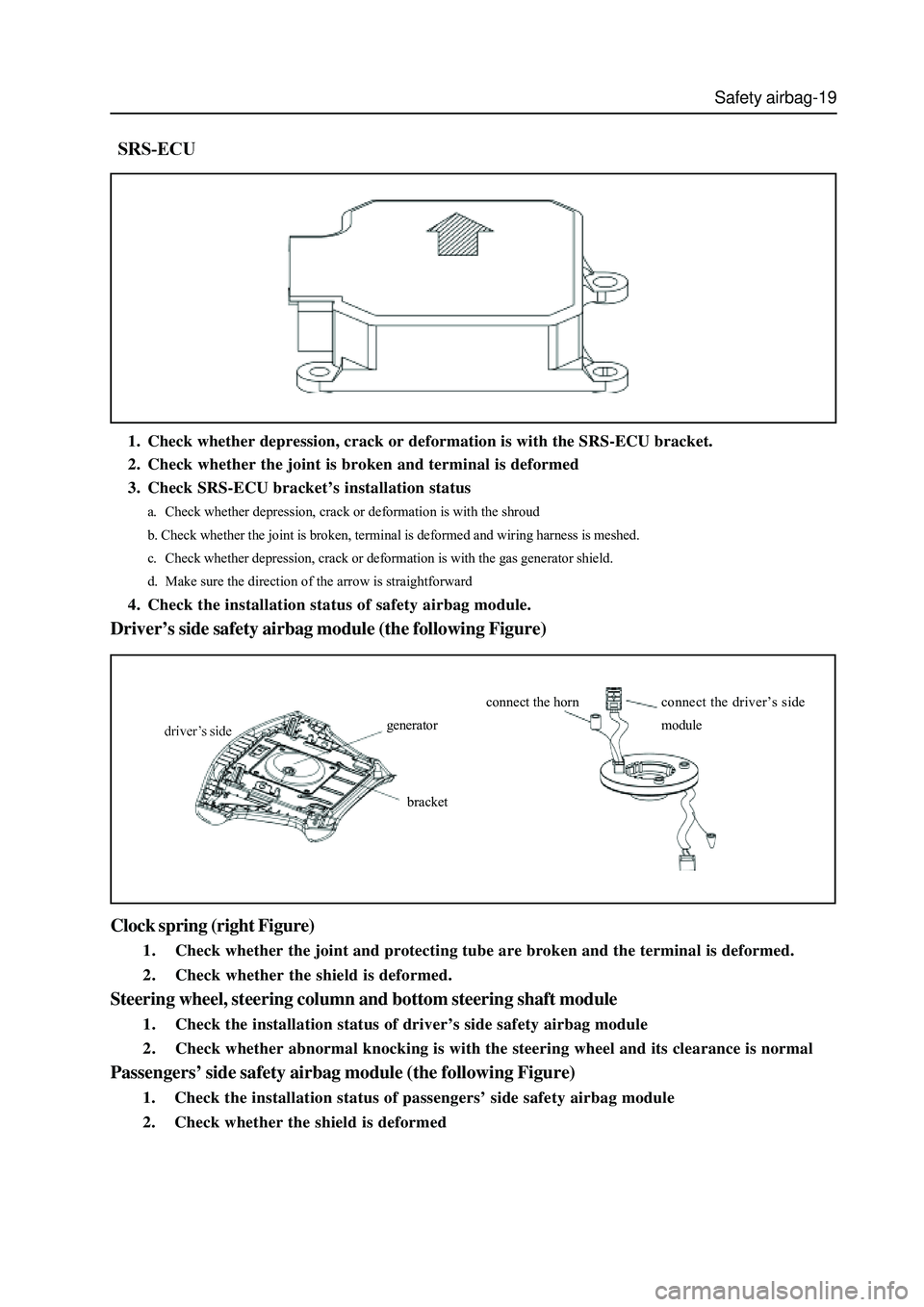

Driver’s side safety airbag module (the following Figure)

generator

bracketconnect the hornconnect the driver’s side

module

Clock spring (right Figure)

1. Check whether the joint and protecting tube are broken and the terminal is deformed.

2. Check whether the shield is deformed.

Steering wheel, steering column and bottom steering shaft module

1. Check the installation status of driver’s side safety airbag module

2. Check whether abnormal knocking is with the steering wheel and its clearance is normal

Passengers’ side safety airbag module (the following Figure)

1. Check the installation status of passengers’ side safety airbag module

2. Check whether the shield is deformed

Page 390 of 425

Safety airbag-20

Wiring harness joint (instrument cluster wiring harness)

Check whether the wiring harness is well installed, the joint is broken and the terminal is deformed.

Warning

The attentions for use and maintenance for SRS safety airbag are displayed in the Figure. Operate according to the sign and, the

destructed and dirty sign must be replaced with a new one steering

wheel in Figure6-1

Driver’s side safety airbag module in Figure 6.2

Clock spring in Figure 6.3

SRS-ECU in Figure 6.4

Sun visor in Figure 6.5

Passengers’ side safety airbag module in Figure 6.6

Passenger side airbag (PAB)

Page 393 of 425

Safety airbag-23

Driver’s and passengers’ side safety airbag module (DAB, PAB), clock spring

Caution

1. Continue the operation 60 seconds after the removal of accumulator negative. Wrap the negative with insulating

tape for insulation.

2. Safety airbag module and clock spring must not be separated nor repaired, replace the failed ones with new ones.

3. Please pay high attention when using the safety airbag module and clock spring, do not let them fall on the ground

nor fall into water or oil. Moreover, replace the depressed, crack or deformed ones with new ones.

4. After the safety airbag module is released, keep the released side up, store it somewhere flat and do not lay anything

on it.

5. The safety airbag module must not be stored in a place with the temperature above 93

.

6. The released safety airbag module must be replaced with a new one, at the same time test the clock spring, replace

it with a new one if something unusual with it.

7. Use gloves and protection glasses during operating the released safety airbag.

8. The unreleased safety airbag must be abandoned after its release.

Caution

During the removal, the wring harness connector clip must be removed before the removal of other wring harness

connector clips in order to avoid the possible improper release caused by static interferences, which is reversal to the

case of installation.

1. Removal and installation

Driver’s side safety airbag module, passengers’ side safety airbag module, clock spring.

2. Operations before removal.

a. Take out the ignition switch key after the steering wheel and front wheel in straightforward direction.

b. Remove the connections of accumulator negative

3. Driver’s side safety airbag module removal procedure

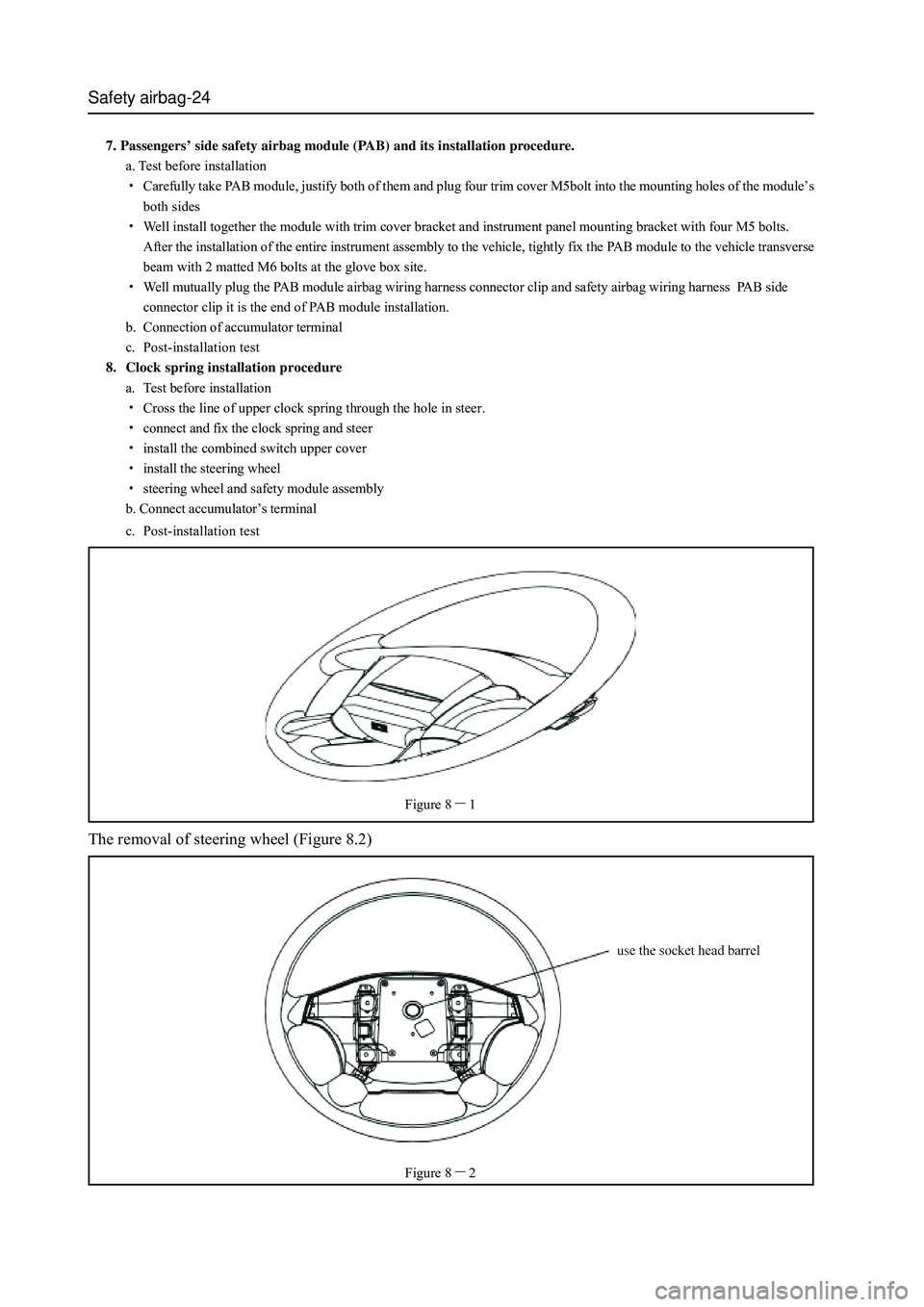

a. Screw off the bolts of two sides, as showed in Figure 8-1

b. Shut off the wiring harness connector clip

c. Remove the safety airbag module assembly

d. Remove the steering wheel

4. Passengers’ side safety airbag module removal procedure

a. Remove all the trim covers and glove boxes of instrument panel separate the PAB module’s airbag wiring harness connector

clip from the safety airbag’s PAB side one.

b. Remove M6 bolts and separate PAB module from instrument panel armed beam.

c. Remove the instrument panel itself.

d. Remove the M5bolts of two sides of four PAB modules.

5. Clock spring removal procedure

a. Remove DAB module (shut off the connecting connector clip)

b. Carefully remove the steer

c. Open the combined switch upper shield, find and shut off the bottom wring harness connector clip

d. Remove the clock spring from the steer

6. Driver’s side safety airbag module (DAB) and its installation procedure

Page 394 of 425

Safety airbag-24

Figure 81

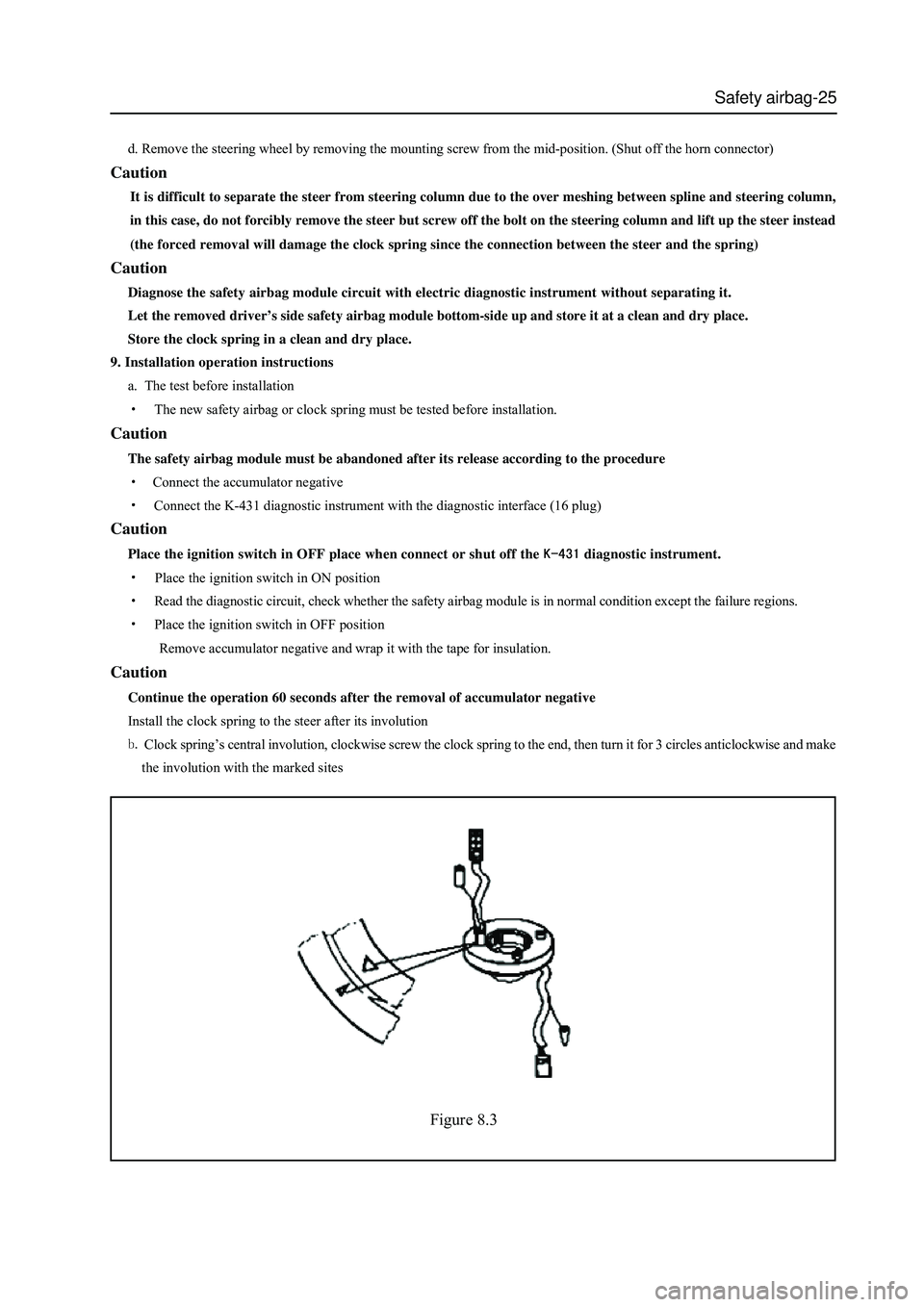

The removal of steering wheel (Figure 8.2)

Figure 82

7. Passengers’ side safety airbag module (PAB) and its installation procedure.

a. Test before installation

Carefully take PAB module, justify both of them and plug four trim cover M5bolt into the mounting holes of the module’s

both sides

Well install together the module with trim cover bracket and instrument panel mounting bracket with four M5 bolts.

After the installation of the entire instrument assembly to the vehicle, tightly fix the PAB module to the vehicle transverse

beam with 2 matted M6 bolts at the glove box site.

Well mutually plug the PAB module airbag wiring harness connector clip and safety airbag wiring harness PAB side

connector clip it is the end of PAB module installation.

b. Connection of accumulator terminal

c. Post-installation test

8. Clock spring installation procedure

a. Test before installation

Cross the line of upper clock spring through the hole in steer.

connect and fix the clock spring and steer

install the combined switch upper cover

install the steering wheel

steering wheel and safety module assembly

b. Connect accumulator’s terminal

c. Post-installation test

Page 395 of 425

Safety airbag-25

Figure 8.3

d. Remove the steering wheel by removing the mounting screw from the mid-position. (Shut off the horn connector)

Caution

It is difficult to separate the steer from steering column due to the over meshing between spline and steering column,

in this case, do not forcibly remove the steer but screw off the bolt on the steering column and lift up the steer instead

(the forced removal will damage the clock spring since the connection between the steer and the spring)

Caution

Diagnose the safety airbag module circuit with electric diagnostic instrument without separating it.

Let the removed driver’s side safety airbag module bottom-side up and store it at a clean and dry place.

Store the clock spring in a clean and dry place.

9. Installation operation instructions

a. The test before installation

The new safety airbag or clock spring must be tested before installation.

Caution

The safety airbag module must be abandoned after its release according to the procedure

Connect the accumulator negative

Connect the K-431 diagnostic instrument with the diagnostic interface (16 plug)

Caution

Place the ignition switch in OFF place when connect or shut off the diagnostic instrument.

Place the ignition switch in ON position

Read the diagnostic circuit, check whether the safety airbag module is in normal condition except the failure regions.

Place the ignition switch in OFF position

Remove accumulator negative and wrap it with the tape for insulation.

Caution

Continue the operation 60 seconds after the removal of accumulator negative

Install the clock spring to the steer after its involution

Clock spring’s central involution, clockwise screw the clock spring to the end, then turn it for 3 circles anticlockwise and make

the involution with the marked sites