clock GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 147 of 425

v. Install the thrust disc on the cylinder internal wheel axle. Refer to Figure 8.24and 8.19.

w. Connect the C2 /clutch C4 wheel axle assembly in clutch C4 disc, install the clutch C2 disc. Install the C3 wheel axle and

reinforce it by ring spring; ensure the ring spring is installed in the groove fixedly. Please refer to Figure 8.24.

10. Clutch C3 and reverse central gear system

The assembly procedure of clutch C3 and reverse central gear assembly (refer to Figure 8.28) is shown as follows:

Check the cleanness of hole on cylinder. Caution:

It should take out the clutch clearance assembly before immerse the assembly into the automatic transmission fluid

(ATF).

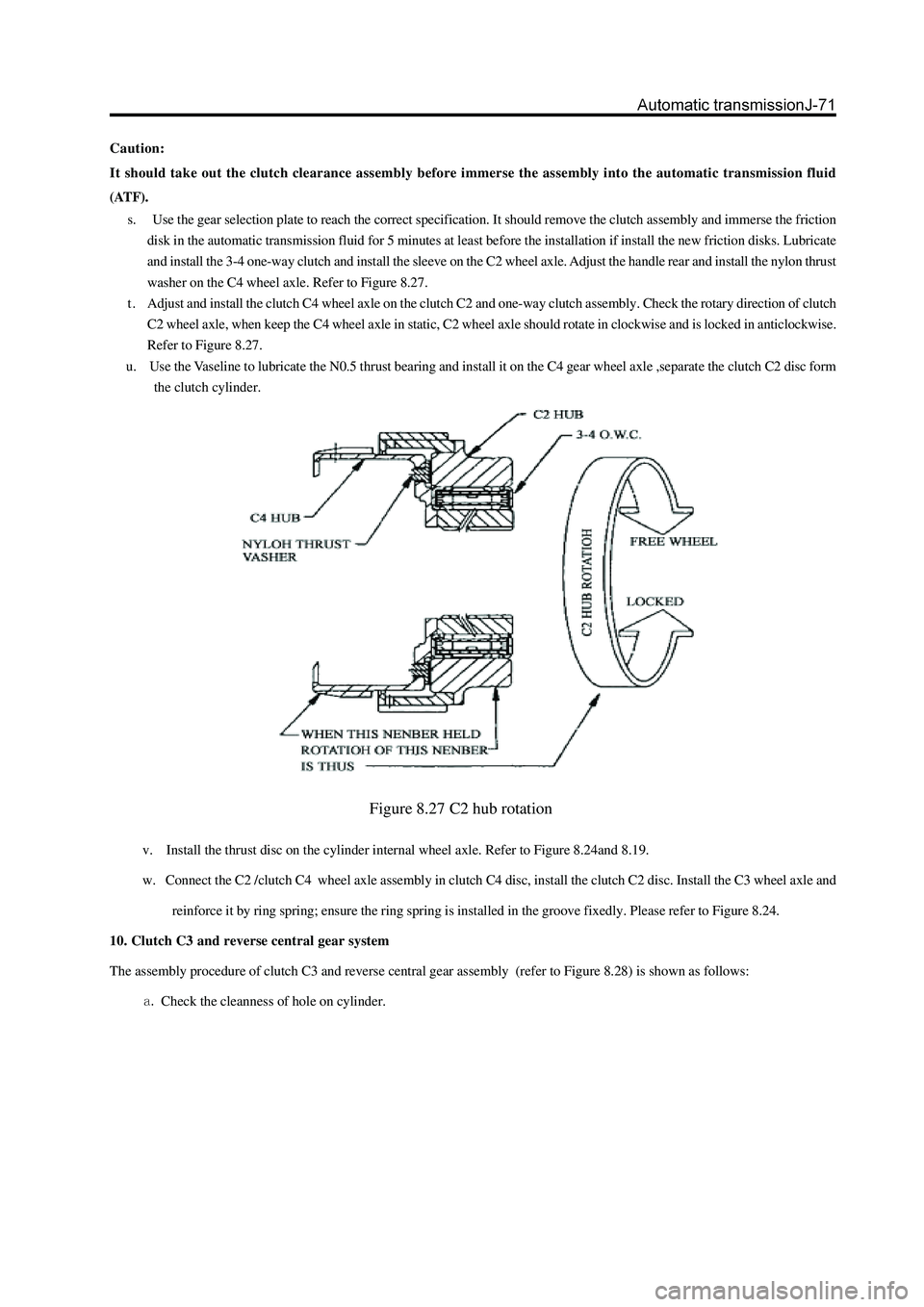

s. Use the gear selection plate to reach the correct specification. It should remove the clutch assembly and immerse the friction

disk in the automatic transmission fluid for 5 minutes at least before the installation if install the new friction disks. Lubricate

and install the 3-4 one-way clutch and install the sleeve on the C2 wheel axle. Adjust the handle rear and install the nylon thrust

washer on the C4 wheel axle. Refer to Figure 8.27.

t . Adjust and install the clutch C4 wheel axle on the clutch C2 and one-way clutch assembly. Check the rotary direction of clutch

C2 wheel axle, when keep the C4 wheel axle in static, C2 wheel axle should rotate in clockwise and is locked in anticlockwise.

Refer to Figure 8.27.

u. Use the Vaseline to lubricate the N0.5 thrust bearing and install it on the C4 gear wheel axle ,separate the clutch C2 disc form

the clutch cylinder.

Figure 8.27 C2 hub rotation

Page 236 of 425

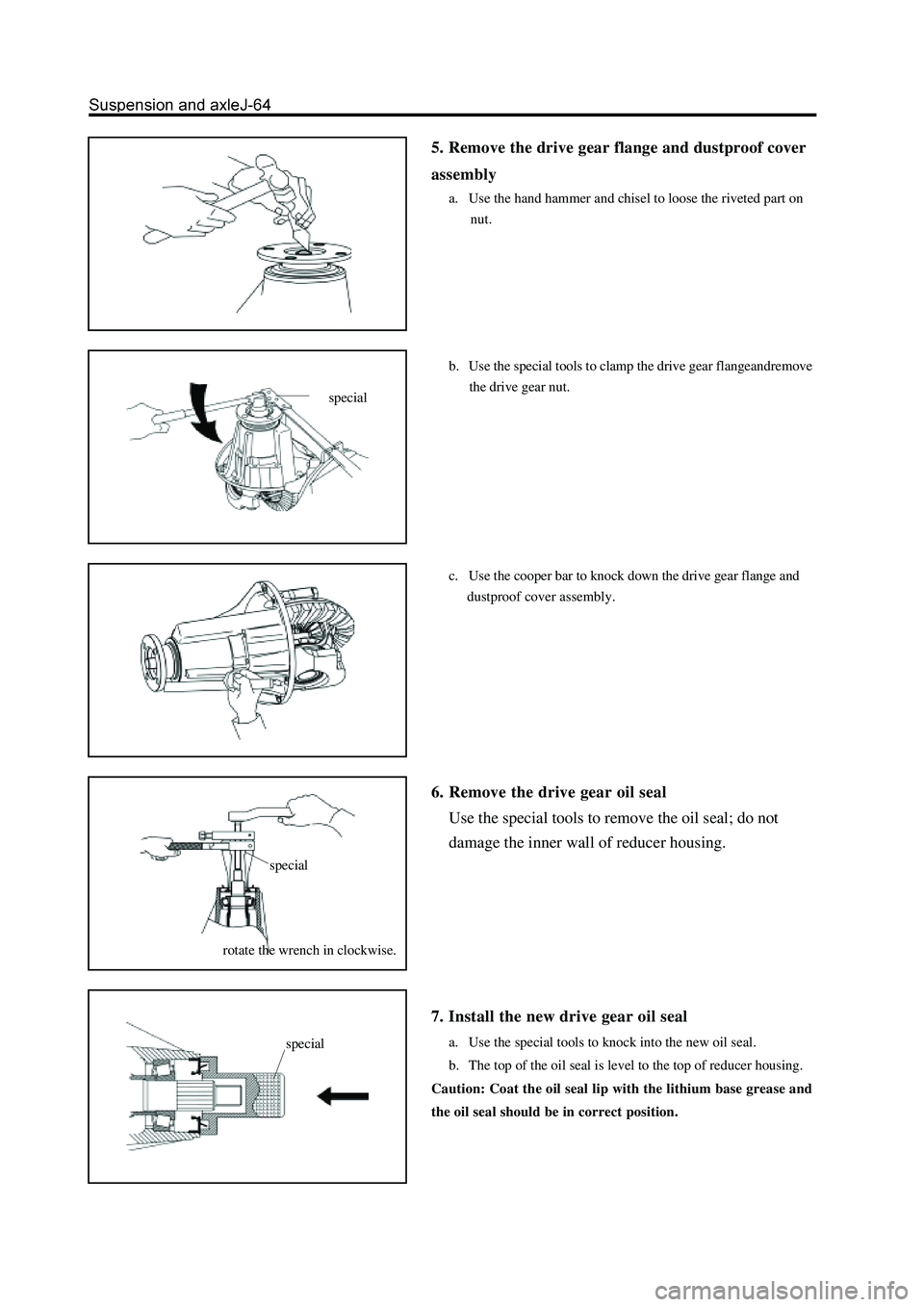

5. Remove the drive gear flange and dustproof cover

assembly

a. Use the hand hammer and chisel to loose the riveted part on

nut.

b. Use the special tools to clamp the drive gear flangeandremove

the drive gear nut.

c. Use the cooper bar to knock down the drive gear flange and

dustproof cover assembly.

6. Remove the drive gear oil seal

Use the special tools to remove the oil seal; do not

damage the inner wall of reducer housing.

7. Install the new drive gear oil seal

a. Use the special tools to knock into the new oil seal.

b. The top of the oil seal is level to the top of reducer housing.

Caution: Coat the oil seal lip with the lithium base grease and

the oil seal should be in correct position.

special

rotate the wrench in clockwise.

specialspecial

Page 251 of 425

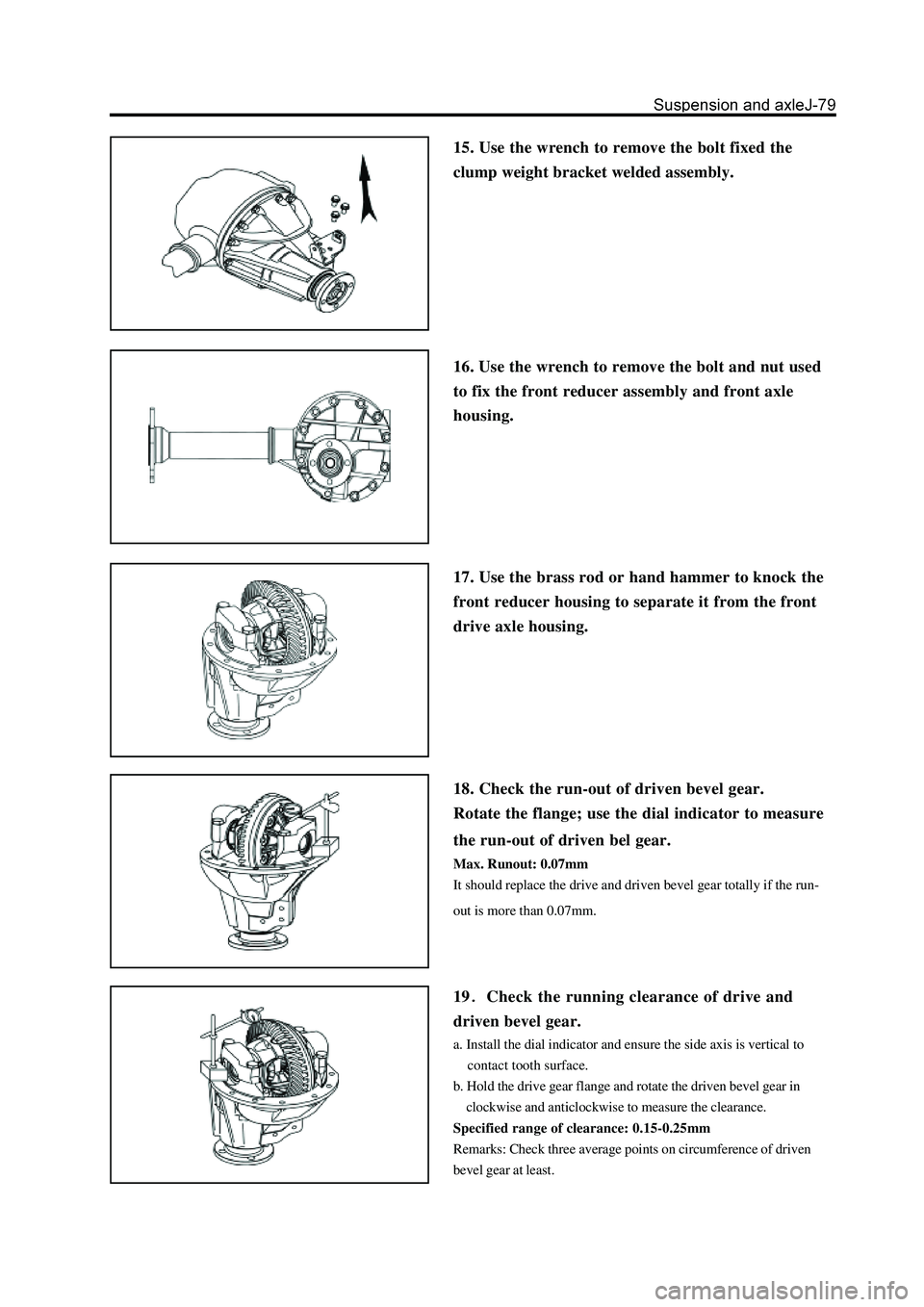

15. Use the wrench to remove the bolt fixed the

clump weight bracket welded assembly.

16. Use the wrench to remove the bolt and nut used

to fix the front reducer assembly and front axle

housing.

17. Use the brass rod or hand hammer to knock the

front reducer housing to separate it from the front

drive axle housing.

18. Check the run-out of driven bevel gear.

Rotate the flange; use the dial indicator to measure

the run-out of driven bel gear.

Max. Runout: 0.07mm

It should replace the drive and driven bevel gear totally if the run-

out is more than 0.07mm.

19Check the running clearance of drive and

driven bevel gear.

a. Install the dial indicator and ensure the side axis is vertical to

contact tooth surface.

b. Hold the drive gear flange and rotate the driven bevel gear in

clockwise and anticlockwise to measure the clearance.

Specified range of clearance: 0.15-0.25mm

Remarks: Check three average points on circumference of driven

bevel gear at least.

Page 253 of 425

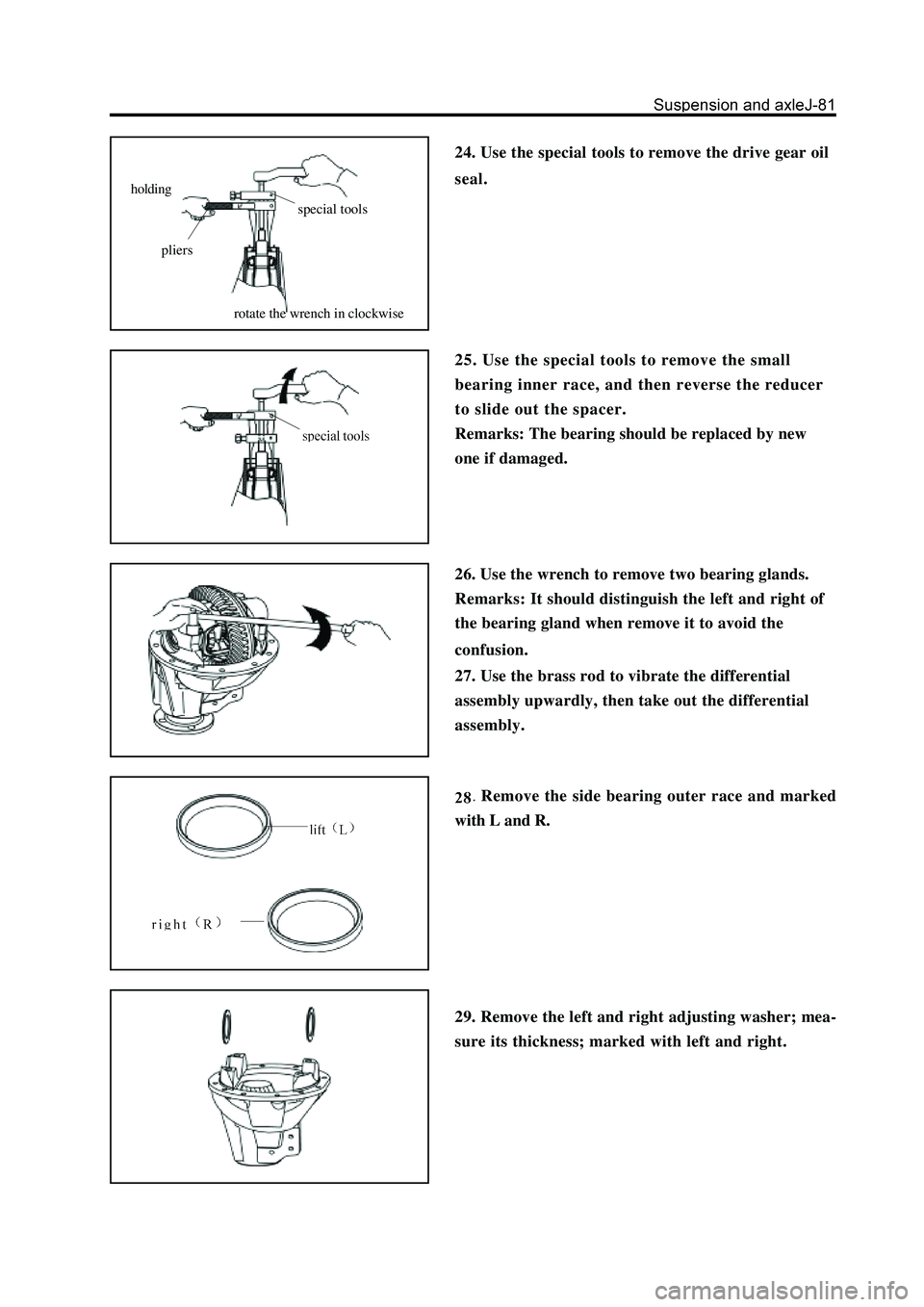

25. Use the special tools to remove the small

bearing inner race, and then reverse the reducer

to slide out the spacer.

Remarks: The bearing should be replaced by new

one if damaged.

26. Use the wrench to remove two bearing glands.

Remarks: It should distinguish the left and right of

the bearing gland when remove it to avoid the

confusion.

Remove the side bearing outer race and marked

with L and R.

29. Remove the left and right adjusting washer; mea-

sure its thickness; marked with left and right. 27. Use the brass rod to vibrate the differential

assembly upwardly, then take out the differential

assembly.

holding

pliers

special tools

rotate the wrench in clockwise

24. Use the special tools to remove the drive gear oil

seal.

Page 261 of 425

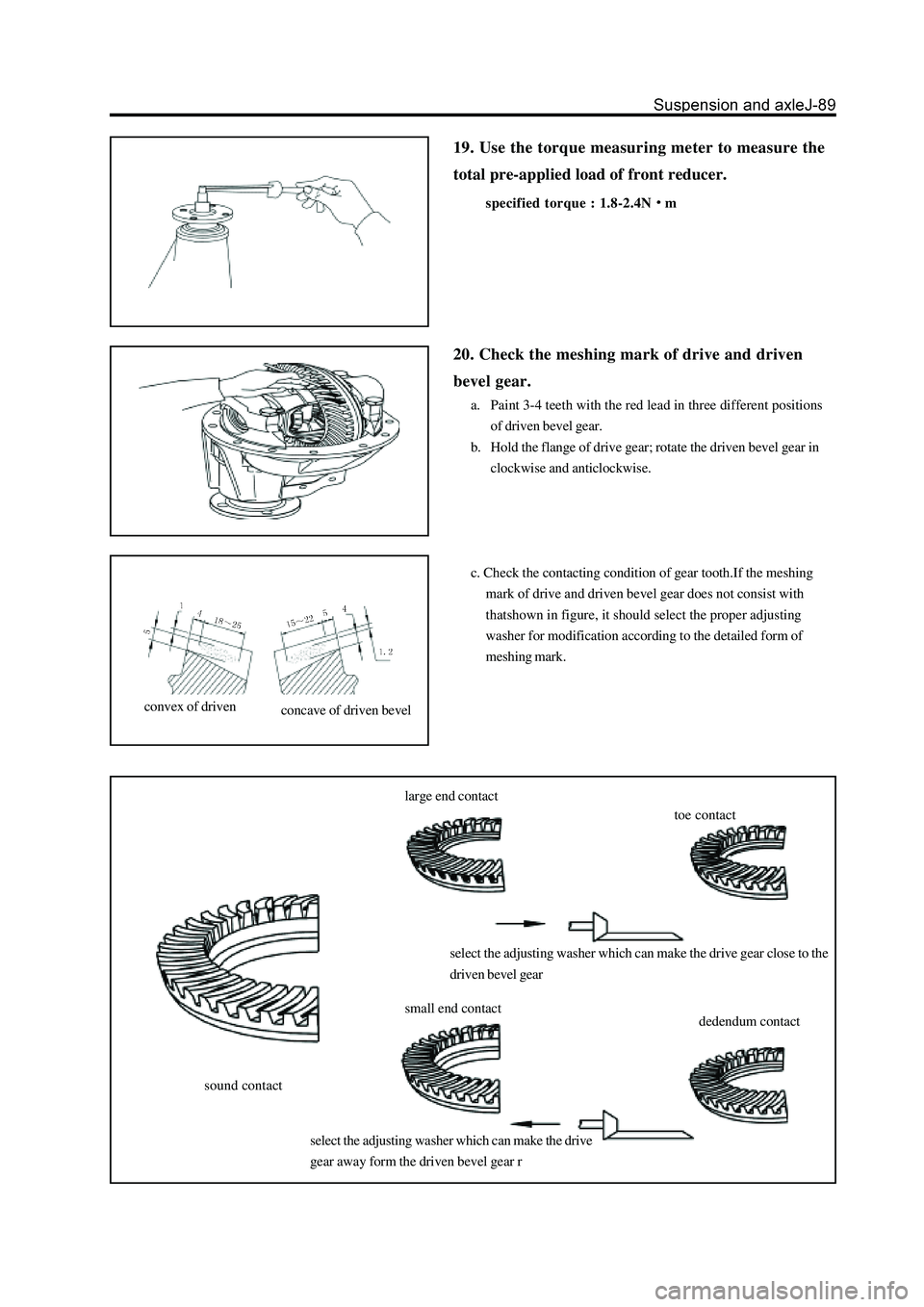

19. Use the torque measuring meter to measure the

total pre-applied load of front reducer.

specified torque : 1.8-2.4Nm

sound contactlarge end contact

toe contact

select the adjusting washer which can make the drive gear close to the

driven bevel gear

select the adjusting washer which can make the drive

gear away form the driven bevel gear rsmall end contact

dedendum contact

20. Check the meshing mark of drive and driven

bevel gear.

a. Paint 3-4 teeth with the red lead in three different positions

of driven bevel gear.

b. Hold the flange of drive gear; rotate the driven bevel gear in

clockwise and anticlockwise.

c. Check the contacting condition of gear tooth.If the meshing

mark of drive and driven bevel gear does not consist with

thatshown in figure, it should select the proper adjusting

washer for modification according to the detailed form of

meshing mark.

convex of drivenconcave of driven bevel

Page 279 of 425

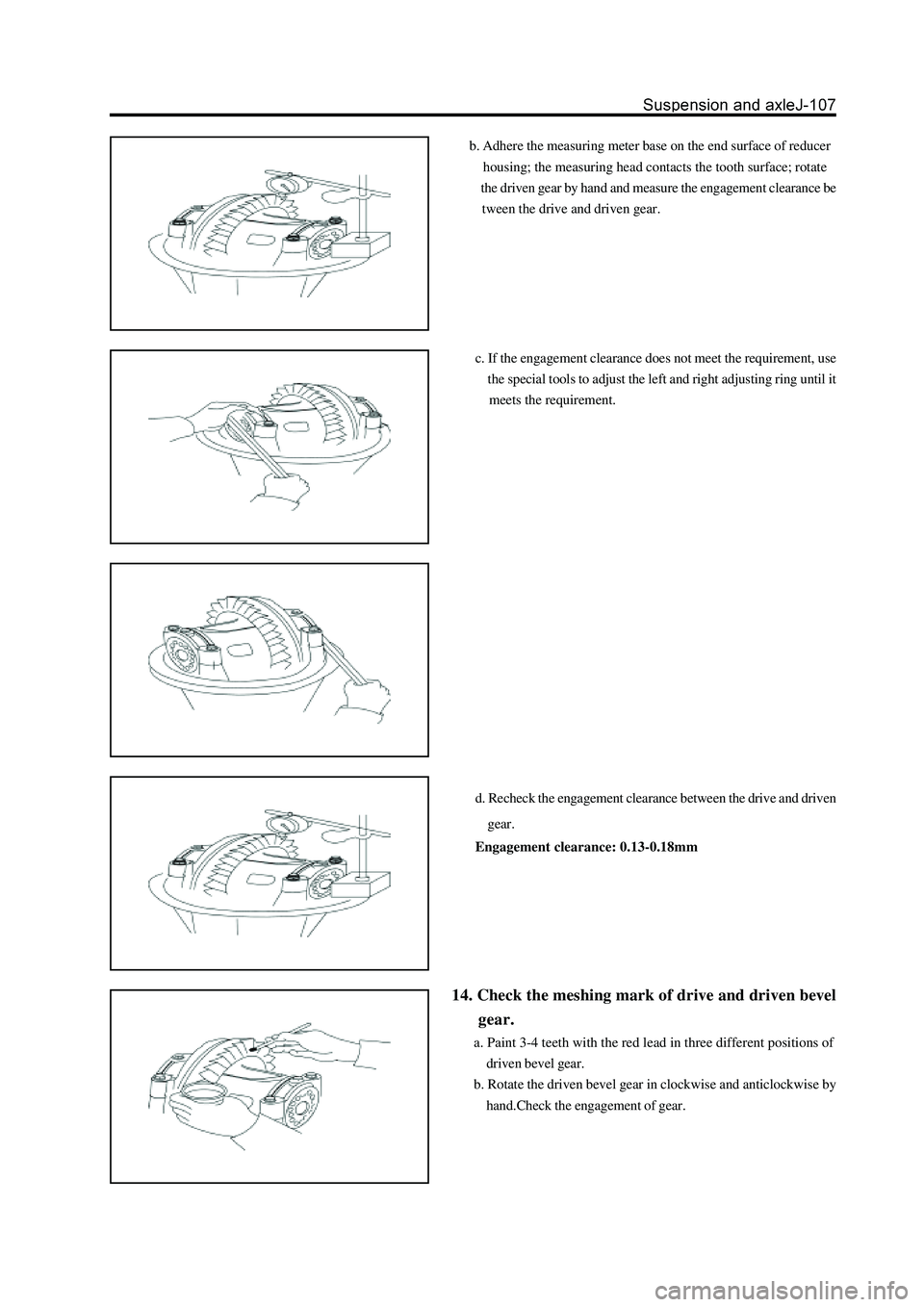

b. Adhere the measuring meter base on the end surface of reducer

housing; the measuring head contacts the tooth surface; rotate

the driven gear by hand and measure the engagement clearance be

tween the drive and driven gear.

c. If the engagement clearance does not meet the requirement, use

the special tools to adjust the left and right adjusting ring until it

meets the requirement.

d. Recheck the engagement clearance between the drive and driven

gear.

Engagement clearance: 0.13-0.18mm

14. Check the meshing mark of drive and driven bevel

gear.

a. Paint 3-4 teeth with the red lead in three different positions of

driven bevel gear.

b. Rotate the driven bevel gear in clockwise and anticlockwise by

hand.Check the engagement of gear.

Page 314 of 425

Brake-28

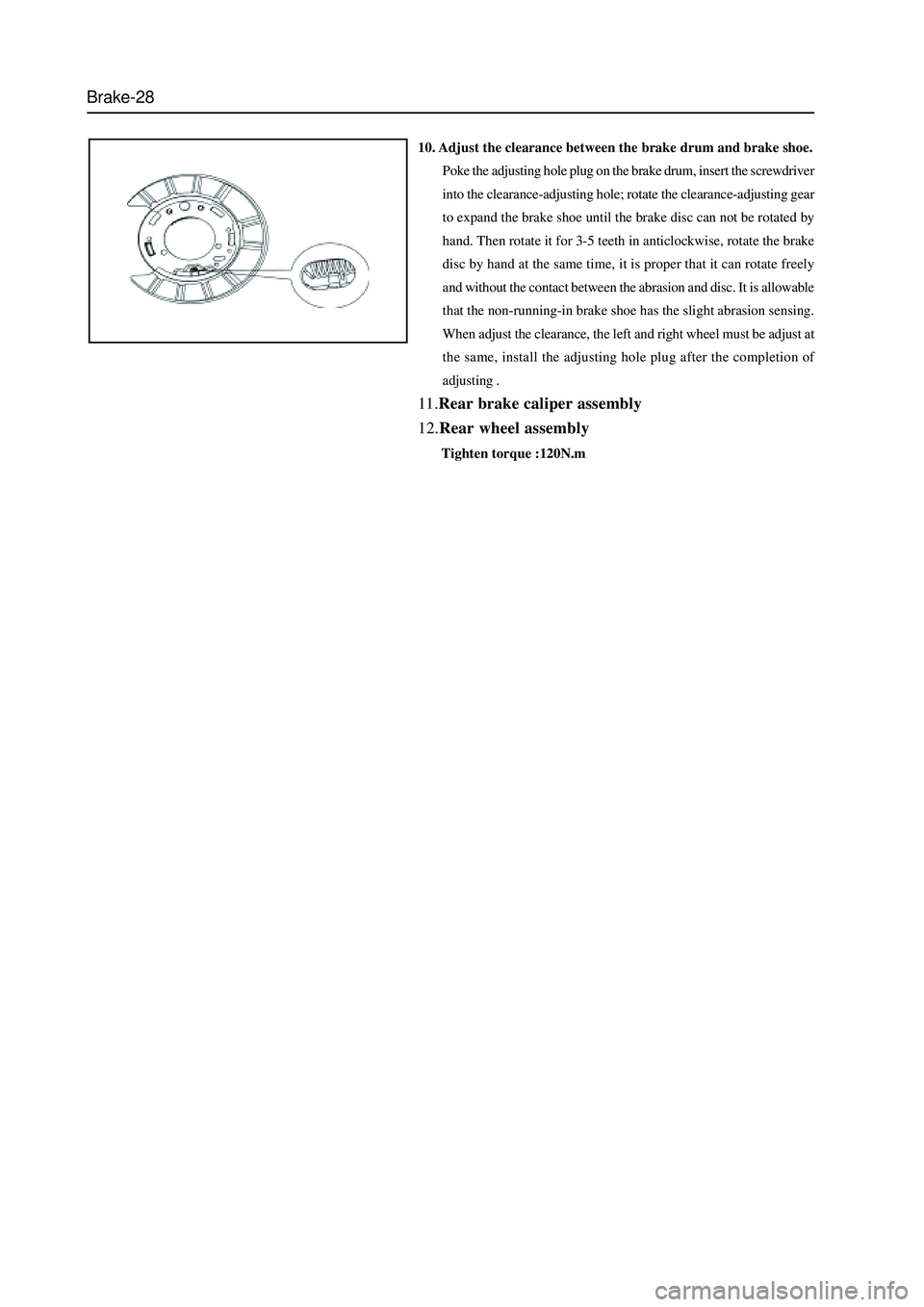

10. Adjust the clearance between the brake drum and brake shoe.

Poke the adjusting hole plug on the brake drum, insert the screwdriver

into the clearance-adjusting hole; rotate the clearance-adjusting gear

to expand the brake shoe until the brake disc can not be rotated by

hand. Then rotate it for 3-5 teeth in anticlockwise, rotate the brake

disc by hand at the same time, it is proper that it can rotate freely

and without the contact between the abrasion and disc. It is allowable

that the non-running-in brake shoe has the slight abrasion sensing.

When adjust the clearance, the left and right wheel must be adjust at

the same, install the adjusting hole plug after the completion of

adjusting .

11.Rear brake caliper assembly

12.Rear wheel assembly

Tighten torque :120N.m

Page 355 of 425

CD Player and Air Conditioning System-2

CD Player

Function Overview

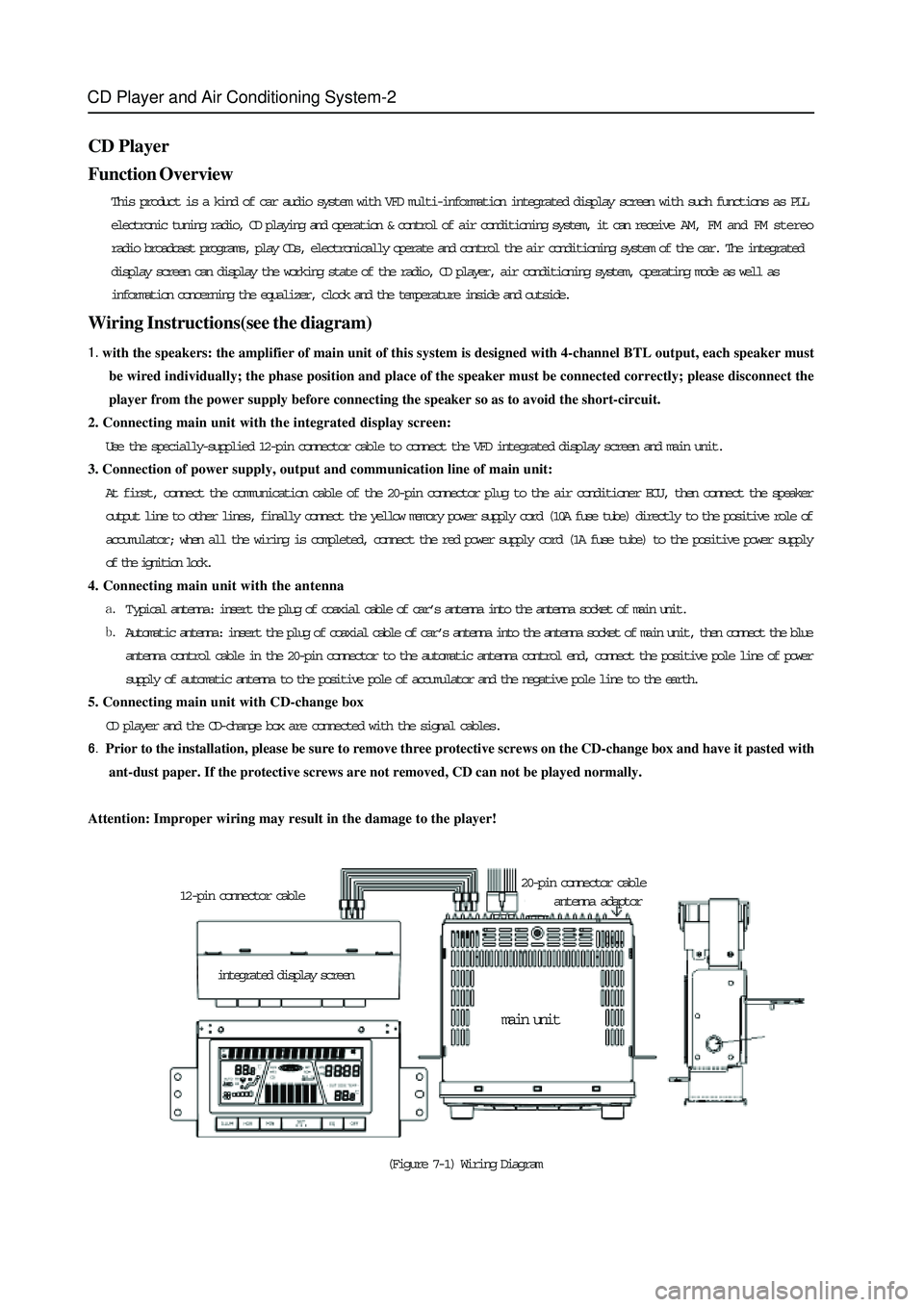

This product is a kind of car audio system with VFD multi-information integrated display screen with such functions as PLL

electronic tuning radio, CD playing and operation & control of air conditioning system, it can receive AM, FM and FM stereo

radio broadcast programs, play CDs, electronically operate and control the air conditioning system of the car. The integrated

display screen can display the working state of the radio, CD player, air conditioning system, operating mode as well as

information concerning the equalizer, clock and the temperature inside and outside.

Wiring Instructions(see the diagram)

with the speakers: the amplifier of main unit of this system is designed with 4-channel BTL output, each speaker must

be wired individually; the phase position and place of the speaker must be connected correctly; please disconnect the

player from the power supply before connecting the speaker so as to avoid the short-circuit.

2. Connecting main unit with the integrated display screen:

Use the specially-supplied 12-pin connector cable to connect the VFD integrated display screen and main unit.

3. Connection of power supply, output and communication line of main unit:

At first, connect the communication cable of the 20-pin connector plug to the air conditioner ECU, then connect the speaker

output line to other lines, finally connect the yellow memory power supply cord (10A fuse tube) directly to the positive role of

accumulator; when all the wiring is completed, connect the red power supply cord (1A fuse tube) to the positive power supply

of the ignition lock.

4. Connecting main unit with the antenna

T ypical antenna: insert the plug of coaxial cable of car’s antenna into the antenna socket of main unit.

Automatic antenna: insert the plug of coaxial cable of car’s antenna into the antenna socket of main unit, then connect the blue

antenna control cable in the 20-pin connector to the automatic antenna control end, connect the positive pole line of power

supply of automatic antenna to the positive pole of accumulator and the negative pole line to the earth.

5. Connecting main unit with CD-change box

CD player and the CD-change box are connected with the signal cables.

Prior to the installation, please be sure to remove three protective screws on the CD-change box and have it pasted with

ant-dust paper. If the protective screws are not removed, CD can not be played normally.

Attention: Improper wiring may result in the damage to the player!

(Figure 7-1) Wiring Diagram integrated display screen 12-pin connector cable20-pin connector cable

antenna adaptor

main unit

Page 358 of 425

CD Player and Air Conditioning System-5

1. integrated display screen 2. CD player 3. Air conditioner ECU 4. Temperature sensor the evaporator 5. Outside

temperature sensor

6. Outside temperature sensor 7. Speed-adjusting module 8. Temperature damper executor 9. Mode damper executor

10. Fresh air damper executor

Definition of each button on CD player of air conditioner panel

[1] Button to increase the temperature [7] wind conveying mode button

[2] Button to decrease the temperature[8] button to start air conditioner

[3] automatic operation button[9] button to decrease the wind amount

[4] front-defrost button[10] power-off button of air conditioner

[5] rear-defrost button[11] button to increase the wind amount

[6] external circulation button

Definition of each button in air conditioning display zone of the integrated display screen

[1] display of inside temperature setting of air conditioner[5] switch button of outside temperature display

[2] display of automatic operation of air conditioner[6] display zone of outside temperature

[3] display zone of wind conveying mode of air conditioner[7] clock display zone

[4] display zone of wind amount of air conditioner

Control and display unit:Control and display unit of the air conditioner mainly consists of:

Air conditioner ECU: The CC6460K model is designed with the individual air conditioner ECU to control the overall operation

of air conditioning system; Air conditioner ECU is installed under the bottom of CD player.The control panel of air conditioner

is designed with an integrated pattern with the control panel of CD player: to regulate, control and set the operation of the air

conditioning system.

Integrated display screen: display the working condition of air conditioning system of the car; relevant functions of air

conditioning system can be found to be displayed in different zone in the integrated display screen.

The sensor

Sensors of CC6460K Model automatic air conditioning system include: inside temperature sensor, outside temperature

sensor, temperature sensor executor of the evaporator.

Executor components include: mode selection executor motor, cold & hot executor motor, internal & external circulation

executor motor.

Trouble Diagnosis and Repair of Automatic Air Conditioning System

1. Self-diagnosis of the system

CC6460K air conditioning system is designed with the system self-diagnosis function. When the air conditioning system fails to

work, the self-diagnosis function designed for the car can be activated for the initial trouble diagnosis.

Operating directions:

At first, start the engine (turn the ignition switch from OFF to ON) and press OFF , A U T O, RR and MODE successively and the

pressing of MODE switch shall last at least 2 seconds. The button must be pressed down within 10 seconds when the engine is

started (the ignition switch is turned to ON position).If the system is supposed to be released, then press A U T O switch or turn

off the ignition switch (OFF) .If one step is supposed to switch to another step, then press TEMP (HOT) or TEMP (COLD)

switch based on the needs.

Page 372 of 425

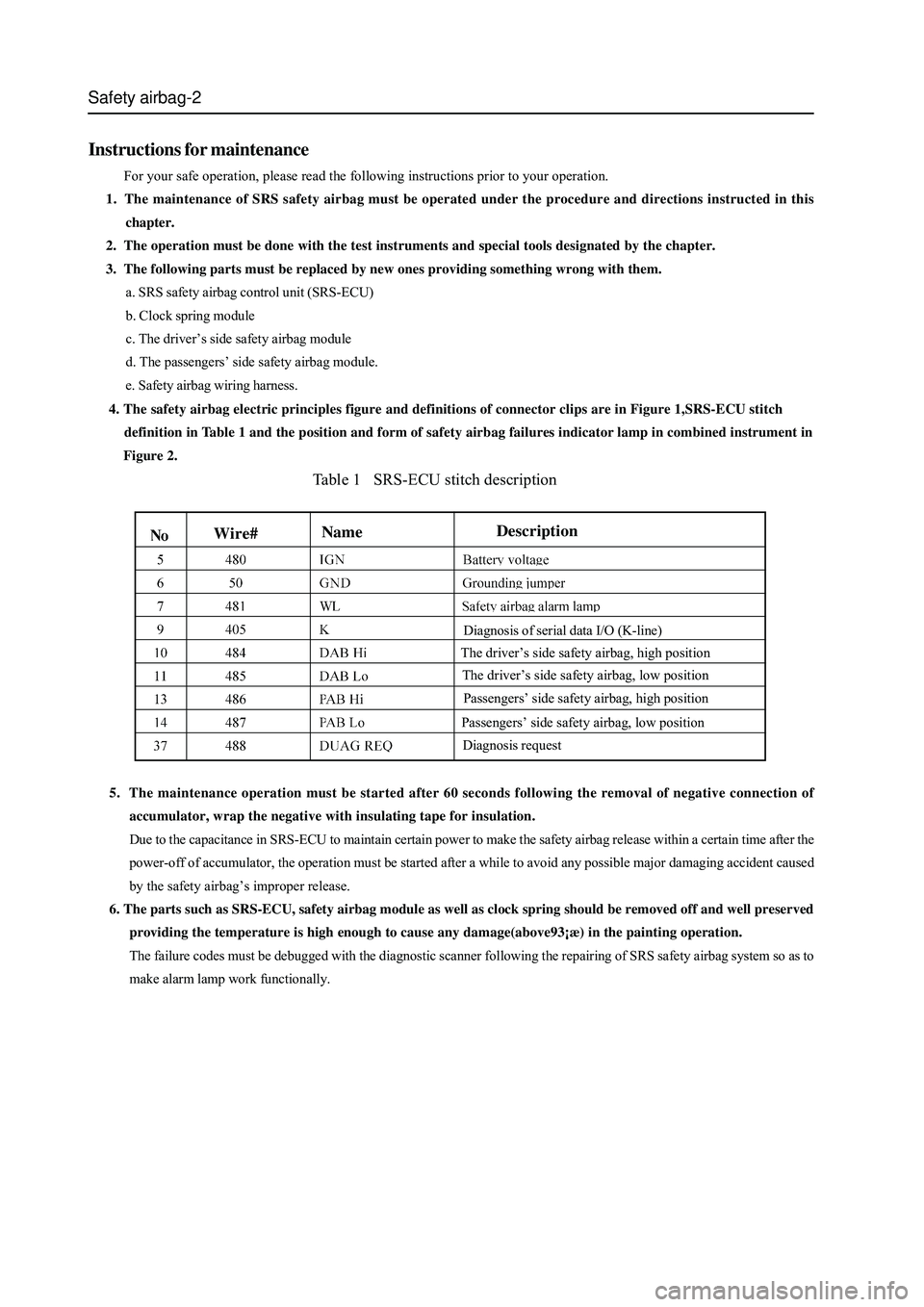

Safety airbag-2

Table 1 SRS-ECU stitch description

5. The maintenance operation must be started after 60 seconds following the removal of negative connection of

accumulator, wrap the negative with insulating tape for insulation.

Due to the capacitance in SRS-ECU to maintain certain power to make the safety airbag release within a certain time after the

power-off of accumulator, the operation must be started after a while to avoid any possible major damaging accident caused

by the safety airbag’s improper release.

6. The parts such as SRS-ECU, safety airbag module as well as clock spring should be removed off and well preserved

providing the temperature is high enough to cause any damage(above93¡æ) in the painting operation.

The failure codes must be debugged with the diagnostic scanner following the repairing of SRS safety airbag system so as to

make alarm lamp work functionally.

Instructions for maintenance

For your safe operation, please read the following instructions prior to your operation.

1. The maintenance of SRS safety airbag must be operated under the procedure and directions instructed in this

chapter.

2. The operation must be done with the test instruments and special tools designated by the chapter.

3. The following parts must be replaced by new ones providing something wrong with them.

a. SRS safety airbag control unit (SRS-ECU)

b. Clock spring module

c. The driver’s side safety airbag module

d. The passengers’ side safety airbag module.

e. Safety airbag wiring harness.

4. The safety airbag electric principles figure and definitions of connector clips are in Figure 1,SRS-ECU stitch

definition in Table 1 and the position and form of safety airbag failures indicator lamp in combined instrument in

Figure 2.

The driver’s side safety airbag, low position

Wire#Description

Name

Diagnosis request

The driver’s side safety airbag, high position

Passengers’ side safety airbag, high position

Passengers’ side safety airbag, low position

Diagnosis of serial data I/O (K-line)