suspension GREAT WALL HOVER 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 215 of 425

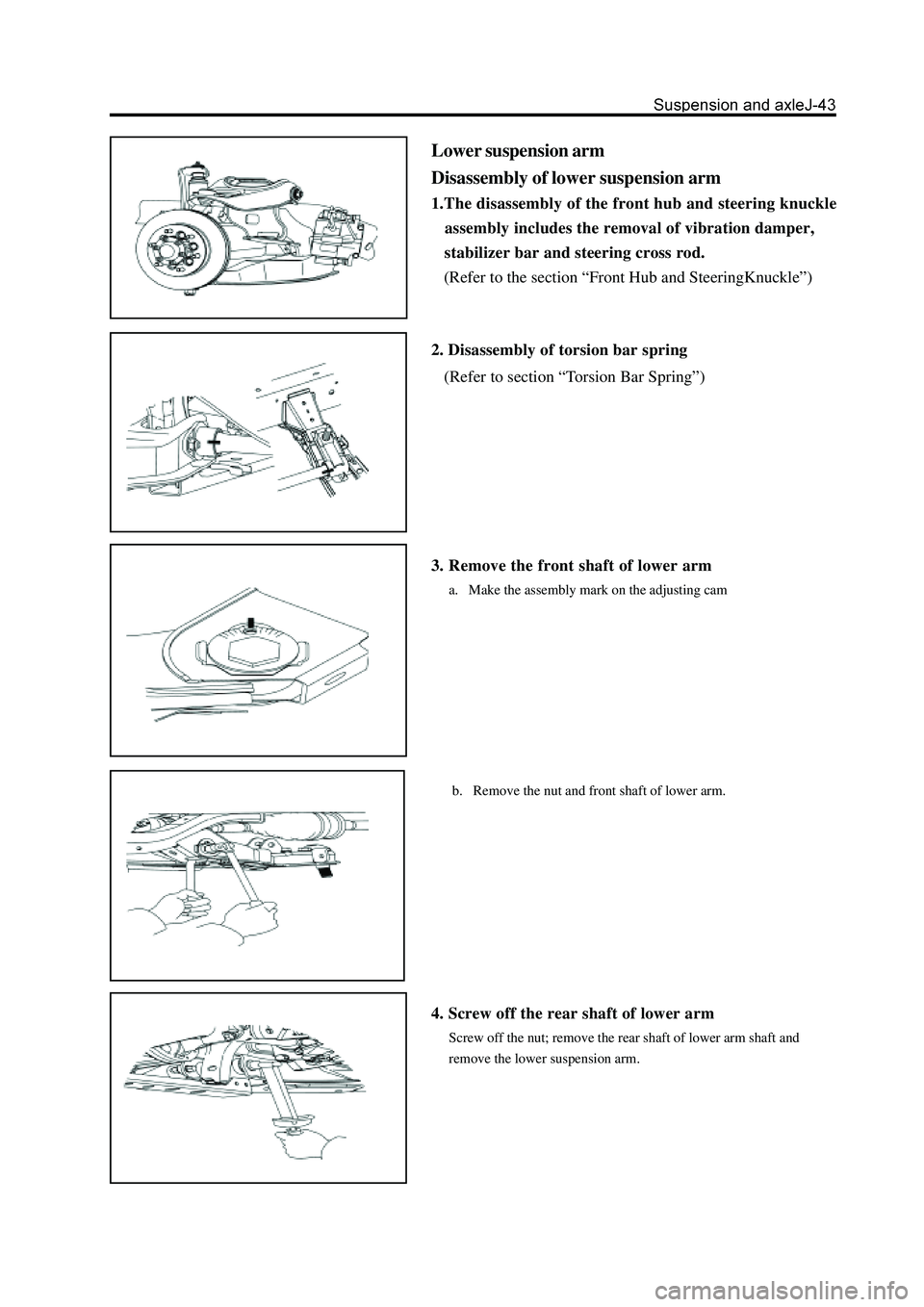

Lower suspension arm

Disassembly of lower suspension arm

1.The disassembly of the front hub and steering knuckle

assembly includes the removal of vibration damper,

stabilizer bar and steering cross rod.

(Refer to the section “Front Hub and SteeringKnuckle”)

2. Disassembly of torsion bar spring

(Refer to section “Torsion Bar Spring”)

3. Remove the front shaft of lower arm

a. Make the assembly mark on the adjusting cam

b. Remove the nut and front shaft of lower arm.

4. Screw off the rear shaft of lower arm

Screw off the nut; remove the rear shaft of lower arm shaft and

remove the lower suspension arm.

Page 216 of 425

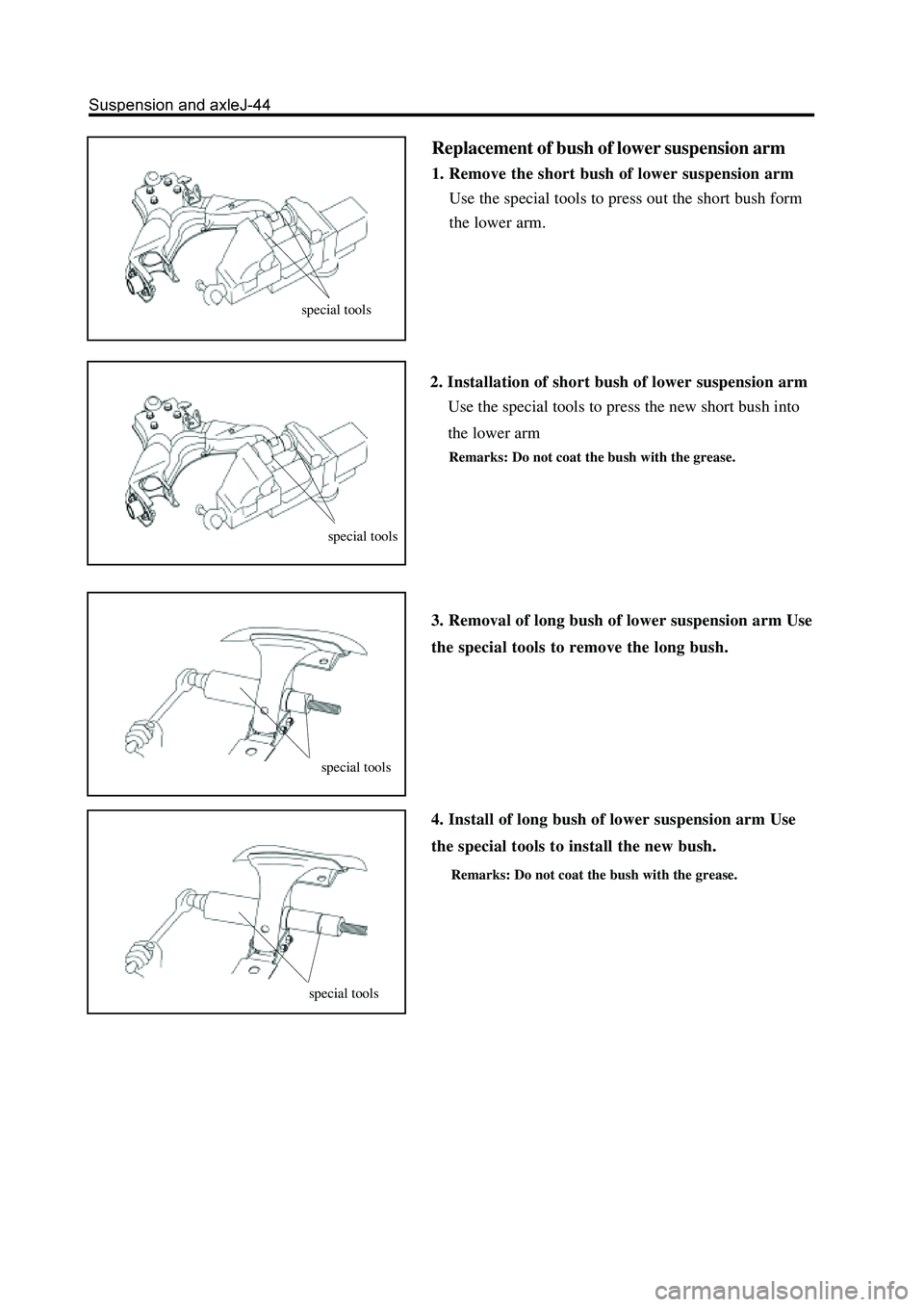

Replacement of bush of lower suspension arm

1. Remove the short bush of lower suspension arm

Use the special tools to press out the short bush form

the lower arm.

2. Installation of short bush of lower suspension arm

Use the special tools to press the new short bush into

the lower arm

Remarks: Do not coat the bush with the grease.

3. Removal of long bush of lower suspension arm Use

the special tools to remove the long bush.

special tools

special tools

4. Install of long bush of lower suspension arm Use

the special tools to install the new bush.

Remarks: Do not coat the bush with the grease.

special tools

special tools

Page 217 of 425

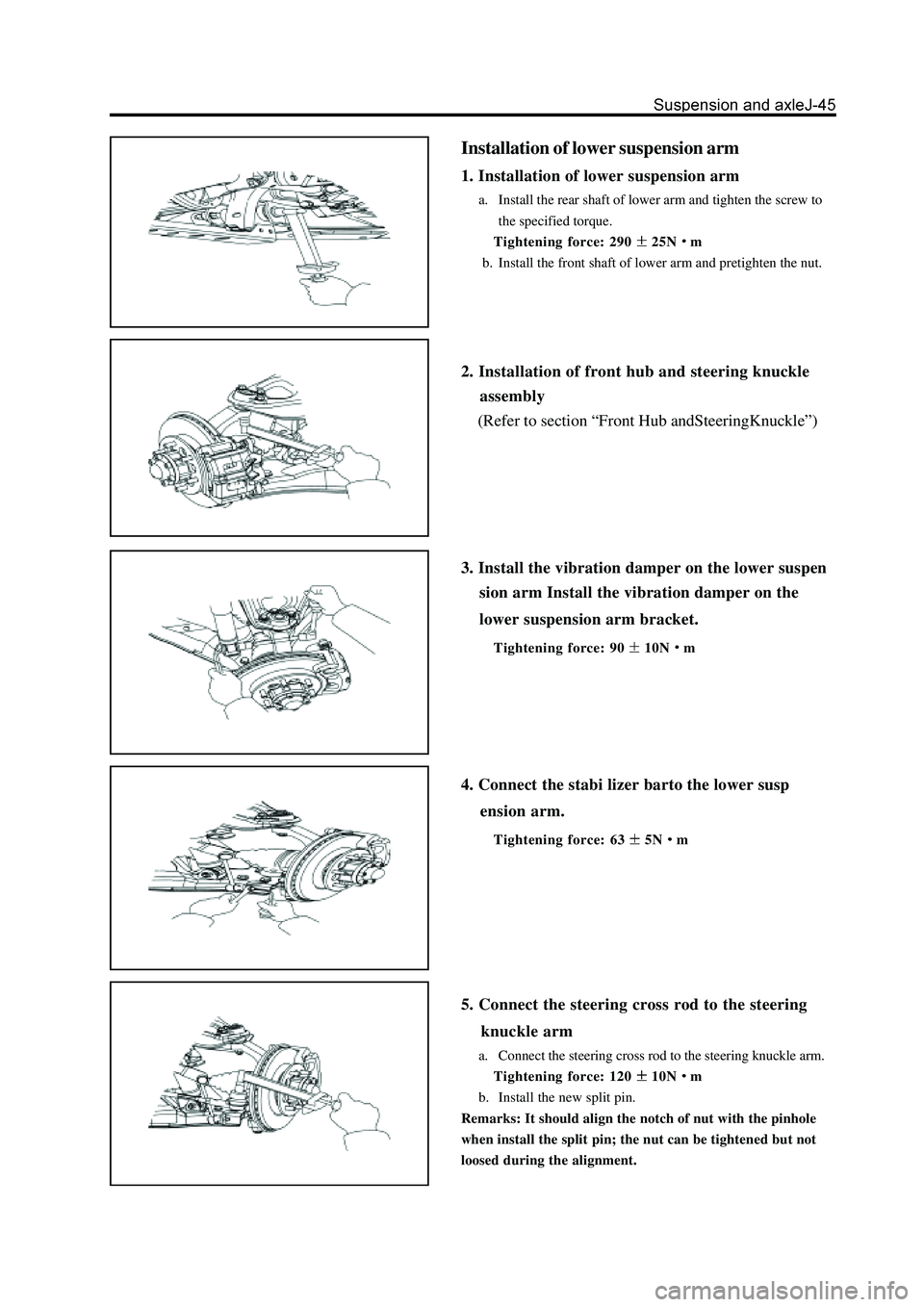

Installation of lower suspension arm

1. Installation of lower suspension arm

a. Install the rear shaft of lower arm and tighten the screw to

the specified torque.

Tightening force: 290

25Nm

b. Install the front shaft of lower arm and pretighten the nut.

2. Installation of front hub and steering knuckle

assembly

(Refer to section “Front Hub andSteeringKnuckle”)

3. Install the vibration damper on the lower suspen

sion arm Install the vibration damper on the

lower suspension arm bracket.

Tightening force: 9010Nm

4. Connect the stabi lizer barto the lower susp

ension arm.

Tightening force: 635Nm

5. Connect the steering cross rod to the steering

knuckle arm

a. Connect the steering cross rod to the steering knuckle arm.

Tightening force: 120

10Nm

b. Install the new split pin.

Remarks: It should align the notch of nut with the pinhole

when install the split pin; the nut can be tightened but not

loosed during the alignment.

Page 219 of 425

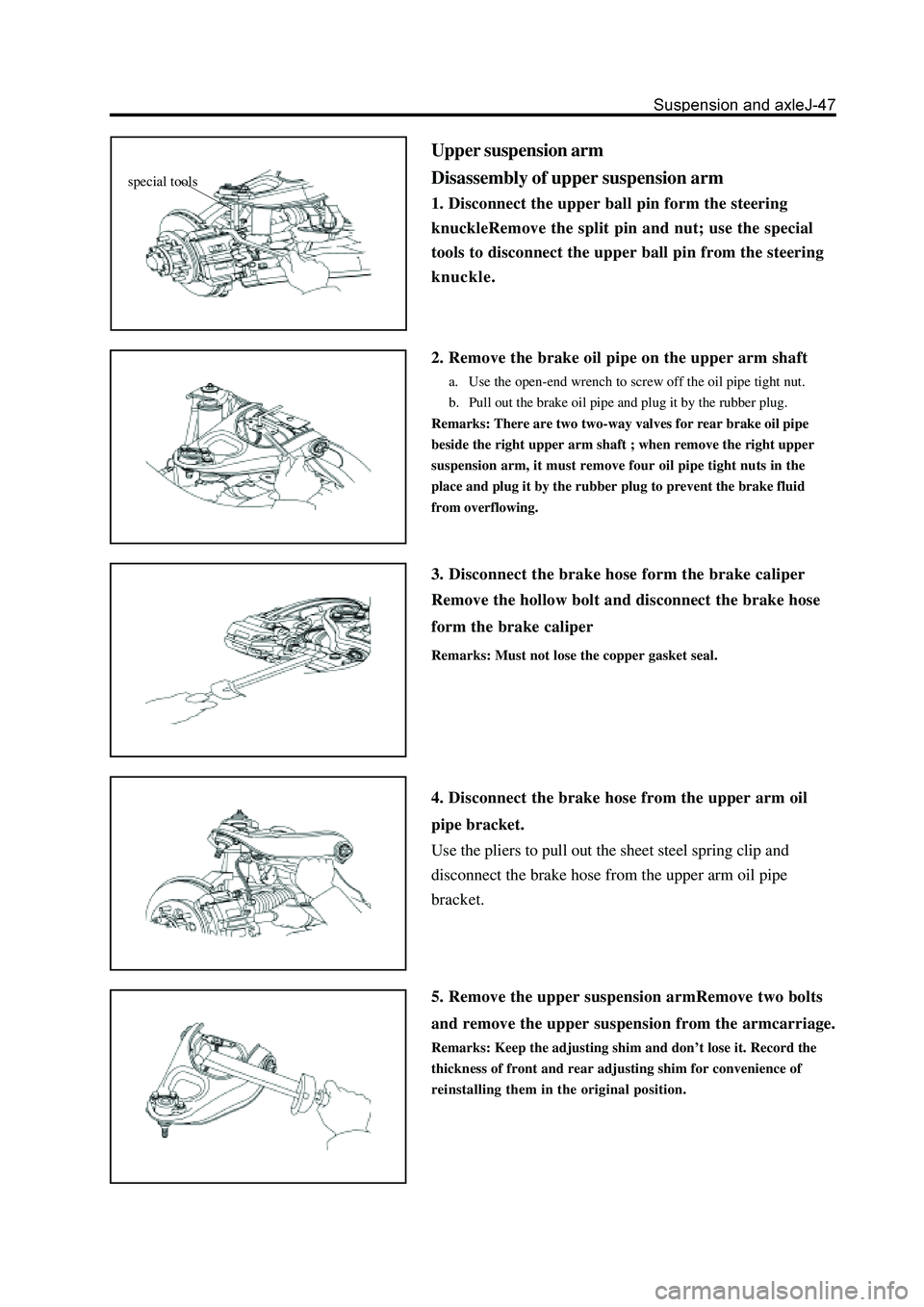

Upper suspension arm

Disassembly of upper suspension arm

1. Disconnect the upper ball pin form the steering

knuckleRemove the split pin and nut; use the special

tools to disconnect the upper ball pin from the steering

knuckle.

2. Remove the brake oil pipe on the upper arm shaft

a. Use the open-end wrench to screw off the oil pipe tight nut.

b. Pull out the brake oil pipe and plug it by the rubber plug.

Remarks: There are two two-way valves for rear brake oil pipe

beside the right upper arm shaft ; when remove the right upper

suspension arm, it must remove four oil pipe tight nuts in the

place and plug it by the rubber plug to prevent the brake fluid

from overflowing.

3. Disconnect the brake hose form the brake caliper

Remove the hollow bolt and disconnect the brake hose

form the brake caliper

Remarks: Must not lose the copper gasket seal.

4. Disconnect the brake hose from the upper arm oil

pipe bracket.

Use the pliers to pull out the sheet steel spring clip and

disconnect the brake hose from the upper arm oil pipe

bracket.

5. Remove the upper suspension armRemove two bolts

and remove the upper suspension from the armcarriage.

Remarks: Keep the adjusting shim and don’t lose it. Record the

thickness of front and rear adjusting shim for convenience of

reinstalling them in the original position.

special tools

Page 221 of 425

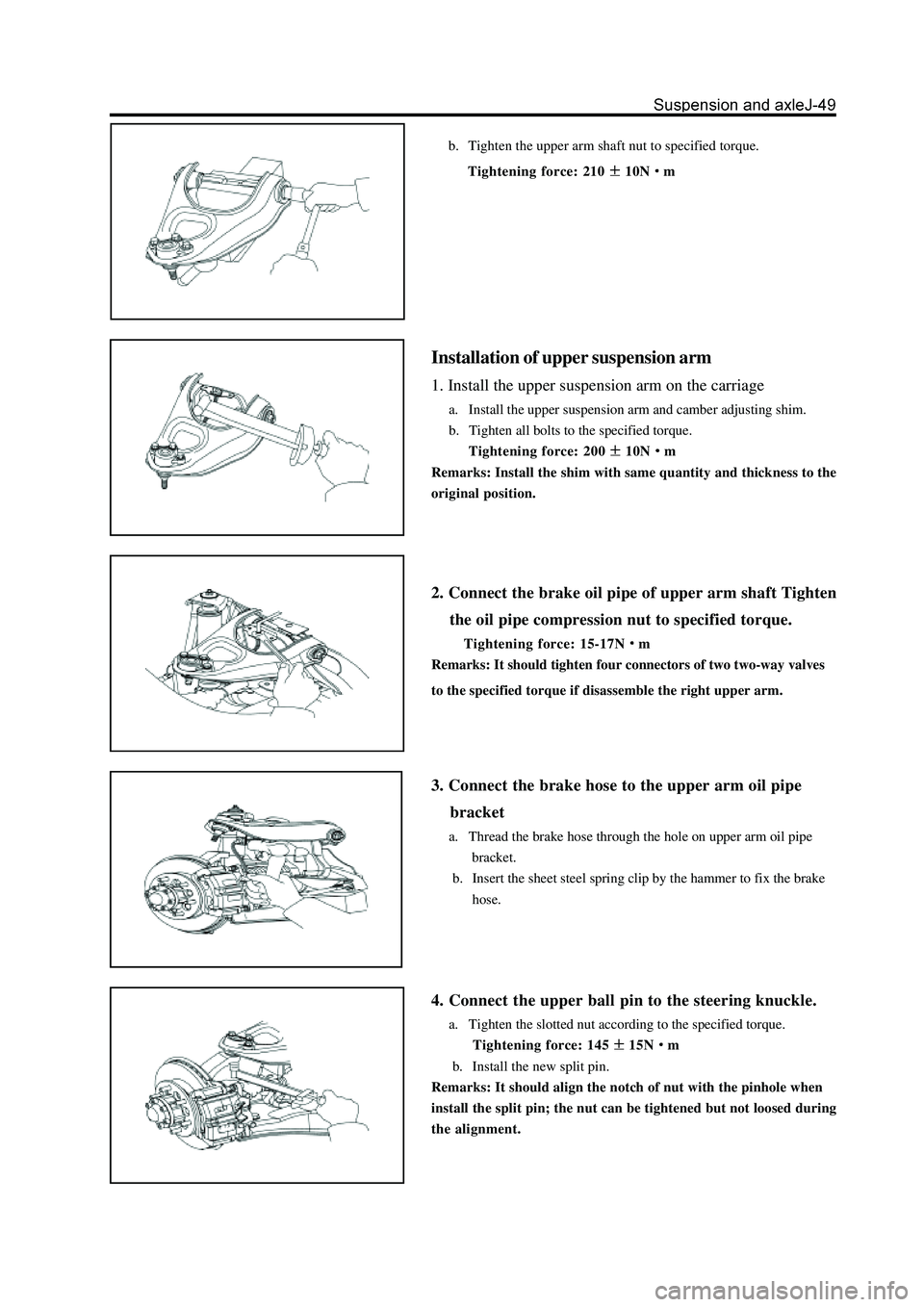

b. Tighten the upper arm shaft nut to specified torque.

Tightening force: 210

10Nm

Installation of upper suspension arm

1. Install the upper suspension arm on the carriage

a. Install the upper suspension arm and camber adjusting shim.

b. Tighten all bolts to the specified torque.

Tightening force: 200

10Nm

Remarks: Install the shim with same quantity and thickness to the

original position.

2. Connect the brake oil pipe of upper arm shaft Tighten

the oil pipe compression nut to specified torque.

Tightening force: 15-17Nm

Remarks: It should tighten four connectors of two two-way valves

to the specified torque if disassemble the right upper arm.

3. Connect the brake hose to the upper arm oil pipe

bracket

a. Thread the brake hose through the hole on upper arm oil pipe

bracket.

b. Insert the sheet steel spring clip by the hammer to fix the brake

hose.

4. Connect the upper ball pin to the steering knuckle.

a. Tighten the slotted nut according to the specified torque.

Tightening force: 145

15Nm

b. Install the new split pin.

Remarks: It should align the notch of nut with the pinhole when

install the split pin; the nut can be tightened but not loosed during

the alignment.

Page 284 of 425

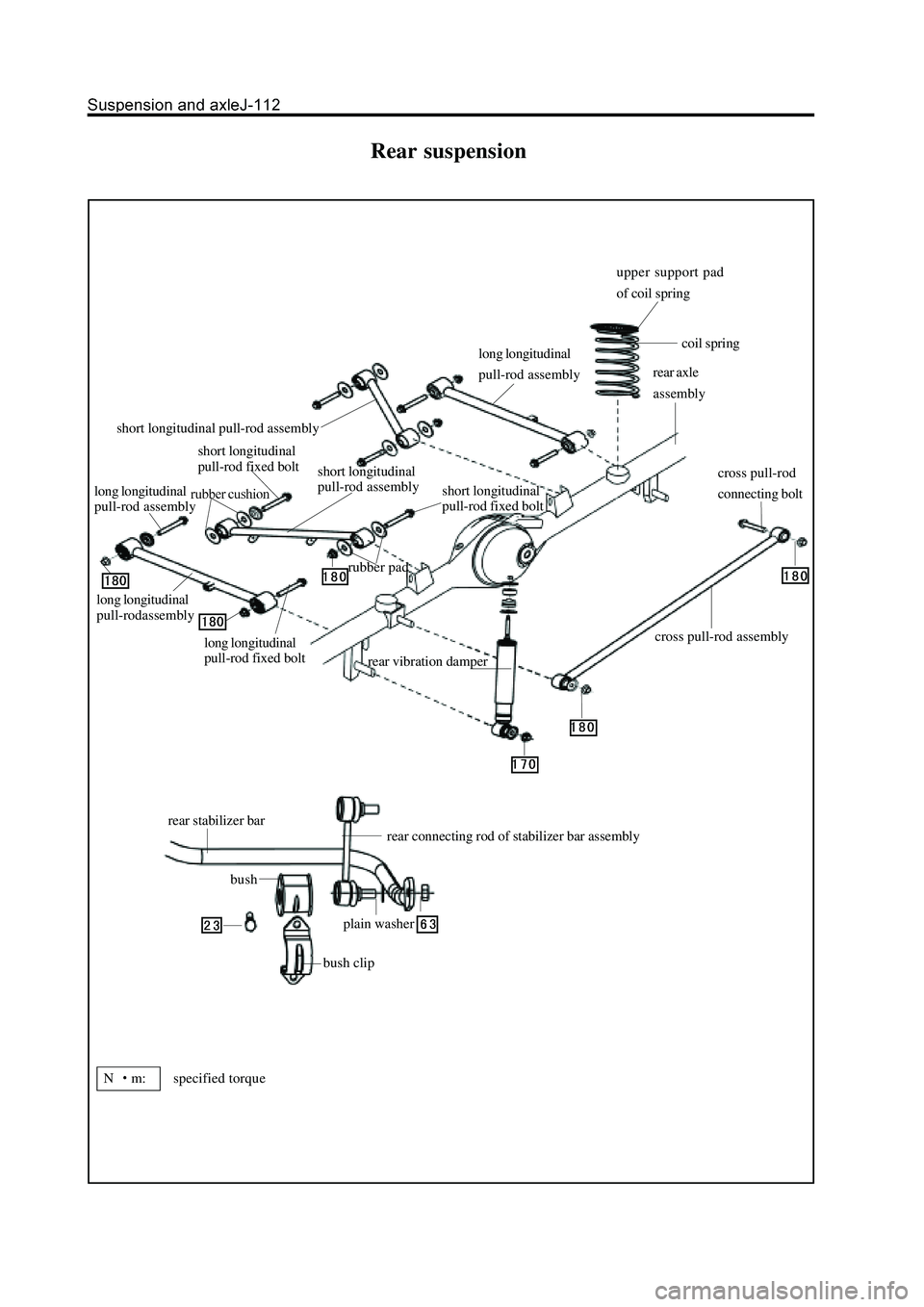

Rear suspension

N m: specified torque

bush clip

bush

rear stabilizer barrear connecting rod of stabilizer bar assembly

plain washer

short longitudinal

pull-rod fixed bolt

rubber padshort longitudinal

pull-rod fixed bolt

long longitudinal

pull-rod assembly

long longitudinal

pull-rod fixed bolt

long longitudinal

pull-rodassembly

short longitudinal

pull-rod assembly

rear axle

assembly

coil spring

upper support pad

of coil spring

short longitudinal pull-rod assembly

long longitudinal

pull-rod assembly

rear vibration damper

cross pull-rod assembly

cross pull-rod

connecting bolt

Page 316 of 425

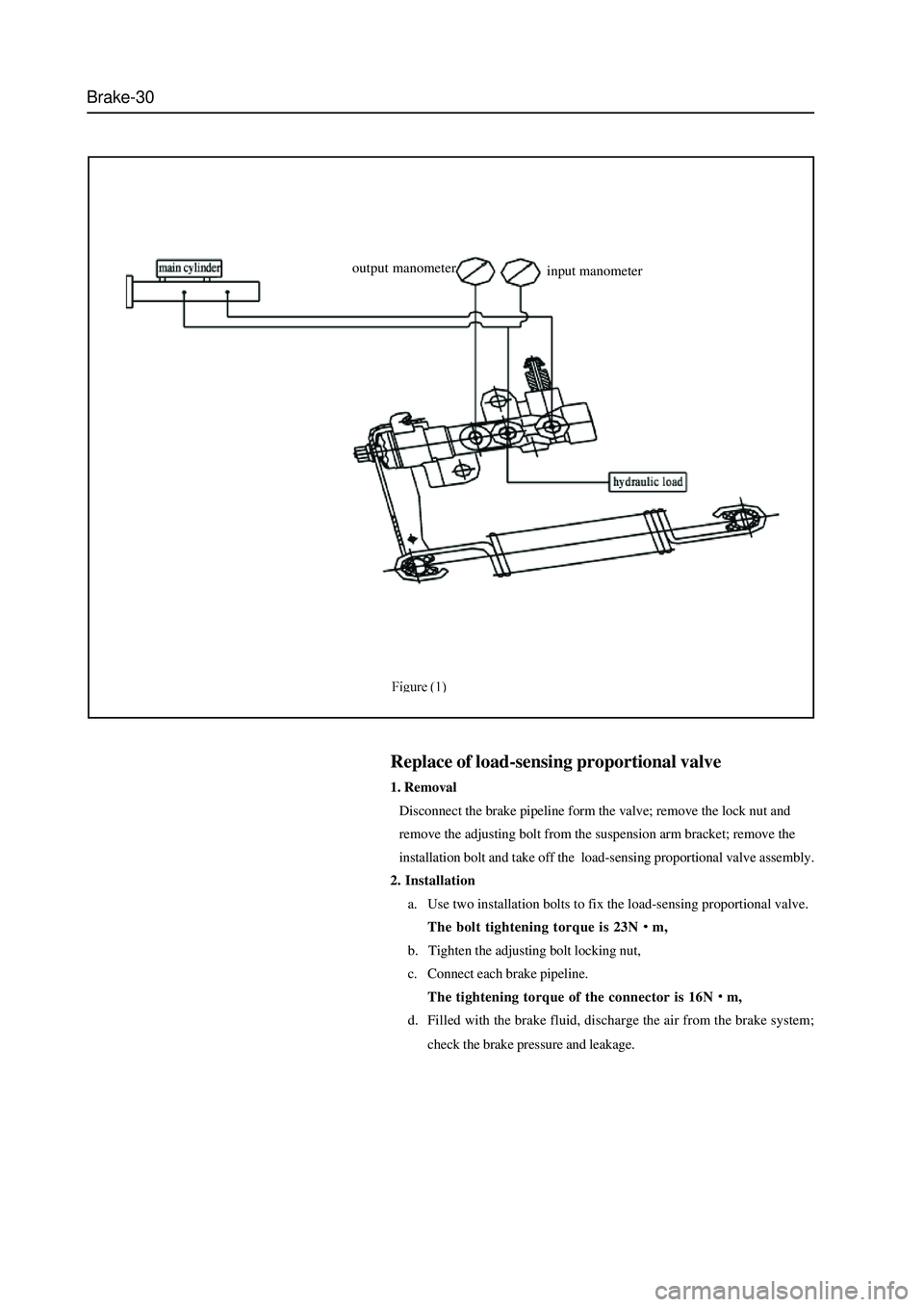

Brake-30

Replace of load-sensing proportional valve

1. Removal

Disconnect the brake pipeline form the valve; remove the lock nut and

remove the adjusting bolt from the suspension arm bracket; remove the

installation bolt and take off the load-sensing proportional valve assembly.

2. Installation

a. Use two installation bolts to fix the load-sensing proportional valve.

The bolt tightening torque is 23N

m,

b. Tighten the adjusting bolt locking nut,

c. Connect each brake pipeline.

The tightening torque of the connector is 16N

m,

d. Filled with the brake fluid, discharge the air from the brake system;

check the brake pressure and leakage. output manometer

input manometer

Page 409 of 425

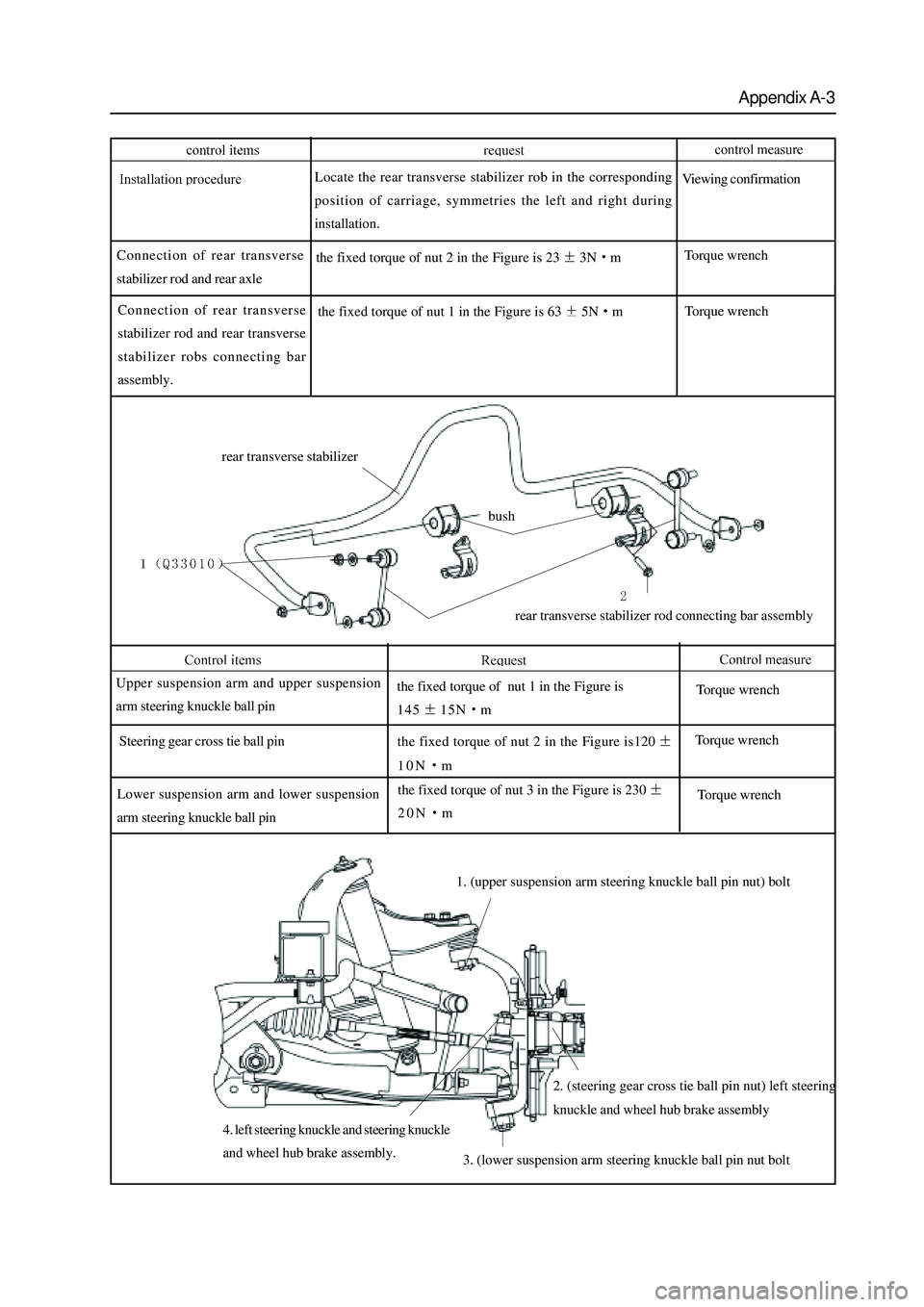

Appendix A-3

1. (upper suspension arm steering knuckle ball pin nut) bolt

Locate the rear transverse stabilizer rob in the corresponding

position of carriage, symmetries the left and right during

installation.

Connection of rear transverse

stabilizer rod and rear axleViewing confirmation

the fixed torque of nut 2 in the Figure is 23

3NmTorque wrench

Connection of rear transverse

stabilizer rod and rear transverse

stabilizer robs connecting bar

assembly.the fixed torque of nut 1 in the Figure is 63

5NmTorque wrench

rear transverse stabilizer

rear transverse stabilizer rod connecting bar assembly bush

Upper suspension arm and upper suspension

arm steering knuckle ball pin

Steering gear cross tie ball pin

Lower suspension arm and lower suspension

arm steering knuckle ball pinthe fixed torque of nut 1 in the Figure is

145

15Nm

the fixed torque of nut 2 in the Figure is120

10Nm

the fixed torque of nut 3 in the Figure is 230

20Nm

Torque wrench

Torque wrench

Torque wrench

2. (steering gear cross tie ball pin nut) left steering

knuckle and wheel hub brake assembly

3. (lower suspension arm steering knuckle ball pin nut bolt 4. left steering knuckle and steering knuckle

and wheel hub brake assembly.

Page 423 of 425

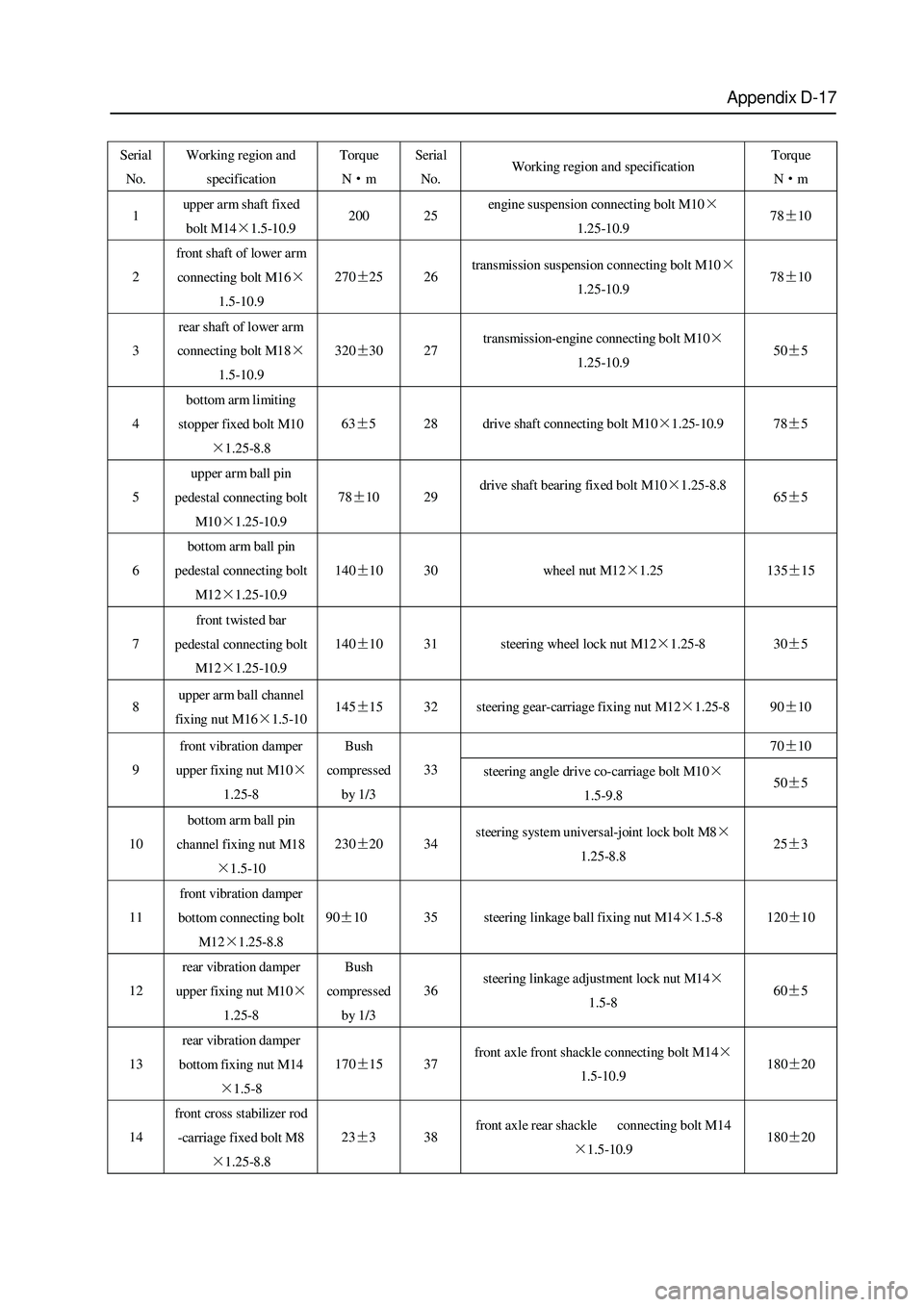

Appendix D-17

Serial

No. Working region and

specification Torque

N·m Serial

No. Working region and specification Torque

N·m

1 upper arm shaft fixed

bolt M14×1.5-10.9 200 25 engine suspension connecting bolt M10×

1.25-10.9 78±10

2 front shaft of lower arm

connecting bolt M16×

1.5-10.9 270±25 26 transmission suspension connecting bolt M10×

1.25-10.9 78±10

3 rear shaft of lower arm

connecting bolt M18×

1.5-10.9 320±30 27 transmission-engine connecting bolt M10×

1.25-10.9 50±5

4 b ottom ar m l imit ing

stopper fixed bolt M10

×1.25-8.8 63±5 28 drive shaft connecting bolt M10×1.25-10.9 78±5

5 upper arm ball pin

pedestal connecting bolt

M10×1.25-10.9 78±10 29 drive shaft bearing fixed bolt M10×1.25-8.8

65±5

6 bottom ar m ball p in

pedestal connecting bolt

M12×1.25-10.9 140±10 30 wheel nut M12×1.25 135±15

7 front twisted bar

pedestal connecting bolt

M12×1.25-10.9 140±10 31 steering wheel lock nut M12×1.25-8 30±5

8 upper arm ball channel

fixing nut M16×1.5-10 145±15 32 steering gear-carriage fixing nut M12×1.25-8 90±10

70±10

9 front vibration damper

upper fixing nut M10×

1.25-8 Bush

co mpr es sed

by 1/3 33

steering angle drive co-carriage bolt M10×

1.5-9.8 50±5

10 bottom ar m ball p in

channel fixing nut M18

×1.5-10 230±20 34 steering system universal-joint lock bolt M8×

1.25-8.8 25±3

11 front vibration damper

bottom connecting bolt

M12×1.25-8.8 90±10 35 steering linkage ball fixing nut M14×1.5-8 120±10

12 rear vibration damper

upper fixing nut M10×

1.25-8 Bush

co mpr es sed

by 1/3 36 steering linkage adjustment lock nut M14×

1.5-8 60±5

13 rear vibration damper

bottom fixing nut M14

×1.5-8 170±15 37 front axle front shackle connecting bolt M14×

1.5-10.9 180±20

14 front cross stabilizer rod

-carriage fixed bolt M8

×1.25-8.8 23±3 38 front axle rear shackle connecting bolt M14

×1.5-10.9 180±20

Page 424 of 425

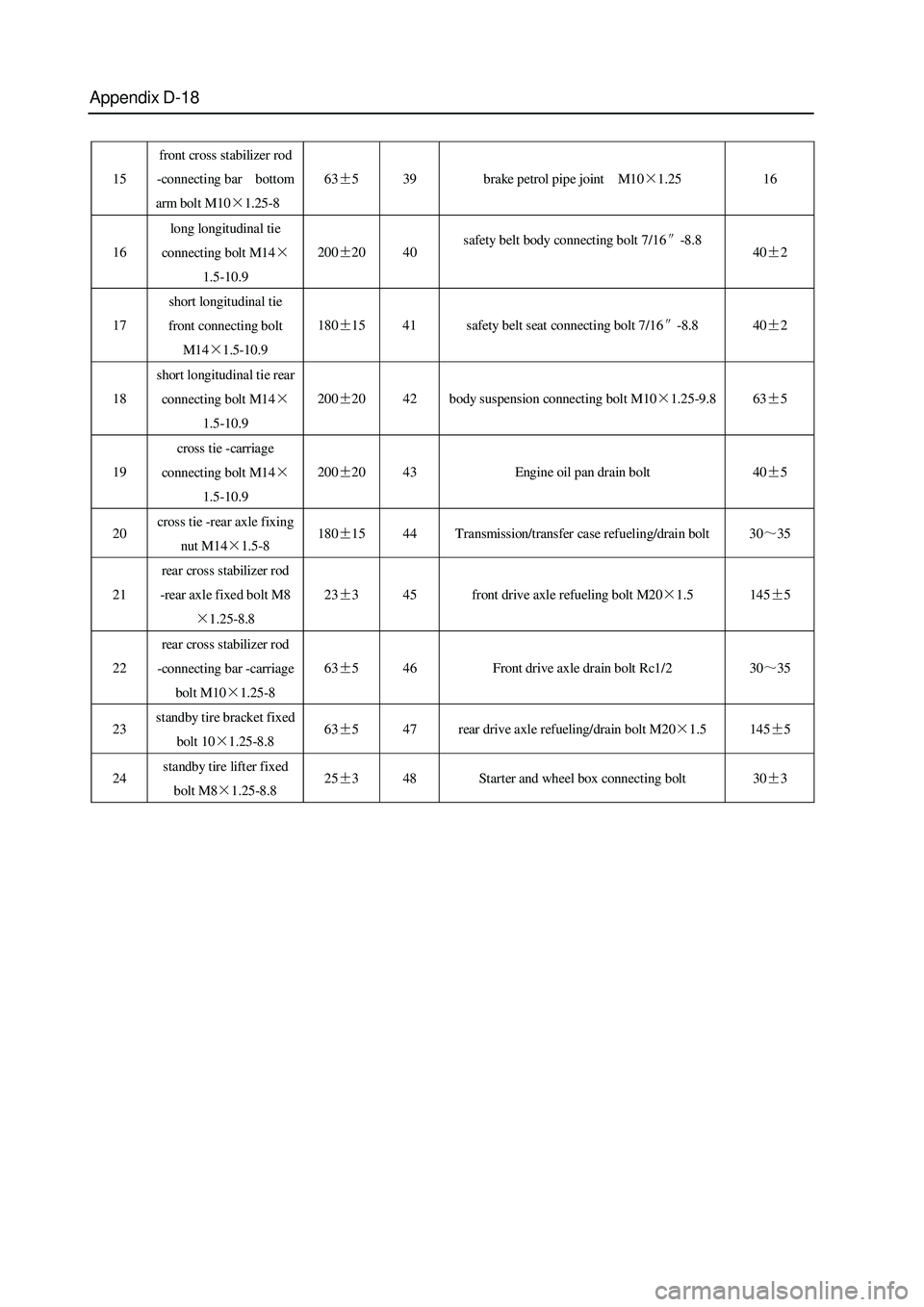

Appendix D-18

15 front cross stabilizer rod

-connecting bar bottom

arm bolt M10×1.25-8 63±5 39 brake petrol pipe joint M10×1.25 16

16 long longitudinal tie

connecting bolt M14×

1.5-10.9 200±20 40 safety belt body connecting bolt 7/16″-8.8

40±2

17 short longitudinal tie

front connecting bolt

M14×1.5-10.9 180±15 41 safety belt seat connecting bolt 7/16″-8.8 40±2

18 short longitudinal tie rear

connecting bolt M14×

1.5-10.9 200±20 42 body suspension connecting bolt M10×1.25-9.8 63±5

19 cross tie -carriage

connecting bolt M14×

1.5-10.9 200±20 43 Engine oil pan drain bolt 40±5

20 cross tie -rear axle fixing

nut M14×1.5-8 180±15 44 Transmission/transfer case refueling/drain bolt 30~35

21 rear cross stabilizer rod

-rear axle fixed bolt M8

×1.25-8.8 23±3 45 front drive axle refueling bolt M20×1.5 145±5

22 rear cross stabilizer rod

-connecting bar -carriage

bolt M10×1.25-8 63±5 46 Front drive axle drain bolt Rc1/2 30~35

23 standby tire bracket fixed

bolt 10×1.25-8.8 63±5 47 rear drive axle refueling/drain bolt M20×1.5 145±5

24 standby tire lifter fixed

bolt M8×1.25-8.8 25±3 48 Starter and wheel box connecting bolt 30±3