suspension GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 187 of 425

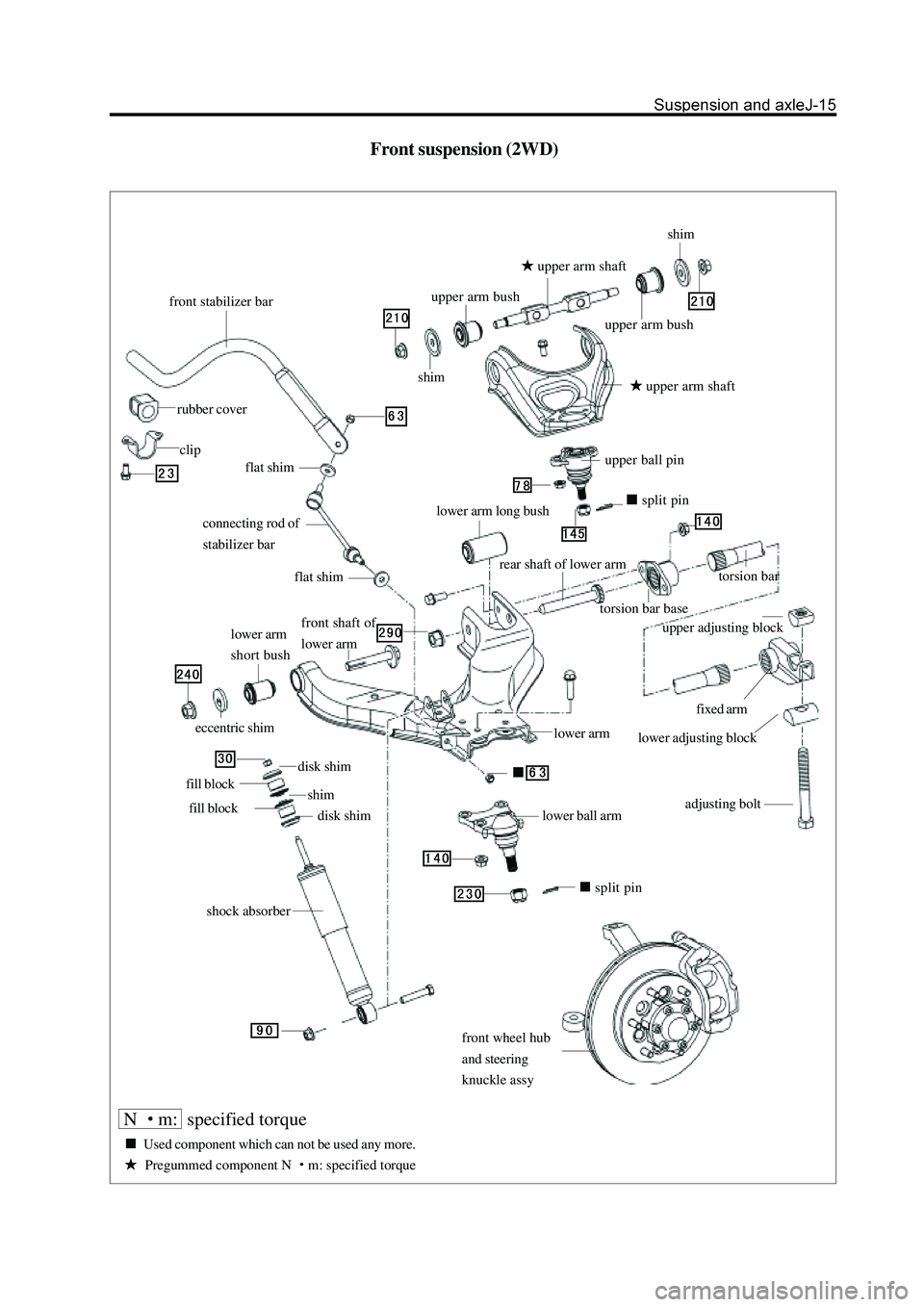

Front suspension (2WD)

front stabilizer bar

rubber cover

clip

connecting rod of

stabilizer bar

flat shim

front shaft of

lower arm

split pin

adjusting bolt

lower adjusting block

fixed arm

upper adjusting block

lower arm

rear shaft of lower arm

torsion bar base

torsion bar

lower arm long bushsplit pin

upper ball pin

upper arm shaft

upper arm bush

flat shim

lower arm

short bush

eccentric shim

disk shim

fill block

fill block

disk shim shim

shock absorbershimshim

upper arm bush

upper arm shaft

lower ball arm

front wheel hub

and steering

knuckle assy

N m: specified torque

Used component which can not be used any more.

Pregummed component N m: specified torque

Page 191 of 425

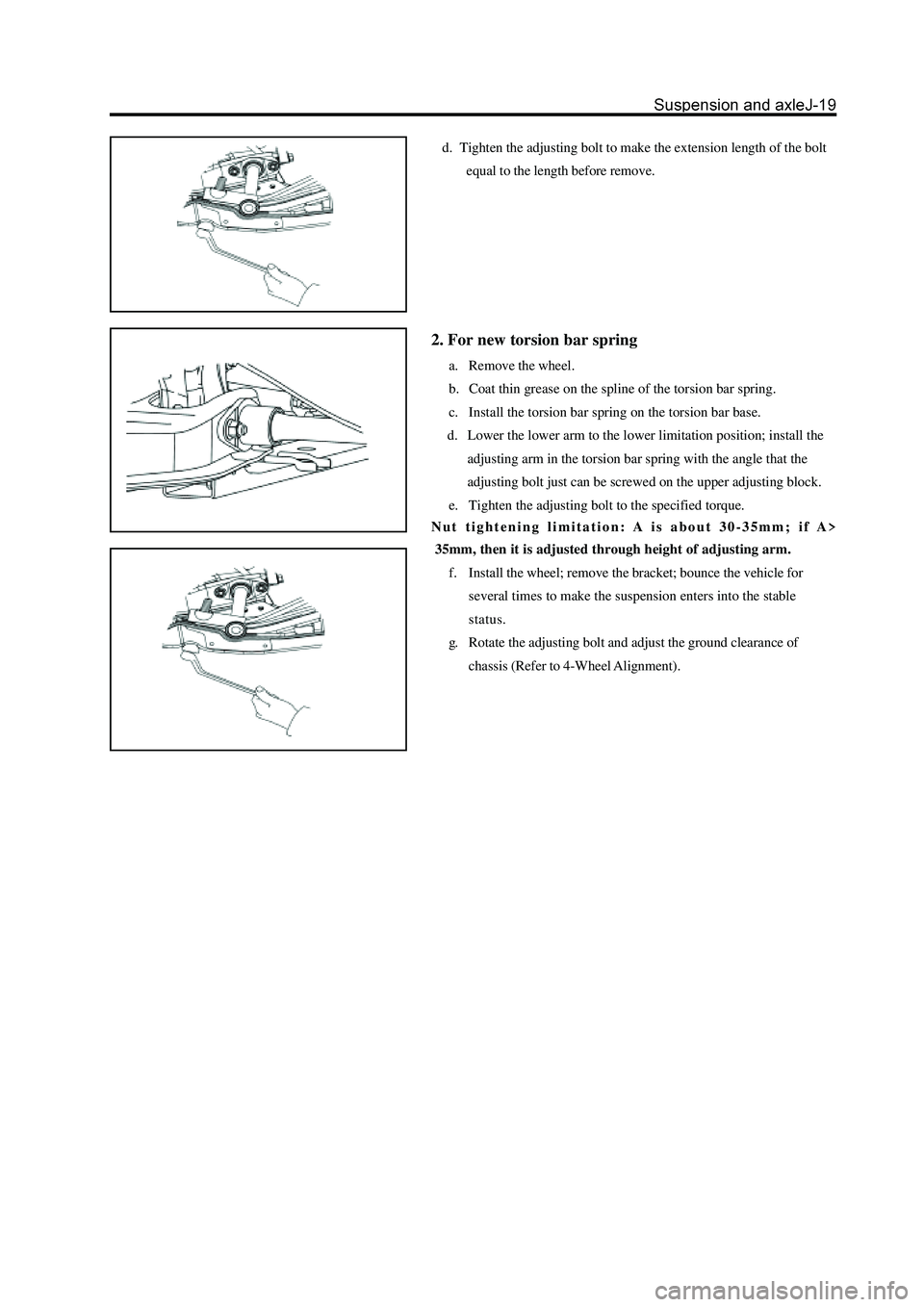

d. Tighten the adjusting bolt to make the extension length of the bolt

equal to the length before remove.

2. For new torsion bar spring

a. Remove the wheel.

b. Coat thin grease on the spline of the torsion bar spring.

c. Install the torsion bar spring on the torsion bar base.

d. Lower the lower arm to the lower limitation position; install the

adjusting arm in the torsion bar spring with the angle that the

adjusting bolt just can be screwed on the upper adjusting block.

e. Tighten the adjusting bolt to the specified torque.

Nut tightening limitation: A is about 30-35mm; if A>

35mm, then it is adjusted through height of adjusting arm.

f. Install the wheel; remove the bracket; bounce the vehicle for

several times to make the suspension enters into the stable

status.

g. Rotate the adjusting bolt and adjust the ground clearance of

chassis (Refer to 4-Wheel Alignment).

Page 192 of 425

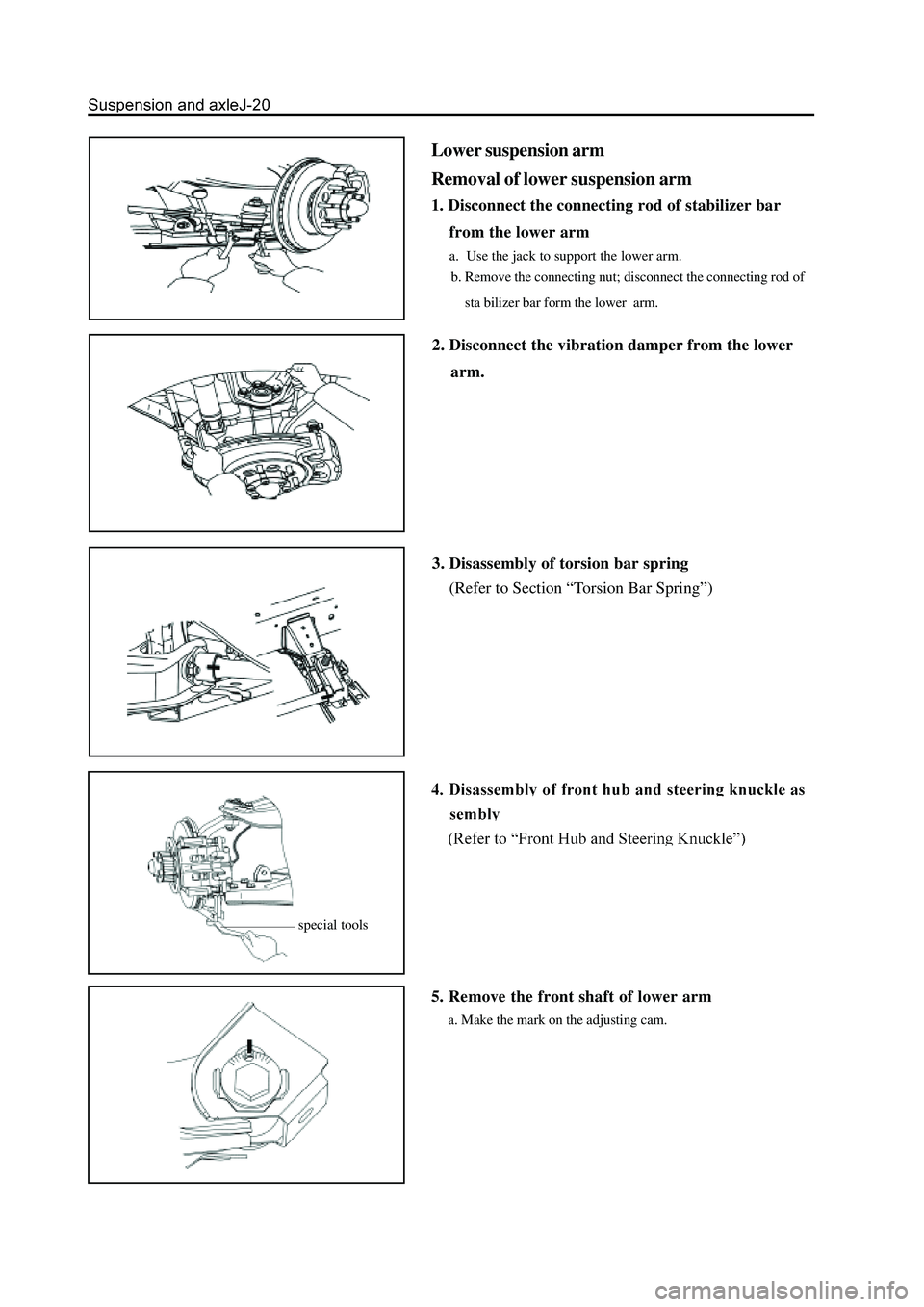

2. Disconnect the vibration damper from the lower

arm.

3. Disassembly of torsion bar spring

(Refer to Section “Torsion Bar Spring”)

Lower suspension arm

Removal of lower suspension arm

1. Disconnect the connecting rod of stabilizer bar

from the lower arm

a. Use the jack to support the lower arm.

b. Remove the connecting nut; disconnect the connecting rod of

sta bilizer bar form the lower arm.

5. Remove the front shaft of lower arm

a. Make the mark on the adjusting cam.

special tools

Page 193 of 425

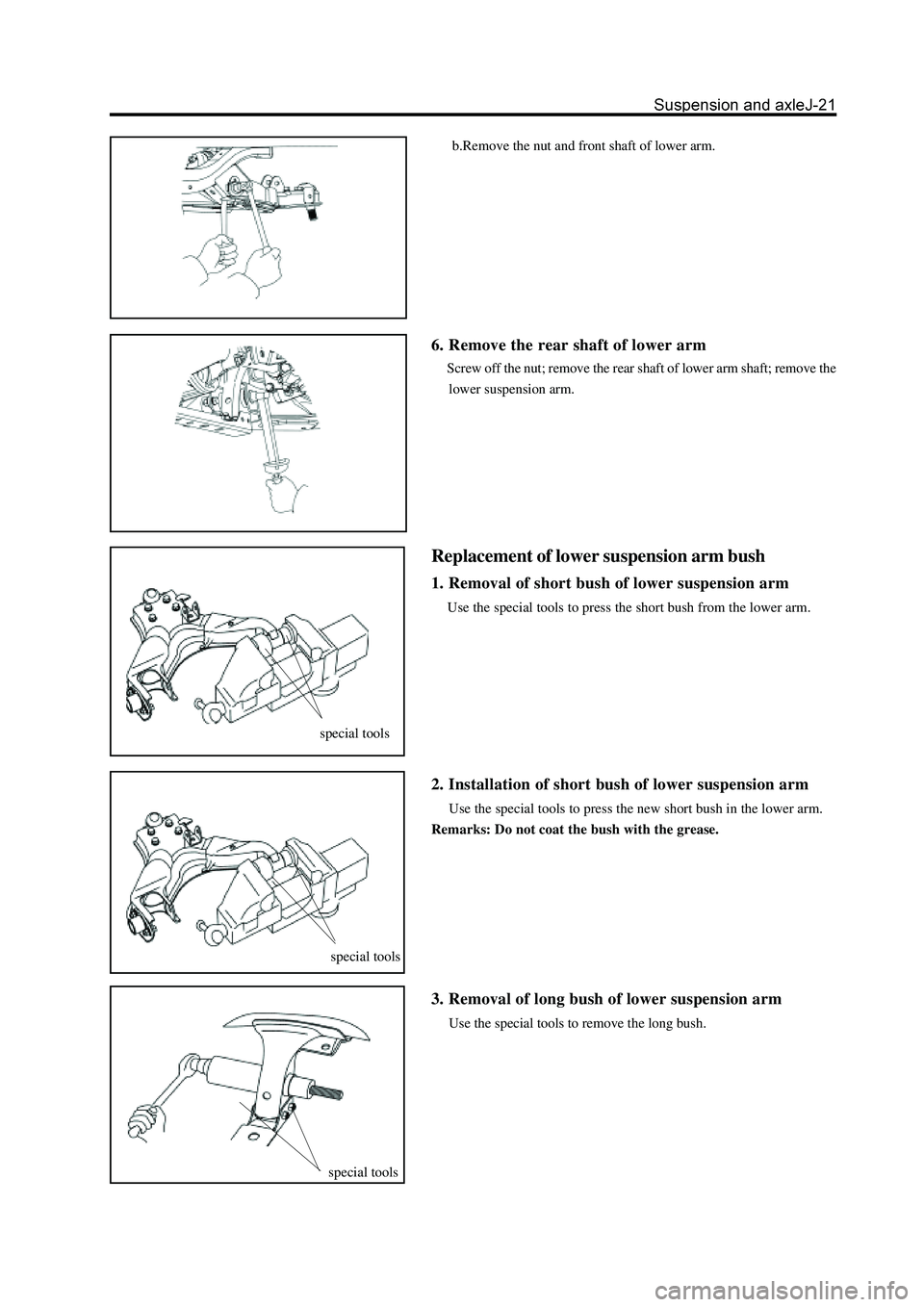

b.Remove the nut and front shaft of lower arm.

6. Remove the rear shaft of lower arm

Screw off the nut; remove the rear shaft of lower arm shaft; remove the

lower suspension arm.

Replacement of lower suspension arm bush

1. Removal of short bush of lower suspension arm

Use the special tools to press the short bush from the lower arm.

2. Installation of short bush of lower suspension arm

Use the special tools to press the new short bush in the lower arm.

Remarks: Do not coat the bush with the grease.

special tools

special tools

3. Removal of long bush of lower suspension arm

Use the special tools to remove the long bush.

special tools

Page 194 of 425

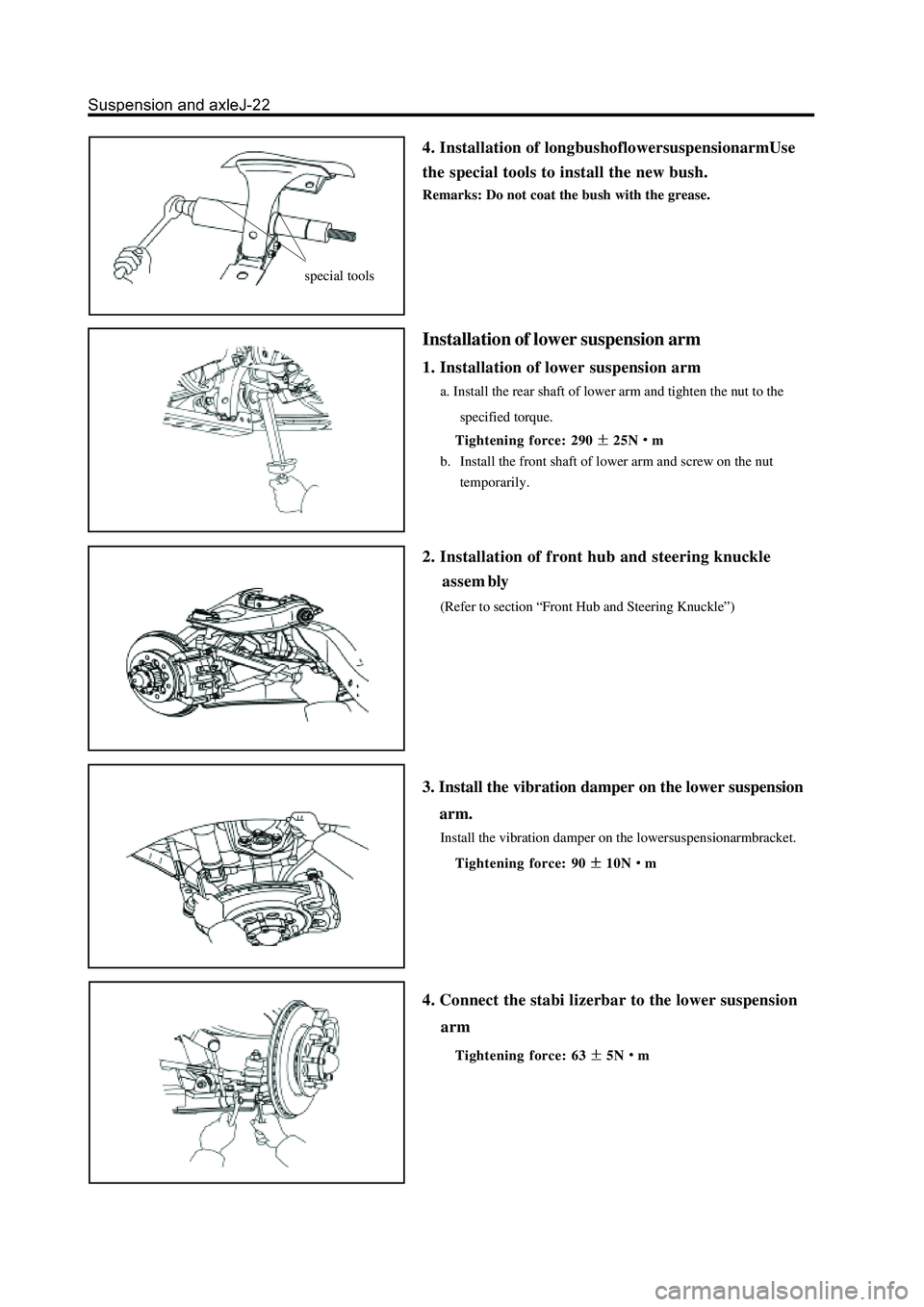

4. Installation of longbushoflowersuspensionarmUse

the special tools to install the new bush.

Remarks: Do not coat the bush with the grease.

Installation of lower suspension arm

1. Installation of lower suspension arm

a. Install the rear shaft of lower arm and tighten the nut to the

specified torque.

Tightening force: 290

25Nm

b. Install the front shaft of lower arm and screw on the nut

temporarily.

2. Installation of front hub and steering knuckle

assem bly

(Refer to section “Front Hub and Steering Knuckle”)

3. Install the vibration damper on the lower suspension

arm.

Install the vibration damper on the lowersuspensionarmbracket.

Tightening force: 90

10Nm

4. Connect the stabi lizerbar to the lower suspension

arm

Tightening force: 635Nm

special tools

Page 196 of 425

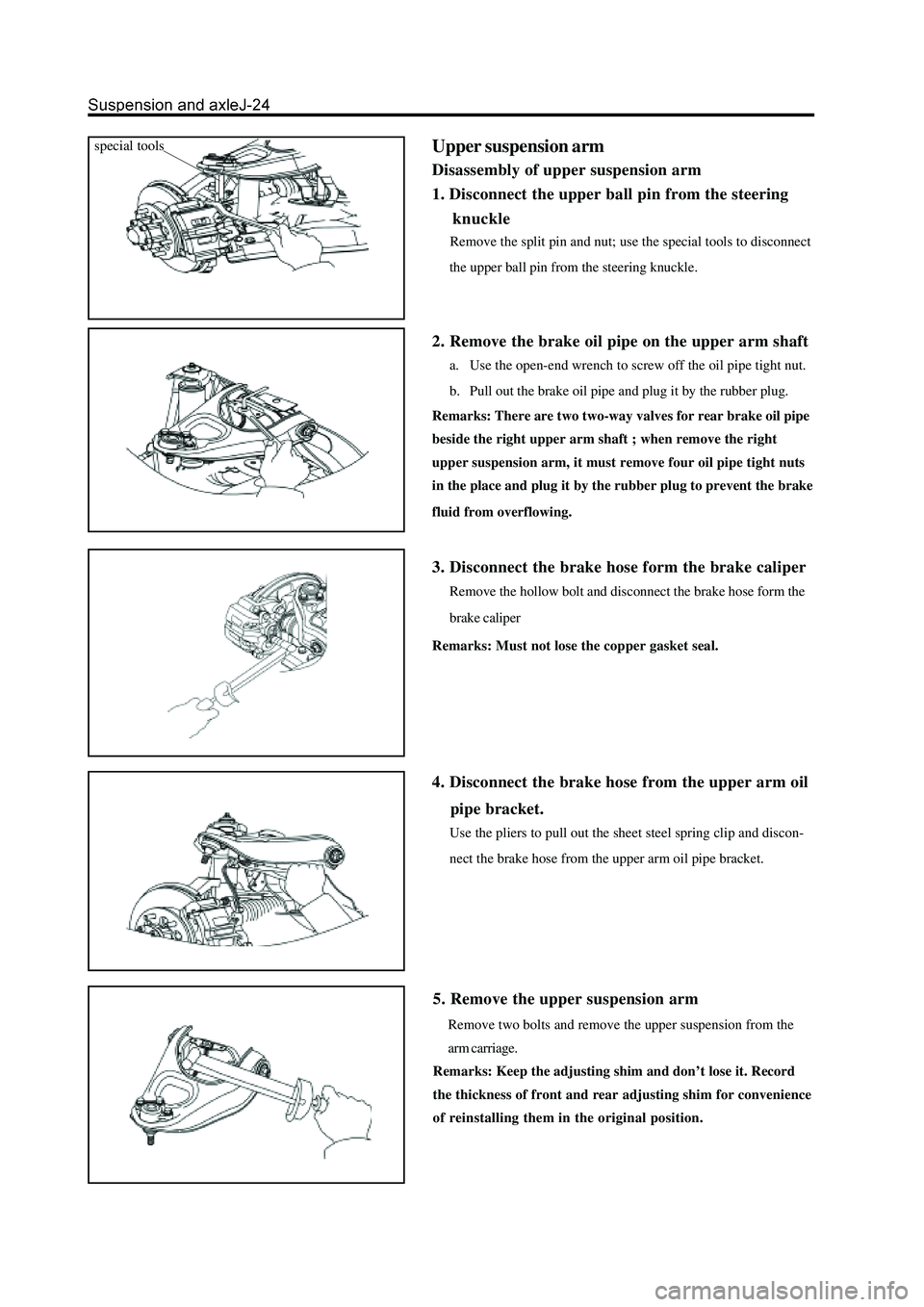

special toolsUpper suspension arm

Disassembly of upper suspension arm

1. Disconnect the upper ball pin from the steering

knuckle

Remove the split pin and nut; use the special tools to disconnect

the upper ball pin from the steering knuckle.

2. Remove the brake oil pipe on the upper arm shaft

a. Use the open-end wrench to screw off the oil pipe tight nut.

b. Pull out the brake oil pipe and plug it by the rubber plug.

Remarks: There are two two-way valves for rear brake oil pipe

beside the right upper arm shaft ; when remove the right

upper suspension arm, it must remove four oil pipe tight nuts

in the place and plug it by the rubber plug to prevent the brake

fluid from overflowing.

3. Disconnect the brake hose form the brake caliper

Remove the hollow bolt and disconnect the brake hose form the

brake caliper

Remarks: Must not lose the copper gasket seal.

4. Disconnect the brake hose from the upper arm oil

pipe bracket.

Use the pliers to pull out the sheet steel spring clip and discon-

nect the brake hose from the upper arm oil pipe bracket.

5. Remove the upper suspension arm

Remove two bolts and remove the upper suspension from the

arm carriage.

Remarks: Keep the adjusting shim and don’t lose it. Record

the thickness of front and rear adjusting shim for convenience

of reinstalling them in the original position.

Page 198 of 425

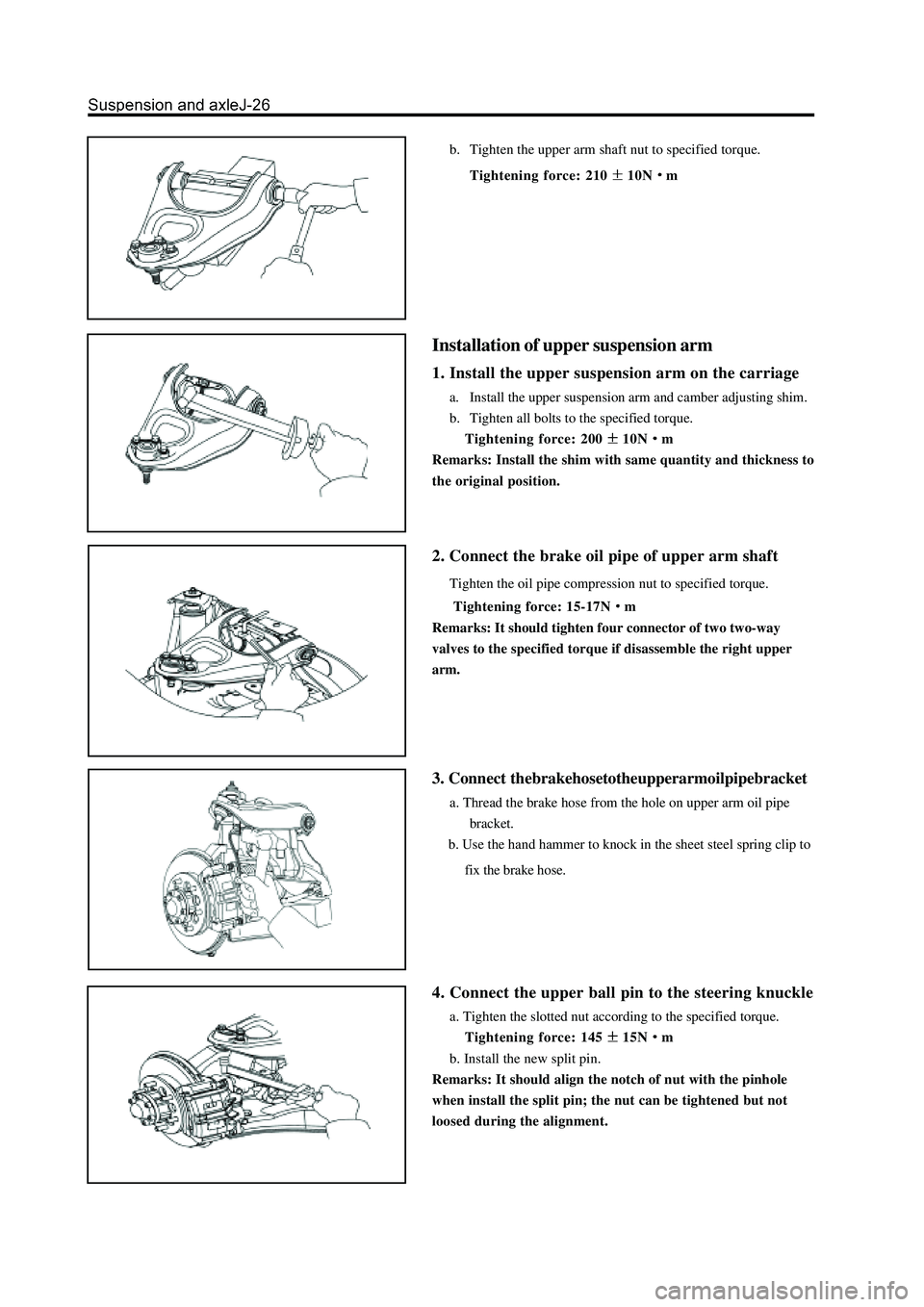

b. Tighten the upper arm shaft nut to specified torque.

Tightening force: 210

10Nm

Installation of upper suspension arm

1. Install the upper suspension arm on the carriage

a. Install the upper suspension arm and camber adjusting shim.

b. Tighten all bolts to the specified torque.

Tightening force: 200

10Nm

Remarks: Install the shim with same quantity and thickness to

the original position.

2. Connect the brake oil pipe of upper arm shaft

Tighten the oil pipe compression nut to specified torque.

Tightening force: 15-17N

m

Remarks: It should tighten four connector of two two-way

valves to the specified torque if disassemble the right upper

arm.

3. Connect thebrakehosetotheupperarmoilpipebracket

a. Thread the brake hose from the hole on upper arm oil pipe

bracket.

b. Use the hand hammer to knock in the sheet steel spring clip to

fix the brake hose.

4. Connect the upper ball pin to the steering knuckle

a. Tighten the slotted nut according to the specified torque.

Tightening force: 145

15Nm

b. Install the new split pin.

Remarks: It should align the notch of nut with the pinhole

when install the split pin; the nut can be tightened but not

loosed during the alignment.

Page 201 of 425

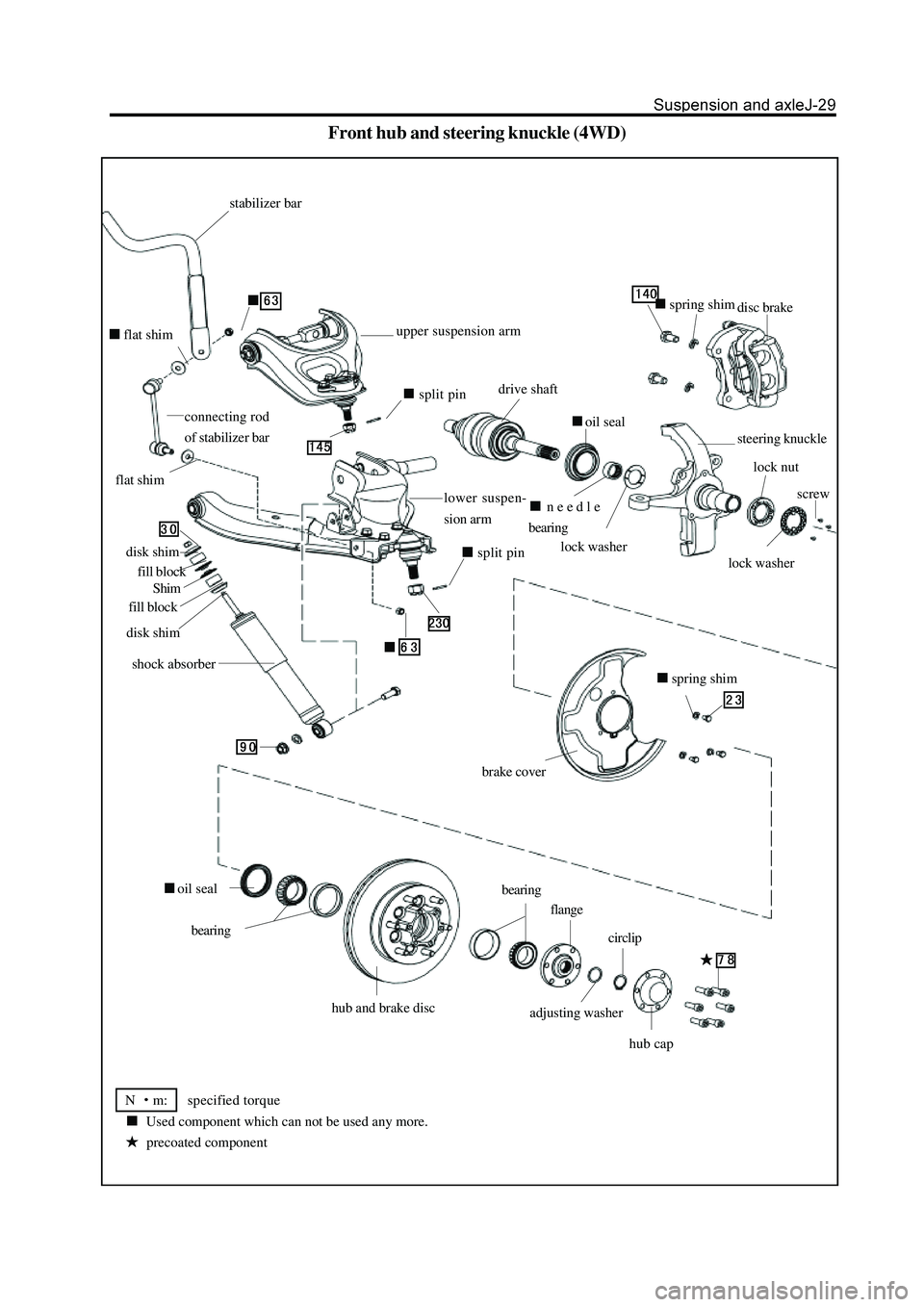

N m: specified torque

Used component which can not be used any more.

precoated component

Front hub and steering knuckle (4WD)

stabilizer bar

flat shim

connecting rod

of stabilizer bar

hub and brake disc

flange

adjusting washer

circlip

hub cap

spring shimdisc brake

split pin

lower suspen-

sion arm

split pin

upper suspension arm

drive shaft

oil seal

needle

bearing

lock washer

steering knuckle

lock nut

lock washer

screw

brake cover

spring shim

flat shim

disk shimShim

fill blockfill block disk shim

oil seal

bearingbearing shock absorber

Page 210 of 425

clip

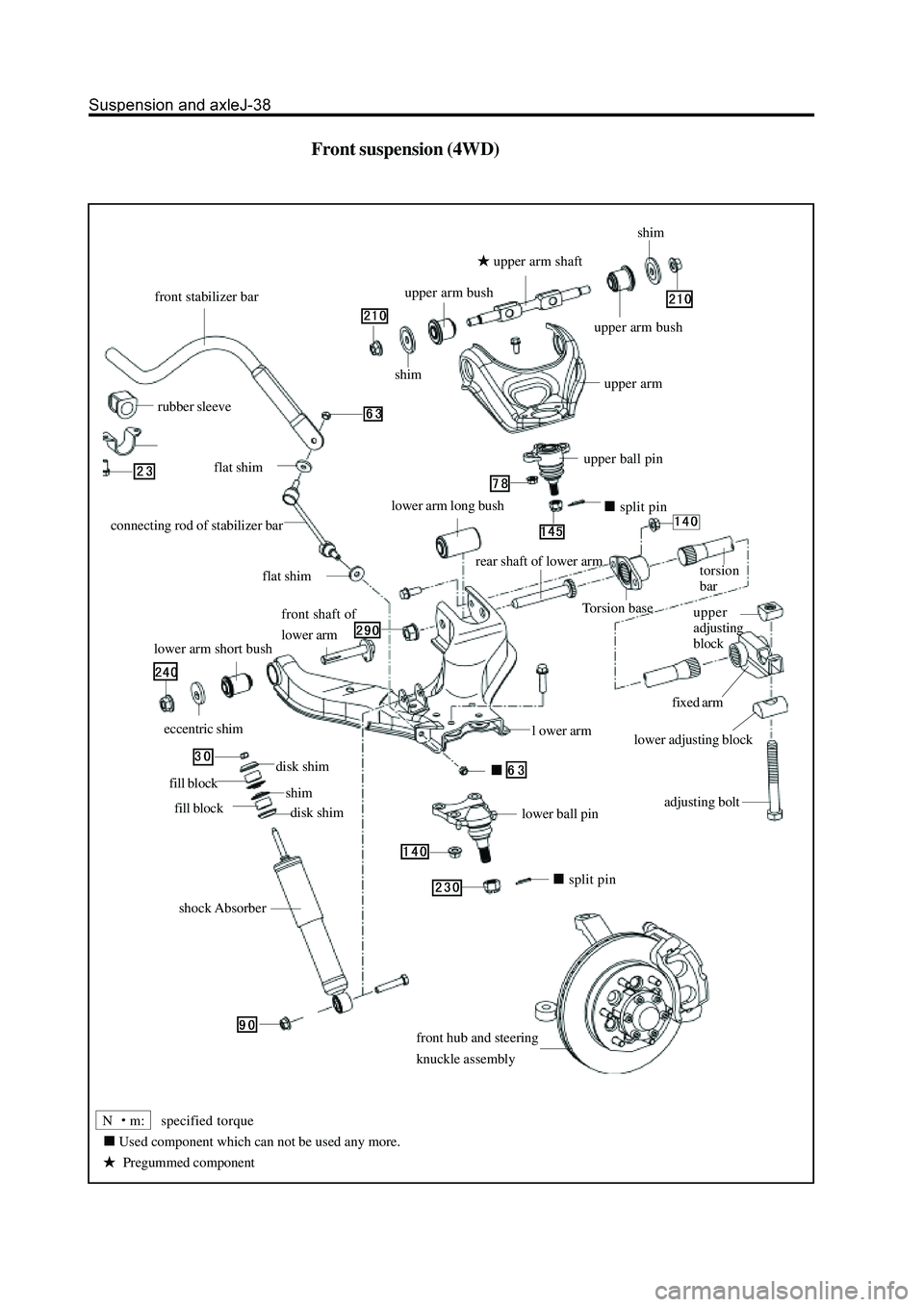

Front suspension (4WD)

N m: specified torque

Used component which can not be used any more.

Pregummed component

rubber sleeve

front shaft of

lower arm

disk shim

fill blockshimfill blockdisk shim

shock Absorber

front hub and steering

knuckle assembly

split pin

lower ball pinadjusting bolt

lower adjusting block

fixed arm

upper

adjusting

block

l ower arm

rear shaft of lower arm

Torsion base

torsion

bar

lower arm long bushsplit pin

upper ball pin

upper arm

shim

upper arm bush

upper arm shaft

upper arm bush

shim

front stabilizer bar

flat shim

connecting rod of stabilizer bar

flat shim

lower arm short bush

eccentric shim

Page 214 of 425

d. Tighten the adjusting bolt and make the extension length of the

bolt equal to the value before disassembly.

2. For new torsion bar spring

a. Remove the wheel.

b. Coat the spline of torsion bar spring with thin grease.

c. Install the torsion bar spring on the torsion bar base.

d. Lower the lower arm to the lower limitation position; install

the adjusting arm in the torsion bar spring with the angle that

the adjusting bolt just can be screwed on the upper adjusting

block.

Remarks: It can repeat for several times until proper when

adjust the angle.

e. Tighten the adjusting bolt to the specified torque.

Nut tightening limitation: A is about 20-35mm; if A>35mm,

then it is adjusted through height of adjusting arm.

f. Install the wheel; remove the bracket; bounce the vehicle for

several times to make the suspension enters into the stable

status.

g. Rotate the adjusting bolt and adjust the ground clearance of

chassis (Refer to 4-Wheel Alignment).