automatic transmission GREAT WALL HOVER 2006 Service Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 115 of 425

Automatic transmission-39

Power transmission locking of automatic and manual 3rd-Gear

When the automatic 3rd-Gear and manual 3rd-Gear is locked, the drive of transmission is basically same as that in automatic 3rd-

Gear. But it provide the variable torque drive without slide for the application of torque converter locking clutch.

Control:

The control for the automatic 3

rd-Gear locking and manual 3rd-Gear locking is basically same as that for automatic 3rd –Gear. But

it should be described additionally that the automatic 3

rd-Gear and manual 3rd-gear locking needs the action for variable torque

clutch loop by solenoid valve S7.

When the solenoid valve S7 is opened, the variable torque clutch control valve is closed and allow the oil feed of S7 loop pass

through the solenoid valve S7 to drainage port. It makes the control valve moves to the clutch combination position.

The loop oil from the line 500 flows into the combination part of variable torque clutch through the converter clutch control

valve through the action of variable torque clutch control valve.

The variable torque clutch release oil is drained from the variable torque clutch control valve.

The torque converter loop oil flows into the oil cooler and lubrication loop through the variable clutch control valve.

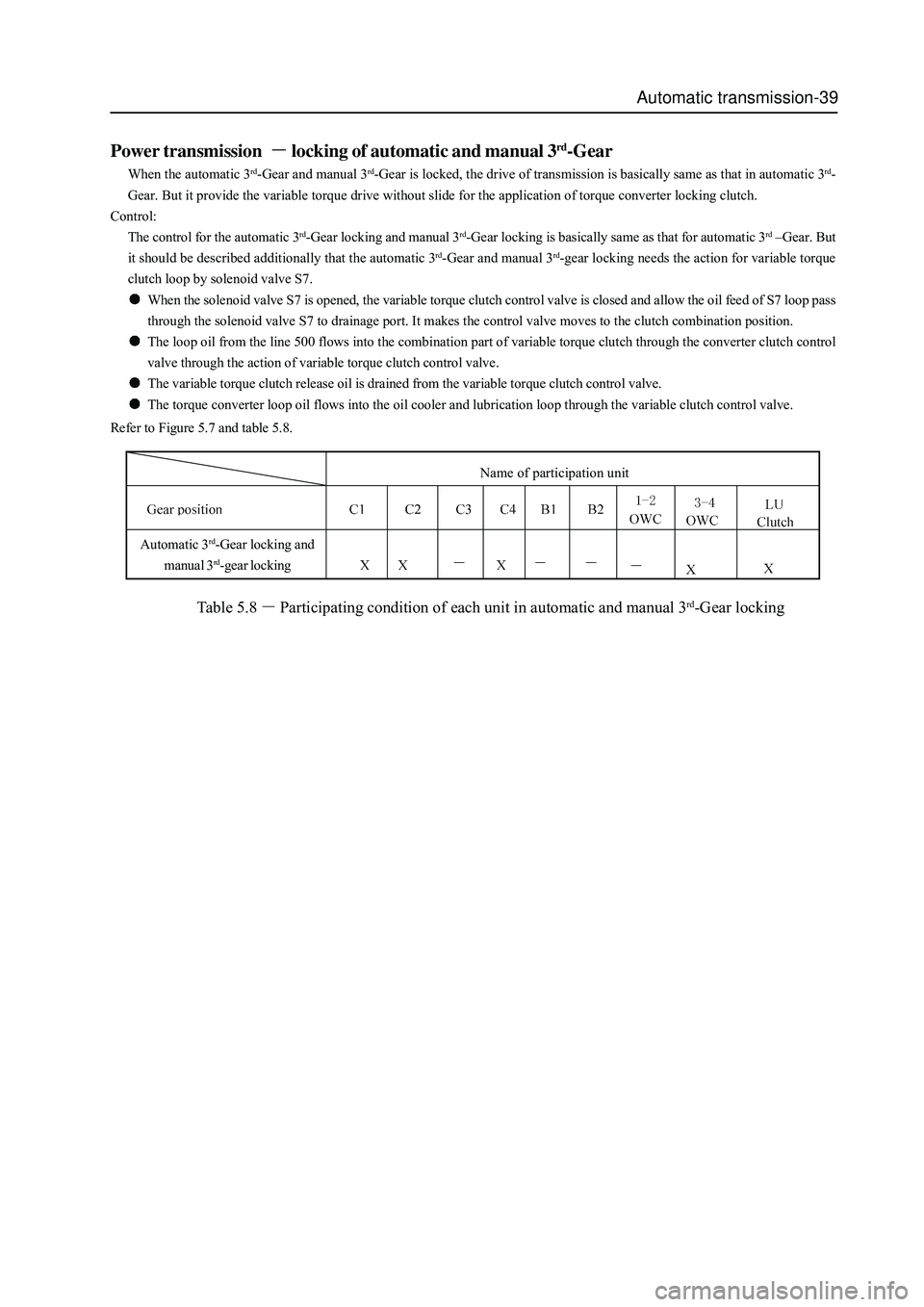

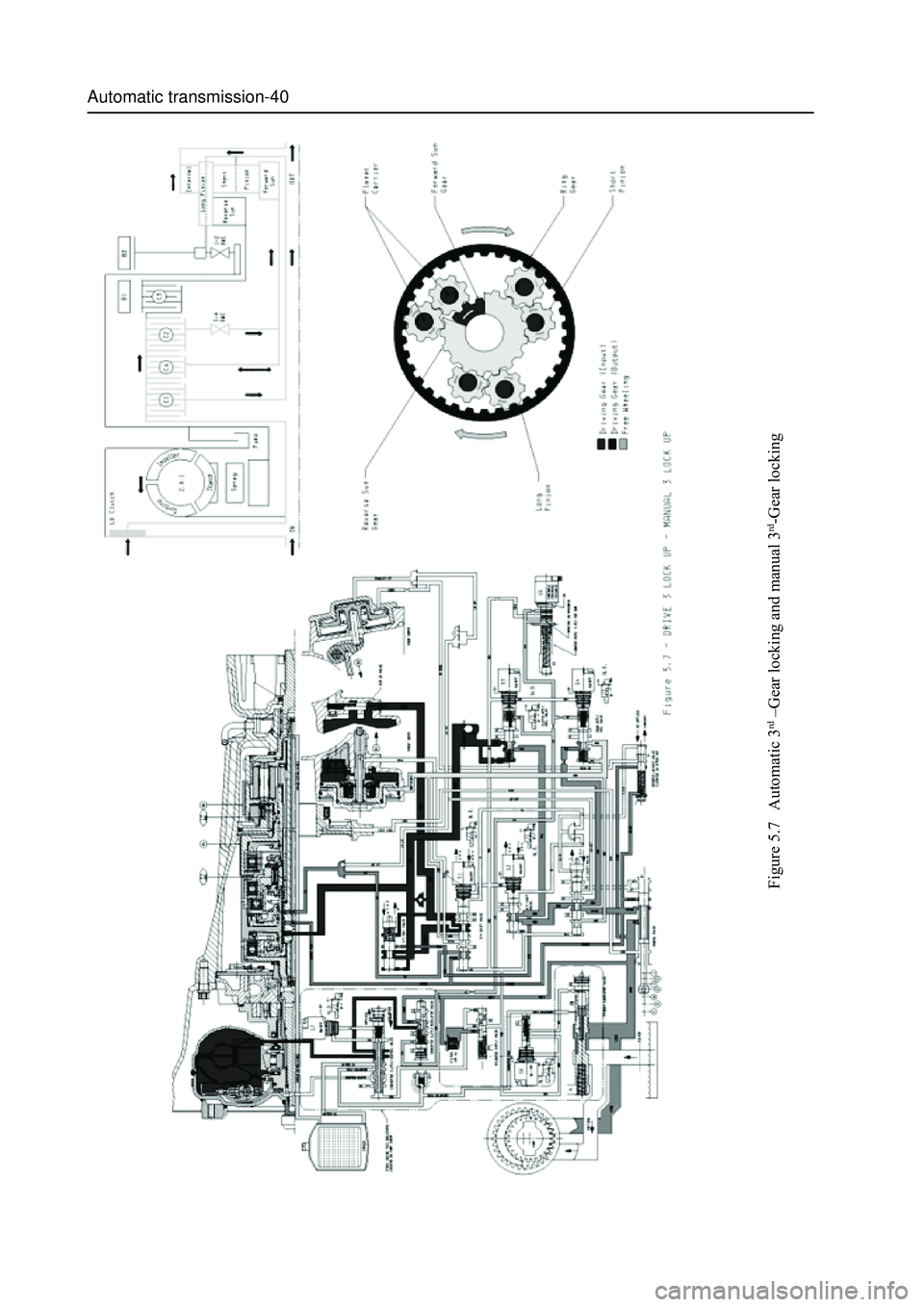

Refer to Figure 5.7 and table 5.8.

Table 5.8Participating condition of each unit in automatic and manual 3rd-Gear locking

Automatic 3rd-Gear locking and

manual 3

rd-gear locking

Name of participation unit

Page 116 of 425

Automatic transmission-40

Figure 5.7 Automatic 3

rd –Gear locking and manual 3

rd-Gear locking

Page 117 of 425

Automatic transmission-41

In automatic 4th-Gear (overspeed gear), the drive of transmission is sent to the front clutch cylinder through the input shaft. The

operation principle of each function assembly of transmission is shown as follows:

The engagement of clutch C1 drives the planetary gear carrier rotates in clockwise rotation.

The engagement of B1 brake belt makes the reverse sun gear to stop.

When the planetary gear carrier rotates, the long planetary gear rotates around the static reverse sun gear, at the same time, it

rotates around its axial line to drive the gear ring and output shaft to generate the forward movement in the speed higher than

that of input shaft (i.e. overspeed) clockwise.

The forward central gear rotates in the speed higher than input shaft and is more than the speed when 3-4 one-way clutch

(OWC) is engaged.

The engagement of clutch C2 is used to reduce the speed difference generated by 3-4 one-way clutch (OWC).

Control:

In the stable status, the status of solenoid valve and valve is shown as follows:

The solenoid valve S1 is powered on ; S2 is powered off.

When the solenoid valve S1 is powered on, the small end of 3-4 shift valve is in 4th-Gear position for the pressure of line 500.

When the solenoid valve S2 is powered off, the large opening of 2-3 shifting valve is in 4th- Gear position for the pressure of

line 500.

The 1-2 Gear shifting valve is kept in 4th-Gear position for the pressure of S2 oil loop.

The 2nd-Gear loop oil (line pressure) from the 1-2 shift valve flows into the brake belt combination regulating valve and 2-3

shift valve directly.

The brake belt combination regulating valve provides the 2nd-Gear loop oil for the brake belt attachment loop (BAF) (adjusted

by product of line pressure and valve ratio)

The brake belt combination lip oil is directly supplied to:

External combination part of front servo

Enter into the internal combination part of front servo piston through 3-4 shift valve

The 1st-Gear-2 switch valve provides a oil-drain port when the transmission is switched to 1st-Gear.

The 2nd-Gear loop oil in 2-3shift valve flows into the 3rd-Gear loop directly.

The 3rd-Gear loop oil from the 2-3 shift valve flows into the clutch combination regulating valve and 4th-Gear-3 sequence

valve directly

The clutch combination regulator valve supplies the oil for the clutch combination loop (CAF) (Regulated by the product of

line pressure and valve rate)

CAF oil is directly supplied to:

clutch C1

4th-Gear-3 sequence valve

The drive oil(line pressure) form the manual-operated valve forces the engagement of clutch C2

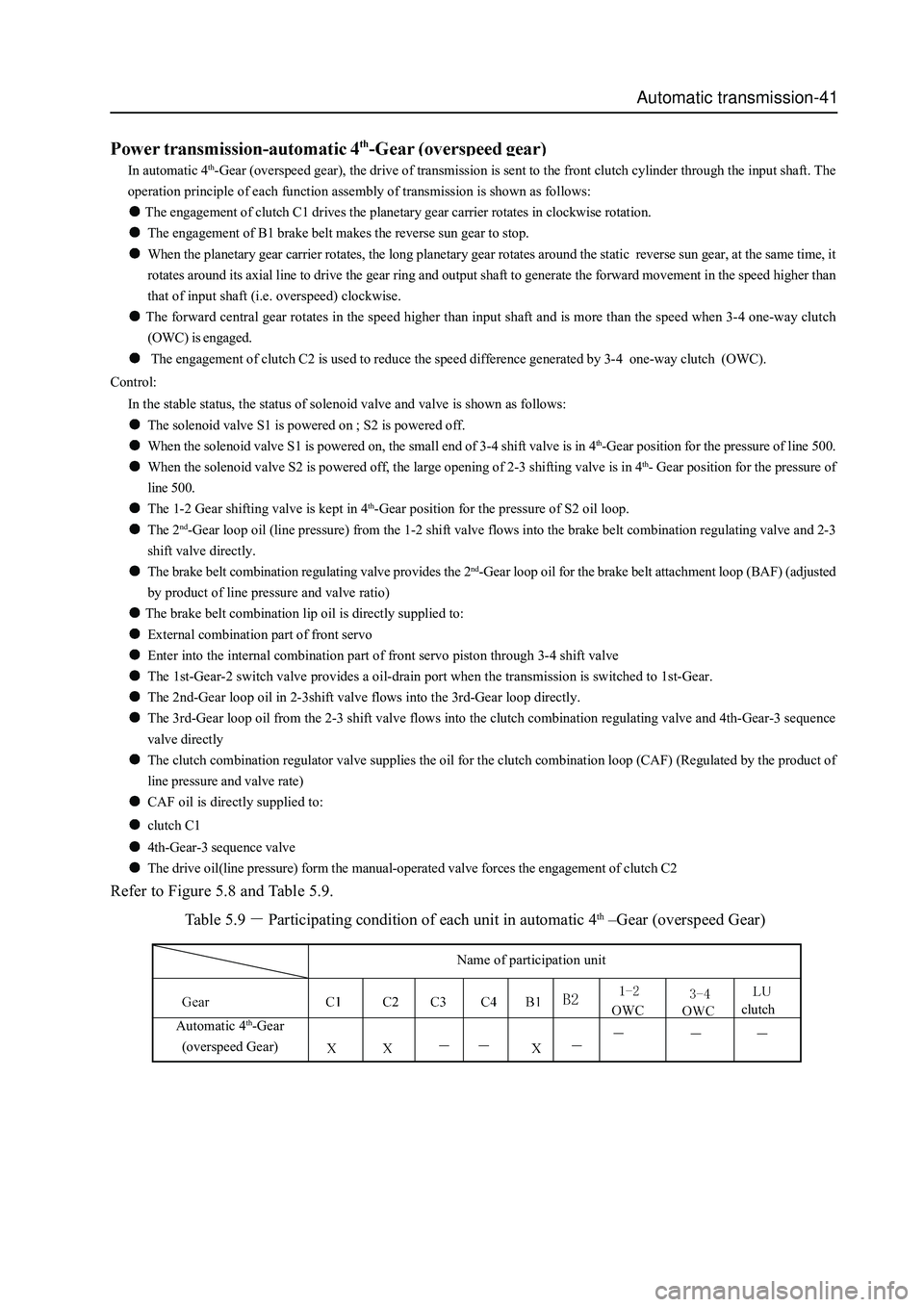

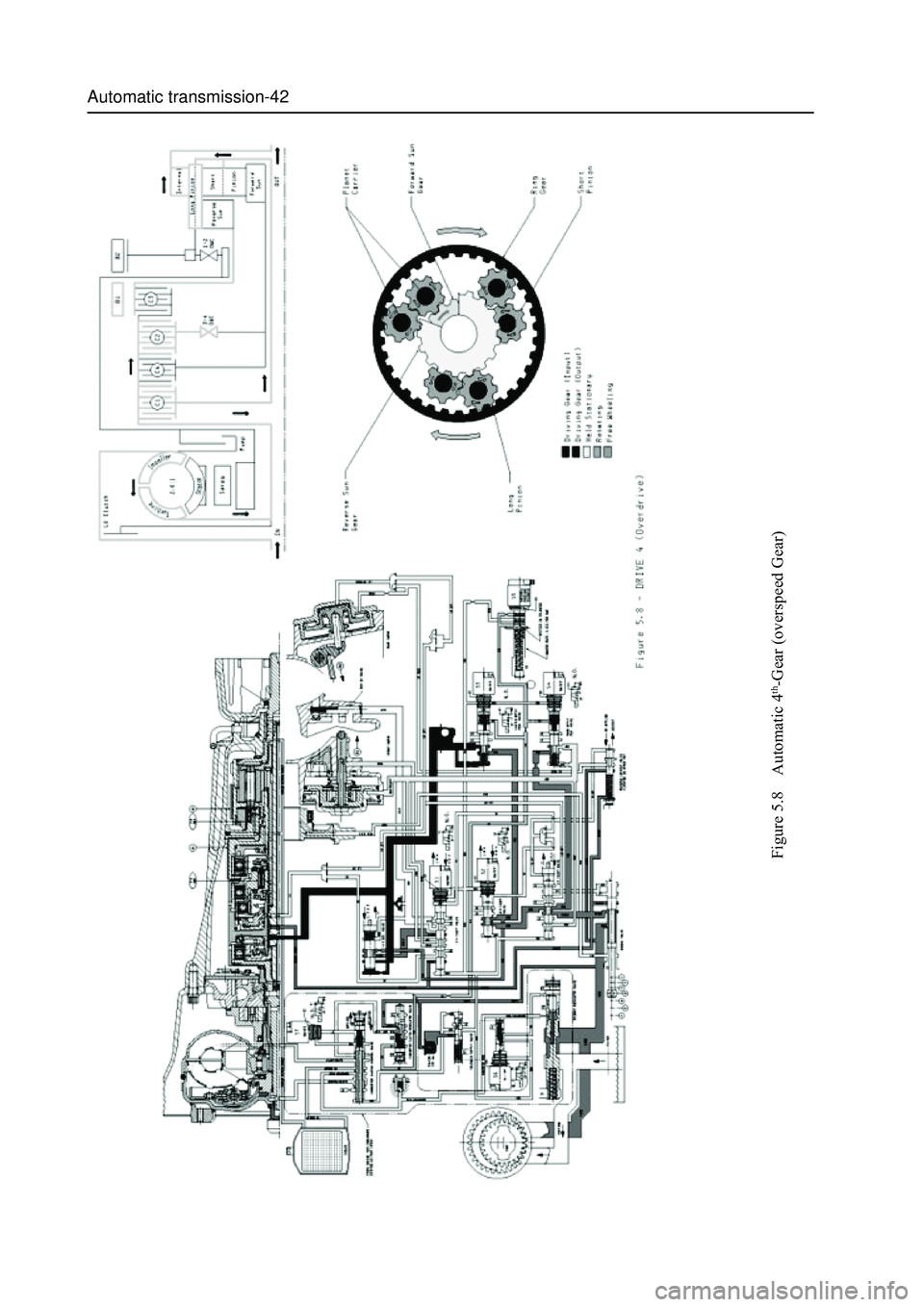

Refer to Figure 5.8 and Table 5.9.

Table 5.9

Participating condition of each unit in automatic 4th –Gear (overspeed Gear)

clutch

Name of participation unit

Automatic 4

th-Gear

(overspeed Gear)

Page 118 of 425

Automatic transmission-42

Figure 5.8 Automatic 4

th-Gear (overspeed Gear)

Page 119 of 425

Automatic transmission-43

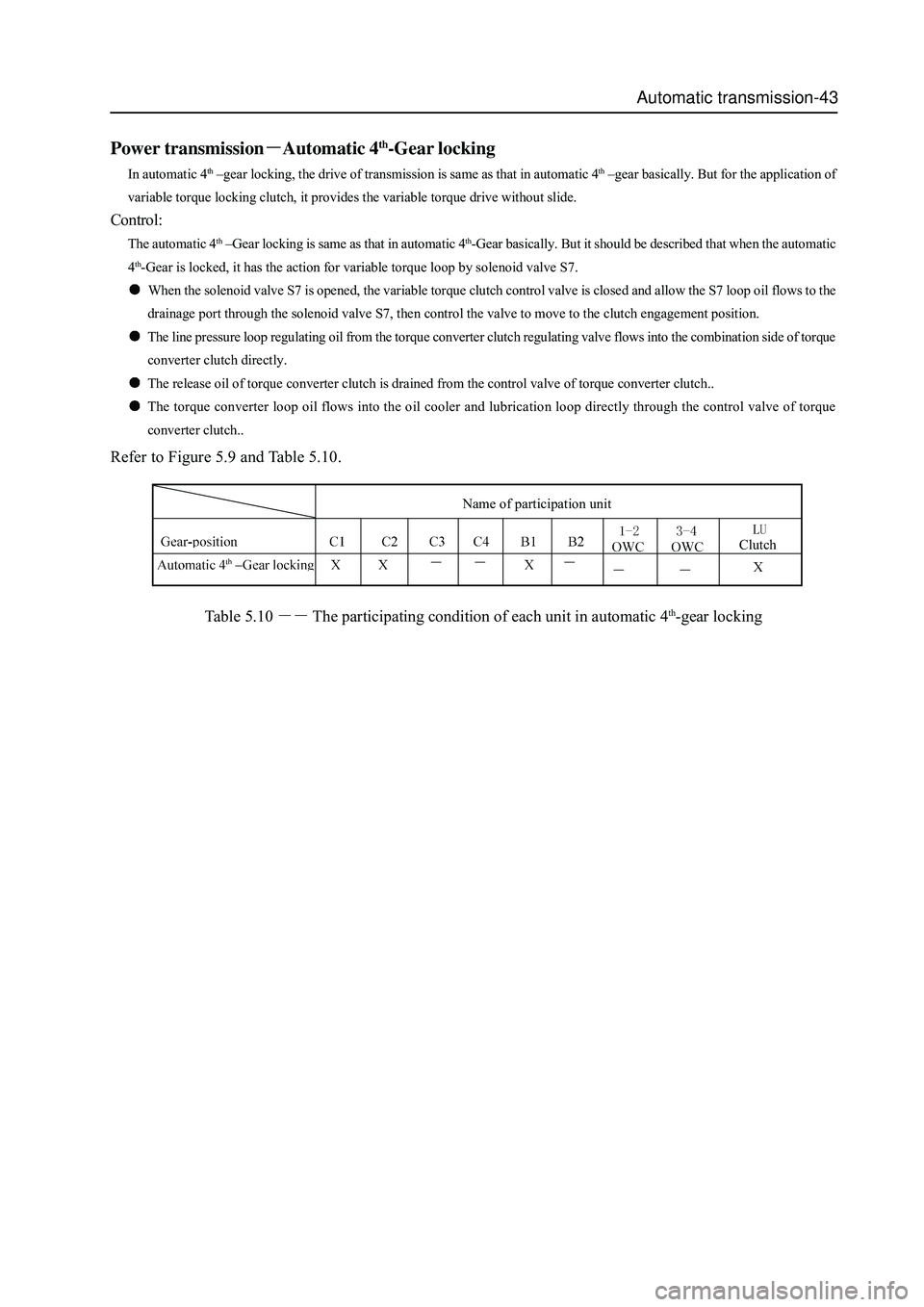

Power transmissionAutomatic 4th-Gear locking

In automatic 4th –gear locking, the drive of transmission is same as that in automatic 4th –gear basically. But for the application of

variable torque locking clutch, it provides the variable torque drive without slide.

Control:

The automatic 4th –Gear locking is same as that in automatic 4th-Gear basically. But it should be described that when the automatic

4

th-Gear is locked, it has the action for variable torque loop by solenoid valve S7.

When the solenoid valve S7 is opened, the variable torque clutch control valve is closed and allow the S7 loop oil flows to the

drainage port through the solenoid valve S7, then control the valve to move to the clutch engagement position.

The line pressure loop regulating oil from the torque converter clutch regulating valve flows into the combination side of torque

converter clutch directly.

The release oil of torque converter clutch is drained from the control valve of torque converter clutch..

The torque converter loop oil flows into the oil cooler and lubrication loop directly through the control valve of torque

converter clutch..

Refer to Figure 5.9 and Table 5.10.

Table 5.10

The participating condition of each unit in automatic 4th-gear locking

Clutch

Name of participation unit

Page 120 of 425

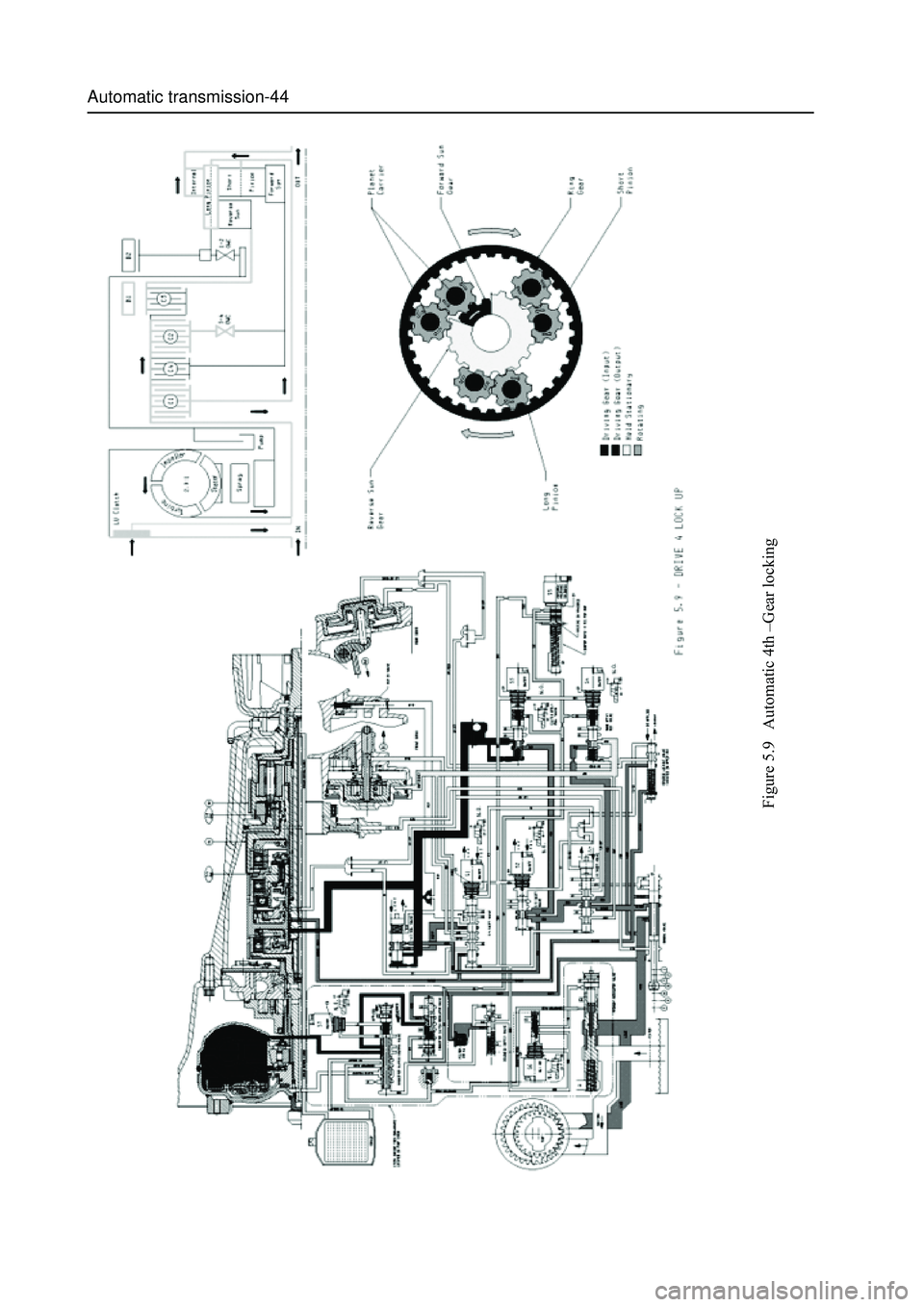

Automatic transmission-44

Figure 5.9 Automatic 4th –Gear locking

Page 121 of 425

Automatic transmission-45

Diagnosis and test

Test system

1. Recommended test equipment and program

The test equipment and control unit for design will be used for the test of all vehicles. The parts for transmission test includes:

Tester for service after sales

Special vehicle for test

2. Tester for service after sales

After the special programming, the tester equipped with special car test software can be used to test the specified system and unit.

The program allows the normal communication between the transmission control units (TCUs) .

The computer needs the required information from the customer and select the necessary data through the manual. For example:

view the code, clear the error code and make the real-time operation. For detailed operating instruction refer to user’s manual.

The equipment can be used by the trained specialized persons, such as technician, machinist to test the electronic and loop

problem related to transmission. The testable information includes: the engine speed, rode (shaft speed), transmission fluid

temperature, position of throttle position, status of solenoid valve and gear and position of operating lever. Additionally, it can be

used to detect the current and stored problem.

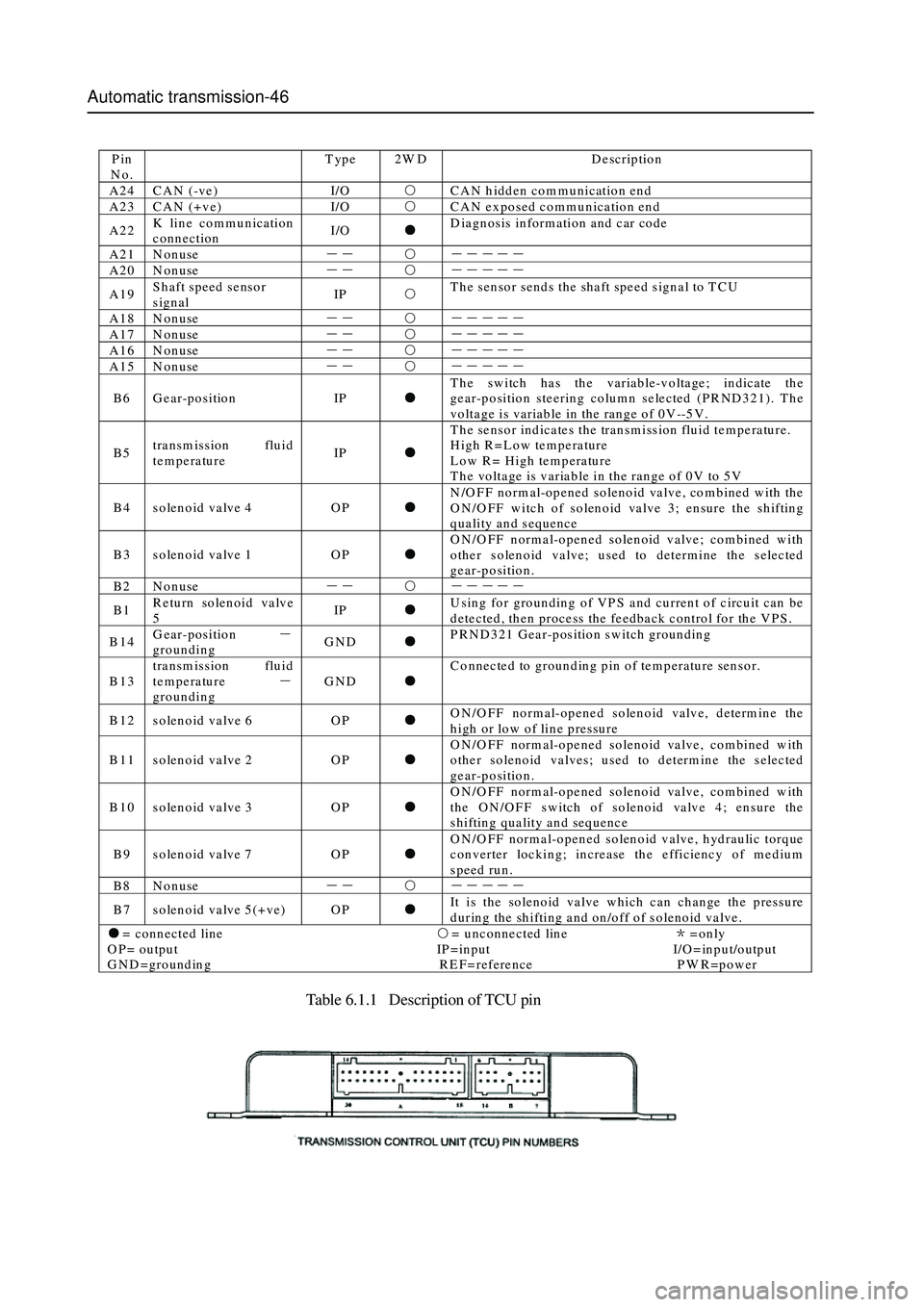

3. Description of TCU pin

The description of TCU pin code had been listed in Table 6.1.1

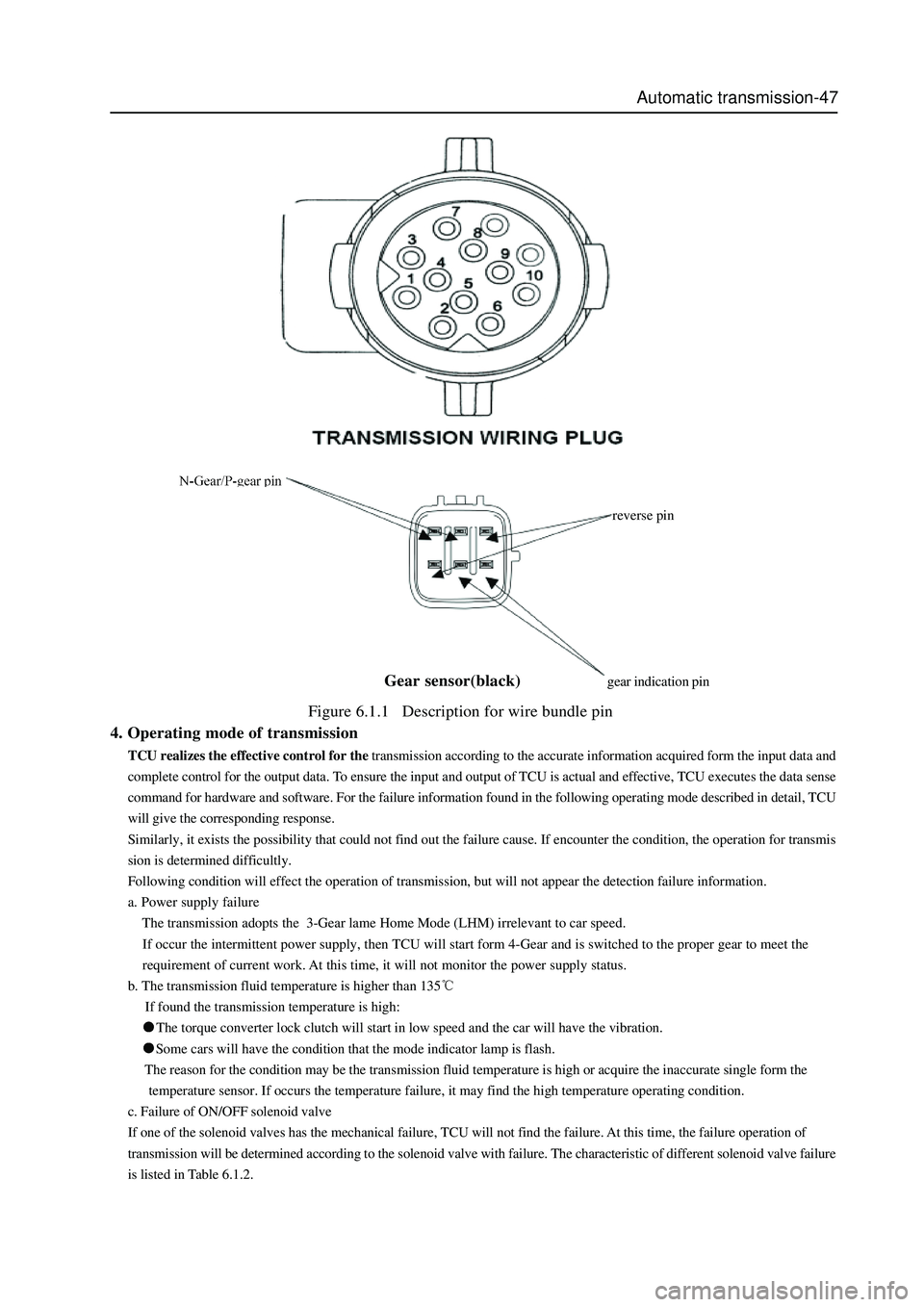

For description of wire bunch refer to Figure 6.1.1

Pin No. Function Type 2WD description

A14 Public grounding GND

● Negative pole of TCU supply, connected to negative pole of

battery.

A13 Nonuse

--

○ -----

A12 M ode indicator la mp

Snowland mode OP

● Indicate that select the “Snowland M ode” operating method.

A11 Parking-Gear indicator lamp O P

● T he drive instrum ent panel indicator la mp indicates tha t is in

the “Parking G ear”

A10 Reverse-Gear indicator lamp OP

● T he drive instrum ent panel indicator la mp indicates tha t is in

“ Revers e G ear”

A9 N-G ear indicator lamp O P

● T he drive instrum ent panel indicator la mp indicates tha t is in

“Idle N Gear”

A8 Nonuse -- ○ -----

A7 Nonuse -- ○ -----

A6 M ode indicator la mp

dynamic mode OP

● Indicate that select the “ dyna m ic mode” operating method.

A5 Nonuse ―― ○ ---――

A4 Nonuse ―― ○ -----

A3 Nonuse ―― ○ -----

A2 Mode switch IP

● The switch is used to select the “economic mode”, “dynamic

m ode” and “ snowla nd mode”. T he voltage is varia ble in

range of 0 V-2V .

A1 Nonuse ―― ○ -----

A30 Power supply PWR

● Power supply for TCU; is the main power source of drive

unit and solenoid valve.

A29 Nonuse ―― ○ -----

A28 1st-G ear indicator lamp

/1st-G ear position﹡ OP

● Drive the instrument panel indicator lamp indication, indicate

that the gear-position is in “1st-G ear”

A27 2nd-G ear indicator lamp

/2nd-G ear position OP

● Drive the instrument panel indicator lamp indication, indicate

that the gear-position is in “2nd-G ear”

A26 3rd-G ear indicator lamp

/3rd-Gear position﹡ OP

● Drive the instrument panel indicator lamp indication, indicate

that the gear-position is in “3rd-Gear”

A25 Automatic gear indicator

lamp /4th –Gear position OP

● Drive the instrument panel indicator lamp indication, indicate

that the gear-position is in “automatic-Gear”

Page 122 of 425

Automatic transmission-46

Pin

No. Type 2W D Description

A24 CAN (-ve) I/O ○ CAN hidden communication end

A23 CAN (+ve) I/O ○ CAN exposed communication end

A22 K line communication

connection I/O ● Diagnosis information and car code

A21 Nonuse ―― ○ -----

A20 Nonuse ―― ○ -----

A19 Shaft speed sensor

signal IP ○ The sensor sends the shaft speed signal to T CU

A18 Nonuse ―― ○ -----

A17 Nonuse ―― ○ -----

A16 Nonuse ―― ○ -----

A15 Nonuse ―― ○ -----

B6 Gear-position IP ● T h e sw itch ha s th e variab le-vo ltage ; in dicate the

gear-position steering colum n selected (PRND321). The

vo ltage is variab le in the ran ge o f 0 V --5 V .

B5 transm ission fluid

temperature IP ● The sensor indicates the transmission fluid temperature.

High R=Low temperature

Low R= High temperature

The voltage is variable in the range of 0V to 5V

B 4 so leno id va lve 4 O P ● N /O FF no rm al-op ened so leno id valve , co m b ined w ith the

O N /O FF w itch o f so len oid valve 3; en sure the sh ifting

quality and sequence

B 3 so leno id va lve 1 O P ● ON/OFF normal-opened solenoid valve; combined with

o the r so leno id va lve; u sed to determ ine the selected

gear-position.

B2 Nonuse ―― ○ -----

B1 R e tu rn so len oid va lve

5 IP ● Using for grounding of VPS and current of circuit can be

detected, then process the feedback control for the VPS.

B14 Gear-position -

grounding GND ● PRND321 Gear-position switch grounding

B13 transm ission fluid

temperature -

grounding GND ● Connected to grounding pin of temperature sensor.

B12 solenoid valve 6 OP ● ON/OFF normal-opened solenoid valve, determine the

high or low of line pressure

B11 solenoid valve 2 OP ● O N /O FF norm al-o pened so leno id va lve, co m bined w ith

o the r so leno id valves; u sed to d eterm ine the selected

gear-position.

B10 solenoid valve 3 OP ● O N /O FF norm al-o pened so leno id va lve, co m bined w ith

the O N /O FF sw itch of solenoid valve 4; ensure the

shifting quality and sequence

B 9 so leno id va lve 7 O P ● ON/OFF normal-opened solenoid valve, hydraulic torque

converter locking; increase the efficiency of medium

speed run.

B8 Nonuse ―― ○ -----

B 7 so leno id va lve 5 (+ ve) O P ● It is the so leno id va lve w hich can ch an ge th e p ressu re

d urin g the sh iftin g a nd on /o ff o f so leno id valve .

●= connected line ○= unconnected line *=only

OP= output IP=input I/O=input/output

GND=grounding REF=reference PWR=power

Table 6.1.1 Description of TCU pin

Page 123 of 425

Automatic transmission-47

4. Operating mode of transmission

TCU realizes the effective control for the transmission according to the accurate information acquired form the input data and

complete control for the output data. To ensure the input and output of TCU is actual and effective, TCU executes the data sense

command for hardware and software. For the failure information found in the following operating mode described in detail, TCU

will give the corresponding response.

Similarly, it exists the possibility that could not find out the failure cause. If encounter the condition, the operation for transmis

sion is determined difficultly.

Following condition will effect the operation of transmission, but will not appear the detection failure information.

a. Power supply failure

The transmission adopts the 3-Gear lame Home Mode (LHM) irrelevant to car speed.

If occur the intermittent power supply, then TCU will start form 4-Gear and is switched to the proper gear to meet the

requirement of current work. At this time, it will not monitor the power supply status.

b. The transmission fluid temperature is higher than 135

If found the transmission temperature is high:

The torque converter lock clutch will start in low speed and the car will have the vibration.

Some cars will have the condition that the mode indicator lamp is flash.

The reason for the condition may be the transmission fluid temperature is high or acquire the inaccurate single form the

temperature sensor. If occurs the temperature failure, it may find the high temperature operating condition.

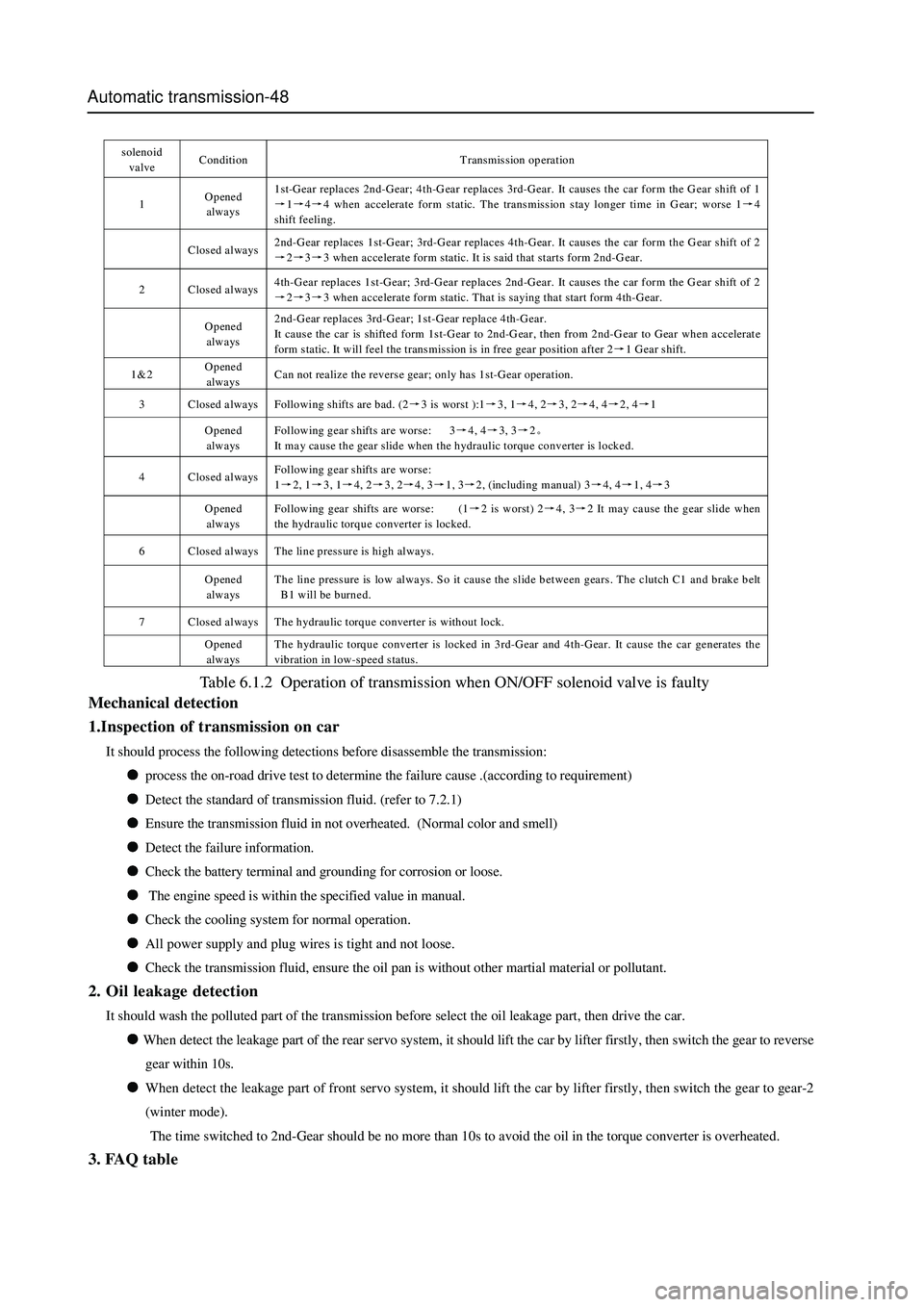

c. Failure of ON/OFF solenoid valve

If one of the solenoid valves has the mechanical failure, TCU will not find the failure. At this time, the failure operation of

transmission will be determined according to the solenoid valve with failure. The characteristic of different solenoid valve failure

is listed in Table 6.1.2.

reverse pin

gear indication pin

Gear sensor(black)

Figure 6.1.1 Description for wire bundle pin

Page 124 of 425

Automatic transmission-48

s oleno id

valve Condition Transmission operation

1 Opened

always 1st-Gear replaces 2nd-Gear; 4th-Gear replaces 3rd-Gear. It causes the car form the G ear shift of 1

→1→4→4 when accelerate form static. The transmission stay longer time in Gear; worse 1→4

shift feeling.

Closed always 2nd-Gear replaces 1st-Gear; 3rd-Gear replaces 4th-Gear. It causes the car form the G ear shift of 2

→2→3→3 when accelerate form static. It is said that starts form 2nd-Gear.

2 Closed always 4th-Gear replaces 1st-Gear; 3rd-Gear replaces 2nd-Gear. It causes the car form the G ear shift of 2

→2→3→3 when accelerate form static. That is saying that start form 4th-Gear.

Opened

always 2nd-Gear replaces 3rd-Gear; 1st-Gear replace 4th-Gear.

It cause the car is shifted form 1st-Gear to 2nd-Gear, then from 2nd-G ear to Gear when accelerate

form static. It will feel the transmission is in free gear position after 2→1 Gear shift.

1&2 Opened

always Can not realize the reverse gear; only has 1st-Gear operation.

3 Closed always Following shifts are bad. (2→3 is worst ):1→3, 1→4, 2→3, 2→4, 4→2, 4→1

Opened

always Following gear shifts are worse: 3→4, 4→3, 3→2。

It may cause the gear slide when the hydraulic torque converter is locked.

4 Closed always Following gear shifts are worse:

1→2, 1→3, 1→4, 2→3, 2→4, 3→1, 3→2, (including manual) 3→4, 4→1, 4→3

Opened

always Following gear shifts are worse: (1→2 is worst) 2→4, 3→2 It may cause the gear slide when

the hydraulic torque converter is locked.

6 Closed always The line pressure is high always.

Opened

always The line pressure is low always. So it cause the slide between gears. The clutch C1 and brake belt

B1 will be burned.

7 Closed always The hydraulic torque converter is without lock.

Opened

always The hydraulic torque converter is locked in 3rd-Gear and 4th-Gear. It cause the car generates the

vibration in low-speed status.

Table 6.1.2 Operation of transmission when ON/OFF solenoid valve is faulty

Mechanical detection

1.Inspection of transmission on car

It should process the following detections before disassemble the transmission:

process the on-road drive test to determine the failure cause .(according to requirement)

Detect the standard of transmission fluid. (refer to 7.2.1)

Ensure the transmission fluid in not overheated. (Normal color and smell)

Detect the failure information.

Check the battery terminal and grounding for corrosion or loose.

The engine speed is within the specified value in manual.

Check the cooling system for normal operation.

All power supply and plug wires is tight and not loose.

Check the transmission fluid, ensure the oil pan is without other martial material or pollutant.

2. Oil leakage detection

It should wash the polluted part of the transmission before select the oil leakage part, then drive the car.

When detect the leakage part of the rear servo system, it should lift the car by lifter firstly, then switch the gear to reverse

gear within 10s.

When detect the leakage part of front servo system, it should lift the car by lifter firstly, then switch the gear to gear-2

(winter mode).

The time switched to 2nd-Gear should be no more than 10s to avoid the oil in the torque converter is overheated.

3. FAQ table