belt GREAT WALL HOVER 2006 Service Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 385 of 425

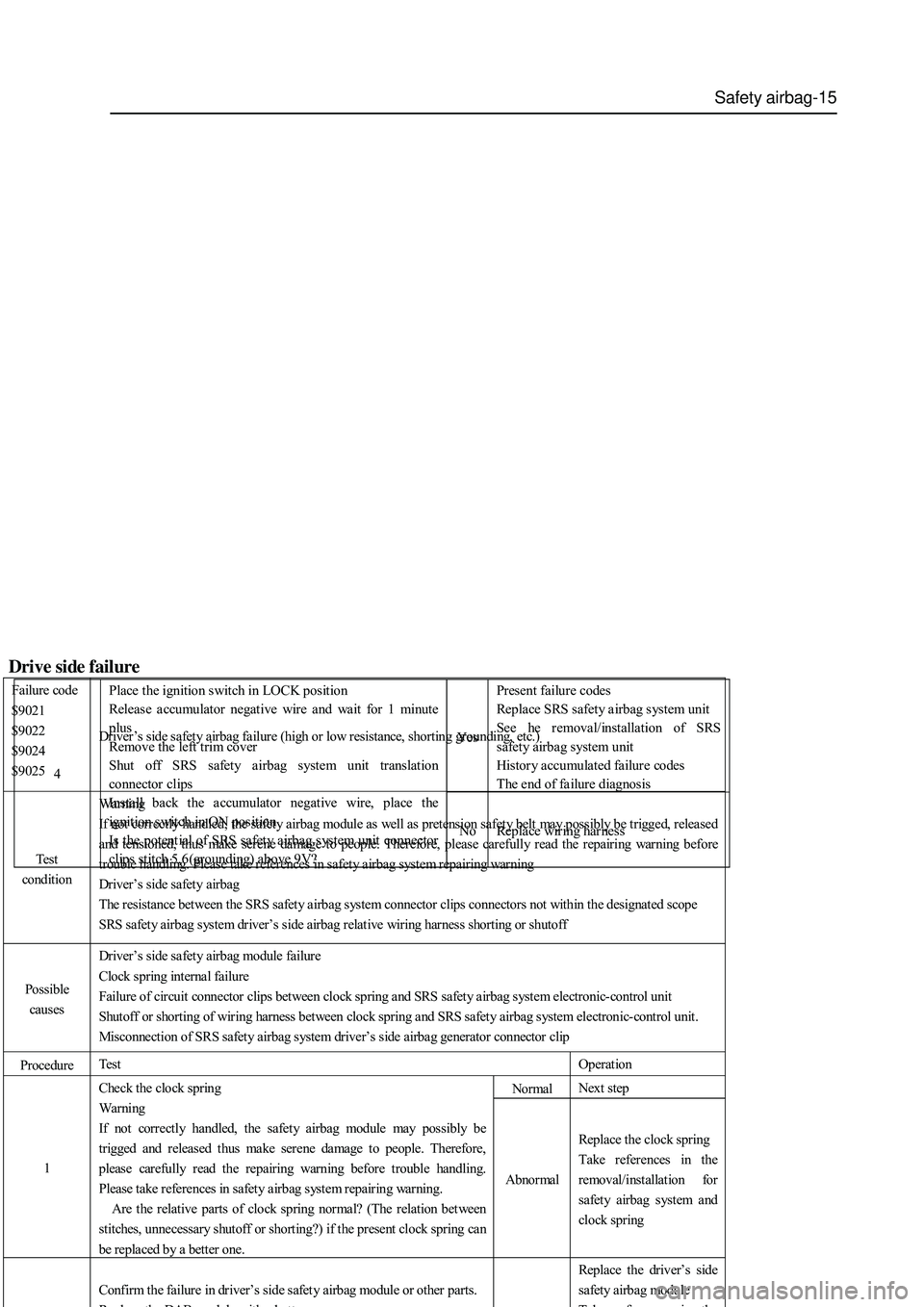

Safety airbag-15

Yes Present failure codes

Replace SRS safety airbag system unit

See he removal/installation of SRS

safety airbag system unit

History accumulated failure codes

The end of failure diagnosis

4 Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute

plus

Remove the left trim cover

Shut off SRS safety airbag system unit translation

connector clips

Install back the accumulator negative wire, place the

ignition switch in ON position

Is the potential of SRS safety airbag system unit connector

clips stitch 5,6(grounding) above 9V? No Replace wiring harness

Drive side failure

Failure code

$9021

$9022

$9024

$9025 Driver ’s side safety airbag failure (high or low resistance, shorting grounding, etc.)

Tes t

condition Warni ng

If not correctly handled, the safety airbag module as well as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people. Therefore, please carefully read the repairing warning before

trouble handling. Please take references in safety airbag system repairing warning

Driver’s side safety airbag

The resistance between the SRS safety airbag system connector clips connectors not within the designated scope

SRS safet y airbag system driver’s side airbag relative wiring harness shorting or shutoff

Possible

caus es Driver’s side safety airbag module failure

Clock spring internal failure

Failure of circuit connector clips between clock spring and SRS safety airbag system electronic-control unit

Shutoff or shorting of wiring harness between clock spring and SRS safety airbag system electronic-control unit.

Misconnection of SRS safety airbag system driver’s side airbag generator connector clip

Procedure Tes t Operation

Normal Next step

1 Check the clock spring

Warni ng

If not correctly handled, the safety airbag module may possibly be

trigged and released thus make serene damage to people. Therefore,

please carefully read the repairing warning before trouble handling.

Please take references in safety airbag system repairing warning.

Are the relative parts of clock spring normal? (The relation bet ween

stitches, unnecessary shutoff or shorting?) if the pr esent clock spring ca n

be replaced by a better one. Abnormal Replace the clock spring

Take references in the

removal/installation for

safety airbag system and

clock spring

Replace the driver’s side

safety airbag module

Tk f i th

Confirm the failure in driver’s side safety airbag module or other parts.

Rl thDAB dl ithbtt

Page 387 of 425

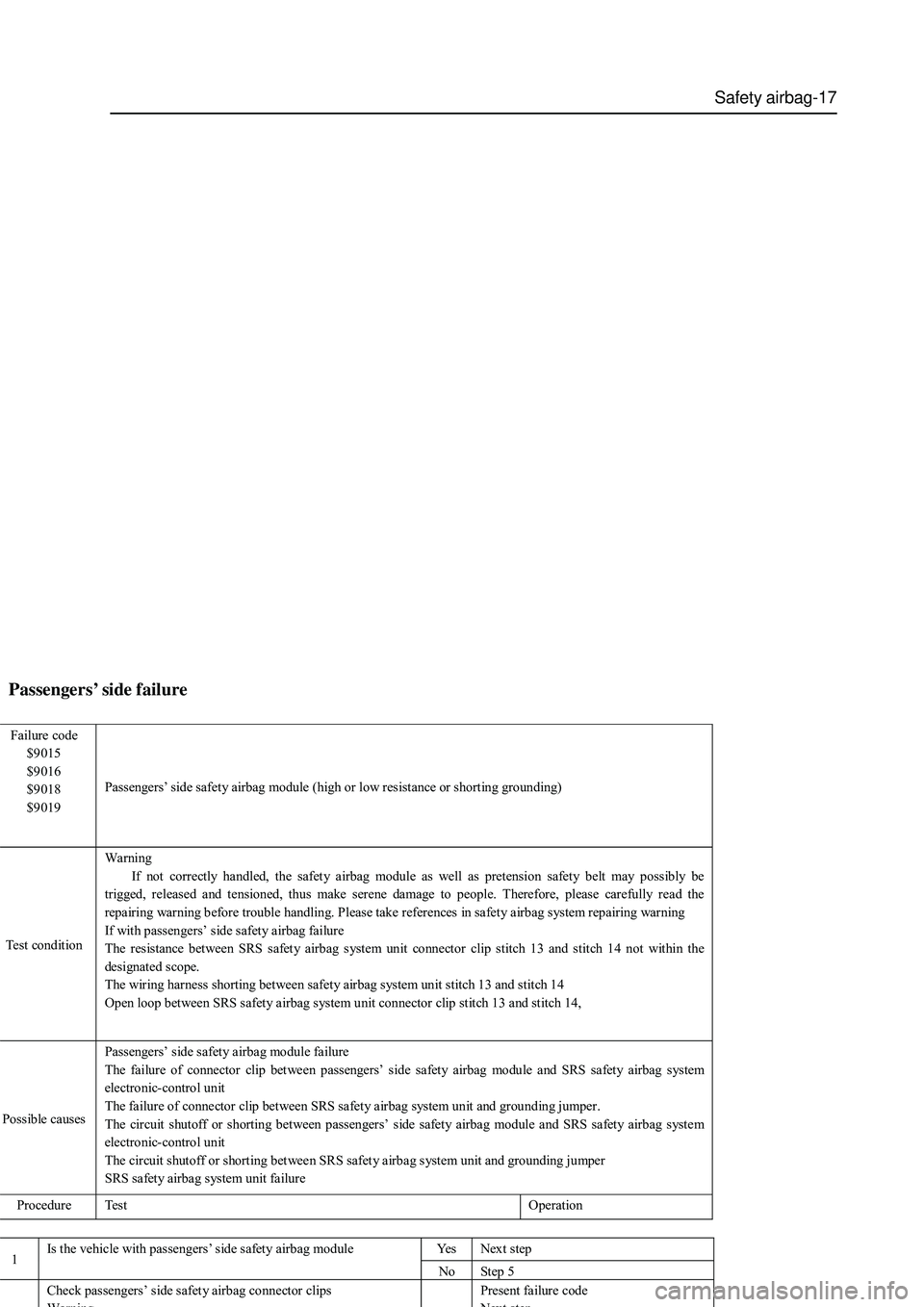

Safety airbag-17

Passengers’ side failure

Failure code

$9015

$9016

$9018

$9019 Passengers’ side safety airbag module (high or low resistance or shorting grounding)

Tes t co n d it i o n Warning

If not correctly handled, the safety airbag module as well as pretension safety belt may possibly be

trigged, released and tensioned, thus make serene damage to people. Therefore, please carefully read the

repairing warning before trouble handling. Please take references in safety airbag system repairing warning

If with passengers’ side safety airbag failure

The resistance between SRS safety airbag system unit connector clip stitch 13 and stitch 14 not within the

designated scope.

The wiring harness shorting between safety airbag system unit stitch 13 and stitch 14

Open loop between SRS safety airbag system unit connector clip stitch 13 and stitch 14,

Possible causes Passengers’ side safety airbag module failure

The failure of connector clip between passengers’ side safety airbag module and SRS safety airbag system

electronic-control unit

The failure of connector clip between SRS safety airbag system unit and grounding jumper.

The circuit shutoff or shorting between passengers’ side safety airbag module and SRS safety airbag system

electronic-control unit

The circuit shutoff or shorting between SRS safety airbag system unit and grounding jumper

SRS safety airbag system unit failure

Procedure Test Operation

Yes Next step

1 Is the vehicle with passengers’ side safety airbag module

No Step 5

Present failure code

Next step

Check passengers’ side safety airbag connector clips

Warning

Page 402 of 425

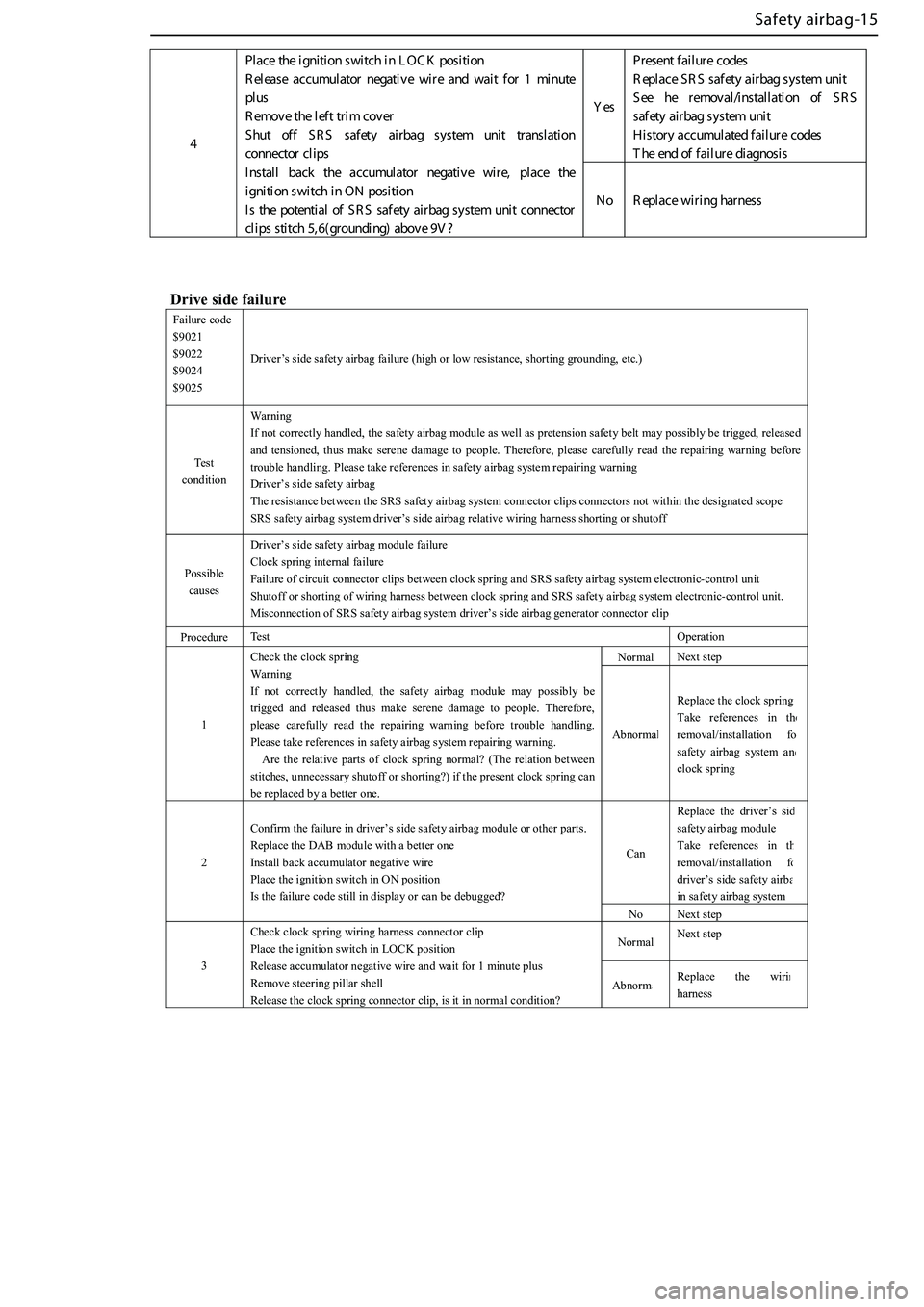

Safety airbag-15

Y esPr

esen t f

ailu re codes

R e plac e S R S saf ety airb ag system unit

S e e h e removal/ins talla tion ofS R

S

sa f ety airb ag system unit

Hi stor y a ccum ulated failu re code

s

T h e e nd offailur e d iagn osis4 Pl

ac e t he i gnition switch i nL O C K position

R e l eas e a ccum ulator negative wire and w ait f or 1 m inut

e

pl us

R e mo vethe l eft t rim c over

Sh ut off S R S safety airb ag system unit tran slat io

n

co nn ecto r cl ips

I n stal l b ack t he

accu mulato r n egativ e w ire, plac e t he

ig nition switch inON position

I s the p oten tial of S R S s afety a irba g s ystem u nit c

onne ctor

cl ip s s titc h 5 , 6( g roun ding ) a bove 9V

? No

R eplac e w irin g h arne ss

Drive side failure

Failure code

$9021

$9022

$9024

$9025

Driver’s side safety airbag failure (high or low resistance, shorting grounding, etc.)

Test

condition

Warning

If not correctly handled, the safety airbag module as well as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people. Therefore, please carefully read the repairing warning before

trouble handling. Please take references in safety airbag system repairing warning

Driver’s side safety airbag

The resistance between the SRS safety airbag system connector clips connectors not within the designated scope

SRS safety airbag system driver’s side airbag relative wiring harness shorting or shutoff

Possible

causes

Driver’s side safety airbag module failure

Clock spring internal failure

Failure of circuit connector clips between clock spring and SRS safety airbag system electronic-control unit

Shutoff or shorting of wiring harness between clock spring and SRS safety airbag system electronic-control unit.

Misconnection of SRS safety airbag system driver’s side airbag generator connector clip

Procedure Test Operation

Normal Next step

1

Check the clock spring

Warning

If not correctly handled, the safety airbag module may possibly be

trigged and released thus make serene damage to people. Therefore,

please carefully read the repairing warning before trouble handling.

Please take references in safety airbag system repairing warning.

Are the relative parts of clock spring normal? (The relation between

stitches, unnecessary shutoff or shorting?) if the present clock spring can

be replaced by a better one.

Abnormal

Replace the clock spring

Take references in the

removal/installation for

safety airbag system and

clock spring

Can

Replace the driver’s side

safety airbag module

Take references in the

removal/installation for

driver’s side safety airbag

in safety airbag system

2

Confirm the failure in driver’s side safety airbag module or other parts.

Replace the DAB module with a better one

Install back accumulator negative wire

Place the ignition switch in ON position

Is the failure code still in display or can be debugged?

No Next step

Normal Next step

3

Check clock spring wiring harness connector clip

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute plus

Remove steering pillar shell

Release the clock spring connector clip, is it in normal condition? Abnormal Replace the wiring

harness

Page 404 of 425

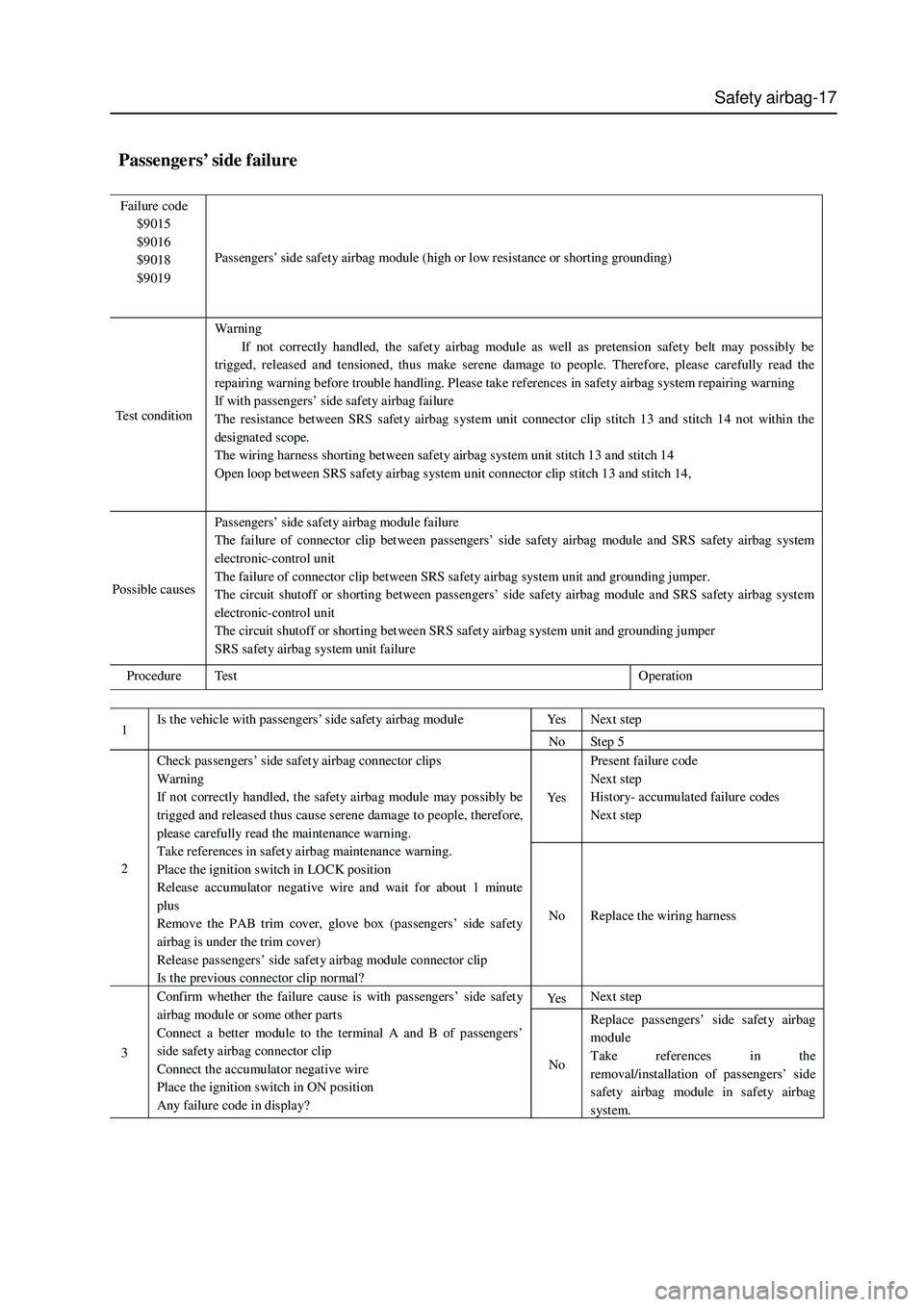

Safety airbag-17

Passengers’ side failure

Failure code

$9015

$9016

$9018

$9019 Passengers’ side safety airbag module (high or low resistance or shorting grounding)

Tes t co n d it i o n Warning

If not correctly handled, the safety airbag module as well as pretension safety belt may possibly be

trigged, released and tensioned, thus make serene damage to people. Therefore, please carefully read the

repairing warning before trouble handling. Please take references in safety airbag system repairing warning

If with passengers’ side safety airbag failure

The resistance between SRS safety airbag system unit connector clip stitch 13 and stitch 14 not within the

designated scope.

The wiring harness shorting between safety airbag system unit stitch 13 and stitch 14

Open loop between SRS safety airbag system unit connector clip stitch 13 and stitch 14,

Possible causes Passengers’ side safety airbag module failure

The failure of connector clip between passengers’ side safety airbag module and SRS safety airbag system

electronic-control unit

The failure of connector clip between SRS safety airbag system unit and grounding jumper.

The circuit shutoff or shorting between passengers’ side safety airbag module and SRS safety airbag system

electronic-control unit

The circuit shutoff or shorting between SRS safety airbag system unit and grounding jumper

SRS safety airbag system unit failure

Procedure Test Operation

Yes Next step

1 Is the vehicle with passengers’ side safety airbag module

No Step 5

Ye s Present failure code

Next step

History- accumulated failure codes

Next step

2 Check passengers’ side safety airbag connector clips

Warning

If not correctly handled, the safety airbag module may possibly be

trigged and released thus cause serene damage to people, therefore,

please carefully read the maintenance warning.

Take references in safety airbag maintenance warning.

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for about 1 minute

plus

Remove the PAB trim cover, glove box (passengers’ side safety

airbag is under the trim cover)

Release passengers’ side safety airbag module connector clip

Is the previous connector clip normal? No Replace the wiring harness

Ye s Next step

3 Confirm whether the failure cause is with passengers’ side safet y

airbag module or some other parts

Connect a better module to the terminal A and B of passengers’

side safety airbag connector clip

Connect the accumulator negative wire

Place the ignition switch in ON position

Any failure code in display? No Replace passengers’ side safety airbag

module

Take references in the

removal/installation of passengers’ side

safety airbag module in safety airbag

system.

Page 412 of 425

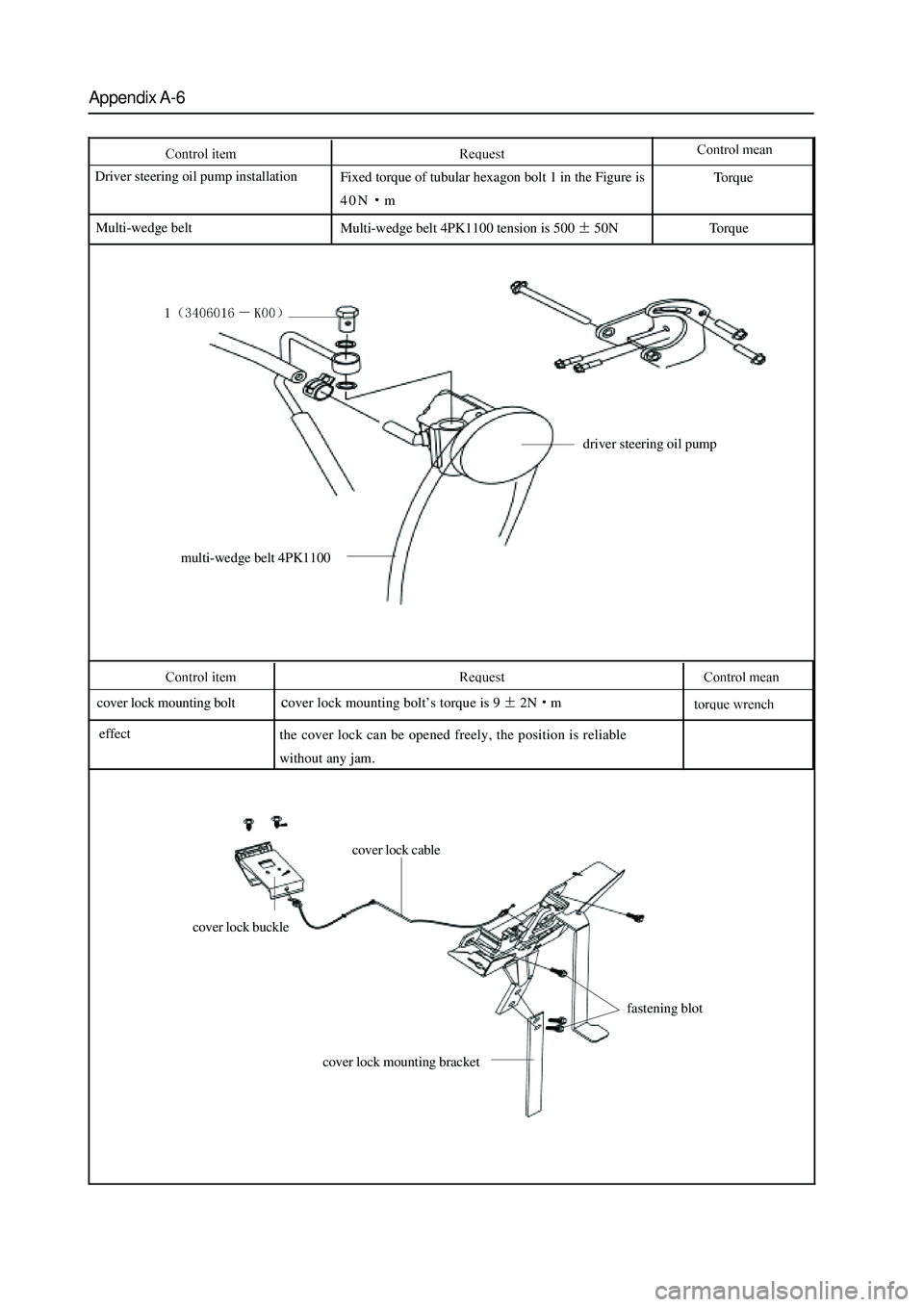

Appendix A-6

Driver steering oil pump installation

Fixed torque of tubular hexagon bolt 1 in the Figure is

40N

m

Multi-wedge belt

Multi-wedge belt 4PK1100 tension is 500

50NTorque

Torque

multi-wedge belt 4PK1100driver steering oil pump

cover lock mounting bolt

effect

cover lock mounting bolt’s torque is 92Nm

the cover lock can be opened freely, the position is reliable

without any jam.

cover lock cable

cover lock buckle

fastening blot

cover lock mounting bracket

Page 424 of 425

Appendix D-18

15 front cross stabilizer rod

-connecting bar bottom

arm bolt M10×1.25-8 63±5 39 brake petrol pipe joint M10×1.25 16

16 long longitudinal tie

connecting bolt M14×

1.5-10.9 200±20 40 safety belt body connecting bolt 7/16″-8.8

40±2

17 short longitudinal tie

front connecting bolt

M14×1.5-10.9 180±15 41 safety belt seat connecting bolt 7/16″-8.8 40±2

18 short longitudinal tie rear

connecting bolt M14×

1.5-10.9 200±20 42 body suspension connecting bolt M10×1.25-9.8 63±5

19 cross tie -carriage

connecting bolt M14×

1.5-10.9 200±20 43 Engine oil pan drain bolt 40±5

20 cross tie -rear axle fixing

nut M14×1.5-8 180±15 44 Transmission/transfer case refueling/drain bolt 30~35

21 rear cross stabilizer rod

-rear axle fixed bolt M8

×1.25-8.8 23±3 45 front drive axle refueling bolt M20×1.5 145±5

22 rear cross stabilizer rod

-connecting bar -carriage

bolt M10×1.25-8 63±5 46 Front drive axle drain bolt Rc1/2 30~35

23 standby tire bracket fixed

bolt 10×1.25-8.8 63±5 47 rear drive axle refueling/drain bolt M20×1.5 145±5

24 standby tire lifter fixed

bolt M8×1.25-8.8 25±3 48 Starter and wheel box connecting bolt 30±3