belt GREAT WALL HOVER 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 165 of 425

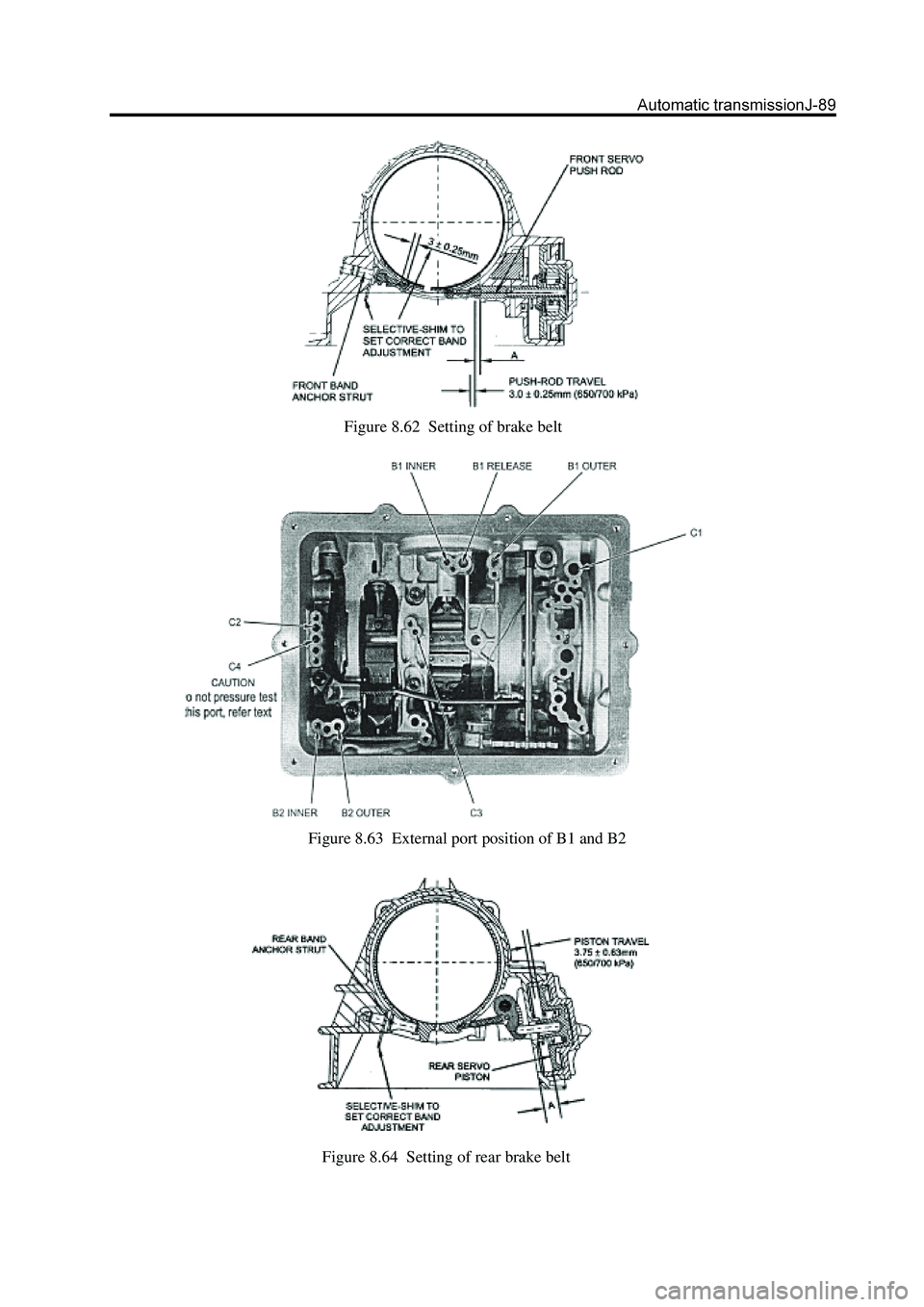

Figure 8.62 Setting of brake belt

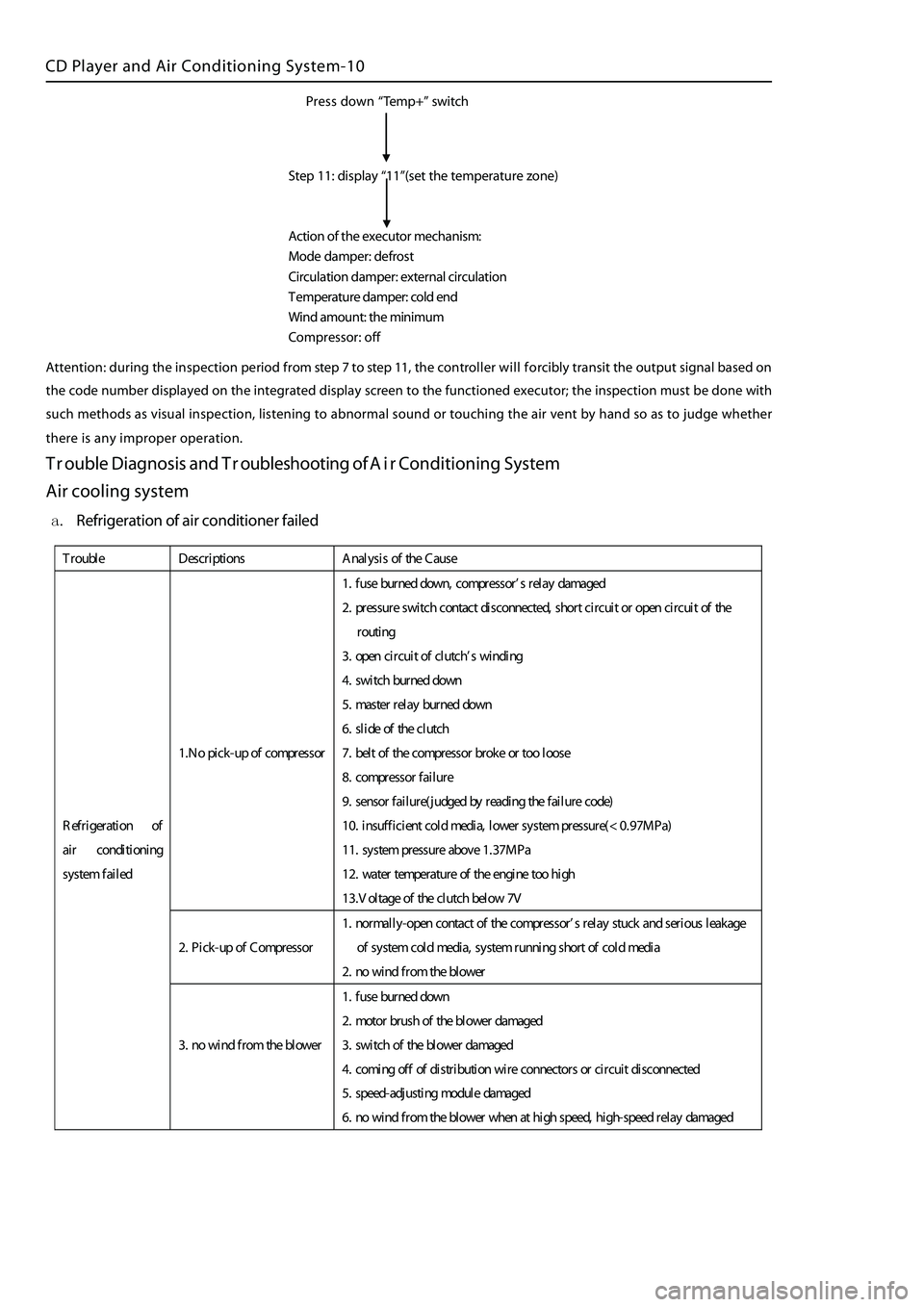

Figure 8.63 External port position of B1 and B2

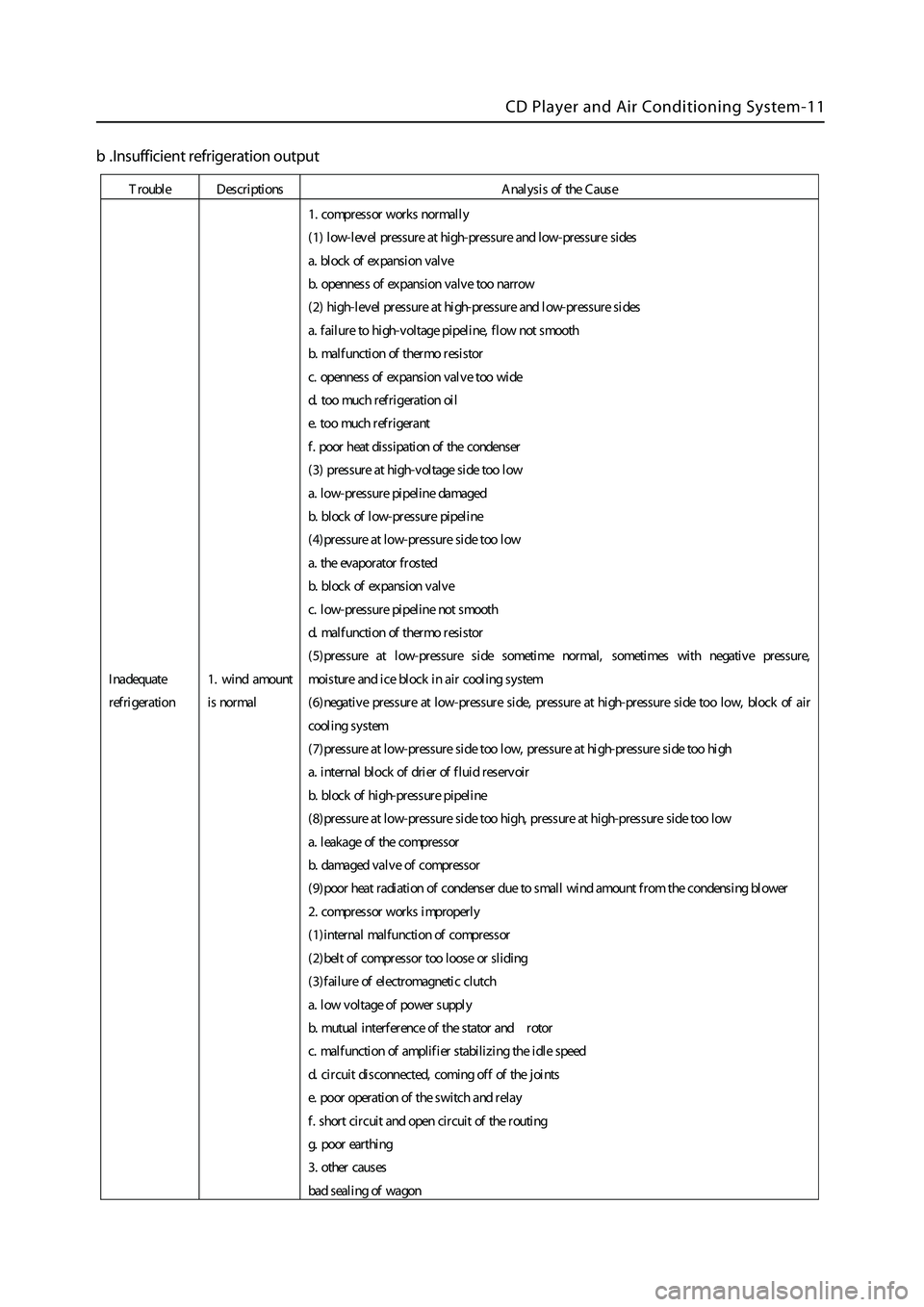

Figure 8.64 Setting of rear brake belt

Page 324 of 425

Steering-5

Technical requirements

1.The fastening torque of the mounting bolts of the integral power

steering gear assembly is

2.The fastening torque of the connecting bolts of the steering drive sub-

assembly and the integral power steering gear assembly is

3. The fastening torque of the connecting bolts of the steering drive

assembly and the left horizontal beam of the frame is

4. The fastening torque of the mounting bolts of the power steering

pump is 40N.m.

5. The tension force of multi-wedge belt 4PK1100 is 4PK1100.

6. Centering fastening of the handwheel: steer the front wheel to the

right front and remove the handwheel without changing the position

of the steering stem, install the handwheel aligning the center, the

radials of the handwheel should be at the left & right centering state;

the symbol of “the Great Wall” on the steering wheel shall be in

driver’s straight view position, secure the nut firmly with the

fastening torque of

7. Inspection of free clearance of the handwheel

Steer the car in a straight direction and stop the engine, apply a 5N force to

the handwheel along the circumference, left turn the handwheel and stop

the turning when the resistance is increasingly felt with each turn; then right

turn the handwheel and stop the turning when the resistance is increasingly

felt with each turn; the angle rotated along the circumference is the free

clearance of the handwheel, whose standard value shall be below 20

, and

the angle from the center to the right shall not be more than 10

Page 363 of 425

CD Player and Air Conditioning System-10

Refrigeration of air conditioner failed

T rou ble Des crip tion s Ana l ysis o f the Cause

1.No pick -up o f com pressor 1.

fuse burned down , com presso r’s r elay dama ge

d

2. pressu re sw itch contac t d isco nn ected, short c ircu itor open circ uit o f the

ro utin

g

3. open circ ui t o f clutch’ s w indi ng

4. sw itch burned down

5. ma ster relay b urne d d ow

n

6.

s lid e o f the clut ch

7. beltof the c om presso r b roke ortoo l oose

8. comp ressor failur

e

9. sens or failur e(ju dg ed by read ing t he failu recode

)

10. insu ffic ient cold me dia, lowe r system p ress ur e(< 0 .97M Pa

)

11. system pressu re abov e 1 .37M Pa

12. water t em peratu re of the e ngine t oo high

13. V oltag e o f the clut ch below 7

V

2. Pick -up o f Com pressor 1.

norm

ally -ope n c ontact of the c om presso r’s r elay stuc k a nd seriou s leaka ge

of system cold me dia, system runn ing s hortof cold me di

a

2. no wind from the b lowe

r

R e frig eratio n of

ai r c ondition in

g

syst emfaile

d

3.no wind from the b lowe

r 1.

fuse burned down

2. mo tor b rush ofthe b lowe r dam aged

3. sw itch ofthe b lowe r dam aged

4. comi ng off o f d istrib utio n w ire c onnector s o r circu itdisc

onne cted

5. speed-ad justin g m odule d amaged

6. no wind from the b lowe r w hen a t high s peed, h igh- sp ee d r elay dama ge

d

Press down “Temp+” switch

Step 11: display “11”(set the temperature zone)

Action of the executor mechanism

:

M ode damper: defrost

Circulation damper: external circulation

Te mperature damper: cold end

Wind amount: the minimum

Compressor: off

Attention: during the inspection period fr om step 7 to step 11, the controlle r

will for cibly transit the output signal based on

the code number displayed on the integrated display screen to the functioned executor; the inspection must be done with

such

m ethods as visual inspection, listening to abnormal sound or touching the air vent by hand so as to judge whether

there is any improper operation.

T rouble Diagnosis and T roubleshooting of A i r Conditioning System

Air cooling system

Page 364 of 425

CD Player and Air Conditioning System-11

b .Insufficient refrigeration output

T rou ble D escrip tion s Ana l ysis o f the Cause

I nad equate

re fri g eratio

n 1.

wind amount

is no rm al 1.

comp ress or wo rks n orma ll

y

(1 ) low- leve l p ressu reathigh -pressu reand l ow -pressu reside

s

a. bloc k o f exp ansion valv

e

b. op enness of expa nsion v alve too n arro

w

(2 ) h igh- leve l p ressu reathigh -pressu reand l ow -pressu reside

s

a. failur e t o h igh- vo ltag e p ip

elin e,flow not smooth

b. ma lfun ctio n o f the rm o resisto

r

c. op

enne ssof expa nsion v alve too w ide

d. too m uch r efrige ration oi

l

e. too m uch r efrige rant

f. po or heat diss ipatio n o f the cond ense

r

(3 ) p ress ure a t high- vo ltag e s ide t oo lo

w

a. low- pr

essu repipe line dama ged

b. bloc k o f low -pressu repipe lin

e

(4 )pressu reatlow- pr

essu reside too l ow

a. the e vapo rato r f rosted

b. bloc k o f expansion valv

e

c. low- pr

essu repipe line not smo oth

d. ma lfun ctio n o f the rm o resisto

r

(5 )pressu re at low- pr

essu re side some time norm al, s ometim es with negative pressu re,

mo istu re and i ce bloc k i n a irco oling s yste

m

(6 )neg ative p ress ur e a t low -pressu reside , p ressu reathigh -pressu reside too l ow , block ofai

r

co oling s yste

m

(7 )pressu reatlow- pr

essu reside too l ow , pressu reathigh -pressu reside too h i gh

a. intern al bloc k o f drier of f lui d r eservo ir

b. bloc k o f high- pr essu re pipe lin

e

(8 )pressu reatlow- pr

essu reside too h igh, pressu re athigh -press ure s ide t oo low

a. leak ag e o f the comp resso

r

b. dama ged v alve ofcomp resso

r

(9 )poo r h eat r ad iation ofcond enser d ue tosm all w ind a mo unt from t hecond ensing blow er

2. comp ress or wo rks i mp rope rl

y

(1 )int erna l m alfu nc tion ofcomp ress or

(2 )belt o f com pr

esso r too loos e o r slidi ng

(3 )fai lu re of elec trom agnetic c lutc

h

a. low vol tage ofpowe r suppl

y

b. mu tual interfer en ce ofthe s tato r and roto

r

c. ma lfun ctio n o f amp lifier s tabi lizi ng the i dle s peed

d. circ uit d isco nn ected, comi ng off o f the joi n ts

e. po or operatio n o f the sw itch and r elay

f. sh ort c ircu itan d o pen c ircu itof the r outing

g. po or earthi ng

3. othe r c ause

s

ba d s ealin g o f w agon

Page 370 of 425

CD Player and Air Conditioning System-17

Daily Maintenance of Air Conditioning System

In order to ensure normal operation of air conditioning system, maintenance and care services shall be frequently performed for the

air conditioning system. The daily maintenance of air conditioning system is illustrated as follows:

1. Inspect, wash and clean the condenser of air conditioning system, requiring that radiator pins are clean and there is no dirt

between the pins. After the car runs in the rain or on the muddy road, the fan of the condenser should be inspected to find

whether it bears the earth, sand, stone and etc, and remove them if any.

2. Check the quantity of the working media of the refrigerating system; when the compressor set works normally, observe the

liquid viewing glass, under the normal circumstance, there shall be not air bubbles in the glass.

3. Inspect the drive belt. The belt between the compressor and the engine should be tensioned.

4. Check if there is any abnormal noise or odor in the air conditioning system.

5. Check if the temperature difference between the air inlet and outlet of the compressor is normal.

6. Check if the hose of the refrigerating system is in an apparent good condition and connections of all joints are secure.

7. Check if the pipeline of the refrigerating system collides with other parts and components, and if there is any oil leakage trace

left at each joint.

8. Check if the circuit connection of the refrigerating system is secure and if there is an occurrence of short circuit and falling off

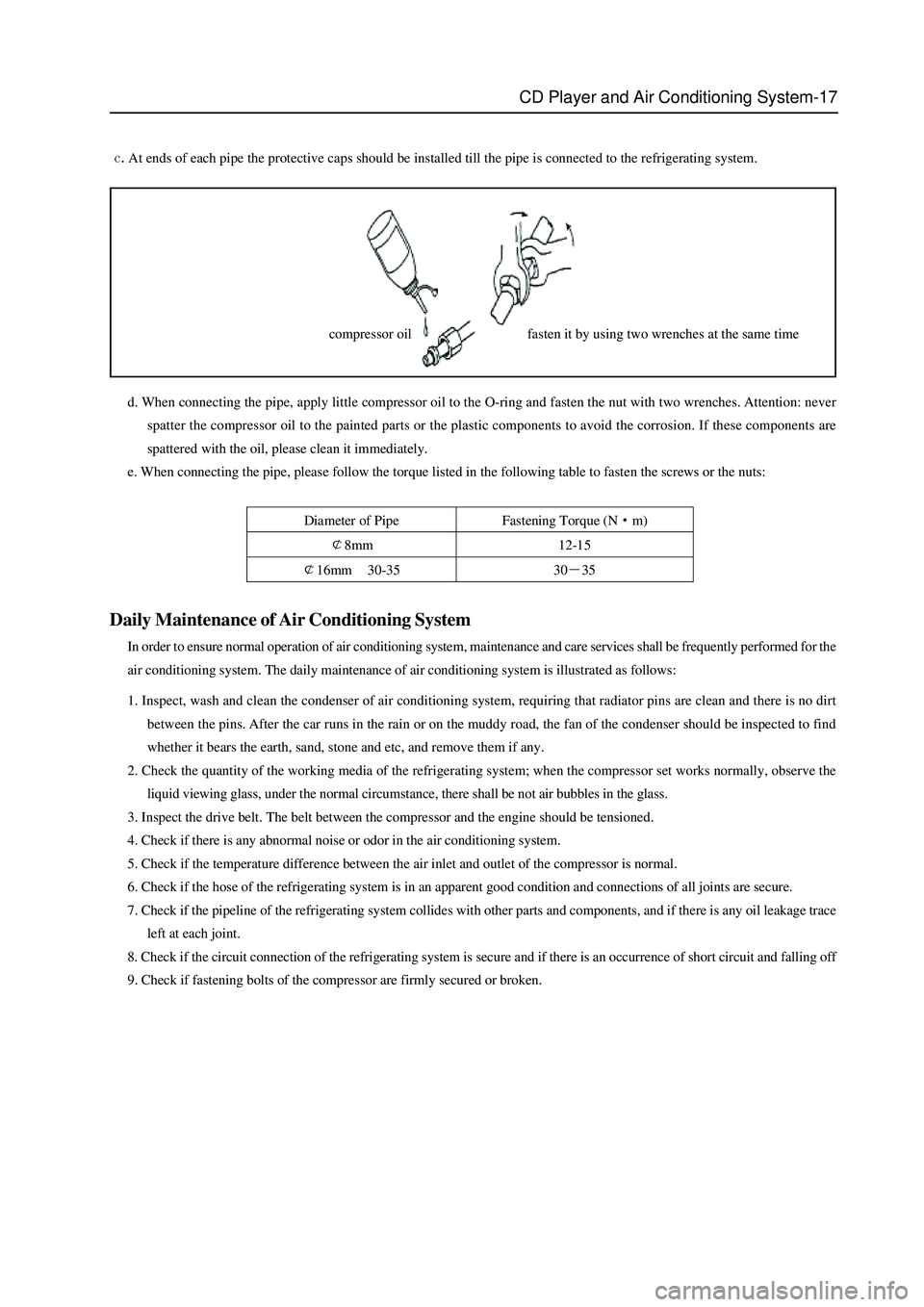

9. Check if fastening bolts of the compressor are firmly secured or broken. d. When connecting the pipe, apply little compressor oil to the O-ring and fasten the nut with two wrenches. Attention: never

spatter the compressor oil to the painted parts or the plastic components to avoid the corrosion. If these components are

spattered with the oil, please clean it immediately.

e. When connecting the pipe, please follow the torque listed in the following table to fasten the screws or the nuts:

Diameter of Pipe Fastening Torque (N·m)

¢8mm 12-15

¢16mm 30-35 30-35

At ends of each pipe the protective caps should be installed till the pipe is connected to the refrigerating system.

compressor oil fasten it by using two wrenches at the same time

Page 377 of 425

Safety airbag-7

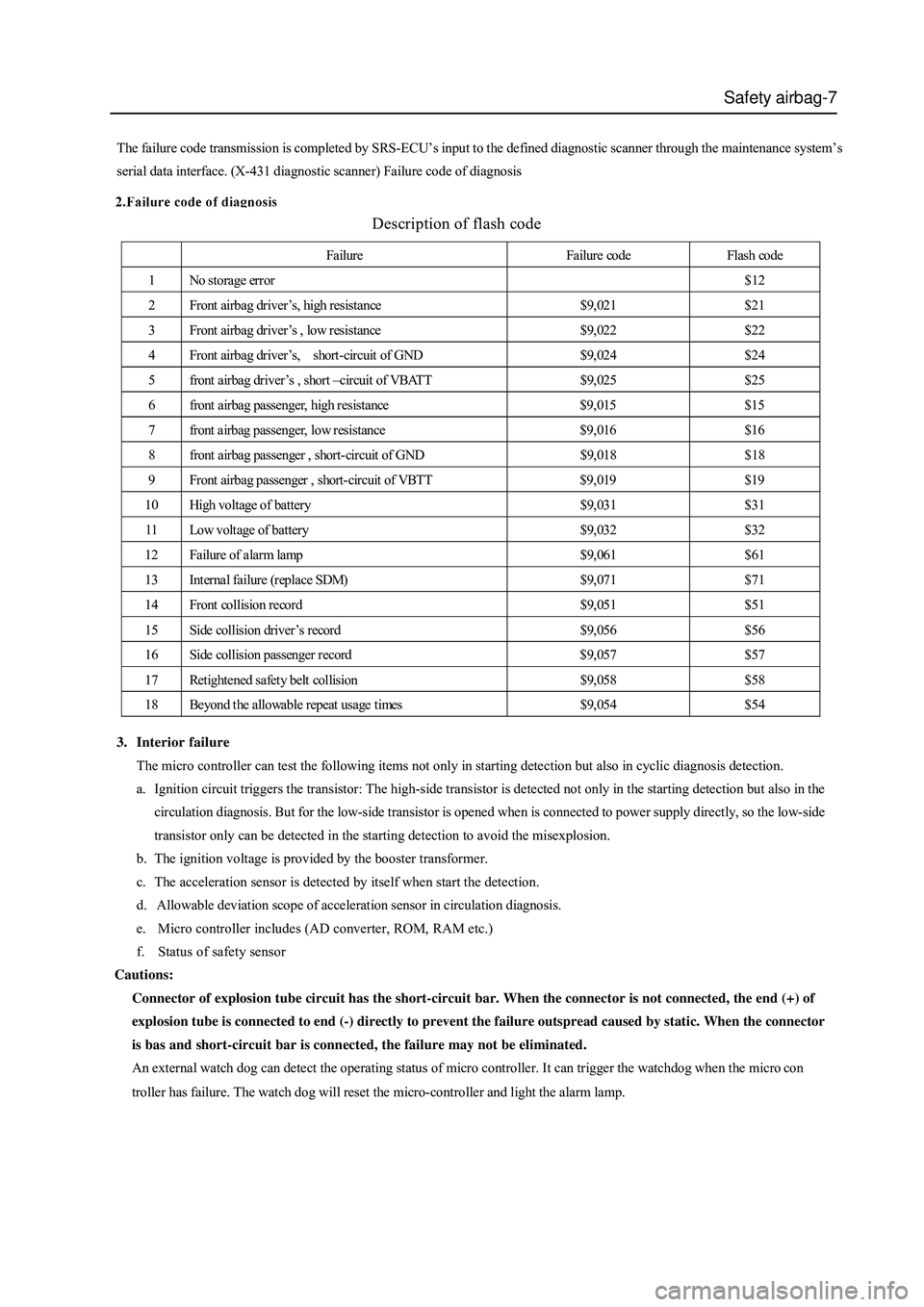

Description of flash code

The failure code transmission is completed by SRS-ECU’s input to the defined diagnostic scanner through the maintenance system’s

serial data interface. (X-431 diagnostic scanner) Failure code of diagnosis

Failure Failure code Flash code

1 No storage error $12

2 Front airbag driver’s, high resistance $9,021 $21

3 Front airbag driver’s , low resistance $9,022 $22

4 Front airbag driver ’s, short-circuit of GND $9,024 $24

5 front airbag driver ’s , short –circuit of VBATT $9,025 $25

6 front airbag passenger, high resistance $9,015 $15

7 front airbag passenger, low resistance $9,016 $16

8 front airbag passenger , short-circuit of GND $9,018 $18

9 Front airbag passenger , short-circuit of VBTT $9,019 $19

10 High voltage of battery $9,031 $31

11 Low voltage of battery $9,032 $32

12 Failure of alarm lamp $9,061 $61

13 Internal failure (replace SDM) $9,071 $71

14 Front collision record $9,051 $51

15 Side collision driver’s record $9,056 $56

16 Side collision passenger record $9,057 $57

17 Retightened safety belt collision $9,058 $58

18 Beyond the allowable repeat usage times $9,054 $54

3. Interior failure

The micro controller can test the following items not only in starting detection but also in cyclic diagnosis detection.

a. Ignition circuit triggers the transistor: The high-side transistor is detected not only in the starting detection but also in the

circulation diagnosis. But for the low-side transistor is opened when is connected to power supply directly, so the low-side

transistor only can be detected in the starting detection to avoid the misexplosion.

b. The ignition voltage is provided by the booster transformer.

c. The acceleration sensor is detected by itself when start the detection.

d. Allowable deviation scope of acceleration sensor in circulation diagnosis.

e. Micro controller includes (AD converter, ROM, RAM etc.)

f. Status of safety sensor

Cautions:

Connector of explosion tube circuit has the short-circuit bar. When the connector is not connected, the end (+) of

explosion tube is connected to end (-) directly to prevent the failure outspread caused by static. When the connector

is bas and short-circuit bar is connected, the failure may not be eliminated.

An external watch dog can detect the operating status of micro controller. It can trigger the watchdog when the micro con

troller has failure. The watch dog will reset the micro-controller and light the alarm lamp.

Page 378 of 425

Safety airbag-8

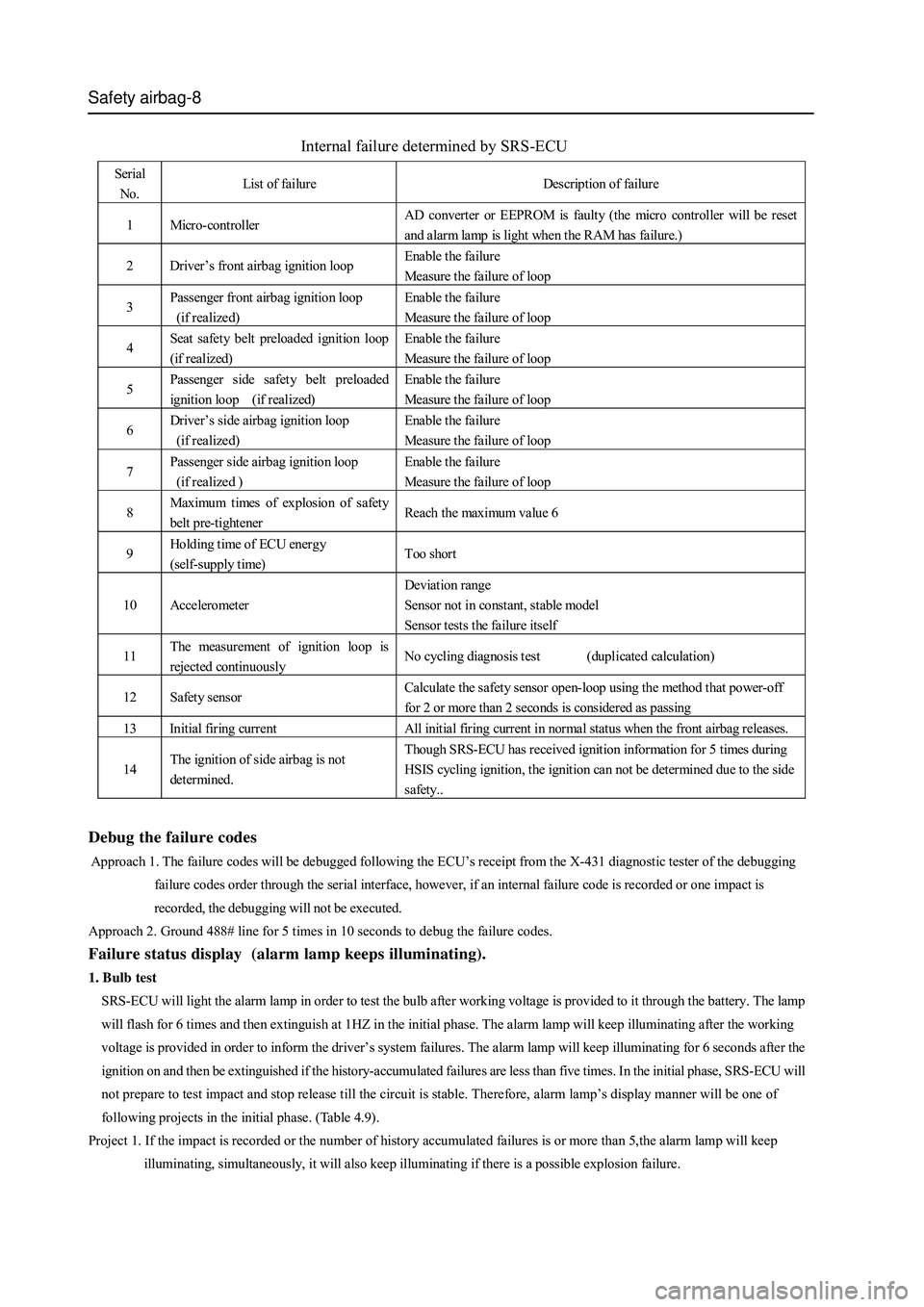

Internal failure determined by SRS-ECU

Serial

No. List of failure Description of failure

1 Micro-controller AD converter or EEPROM is faulty (the micro controller will be reset

and alarm lamp is light when the RAM has failure.)

2 Driver’s front airbag ignition loop Enable the failure

Measure the failure of loop

3 Passenger front airbag ignition loop

(if realized) Enable the failure

Measure the failure of loop

4 Seat safety belt preloaded ignition loop

(if realized) Enable the failure

Measure the failure of loop

5 Passenger side safety belt preloaded

ignition loop (if realized) Enable the failure

Measure the failure of loop

6 Driver’s side airbag ignition loop

(if realized) Enable the failure

Measure the failure of loop

7 Passenger side airbag ignition loop

(if realized ) Enable the failure

Measure the failure of loop

8 Maximum times of explosion of safet y

belt pre-tightener Reach the maximum value 6

9 Holding time of ECU ener gy

(self-supply time) Too short

10 Accelerometer Deviation range

Sensor not in constant, stable model

Sensor tests the failure itself

11 The measurement of ignition loop is

rejected continuously No cycling diagnosis test (duplicated calculation)

12 Safety sensor Calculate the safety sensor open-loop using the method that power-off

for 2 or more than 2 seconds is considered as passing

13 Initial firing current All initial firing current in normal status when the front airbag releases.

14 The ignition of side airbag is not

determined. Though SRS-ECU has received ignition information for 5 times during

HSIS cycling ignition, the ignition can not be determined due to the side

safety..

Debug the failure codes

Approach 1. The failure codes will be debugged following the ECU’s receipt from the X-431 diagnostic tester of the debugging

failure codes order through the serial interface, however, if an internal failure code is recorded or one impact is

recorded, the debugging will not be executed.

Approach 2. Ground 488# line for 5 times in 10 seconds to debug the failure codes.

Failure status display (alarm lamp keeps illuminating).

1. Bulb test

SRS-ECU will light the alarm lamp in order to test the bulb after working voltage is provided to it through the battery. The lamp

will flash for 6 times and then extinguish at 1HZ in the initial phase. The alarm lamp will keep illuminating after the working

voltage is provided in order to inform the driver’s system failures. The alarm lamp will keep illuminating for 6 seconds after the

ignition on and then be extinguished if the history-accumulated failures are less than five times. In the initial phase, SRS-ECU will

not prepare to test impact and stop release till the circuit is stable. Therefore, alarm lamp’s display manner will be one of

following projects in the initial phase. (Table 4.9).

Project 1. If the impact is recorded or the number of history accumulated failures is or more than 5,the alarm lamp will keep

illuminating, simultaneously, it will also keep illuminating if there is a possible explosion failure.

Page 380 of 425

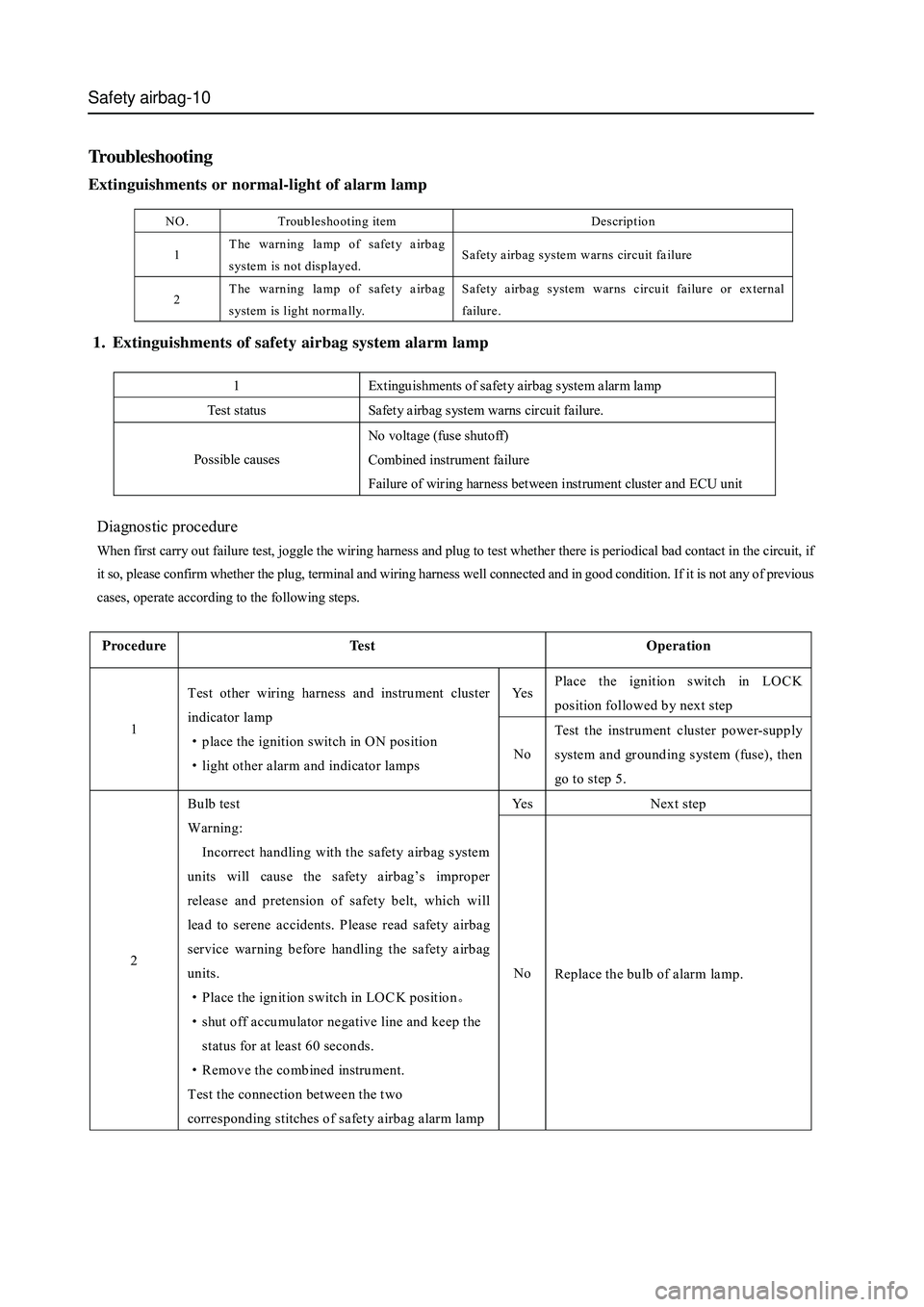

Safety airbag-10

1. Extinguishments of safety airbag system alarm lamp

Troubleshooting

Extinguishments or normal-light of alarm lamp

NO . Troubleshooting item Description

1 T he warning la mp of safety a irbag

system is not displayed. Safety airbag system warns circuit failure

2 T he warning la mp of safety a irbag

system is light normally. Safety airbag system warns circuit failure or external

failure.

1 Extinguishments of safety airbag system alarm lamp

Test status Safety airbag system warns circuit failure.

Possible causes No voltage (fuse shutoff)

Combined instrument failure

Failure of wiring harness between instrument cluster and ECU unit

Diagnostic procedure

When first carry out failure test, joggle the wiring harness and plug to test whether there is periodical bad contact in the circuit, if

it so, please confirm whether the plug, terminal and wiring harness well connected and in good condition. If it is not any of previous

cases, operate according to the following steps.

Procedure Te s t Operation

Ye s Place the ignition switch in LOCK

position followed by next step

1 Test other wiring harness and instrument cluster

indicator lamp

·place the ignition switch in ON position

·light other alarm and indicator lamps No Test the instrument cluster power-supply

system and grounding s ystem (fuse), then

go to step 5.

Yes Next step

2 Bulb test

Warning:

Incorrect handling with the safety airbag system

units will cause the safety airbag’s improper

release and pretension of safety belt, which will

lead to serene accidents. Please read safety airbag

service warning before handling the safety airbag

units.

·Place the ignition switch in LOCK position。

·shut off accumulator negative line and keep the

status for at least 60 seconds.

·Remove the combined instrument.

Test the connection between the two

corresponding stitches of safety airbag alarm lamp No

Rep la ce th e b ulb of a larm la mp.

Page 382 of 425

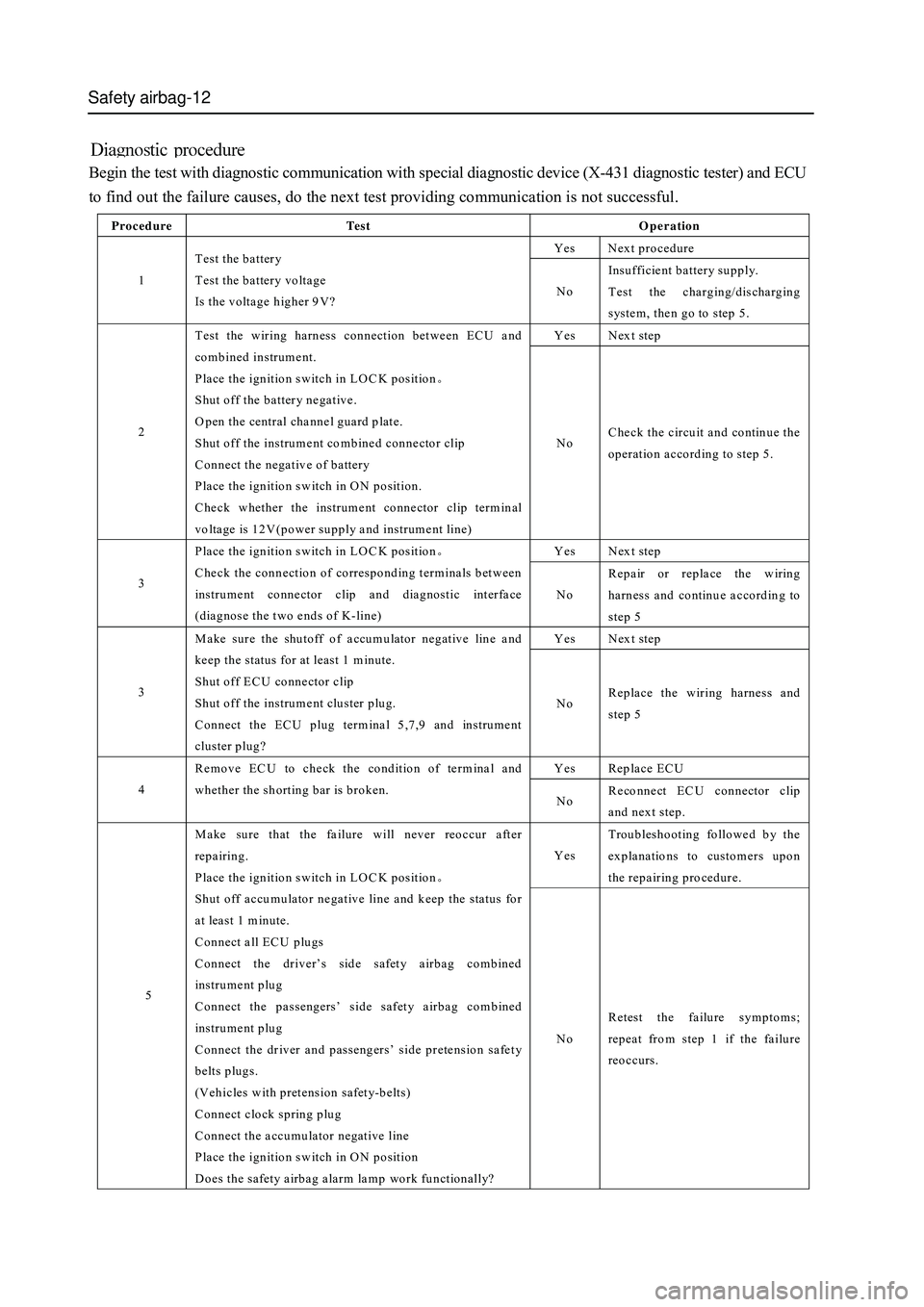

Safety airbag-12

Begin the test with diagnostic communication with special diagnostic device (X-431 diagnostic tester) and ECU

to find out the failure causes, do the next test providing communication is not successful.

Procedure Te s t Operation

Yes Next procedure

1 Test the battery

Test the battery voltage

Is the voltage higher 9V? No Insufficient battery supply.

Test the charging/discharging

system, then go to step 5.

Yes Next step

2 Test the wiring harness connection between ECU and

combined instrument.

Place the ignition switch in LO C K position。

Shut off the battery negative.

O pen the central channel guard plate.

Shut off the instrument combined connector clip

Connect the negative of battery

Place the ignition switch in ON position.

Check whether the instrument connector clip terminal

voltage is 12V(power supply and instrument line) No Check the circuit and continue the

operation according to step 5.

Yes Next step

3 Place the ignition switch in LO C K position。

Check the connection of corresponding terminals between

instrument connector clip and diagnostic interface

(diagnose the two ends of K-line) No Repair or replace the wiring

harness and continue according to

step 5

Yes Next step

3 Make sure the shutoff of accumulator negative line and

keep the status for at least 1 minute.

Shut off ECU connector clip

Shut off the instrument cluster plug.

Connect the ECU plug terminal 5,7,9 and instrument

cluster plug? No Replace the wiring harness and

step 5

Yes Replace ECU

4 Remove EC U to check the condition of term inal and

whether the shorting bar is broken.

No Reconnect EC U connector clip

and next step.

Yes Troubleshooting followed by the

explanations to customers upon

the repair ing pro ced ur e.

5

Make sure that the failure will never reoccur after

repairing.

Place the ignition switch in LO C K position。

Shut off accumulator negative line and keep the status for

at least 1 m in ute.

Connect all ECU plugs

Connect the driver’s side safety airbag combined

instrum ent p lug

Connect the passengers’ side safety airbag combined

instrum ent p lug

Connect the driver and passengers’ side pretension safety

belts plugs.

(Vehicles with pretension safety-b elts)

Connect clock spring plug

Connect the accumulator negative line

Place the ignition switch in ON position

Does the safety airbag alarm lamp work functionally? No Retest the failure symptoms;

repeat from step 1 if the failure

reoccurs.

Page 384 of 425

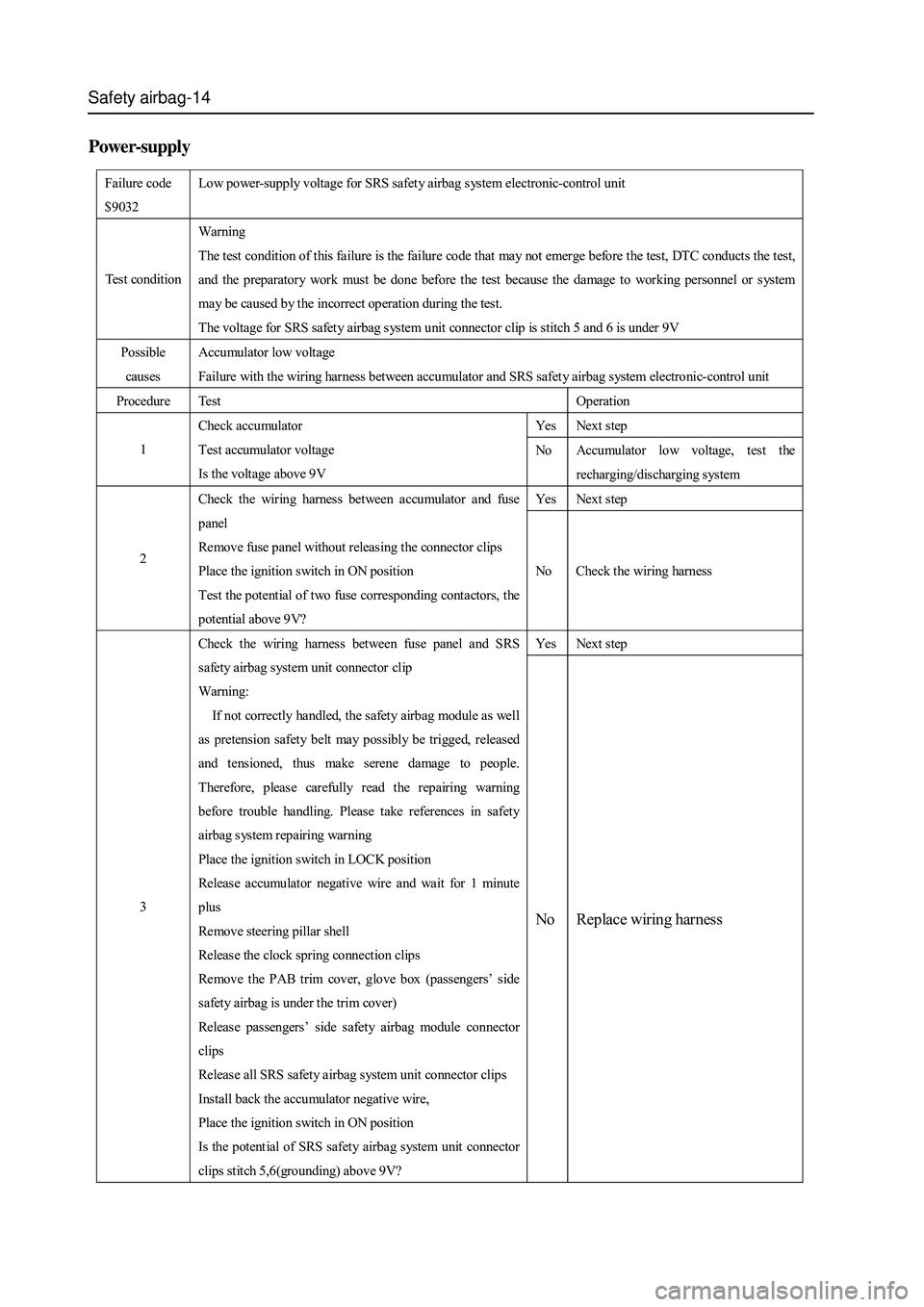

Safety airbag-14

Power-supply

Failure code

$9032 Low power-supply voltage for SRS safety airbag system electronic-control unit

Test condition Warning

The test condition of this failure is the failure code that may not emerge before the test, DTC conducts the test,

and the preparatory work must be done before the test because the damage to working personnel or system

may be caused by the incorrect op eration during the test.

The voltage for SRS safety airbag system unit connector clip is stitch 5 and 6 is under 9V

Possible

caus es Accumulator low voltage

Failure with the wiring harness between accumulator and SRS safety airbag system electronic-control unit

Procedure Test Operation

Yes Next step

1 Check accumulator

Test accumulator voltage

Is the voltage above 9V No Accumulator low voltage, test the

recharging/discharging system

Yes Next step

2 Check the wiring harness between accumulator and fuse

panel

Remove fuse panel without releasing the connector clips

Place the ignition switch in ON position

Test the potential of two fuse corresponding contactors, the

potential above 9V? No Check the wiring harness

Yes Next step

3 Check the wiring harness between fuse panel and SRS

safety airbag system unit connector clip

Warning:

If not correctly handled, the safety airbag module as well

as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people.

Ther efor e, pleas e carefully r ead the r epairing warning

before trouble handling. Please take references in safety

airbag system repairing warning

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute

plus

Remove steering pillar shell

Release the clock spring connection clips

Remove the PAB trim cover, glove box (passengers’ side

safety airbag is under the trim cover)

Release passengers’ side safety airbag module connector

clips

Release all SRS safety airbag system unit connector clips

Install back the accumulator negative wire,

Place the ignition switch in ON position

Is the potential of SRS safety airbag system unit connector

clips stitch 5,6(grounding) above 9V? No Replace wiring harness