wheel GREAT WALL HOVER 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 302 of 425

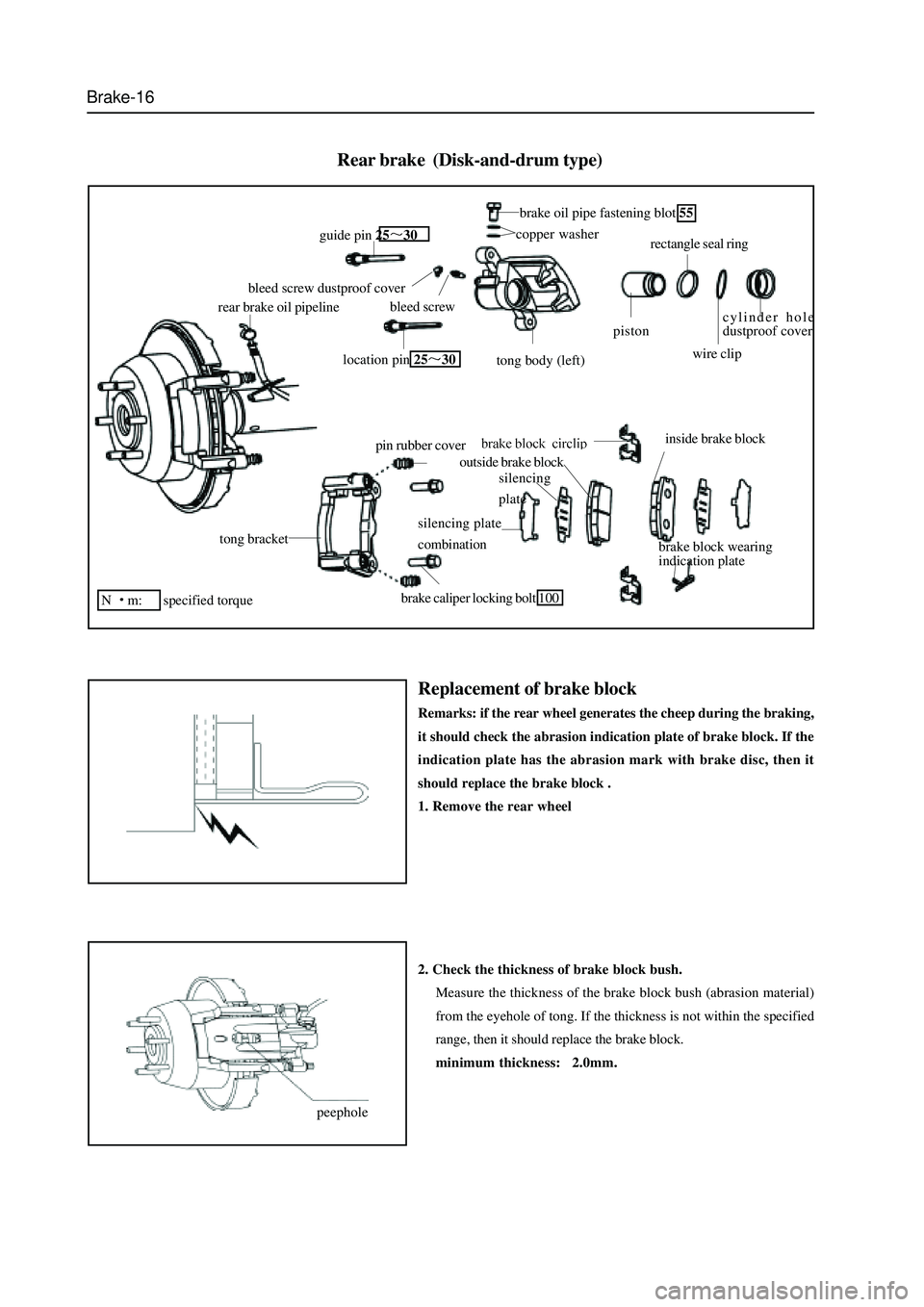

Brake-16

Rear brake (Disk-and-drum type)

tong bracket

pin rubber cover

brake caliper locking bolt 100

silencing plate

combination

outside brake block

inside brake block

brake block wearing

indication plate

cylinder hole

dustproof cover

wire clip

rectangle seal ring

piston

tong body (left)

copper washer

brake oil pipe fastening blot 55

location pin 2530

bleed screw

bleed screw dustproof cover

guide pin 2530

rear brake oil pipeline

N

m: specified torque

peepholesilencing

plate

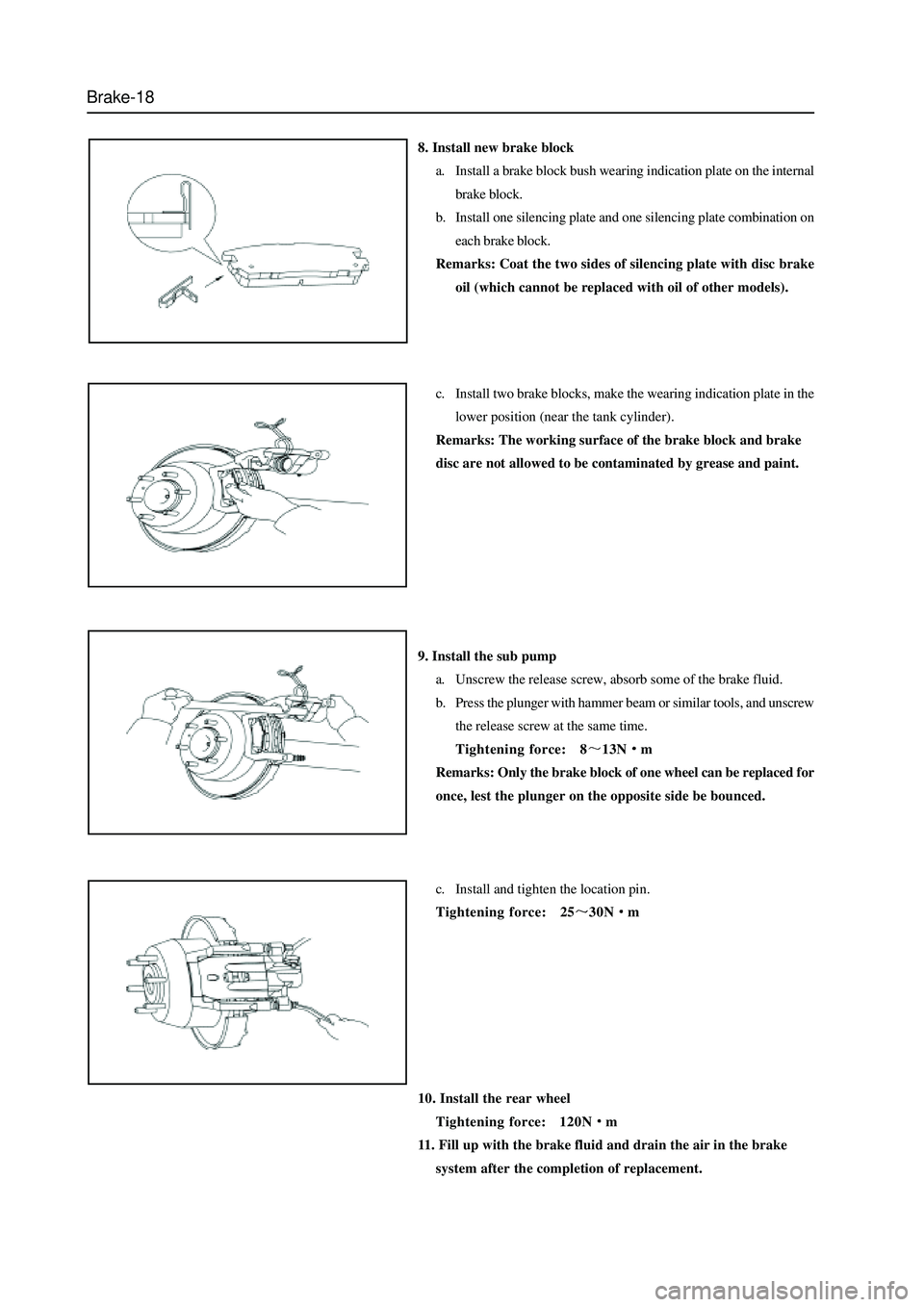

Replacement of brake block

Remarks: if the rear wheel generates the cheep during the braking,

it should check the abrasion indication plate of brake block. If the

indication plate has the abrasion mark with brake disc, then it

should replace the brake block .

1. Remove the rear wheel

2. Check the thickness of brake block bush.

Measure the thickness of the brake block bush (abrasion material)

from the eyehole of tong. If the thickness is not within the specified

range, then it should replace the brake block.

minimum thickness: 2.0mm.

Page 304 of 425

Brake-18

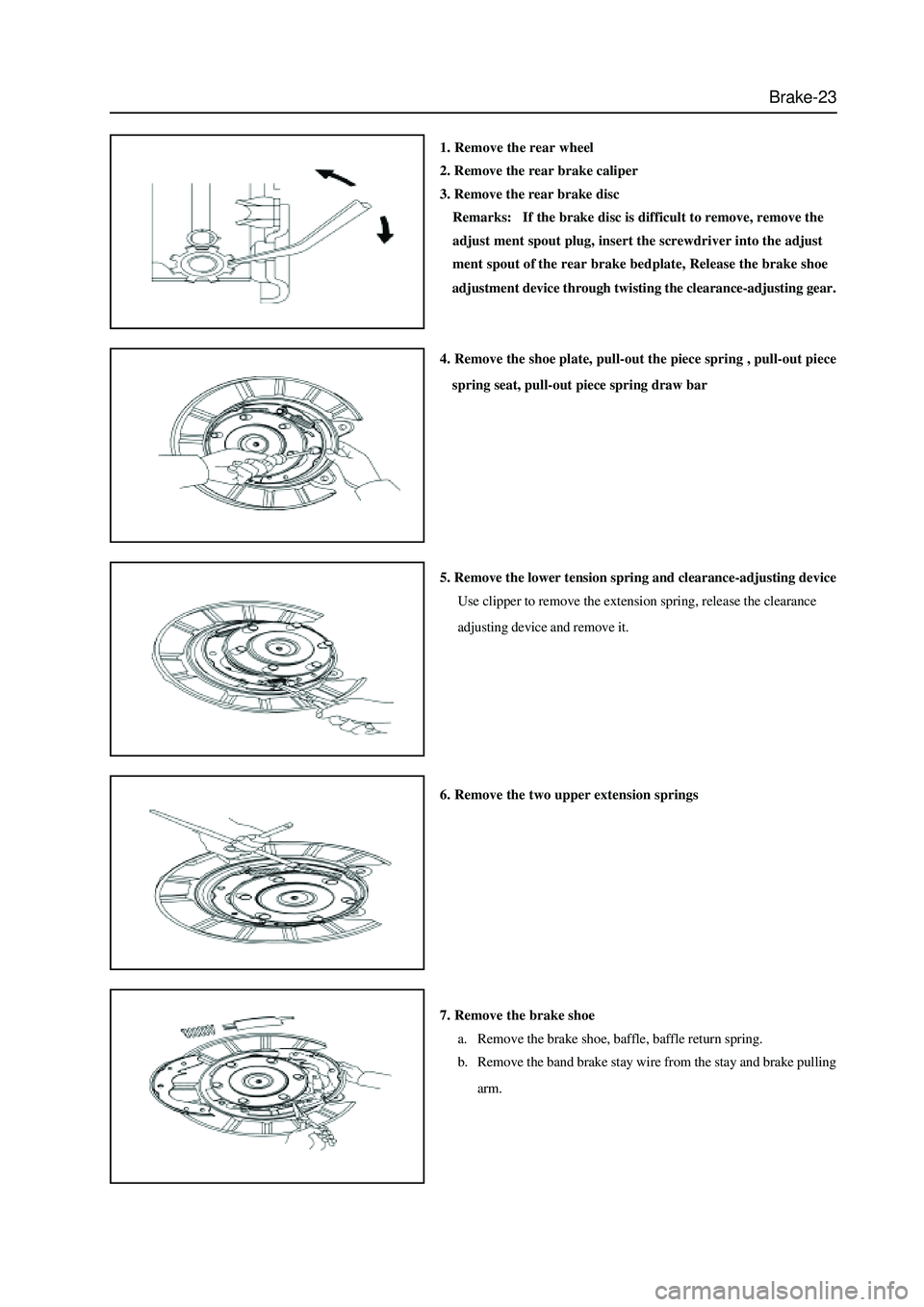

8. Install new brake block

a. Install a brake block bush wearing indication plate on the internal

brake block.

b. Install one silencing plate and one silencing plate combination on

each brake block.

Remarks: Coat the two sides of silencing plate with disc brake

oil (which cannot be replaced with oil of other models).

c. Install two brake blocks, make the wearing indication plate in the

lower position (near the tank cylinder).

Remarks: The working surface of the brake block and brake

disc are not allowed to be contaminated by grease and paint.

9. Install the sub pump

a. Unscrew the release screw, absorb some of the brake fluid.

b. Press the plunger with hammer beam or similar tools, and unscrew

the release screw at the same time.

Tightening force: 8

13Nm

Remarks: Only the brake block of one wheel can be replaced for

once, lest the plunger on the opposite side be bounced.

c. Install and tighten the location pin.

Tightening force: 25

30Nm

10. Install the rear wheel

Tightening force: 120N

m

11. Fill up with the brake fluid and drain the air in the brake

system after the completion of replacement.

Page 309 of 425

Brake-23

1. Remove the rear wheel

2. Remove the rear brake caliper

3. Remove the rear brake disc

Remarks: If the brake disc is difficult to remove, remove the

adjust ment spout plug, insert the screwdriver into the adjust

ment spout of the rear brake bedplate, Release the brake shoe

adjustment device through twisting the clearance-adjusting gear.

4. Remove the shoe plate, pull-out the piece spring , pull-out piece

spring seat, pull-out piece spring draw bar

5. Remove the lower tension spring and clearance-adjusting device

Use clipper to remove the extension spring, release the clearance

adjusting device and remove it.

6. Remove the two upper extension springs

7. Remove the brake shoe

a. Remove the brake shoe, baffle, baffle return spring.

b. Remove the band brake stay wire from the stay and brake pulling

arm.

Page 311 of 425

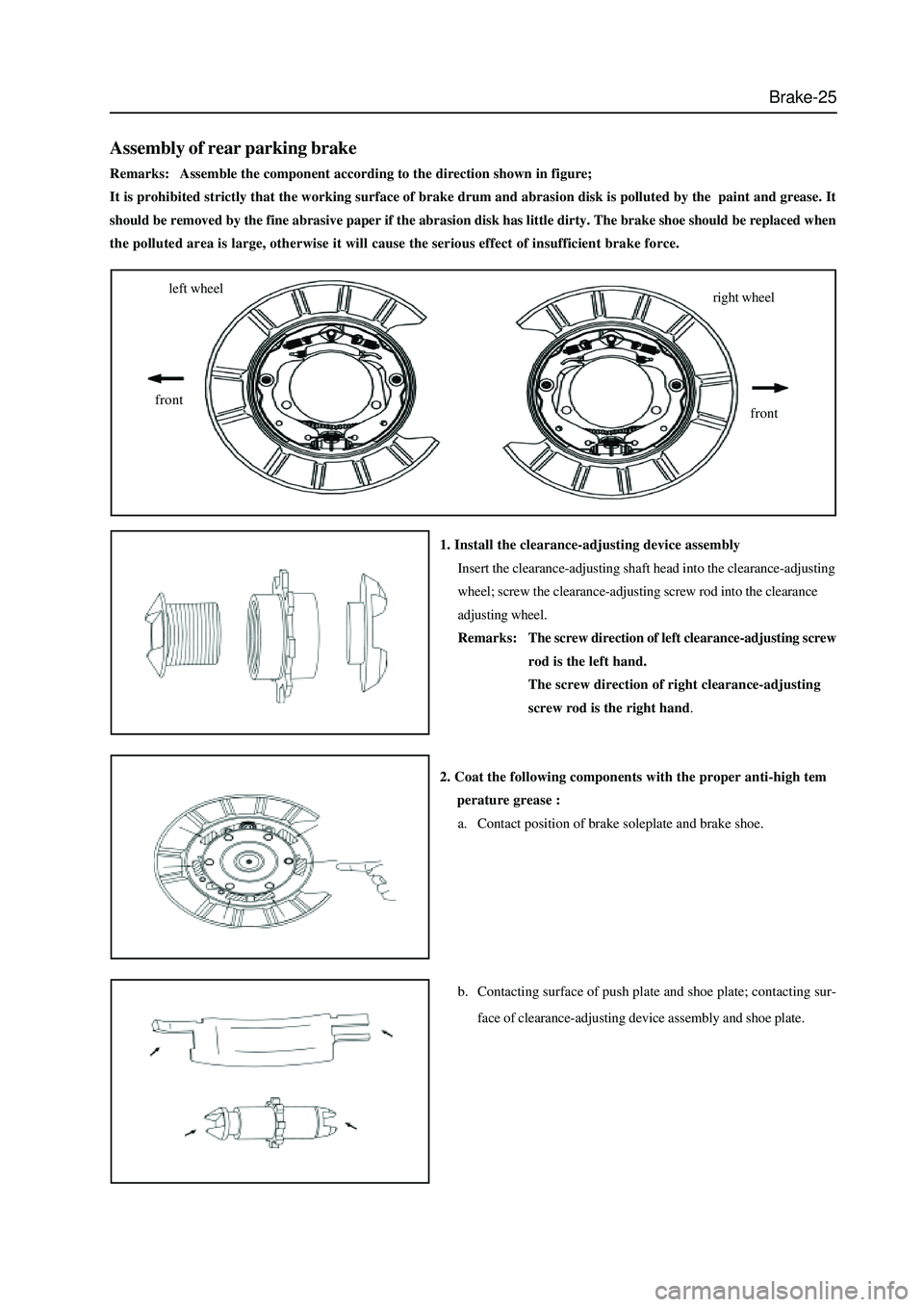

Brake-25

1. Install the clearance-adjusting device assembly

Insert the clearance-adjusting shaft head into the clearance-adjusting

wheel; screw the clearance-adjusting screw rod into the clearance

adjusting wheel.

Remarks:The screw direction of left clearance-adjusting screw

rod is the left hand.

The screw direction of right clearance-adjusting

screw rod is the right hand.

2. Coat the following components with the proper anti-high tem

perature grease :

a. Contact position of brake soleplate and brake shoe.

b. Contacting surface of push plate and shoe plate; contacting sur-

face of clearance-adjusting device assembly and shoe plate.

Assembly of rear parking brake

Remarks: Assemble the component according to the direction shown in figure;

It is prohibited strictly that the working surface of brake drum and abrasion disk is polluted by the paint and grease. It

should be removed by the fine abrasive paper if the abrasion disk has little dirty. The brake shoe should be replaced when

the polluted area is large, otherwise it will cause the serious effect of insufficient brake force.

left wheel

frontright wheel

front

Page 314 of 425

Brake-28

10. Adjust the clearance between the brake drum and brake shoe.

Poke the adjusting hole plug on the brake drum, insert the screwdriver

into the clearance-adjusting hole; rotate the clearance-adjusting gear

to expand the brake shoe until the brake disc can not be rotated by

hand. Then rotate it for 3-5 teeth in anticlockwise, rotate the brake

disc by hand at the same time, it is proper that it can rotate freely

and without the contact between the abrasion and disc. It is allowable

that the non-running-in brake shoe has the slight abrasion sensing.

When adjust the clearance, the left and right wheel must be adjust at

the same, install the adjusting hole plug after the completion of

adjusting .

11.Rear brake caliper assembly

12.Rear wheel assembly

Tighten torque :120N.m

Page 315 of 425

Brake-29

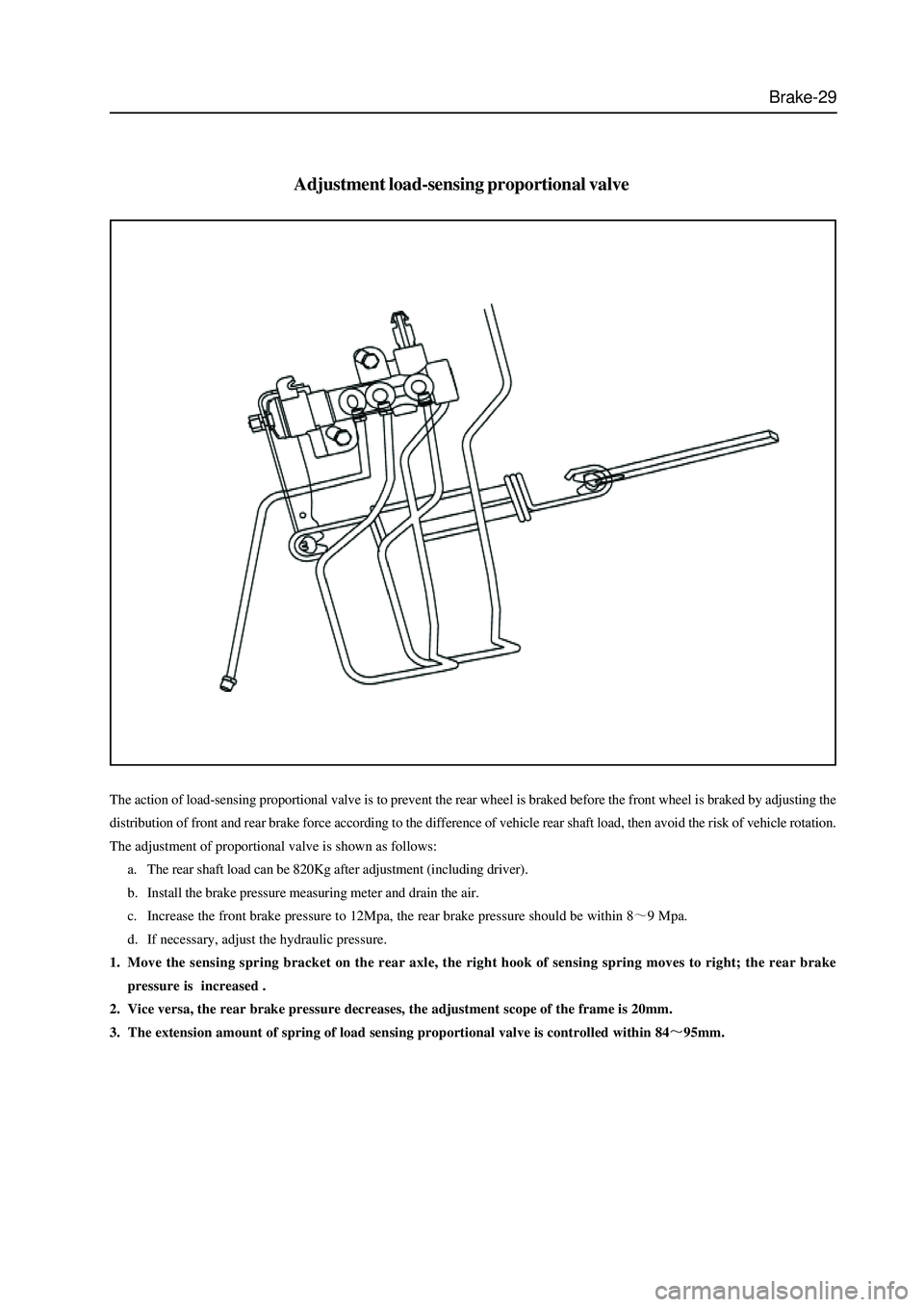

The action of load-sensing proportional valve is to prevent the rear wheel is braked before the front wheel is braked by adjusting the

distribution of front and rear brake force according to the difference of vehicle rear shaft load, then avoid the risk of vehicle rotation.

The adjustment of proportional valve is shown as follows:

a. The rear shaft load can be 820Kg after adjustment (including driver).

b. Install the brake pressure measuring meter and drain the air.

c. Increase the front brake pressure to 12Mpa, the rear brake pressure should be within 8

9 Mpa.

d. If necessary, adjust the hydraulic pressure.

1. Move the sensing spring bracket on the rear axle, the right hook of sensing spring moves to right; the rear brake

pressure is increased .

2. Vice versa, the rear brake pressure decreases, the adjustment scope of the frame is 20mm.

3. The extension amount of spring of load sensing proportional valve is controlled within 84

95mm.

Adjustment load-sensing proportional valve

Page 317 of 425

Brake-31

Antilock Braking System (ABS)

Cautions

1. It must not remove or install the electric elements and wire bunch plug when the ignition switch is in ON to avoid

the damage of ECU. It should turn off the ignition switch if needs disassembly.

2. Pay attention to do not knock or impact the ABS ECU during the maintenance and repair, for it will damage the

ABS ECU easily.

3. The wheel speed sensor and hydraulic unit (integrated with ECU) of BOSCH ABS8.0 can not be repaired, it should

be replaced in integral if damaged.

4. After the brake system is maintained, the brake pedal maybe soft. Discharge the air according to the normal brake

system.

5. It must use the brake fluid from original manufacturer; the brake fluid of different number cannot be used in mixed,

otherwise it will cause the failure of brake system. Select the tyre of original type as most as possible

Repair of Antilock Braking System (ABS)

1. It should process the failure diagnosis for the brake system before process the ABS failure diagnosis. It can

diagnose out the failure rapidly by using Table 1. In Table 1, the small number means the failure which occurs most

possibly. Check each element according to the sequence and maintain or replace it if necessary.

2. Check the following elements for normal operation before the diagnosis:

Brake fluid level and brake fluid quality

Pressure of tyre, size of tyre, shape and depth of tyre figure

Other brake component

These components will affect the brake effect of the ABS. Check the system sensor, connecting wire and connector for correct

installation, arrangement and connection. Ensure the completeness of fuse, repair or replace it if necessary.

3. Process the analysis and diagnosis according to the ABS advanced by owner. Use the diagnosis instrument (Annex

1) for final check and confirmation. It must process the run inspection after the competition of all ABS maintenance.

The test condition is shown as follows:

a. Confirm the tyre complies with the requirement, the tyre pressure is normal.

b. The brake system (including brake light ) is normal

c. The brake system is without leakage.

d. The position and installation of wheel speed sensor is correct.

e. All fuses are normal.

4. test method:

Run for 1 min at least when the vehicle speed is beyond 40Km/h, process a proper brake. Then read out the failure code to

ensure the ABS is without failure code.

Page 324 of 425

Steering-5

Technical requirements

1.The fastening torque of the mounting bolts of the integral power

steering gear assembly is

2.The fastening torque of the connecting bolts of the steering drive sub-

assembly and the integral power steering gear assembly is

3. The fastening torque of the connecting bolts of the steering drive

assembly and the left horizontal beam of the frame is

4. The fastening torque of the mounting bolts of the power steering

pump is 40N.m.

5. The tension force of multi-wedge belt 4PK1100 is 4PK1100.

6. Centering fastening of the handwheel: steer the front wheel to the

right front and remove the handwheel without changing the position

of the steering stem, install the handwheel aligning the center, the

radials of the handwheel should be at the left & right centering state;

the symbol of “the Great Wall” on the steering wheel shall be in

driver’s straight view position, secure the nut firmly with the

fastening torque of

7. Inspection of free clearance of the handwheel

Steer the car in a straight direction and stop the engine, apply a 5N force to

the handwheel along the circumference, left turn the handwheel and stop

the turning when the resistance is increasingly felt with each turn; then right

turn the handwheel and stop the turning when the resistance is increasingly

felt with each turn; the angle rotated along the circumference is the free

clearance of the handwheel, whose standard value shall be below 20

, and

the angle from the center to the right shall not be more than 10

Page 388 of 425

Safety airbag-18

Impact-vehicle diagnosis

Test SRS-ECU diagnostic signals

1. Connect the (X-431 diagnostic test’s) diagnostic joint

2. Read the diagnostic results with X-431 diagnostic tester

Repairing procedure

1.When safety airbag is released.

The following parts should be replaced with new ones

a. Passengers’ side safety airbag module

b. SRS-ECU

c. Driver’s side safety airbag module

2 Check the following parts; replace them with new ones providing something wrong with them.

a. Clock spring

b. Steering-wheel, steering column, bottom steering shaft module

3.Driver’s side safety airbag module’s installation status towards the steering wheel.

a. Check whether abnormal knocking is with the steering wheel, its activity is in good condition and its clearance is normal.

b. Check whether the wiring harness joint is broken and its terminal is deformed.

Caution: Due to the impact, the diagnostic instrument cannot communicate with SRS-ECU when accumulator is lack of

power, in this case, check and maintain the instrument panel wiring harness or utilize the extension power supply.

Page 389 of 425

Safety airbag-19

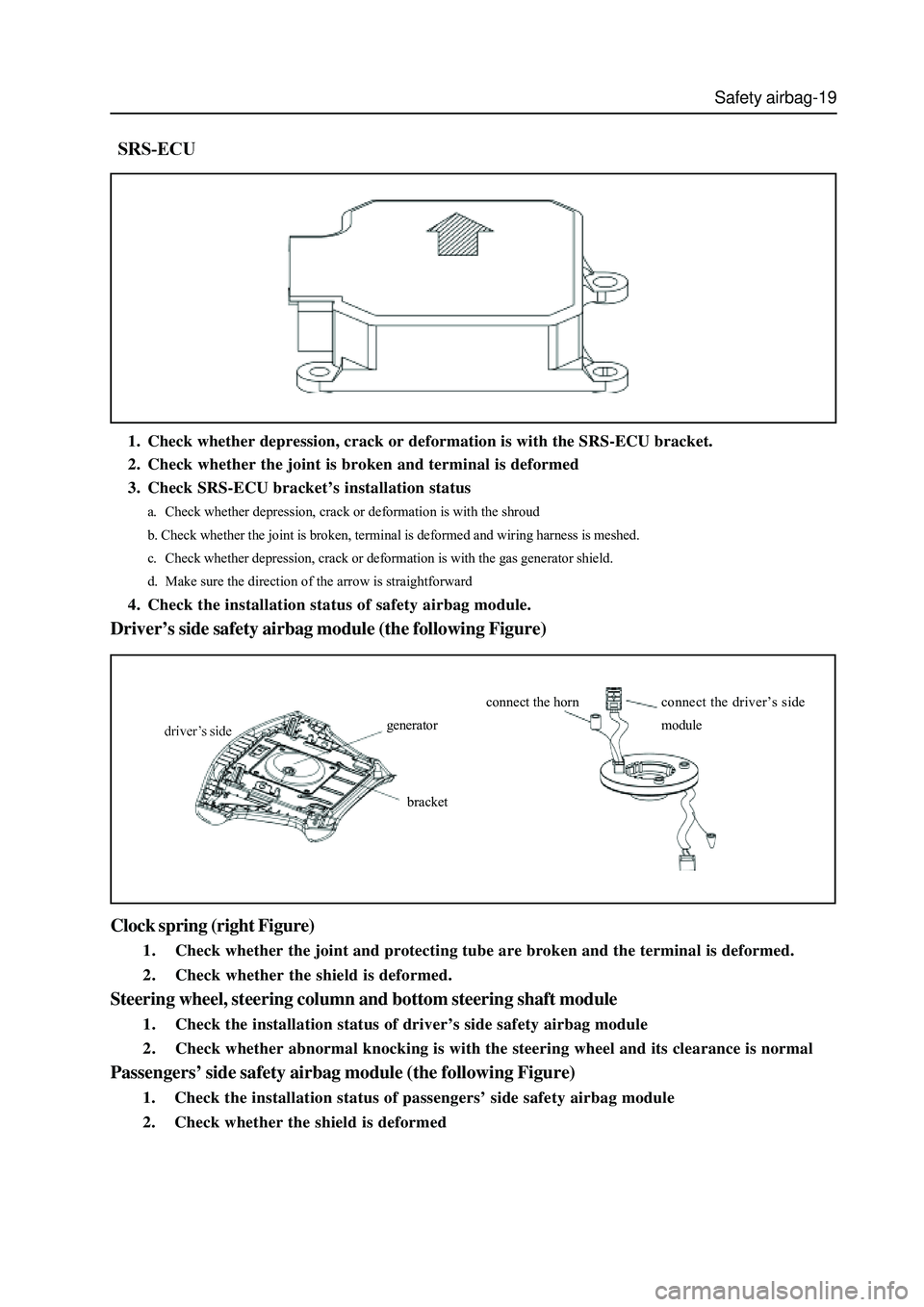

1. Check whether depression, crack or deformation is with the SRS-ECU bracket.

2. Check whether the joint is broken and terminal is deformed

3. Check SRS-ECU bracket’s installation status

a. Check whether depression, crack or deformation is with the shroud

b. Check whether the joint is broken, terminal is deformed and wiring harness is meshed.

c. Check whether depression, crack or deformation is with the gas generator shield.

d. Make sure the direction of the arrow is straightforward

4. Check the installation status of safety airbag module.

Driver’s side safety airbag module (the following Figure)

generator

bracketconnect the hornconnect the driver’s side

module

Clock spring (right Figure)

1. Check whether the joint and protecting tube are broken and the terminal is deformed.

2. Check whether the shield is deformed.

Steering wheel, steering column and bottom steering shaft module

1. Check the installation status of driver’s side safety airbag module

2. Check whether abnormal knocking is with the steering wheel and its clearance is normal

Passengers’ side safety airbag module (the following Figure)

1. Check the installation status of passengers’ side safety airbag module

2. Check whether the shield is deformed