wheel GREAT WALL HOVER 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 214 of 425

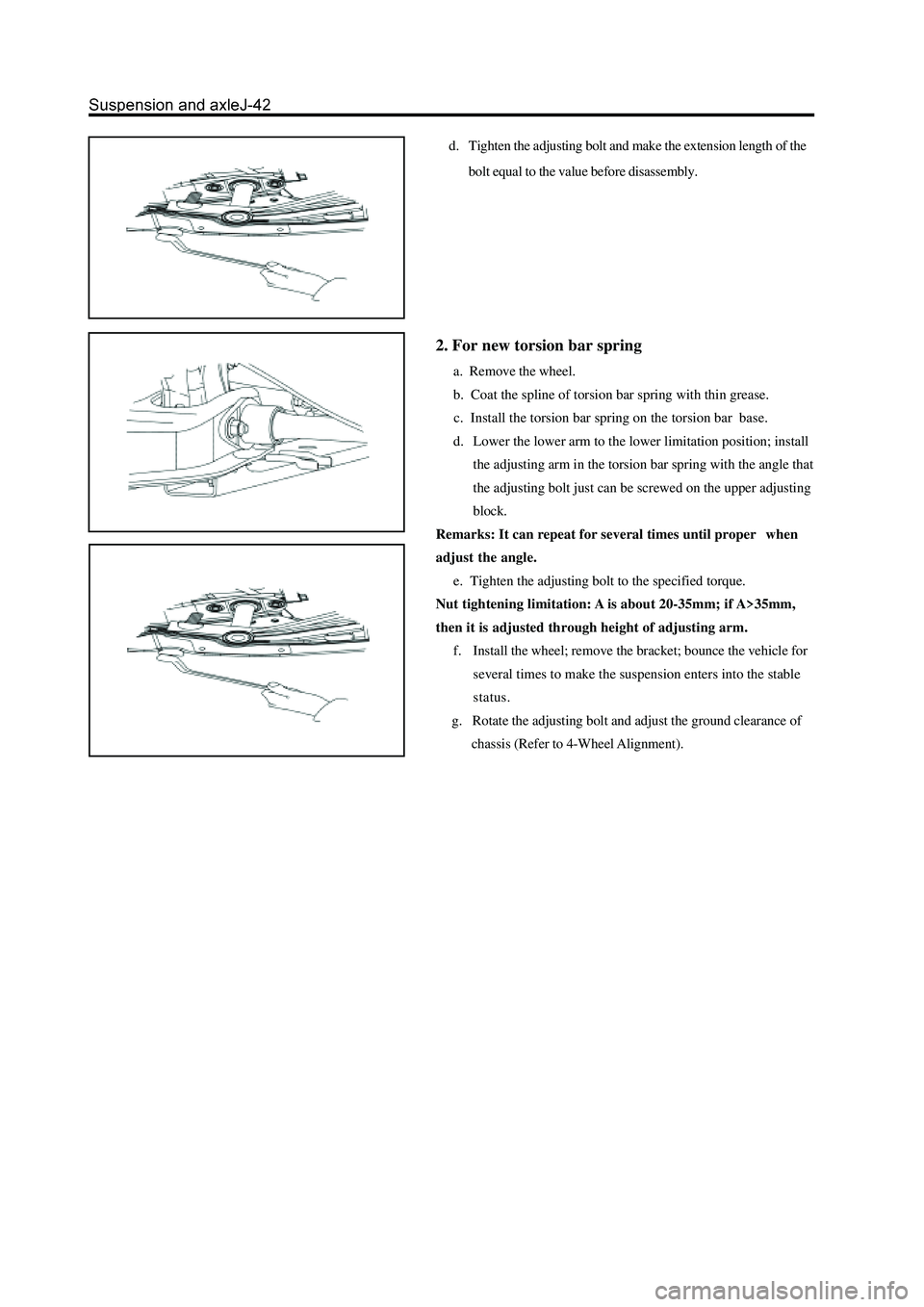

d. Tighten the adjusting bolt and make the extension length of the

bolt equal to the value before disassembly.

2. For new torsion bar spring

a. Remove the wheel.

b. Coat the spline of torsion bar spring with thin grease.

c. Install the torsion bar spring on the torsion bar base.

d. Lower the lower arm to the lower limitation position; install

the adjusting arm in the torsion bar spring with the angle that

the adjusting bolt just can be screwed on the upper adjusting

block.

Remarks: It can repeat for several times until proper when

adjust the angle.

e. Tighten the adjusting bolt to the specified torque.

Nut tightening limitation: A is about 20-35mm; if A>35mm,

then it is adjusted through height of adjusting arm.

f. Install the wheel; remove the bracket; bounce the vehicle for

several times to make the suspension enters into the stable

status.

g. Rotate the adjusting bolt and adjust the ground clearance of

chassis (Refer to 4-Wheel Alignment).

Page 218 of 425

6. Install the torsion bar spring

(Refer to the section “Torsion Bar Spring”)

7. Tighten the nut of front shaft of lower arm to the

specified torque

a. Install the wheel, remove the bracket and bounce the vehicle

for several times to make the vibration damper enters into the

stable status.

b. Align the assembly mark and tighten the nut to the specified

torque.

Tightening force: 240

20Nm

8. Check the wheel alignment parameter

(Refer to 4-Wheel Alignment)

Page 222 of 425

5. Connect the brake hose to the brake caliper.

Install the copper gasket seal and tighten the hollow bolt to the

specified torque.

Tightening force: 50±5N·m

6. Discharge the air in front brake system

(Refer to relevant chapter)

Remarks: It must discharge the air in the rear brake system

i f disassembly the right upper arm.

7. Check the brake fluid for leakage

8. Tighten the upper arm front shaft nut to the

specified torque

a. Install the wheel, remove the bracket and bounce the vehicle for

several times to make the vibration damper enters into the stable

status.

b.Align the assembly mark and tighten the nut to the specified

torque.

Tightening force: 240±20N·m

9. Check the wheel alignment parameter

(Refer to 4-Wheel Alignment)

Page 225 of 425

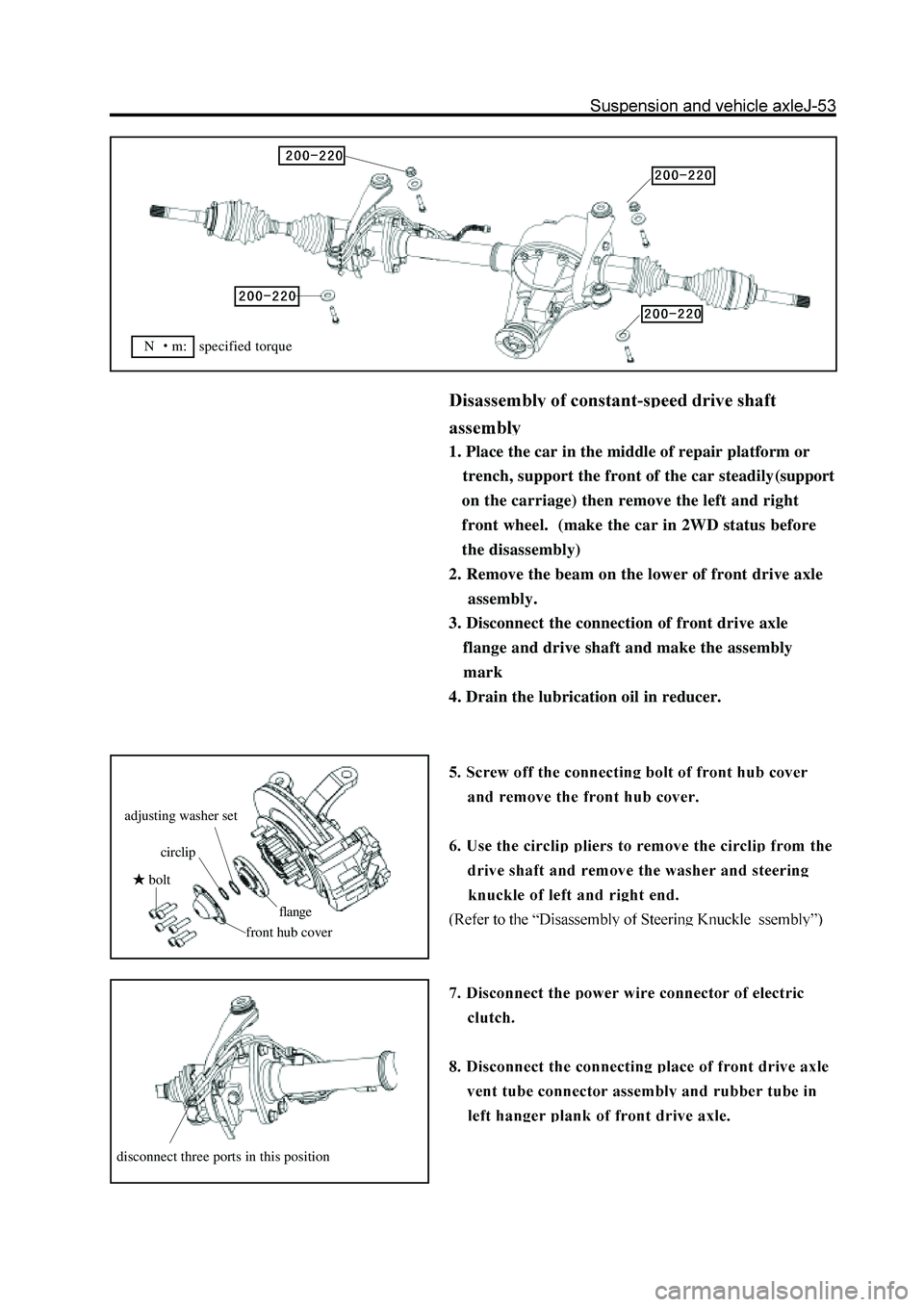

1. Place the car in the middle of repair platform or

trench, support the front of the car steadily(support

on the carriage) then remove the left and right

front wheel. (make the car in 2WD status before

the disassembly)

2. Remove the beam on the lower of front drive axle

assembly.

3. Disconnect the connection of front drive axle

flange and drive shaft and make the assembly

mark

4. Drain the lubrication oil in reducer.

bolt

front hub cover

circlip

adjusting washer set

flange

disconnect three ports in this position

N m: specified torque

Page 235 of 425

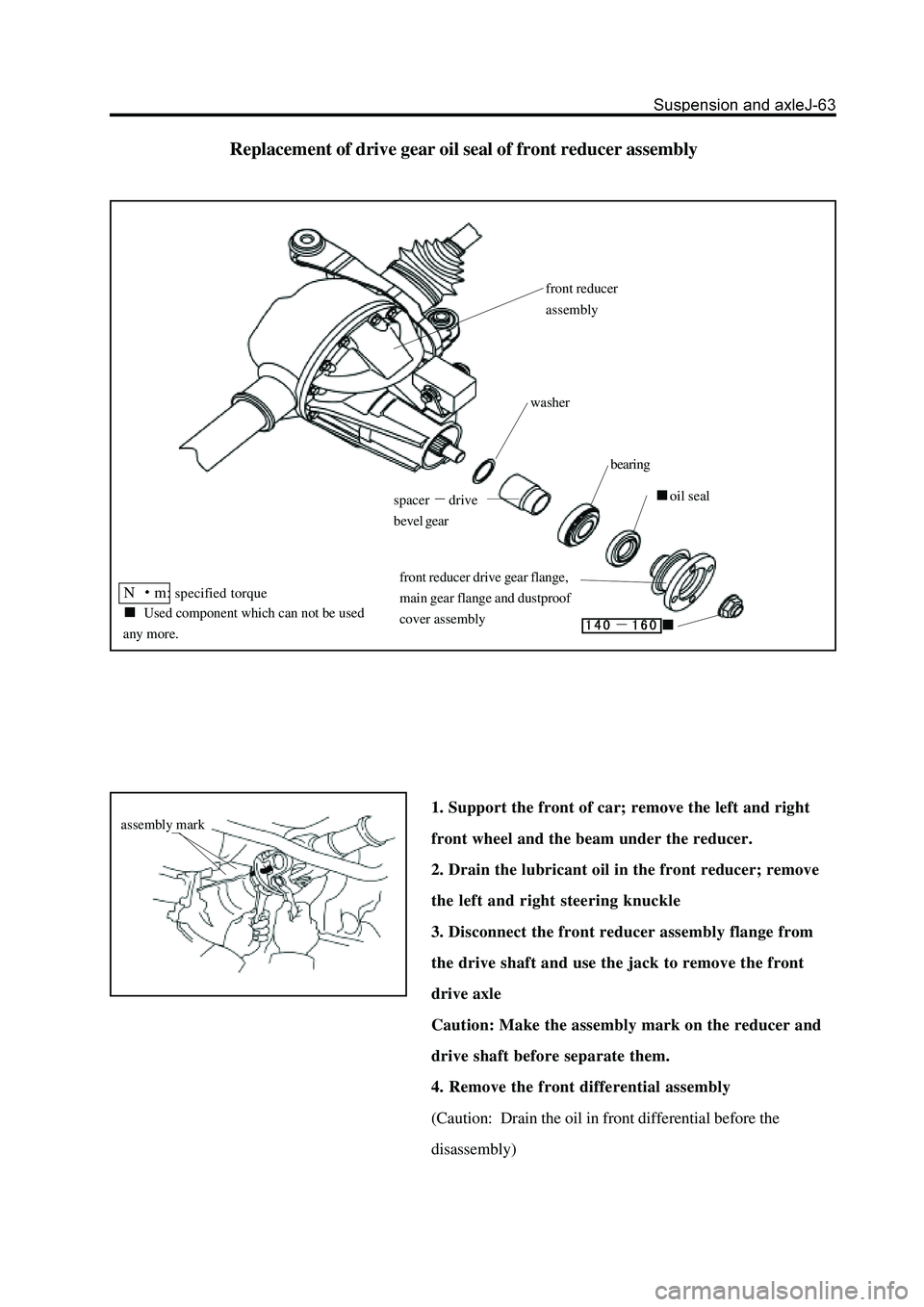

Replacement of drive gear oil seal of front reducer assembly

1. Support the front of car; remove the left and right

front wheel and the beam under the reducer.

2. Drain the lubricant oil in the front reducer; remove

the left and right steering knuckle

3. Disconnect the front reducer assembly flange from

the drive shaft and use the jack to remove the front

drive axle

Caution: Make the assembly mark on the reducer and

drive shaft before separate them.

4. Remove the front differential assembly

(Caution: Drain the oil in front differential before the

disassembly)

front reducer

assembly

washer

spacer drive

bevel gear

bearing

oil seal

front reducer drive gear flange,

main gear flange and dustproof

cover assembly

Used component which can not be used

any more.

N m: specified torque

assembly mark

Page 240 of 425

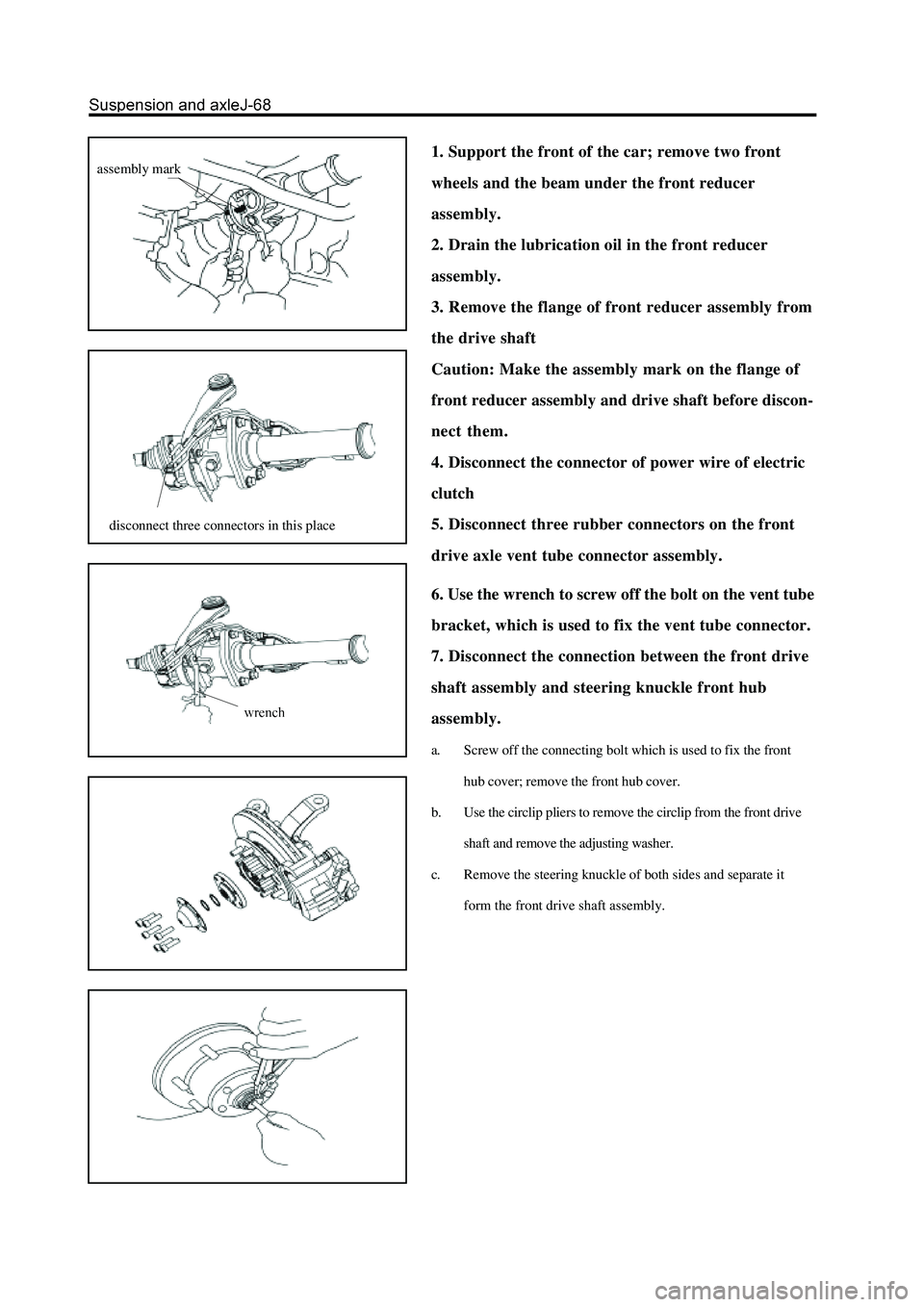

6. Use the wrench to screw off the bolt on the vent tube

bracket, which is used to fix the vent tube connector.

7. Disconnect the connection between the front drive

shaft assembly and steering knuckle front hub

assembly.

a. Screw off the connecting bolt which is used to fix the front

hub cover; remove the front hub cover.

b. Use the circlip pliers to remove the circlip from the front drive

shaft and remove the adjusting washer.

c. Remove the steering knuckle of both sides and separate it

form the front drive shaft assembly.

1. Support the front of the car; remove two front

wheels and the beam under the front reducer

assembly.

2. Drain the lubrication oil in the front reducer

assembly.

3. Remove the flange of front reducer assembly from

the drive shaft

Caution: Make the assembly mark on the flange of

front reducer assembly and drive shaft before discon-

nect them.

4. Disconnect the connector of power wire of electric

clutch

5. Disconnect three rubber connectors on the front

drive axle vent tube connector assembly.

assembly mark

disconnect three connectors in this place

Page 242 of 425

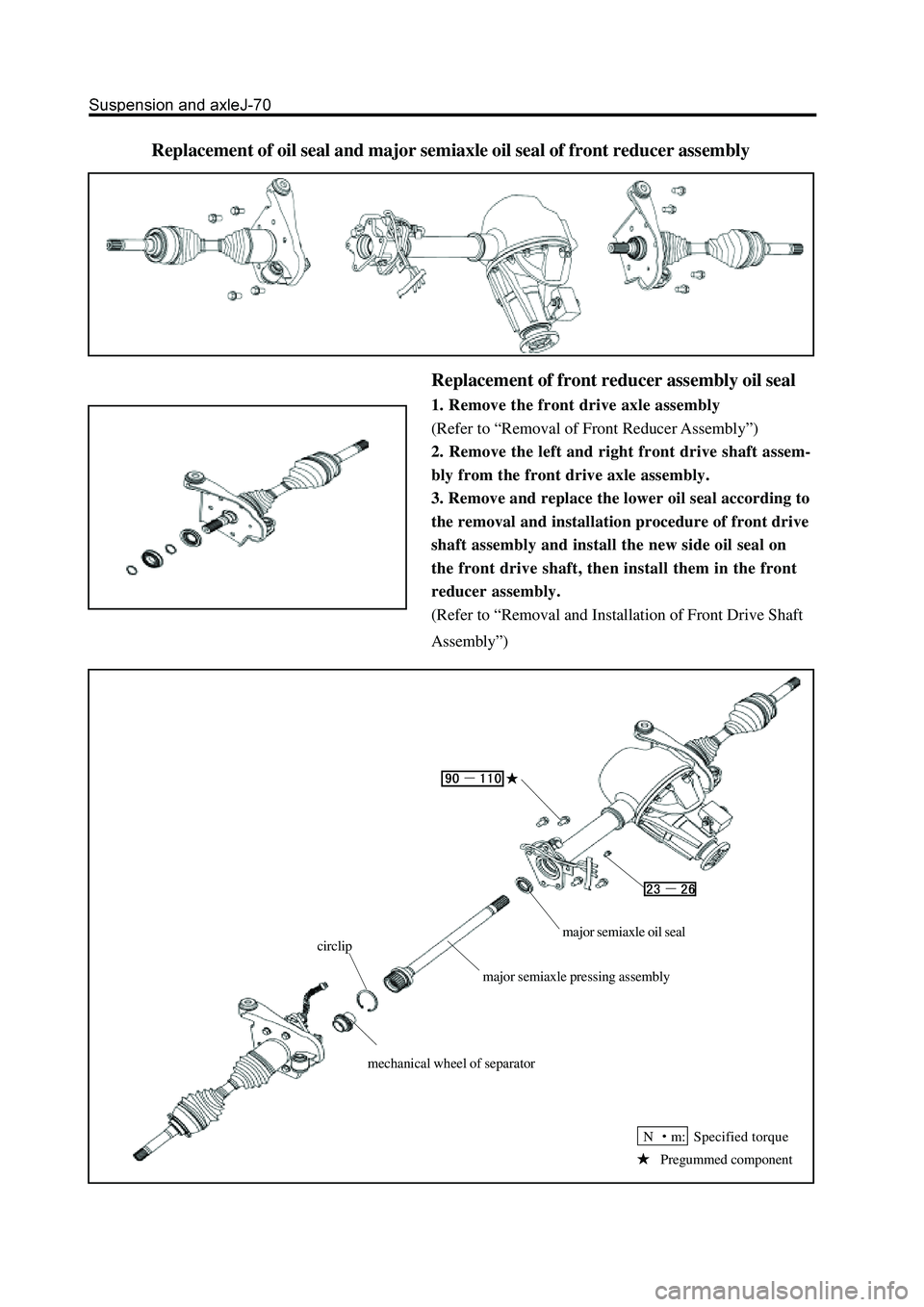

Replacement of front reducer assembly oil seal

1. Remove the front drive axle assembly

(Refer to “Removal of Front Reducer Assembly”)

2. Remove the left and right front drive shaft assem-

bly from the front drive axle assembly.

3. Remove and replace the lower oil seal according to

the removal and installation procedure of front drive

shaft assembly and install the new side oil seal on

the front drive shaft, then install them in the front

reducer assembly.

(Refer to “Removal and Installation of Front Drive Shaft

Assembly”)

Replacement of oil seal and major semiaxle oil seal of front reducer assembly

major semiaxle oil seal

major semiaxle pressing assembly

circlip

mechanical wheel of separator

Pregummed component N

m: Specified torque

Page 243 of 425

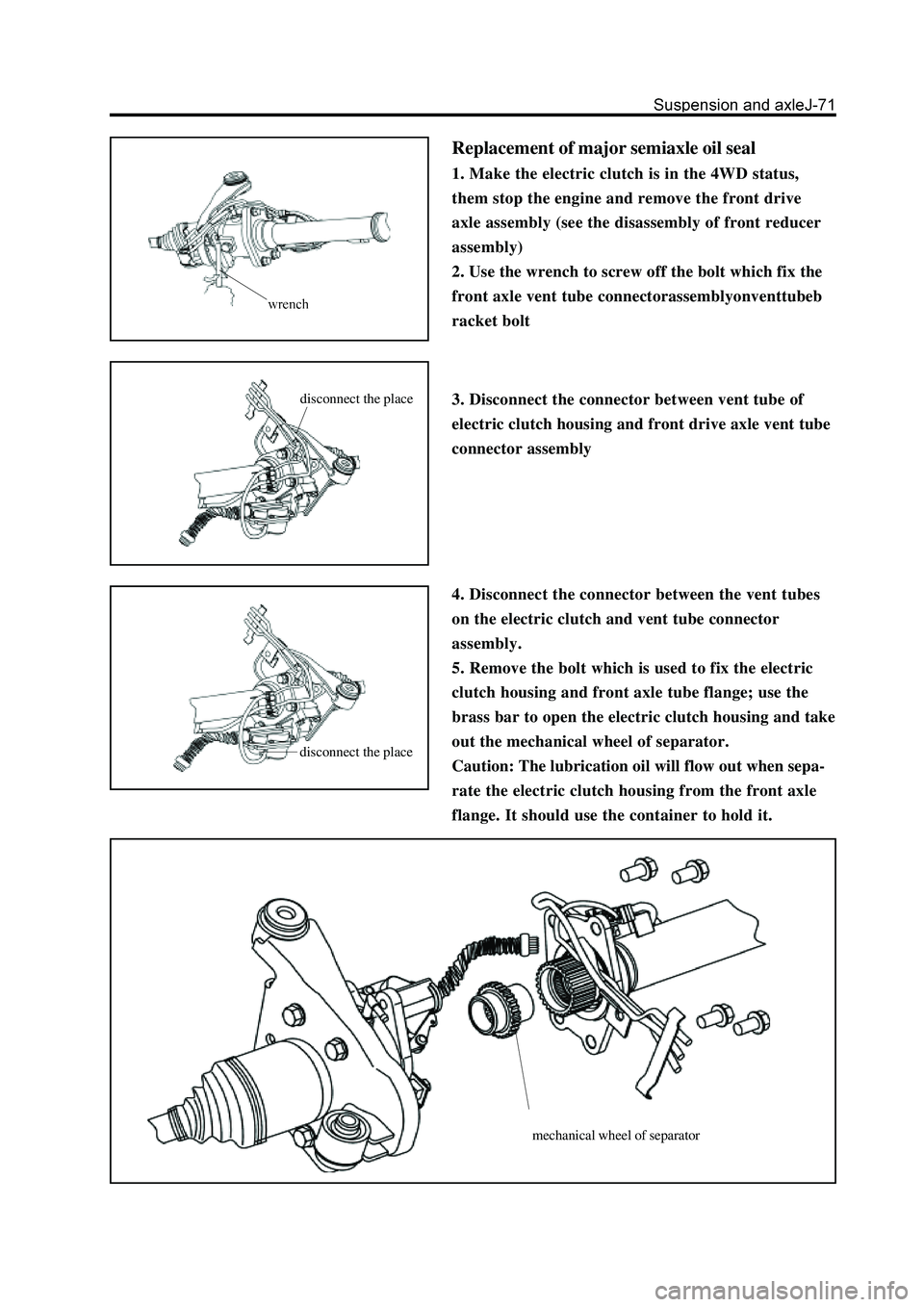

Replacement of major semiaxle oil seal

1. Make the electric clutch is in the 4WD status,

them stop the engine and remove the front drive

axle assembly (see the disassembly of front reducer

assembly)

2. Use the wrench to screw off the bolt which fix the

front axle vent tube connectorassemblyonventtubeb

racket bolt

3. Disconnect the connector between vent tube of

electric clutch housing and front drive axle vent tube

connector assembly

4. Disconnect the connector between the vent tubes

on the electric clutch and vent tube connector

assembly.

5. Remove the bolt which is used to fix the electric

clutch housing and front axle tube flange; use the

brass bar to open the electric clutch housing and take

out the mechanical wheel of separator.

Caution: The lubrication oil will flow out when sepa-

rate the electric clutch housing from the front axle

flange. It should use the container to hold it.

mechanical wheel of separator

disconnect the place

disconnect the place

Page 246 of 425

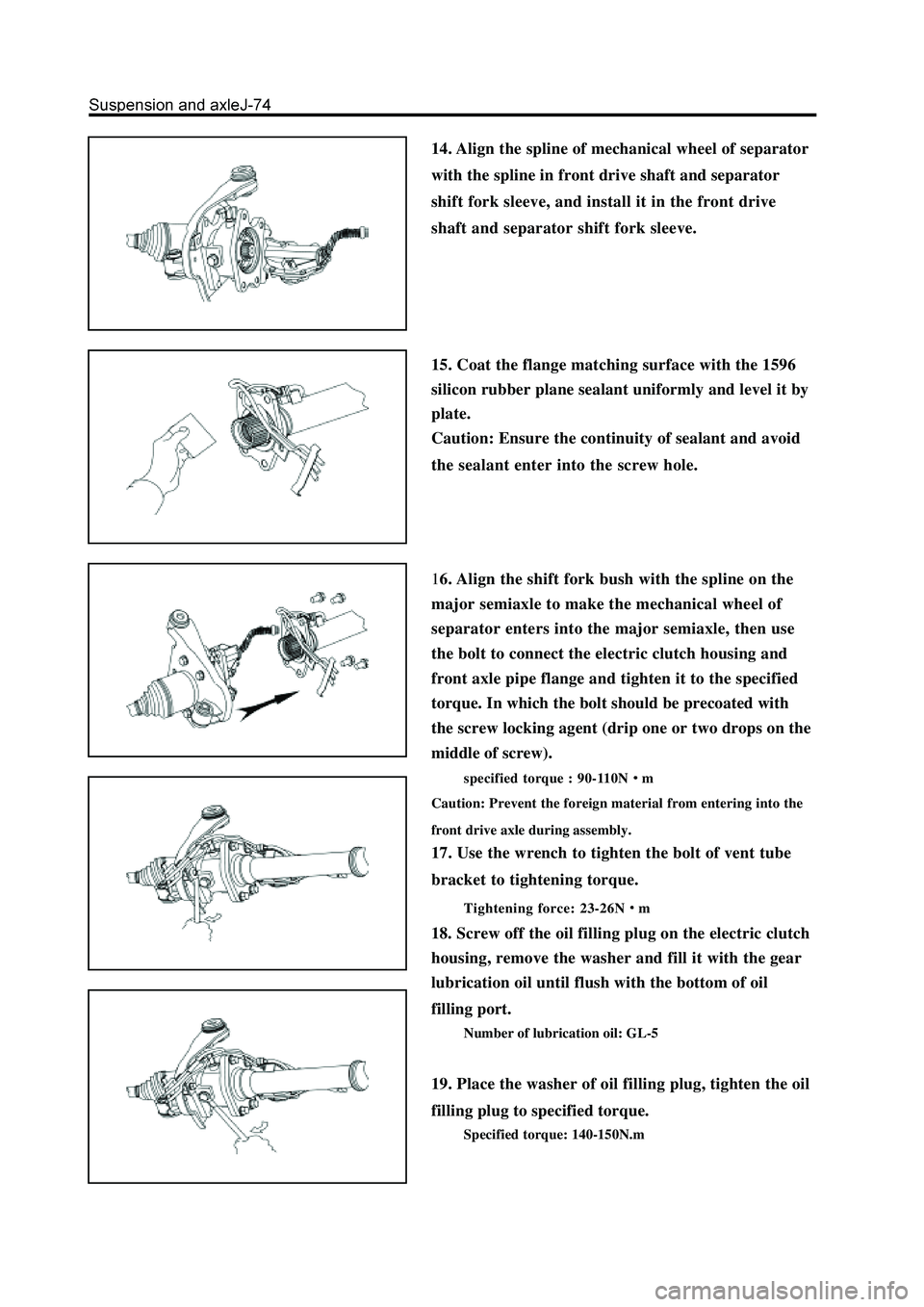

14. Align the spline of mechanical wheel of separator

with the spline in front drive shaft and separator

shift fork sleeve, and install it in the front drive

shaft and separator shift fork sleeve.

15. Coat the flange matching surface with the 1596

silicon rubber plane sealant uniformly and level it by

plate.

Caution: Ensure the continuity of sealant and avoid

the sealant enter into the screw hole.

16. Align the shift fork bush with the spline on the

major semiaxle to make the mechanical wheel of

separator enters into the major semiaxle, then use

the bolt to connect the electric clutch housing and

front axle pipe flange and tighten it to the specified

torque. In which the bolt should be precoated with

the screw locking agent (drip one or two drops on the

middle of screw).

specified torque : 90-110Nm

Caution: Prevent the foreign material from entering into the

front drive axle during assembly.

17. Use the wrench to tighten the bolt of vent tube

bracket to tightening torque.

Tightening force: 23-26Nm

18. Screw off the oil filling plug on the electric clutch

housing, remove the washer and fill it with the gear

lubrication oil until flush with the bottom of oil

filling port.

Number of lubrication oil: GL-5

19. Place the washer of oil filling plug, tighten the oil

filling plug to specified torque.

Specified torque: 140-150N.m

Page 248 of 425

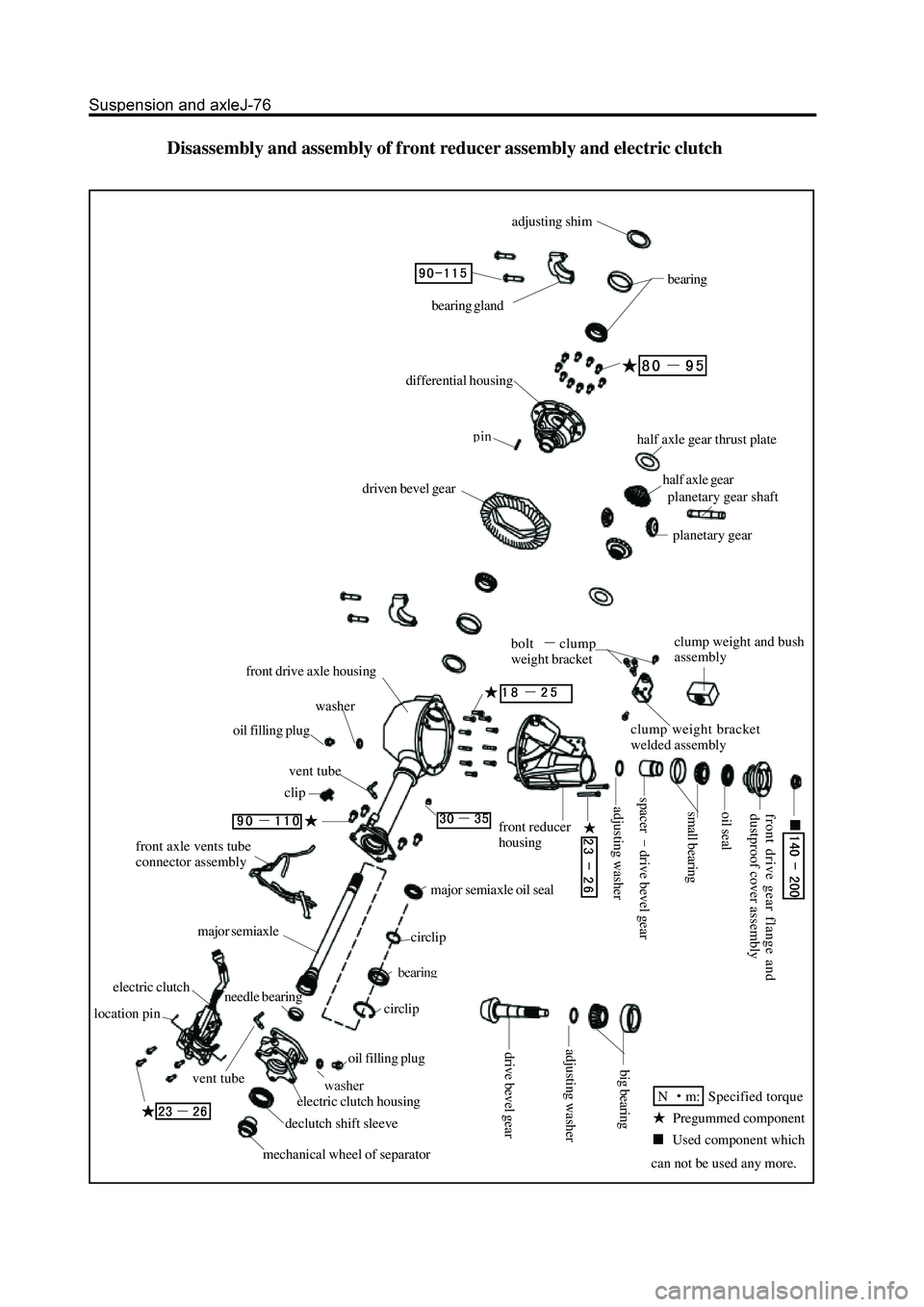

Disassembly and assembly of front reducer assembly and electric clutch

adjusting shim

bearing gland

differential housing

driven bevel gear

front drive axle housing

washer

oil filling plug

vent tube

clip

front axle vents tube

connector assembly

major semiaxle

needle bearingelectric clutch

location pin

vent tube

mechanical wheel of separator

declutch shift sleeve

electric clutch housing

oil filling plug

circlip

major semiaxle oil seal

half axle gear thrust plate

half axle gear

planetary gear shaft

planetary gear

bolt clump

weight bracketclump weight and bush

assembly

clump weight bracket

welded assembly

front reducer

housing

adjusting washerspacer

drive bevel gear

small bearingoil sealfront drive gear flange and

dustproof cover assembly

drive bevel gearadjusting washer

Pregummed component

N m: Specified torque

Used component which

can not be used any more.bearing

circlip

big bearing