wheel bolts GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 39 of 425

Clutch-9

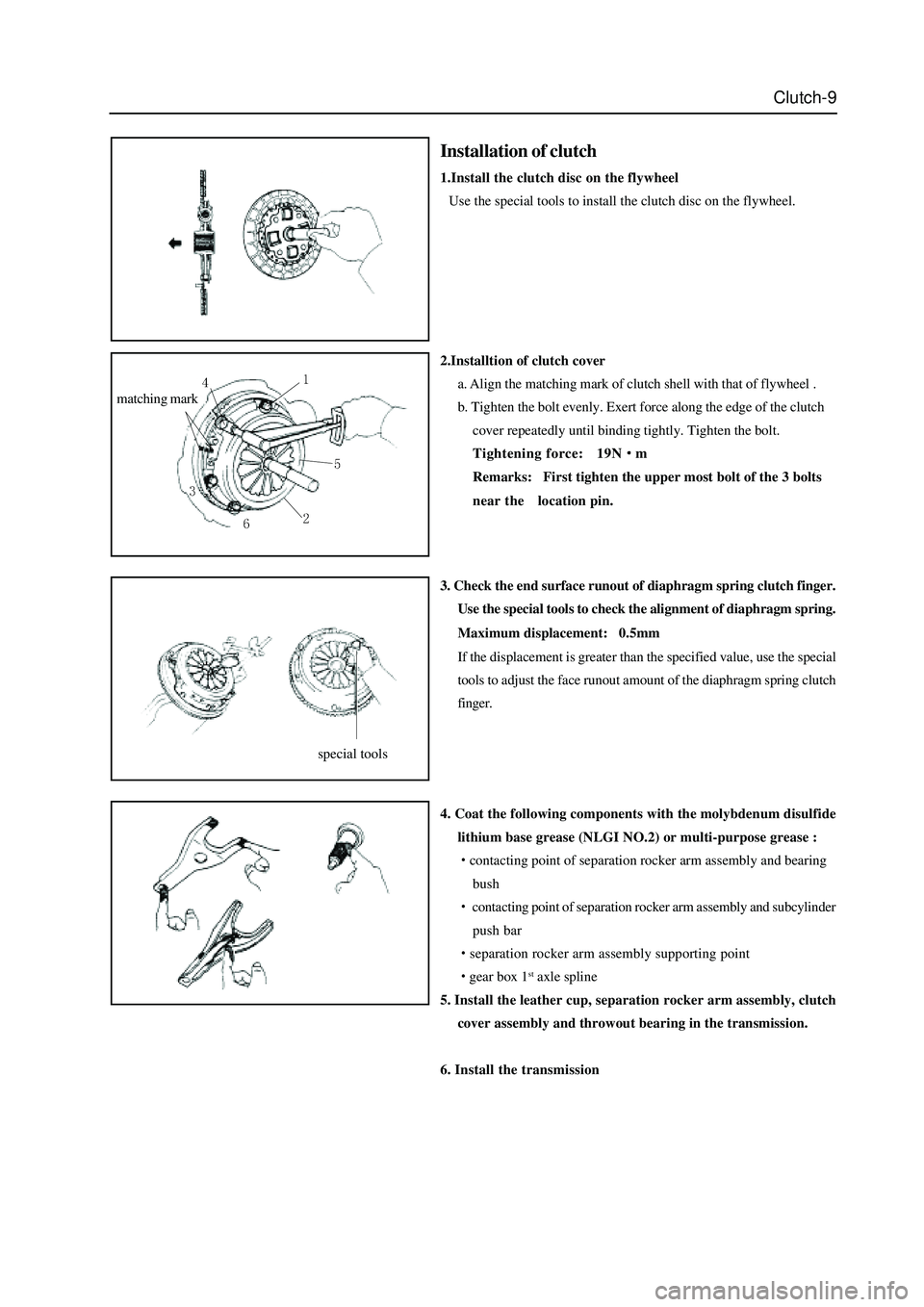

2.Installtion of clutch cover

a. Align the matching mark of clutch shell with that of flywheel .

b. Tighten the bolt evenly. Exert force along the edge of the clutch

cover repeatedly until binding tightly. Tighten the bolt.

Tightening force: 19N

m

Remarks: First tighten the upper most bolt of the 3 bolts

near thelocation pin.

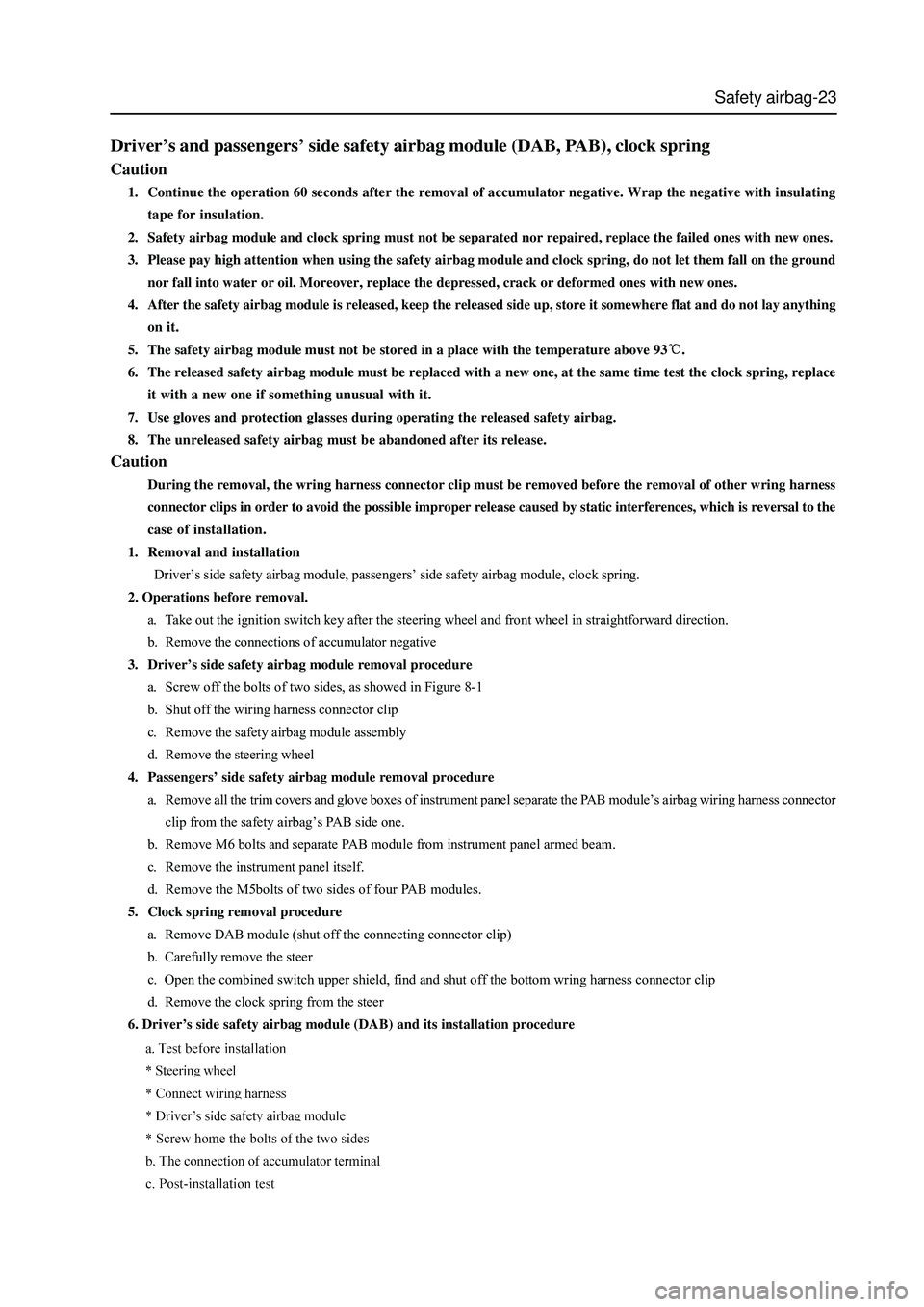

3. Check the end surface runout of diaphragm spring clutch finger.

Use the special tools to check the alignment of diaphragm spring.

Maximum displacement: 0.5mm

If the displacement is greater than the specified value, use the special

tools to adjust the face runout amount of the diaphragm spring clutch

finger.

4. Coat the following components with the molybdenum disulfide

lithium base grease (NLGI NO.2) or multi-purpose grease :

contacting point of separation rocker arm assembly and bearing

bush

contacting point of separation rocker arm assembly and subcylinder

push bar

separation rocker arm assembly supporting point

gear box 1st axle spline

5. Install the leather cup, separation rocker arm assembly, clutch

cover assembly and throwout bearing in the transmission.

6. Install the transmission

matching mark

Installation of clutch

1.Install the clutch disc on the flywheel

Use the special tools to install the clutch disc on the flywheel.

special tools

Page 324 of 425

Steering-5

Technical requirements

1.The fastening torque of the mounting bolts of the integral power

steering gear assembly is

2.The fastening torque of the connecting bolts of the steering drive sub-

assembly and the integral power steering gear assembly is

3. The fastening torque of the connecting bolts of the steering drive

assembly and the left horizontal beam of the frame is

4. The fastening torque of the mounting bolts of the power steering

pump is 40N.m.

5. The tension force of multi-wedge belt 4PK1100 is 4PK1100.

6. Centering fastening of the handwheel: steer the front wheel to the

right front and remove the handwheel without changing the position

of the steering stem, install the handwheel aligning the center, the

radials of the handwheel should be at the left & right centering state;

the symbol of “the Great Wall” on the steering wheel shall be in

driver’s straight view position, secure the nut firmly with the

fastening torque of

7. Inspection of free clearance of the handwheel

Steer the car in a straight direction and stop the engine, apply a 5N force to

the handwheel along the circumference, left turn the handwheel and stop

the turning when the resistance is increasingly felt with each turn; then right

turn the handwheel and stop the turning when the resistance is increasingly

felt with each turn; the angle rotated along the circumference is the free

clearance of the handwheel, whose standard value shall be below 20

, and

the angle from the center to the right shall not be more than 10

Page 393 of 425

Safety airbag-23

Driver’s and passengers’ side safety airbag module (DAB, PAB), clock spring

Caution

1. Continue the operation 60 seconds after the removal of accumulator negative. Wrap the negative with insulating

tape for insulation.

2. Safety airbag module and clock spring must not be separated nor repaired, replace the failed ones with new ones.

3. Please pay high attention when using the safety airbag module and clock spring, do not let them fall on the ground

nor fall into water or oil. Moreover, replace the depressed, crack or deformed ones with new ones.

4. After the safety airbag module is released, keep the released side up, store it somewhere flat and do not lay anything

on it.

5. The safety airbag module must not be stored in a place with the temperature above 93

.

6. The released safety airbag module must be replaced with a new one, at the same time test the clock spring, replace

it with a new one if something unusual with it.

7. Use gloves and protection glasses during operating the released safety airbag.

8. The unreleased safety airbag must be abandoned after its release.

Caution

During the removal, the wring harness connector clip must be removed before the removal of other wring harness

connector clips in order to avoid the possible improper release caused by static interferences, which is reversal to the

case of installation.

1. Removal and installation

Driver’s side safety airbag module, passengers’ side safety airbag module, clock spring.

2. Operations before removal.

a. Take out the ignition switch key after the steering wheel and front wheel in straightforward direction.

b. Remove the connections of accumulator negative

3. Driver’s side safety airbag module removal procedure

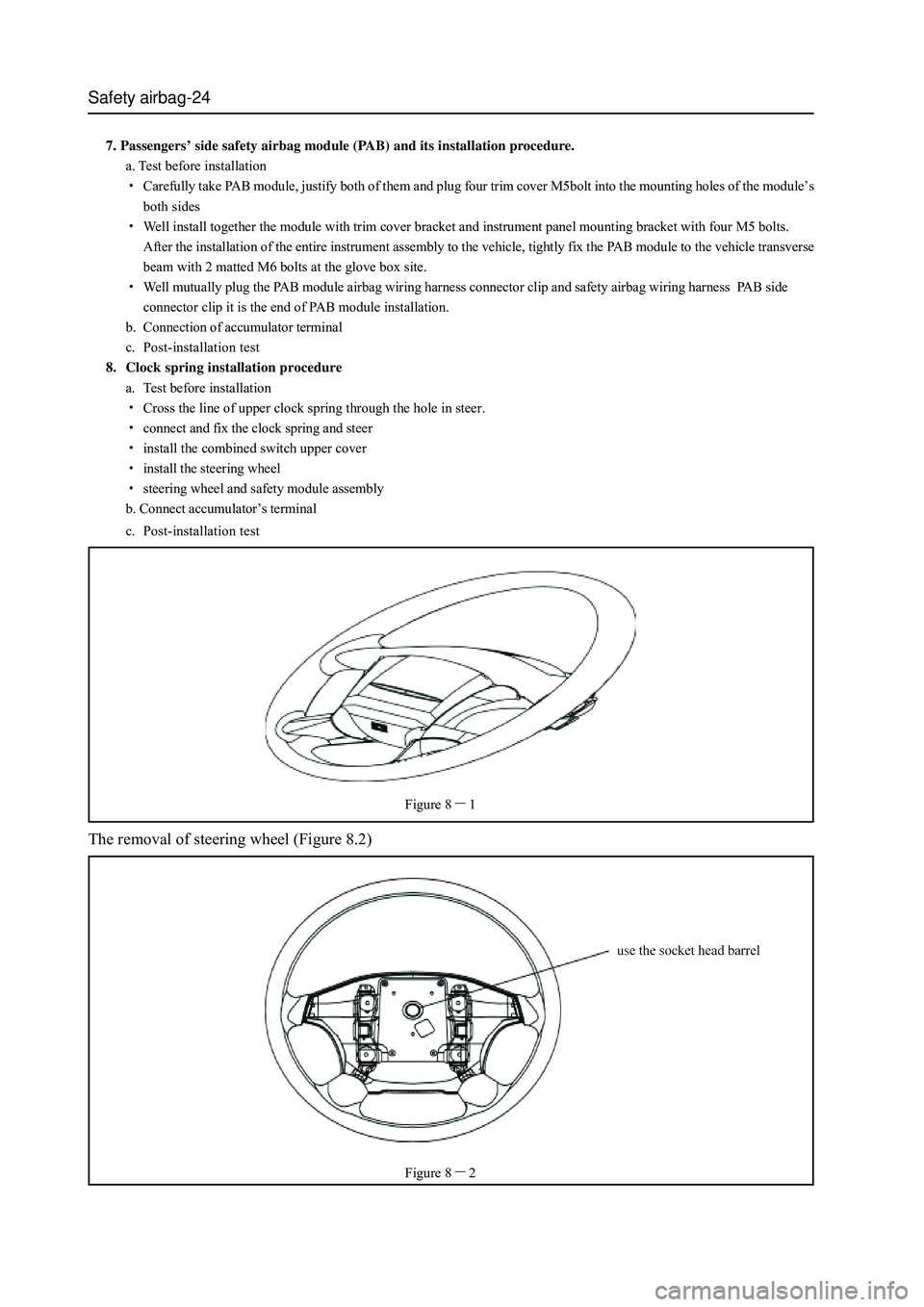

a. Screw off the bolts of two sides, as showed in Figure 8-1

b. Shut off the wiring harness connector clip

c. Remove the safety airbag module assembly

d. Remove the steering wheel

4. Passengers’ side safety airbag module removal procedure

a. Remove all the trim covers and glove boxes of instrument panel separate the PAB module’s airbag wiring harness connector

clip from the safety airbag’s PAB side one.

b. Remove M6 bolts and separate PAB module from instrument panel armed beam.

c. Remove the instrument panel itself.

d. Remove the M5bolts of two sides of four PAB modules.

5. Clock spring removal procedure

a. Remove DAB module (shut off the connecting connector clip)

b. Carefully remove the steer

c. Open the combined switch upper shield, find and shut off the bottom wring harness connector clip

d. Remove the clock spring from the steer

6. Driver’s side safety airbag module (DAB) and its installation procedure

Page 394 of 425

Safety airbag-24

Figure 81

The removal of steering wheel (Figure 8.2)

Figure 82

7. Passengers’ side safety airbag module (PAB) and its installation procedure.

a. Test before installation

Carefully take PAB module, justify both of them and plug four trim cover M5bolt into the mounting holes of the module’s

both sides

Well install together the module with trim cover bracket and instrument panel mounting bracket with four M5 bolts.

After the installation of the entire instrument assembly to the vehicle, tightly fix the PAB module to the vehicle transverse

beam with 2 matted M6 bolts at the glove box site.

Well mutually plug the PAB module airbag wiring harness connector clip and safety airbag wiring harness PAB side

connector clip it is the end of PAB module installation.

b. Connection of accumulator terminal

c. Post-installation test

8. Clock spring installation procedure

a. Test before installation

Cross the line of upper clock spring through the hole in steer.

connect and fix the clock spring and steer

install the combined switch upper cover

install the steering wheel

steering wheel and safety module assembly

b. Connect accumulator’s terminal

c. Post-installation test

Page 401 of 425

Safety airbag-31

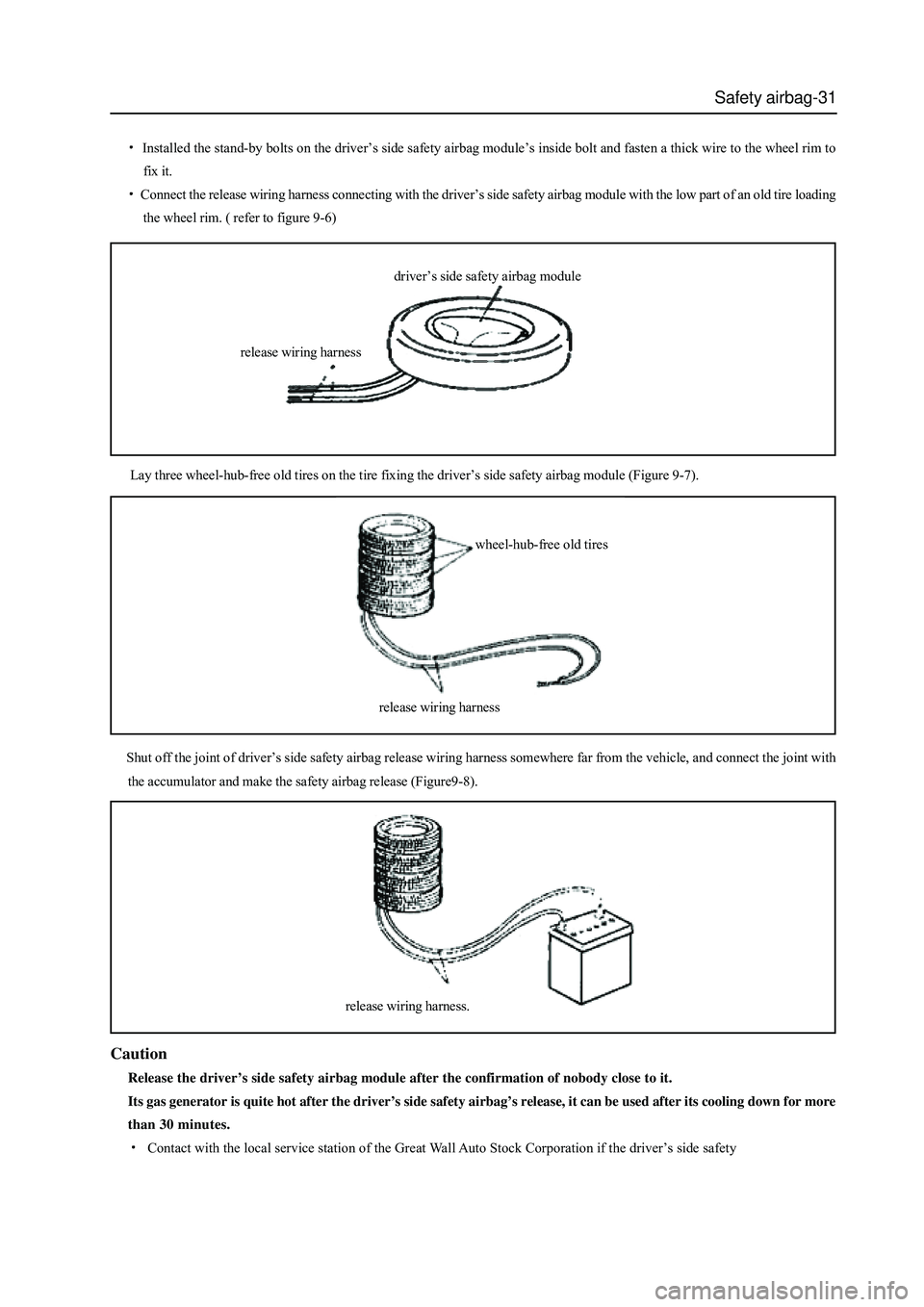

release wiring harness.

driver’s side safety airbag module

release wiring harness

Installed the stand-by bolts on the driver’s side safety airbag module’s inside bolt and fasten a thick wire to the wheel rim to

fix it.

Connect the release wiring harness connecting with the driver’s side safety airbag module with the low part of an old tire loading

the wheel rim. ( refer to figure 9-6)

Lay three wheel-hub-free old tires on the tire fixing the driver’s side safety airbag module (Figure 9-7).

wheel-hub-free old tires

release wiring harness

Shut off the joint of driver’s side safety airbag release wiring harness somewhere far from the vehicle, and connect the joint with

the accumulator and make the safety airbag release (Figure9-8).

Caution

Release the driver’s side safety airbag module after the confirmation of nobody close to it.

Its gas generator is quite hot after the driver’s side safety airbag’s release, it can be used after its cooling down for more

than 30 minutes.

Contact with the local service station of the Great Wall Auto Stock Corporation if the driver’s side safety