wiring GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 9 of 425

Preface

Table of Contents

Instruction How to use the manual

Chapter 1 Overview of the entire car (parameters)

Chapter 2 Fuel supply system and exhaust air system

Chapter 3 Clutch

Chapter 4 Transmission

Chapter 5 Automatic transmission

Chapter 6 Driving shaft

Chapter 7 Suspension and vehicle axle

Chapter 8 Brake (ABS)

Chapter 9 Steering

Chapter 10 Car body electric appliance

Chapter 11 CD player and air-conditioning system

Chapter 12 Safety airbag

Annex:

Important components guarantee and requirement

List of non-metal material consumption

Special tools

D Important working components and tightening torque

E Electric wiring diagram

Page 86 of 425

Automatic transmission-10

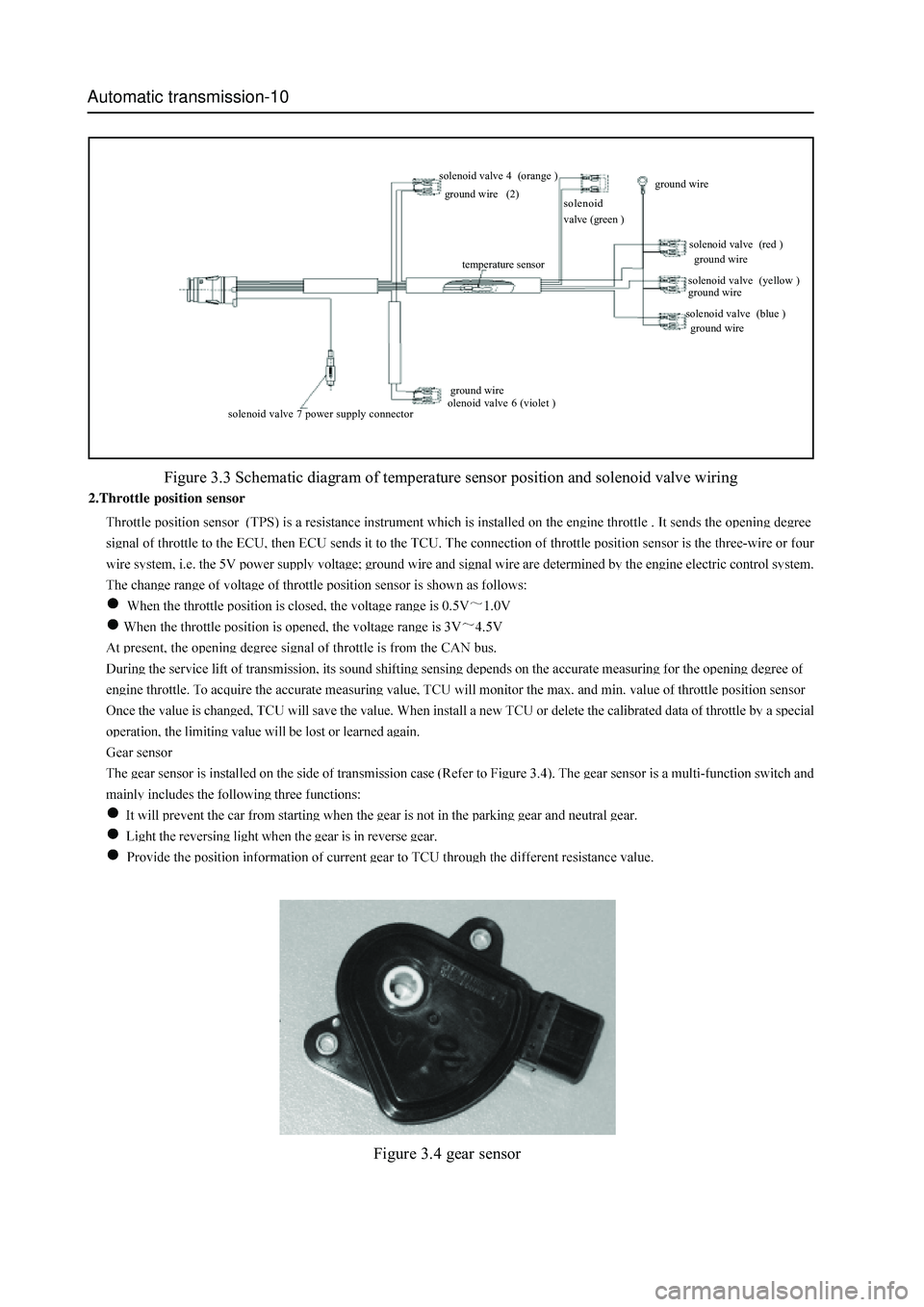

Figure 3.3 Schematic diagram of temperature sensor position and solenoid valve wiring

2.Throttle position sensor

Figure 3.4 gear sensor

solenoid valve 4 (orange )

ground wire (2)

solenoid valve 7 power supply connectorolenoid valve 6 (violet ) ground wiretemperature sensor solenoid valve (red ) ground wire

solenoid

valve (green )

solenoid valve (yellow )

solenoid valve (blue ) ground wire

ground wire

ground wire

Page 355 of 425

CD Player and Air Conditioning System-2

CD Player

Function Overview

This product is a kind of car audio system with VFD multi-information integrated display screen with such functions as PLL

electronic tuning radio, CD playing and operation & control of air conditioning system, it can receive AM, FM and FM stereo

radio broadcast programs, play CDs, electronically operate and control the air conditioning system of the car. The integrated

display screen can display the working state of the radio, CD player, air conditioning system, operating mode as well as

information concerning the equalizer, clock and the temperature inside and outside.

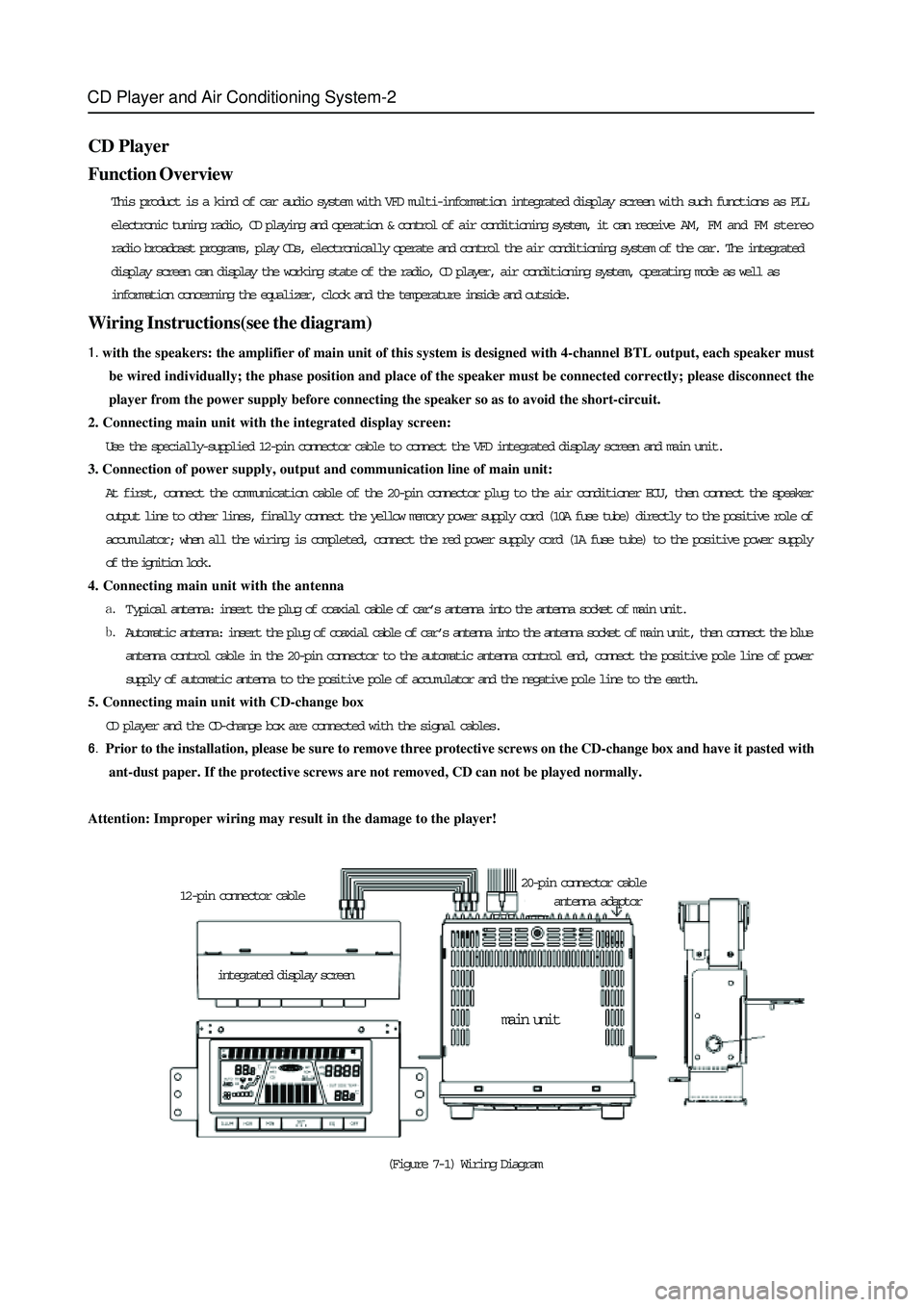

Wiring Instructions(see the diagram)

with the speakers: the amplifier of main unit of this system is designed with 4-channel BTL output, each speaker must

be wired individually; the phase position and place of the speaker must be connected correctly; please disconnect the

player from the power supply before connecting the speaker so as to avoid the short-circuit.

2. Connecting main unit with the integrated display screen:

Use the specially-supplied 12-pin connector cable to connect the VFD integrated display screen and main unit.

3. Connection of power supply, output and communication line of main unit:

At first, connect the communication cable of the 20-pin connector plug to the air conditioner ECU, then connect the speaker

output line to other lines, finally connect the yellow memory power supply cord (10A fuse tube) directly to the positive role of

accumulator; when all the wiring is completed, connect the red power supply cord (1A fuse tube) to the positive power supply

of the ignition lock.

4. Connecting main unit with the antenna

T ypical antenna: insert the plug of coaxial cable of car’s antenna into the antenna socket of main unit.

Automatic antenna: insert the plug of coaxial cable of car’s antenna into the antenna socket of main unit, then connect the blue

antenna control cable in the 20-pin connector to the automatic antenna control end, connect the positive pole line of power

supply of automatic antenna to the positive pole of accumulator and the negative pole line to the earth.

5. Connecting main unit with CD-change box

CD player and the CD-change box are connected with the signal cables.

Prior to the installation, please be sure to remove three protective screws on the CD-change box and have it pasted with

ant-dust paper. If the protective screws are not removed, CD can not be played normally.

Attention: Improper wiring may result in the damage to the player!

(Figure 7-1) Wiring Diagram integrated display screen 12-pin connector cable20-pin connector cable

antenna adaptor

main unit

Page 372 of 425

Safety airbag-2

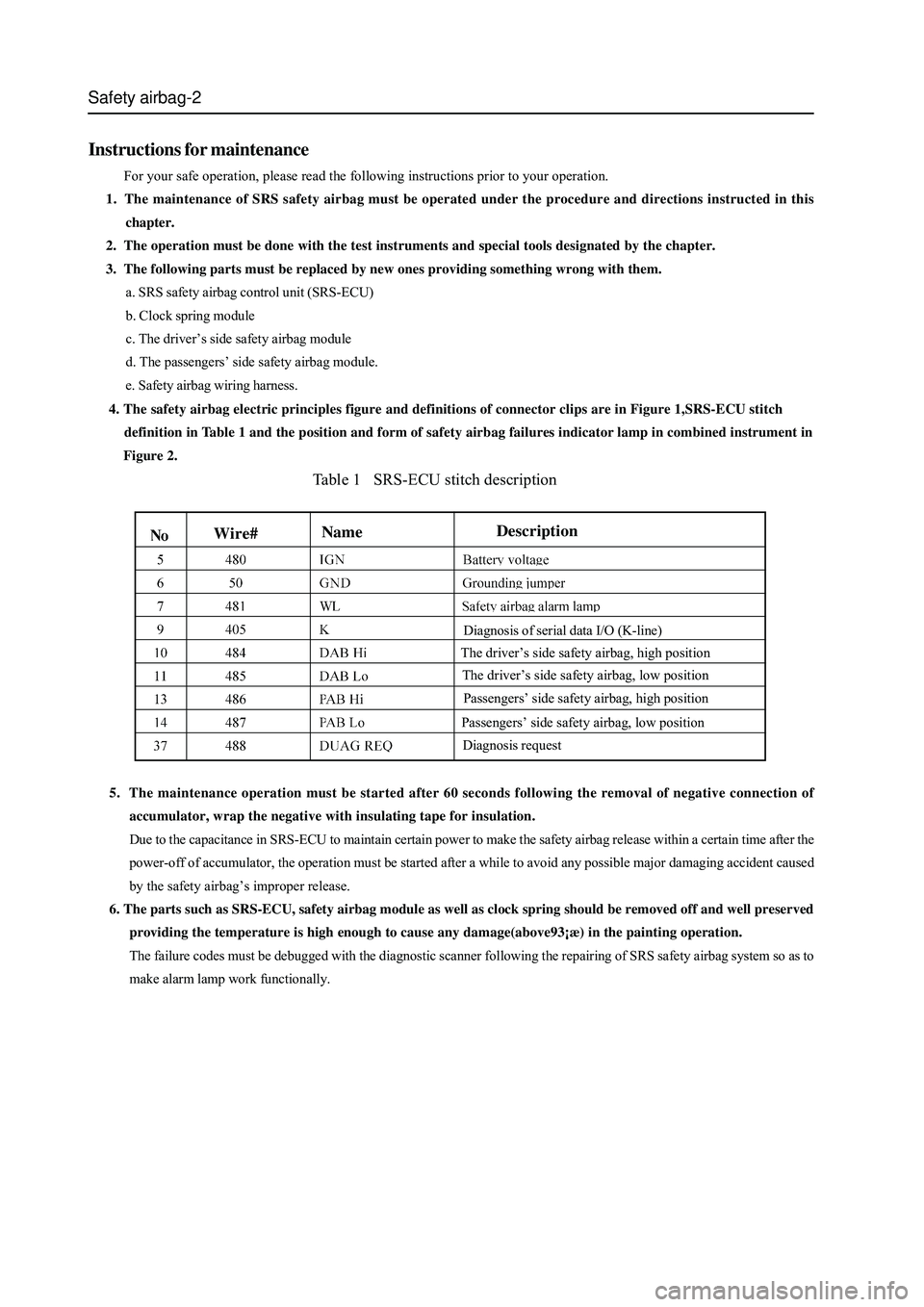

Table 1 SRS-ECU stitch description

5. The maintenance operation must be started after 60 seconds following the removal of negative connection of

accumulator, wrap the negative with insulating tape for insulation.

Due to the capacitance in SRS-ECU to maintain certain power to make the safety airbag release within a certain time after the

power-off of accumulator, the operation must be started after a while to avoid any possible major damaging accident caused

by the safety airbag’s improper release.

6. The parts such as SRS-ECU, safety airbag module as well as clock spring should be removed off and well preserved

providing the temperature is high enough to cause any damage(above93¡æ) in the painting operation.

The failure codes must be debugged with the diagnostic scanner following the repairing of SRS safety airbag system so as to

make alarm lamp work functionally.

Instructions for maintenance

For your safe operation, please read the following instructions prior to your operation.

1. The maintenance of SRS safety airbag must be operated under the procedure and directions instructed in this

chapter.

2. The operation must be done with the test instruments and special tools designated by the chapter.

3. The following parts must be replaced by new ones providing something wrong with them.

a. SRS safety airbag control unit (SRS-ECU)

b. Clock spring module

c. The driver’s side safety airbag module

d. The passengers’ side safety airbag module.

e. Safety airbag wiring harness.

4. The safety airbag electric principles figure and definitions of connector clips are in Figure 1,SRS-ECU stitch

definition in Table 1 and the position and form of safety airbag failures indicator lamp in combined instrument in

Figure 2.

The driver’s side safety airbag, low position

Wire#Description

Name

Diagnosis request

The driver’s side safety airbag, high position

Passengers’ side safety airbag, high position

Passengers’ side safety airbag, low position

Diagnosis of serial data I/O (K-line)

Page 380 of 425

Safety airbag-10

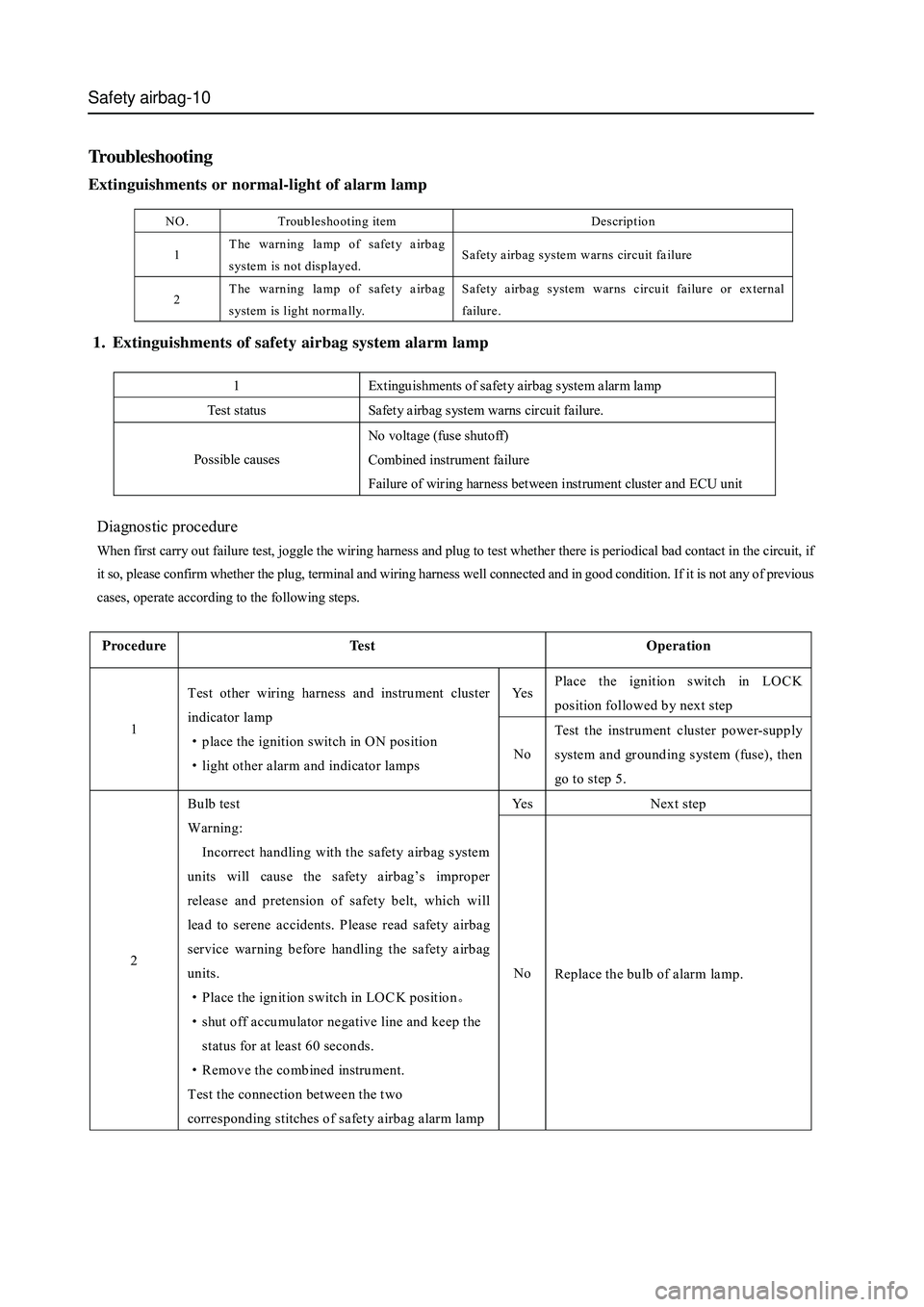

1. Extinguishments of safety airbag system alarm lamp

Troubleshooting

Extinguishments or normal-light of alarm lamp

NO . Troubleshooting item Description

1 T he warning la mp of safety a irbag

system is not displayed. Safety airbag system warns circuit failure

2 T he warning la mp of safety a irbag

system is light normally. Safety airbag system warns circuit failure or external

failure.

1 Extinguishments of safety airbag system alarm lamp

Test status Safety airbag system warns circuit failure.

Possible causes No voltage (fuse shutoff)

Combined instrument failure

Failure of wiring harness between instrument cluster and ECU unit

Diagnostic procedure

When first carry out failure test, joggle the wiring harness and plug to test whether there is periodical bad contact in the circuit, if

it so, please confirm whether the plug, terminal and wiring harness well connected and in good condition. If it is not any of previous

cases, operate according to the following steps.

Procedure Te s t Operation

Ye s Place the ignition switch in LOCK

position followed by next step

1 Test other wiring harness and instrument cluster

indicator lamp

·place the ignition switch in ON position

·light other alarm and indicator lamps No Test the instrument cluster power-supply

system and grounding s ystem (fuse), then

go to step 5.

Yes Next step

2 Bulb test

Warning:

Incorrect handling with the safety airbag system

units will cause the safety airbag’s improper

release and pretension of safety belt, which will

lead to serene accidents. Please read safety airbag

service warning before handling the safety airbag

units.

·Place the ignition switch in LOCK position。

·shut off accumulator negative line and keep the

status for at least 60 seconds.

·Remove the combined instrument.

Test the connection between the two

corresponding stitches of safety airbag alarm lamp No

Rep la ce th e b ulb of a larm la mp.

Page 381 of 425

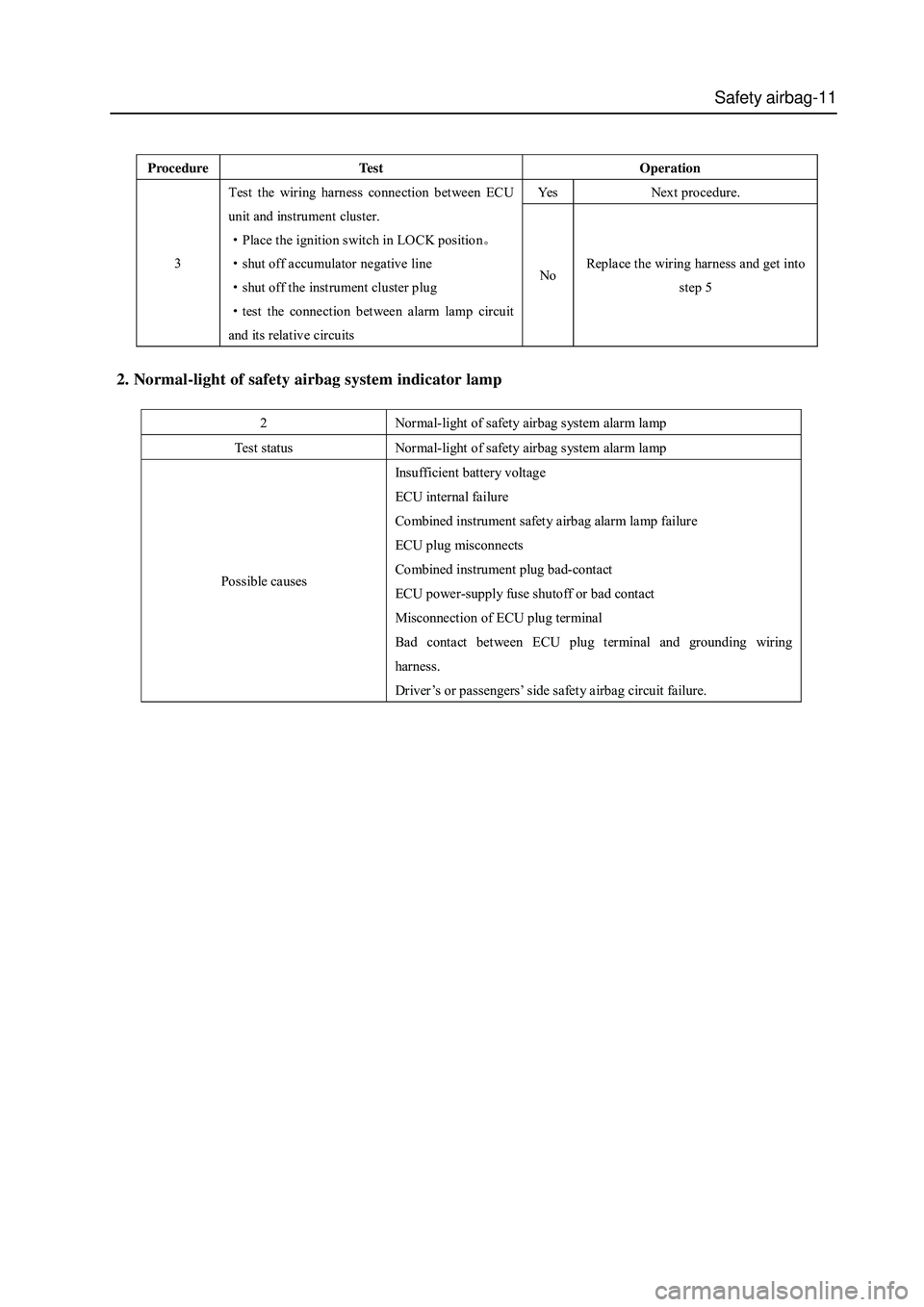

Safety airbag-11

2. Normal-light of safety airbag system indicator lamp

2 Normal-light of safety airbag system alarm lamp

Test status Normal-light of safety airbag system alarm lamp

Possible causes Insufficient battery voltage

ECU internal failure

Combined instrument safety airbag alarm lamp failure

ECU plug misconnects

Combined instrument plug bad-contact

ECU power-supply fuse shutoff or bad contact

Misconnection of ECU plug terminal

Bad contact between ECU plug terminal and grounding wiring

harness.

Driver ’s or passengers’ side safety airbag circuit failure.

Procedure Te s t Operation

Yes Next procedure.

3 Test the wiring harness connection between ECU

unit and instrument cluster.

·Place the ignition switch in LOCK position。

·shut off accumulator negative line

·shut off the instrument cluster plug

·test the connection b etween alarm lamp circuit

and its relative circuits No Replace the wiring harness and get into

step 5

Page 382 of 425

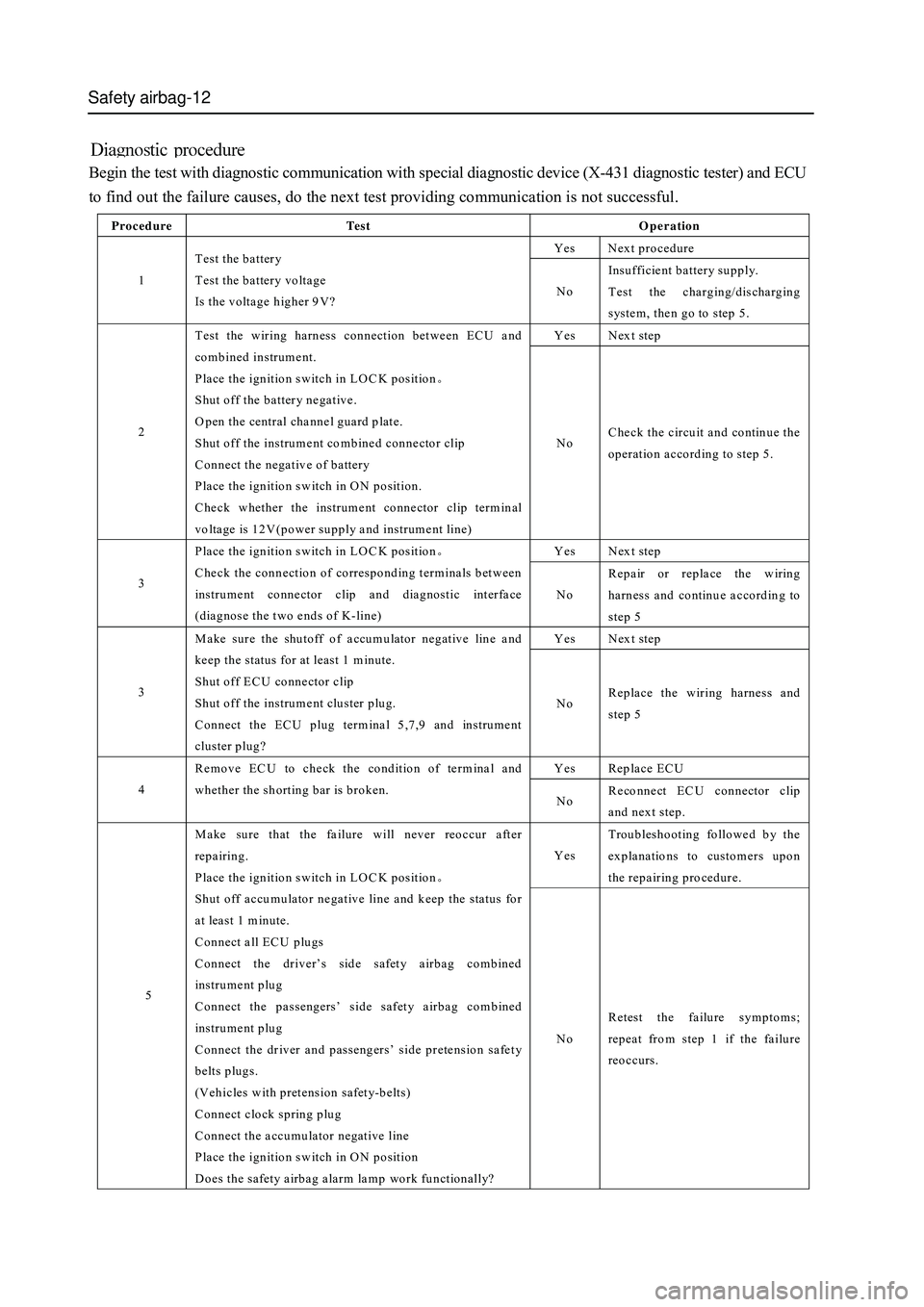

Safety airbag-12

Begin the test with diagnostic communication with special diagnostic device (X-431 diagnostic tester) and ECU

to find out the failure causes, do the next test providing communication is not successful.

Procedure Te s t Operation

Yes Next procedure

1 Test the battery

Test the battery voltage

Is the voltage higher 9V? No Insufficient battery supply.

Test the charging/discharging

system, then go to step 5.

Yes Next step

2 Test the wiring harness connection between ECU and

combined instrument.

Place the ignition switch in LO C K position。

Shut off the battery negative.

O pen the central channel guard plate.

Shut off the instrument combined connector clip

Connect the negative of battery

Place the ignition switch in ON position.

Check whether the instrument connector clip terminal

voltage is 12V(power supply and instrument line) No Check the circuit and continue the

operation according to step 5.

Yes Next step

3 Place the ignition switch in LO C K position。

Check the connection of corresponding terminals between

instrument connector clip and diagnostic interface

(diagnose the two ends of K-line) No Repair or replace the wiring

harness and continue according to

step 5

Yes Next step

3 Make sure the shutoff of accumulator negative line and

keep the status for at least 1 minute.

Shut off ECU connector clip

Shut off the instrument cluster plug.

Connect the ECU plug terminal 5,7,9 and instrument

cluster plug? No Replace the wiring harness and

step 5

Yes Replace ECU

4 Remove EC U to check the condition of term inal and

whether the shorting bar is broken.

No Reconnect EC U connector clip

and next step.

Yes Troubleshooting followed by the

explanations to customers upon

the repair ing pro ced ur e.

5

Make sure that the failure will never reoccur after

repairing.

Place the ignition switch in LO C K position。

Shut off accumulator negative line and keep the status for

at least 1 m in ute.

Connect all ECU plugs

Connect the driver’s side safety airbag combined

instrum ent p lug

Connect the passengers’ side safety airbag combined

instrum ent p lug

Connect the driver and passengers’ side pretension safety

belts plugs.

(Vehicles with pretension safety-b elts)

Connect clock spring plug

Connect the accumulator negative line

Place the ignition switch in ON position

Does the safety airbag alarm lamp work functionally? No Retest the failure symptoms;

repeat from step 1 if the failure

reoccurs.

Page 384 of 425

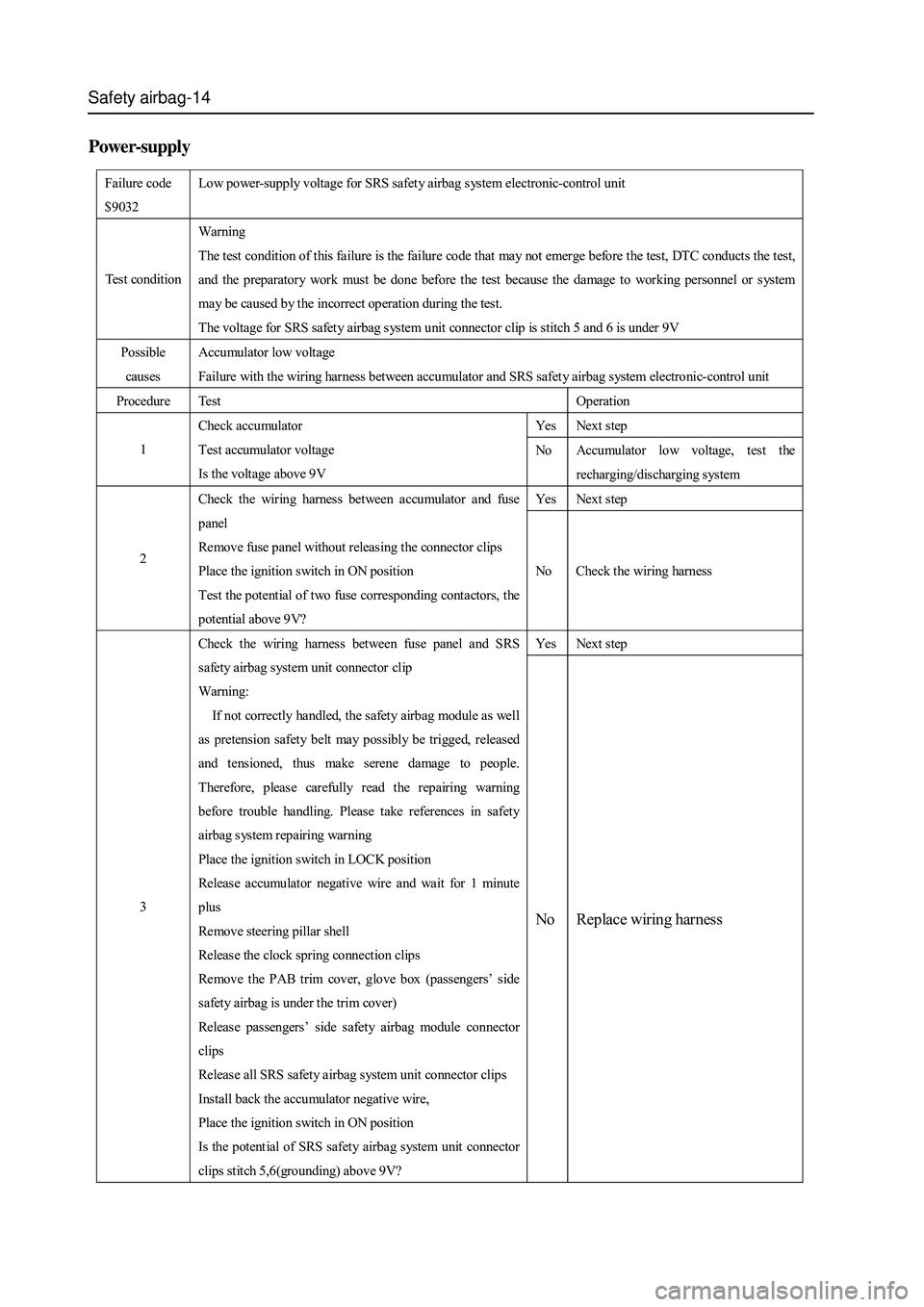

Safety airbag-14

Power-supply

Failure code

$9032 Low power-supply voltage for SRS safety airbag system electronic-control unit

Test condition Warning

The test condition of this failure is the failure code that may not emerge before the test, DTC conducts the test,

and the preparatory work must be done before the test because the damage to working personnel or system

may be caused by the incorrect op eration during the test.

The voltage for SRS safety airbag system unit connector clip is stitch 5 and 6 is under 9V

Possible

caus es Accumulator low voltage

Failure with the wiring harness between accumulator and SRS safety airbag system electronic-control unit

Procedure Test Operation

Yes Next step

1 Check accumulator

Test accumulator voltage

Is the voltage above 9V No Accumulator low voltage, test the

recharging/discharging system

Yes Next step

2 Check the wiring harness between accumulator and fuse

panel

Remove fuse panel without releasing the connector clips

Place the ignition switch in ON position

Test the potential of two fuse corresponding contactors, the

potential above 9V? No Check the wiring harness

Yes Next step

3 Check the wiring harness between fuse panel and SRS

safety airbag system unit connector clip

Warning:

If not correctly handled, the safety airbag module as well

as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people.

Ther efor e, pleas e carefully r ead the r epairing warning

before trouble handling. Please take references in safety

airbag system repairing warning

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute

plus

Remove steering pillar shell

Release the clock spring connection clips

Remove the PAB trim cover, glove box (passengers’ side

safety airbag is under the trim cover)

Release passengers’ side safety airbag module connector

clips

Release all SRS safety airbag system unit connector clips

Install back the accumulator negative wire,

Place the ignition switch in ON position

Is the potential of SRS safety airbag system unit connector

clips stitch 5,6(grounding) above 9V? No Replace wiring harness

Page 385 of 425

Safety airbag-15

Yes Present failure codes

Replace SRS safety airbag system unit

See he removal/installation of SRS

safety airbag system unit

History accumulated failure codes

The end of failure diagnosis

4 Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute

plus

Remove the left trim cover

Shut off SRS safety airbag system unit translation

connector clips

Install back the accumulator negative wire, place the

ignition switch in ON position

Is the potential of SRS safety airbag system unit connector

clips stitch 5,6(grounding) above 9V? No Replace wiring harness

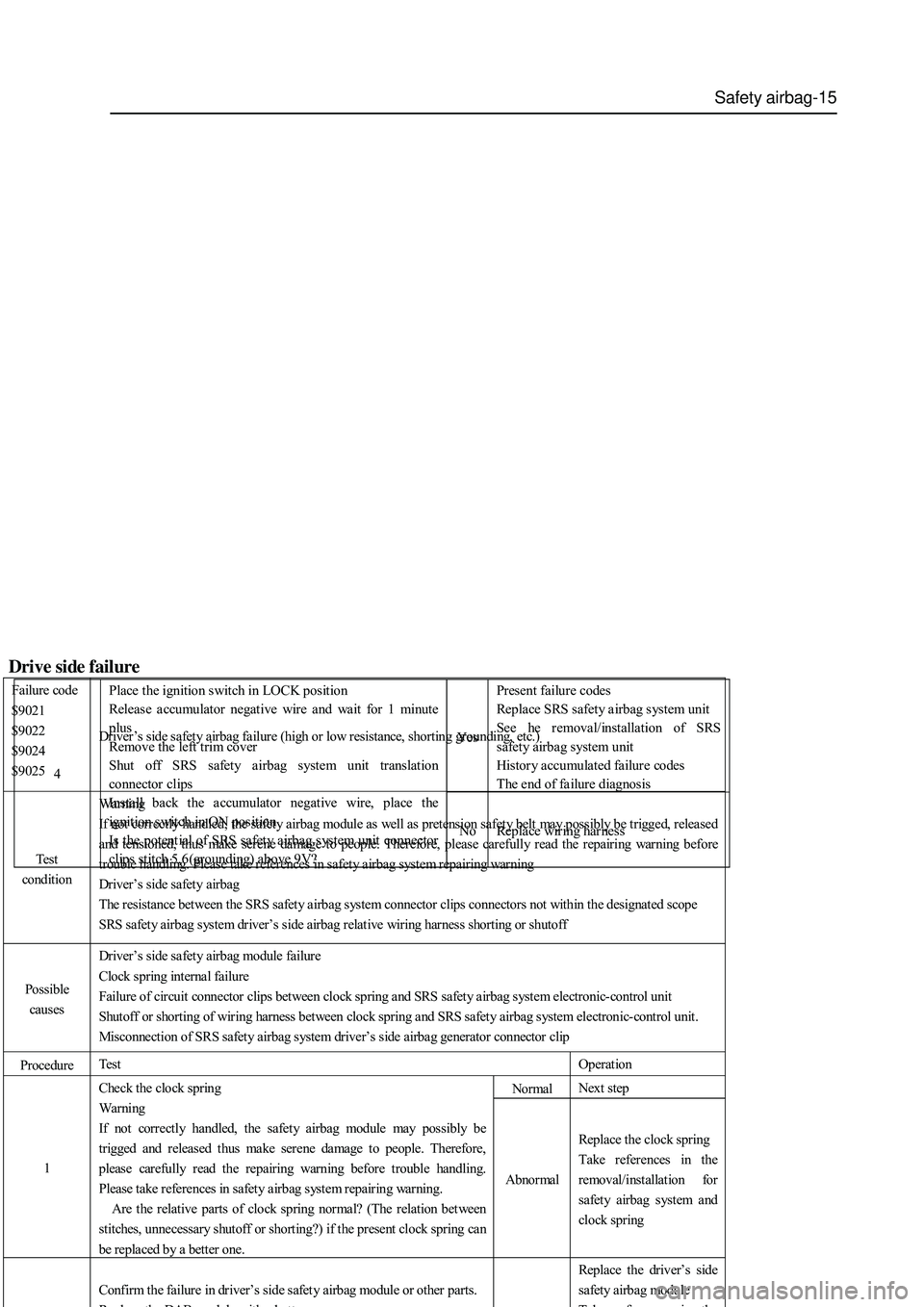

Drive side failure

Failure code

$9021

$9022

$9024

$9025 Driver ’s side safety airbag failure (high or low resistance, shorting grounding, etc.)

Tes t

condition Warni ng

If not correctly handled, the safety airbag module as well as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people. Therefore, please carefully read the repairing warning before

trouble handling. Please take references in safety airbag system repairing warning

Driver’s side safety airbag

The resistance between the SRS safety airbag system connector clips connectors not within the designated scope

SRS safet y airbag system driver’s side airbag relative wiring harness shorting or shutoff

Possible

caus es Driver’s side safety airbag module failure

Clock spring internal failure

Failure of circuit connector clips between clock spring and SRS safety airbag system electronic-control unit

Shutoff or shorting of wiring harness between clock spring and SRS safety airbag system electronic-control unit.

Misconnection of SRS safety airbag system driver’s side airbag generator connector clip

Procedure Tes t Operation

Normal Next step

1 Check the clock spring

Warni ng

If not correctly handled, the safety airbag module may possibly be

trigged and released thus make serene damage to people. Therefore,

please carefully read the repairing warning before trouble handling.

Please take references in safety airbag system repairing warning.

Are the relative parts of clock spring normal? (The relation bet ween

stitches, unnecessary shutoff or shorting?) if the pr esent clock spring ca n

be replaced by a better one. Abnormal Replace the clock spring

Take references in the

removal/installation for

safety airbag system and

clock spring

Replace the driver’s side

safety airbag module

Tk f i th

Confirm the failure in driver’s side safety airbag module or other parts.

Rl thDAB dl ithbtt

Page 386 of 425

Safety airbag-16

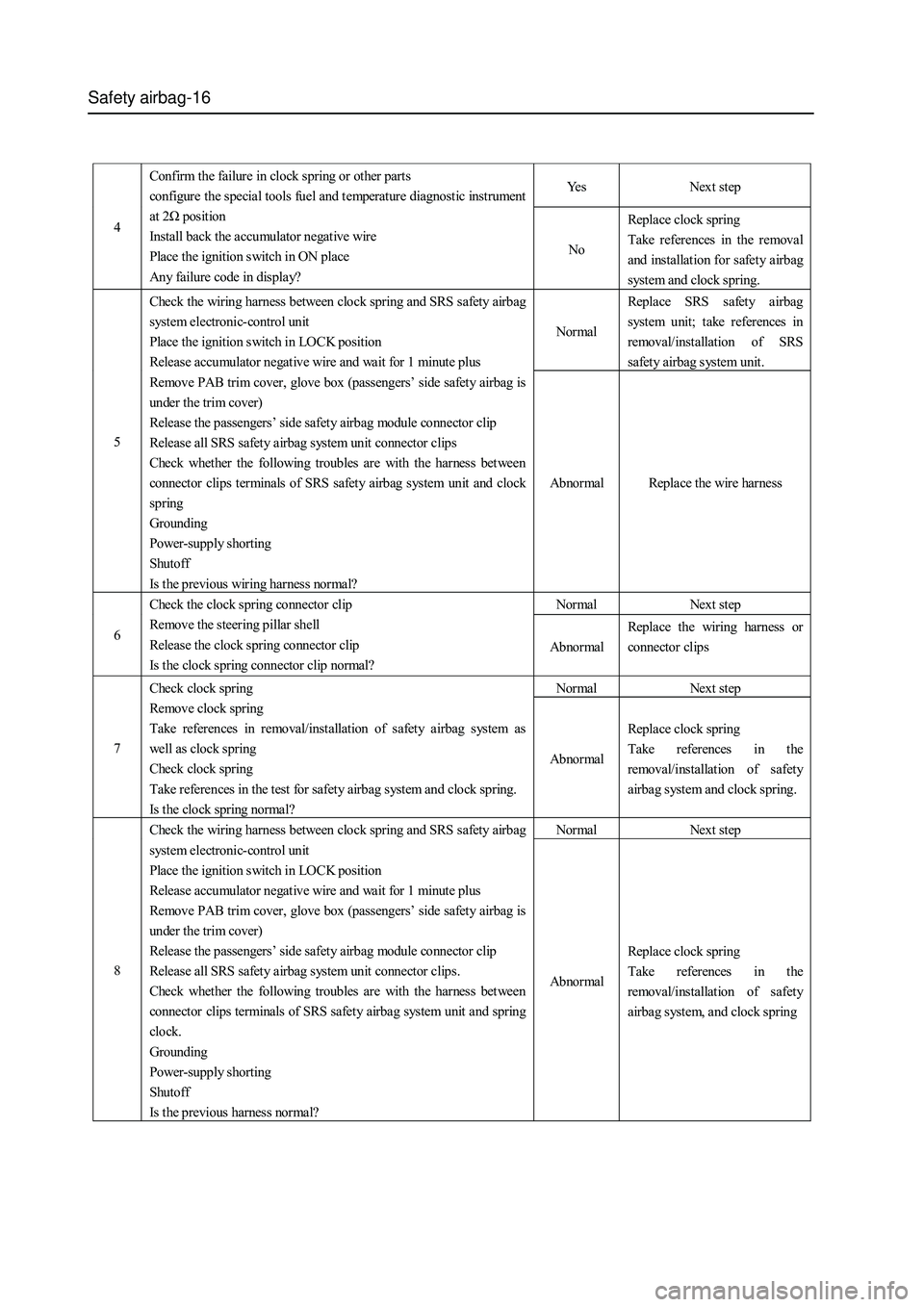

Yes Next step

4 Confirm the failure in clock spring or other parts

configure the special tools fuel and t emperature diagnostic instrument

at 2Ω position

Install back the accumulator negative wire

Place the ignition switch in ON place

Any failure code in display? No Replace clock spring

Take references in the removal

and installation for safety airbag

system and clock spring.

Nor mal Replace SRS safety airbag

system unit; take references in

removal/installation of SRS

safety airbag system unit.

5 Check the wiring harness between clock spring and SRS safety airbag

system electronic-control unit

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute plus

Remove PAB trim cover, glove box (passengers’ side safety airbag is

under the trim cover)

Release the passengers’ side safety airbag module connector clip

Release all SRS safety airbag system unit connector clips

Check whether the following troubles are with the harness between

connector clips terminals of SRS safety airbag system unit and clock

spring

Grounding

Power-supply shorting

Shutoff

Is the previous wiring harness normal? Abnormal Replace the wire harness

Nor mal Next step

6 Check the clock spring connector clip

Remove the steering pillar shell

Release the clock spring connector clip

Is the clock spring connector clip normal? Abnormal Replace the wiring harness or

connector clips

Nor mal Next step

7 Check clock spring

Remove clock spring

Take references in removal/installation of safet y airbag system as

well as clock spring

Check clock spring

Take references in the test for safety airbag system and clock spring.

Is the clock spring normal? Abnormal Replace clock spring

Take references in the

removal/installation of safety

airbag system and clock spring.

Nor mal Next step

8 Check the wiring harness between clock spring and SRS safety airbag

system electronic-control unit

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute plus

Remove PAB trim cover, glove box (passengers’ side safety airbag is

under the trim cover)

Release the passengers’ side safety airbag module connector clip

Release all SRS safety airbag system unit connector clips.

Check whether the following troubles are with the harness between

connector clips terminals of SRS safety airbag system unit and spring

clock.

Grounding

Power-supply shorting

Shutoff

Is the previous harness normal? Abnormal Replace clock spring

Take references in the

removal/installation of safety

airbag system, and clock spring