wiring GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 387 of 425

Safety airbag-17

Passengers’ side failure

Failure code

$9015

$9016

$9018

$9019 Passengers’ side safety airbag module (high or low resistance or shorting grounding)

Tes t co n d it i o n Warning

If not correctly handled, the safety airbag module as well as pretension safety belt may possibly be

trigged, released and tensioned, thus make serene damage to people. Therefore, please carefully read the

repairing warning before trouble handling. Please take references in safety airbag system repairing warning

If with passengers’ side safety airbag failure

The resistance between SRS safety airbag system unit connector clip stitch 13 and stitch 14 not within the

designated scope.

The wiring harness shorting between safety airbag system unit stitch 13 and stitch 14

Open loop between SRS safety airbag system unit connector clip stitch 13 and stitch 14,

Possible causes Passengers’ side safety airbag module failure

The failure of connector clip between passengers’ side safety airbag module and SRS safety airbag system

electronic-control unit

The failure of connector clip between SRS safety airbag system unit and grounding jumper.

The circuit shutoff or shorting between passengers’ side safety airbag module and SRS safety airbag system

electronic-control unit

The circuit shutoff or shorting between SRS safety airbag system unit and grounding jumper

SRS safety airbag system unit failure

Procedure Test Operation

Yes Next step

1 Is the vehicle with passengers’ side safety airbag module

No Step 5

Present failure code

Next step

Check passengers’ side safety airbag connector clips

Warning

Page 388 of 425

Safety airbag-18

Impact-vehicle diagnosis

Test SRS-ECU diagnostic signals

1. Connect the (X-431 diagnostic test’s) diagnostic joint

2. Read the diagnostic results with X-431 diagnostic tester

Repairing procedure

1.When safety airbag is released.

The following parts should be replaced with new ones

a. Passengers’ side safety airbag module

b. SRS-ECU

c. Driver’s side safety airbag module

2 Check the following parts; replace them with new ones providing something wrong with them.

a. Clock spring

b. Steering-wheel, steering column, bottom steering shaft module

3.Driver’s side safety airbag module’s installation status towards the steering wheel.

a. Check whether abnormal knocking is with the steering wheel, its activity is in good condition and its clearance is normal.

b. Check whether the wiring harness joint is broken and its terminal is deformed.

Caution: Due to the impact, the diagnostic instrument cannot communicate with SRS-ECU when accumulator is lack of

power, in this case, check and maintain the instrument panel wiring harness or utilize the extension power supply.

Page 389 of 425

Safety airbag-19

1. Check whether depression, crack or deformation is with the SRS-ECU bracket.

2. Check whether the joint is broken and terminal is deformed

3. Check SRS-ECU bracket’s installation status

a. Check whether depression, crack or deformation is with the shroud

b. Check whether the joint is broken, terminal is deformed and wiring harness is meshed.

c. Check whether depression, crack or deformation is with the gas generator shield.

d. Make sure the direction of the arrow is straightforward

4. Check the installation status of safety airbag module.

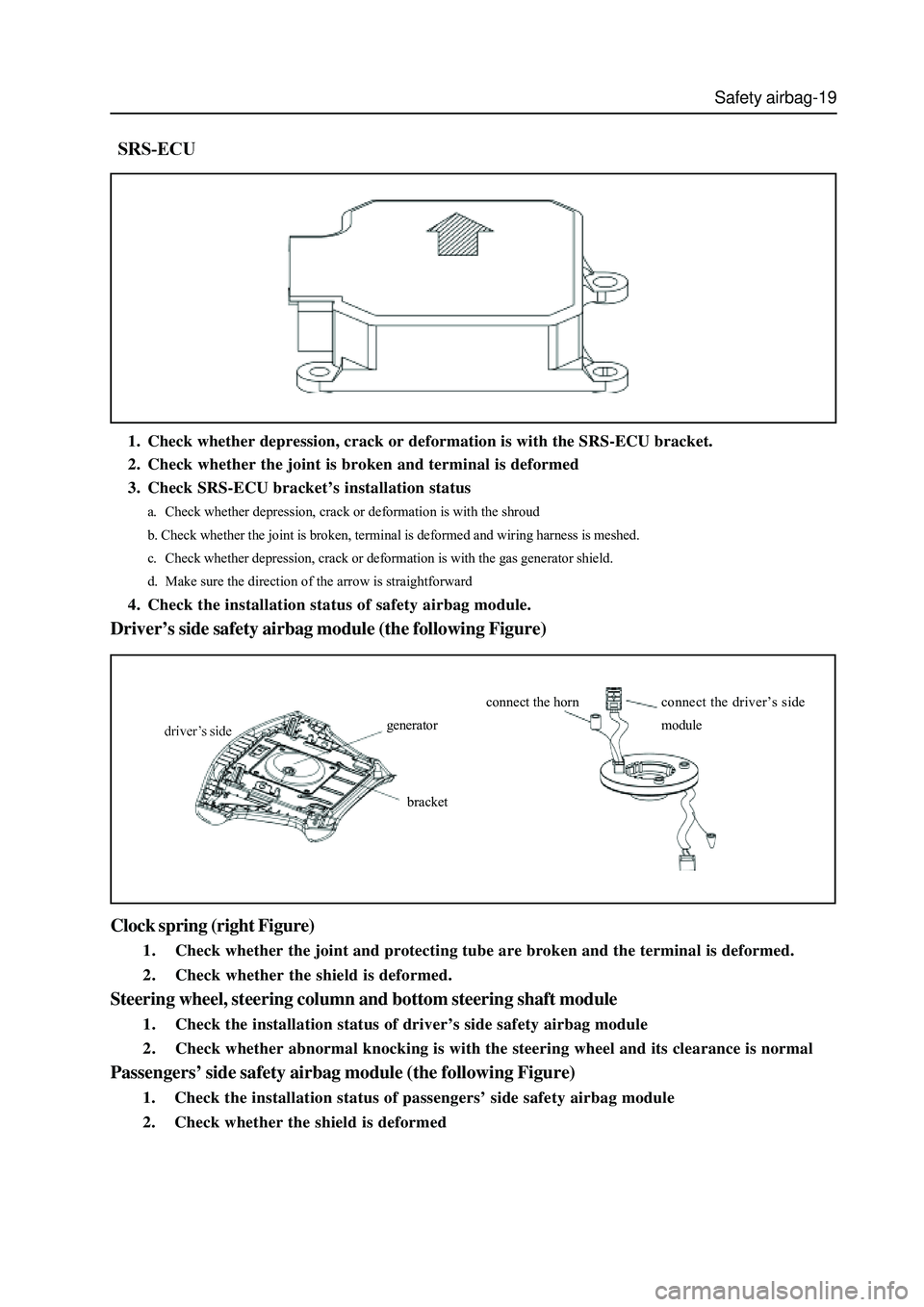

Driver’s side safety airbag module (the following Figure)

generator

bracketconnect the hornconnect the driver’s side

module

Clock spring (right Figure)

1. Check whether the joint and protecting tube are broken and the terminal is deformed.

2. Check whether the shield is deformed.

Steering wheel, steering column and bottom steering shaft module

1. Check the installation status of driver’s side safety airbag module

2. Check whether abnormal knocking is with the steering wheel and its clearance is normal

Passengers’ side safety airbag module (the following Figure)

1. Check the installation status of passengers’ side safety airbag module

2. Check whether the shield is deformed

Page 390 of 425

Safety airbag-20

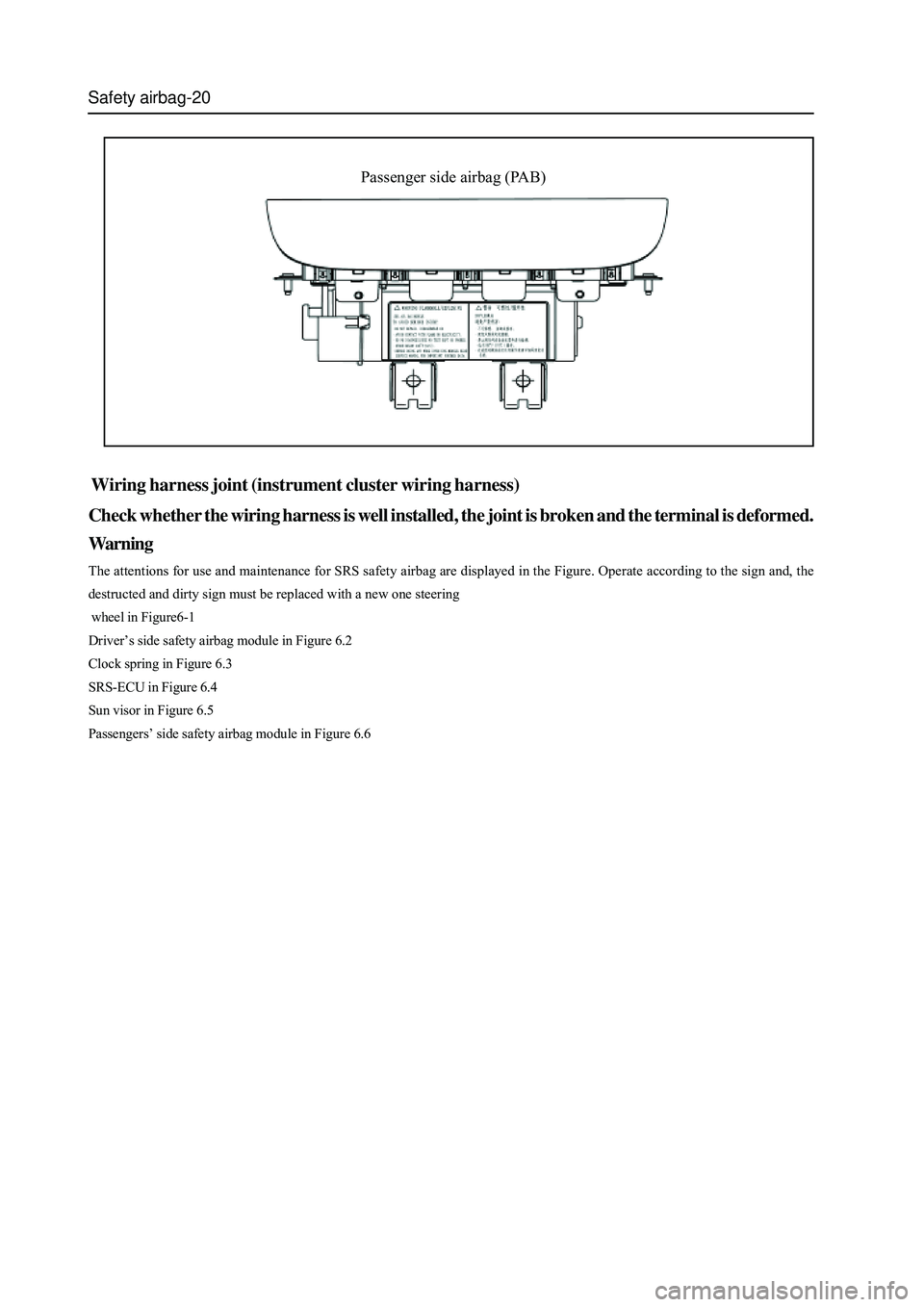

Wiring harness joint (instrument cluster wiring harness)

Check whether the wiring harness is well installed, the joint is broken and the terminal is deformed.

Warning

The attentions for use and maintenance for SRS safety airbag are displayed in the Figure. Operate according to the sign and, the

destructed and dirty sign must be replaced with a new one steering

wheel in Figure6-1

Driver’s side safety airbag module in Figure 6.2

Clock spring in Figure 6.3

SRS-ECU in Figure 6.4

Sun visor in Figure 6.5

Passengers’ side safety airbag module in Figure 6.6

Passenger side airbag (PAB)

Page 393 of 425

Safety airbag-23

Driver’s and passengers’ side safety airbag module (DAB, PAB), clock spring

Caution

1. Continue the operation 60 seconds after the removal of accumulator negative. Wrap the negative with insulating

tape for insulation.

2. Safety airbag module and clock spring must not be separated nor repaired, replace the failed ones with new ones.

3. Please pay high attention when using the safety airbag module and clock spring, do not let them fall on the ground

nor fall into water or oil. Moreover, replace the depressed, crack or deformed ones with new ones.

4. After the safety airbag module is released, keep the released side up, store it somewhere flat and do not lay anything

on it.

5. The safety airbag module must not be stored in a place with the temperature above 93

.

6. The released safety airbag module must be replaced with a new one, at the same time test the clock spring, replace

it with a new one if something unusual with it.

7. Use gloves and protection glasses during operating the released safety airbag.

8. The unreleased safety airbag must be abandoned after its release.

Caution

During the removal, the wring harness connector clip must be removed before the removal of other wring harness

connector clips in order to avoid the possible improper release caused by static interferences, which is reversal to the

case of installation.

1. Removal and installation

Driver’s side safety airbag module, passengers’ side safety airbag module, clock spring.

2. Operations before removal.

a. Take out the ignition switch key after the steering wheel and front wheel in straightforward direction.

b. Remove the connections of accumulator negative

3. Driver’s side safety airbag module removal procedure

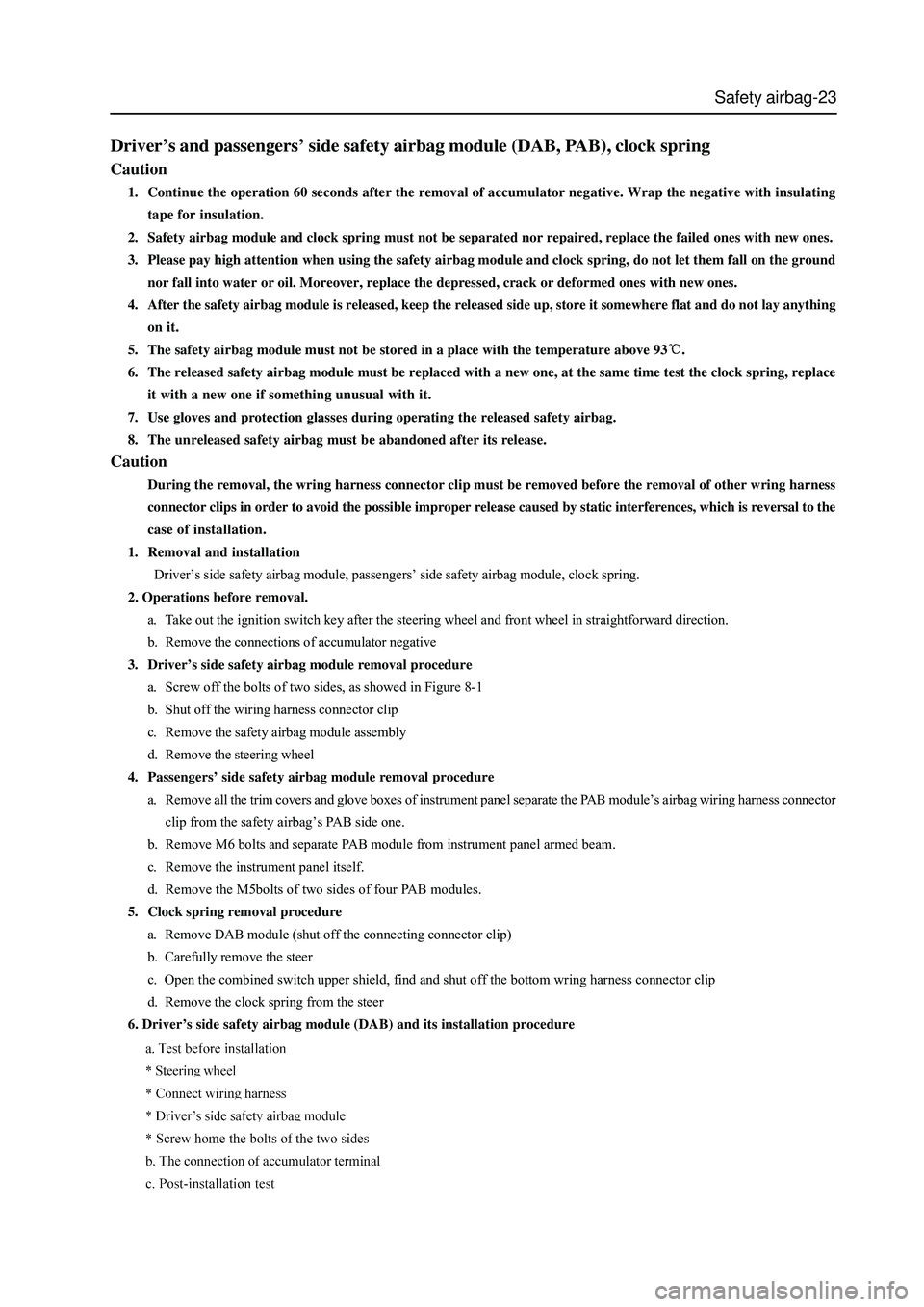

a. Screw off the bolts of two sides, as showed in Figure 8-1

b. Shut off the wiring harness connector clip

c. Remove the safety airbag module assembly

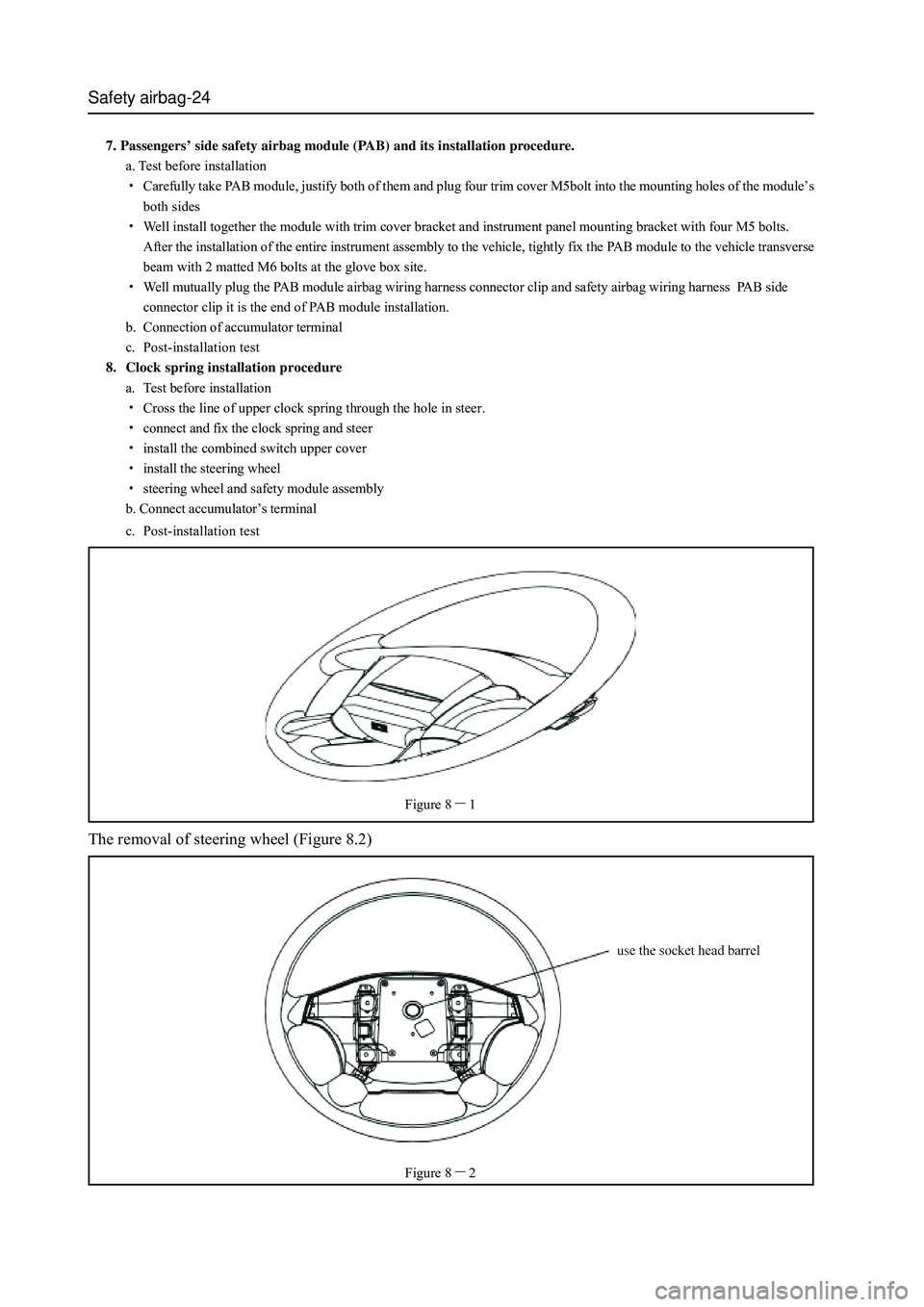

d. Remove the steering wheel

4. Passengers’ side safety airbag module removal procedure

a. Remove all the trim covers and glove boxes of instrument panel separate the PAB module’s airbag wiring harness connector

clip from the safety airbag’s PAB side one.

b. Remove M6 bolts and separate PAB module from instrument panel armed beam.

c. Remove the instrument panel itself.

d. Remove the M5bolts of two sides of four PAB modules.

5. Clock spring removal procedure

a. Remove DAB module (shut off the connecting connector clip)

b. Carefully remove the steer

c. Open the combined switch upper shield, find and shut off the bottom wring harness connector clip

d. Remove the clock spring from the steer

6. Driver’s side safety airbag module (DAB) and its installation procedure

Page 394 of 425

Safety airbag-24

Figure 81

The removal of steering wheel (Figure 8.2)

Figure 82

7. Passengers’ side safety airbag module (PAB) and its installation procedure.

a. Test before installation

Carefully take PAB module, justify both of them and plug four trim cover M5bolt into the mounting holes of the module’s

both sides

Well install together the module with trim cover bracket and instrument panel mounting bracket with four M5 bolts.

After the installation of the entire instrument assembly to the vehicle, tightly fix the PAB module to the vehicle transverse

beam with 2 matted M6 bolts at the glove box site.

Well mutually plug the PAB module airbag wiring harness connector clip and safety airbag wiring harness PAB side

connector clip it is the end of PAB module installation.

b. Connection of accumulator terminal

c. Post-installation test

8. Clock spring installation procedure

a. Test before installation

Cross the line of upper clock spring through the hole in steer.

connect and fix the clock spring and steer

install the combined switch upper cover

install the steering wheel

steering wheel and safety module assembly

b. Connect accumulator’s terminal

c. Post-installation test

Page 396 of 425

Safety airbag-26

Do the troubleshooting if the alarm lamp re-illuminates after its extinguishments following the 6-second-flashing (or it keeps

illuminating from the very beginning)

10. Test

a. Driver’s side airbag module test (Figure8-3)

Check the following items and replace the corresponding safety airbag module part with anything abnormal with a new one.

Abandon the safety airbag’s old parts after its release according to the instructed procedure.

Caution

Do not jam the clock spring wiring harness during the steering wheel and safety airbag module assembly installation.

After the installation, rotate the steering wheel to left and right positions as enough as possible to confirm whether something

abnormal is with it.

d. Post-installation test.

lightly rotate the steering wheel to the left and right to confirm whether something abnormal and noises will arise.(Driver’s side

safety airbag module, clock spring)

Place the ignition switch in ON place.

SRS alarm lamp flashes in 6 seconds and then extinguishes.

Caution

If without the clock spring central involution, the steering wheel will not be able to rotate at midway, or the clock spring

circuit will be damaged so that jeopardize SRS safety airbag’s normal activities.

The spacer must be removed after replacing a clock spring with a new one, otherwise it will damage the clock spring.

c. Steering wheel and safety airbag module assembly installation.

Install the steering wheel and safety airbag module assembly after clock spring’s central involution.

safety airbag system failure alarm lamp

Caution

The safety airbag module (squib) circuit resistance can even not be tested by the designated tester.

When testing the resistance with an experimental instrument, sometimes the improper release will be caused by the

static interference because of the current in explosion pipe and cause some major damaging accidents.

Whether depression, crack or deformation is with the shroud.

Whether the joint is broken and the terminal is deformed.

Whether depression, crack or deformation is with the gas generator shield.

Safety airbag module. Installation status.

Caution

Replace the safety airbag with depression, crack or deformation with a new one. Its old parts must be abandoned after

its release.

Page 398 of 425

Safety airbag-28

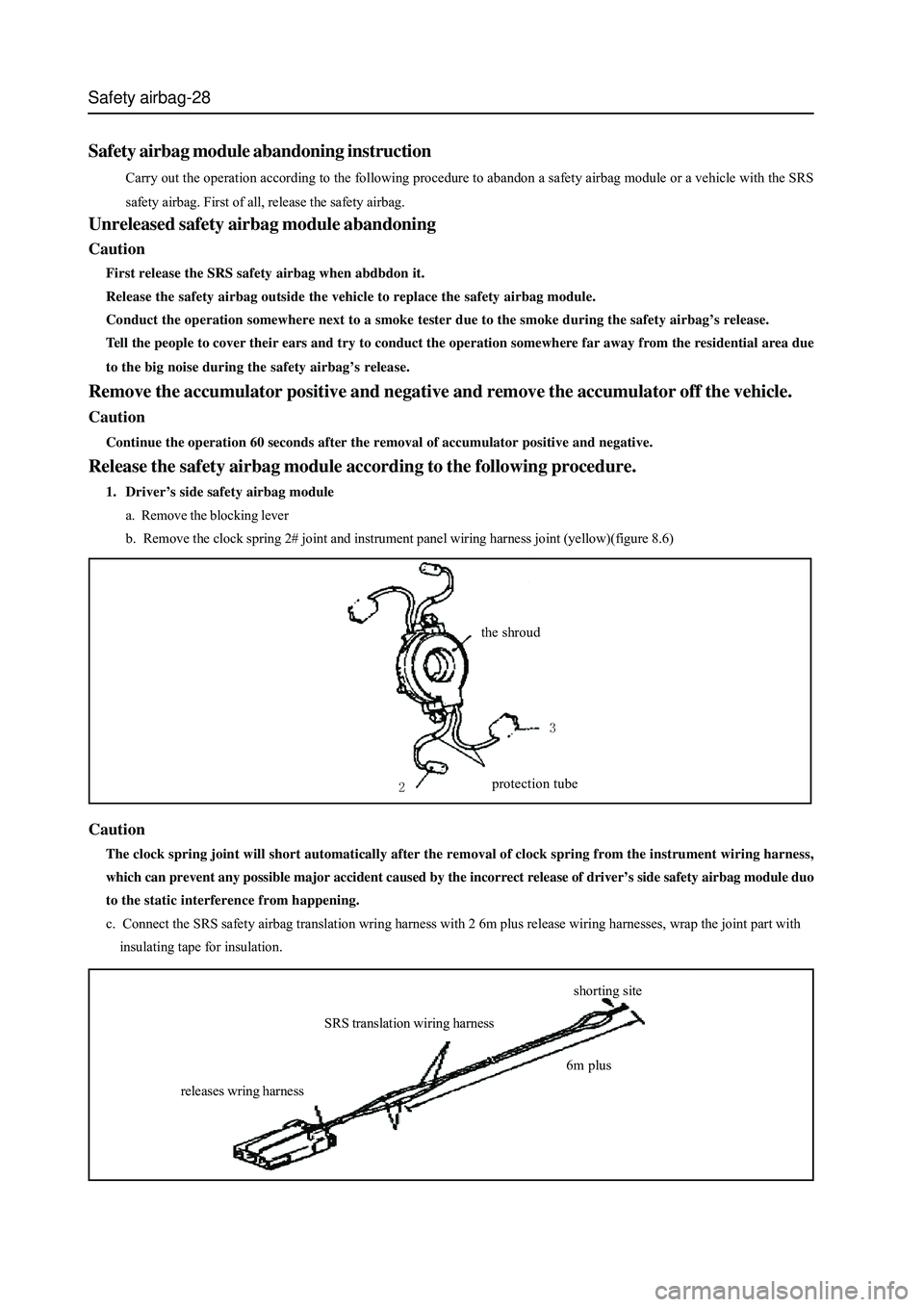

SRS translation wiring harness

releases wring harnessshorting site

6m plus

the shroud

protection tube

Safety airbag module abandoning instruction

Carry out the operation according to the following procedure to abandon a safety airbag module or a vehicle with the SRS

safety airbag. First of all, release the safety airbag.

Unreleased safety airbag module abandoning

Caution

First release the SRS safety airbag when abdbdon it.

Release the safety airbag outside the vehicle to replace the safety airbag module.

Conduct the operation somewhere next to a smoke tester due to the smoke during the safety airbag’s release.

Tell the people to cover their ears and try to conduct the operation somewhere far away from the residential area due

to the big noise during the safety airbag’s release.

Remove the accumulator positive and negative and remove the accumulator off the vehicle.

Caution

Continue the operation 60 seconds after the removal of accumulator positive and negative.

Release the safety airbag module according to the following procedure.

1. Driver’s side safety airbag module

a. Remove the blocking lever

b. Remove the clock spring 2# joint and instrument panel wiring harness joint (yellow)(figure 8.6)

Caution

The clock spring joint will short automatically after the removal of clock spring from the instrument wiring harness,

which can prevent any possible major accident caused by the incorrect release of driver’s side safety airbag module duo

to the static interference from happening.

c. Connect the SRS safety airbag translation wring harness with 2 6m plus release wiring harnesses, wrap the joint part with

insulating tape for insulation.

Page 399 of 425

Safety airbag-29

auto body outer panel.

release wiring harness

auto body outer panel.

releases wring harness. Mutually connect (short) the other end of release wring harness to avoid the possible incorrect release caused by the static

interference.

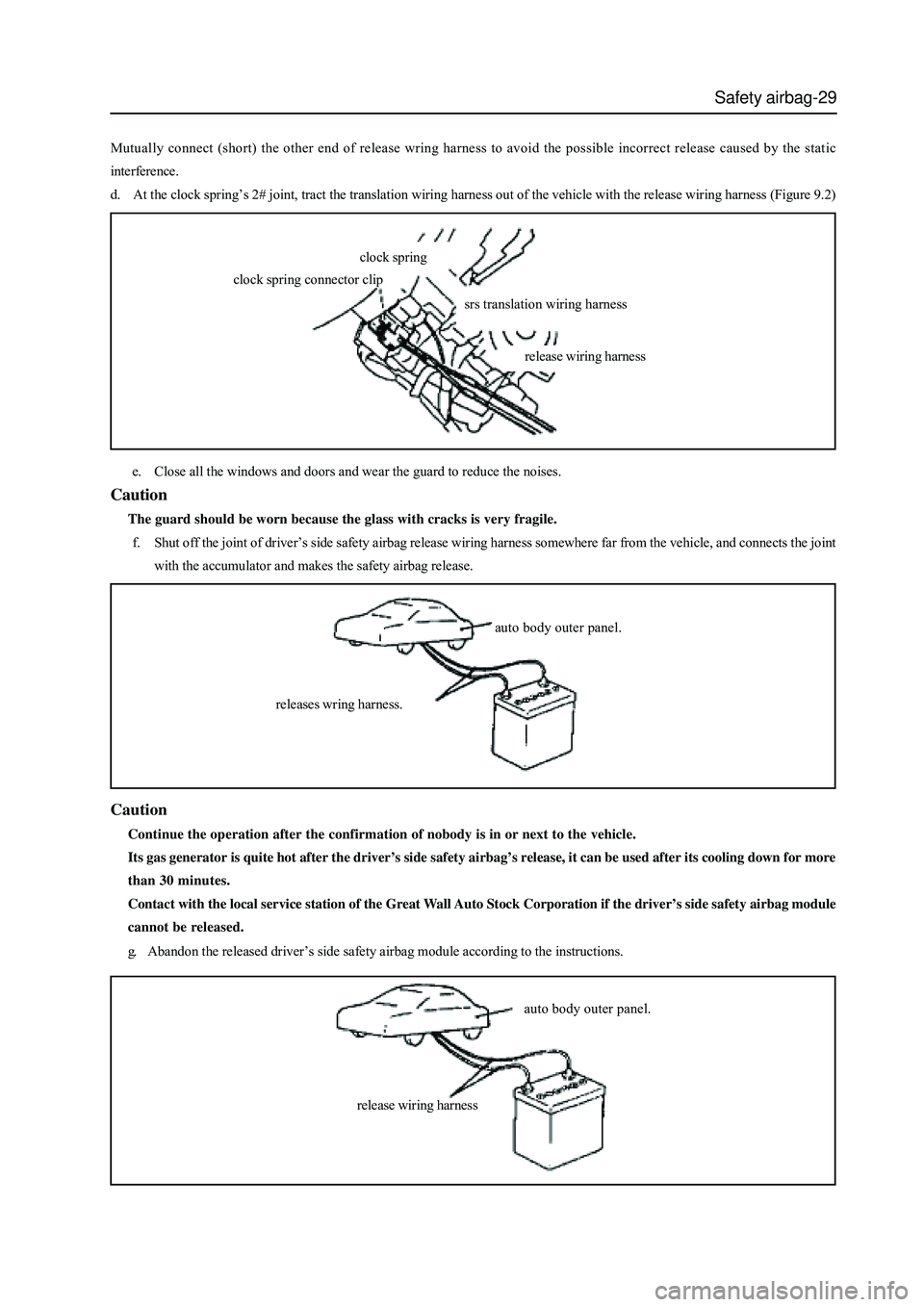

d. At the clock spring’s 2# joint, tract the translation wiring harness out of the vehicle with the release wiring harness (Figure 9.2)

e. Close all the windows and doors and wear the guard to reduce the noises.

Caution

The guard should be worn because the glass with cracks is very fragile.

f. Shut off the joint of driver’s side safety airbag release wiring harness somewhere far from the vehicle, and connects the joint

with the accumulator and makes the safety airbag release.

clock spring connector clipclock spring

srs translation wiring harness

release wiring harness

Caution

Continue the operation after the confirmation of nobody is in or next to the vehicle.

Its gas generator is quite hot after the driver’s side safety airbag’s release, it can be used after its cooling down for more

than 30 minutes.

Contact with the local service station of the Great Wall Auto Stock Corporation if the driver’s side safety airbag module

cannot be released.

g. Abandon the released driver’s side safety airbag module according to the instructions.

Page 400 of 425

Safety airbag-30

wiring harness for release

shorting site

6m plus

2. Release outside the vehicle

Caution

Release the safety airbag somewhere open and plain as well as 6m plus from the obstacles and people

When release the safety airbag outdoors, try to avoid the strong wind and ignite windward in the breeze.

a. Remove the accumulator negative and positive and remove the accumulator.

Caution

Continue the operation 60 seconds after the removal of the accumulator.

b. Release the safety airbag module according to following procedure

driver’s side safety airbag module

remove the driver’s side safety airbag module off the vehicle.

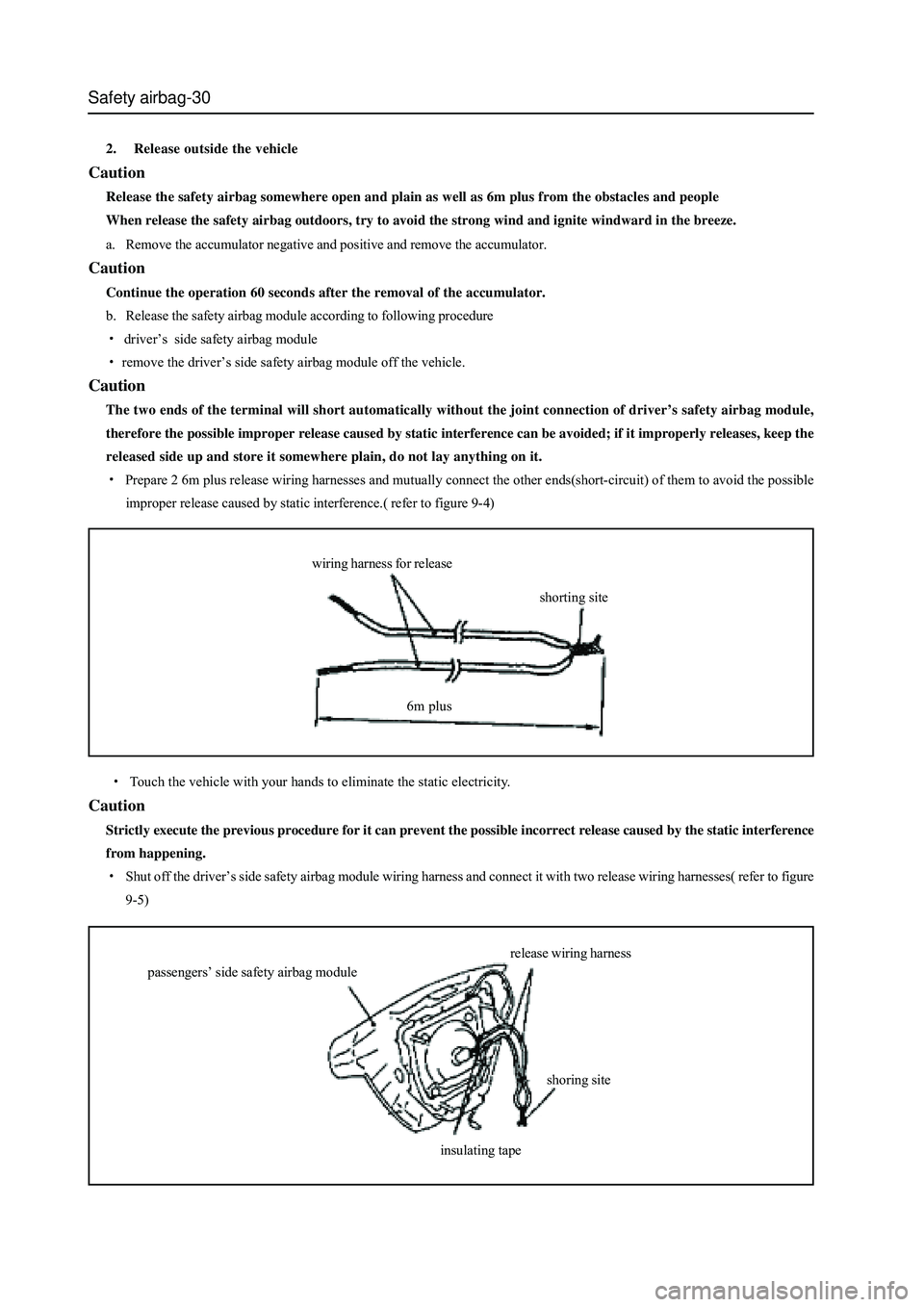

Caution

The two ends of the terminal will short automatically without the joint connection of driver’s safety airbag module,

therefore the possible improper release caused by static interference can be avoided; if it improperly releases, keep the

released side up and store it somewhere plain, do not lay anything on it.

Prepare 2 6m plus release wiring harnesses and mutually connect the other ends(short-circuit) of them to avoid the possible

improper release caused by static interference.( refer to figure 9-4)

Touch the vehicle with your hands to eliminate the static electricity.

Caution

Strictly execute the previous procedure for it can prevent the possible incorrect release caused by the static interference

from happening.

Shut off the driver’s side safety airbag module wiring harness and connect it with two release wiring harnesses( refer to figure

9-5)

release wiring harness

passengers’ side safety airbag module

shoring site

insulating tape