check oil HONDA CIVIC 1996 6.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1271 of 2189

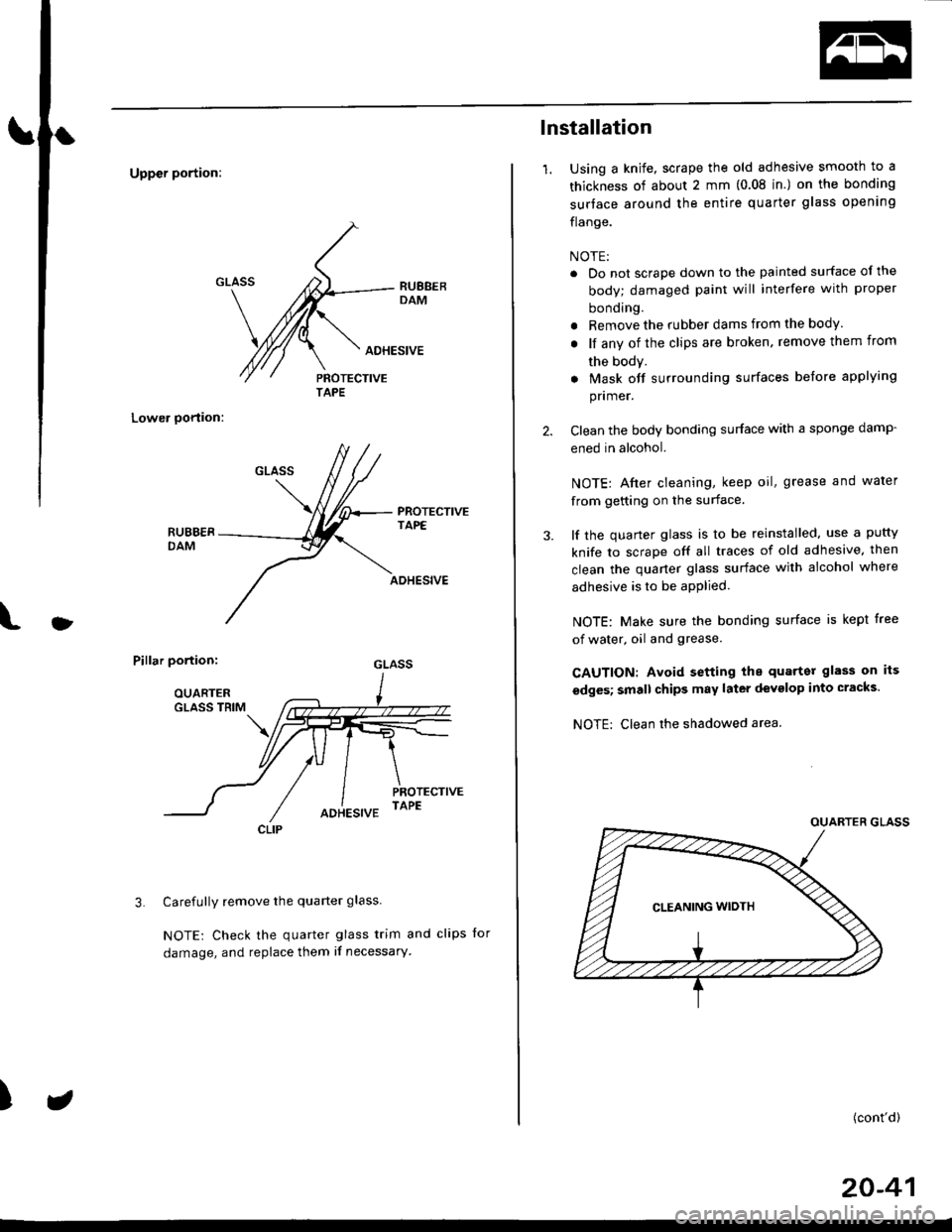

Uppcr portion:

Lower oortion:

PROTECTIVETAPE

l

ADHESIVE

Pillar portion:

Carefully remove the quarter glass

NOTE: Check the quarter glass trim and clips for

damage, and replace them if necessary'

3.

)

AOHESIVE

TAPE

CLIP

lnstallation

1.Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surtace around the entire quarter glass opening

flange.

NOTE:

. Do not scrape down to the painted surface of the

body; damaged paint will interfere with proper

bonding.

r Remove the rubber dams from the body.

. lf any of the clips are broken, remove them from

the body.

. Mask off surrounding surfaces before applying

pnmer.

Clean the body bonding surface with a sponge damp-

ened in alcohol.

NOTE: Afier cleaning, keep oil, grease and water

from getting on the surface.

lf the quarter glass is to be reinstalled, use a putty

knife to scrape off all traces of old adhesive. then

clean the quaner glass surface with alcohol where

adhesive is to be apPlied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setting the quarter glass on its

edges; small chips may later devglop into cracks.

NOTE: Clean rhe shadowed area.

(cont'd)

20-41

Page 1389 of 2189

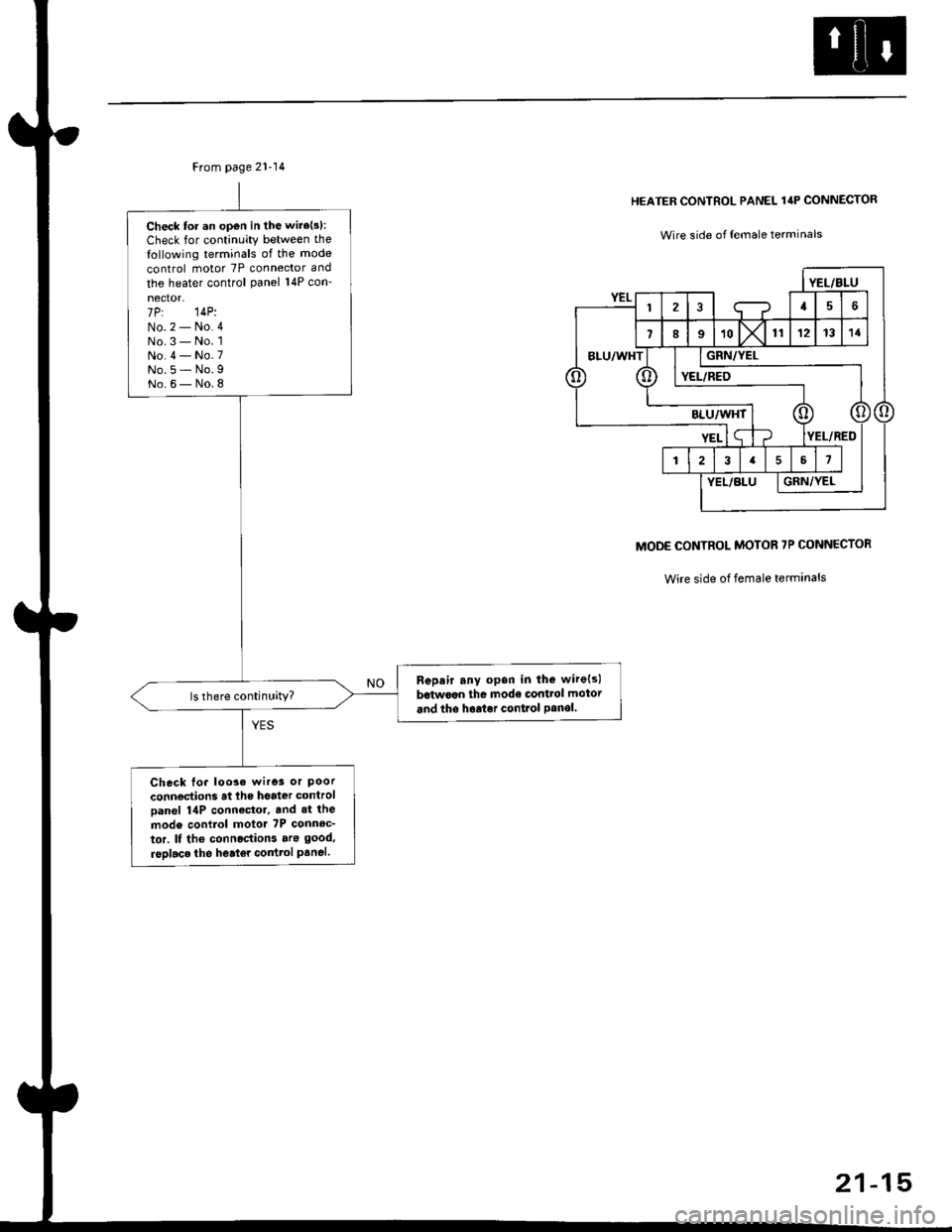

From page 21-14

Check tor an open in the wire{s}:

Check for continuity between the

following terminals of the mode

control motor 7P connector and

the heater control Panel 14P con-

nector-7P: 14P:No.2 - No.4No.3 - No. 1No.4 - No.7No.5 - No.9No.6- No.8

Repair any opsn in the wirels)

bctwoan the mode control motor

and the hoator conlrol Panolls there continuitY?

Check Io. loo3. wires or Poorconnoctions at lhe hoat€r control

Danel 14P connactor, and 3t the

mod6 conilol motot 7P connec-

tor. It tho connoctions ara good.

rsDlaco the heat€r coilttol panel.

HEATER CONTROL PANEL 14P CONNECTOR

Wire side of {emale terminals

MODE CONTROL MOTOR 7P CONNECTOR

Wire side of female terminals

21-15

Page 1437 of 2189

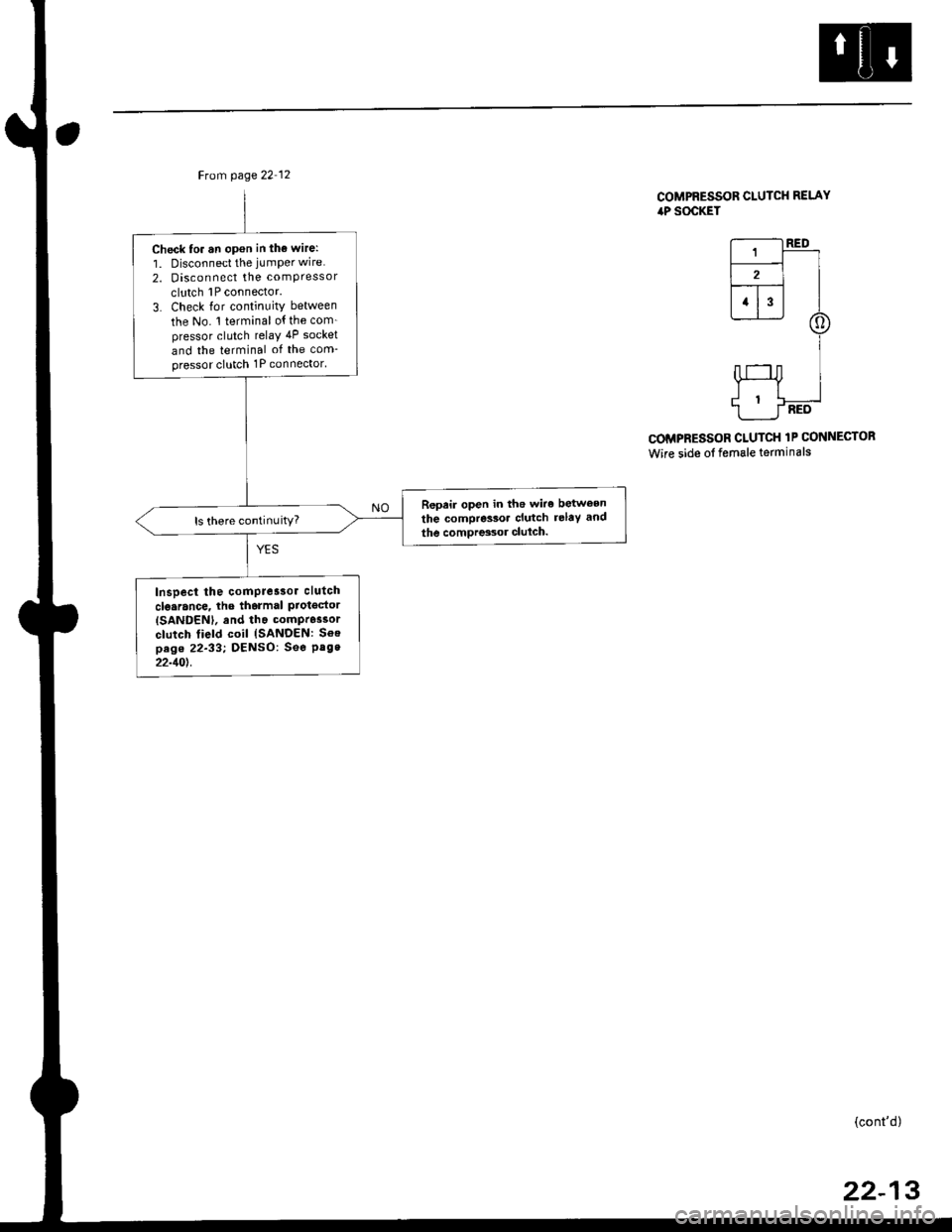

Ftom page 22 12

Check to. an opon in tho wire:

1. Disconnect the jumper wire

2. Disconnect the comPressor

clutch 1P connector.

3. Check lor continuity between

the No. 1 terminal o{ the com_pressor clutch relaY 4P socket

and the terminal of the com-pressor clutch 1P connector'

Repeir open in the wiro between

the compressoa clutch relaY and

the comDres3or clulch.ls there continuity?

Inspect the comPre3sor clutch

clo.rance, lhe tharmal ProtgdorISANDENI, and tha compr6ssor

clutch field coil {SANDEN: Soepag. 22-33; DENSO: See Pag.22-10t.

COMPRESSOR CLUTCH RELAYiaP SOCKET

r--------t RED

L-r-]-_ll2l I--r- |l1l3l I

@

I

HI

1___J-RED

COMPRESSOR CLUTCH 1P CONNECTOR

Wire side of female terminals

(cont'd)

22-13

Page 1450 of 2189

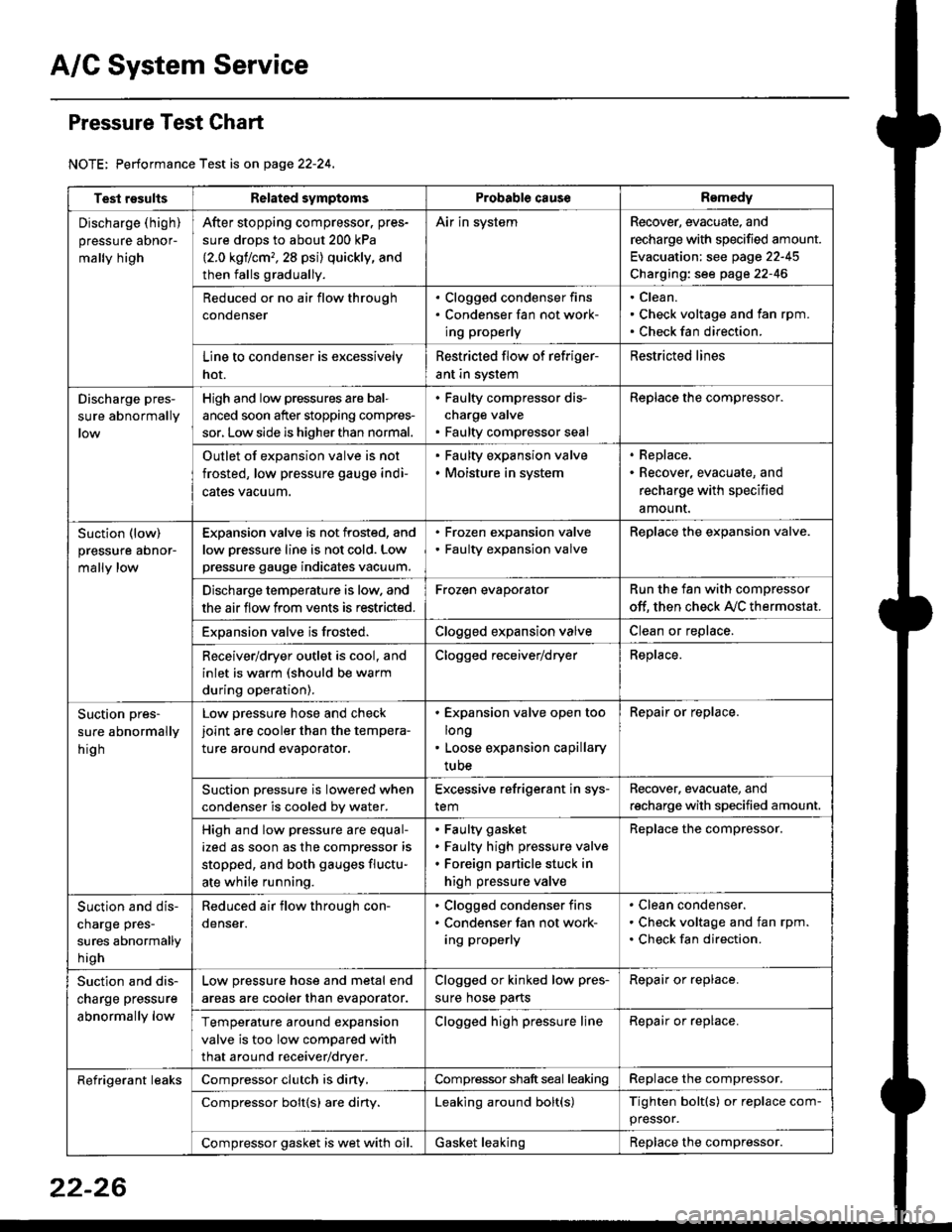

A/C System Service

Pressure Test Chart

NOTE: Performance Test is on page 22-24,

Test resultsRelated symptomsProbabl€ causeRemedy

Discharge (high)

pressure aDnor-

mally high

After stopping compressor. pres-

sure drops to about 200 kPa

{2.0 kgflcm,,28 psi) quickly, and

then falls gradually.

Air in systemRecover, evacuate, and

recharge with specified amount.

Evacuation: see page 22-45

Charging: see page 22-46

Reduced or no air flow through

condenser

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean.

Check voltage and fan rpm.

Check fan direction.

Line to condenser is excessively

hot.

Restricted flow of refriger-

ant in system

Restricted lines

Discharge pres-

sure abnormally

High and low pressures are bal-

anced soon after stopping compres-

sor, Low side is higher than normal.

. Faulty compressor dis-

charge valve. Faulty compressor seal

Replace the compressor.

Outlet of expansion valve is not

frosted, low pressure gauge indi-

cales vacuum.

. Faulty expansion valve. Moisture in system

. Replace,. Recover, evacuate, and

recharge with specified

amount.

Suction (low)

pressure abnor-

mally low

Expansion valve is not frosted, and

low oressure line is not cold. Low

pressure gauge indicates vacuum.

. Frozen expansion valve. Faulty expansion valve

ReDlace the exoansion valve.

Discharge temperature is low. and

the air flow from vents is restricted.

Frozen evaporatorRun the fan with compressor

off. then check A,/C thermostat.

Exoansion valve is frosted.Clogged expansion valveClean or replace.

Receiver/dryer outlet is cool, and

inlet is warm (should be warm

during operation).

Clogged receiver/dryerReplace.

Suction pres-

sure abnormally

hig h

Low pressure hose and check

joint are cooler than the tempera-

ture around evaporator.

. Expansion valve open too

long. Loose expansion capillary

tube

Repair or replace.

Suction oressure is lowered when

condenser is cooled bv water.

Excessive refrigerant in sys-

tem

Recover. evacuate, and

recharge with specified amount.

High and low pressure are equal-

ized as soon as the compressor is

stopped, and both gauges fluctu-

ate while running.

Faulty gasket

Faulty high pressure valve

Foreign particle stuck in

high pressure valve

Replace the compressor.

Suction and dis-

charge pres-

sures abnormally

h igh

Reduced air flow through con-

denser.

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean condenser.

Check voltage and fan rpm.

Check fan direction.

Suction and dis-

charge pressure

abnormally low

Low pressure hose and metal end

areas are cooler than evaporator.

Clogged or kinked low pres-

sure hose parts

Repair or replace.

Temperature around expansion

valve is too low compared with

that around receiver/dryer.

Clogged high pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny,Compressor shaft seal leakingReplace the compressor.

Compressor bolt{s) are diny.Leaking around bolt(s)Tighten bolt(s) or replace com-

pressor.

Compressor gasket is wet with oil.Gasket leakingReplace the compressor.

22-26

Page 1457 of 2189

Clutch InsPection

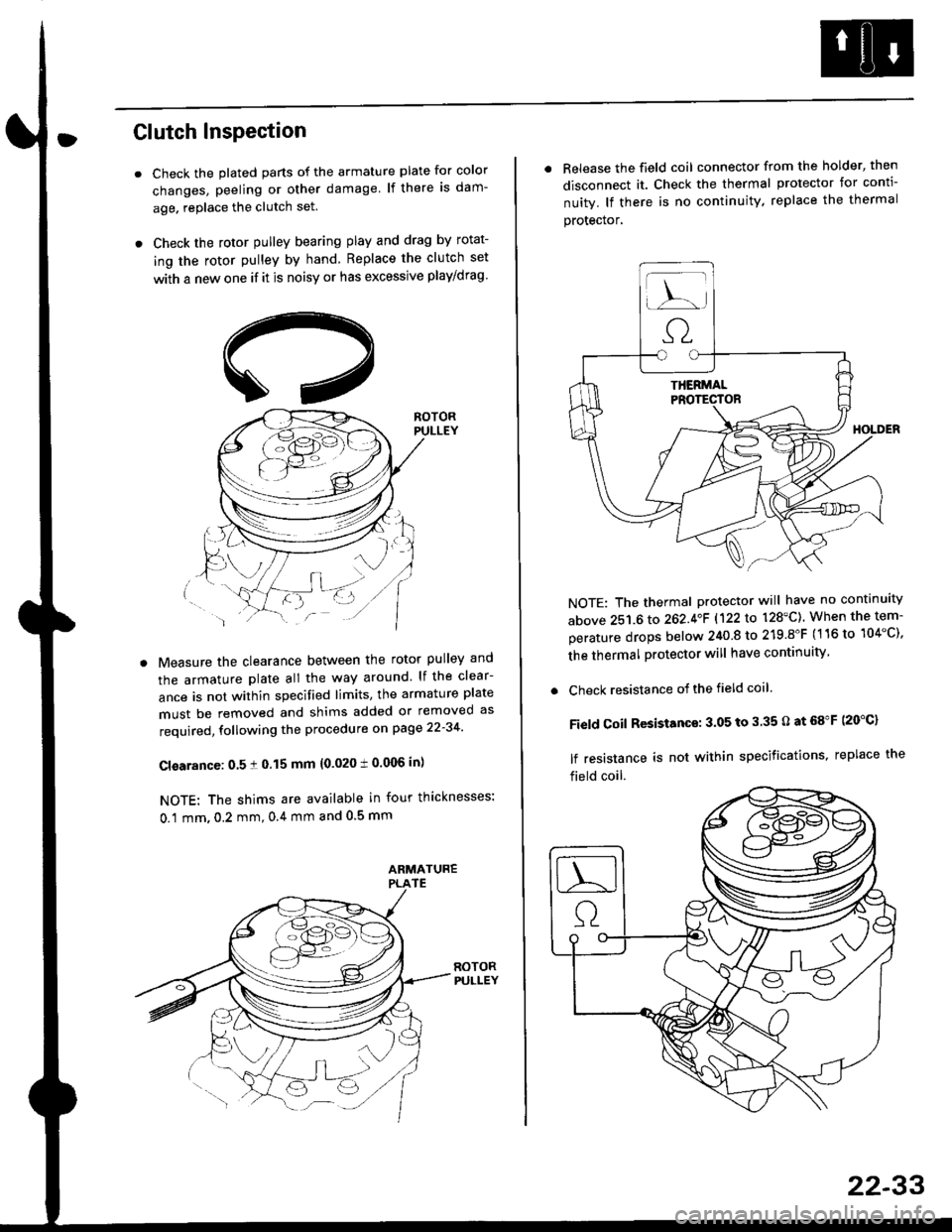

Check the plated parts of the armature plate for color

changes, peeling or other damage lf there is dam-

age. replace the clutch set.

Check the rotor pulley bearing play and drag by rotat-

ing the rotor pulley by hand Replace the clutch set

with a new one if it is noisy or has excessive play/drag

Measure the clearance between the rotor pulley and

the armature plate all the way around lf the clear-

ance is not within specified limits, the armature plate

must be removed and shims added or removed as

required, following the procedure on page 22-34

Cl€arance: 0.5 ! 0.15 mm {0.020 t 0.006 in)

NOTE: The shims are available in four thicknesses:

0.1 mm,0.2 mm,0.4 mm and 0.5 mm

. Release the field coil connector from the holder' then

disconnect it. Check the thermal protector for conti-

nuity. lf there is no continuity. replace the thermal

protecror,

NOTE: The thermal protector will have no continuity

above 251.6 to 262.4oF 1122lo 128'C). When the tem-

perature drops below 240 8 to 219.8"F (116 to 104"C),

the thermal protector will have continuity

. Check resistance of the field coil

Field Coil Resistance: 3.05 to 3.35 O at 68"F (20"C)

lf resistance is not within specifications, replace the

field coil.

22-33

Page 1459 of 2189

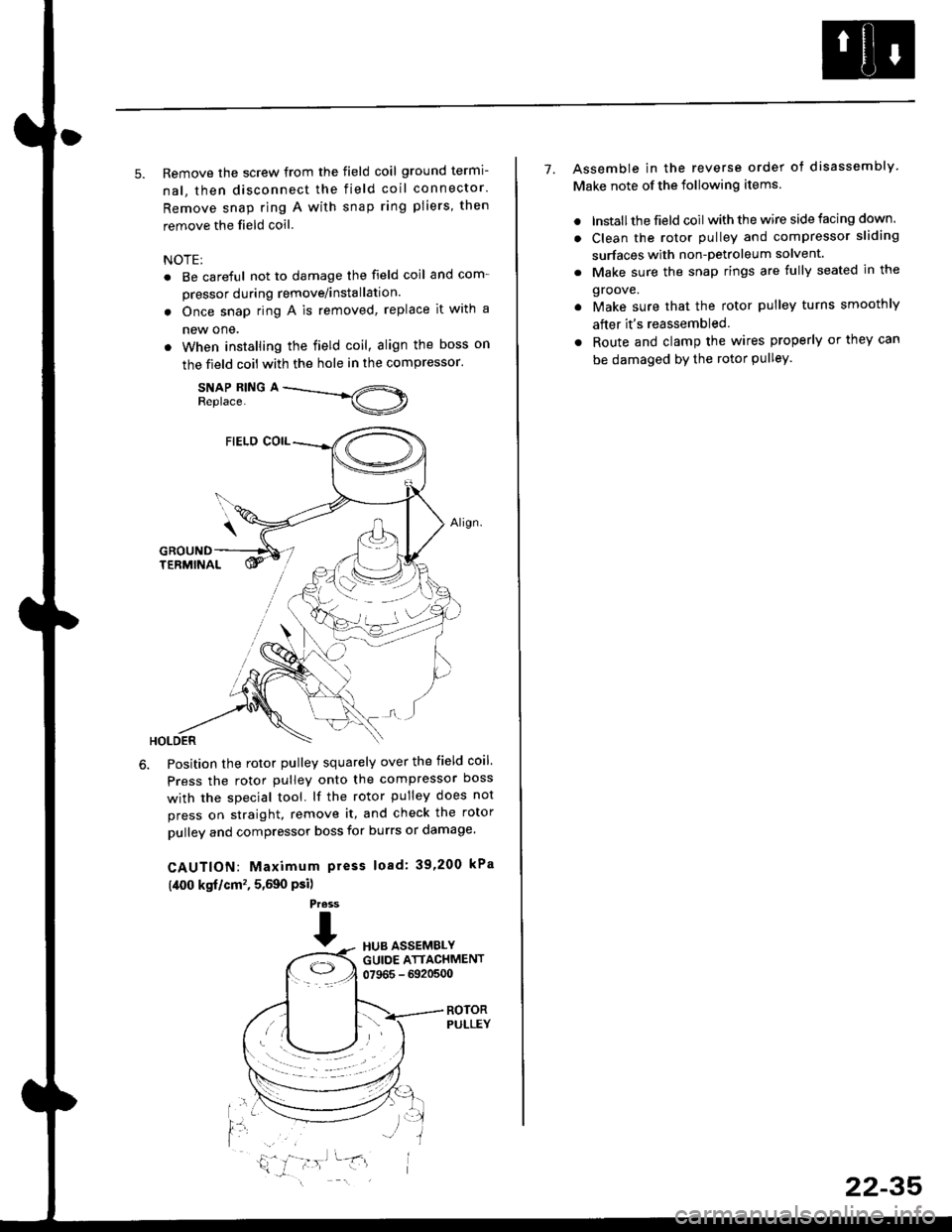

5. Remove the screw from the field coil ground termi-

nal, then disconnect the field coil connector.

Remove snap ring A with snap ring pliers, then

remove the field coil

NOTE:

. Be careful not to damage the field coil and com-

pressor during remove/installation.

. Once snap ring A is removed, replace it with a

new one.

. When installing the field coil, align the boss on

the field coil with the hole in the compressor.

SNAP RING AReplace.

Position the rotor pulley squarely over the field coil.

Press the rotor pulley onto the compressor boss

with the special tool. lf the rotor pulley does not

press on straight, remove it, and check the rotor

pulley and compressor boss for burrs or damage.

CAUTION: Maximum press load: 39,200 kPa

(,[00 kgf/cm'�, 5,590 Psi)

Press

THUB ASSEMBLYGUIDE ATTACHMENT07965 - 6920500

ROTORPULLEY

t'l

i,'

7. Assemble in the reverse order of disassembly

Make note of the following items.

. lnstall the field coil with the wire side facing down.

. Clean the rotor pulley and compressor sliding

surfaces with non-petroleum solvent.

. Make sure the snap rings are fully seated in the

groove.

. Make sure that the rotor pulley turns smoothly

after it's reassembled

. Route and clamp the wires properly or they can

be damaged bY the rotor Pulley.

22-35

Page 1464 of 2189

Compressor (DENSOI

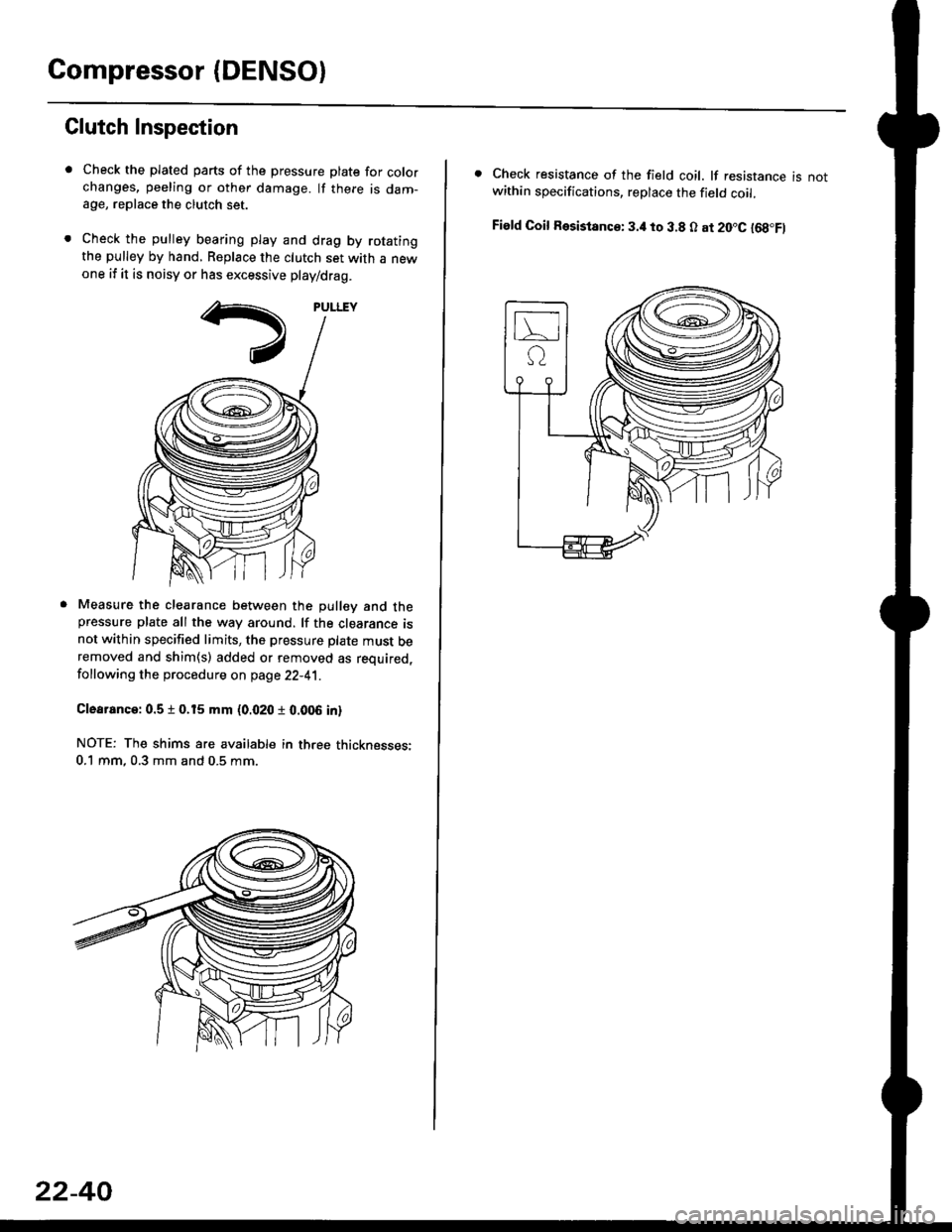

Clutch Inspection

Check the plated parts of the pressure plate for colo.changes, peeling or other damage. lf there is dam-age, replace the clutch set.

Check the pulley bearing play and drag by rotatingthe pulley by hand, Replace the clutch set with a newone if it is noisy or has excessive play/drag.

Measure the clearance between the pullev and thepressure plate all the way around. lf the clearance isnot within specified limits, the pressure plate must beremoved and shim(s) added or removed as required,

following the procedure on page 22-41.

Clearanca:0.5 t 0.15 mm {0.020 r 0.006 in}

NOTE: The shims are availabte in three thicknesses:0.1 mm,0.3 mm and 0.5 mm.

22-40

. Check resistance of the field coil. lf resistance is notwithin specifications, replace the field coil.

Fiald Coil Resistanc€: 3.it to 3.8 O at 20.C l68.Fl

Page 1470 of 2189

A/C System Service

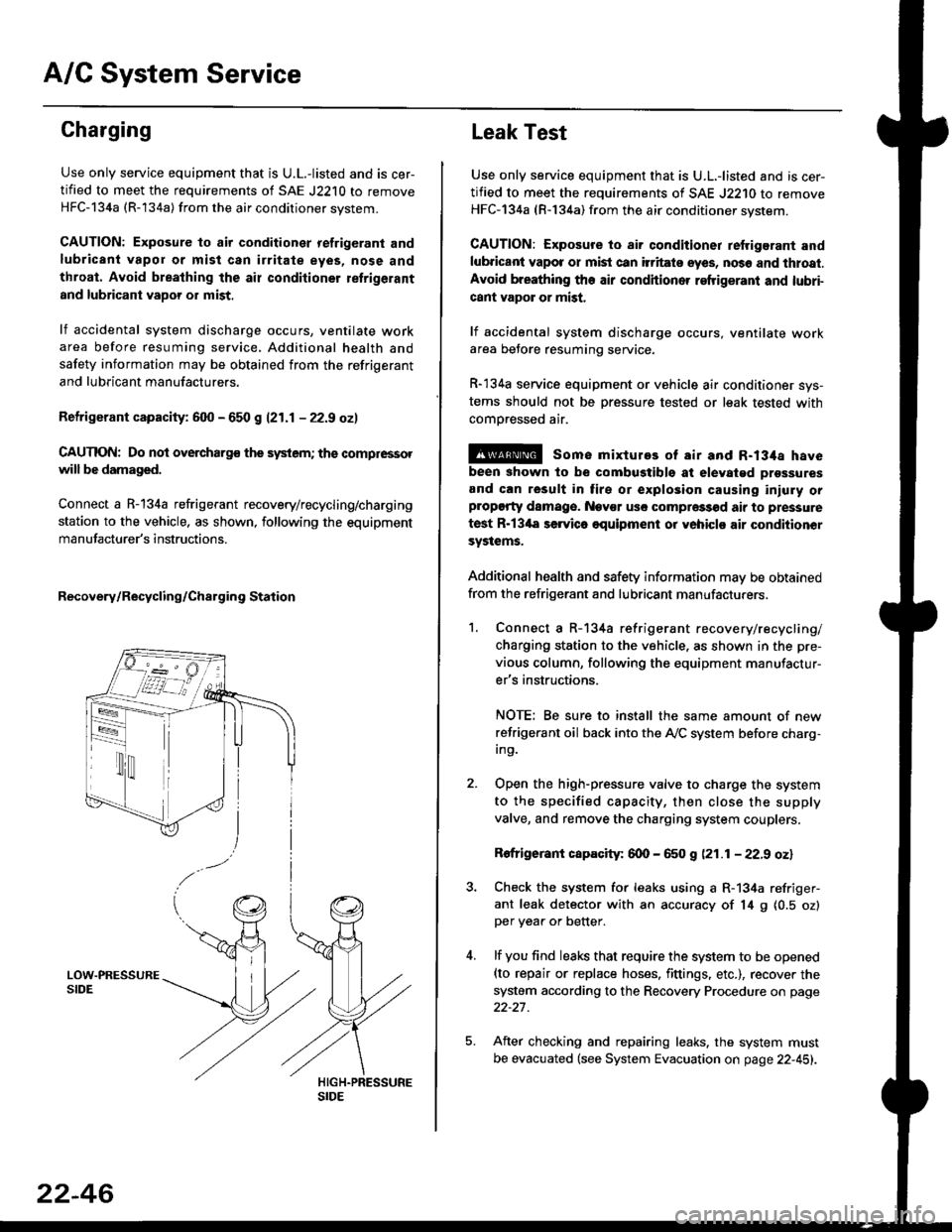

Charging

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritale eyes, nose and

throat. Avoid breathing the air conditioner retrigerant

and lubricant vaoor or mist,

lf accidental system discharge occurs, ventilate workarea before resuming service, Additional health and

safety information may be obtained from the refrigerant

and lubricant manufacturers.

Refrigerant capacityt 600 - 650 g 121.1 - 22.9 ozl

CAUnON: Do not overcharg€ the system; the comprcssor

will be damaged.

Connect a R-134a refrigerant recovery/recycling/charging

station to the vehicle, as shown, following the equipment

manufacturer's instructions.

Recovery/Recycling/Charging Station

22-46

Leak Test

Use only service equipment that is U.L,-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure io air conditioner refrigerant and

lubricant vapot or mist can itritats eyes, no36 and thtoat.

Avoid breathing the air conditioner refrigeranl and lubri-

cant vapor or mist,

lf accidental system discharge occurs, ventilate workarea betore resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comoressed air.

@ some mixtures of air and R-134a have

been shown to be combugtibls at elevatgd prossures

and can result in tire or explosion causing iniuly orplopgrty damage. Nev€r usc compre33od air to pressure

test R-13'la servica oquipment or yohiclo air conditionor

systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. Connect a R-134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown in the pre-

vious column, following the equipment manufactur-

er's instructions.

NOTE; Be sure to install the same amount of new

refrigerant oil back into the A,/C system before charg-In9.

Open the high-pressure valve to charge the system

to the specified capacity, then close the supply

valve, and remove the charging system couplers.

Rofrigerant capacity: 600 - 650 g (21.1 - 22.9 oz)

Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of 14 9 10.5 ozlper yea. or better.

lf you find leaks that require the system to be opened(to repair or replace hoses. fittings. etc.), recover the

system according to the Recovery Procedure on page

22-27.

After checking and repairing leaks. the system must

be evacuated (see System Evacuation on page 22-451.

Page 1566 of 2189

Starting System

Starter Test lcont'dl

Ch€ck tor Wear and Damage

The starter should crank the engine smoothly and

steadily, lf the starter engages. but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter or flywheel ring gear for damage.

. Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held,- lf damaged. replace the gears.

Check Cranking Voltsge and Curr€nt Draw

Cranking voltage should be no less than 8.5 volts.

Current draw should be no more than 350 amperes.

lf cranking voltage is too low, or current draw too high,

check for;

. dead or low batterv.

. open circuit in starter armature commutator seg-

ments,

. starter armature dragging.

. shorted armature winding.

o excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm,

lf speed is too low, check for:

. loose battery or stanerterminals.

. excessively worn starter brushes,

. open circuit in commutator segments.

o dirty or damaged helical spline or drive gear.

. defective drive gear overrunning clutch.

Check Siarter Disengag€ment

With the shift lever in El or @ position (A/T) or with the

clutch pedal depressed (M/T), turn the ignition switch to

START (lll), and release to ON (ll).

The starter drive gear should disengage from the torque

converter or flywheel ring gear when you release the

Key.

lf the drive gear hangs up on the torque converter or fly-

wheel ring gear, check for:

. solenoid plunger and switch malfunction,

. dirty drive gear assembly or damaged overrunning

clutch.

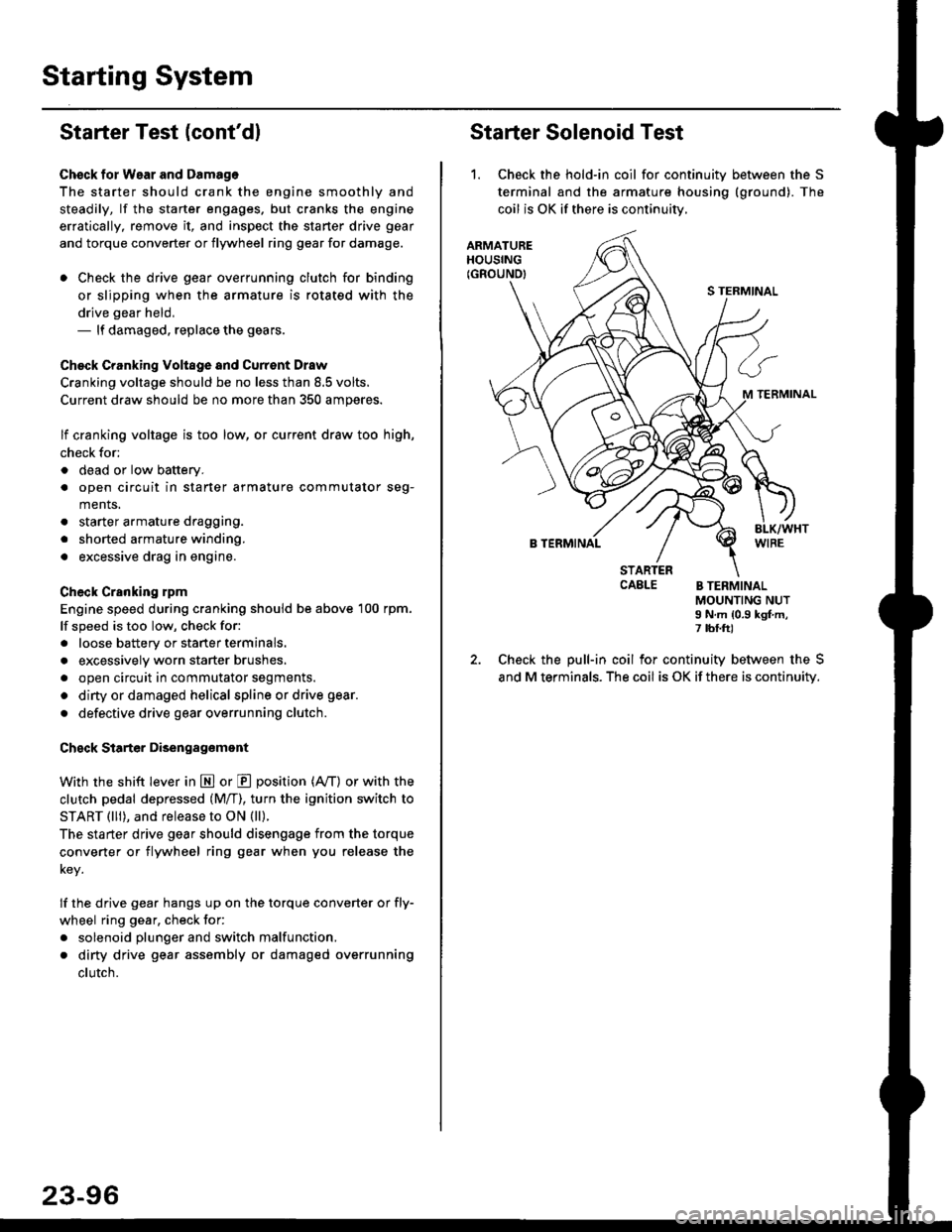

Starter Solenoid Test

1. Check the hold-in coil for continuitv between the S

terminal and the armature housing (ground). The

coil is OK if there is continuitv,

ARMATUREHOUSING(GROUND)

S TERMINAL

M TERMINAL

B TERMINAL

STARTERCAELE B TERMINALMOUNTING NUTI N.m {0.9 kgf.m,7 tbf.ft)

Check the pull-in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

Page 1568 of 2189

Starting System

Armature Inspection and Test (cont'dl

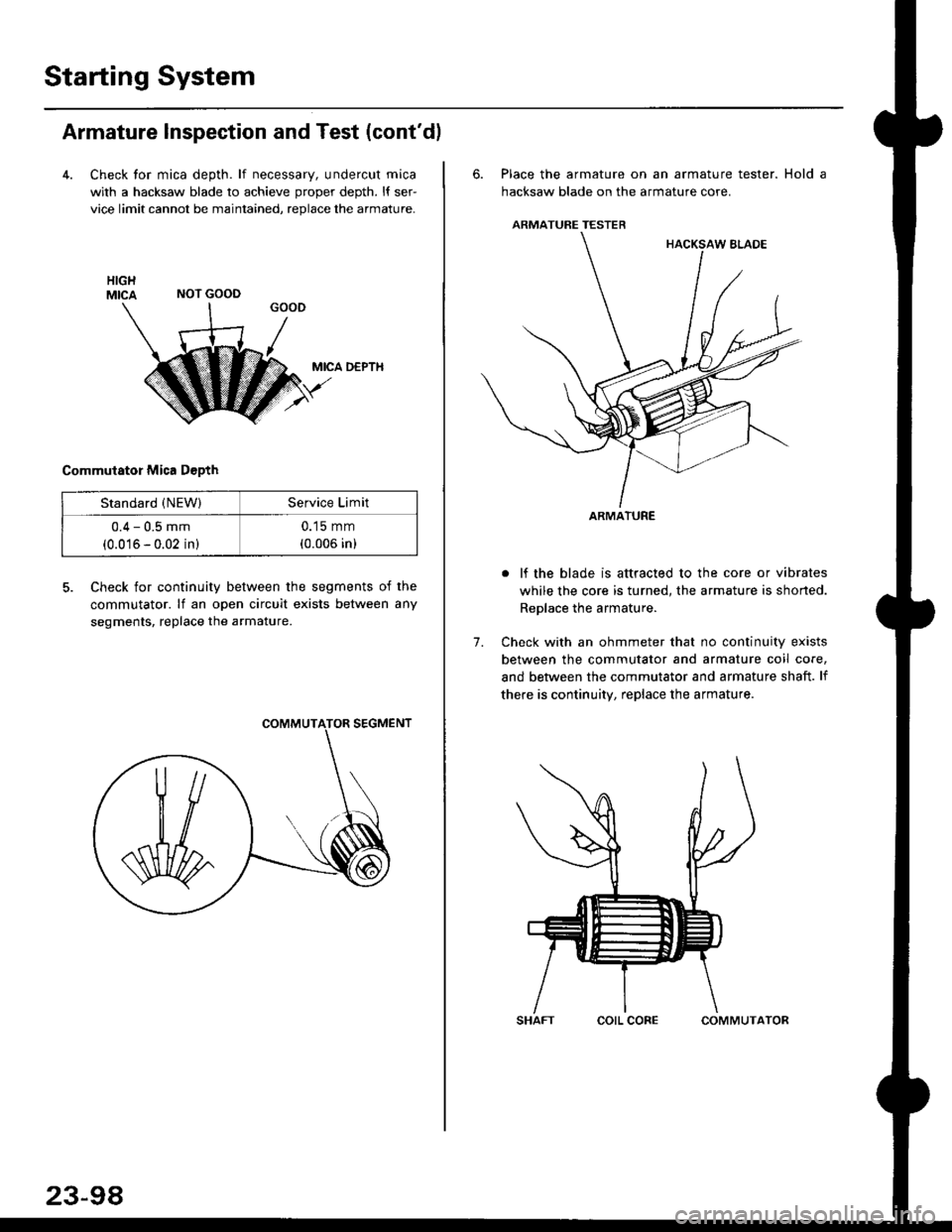

4. Check tor mica depth. lf necessary, undercut mica

with a hacksaw blade to achieve proper depth. l{ ser-

vice limit cannot be maintained, replace the armature.

MICA D€PTH

Commutator Mica D€pth

5. Check for continuity between the segments of the

commutator. lf an open circuit exists between any

segments, replace the armature.

NOT GOOD

Standard (NEW)Service Limit

0.4 - 0.5 mm

(0.016 - 0.02 in)

0.15 mm

(0.006 in)

23-98

corL coFECOMMUTATOR

6. Place the armature on an armature tester. Hold a

hacksaw blade on the armature core.

ARMATURE TESTER

. lf the blade is attracted to the core or vibrates

while the core is turned, the armature is shorted.

Replace the armature.

7. Check with an ohmmeter that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. lf

there is continuity, replace the armature.

ARMATURE