check oil HONDA CIVIC 1996 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 633 of 2189

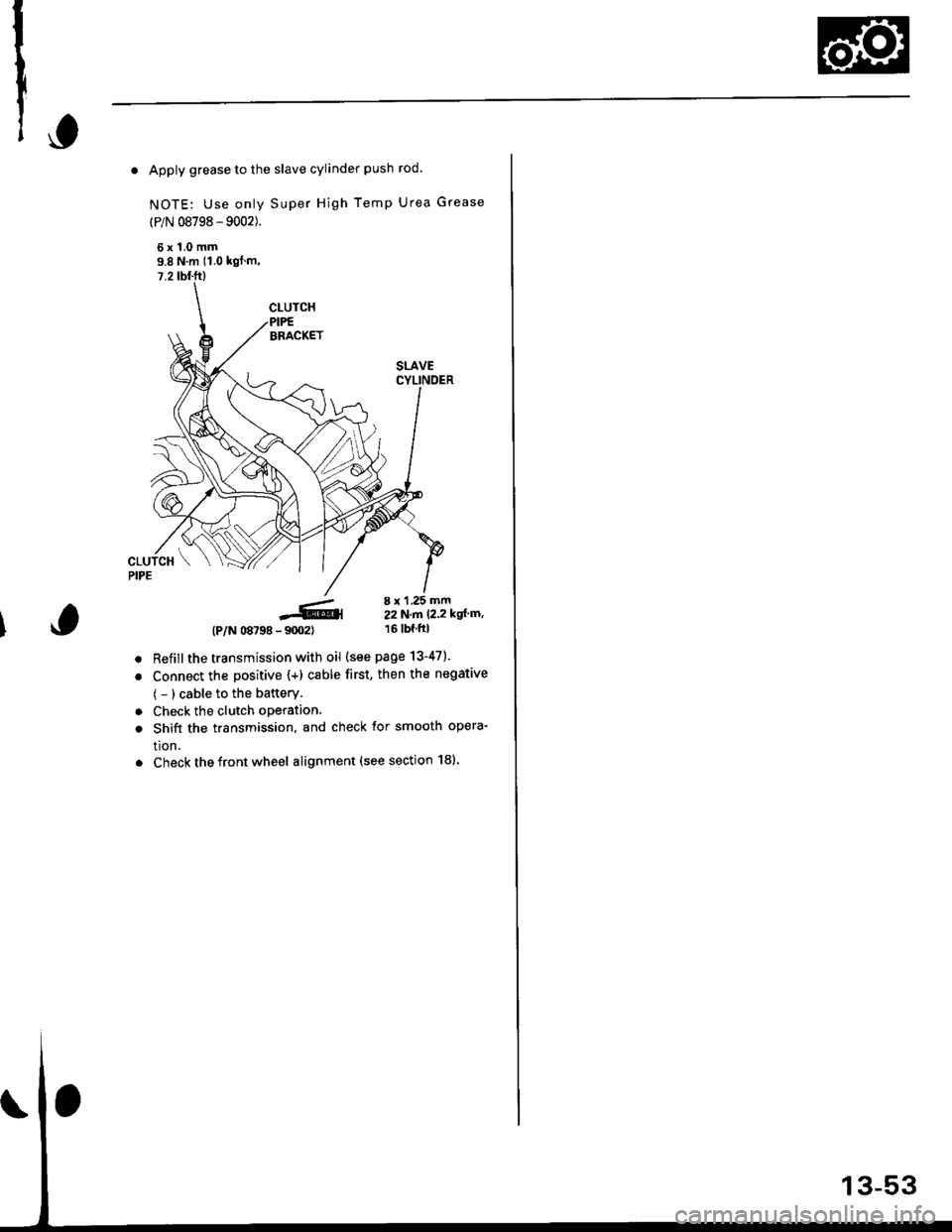

. Apply grease to the slave cylinder push rod.

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

6x1.0mm9.8 N'm (1.0 kgl m,

7.2 tbl.ft)

-6,4- 9m2)

Refillthe transmission with oil (see page 13-47).

Connect the positive (+) cable first, then the negative

( - ) cable to the battery.

Check the clutch oPeration.

Shift the transmission, and check for smooth opera-

tion.

Check the front wheel alignment (see section 181.

(P/N 08798

8 x 1 .25 mm22N.n 12.2 kgl'm,16 tbf.ftl

a

a

a

a

Page 679 of 2189

Automatic Transmission

Special Tools ......... .....'."".'-.-.' 14'2

Description .,....................-...... 14-3

power Flow ......,................. 14"6

Elestronic Control System .... . ................'..'.'.. 14-13

Hvdraulic Control .....'......" 1'l-19

Hydraulic F|ow...... .'.'.".'....11-21

Lock-up System '............ ... t/t'33

Electrical System

Component Locations....,.............'......'.............'.,. 14'39

PCM Circuit Diagram

lA/T Control Syst€m: '96 - 98 Models) .........'.. 1/t-40

PCM Tarminal Volt8ge/Measuring Condhions

{'96 - 98 ModeblA/T Control System ............

PCM Circuit Disgram(A/T Conlrol System: '99 - 00 Modsls) '..........' 14-44

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)A/T Control System ...

Troubleshooting Proceduros ....

Symptom-to-ComPonent Chari

Efectricaf SFiem - '96 - 98 Models '..-.-..."'.'..11-52

Eloqtrical System -'99 - 00 Modols ... .........". 1+54

EleclricatTroubl$hooting ('96 - 98 Models)

Valve Body

Repair .................... ........'.... 14-139

Valve

Assembly

ATF Pump

1,1-1i10

Inspection ...........'.......... 14-141

Main Valvs Body

Disass€mbf y/lnspoction/R.sssembly .'.'.'.'.. -. -. 1 1-1 12

Secondsry Valve BodY

Disa$embfy/lnspoction/Rsassembly ......'.'.'.'. 11-111

Regulator Valve Body

Disa$embly/lnspoction/Rea3sembly ..........'... 14-1{5

Servo Body

Disassombly/lnsp€ction/Reassembly .".'........ 14-146

Lock-up Valv6 Body

Dis$s.mbf y/ln3poction/Rea$embly .'.. -. -..'.'.' 1 1-1 17

Mainsh!ft

Dkassembly/lnep€ction Reassembly ..'...'........ 14'148

Inspoction .............'..........'. l it-149

Countsrshaft

Disa$embly/lnspeqtion/Rea3sembly .......'...'.. 1a-l51

Dba$ombly/Re$s.mblY11-152

til-46

I rl-48

Troubleshooting Flowcharts

Electrical Troubleshooting ('9!t - 00 Models)

Troublsshooting Flowchart3

Lock-up Control Solenoid vslvo A/B AssemblY

RePlacoment

Shift Cont.ol Solenoid Valve A/B A3sembly

Inspestion

Ona-way Clutch

Disassembh/lrupoction/Rca$embly .. "'........ l4-155

Clutch

lllustlttcd Ind.x {A48A, B4RA Transmlssion) ..' 14-156

tustr.tod Index (MrnA Transmi$ionl ............ til-158

...................... 14-153

L

14-56

1+81'

14-105

1+105

Replacoment ......

Mainshaft/Countorshaft Spo€d Sonsors

Replacemsnt ......'."'........... lit'108

Hydraulic System

Symptom-to-Componeni Chart

Hydraulic Sydemr+109

t4-113

1+116

11-117

Rea$emblY

14-106 Difforrr ial

llhdraied Index........ t4-156

B.ckhrh ln3poction. 14-167

Boaring Roplacemont..-..........11-167

..... 14-108 Diftrrsniial Carrior Repl8cemeni .'.-.............'...' lil-168

Oil Sall Romovalt4-t 59

Oil Soal ln3tallstion/Sidc Clearance'......'.....'... 1'l'169

Torqua Convertcr Housing Boarings

Mlin3haft Besring/Oil Scal Roplac.ment ."..'.. lil-172

Counio6hatt Betring R.plscem.nt ..'...... ....... 14-173

Test.....,......14-106

14-107

14-160

11-162

11-171

11-175

Replacement

Test .....,.,..........

Road Te3t

Linear Solenoid AsssmblY

Stall Speed

lllustrated Indax

Transmission/End Cover'. ....

Transmission Hou3ing,.............'.'......'....""..-.-.. 11-128

Torque Conve.ter Housing/Valvo Body ........... 14-130

End Cover

14-itB Park Stop

1+119 In3pection/Adiustmsnt...'......'.'............'...."""'14-175

Transmbgion

Reassombly

11-122 Torquo Convertet/Drivr Plsie ............'.'............'.. . l4-182

Transmission

11.726 Inrtallation

Tranlmission Housing Boarings

Msinsh.ft /CounteEhaft Bearings

B!pltcomgnt

Rcvo.3s ldlor Gear

lnrtallation

Cooler Flushing ..

Shift Cabls

Test

Fluid Level

Checkin9 .........."..'.'.....

Changing

Pressure Testing

Transmission

Transmission

Rgmoval ..

lil-176

.'..........'.'.'..... 1'l-183

.... lil-187

11-132Adiustmont

RemovaUlnttallation1,1-190

lit-191Transmisgion Housing

Removal ... '.'...... ......'..... 14-l3il

Tolque Convgrter Housing/valvs Body

Rsmoval .........,...... ............. 14-136

Valve CaDs

Description .......'................. t 4'138

Shift lndicator Panel

Adiu3tmant ..'.................. 14-192

ATF Coolor Hoses

Connection ..,............,.,....... l'l-192

Shift Lever .,........

Page 783 of 2189

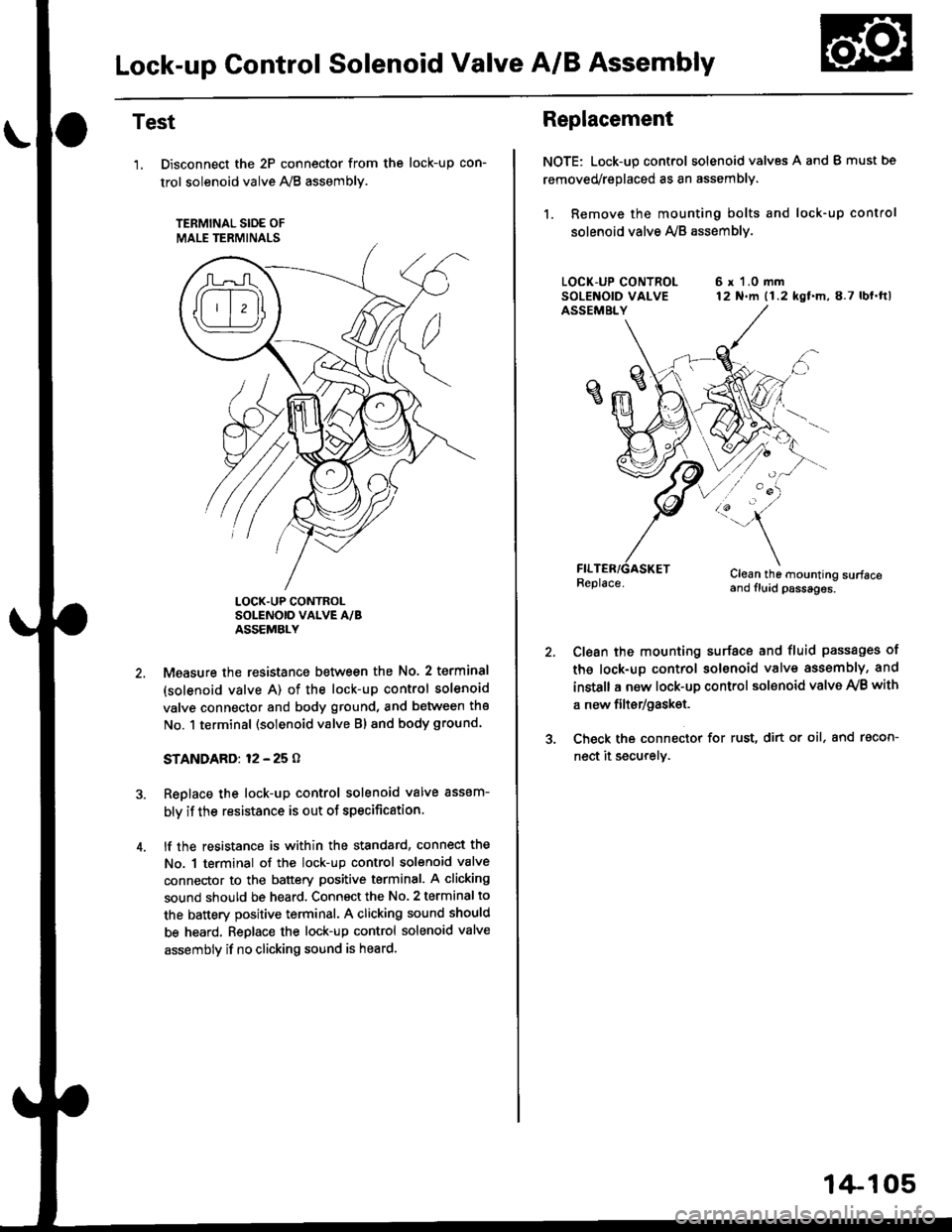

Lock-up Gontrol Solenoid Valve A/B Assembly

Test

'1, Disconnect the 2P connector from the

trol solenoid valve 1y'8 assembly.

TERMINAL SIOE OF

MALE TERMINALS

tocK-up con-

LOCK.UP CONTROLSOLENOID VALVE A/BASSEMBLY

Measure the resistance between the No. 2 terminal

(solenoid valve A) of the lock-up control solenoid

valve connector and body ground, and between the

No. 1 terminal (solenoid valve Bl and body ground.

STANDARD: 12 - 25 O

Replace the lock-up control solenoid valve assem-

bly if the resistance is out of specification.

lf the resistance is within the standard, connect the

No. 1 terminal of the lock-up control solenoid valve

connector to the battery positive terminal. A clicking

sound should be heard. Connsct the No. 2 terminal to

the battery positive terminal. A clicking sound should

be heard. Replace the lock-up control solenoid valve

assembly if no clicking sound is heard.

Replacement

NOTE: Lock-up control solenoid valves A and I must bs

removed/replaced as an assembly.

1. Remove the mounting bolts and lock-up control

solenoid valve Ay'B assemblv.

6 r 1.0 mm12 N.m (1.2 kgf.m,8.7 lbl.ftl

/:'-

Clean the mounting surfaceand fluid psssages.

Clean the mounting surface and fluid passages of

th6 lock-up control solenoid valve assembly, and

instsll a new lock-up control sol€noid valve Ay'B with

a new filtsr/gask€t.

Check the connector for rust, dirt or oil, and racon-

nect it securely.

1+105

Page 784 of 2189

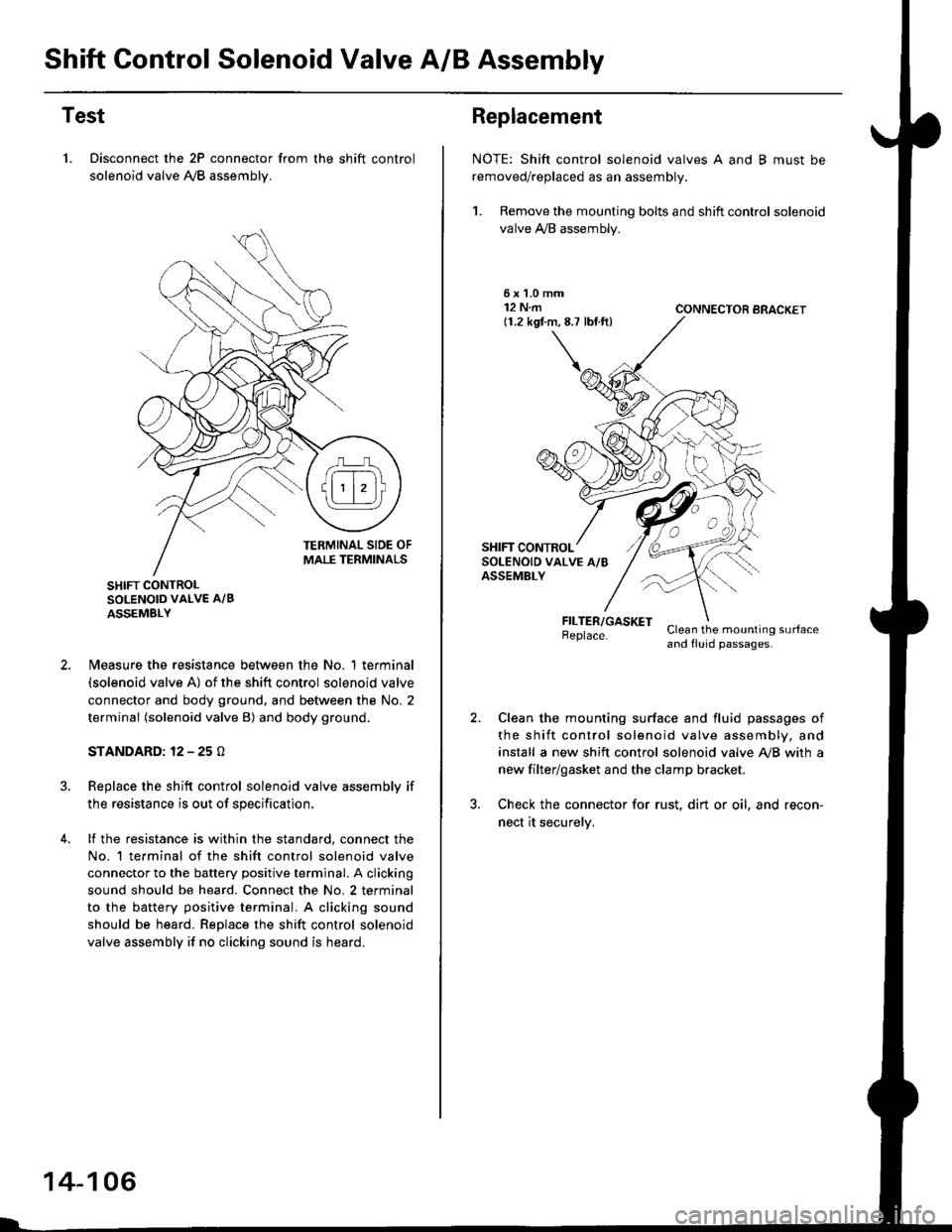

Shift Control Solenoid Valve A/B Assembly

Test

1. Disconnect the 2P connector from the shift control

solenoid valve A,/B assemblv.

SHIFT CONTROLSOLENOID VALVE A/B

ASSEMBLY

N4easure the resistance between the No. 1 terminal(solenoid valve A) of the shift control solenoid valve

connector and body ground, and between the No. 2

terminal (solenoid valve B) and body ground.

STANDARD: 12 - 25 O

Replace the shift control solenoid valve assembly if

the resistance is out of specification,

lf the resistance is within the standard, connect the

No. 1 te.minal of the shift control solenoid valve

connector to the battery positive terminal. A clicking

sound should be heard. Connect the No. 2 terminal

to the battery positive terminal. A clicking sound

should be heard. Replace the shift control solenoid

valve assembly if no clicking sound is heard.

14-106

Replacement

NOTE: Shift control solenoid valves A and B must be

removed/replaced as an assembly.

1. Remove the mounting bolts and shift control solenoid

valve A,/B assembly.

5xL0mm12 N.m(1.2 kgf.m,8.7 lbf.ft)CONNECTOR BRACKET

FILTER/GASKETBeplace.Clean the mounting surfaceand fluid passages.

Clean the mounting surface and fluid passages of

the shift control solenoid valve assembly, and

install a new shift control solenoid valve Ay'B with a

new filter/gasket and the clamp bracket.

Check the connector for rust. dirt or oil. and recon-

nect it securelv,

Page 786 of 2189

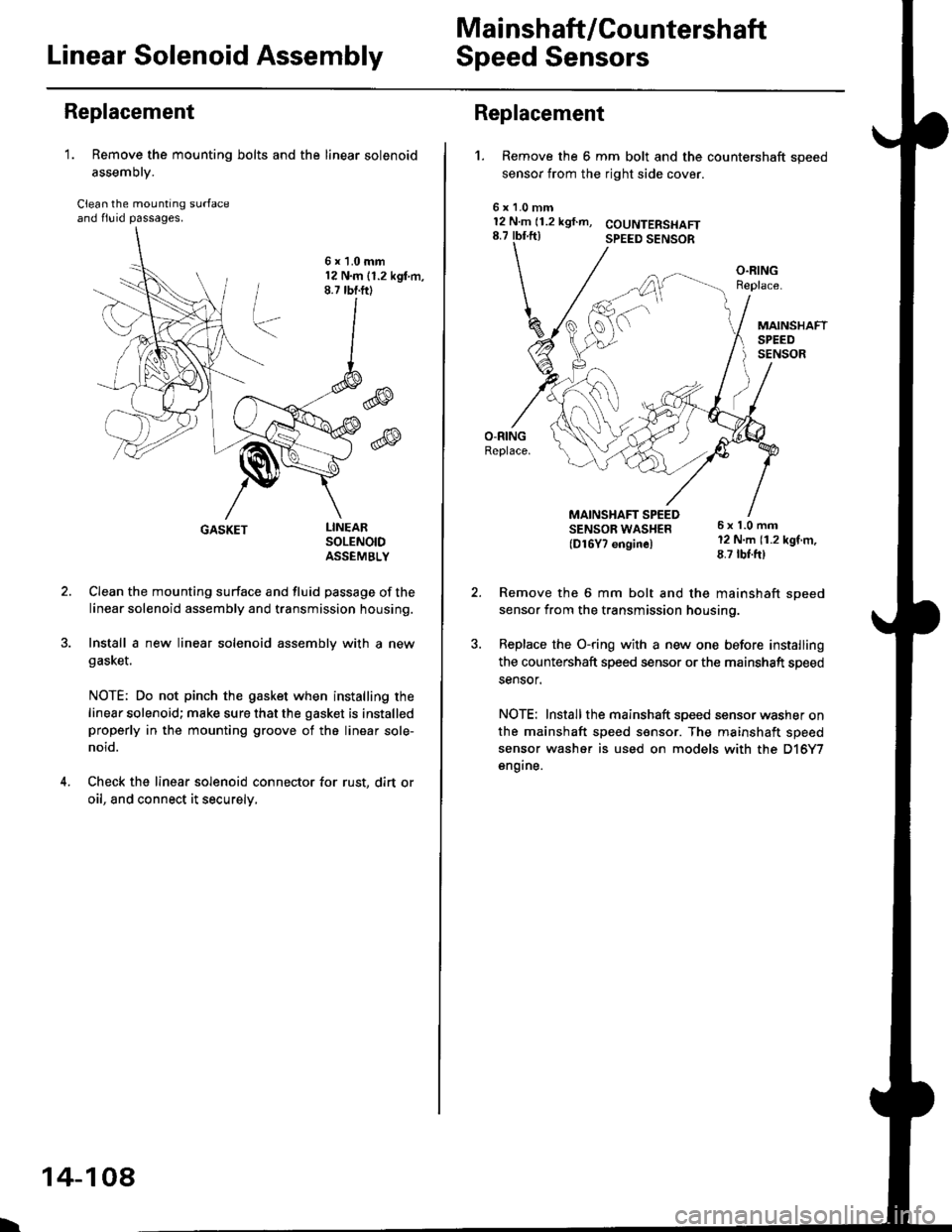

Mai nshaft/Cou ntershaft

Linear Solenoid AssemblySpeed Sensors

Replacement

1. Remove the mounting bolts and the linear solenoid

assemory.

Clean the mounting surfaceand flu id passages.

6x1.0mm12 N.m 11.2 kgl m,8.7 tbf.ftl

@

@

GASKET

Clean the mounting surface and fluid passage of the

linear solenoid assembly and transmission housing.

Install a new linear solenoid assembly with a new

gasl(et.

NOTE; Do not pinch the gasket when installing the

linear solenoid; make sure that the gasket is installedproperly in the mounting groove of the linear sole-

noid.

Check the linear solenoid connector for rust, dirt or

oil, and connect it securely,

LINEARSOLENOIDASSEMELY

I

14-108

Replacement

't.

6x128.7

Remove the 6 mm bolt and the countershaft speed

sensor from the right side cover.

COUNTERSI{AFTSPEED SENSOR

O.RINGReplace.

MAINSHAFTSPEEDSENSOR

MAINSHAFT SPEEDSENSOB WAS}IER(D16Y7 enginel

6x1.0mm12 N.m (1.2 kgf m,8.7 tbf.ft)

1.0 mmN.m (1.2 kgf.m,rbf ft)

\\

/,

%/E:)

Remove the 6 mm bolt and the mainshaft sDeed

sensor from the transmission housino.

Replace the O-ring with a new one before installing

the countershaft speed sensor or th€ mainshaft speed

sensor.

NOTE: Installthe mainshaft speed sensor washer on

the mainshaft speed sensor. The mainshaft speed

sensor washer is used on models with the D'|6Y7

engine.

Page 802 of 2189

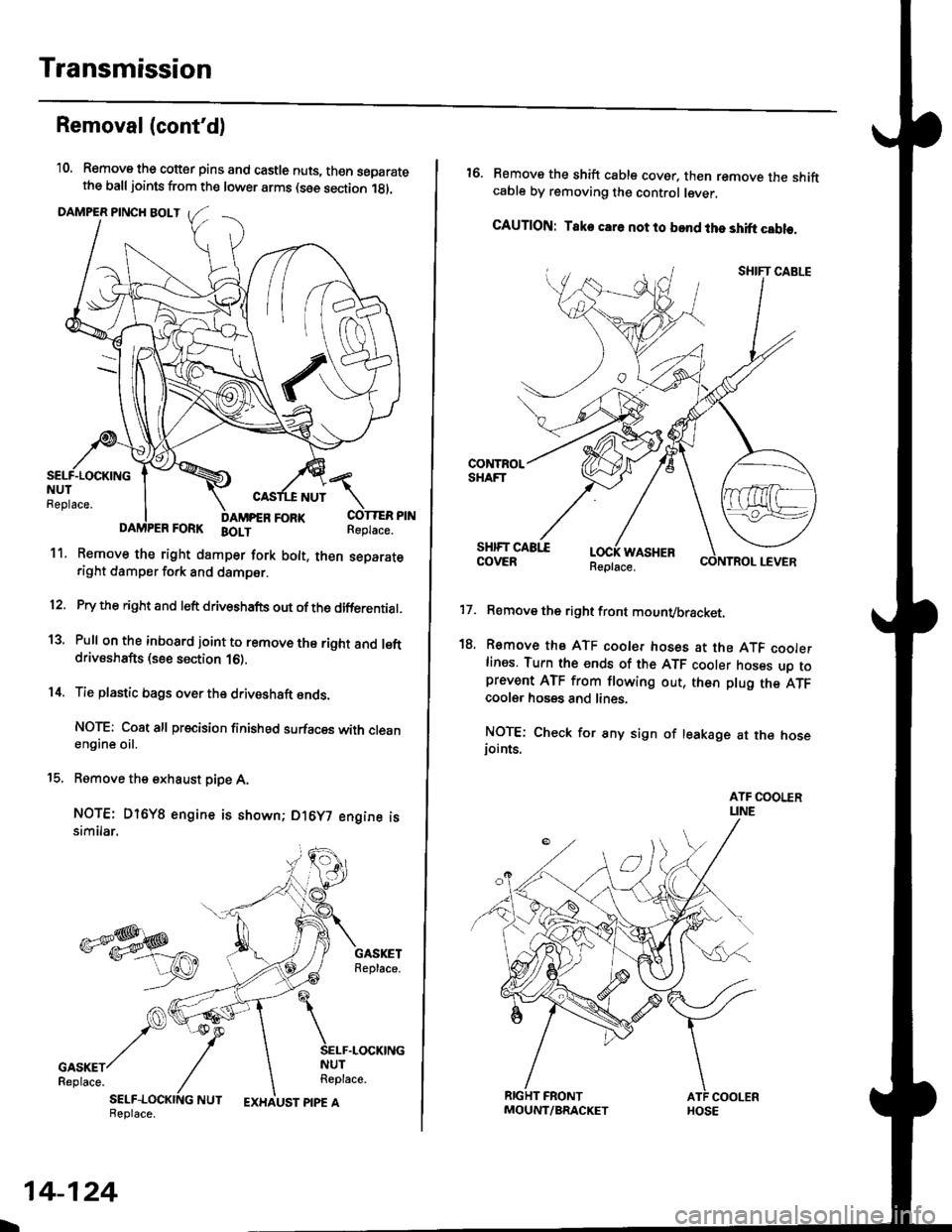

Transmission

Removal(cont'd)

'10. Remove the cotter pins and castle nuts, th€n separatethe balljoints from the lower arms (see section 1gl.

DAMPER PINCH BOLT

NUT

FORI(FORK BOLT

11. Remove the right damper fork bolt. th€nright damper fork and dampor.

COTTER PINReplace.

separate

12.

1a

14.

Pry the right and left driveshafts out ofthe differential.

Pull on the inboard joint to remove the right and leftdrivsshafts (see section 16).

Tie plastic bags over the driveshaft onds.

NOTE: Coat all precision finished surfaces with cleanengine oil.

Remove the exhaust pipe A,

NOTE: Dl6YB engine is shown; D16y7 engine issimilar.

t9.

SELF-LOCKING NUTReplace.

L

14-124

EXHAUST PIPE AMOUNT/BRACKET

17.

18.

16. Remove the shift cable cover. then remove the shiftcable by removing the control lever,

CAUTION: Take car6 not to bond the shift cable.

Remove the right front mounvbracket.

Remove the ATF cooler hoses at the ATF coolerlines. Tufn the ends of the ATF cooler hoses uo toprevent ATF from flowing out, then plug the ATFcooler hosgs and lines.

NOTE: Check for any sign of leakage at the hoseioints.

WASHER

Page 809 of 2189

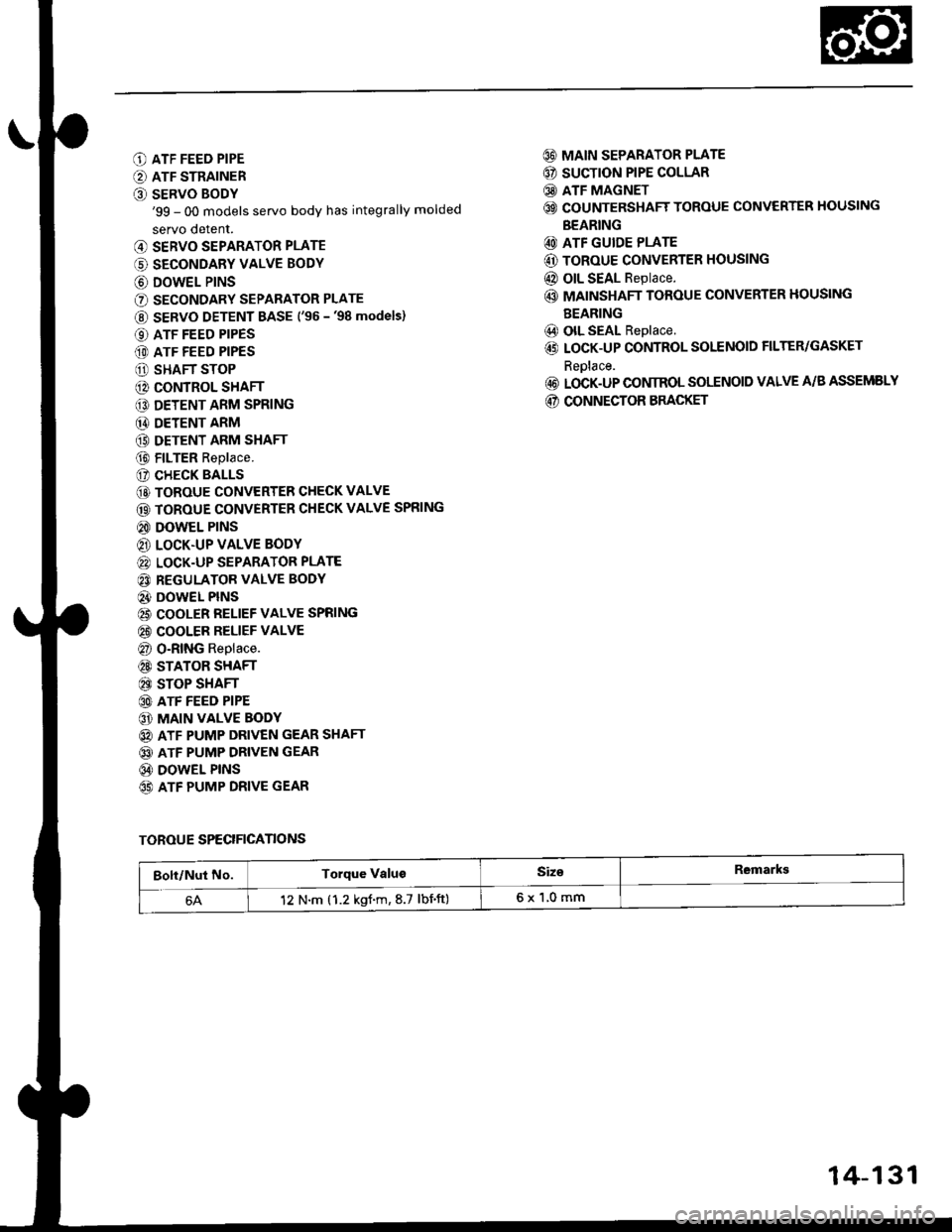

O ATF FEED PIPE

O ATF STRAINER

O SERVO BODY'99 - 00 models servo body has integrally molded

servo detent.

@ SERVO SEPARATOR PLATE

(' SECONDARY VALVE BODY

@ DOWEL P|NS

O SECONDARY SEPARATOR PLATE

@ SERVO DETENT BASE ('�96 -'98 models)

O ATF FEED PIPES

(D ATF FEED PIPES

O SHAFT STOP

@ CONTROL SHAFT

€D DETENT ARM SPRING

@ DETENT ARM

(9 DETENT ARM SHAFT

@ FILTER Replace.

(? CHECK BALLS

@ TOROUE CONVERTER CHECK VALVE

@ TOROUE CONVERTER CHECK VALVE SPRING

@ DOWEL PINS

@ LOCK.UP VALVE BODY

@ LOCK-UP SEPARATOR PLATE

@ REGULATOR VALVE BODY

@} DOWEL PINS

@ COOLER RELIEF VALVE SPRING

@ COOLER RELIEF VALVE

@ O-RING Replace.

@ STATOR SHAFT

@ STOP SHAFT

@ ATF FEED PIPE

@ MAIN VALVE BODY

@ ATF PUMP DRIVEN GEAR SHAFT

@ ATF PUMP DRIVEN GEAR

@ DOWEL PINS

65) ATF PUMP DRIVE GEAR

@ MAIN SEPARATOR PLATE

@ SUCTION PIPE COLLAR

@ ATF MAGNET

@ COUNTERSHAFT TOROUE CONVERTER HOUSING

BEARING

@ ATF GUIDE PLATE

@ ToRoUE CONVERTER HOUSING

@ OIL SEAL Replace.

@ MAINSHAFT TOROUE CONVERTER HOUSING

BEARING

@) olL SEAL Replace.

@ LOCK-UP CONTROL SOLENOID FILTER/GASKET

Reolace.

@ LOCK-UP CONIROL SOLENOID VALVE A/B ASSEMELY

@ CONNECTOR BRACKET

TOROUE SPECIFICANONS

Bolt/Nut No.Torque ValugSiz€Remarkg

12 N.m (1.2 kgf.m,8.7 lbnft)6x1,0mm

14-131

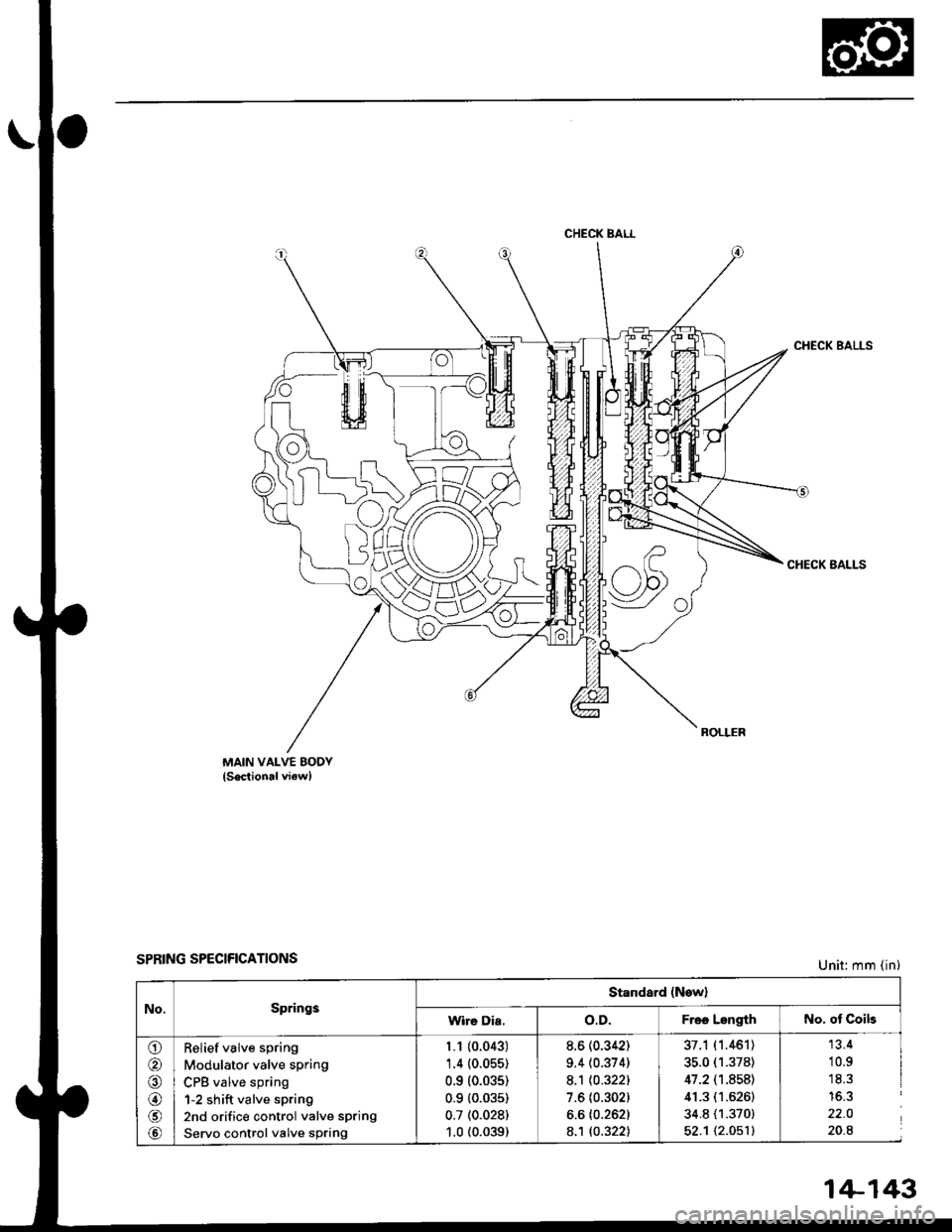

Page 821 of 2189

CHECK BALL

w

MAIN VALVE BODY(Sectional viewl

SPRING SPECIFICATIONS

CHECK BALLS

CHECK BALLS

Unit: mm (in)

No.Springs

Standard (New)

Wire Dia.o.D.Free LengthNo. ot Coils

o

@

@

@

@

@

Relief valve spring

Modulator valve spring

CPB valve spring

1-2 shift valve spring

2nd orifice control valve spring

Servo control valve spring

1.1 (0.043)'1.4 (0.055)

0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

1.0 (0.039)

8.6 (0.342)

9.4 (0.374)

8.1 t0.3221

7.6 {0.302)

6.6 (0.262)

8.'t to.322l

37.1 (1.461)

35.0 (1.378)

47.2 (1.8s8)

41.3 (1.6261

34.8 (1.370)

52.1 t2.O51l

13.4

10.91C ?'15.3

22.0

20.8

1+143

Page 822 of 2189

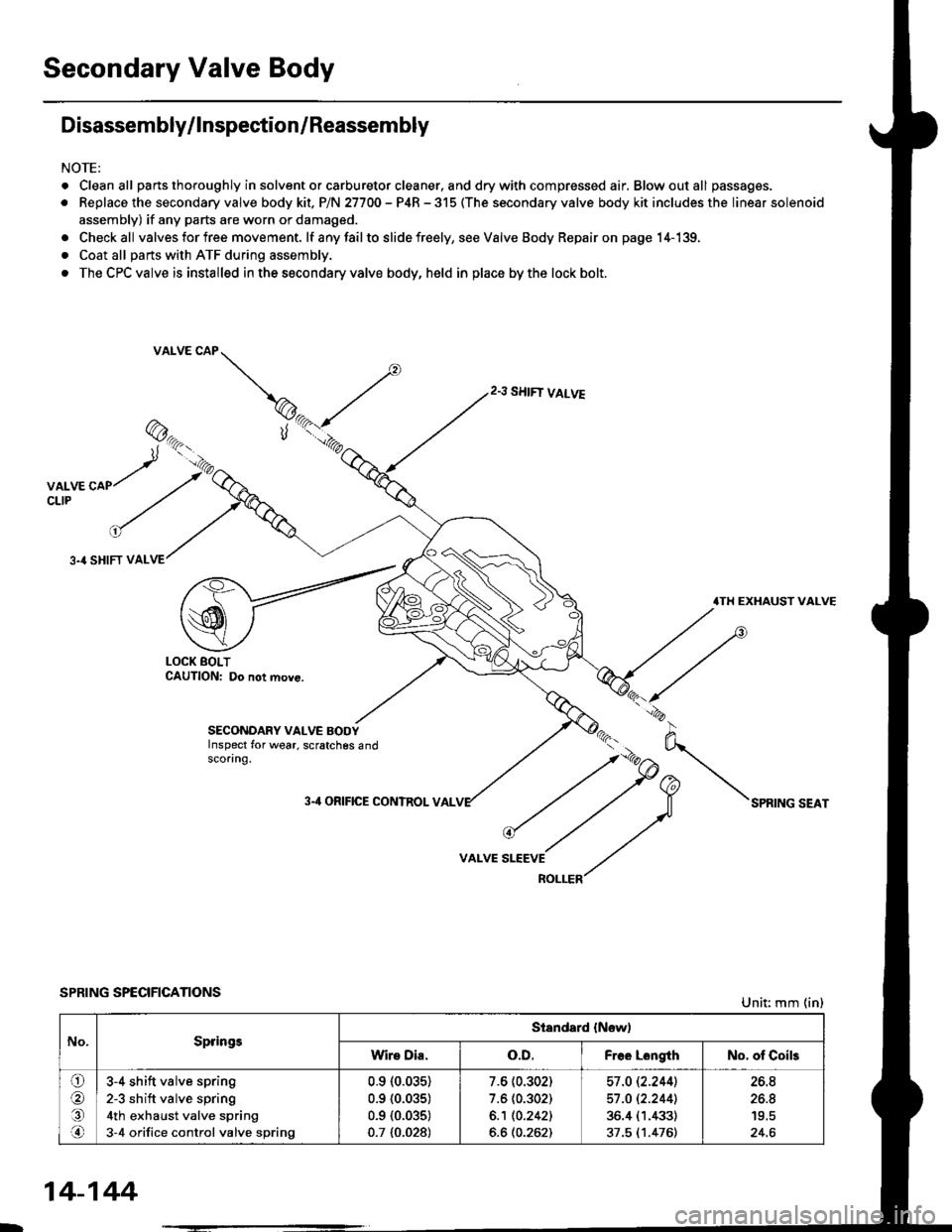

Secondary Valve Body

Disassembly/lnspection/Reassembly

NOTE:

. Cleanall parts thoroughly in solvent or carburetor cleaner. and drywith compressed air, Blowoutall passages.

. Replace the secondary valve body kit. P/N 27700 - P4R - 315 (The secondary valve body kit includes the linear solenoid

assembly) if any parts are worn or damaged.

. Checkall valves for free movement. lf anyfailto slide freely, seeValveBody Repairon page 14-139,

. Coat all parts with ATF during assembly.

. The CPC valve is installed in the secondary valve body, held in place by the lock bolt.

2.3 SHIFT VALVE

3.4 SHIFT VAL

.TH EXHAUST VALVE

LOCK BOLTCAUTION: Do not move.

SECONDARY VALVE BODYInspect for wear, scratches 6ndscoring.

3-'l ORIFICE CONTROL VAL

VALVE

SPRING SPECIFICATIONSUnit: mm (in)

No.SpringsStandard {New)

Wire Dia.o.D.Free LongthNo. of Coils

ora,.n

3-4 shift valve spring

2-3 sh ift valve spring

4th exhaust valve spring

3-4 orifice control valve spring

0.910.035)

0.9 {0.035)

0.9 {0.035)

0.7 {0.028)

7.6 (0.302)

7.6 (0.302)

6.1 10.2421

6.6 (0.262)

57 .O 12.2441

57 .O 12.2441

36.4 (1.433)

37.5 (1.476)

26.8

26.8

24.6

14-144

Page 823 of 2189

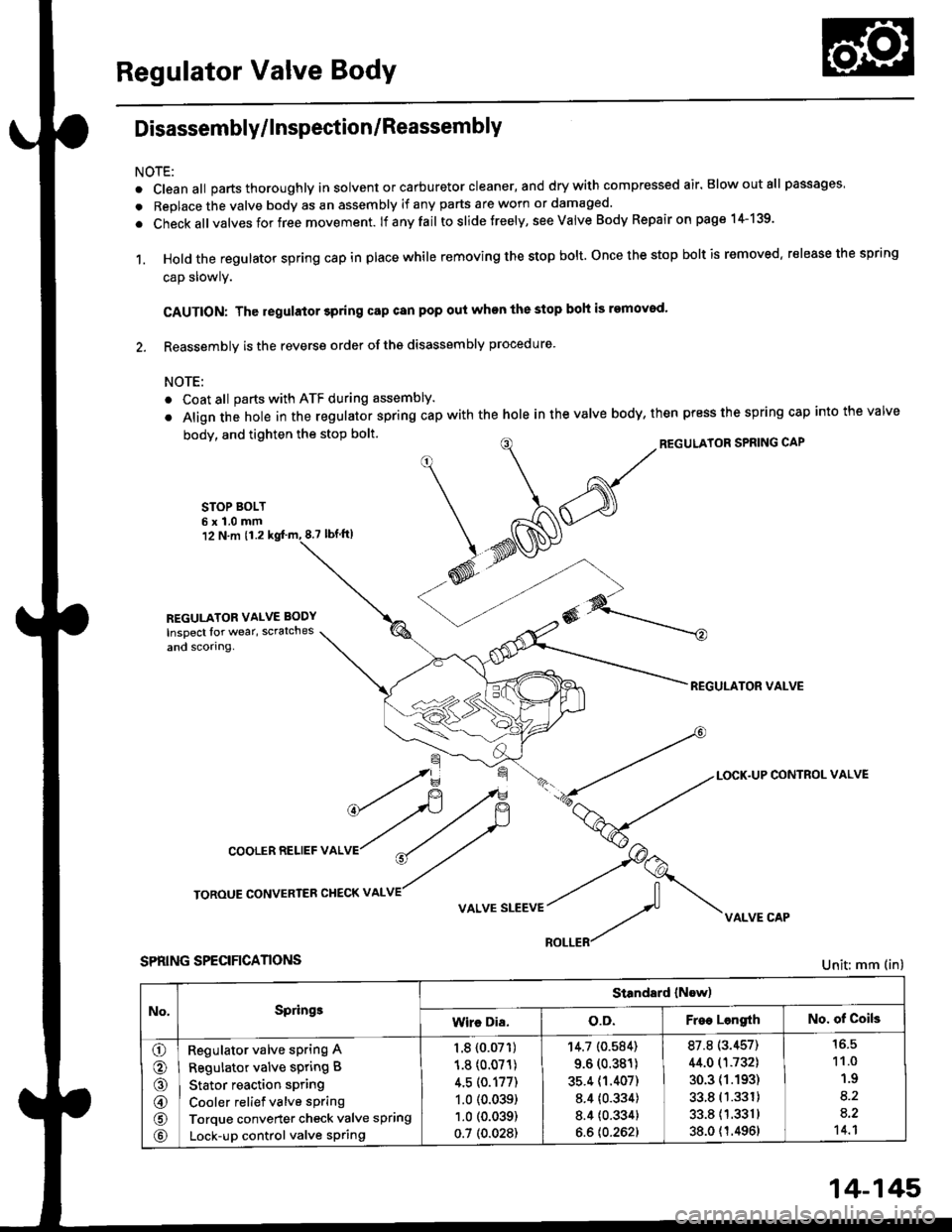

Regulator Valve Body

Disassembly/lnspection/Reassembly

NOTE:

. cleanall parts thoroughly in solvent or carburetor cleaner, and drywith compressed air. Blowoutall passages

. Replace the valve body as an assembly if any parts are worn or damaged.

. check allvalves for free movement. lf anyfail toslidetreely, see valve Body Repairon page 1+139.

1. Hold the regulator spring cap in place while removing the stop bolt. once the stop bolt is removed. release the spring

cap slowly.

CAUTION: The regulator 3pring cap can pop out when the stop boh is removod'

2. Reassembly is the reverse order ofths disassembly procedure.

NOTE:

o Coat all parts with ATF during assembly.

. Align the hole in the regulator spring cap with the hole in the valve body, then press the spring cap into the valve

body, and tighten the stop bolt.

STOP BOLT6x1.0mm12 N.m 11.28.7 tbf.lrl

^/^'ou*'oRsPRrNGcAP

*N@

REGULATOR VALVE

\=f -.-*

*fi /F { a-tLocK.uPcoNrRoLvALVE

cooLERRELlEFvALVr"r?

ry

roRouE coNvERrER cHEcKv ^LvE//

v ^r* "r**::f vi{LvE cAp

SPRING SPECIFICANONS

REGULATOR VALVE BODY

Inspect lor wear, scratches

and scorlng.

Unit: mm (in)

No,Springe

Standard (Now)

Wire Dia.o.D.Free LengrthNo. of Coils

o

o

@

@

@

Regulator valve sPring A

Regulator valve spring B

Stator reaction spring

Cooler relief valve spring

Torque converter check valve spring

Lock-up control valve sPring

1.8 {0.07'�r)

1.8 (0.071)

4.5 (0.177)

1.0 (0.039)

1.0 (0.039)

0.7 (0.028)

'r4.7 (0.584)

9.6 (0.381)

35.4 (1.407)

8.4 {0.334)

8.4 {0.334}

6.6 {0.262}

87.8 (3.457)

44.0 (1.732)

30.3 (1.193)

33.8 (1.331)

33.811.3311

38.0 {1.4961

11.0

1.9

8.2

a.2't 4.1

14-145