Engine control HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 557 of 2189

Emission Control System

Evaporative Emission {EVAP) Controls (cont'dl

\J

tF1456-l

tP14sz-l

EVAPCONTROLCANISTERVENTSHUTVALVE

O.RINGReplace.

EVAPCONTROLCANISTER

ECM/PCM CONNECTOR A I32PI

(To page 11'289)

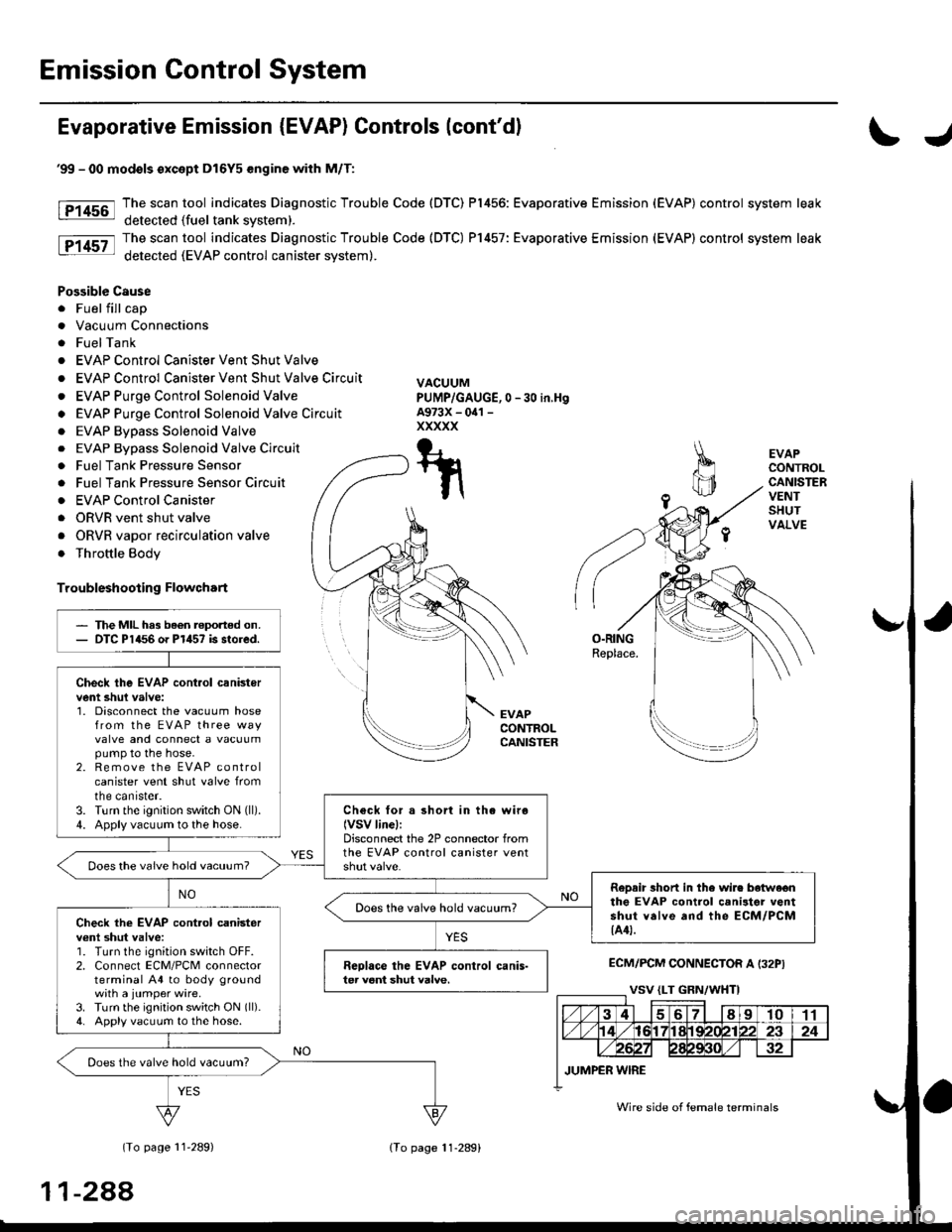

'99 - 00 modols except Dl6Y5 engine with M/T:

The scan tool indicates Diagnostic Trouble Code (DTC) P1456: Evaporative Emission (EVAP) control system leak

detected (fuel tank svstem).

The scan tool indicates Diagnostic Trouble Code (DTC) P1457: Evaporative Emission (EVAP) control system leak

detected (EVAP control canister system).

Possible Cause

. Fuel fill cap

. Vacuum Connections

. FuelTank

. EVAP Control Canister Vent Shut Valve

. EVAP Control Canister Vent Shut Valve Circuit

. EVAP Purge Control Solenoid Valve

o EVAP Purge Control Solenoid Valve Circuit

. EVAP Bypass Solenoid Valve

0 -30 in,Hg

. EVAP Bypass Solenoid Valve Circuit

. Fuel Tank Pressure Sensor

. Fuel Tank Pressure Sensor Circuir

. EVAP Control Canister

. ORVR vent shut valve

. ORVR vapor recirculation valve

. Throttle Body

Troubleshooting Flowchart

VACUUMPUMP/GAUGE,A973X - oal -

xxxxx

T-t

t\

The MIL has been reported on.DTC P1456 o. P1457 is stored.

Check the EVAP cont.ol canistervent shul valve:1. Disconnect the vacuum hosefrom the EVAP three wayvalve and connect a vacuumpump to the hose.2. Remove the EVAP controlcanister vent shut valve fromtne canrster.3. Turn the ignition switch ON (ll).

4. Apply vacuum to the hose.Check for a short in the wiro(VSV linel:Disconnect the 2P connector fromthe EVAP control canister ventDoes the vaive hold vacuum?

RoDair 3hort in the wire botwe€nthe EVAP control canilter ventshut valve and the ECM/PCM{A4t.

Does the valve hold vacuum?Check the EVAP cont.ol canisterv€nl shut valve:1. Turn the ignition switch OFF.2. Connect ECM/PCM connectorterminal A4 to body groundwith a jumper wire.3. Turn the ignition switch ON (ll).

4. Apply vacuum to the hose.

Reolace the EVAP control canis-ter veni shut valve.

Does the valve hold vacuum?

Wire side of female terminals

11-288

lTo page 11-289)

Page 558 of 2189

\

EVAP CONTROLCANISTER VENT SHUTVALVE 2P CONNECTOR IC141I

Wire side of temale terminals

ECM,/PCM CONNECTORS

tG1IBLK/WHT}

A973X -

0/r1 - XXXXX

Wire side of femaletermrnats

\

?,T-t

fl

VACUUMPUMP/GAUGE, 0 -30 in.Hg

\(cont'd)

11-289

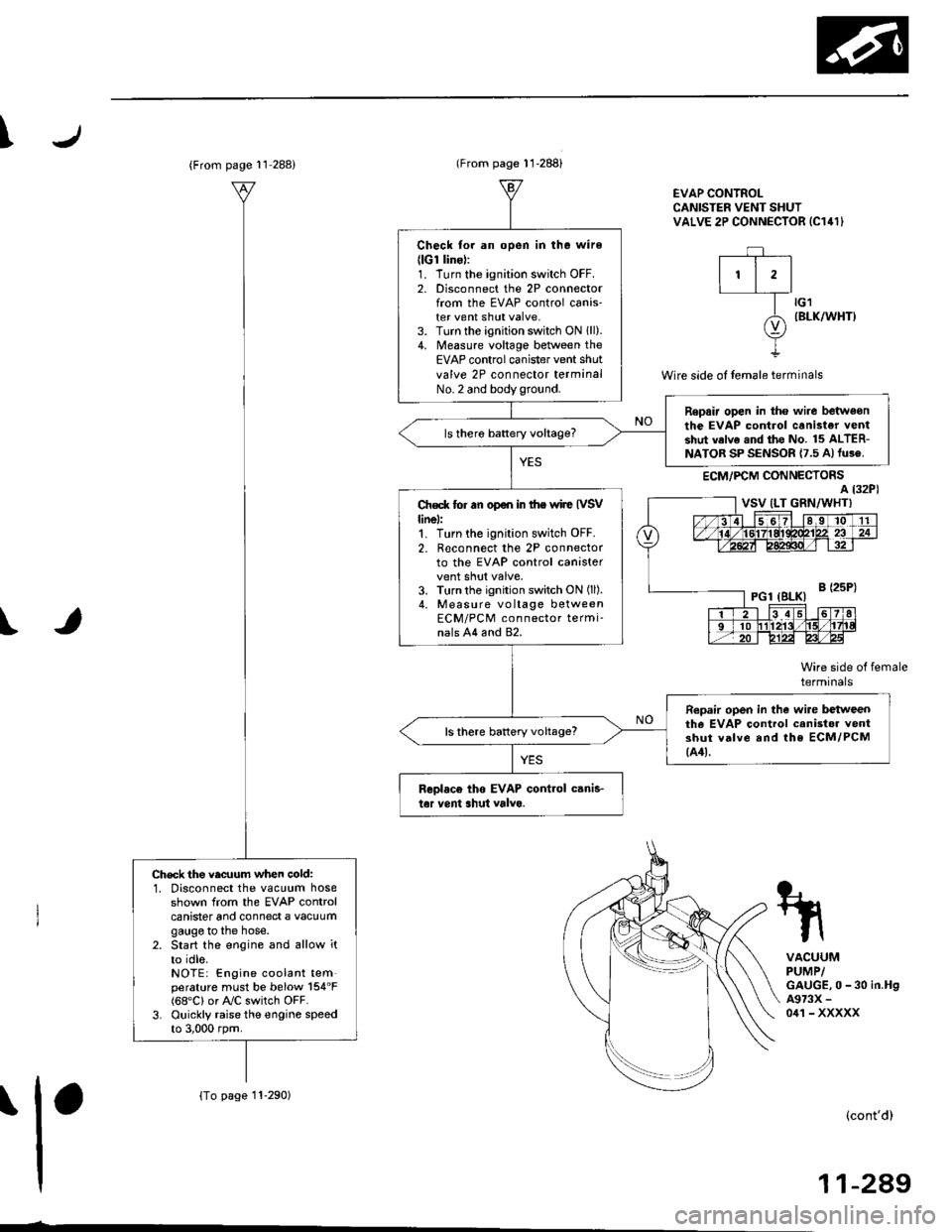

{From page l1 288}

{To page 11-290)

Ch€ck the vac[um when cold:1, Disconnect the vacuum hoseshown from the EVAP controlcanister and connect a vacuumgauge to the hose.2. Start the engine and allow it

to idle.NOTEi Engine coolant temperature must be below 154"F(68'C) or Ay'C switch OFF.3. Ouickly raise the engine speedto 3,000 rpm.

(From page 11-288)

Check for an open in tha wire(lGt linol:1. Turn the ignition switch OFF.2. Disconnect the 2P connectorfrom the EVAP control canis-ter vent shut valve.3. Turn the ignition switch ON lll).4. Measure voltage between theEVAP control canister vent shut

valve 2P connector terminalNo.2 and bodyground.

Repair open in the wire betweenthe EVAP control canister ventshut valve .nd the No. 15 ALTER-NATOR SP SENSOR {7.5 A)fu3e.

ls there battery voltage?

Ch€d( for an op€n in the wiie IVSVlinel:1. Turn the ignition switch OFF.

2. R€connect the 2P connectorto the EVAP control canistervent shut valve,3. Turn the ignition switch ON (ll).

4. Measure vo ltage betweenECM/PCM connector termi-nals A4 and 82.

Repair open in the wire bctweenthe EVAP control canistor ventshut valve and lhe ECM/PCM{44t.

ls there battery voltage?

Rcolaco tho EVAP control canis.t6r vent shut valvo.

a t32P)

-

Page 559 of 2189

Emission Control System

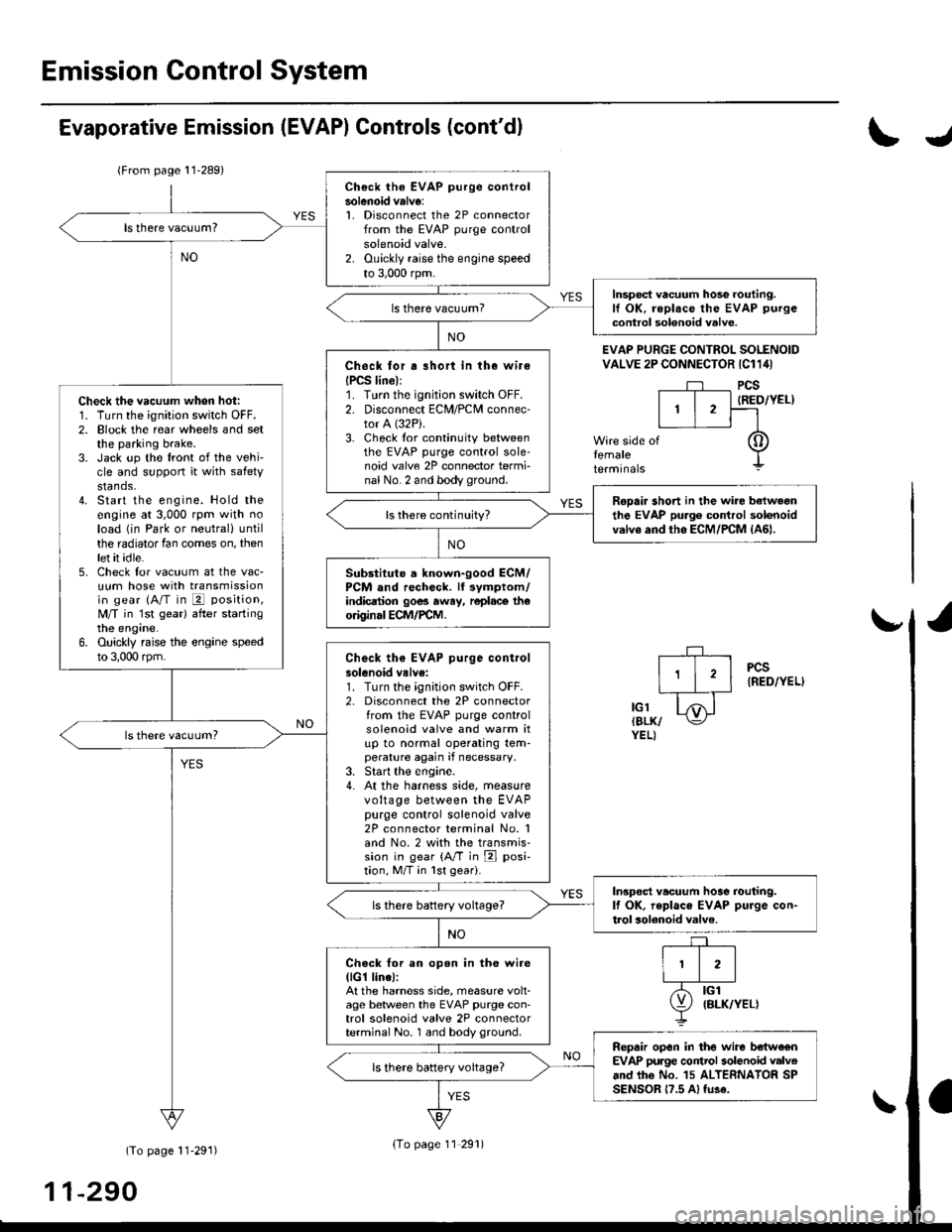

Ch€ck the EVAP purge controlsolenoid valv6:1. Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve.2. Ouickly raise the engine speedto 3,000 rpm.

Insped vacuum hose routing.lf OK. roplace the EVAP purge

control solonoid valve.

Chock tor r short in the wir€

{PCS line):1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connec-tor A (32P).

3- Check tor continuity betweenthe EVAP purge control sole-noid valve 2P connector termi-nal No. 2 and body ground.

Check the vacuum when hot:1. Turn the ignition switch OFF.2. Block the rear wheels and setthe parking brake.3. Jack up the lront of the vehi-cle and support it with safetystands.4. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali until

the radiator fan comes on, thenlet it idle.5. Check for vacuum at the vac-uum hose with transmissionin gear (A/T in E position,

lvl/T in 1st gear) after startingthe engine.6. Ouickly raise the engine speedto 3,000 rpm.

Rooair shoft in the wire belwegnthe EVAP pulg6 control solenoidvalvs and tho ECM/PCM {A61.ls there continuity?

Substitute a known-good ECM/PCM and rech6ck. lt 3ymptom/indicrtion 90e3 rway, r6plac6 th€o.iginal ECM/FCM.

Check th€ EVAP purge controlsolenoid valve:1. Turn the;gnition switch OFF.2. Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve and warm itup to normal operating tem-perature again if necessary.3. Start the engine.4- At the harness side, measurevoltage between the EVAPpurge control solenoid valve2P connector terminal No. 1and No.2 with the transmis-sion in gear {A/T in E posi-tion, M/T in lst geari.

In3pect vacuum hoae routing.lf OK, repl.ce EVAP purge con-trol solonoid valve.ls there battery voltage?

Chock for an open in the wire(lG1 lina):At the harnoss side, measure volt-age beNveen the EVAP purge con-trol solenoid valve 2P connectorterminal No. 1 and body ground.

Repair open in the wire b€lwe€nEVAP purge contrl 3olenoid valv6and lhe No. 15 ALTERNATOR SPSENSOR 17.5 A, fu3e.

ls there battery voltage?

Evaporative Emission (EVAPI Controls (cont'dl

(From page 11-289)

(To page 11-291)

11-290

IJ

EVAP PURGE CONTROL SOLENOIDVALVE 2P CONNECTOR IC114I

PCS

IRED/YEL)

temaletermrnars

of

PCS(RED/YEL)

tGlIBLK/YEL)

{To page 11 291)

Page 563 of 2189

Emission Control System

Evaporative Emission (EVAPI Controls (cont'd)

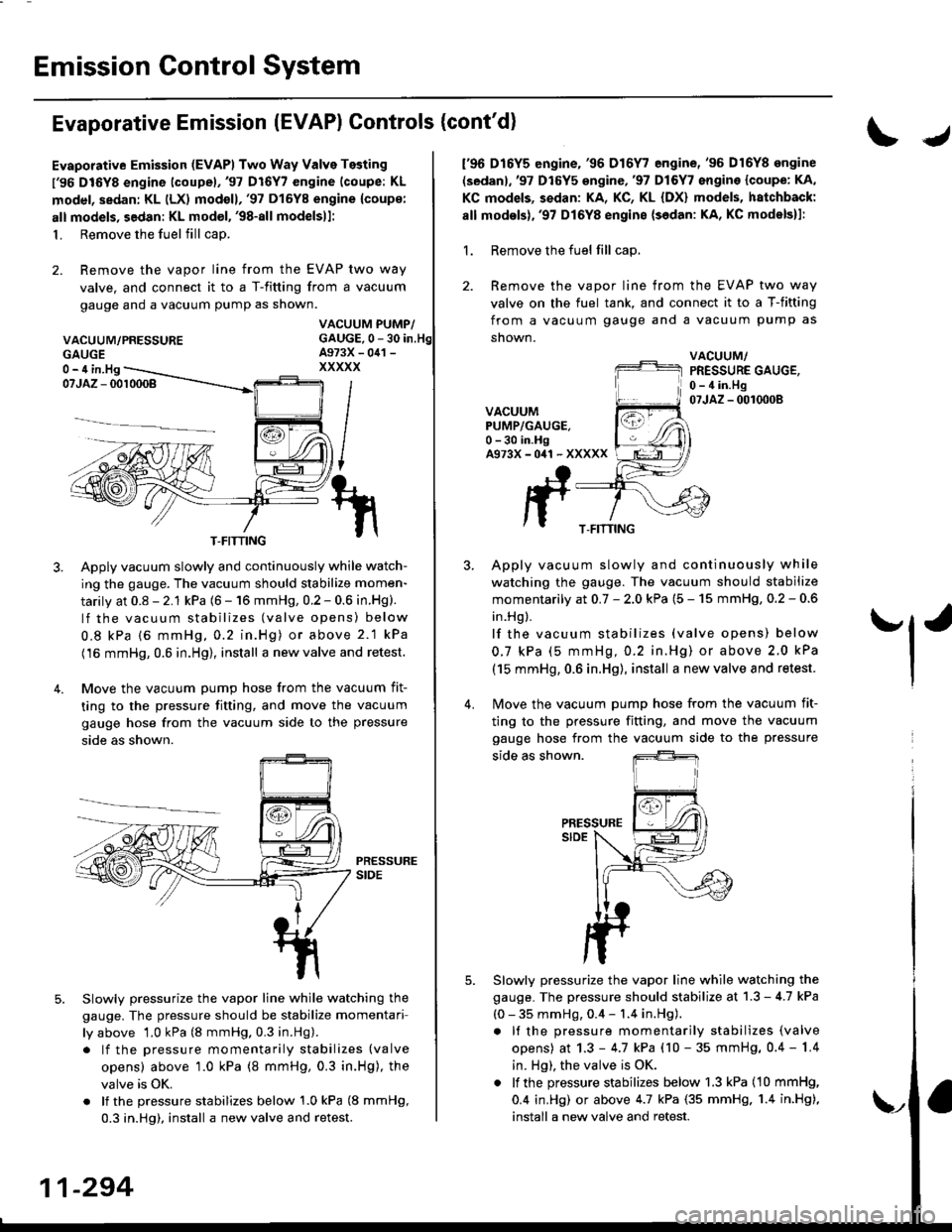

Evaporative Emission (EVAPI Two Way Valve Testing

l'96 DIGYS engine lcoupel,'97 Dl6Y7 engine (coupe: KL

model, sedan: KL (LX) modoll,'97 Dl6Y8 engine {coup€:

alt models, sedan: KL model, '98-all modelsll:

1. Remove the fuel fill cap.

2. Remove the vapor line from the EVAP two way

valve. and connect it to a T-fitting from a vacuum

gauge and a vacuum pump as shown.

VACUUM/PRESSURE

IJ

f96 D16Y5 engine,'96 D16Y7 engine,'96 D16Y8 ongine

(sedanl,'97 D16Y5 engine,'97 Dl6Y7 engine {coupe: KA,

KC models, sedan: KA, KC, KL {DX} models, hatchback:

all modsls),'97 D16Y8 engine {sedan: KA, KC models}l:

1. Remove the fuel fill cap,

2. Remove the vapor line from the EVAP two way

valve on the fuel tank, and connect it to a T-fitting

from a vacuum gauge and a vacuum pump as

snown.

VACUUM/PRESSURE GAUGE,0 - 4 in.Hg07JAZ - 0010008VACUUMPUMP/GAUGE.0 -30 in.HgA973X-041 -XXXXX

Apply vacuum slowly and continuously while watch-

ing the gauge. The vacuum should stabilize momen-

tarily at 0.8 - 2.1 kPa (6 - 16 mmHg, 0.2 - 0.6 in.Hg).

lf the vacuum stabilizes (valve opens) below

0.8 kPa {6 mmHg, 0.2 in.Hg) or above 2.1 kPa

(16 mmHg, 0.6 in.Hg), install a new valve and retest.

Move the vacuum pump hose from the vacuum fit-

ting to the pressure fitting, and move the vacuum

gauge hose from the vacuum side to the pressure

side as shown.

Slowlv pressurize the vapor line while watching the

gauge. The pressure should be stabilize momentari

ly above 1.0 kPa (8 mmHg. 0.3 in.Hg).

. lf the pressure momentarily stabilizes (valve

opens) above '1.0 kPa (8 mmHg, 0.3 in.Hg), the

valve is OK.

. lf the pressure stabilizes below 1.0 kPa (8 mmHg,

0.3 in.Hg), install a new valve and retest.

Apply vacuum slowly and continuously while

watching the gauge. The vacuum should stabilize

momentarily at 0.7 - 2.0 kPa (5 - 15 mmHg, 0.2 - 0.6

in.Hg ).

lf the vacuum stabilizes (valve opens) below

0.7 kPa (5 mmHg,0.2 in.Hg) or above 2.0 kPa

(15 mmHg, 0.6 in.Hg), install a new valve and retest.

Move the vacuum pump hose from the vacuum fit-

'l'

4.

5.

ting to the pressure fitting, and move the

gauge hose from the vacuum side to the

side as shown.

PRESSURESIDE

Slowly pressurize the vapor line while watching the

gauge. The pressure should stabilize at 1.3 - 4.7 kPa

(0 - 35 mmHg, 0.4 - 1.4 in.Hg).

. It the pressure momentarily stabilizes (valve

opens) at 1.3 - 4.7 kPa (10 - 35 mmHg, 0.4 - 1.4

in. Hg), the valve is OK.

. lf the pressure stabilizes below 1.3 kPa (10 mmHg,

0.4 in.Hg) or above 4.7 kPa (35 mmHg. 1.4 in.Hg),

install a new valve and retest.

vacuum

pressure

GAUGE0- 4 in.Hg

T-FITTINGT-FITTING

11-294

\,

Page 681 of 2189

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3

Page 693 of 2189

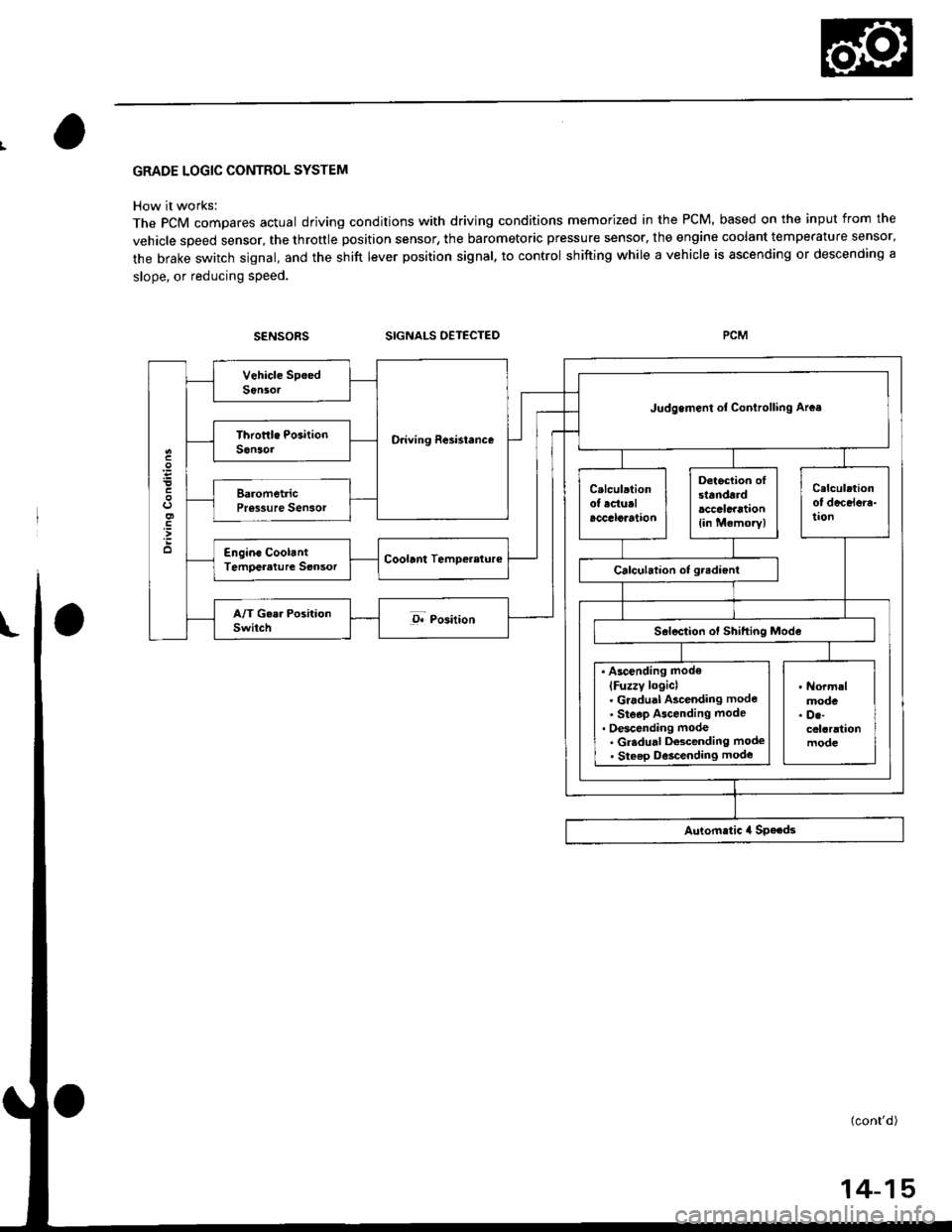

GRADE LOGIC CONTROL SYSTEM

How it works:

The pCM compares actual driving conditions with driving conditions memorized in the PCM, based on the input from the

vehicle speed sensor, the throttle position sensor, the barometoric pressure sensor, the engine coolant temperature sensor,

the brake switch signal, and the shift lever position signal, to control shifting while a vehicle is ascending or descending a

slope, or reducing speed.

SIGNALS OETECTED

O.iving Resi3lence

Judgemenl ot Conirolling Arca

. Ascending mod€

lFuzzy loqicl. Gradual Ascending mode' Ste€p Ascending mode. Oescending mode. Gr.du.l Descending mode. Steep D6cending mode

14-15

Page 694 of 2189

Description

Electronic Control System {cont'dl

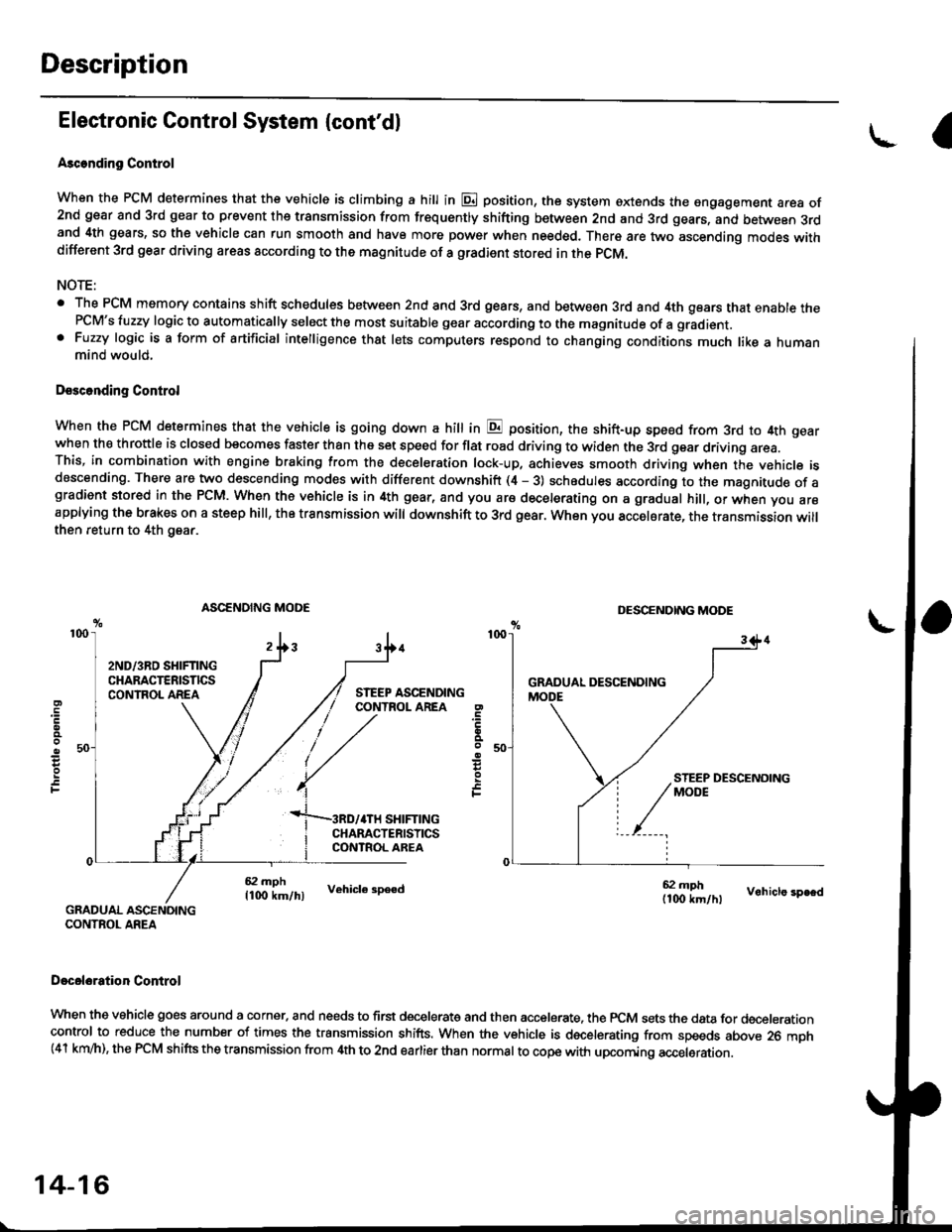

Ascending Control

When the PCM determines that the vehicle is climbing a hill in E position, the system oxtends the sngagement area of2nd gear and 3rd gear to prevent ths transmission from fr€quently shifting between 2nd and 3rd gears, and between 3rdand 4th gears, so the vehicle can run smooth and have more power when needed. There are two ascending modes withdifferent 3rd gear driving areas according to the magnitude of a gradient stored in the pCM.

NOTE:

. The PCM memory contains shift schedules between 2nd and 3rd gears, and between 3rd and 4th gears that enable thePCM's fuzzy logic to automatically select the most suitable gear according to the magnitude of a gradient. Fuzzy logic is a form of artificial intelligence that lets computers respond to changing conditions much like a humanmind would,

Dssconding Control

When the PCM determines that the vehicle is going down a hilt in E position, the shift-up speed from 3rd to 4th gearwhen th€ throftle is closed becomes faster than the set speed for flat road driving to widen the 3rd gear driving area.This, in combination with engine braking from the deceleration lock-up, achieves smooth driving when the vehicle isdescending. There are two descending modes with different downshift (4 - 3) schedules according to the magnitude of agradient stored in the PCM. When the vehicle is in 4th gear, and you are decelerating on a gradual hill, or when you areapplying the brakes on a steep hill, the transmission will downshift to 3rd gear. When you accel6rate, the transmission willthen return to 4th gear.

ASCENDING MODEDESCENDING MODE

4TH SHIFTING

L.

F

CHARACTERISIICSCONTROL AREA

ff.1"11", vehicr. 3pe€dff;Tlr., vohicre speed

GRADUAL ASCENOINGCONTROL AREA

Docel6ration Control

When the vehicle goes around a corner. and needs to first decelerate and then accelerate. the rcM sets the data for decelerationcontrol to reduce the number of times the transmission shifts. When the vehicle is decelerating from speeds above 26 mph(41 km/h), the rcM shifts the transmission from 4th to 2nd earlier than normal to cope with upcoming acceleration.

14-16

Page 697 of 2189

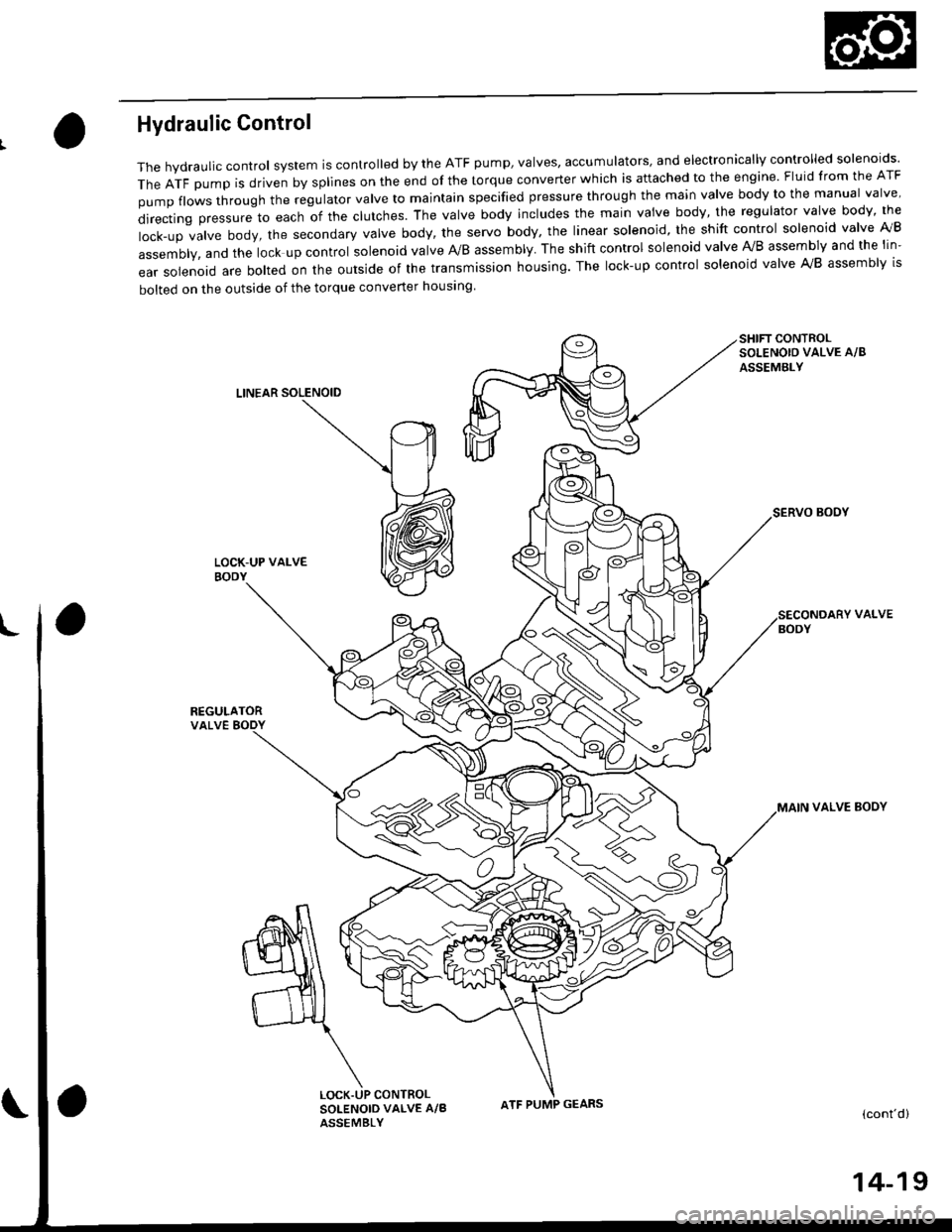

Hydraulic Control

The hydraulic control system is controlled by the ATF pump, valves, accumulators, and electronically controlled solenoids'

TheATFpUmpisdrivenbysp||nesontheendofthetorqueconverterWhichisattachedtotheengine.F|uidfromtheATF

pumpf|owsthroughtheregu|atorva|vetomajntainspecifiedpressurethroughthemainva|vebodytothemanuaIva|ve'

directingpressuretoeachofthec|utches.Theva|vebodyinc|udesthemainvaivebody,theregu|atorvalvebody,the

|ock-upva|vebody,thesecondaryVa|vebody,theservobody,theIinearso|enoid,theshiftcontro|so|enoidva|velVB

assembly, and the lock up control solenoid valve A/B assembly. The shift control solenoid valve Ay'B assembly and the lin-

ear solenoid are bolted on the outside of the transmission housing. The lock-up control solenoid valve A,/B assembly is

bolted on the outside of the torque converter housing

SHIFT CONTROLSOLENOIO VALVE A/8

ASSEMBLY

LINEAR SOLENOID

SERVO BOOY

REGULATORVALVE BODY

VALVE

VALVE BOOY

(cont'd)

CONTROLSOLENOID VALVE A/BASSEMBLY

ATF PUMP GEARS

14-19

Page 700 of 2189

Description

Hydraulic Control (cont'dl

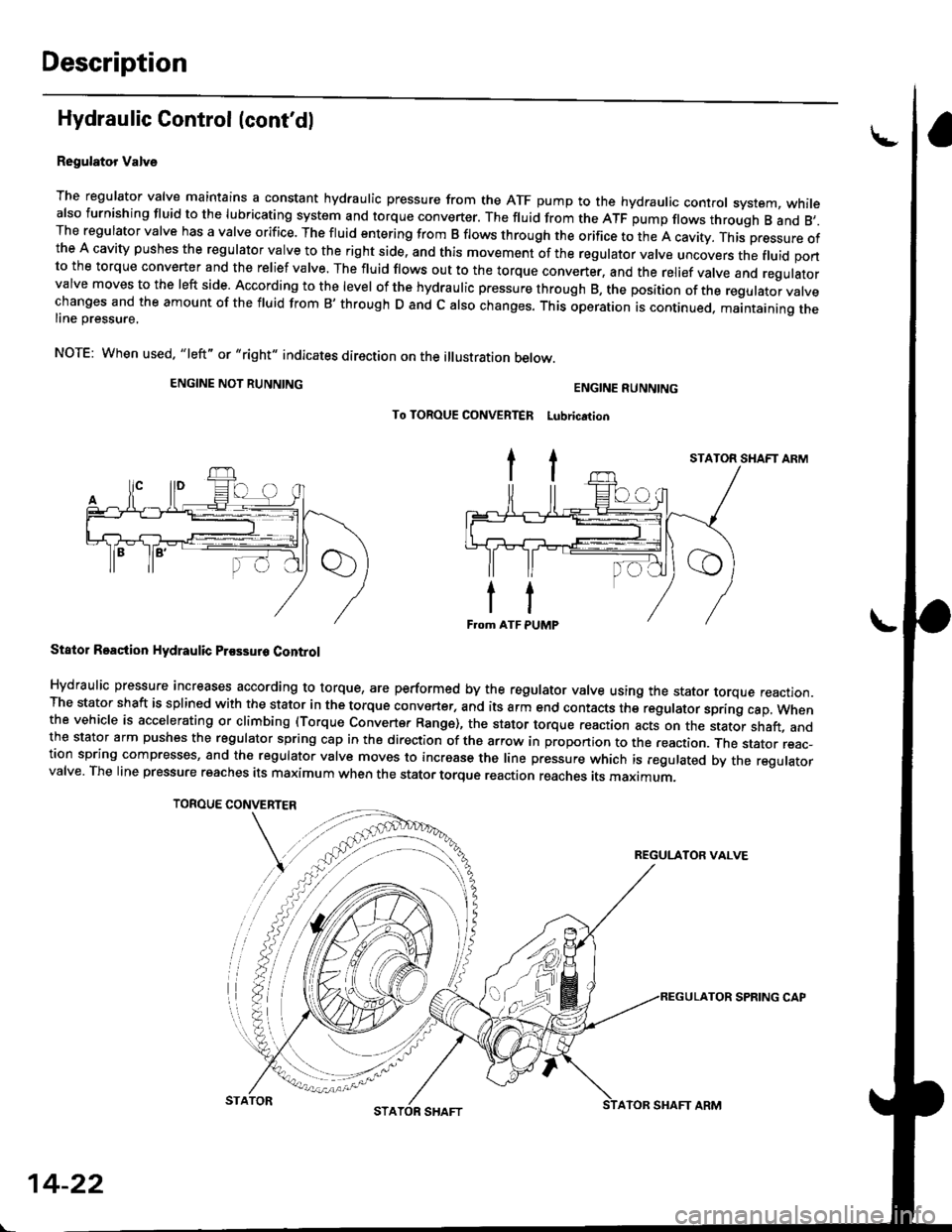

Regulator Valve

The regulator valve maintains a constant hydraulic pressure from the ATF pump to the hydraulic control system, whitealso furnishing fluid to the lubricating system and torque converter. The fluid from the ATF pump flows through B and 8,.The regulator valve has a valve orifice. The fluid entering from B flows through the orifice to the A cavity. This pressure ofthe A cavity pushes the regulator valve to the right side, and this movement of the regulator valve uncovers the fluid portto the torque converter and the relief valve. The fluid flows out to the torque converter, and the relief valve and regulatorvalve moves to the left side. According to the level of the hydraulic pressure through B, the position of the regutator vatvechanges and the amount of the fluid from B' through D and c also changes. This operation is continued. maantaining theline pressure,

NOTE: When used. "|eft" or "right" indicates direction on the illustration betow.

ENGINE NOT RUNNING

TOROUE CONVERTER

ENGINE RUNNING

To TOROUE CONVERTER Lubrication

Stator Roaction Hydraulic Prossur6 Control

Hydraulic pressure increases according to torque, are performed by the regulator valve using the stator torque reaction.The stator shaft is splined with the stator in the torque converter, and its arm end contacts the regulator sprang cap. whenthe vehicle is accelerating or climbing (Torque Convert€r Range), the stator torque reaction acts on the stator shaft, andthe stator arm pushes the regulator spring cap in the direction of the arrow in proponion to the reaction. Jne stator reac-tion spring compresses, and th€ reoulator valve moves to increase the line pressure which is regulated by the regulatorvalve. The line pressure reaches its maximum when the stator torque reaction reaches its maximum.

STATOR SHAFT ARM

REGULATOR VALVE

14-22

STATORATOR SHAFT ARM

SPRING CAP

Page 705 of 2189

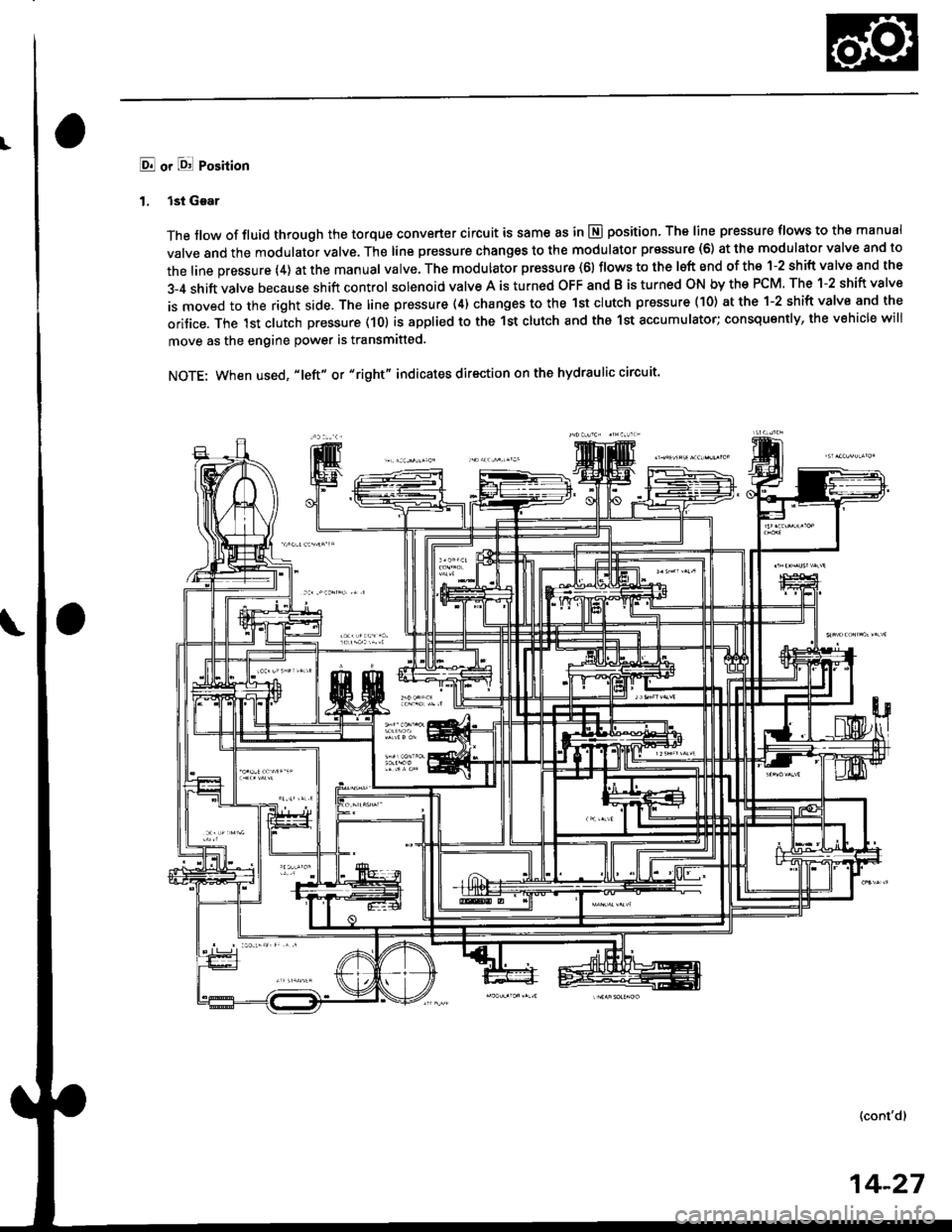

E! or l8! Position

1. lst Gear

The flow of fluid through the torque converter circuit is same as in E position, The line pressure tlows to the manual

valve and the modulator valve. The line pressure changes to the modulator pr€ssure (6) at the modulator valve and to

the line pressure (4) at the manual valve. The modulator pressure (61 flows to the lsft end of the 1-2 shift valve and the

3-4 shift valve because shift control solenoid valve A is turned OFF and B is turned ON by the PCM. The 1-2 shift valve

is moved to the right side. The line pressure (4) changes to the lst clutch pressure (10) at the 1-2 shift valve and the

oritice. The lst clutch pressure (10) is applied to the 1st clutch and tho 1st accumulator; consquently, the vehicle will

move as the engine power is transmitted.

NOTE: When used, "|eft" or "right" indicates direction on the hydraulic circuit'

(cont'd)

14-27