PCM HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 704 of 2189

Description

Hydraulic Flow (cont'd)

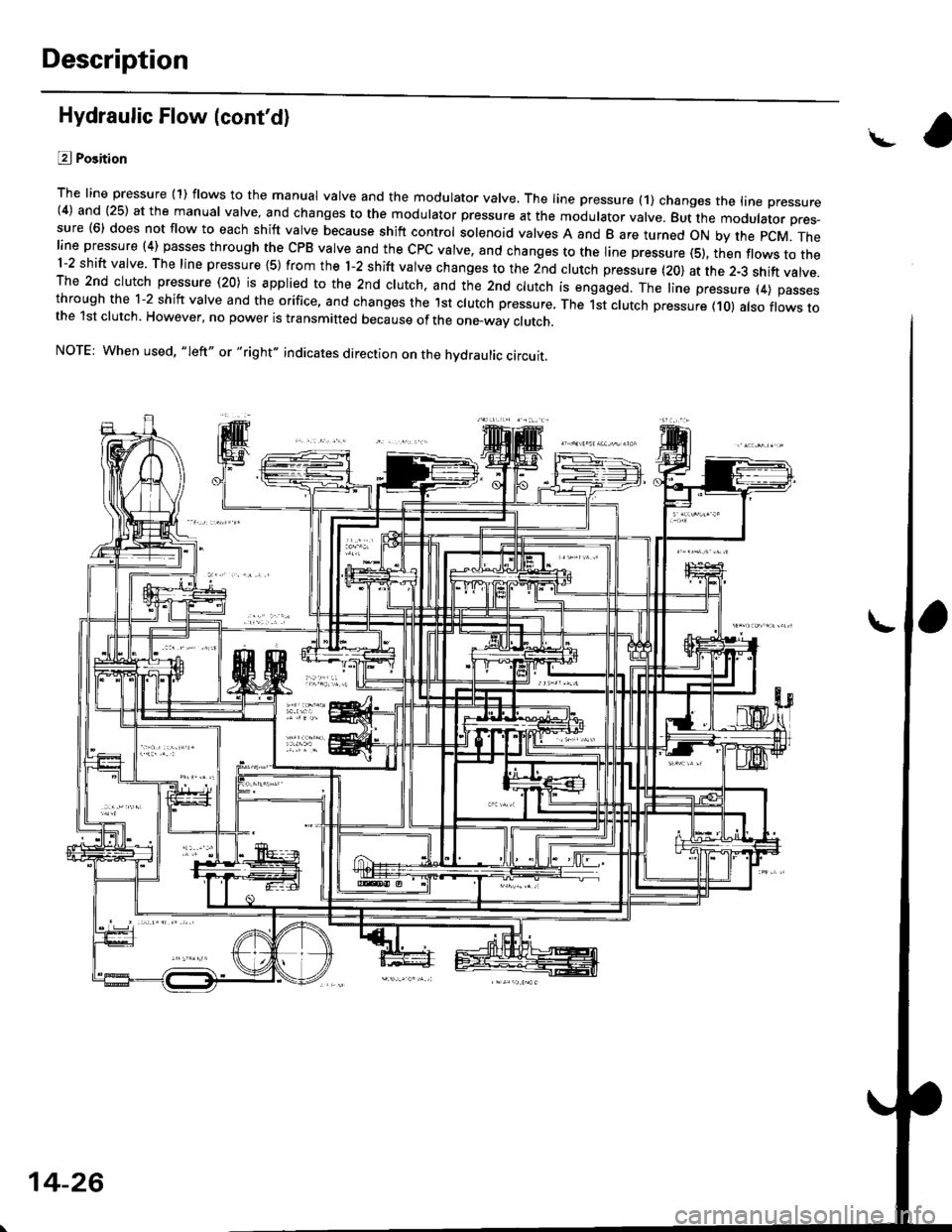

L?j Position

The line pressure (1) flows to the manual valve and the modulator valve. The line pressure (1) changes the trne pressure(4) and (25) at the manual valve. and changes to the modulator pressure at the modulator valve. But the moourator pres-sure (6) does not flow to each shift valve because shift control solenoid valves A and B are turned oN by the pcM. Theline pressure (4) passes through the cPB valve and the cPc valve. and changes to the line pressure (s), th;n flows to the1-2 shift valve. The line pressure {S) from the l-2 shift valve changes to the 2nd clutch pressure (20) at the 2-3 shift valve.The 2nd clutch pressure (20) is applied to the 2nd clutch. and the 2nd clutch is engaged. The line pressure (4) passesthrough the 1-2 shift valve and the orifice, and changes the lst clutch pressure, The 1st clutch pressure (10) atso flows tothe 1st clutch. However, no power is transmitted because of the one_way clutch.

NOTE: When used, "Ieft" or "right" indicates direction on the hvdraulic circuit.

14-26

Page 705 of 2189

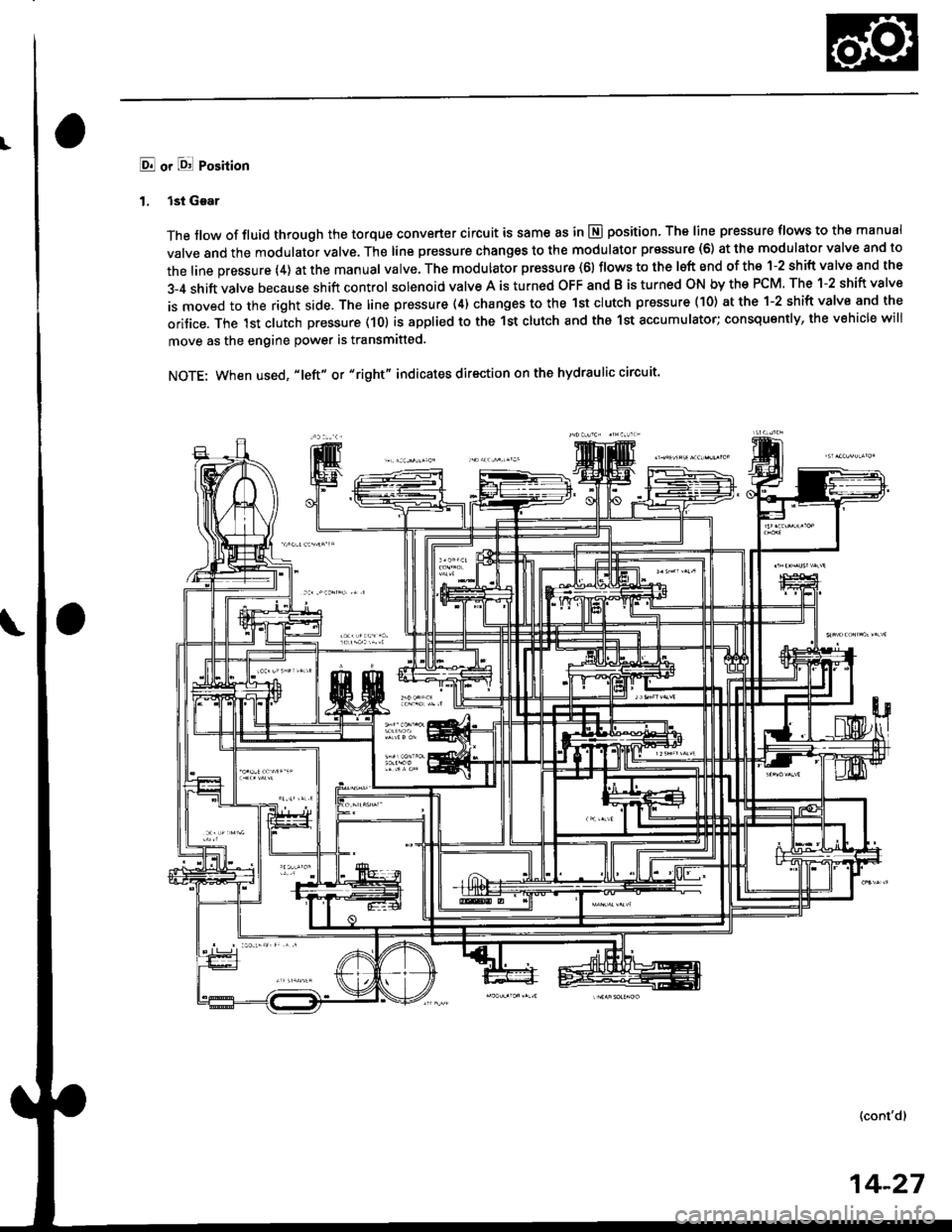

E! or l8! Position

1. lst Gear

The flow of fluid through the torque converter circuit is same as in E position, The line pressure tlows to the manual

valve and the modulator valve. The line pressure changes to the modulator pr€ssure (6) at the modulator valve and to

the line pressure (4) at the manual valve. The modulator pressure (61 flows to the lsft end of the 1-2 shift valve and the

3-4 shift valve because shift control solenoid valve A is turned OFF and B is turned ON by the PCM. The 1-2 shift valve

is moved to the right side. The line pressure (4) changes to the lst clutch pressure (10) at the 1-2 shift valve and the

oritice. The lst clutch pressure (10) is applied to the 1st clutch and tho 1st accumulator; consquently, the vehicle will

move as the engine power is transmitted.

NOTE: When used, "|eft" or "right" indicates direction on the hydraulic circuit'

(cont'd)

14-27

Page 706 of 2189

Description

Hydraulic Flow (cont'd)

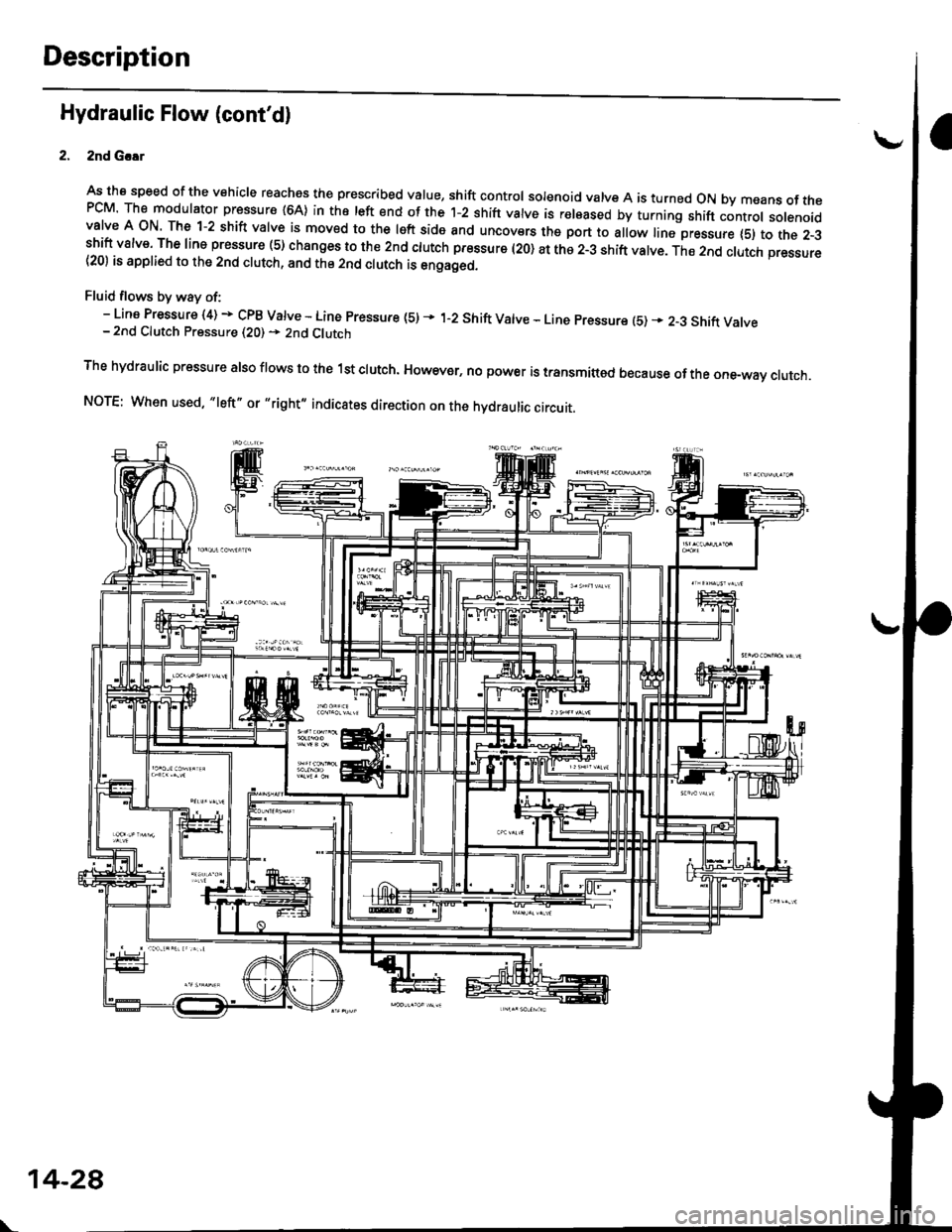

2nd G.!r

As tha speed of the vehicle reaches the prescribed value, shift control solenoid valve A is turned oN by means of thePCM The modulator pressure {64} in the left end of the 1-2 shift valve is r€leased by turning shift controt sotenoidvalve A oN The 1-2 shift valve is moved to the left side and uncovers the port to allow line pressure {5) to the z-3shift valve. The line pressure (5) changes to the 2nd ctutch pfessure l2O) at the 2-3 shift valve. The 2nd clutch pressure(20) is applied to the 2nd clutch, and the 2nd clutch is engaged.

Fluid flows by way of:- Line Pressure (4) + cPB varve - Line pressure (s) * 'r-2 shift varve - Line pressure (5) * 2-3 shift varve- 2nd Clutch Pressure (20) + 2nd Clutch

The hydraulic pressure also flows to the 1st clutch. However, no power is transmittod because of the one-way ctutch.

NOTE: When used, "|eft" or ,,right,, indicates direction on the hydraulic circuit.

\-

14-28

Page 707 of 2189

I

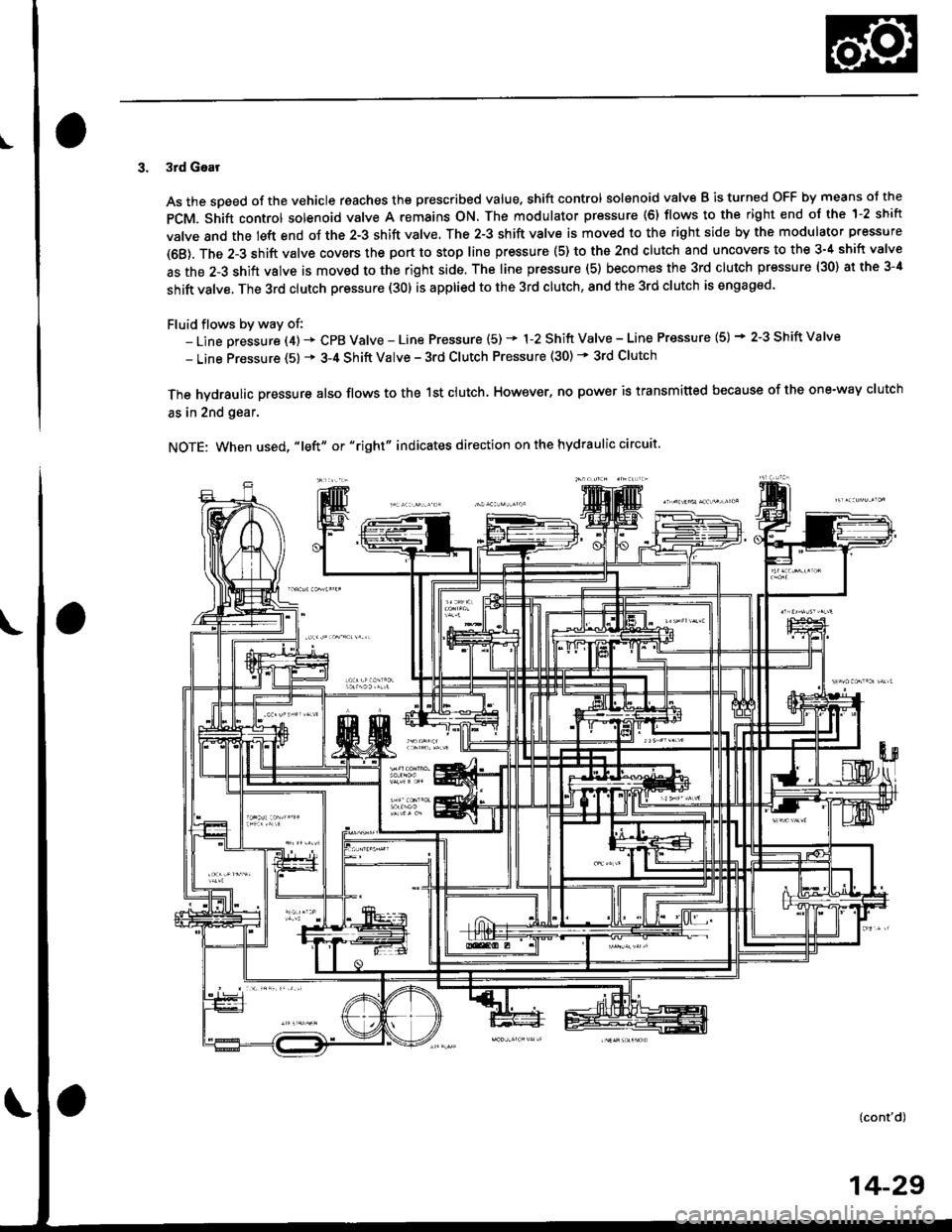

3. 3rd Gear

As the soeed of the vehicle reaches the prescribed value, shift control solenoid valve B is turned OFF by means ol the

pCM. Shift control solenoid valve A remains ON. The modulator pressure (6) flows to the right end of the 1-2 shift

valve and the left end oJ the 2-3 shift valve. The 2-3 shift valve is moved to the right side by the modulator pressure

(68). The 2-3 shift valve covers the port to stop line pressure (5) to the 2nd clutch and uncovers to the 3-4 shift valve

as the 2-3 shift valve is moved to the right side. The line pressure (5) becomes the 3rd clutch pressure (30) at the 3-4

shift valve. The 3rd clutch pressure (30) is applied to the 3rd clutch, and the 3rd clutch is engaged'

Fluid flows by way of:- Line Dressure (4) * CPB Valve - Line Pressure (5) * 1-2 Shift Valve - Line Pressure (5) * 2-3 Shift Valve

- Line Pressure (5) * 3-4 Shift Valve - 3rd Clutch Pressure (30) - 3rd Clutch

The hvdraulic pressure also flows to the 1st clutch. However, no power is transmitted because of the one-way clutch

as in 2nd gear.

NOTE: When used, "|eft" or "right" indicates direction on the hydraulic circuit.

14-29

Page 708 of 2189

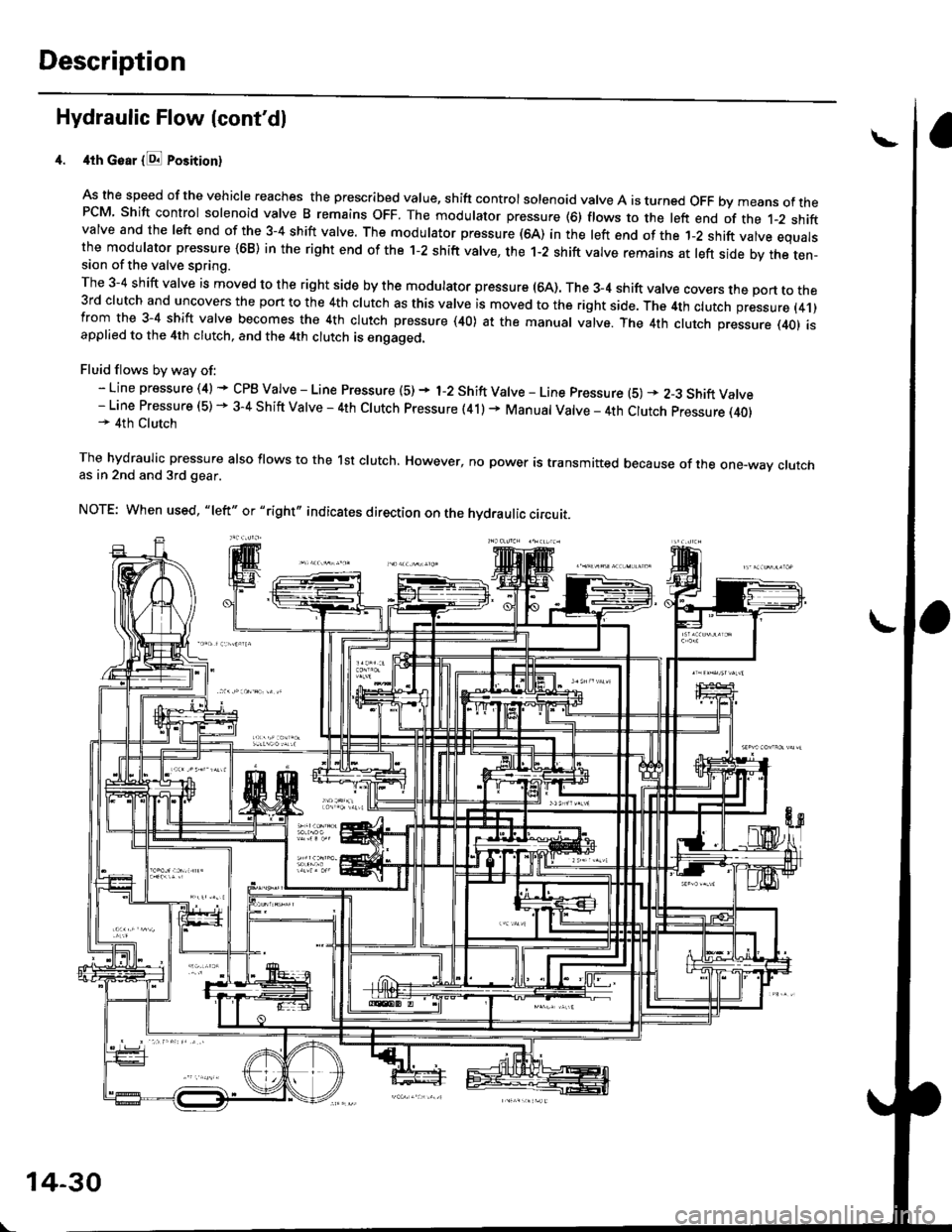

Description

Hydraulic Flow lcont'dl

4th Goar {E Position}

As the speed of the vehicle reaches the prescribed value, shift controlsolenoid valve A is turned OFF bymeans ofthePCM Shift control solenoid valve B remains oFF. The modulator pressure (6) flows to the left end of the t-2 shiftvalve and the left end of the 3-4 shift valve. The modulator pressure (64) in the left end of the 1-2 shift valve equalsthe modulator pressure {68) in the right end of the 1-2 shift valve, the 1-2 shift valve remains at left side by the ten-sion of the valve spring.

The 3-4 shift valve is moved to the right side by the modulator pressure (64). The 3_4 shift valve covers the port to the3rd clutch and uncovers the port to the 4th clutch as this valve is moved to the right side. The 4th clutch pressure (4.1)from the 3-4 shift valve becomes the 4th clutch pressure (40) at the manual valve. The 4th clutch pressure (401 isapplied to the 4th clutch, and the 4th clutch is engaged.

Fluid flows by way of:- Line pressure (4) * CPB Valve - Line Pressure (5) + 1-2 Shift Valve - Line pressure (5) * 2-3 Shift Valve- Line Pressure (5) - 3-4 Shift Valve - 4th Clutch pressure (41) + Manual Valve _ 4th Clutch pressure (40)* 4th Clutch

The hydraulic pressure also flows to the lst clutch. However, no power is transmitted because of the one-way crutchas in 2nd and 3rd gear.

NOTE: When used, "|eft" or "right,, indicates direction on the hydraulic circuit.

\

14-30

Page 709 of 2189

L

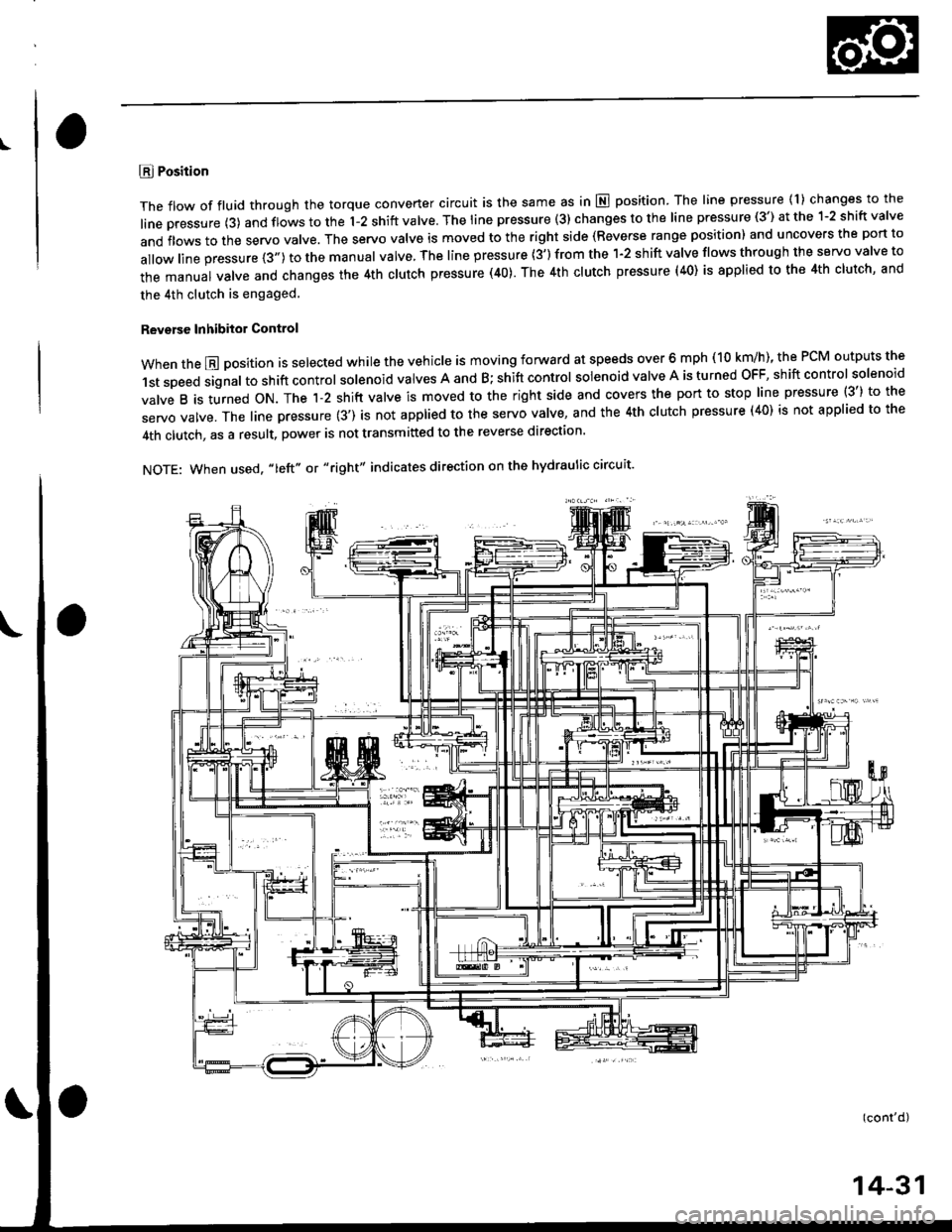

E Position

The flow of fluid through the torque convefter circuit is the same as in E position The line pressure (1) changes to the

line pressure (3) and flows to the l-2 shift valve. The iine pressure (3) changes to the line pressure (3') at the 'l-2 shift valve

and flows to the servo valve. The servo valve is moved to the right side (Reverse range position) and uncovers the port to

allow line pressure {3") to the manual valve, The line pressure {3') from the 1-2 shift valve flows through the servo valve to

the manual valve and changes the 4th clutch pressure (40). The 4th clutch pressure (40) is applied to the 4th clutch, and

the 4th clutch is engaged,

Reverse Inhibitor Control

When the E position is selected while the vehicle is moving forward at spe€ds over 6 mph (10 km/h)' the PCM outputs the

1st speed signal to shift control solenoid valves A and B; shift control solenoid valve A is turned oFF, shift control solenoid

valve B is turned ON. The 1-2 shift valve is moved to the right side and covers the port to stop line pressure (3') to the

servo valve. The line pressure (3'�) is not applied to the servo valve, and the 4th clutch pressure (40) is not applied to the

4th clutch, as a result, power is not transmitted to the reverse direction'

When used. 'left" or "right" indicates direction on the hydraulic circuit'

14-31

Page 712 of 2189

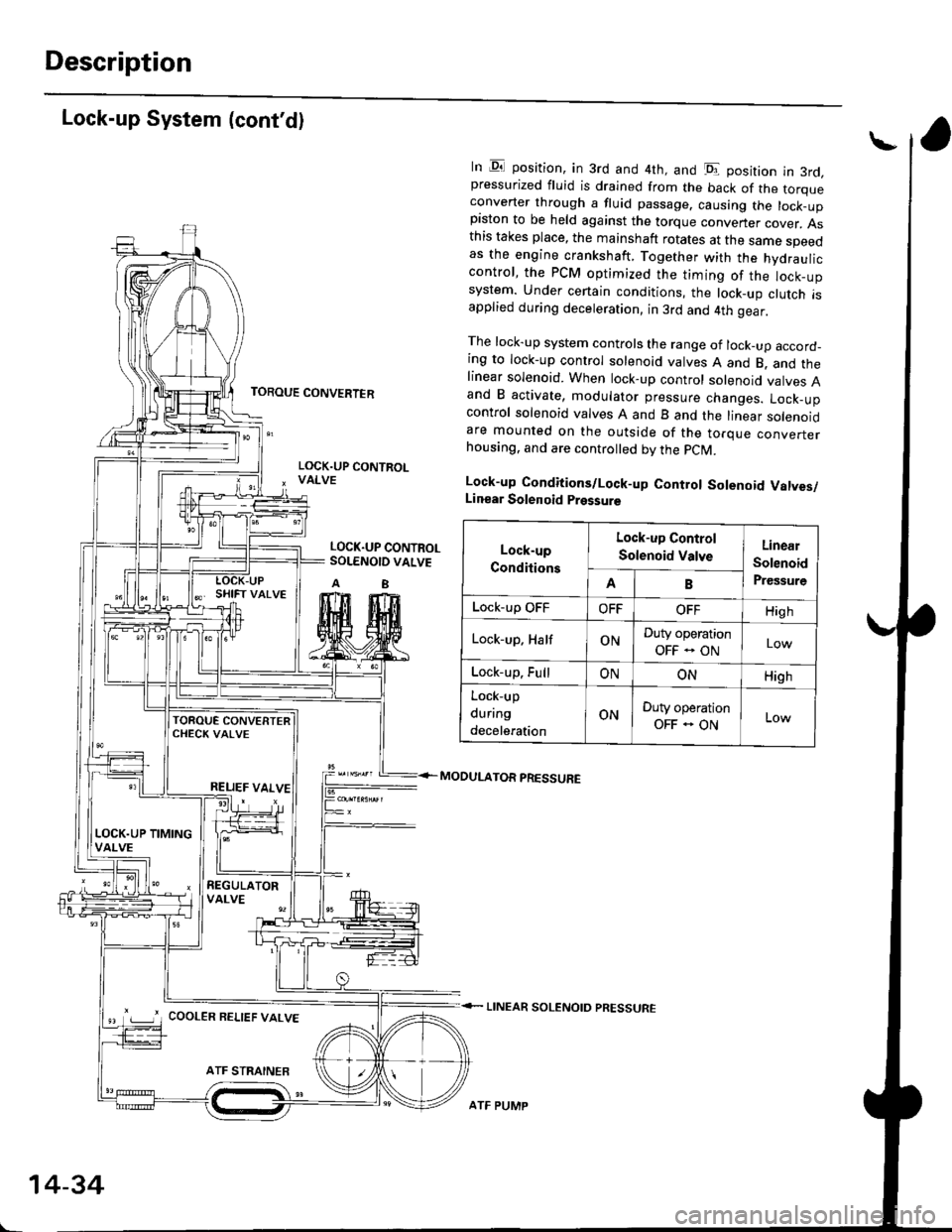

Description

Lock-up System (cont'd)

TOROUE CONVERTER

In B.rl position, in 3rd and 4th, and lDl_- position in 3rd.pressurized fluid is drajned from the back of the torqueconverter through a fluid passage. causing the lock-uppiston to be held against the torque convener cover. Asthis takes place, the mainshaft rotates at the same speedas the engine crankshaft, Together with the hydrauliccontrol, the PCM optimized the timing of the lock_upsystem. Under certain conditions, the lock_up clutch isapplied during deceleration, in 3rd and 4th gear.

The lock-up system controls the range of lock_up accord_ing to lock-up control solenoid valves A and B. and thelinear solenoid. When lock-up control solenoid valves Aand B activate, modulator pressure changes. Lock_upcontrol solenoid valves A and B and the linear solenoidare mounted on the outside of the torque converterhousing. and are controlled by the pclvl.

Lock-up Conditions/Lock-up Control Solenoid Valves/Linear Solenoid Pressure

MODULATOR PRESSURE

.-- LINEAR SOLENOID PRESSURE

LOCK.UP CONTROL. VALVE

LOCK.UP CONTROLSOLENOID VALVELock-up

Conditions

Lock-up Control

Solenoid ValveLineal

Solenoid

PressureAB

Lock-up OFFOFFOFFHig h

Lock-up. HalfONDuty operation

OFF - ON

Lock-up. FullONONHigh

Lock-up

during

decelerationONDuty operation

OFF * ONLowTOROUE CONVERTERCHECI( VALVE

RELIEF VAI-VE

LOCK.UP TIMINGVALVE

^ r______rr r cooLER RELTEF VALVE

t'-

14-34

ATF PUMP

Page 714 of 2189

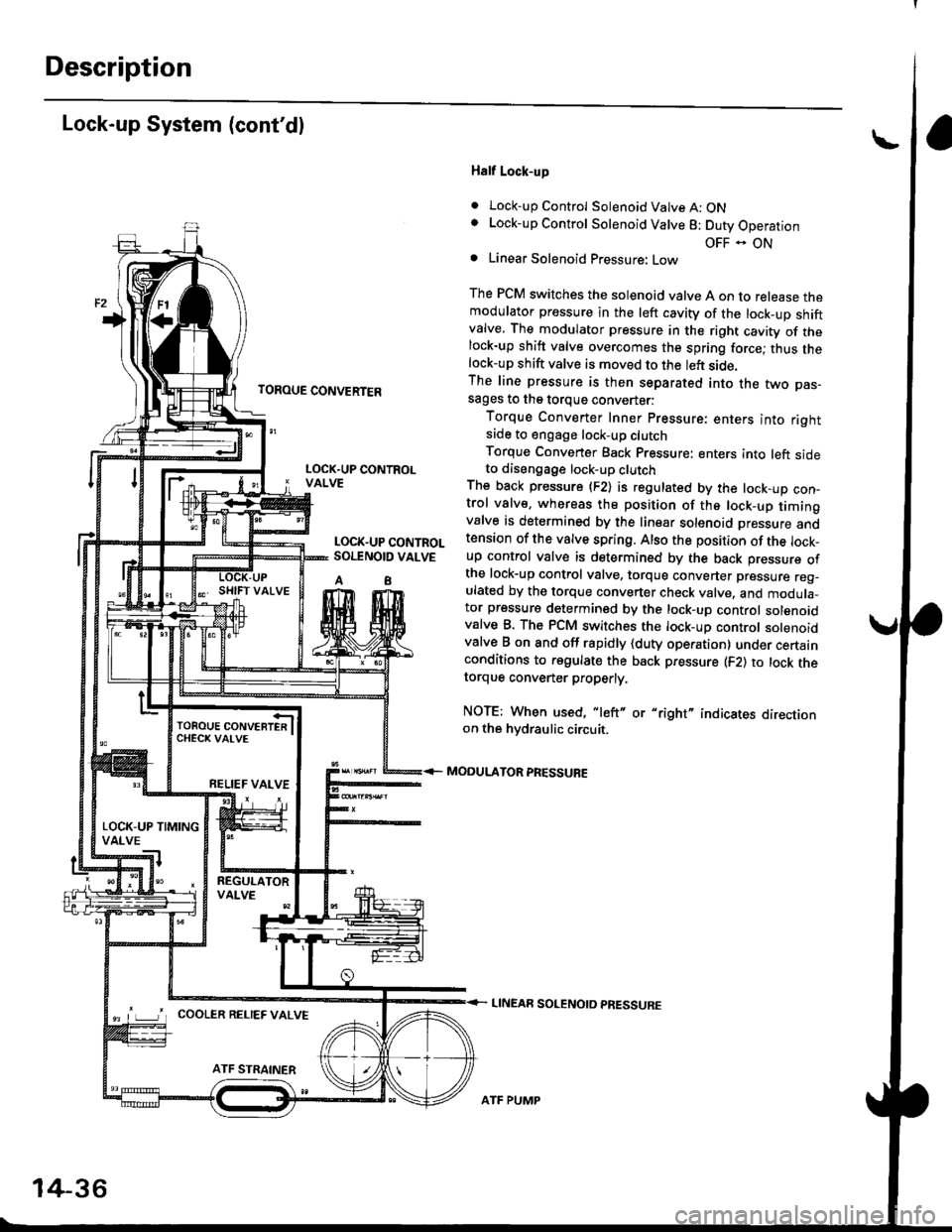

Description

Lock-up System (cont'dl

TOROUE CONVERTER

Half Lock-up

. Lock-up Control Solenoid Valve A: ONLock-up Control Solenoid Valve 8: Duty Operation

OFF - ONLinear Solenoid Pressure: Low

The PCM switches the solenoid valve A on to release themodulator pressure in the left cavity of the lock_up shiftvalve. The modulator pressure in the right cavity of thelock-up shift valve overcomes the spring force; thus thelock-up shift valve is moved to the left side.The line pressure is then separated into the two pas-sages to the torque converter:

Torque Converter Inner pressure: enters into rightsade to engage lock-up clutch

Torque Converter Back pressure: enters into left sideto diseogage lock-up clutchThe back pressure (F2) is regulated by the lock-up con-trol valve, whereas the position of the lock-up timingvalve is determined by the linear solenoid Dressure andtension of the valve spring. Also the position of the lock_up control valve is determined by the back pressure ofthe lock-up control valve, torque converter pressure reg_ulated by the torque converter check valve, and modula_tor pressure determined by the lock-up control solenoidvalve B. The PCM switches the lock-up control solenoidvalve B on and off rapidly {duty operation} under certainconditions to regulate the back pressure (F2) to lock thetorque convener properly.

NOTE: When used, "left" or "right" indicates directionon the hvdraulic circuit.

MODULATOR PRESSURE

LINEAR SOLENOTD PRESSURE

LOCK.UP CONTROLVALVE

LOCK.UP CONTROLSOI.TNOID VALVE

A8

TOROUE CONVERTERCHECK VAI-VE

RELIEF VALVE

LOCK-UP TIMINGVALVE

^ L____J'r cooLER RELTEF valvE

14-36

ATF PUMP

Page 715 of 2189

TOROUE CONVERTER

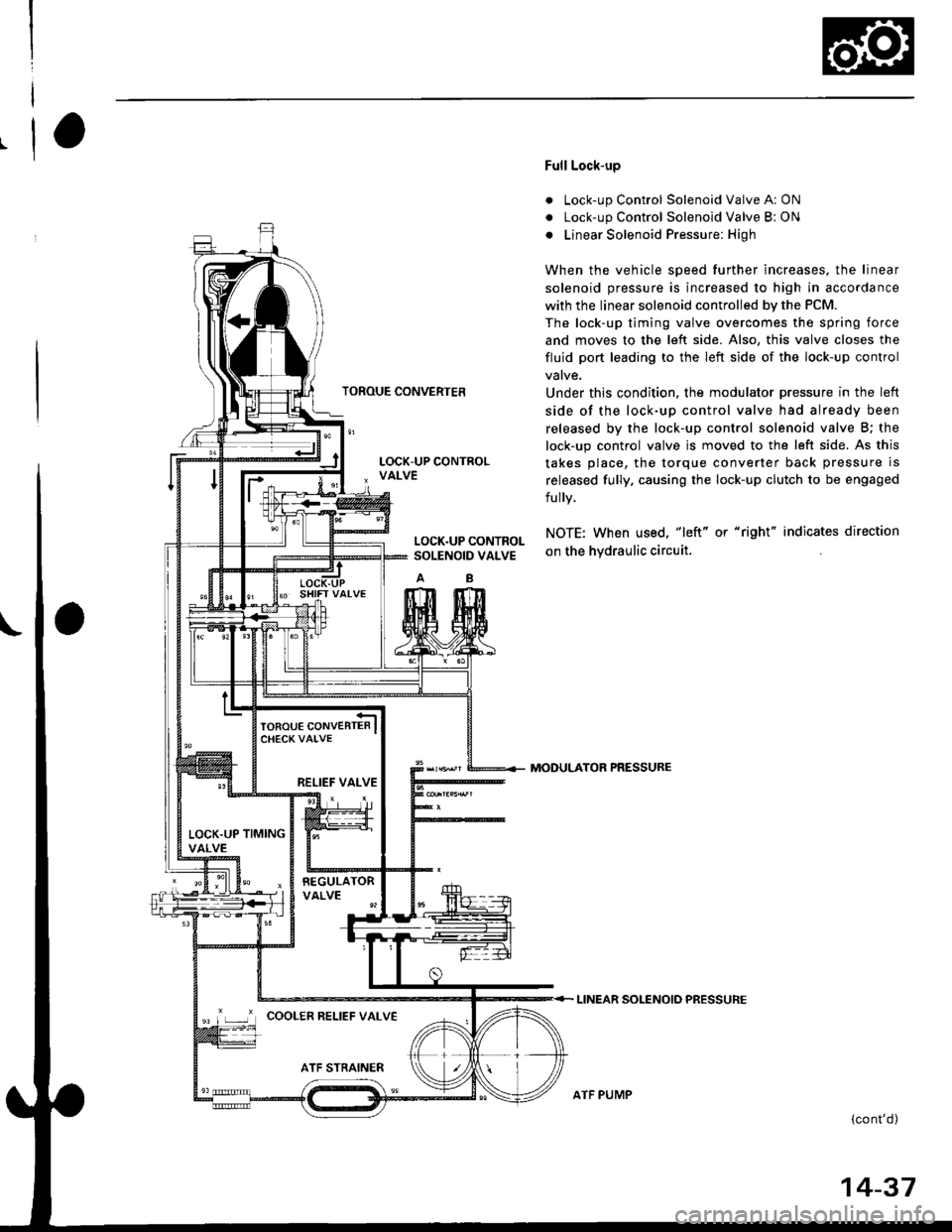

Full Lock-up

. Lock-up Control Solenoid Valve A: ON

. Lock-up Control Solenoid Valve B: ON

o Linear Solenoid Pressure: High

When the vehicle speed further increases. the linear

solenoid pressure is increased to high in accordance

with the linear solenoid controlled bv the PCM.

The lock-up timing valve overcomes the spring force

and moves to the left side. Also, this valve closes the

fluid port leading to the left side of the lock-up control

Under this condition. the modulator pressure in the left

side of the lock-up control valve had already been

released by the lock-up control solenoid valve B; the

lock-up control valve js moved to the left side. As this

takes place, the torque converter back pressure is

released fully. causing the lock-up clutch to be engaged

fully.

NOTE: When used, "|eft" or "right" indicates direction

on the hvdraulic circuit.

MODULATOR PRESSURE

LINEAR SOLENOIO PRESSURE

{cont'd)

LOCK.UP CONTROLSOLENOID VALVE

RELIEF VALVE

LOCK.UP TIMINGVALVE

'r ,-.r' cooLER RELTEF vALvE

ATF PUMP

14-37

Page 716 of 2189

Description

Lock-up System (cont'dl

TOROUE CONVERTER

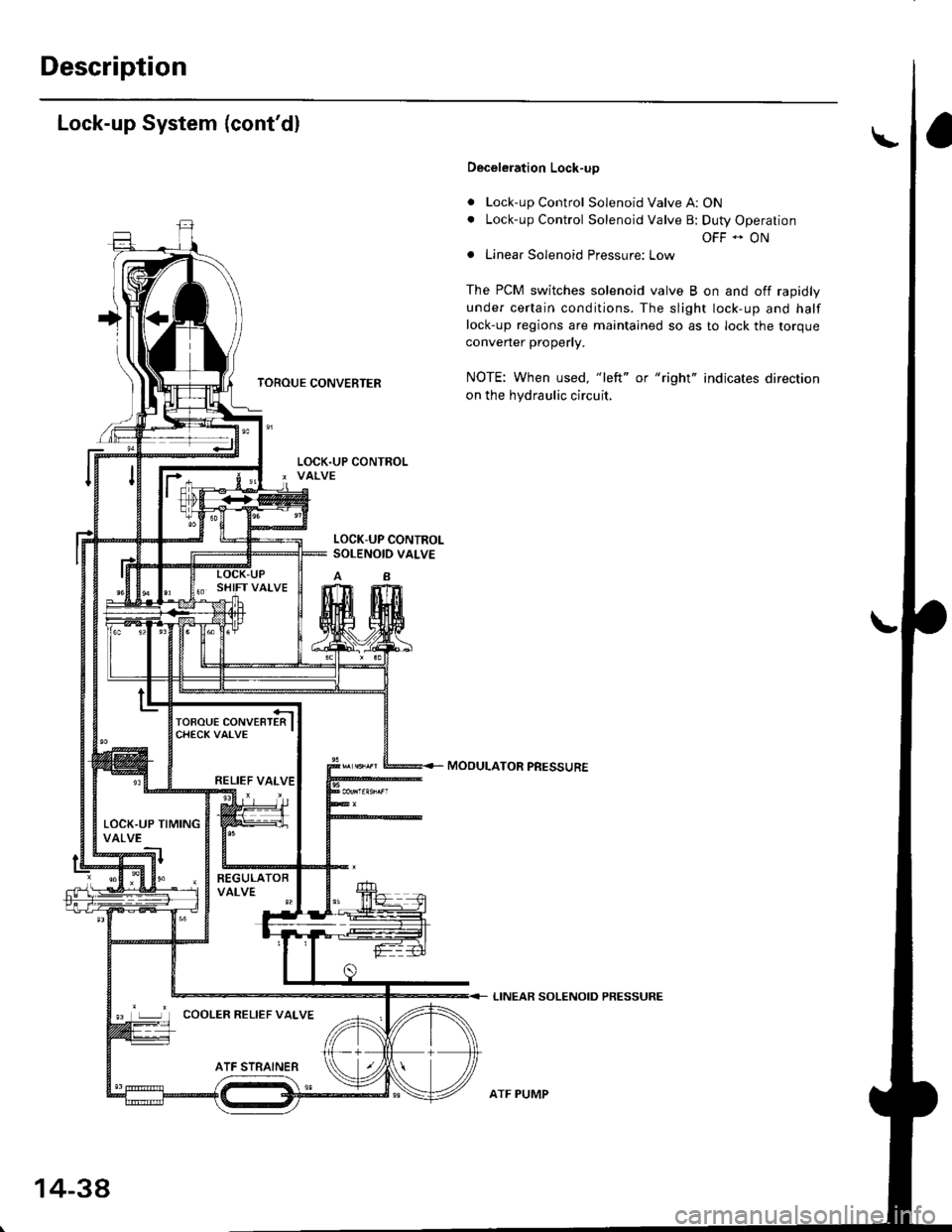

Deceleration Lock-up

. Lock-up Control Solenoid Valve A: ON. Lock-up Control Solenoid Valve B: Duty Operation

OFF - ONa Linear Solenoid Pressure: Low

The PCM switches solenoid valve B on and off rapidly

under certain conditions. The slight lock-up and half

lock-up regions are maintained so as to lock the torque

converter properly.

NOTE: When used, "left" or "right" indicates direction

on the hydraulic circuit,

MOOULATOR PRESSURE

LINEAR SOLENOID PRESSURE

LOCK-UP CONTROLSOLENOID VALVE

RELIEF VALVE

LOCK.UP TIMINGVALVE

COOLER RELIEF VALVE

ATF STRAINER

1434

ATF PUMP