Can HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 469 of 2189

ldle Gontrol System

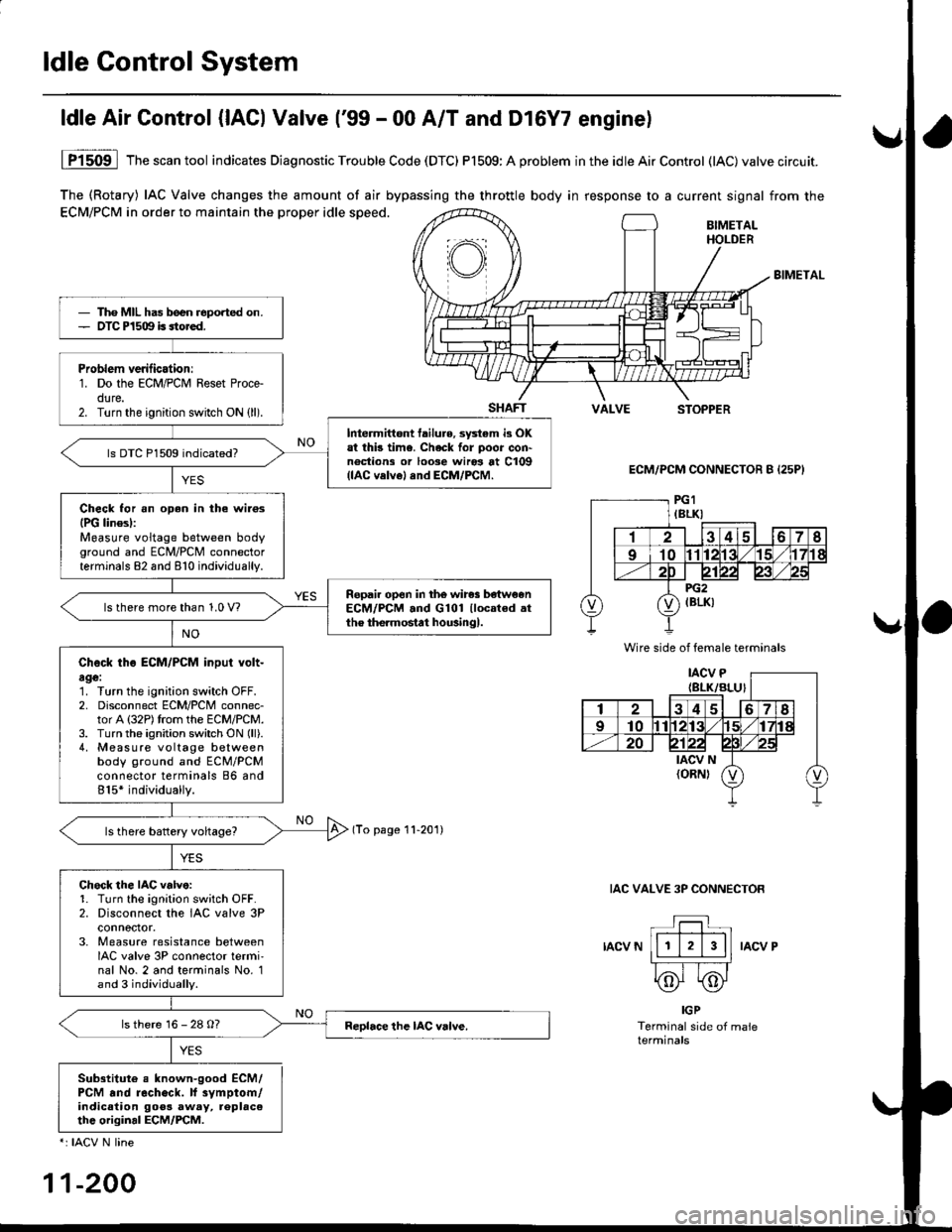

The (Rotary) IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the

ECM/PCM in order to maintain the proper idle speed.BIMETALHOLDER

BIMETAL

SHAFTVALVESTOPPER

ECM/PCM CONNECTOR B {25P}

(To page 11-201)

IAC VALVE 3P CONNECTOR

IACV NIACV P

ldle Air Control {lACl Valve ('99 - 00 A/T and Dl6Y7 enginel

YES

1P1509 lThescantool indicates Diagnostic Trouble Code (DTC) P1509:A problem inthe idleAirControl (lAC)valve circuit.

IGP

Terminal side of maleterminals

Sub3titute e known-good ECM/PCM .nd recheck. lf 3vmptom/indicalion goos away, replac6thc original ECM/PCM.

*: IACV N line

11-200

Tho MIL has b€en reported on.OTC P1509 is sto.ed.

Problem verilicationr1. Do the ECM/PCM Reset Proce-dure.2. Turn the ignition switch ON (ll).

Intermittont tailure, sy3tem i3 OKat thb time. Check for poor con'noctions or loose wiros at C109(lAC velvel and ECM/PCM.

ls DTC P1509 indicated?

Check for an oDen in the wilosIPG linesl:Measure voltage between bodyground and ECM/PCM connectorterminals 82 and 810 individually.

Ropail open in the wires be'tw€enECM/PCM .nd G101 llocated .tthe the.mostat housingl.ls there more than 1.0 V?

Check tho ECM/PCM input volt-age:1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connec-tor A (32P)trom the ECM/PCM.3. Turn the ignition switch ON (ll).

4, Measure voltage betweenbody ground and ECM/PCMconnector terminals 86 and815* individually.

Chock the IAC v.lve:1. Turn the ignition sw;tch OFF.2. Disconnect the IAC valve 3Pconnoctor.3. Measure resistance betweenIAC valve 3P connector termi'nal No. 2 and terminals No. 1and 3 individually.

ls there 16 - 28 O?

Wire side of female terminals

Page 477 of 2189

ldle Control System

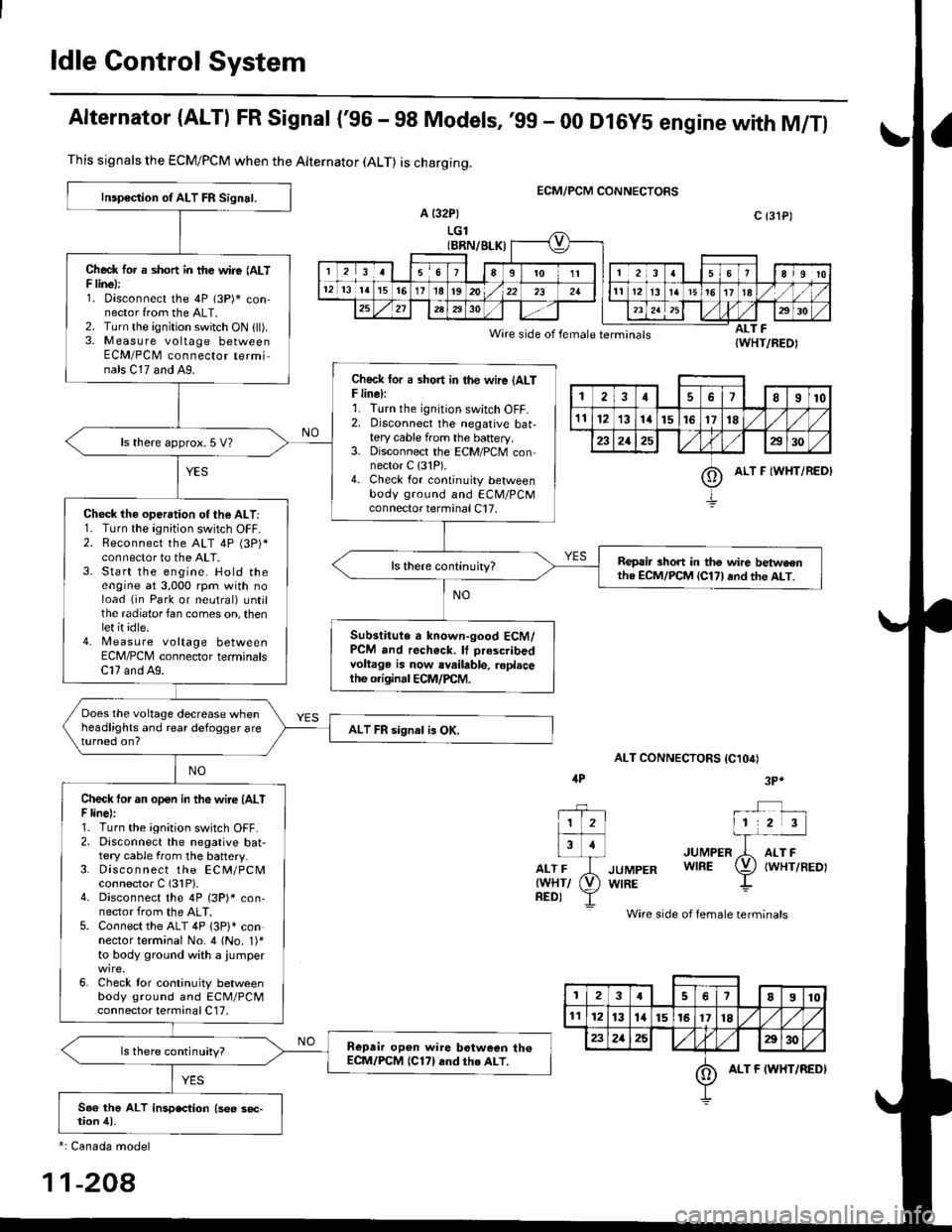

Alternator (ALTI FR Signal {'96 - 98 Models,'99 - 00 Dl6y5 engine with M/Tl

ECM/PCM CONNECTORS

a {32P)

LGl(BRN/BLK)

Wire side of female terminals

ALT CONNECTORS IC1O4I

JUMPER

JUMPER WIRE

WIRE

Wire side of female terminals

ALT F{WHT/REO)

This signals the ECM/PCM when the Alternator (ALT) is charging.

Inspoction of ALT FR Signal.

Check tor a short in tfte wire (ALTF linel:1. oisconnect the 4P (3P)* con-nector from the ALT.2. Turn the ignition switch ON (ll).3. M easu re voltage betweenECM/PCM connector terminals C17 and A9.Check lor a sho.t in the wire {ALTF line):r. I urn rne tgn|lton swtlch ul-f,2. Disconnect the negative bat-tery cable from the baftery.3. Disconnect the ECM/PCM connector C {31P).4. Check for continuity betweenbody ground and ECM/PCMconnector terminal C17.

ls there approx. 5 V?

Check th€ operation of the ALT:1. Turn the ignition switch OFF.2. Reconnect the ALT 4P (3P)*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untjlthe radiator fan comes on, thenlet it idle.4. [,4easu re voltage betweenECM/PCM connector terminalsC17 and A9.

Repair short in the wire betwe€nthe ECM/PCM {Cl71and th€ ALT.

Substitute a known-good ECM/PCM and recheck. It prescribedvoltage is now available, roplacethe originrl ECM/PCM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR signal is OK.

Check tor an open in the wire (AlTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable from the battery.3. Disco n nect the ECM/PCMconnector C (31P).4. Disconnect the 4P (3P)* con,nector from the ALT.5. Connect the ALT 4P 13P)l connector terminal No. 4 (No. 1)'to body ground with a iumper

6. Check lor continuity betweenbody ground and ECM/PCMconnector terminal C17,

Repair op6n wire botween th€ECM/PCM (C171rnd th€ ALT.ls there continuity?

c {31P)

1178I10

1112131415161718

232125a30

oALT F IWHT/REDI

4P3P*

1 2l

Flr

rr-ri-frwHr/ (V)

neor Y

*: Canada model

11-208

3I78910

1l1213l415161718/l

232125E30

oALT F IWHT/REDI

Page 478 of 2189

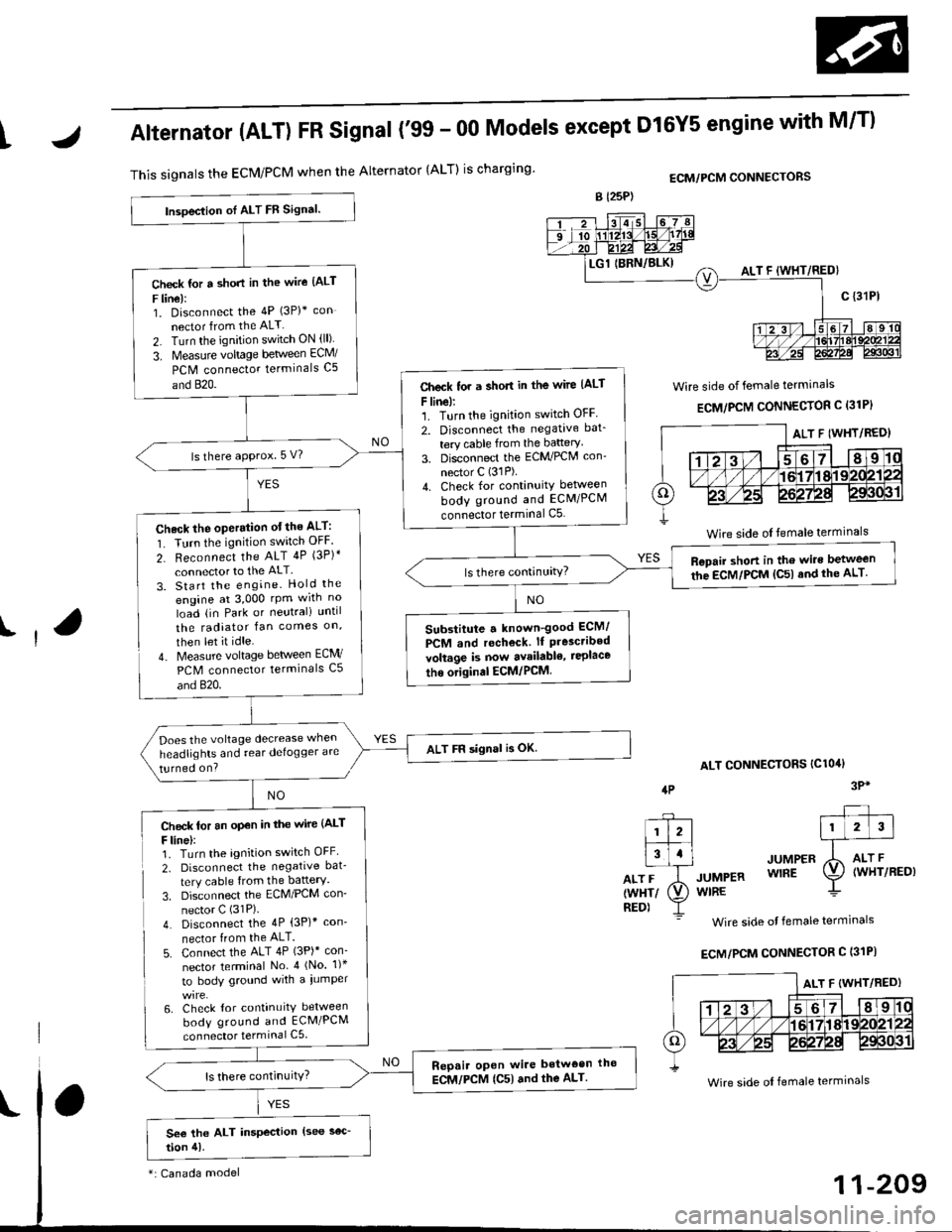

tAlternator (ALT) FR Signal ('99 - 00 Models except Dl6Y5 engine with M/T)

This signals the ECM/PCM when the Alternator {ALT) is chargingECM/PCM CONNECTORS

Wire side of female terminals

ECM/PCM CONNECTOR C (31P}

lt

lP

ALT CONNECTORS IClO4I

JUMPER

JUMpER WlnE

WIRE

Wire side of female termlnals

ECM/PCM CONNECTOR C (31PI

3P*NO

Check lor an op€n in the wire (ALT

F line,:1. Turn the agnition switch OFF

2. Disconnect the negative bat-

tery cable {rom the battery.

3. Disconnect the ECM/PCM con'

nector C (31P).

4. Disconnect the 4P (3P)* con'

nector from the ALT.

5. Connect the ALT 4P (3P)* con-

nector terminal No 4 (No. 1)*

to bodY ground with a iumper

6. Check lor continuity between

body ground and ECM/PCM

connector terminal C5

--?--1l2l|�#i3l.l

otriJrwxrr (V)

neor Y

lnsoeclion oI ALT FB Signal.

Check {or a short in the wire {ALT

F line):1. Disconnect the 4P (3P)+ con

nector from the ALT

2. Turn the ignition switch ON (ll)

3. Measurc voltage between EcM/

PCM connector terminals C5

and 820.Check tor a short in the wirc (ALt

F line):1. Turn the ignition switch OFF

2. Disconnect the negative bat_

tery cable from the baRery'

3. Disconnect the ECM/PCM con'

nector C (31P).

4. Check for continuity between

body ground and ECM/PCM

connector terminal C5

ls there aPProx. 5 V?

Check the operation otthe ALT:

1. Turn the ignition switch OFF.

2- Reconnect the ALT 4P (3P)*

connector to the ALT

3. Start the engine. Hold the

engine at 3,000 rpm wrth no

load {in Park or neutrali until

the radiator fan comes on,

then let it idle.

4- Measure voltage between ECM/

PCM connector terminals C5

and 820.

Repair short in the wire between

the EcM/PCM {C5l and the ALT.

Substitute a known-good ECM/

PCM and rechock. lf P.esc.ibedvoltage is now availabl€, ieplace

tho original ECM/PCM

Does the voltage decrease when

headlights and rear delogger are

turned on?

ALT FF signal is OK.

Repair oPen wire betwoen t|lo

ECM,/PCM {C5) and the ALT.

ALT F (WHT/RED)

Wire side of temale terminals

*: Canada model

Wire side of female termrnals

Page 489 of 2189

ldle Control System

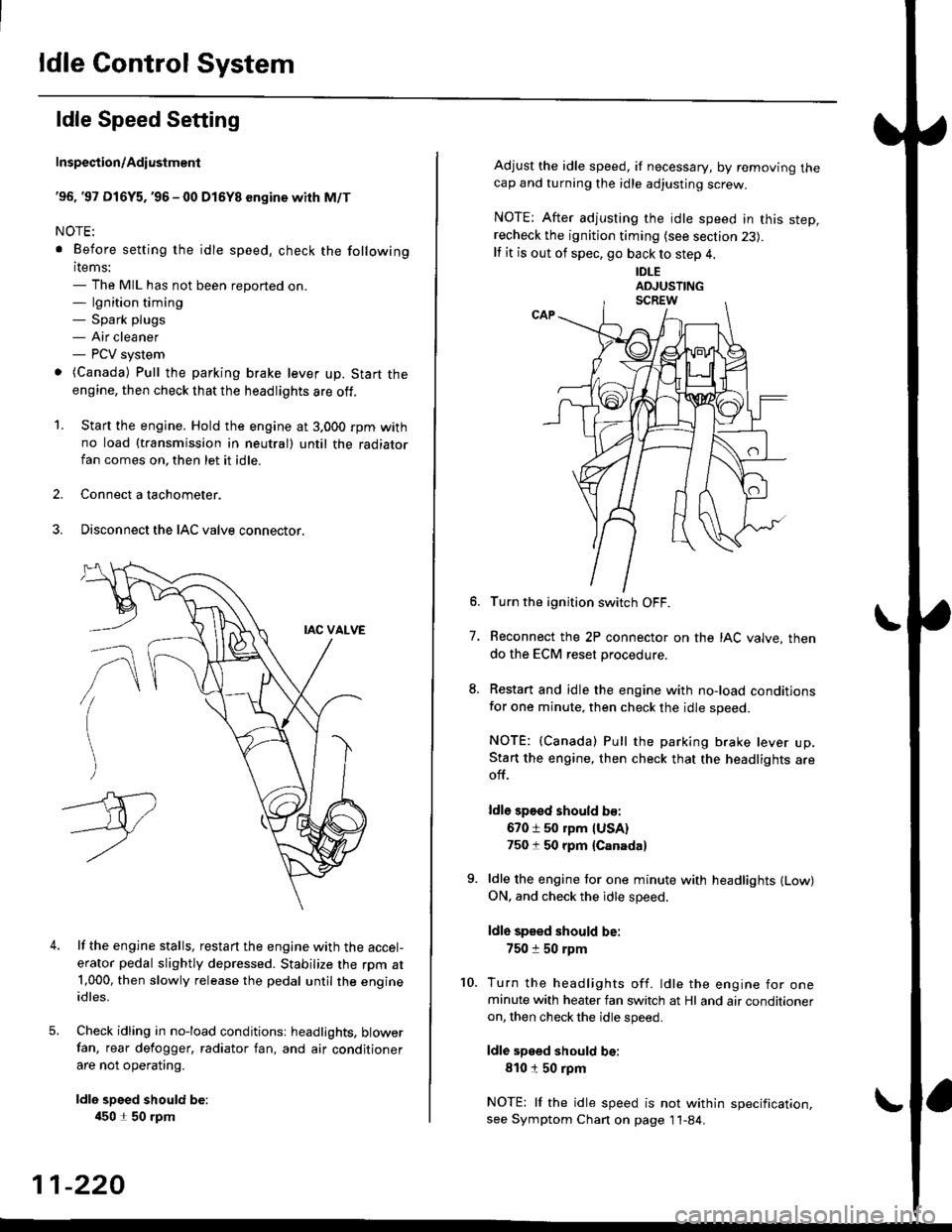

ldle Speed Setting

Inspection/Adiustmenl

'96, '97 Dl6Y5. '96 - 00 Dl5Y8 sngine with M/T

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

o (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3.000 rpm withno load (taansmission in neutral) until the radiatorfan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the IAC valve connector.

4.lf the engine stalls, restart the engine with the accel-

erator pedal slightly depressed. Stabilize the rpm at1,000, then slowly release the pedal until the engineidles.

Check idling in no-load conditionsr headlights. blowerfan. rear defogger, radiator fan, and air conditioner

are not operating.

ldle spsed should be:

450 1 50 rpm

11-220

Adjust the idle speed, if necessary, by removing thecap and turning the idle adjusting screw.

NOTE; After adjusting the idle speed in this step,recheck the ignition timing (see section 23).

lf it is out of spec, go back to step 4.

IDLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connector on the IAC valve, then

do the ECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

ldle sp€sd should b€:

670 i 50 rpm IUSA)750 t 50 rpm {Canada}

9. ldle the engine tor one minute with headlights {Low)ON. and check the idle speed.

ldle speed should be:

750 :r 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air conditioneron, then check the idle speed.

ldle speed should be:

810150 rpm

NOTE: lf the idle speed is not within specification,see Symptom Chan on page 11-84.

Page 490 of 2189

t

t

I

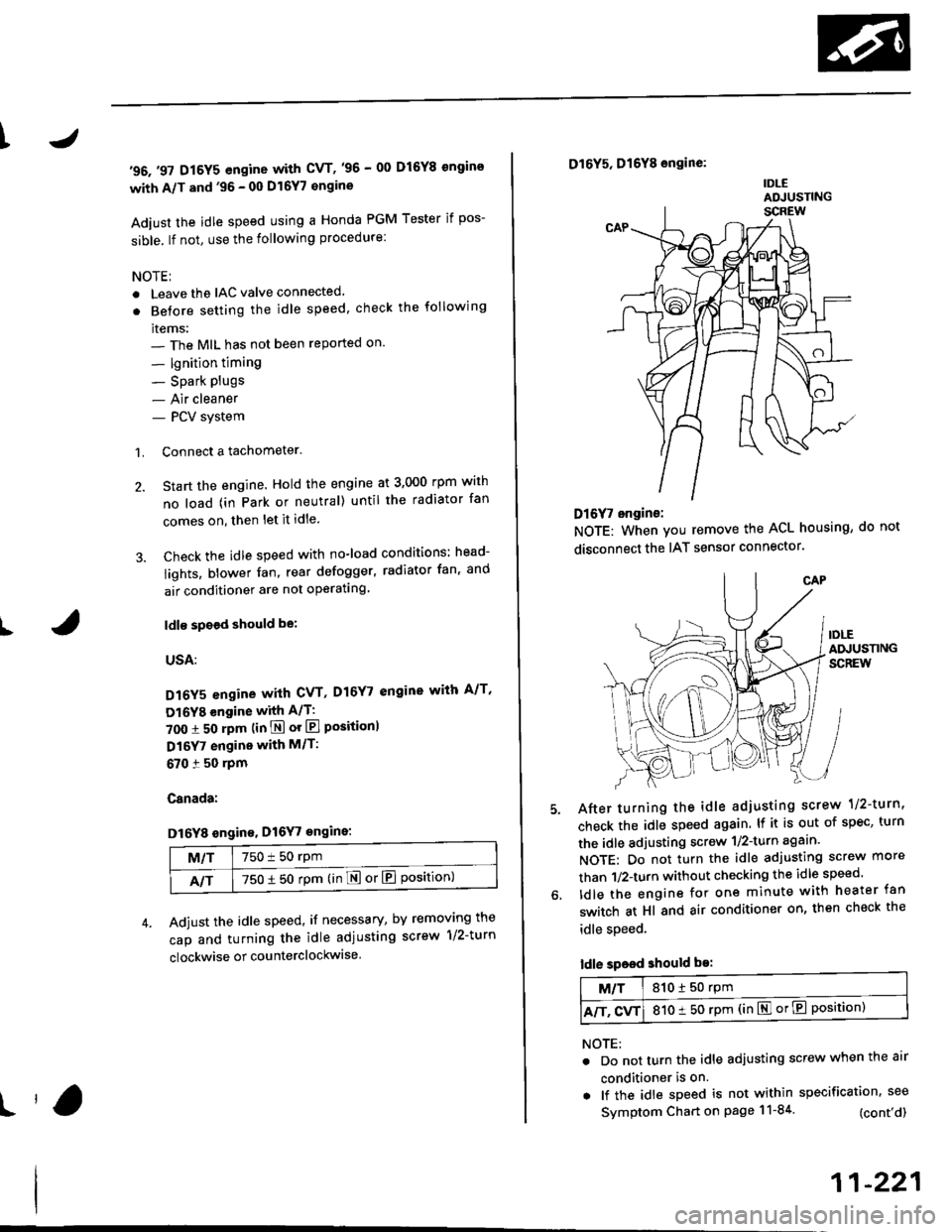

'96.'97 D16Y5 engine with CVT,'96 - 00 D16Y8 ongins

with A/T and'96 - 00 Dl6Y7 €ngine

Adiust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTEI

. Leave the IAC valve connected

. Betore setting the idle speed. check the following

items:- The MIL has not been reported on'

- lgnition timing

- Spark Plugs- Air cleaner- PCV system

1. Connect a tachometer.

2. Start the engine. Hold the engine at 3,000 rpm wirh

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

3. Check the idle speed with no-load conditions: head-

iights, blower fan, rear defogger, radiator fan, and

air conditioner are not operatlng

ldl€ spoed should be:

USA:

D16Y5 engine with CVT, D16Y7 engine with A/T'

Dl6YB engine with A/T:

700 :r 50 rpm (in E or El Positionl

D16Y7 engine with M/T:

670 i 50 rpm

Canada:

Dl6Y8 sngin€, Dl6Y7 engins:

M/T750 t 50 rpm

NT750 1 50 rpm (in E or El Position)

Adjust the idle speed, if necessary, by removing the

cap and turning the idle adiusting screw 1/2-turn

clockwise or counterclockwise

D16Y5, D16Y8 engine:

IDLEADJUSTING

Dl6f, ongine:

NOTE: When you remove the ACL housing, do not

disconnect the IAT sensor connector

After turning the idle adjusting scrow 1/2-turn'

check the idle speed again. lf it is out of spec, turn

the idle adjusting screw 1/2-turn agaan'

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed'

ldle the engine for one minute with heater fan

switch at Hl and air conditioner on, then check the

idle speed.

ldle speed should be:

M/T810150 rpm

A/T. CvT810 t 50 rpm (in El or E Position)

NOTE:

. Do not turn the idle adjusting screw when the air

conditioner is on.

. lf the idle speed is not within specification. see

Symptom Chart on page 11-84 (cont'd)

11-221

Page 491 of 2189

ldle Control System

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

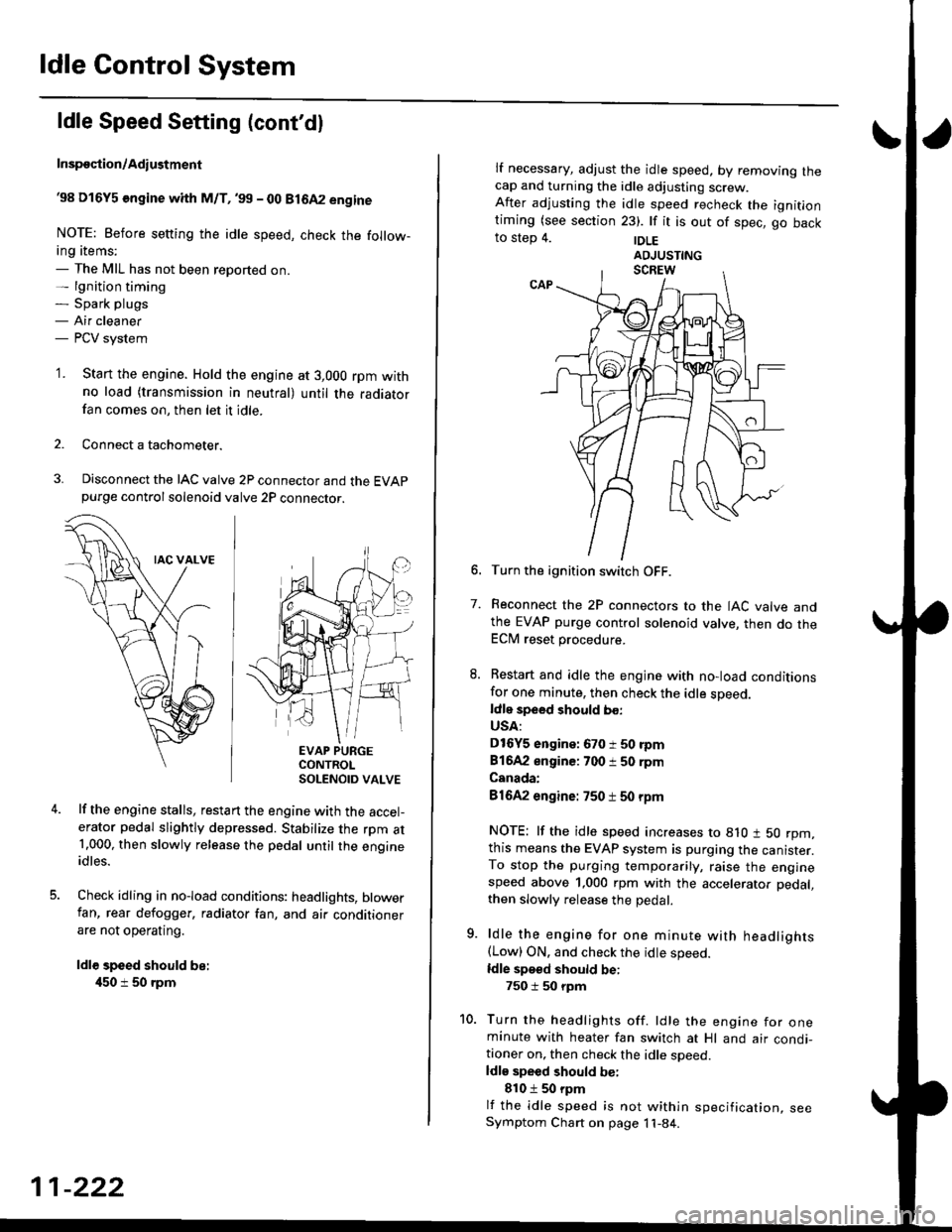

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 492 of 2189

\

I

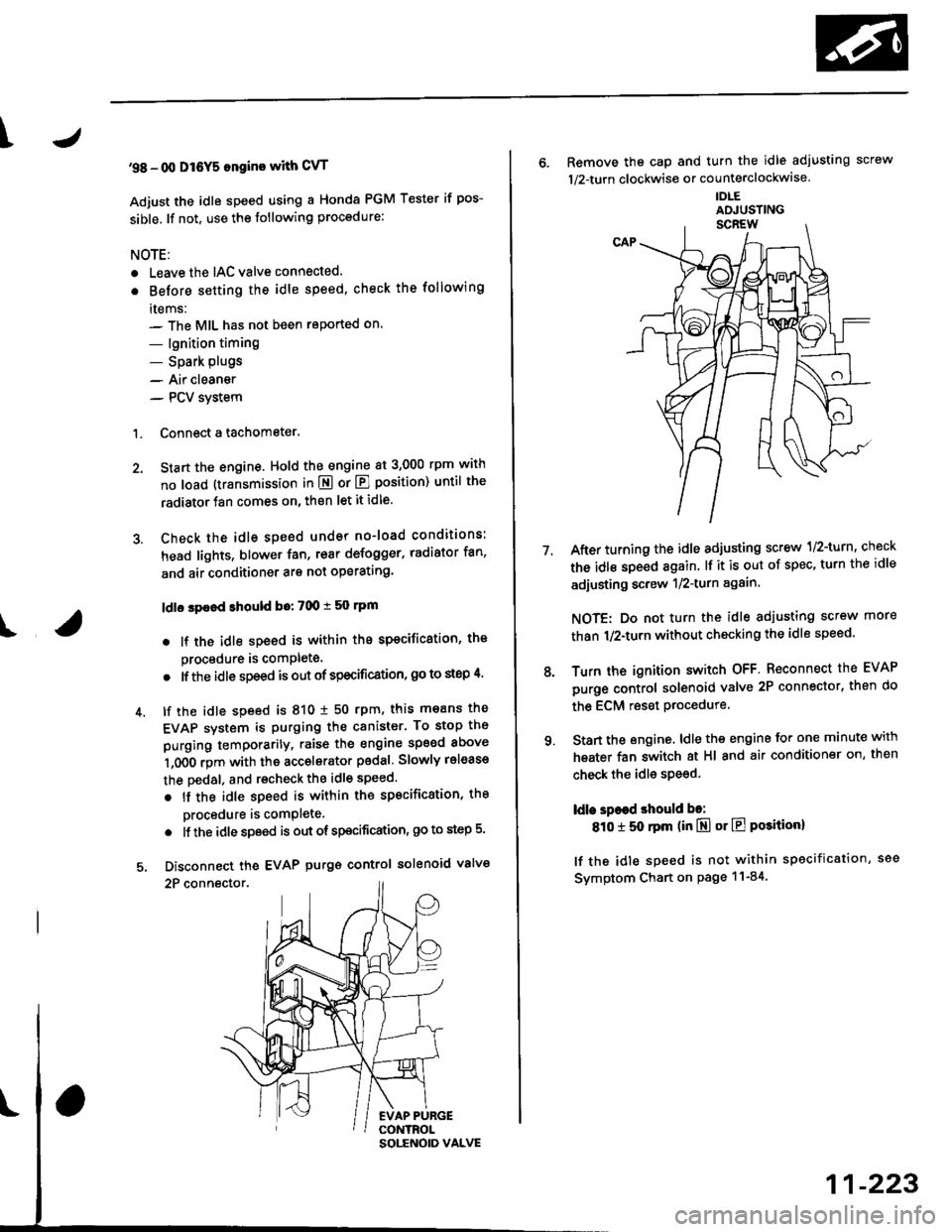

'98 - 0O D16Y5 ongine with CvT

Adjust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTE:

. Leave the IAC valve connected.

. Before s€tting the idle speed, check the following

rtems:- The MIL has not been reported on.

- lgnition timing

- Spark Plugs- Air clean€r

- PCV svstem

'1. Connect a tachometer.

2. Stan the engine. Hold the engine at 3,000 rpm w'th

no load (transmission in E or E] position) until the

radiator Jan comes on, then let it idle.

3. Check the idle speed under no-load conditions:

head lights, blower fan, rear defogger, radiator fan,

and air conditioner are not operatlng.

ldlo spaod ehould bo: 700 t 50 rpm

. lf the idle speed is within the specification, the

procedure is comPlete.

. lf the idle sDeed is out of specitication, 9o to step 4'

4. tf the idle speed is 810 1 50 rpm, this means the

EVAP system is purging the canister. To stop the

purging temporarily, raise the engine speed above

l,OO0 rgm with the accelsrator pedal. Slowly release

the pedal. and rscheck the idl€ speed.

. tf the idle speed is within the specificstion, the

Drocedure is comPlete.

. lf the idle sp€ed is out of spocification, go to step 5.

5. Disconnect th€ EVAP purgs control solenoid valve

2P connector.

EVAP PURGECONTROL

6. Remove the cap and turn the idle adiusting screw

1/2-turn clockwise or counterclockwlse

IDLE

7.After turning the idle adjusting screw 1/2-turn, check

the idl€ speed again. lf it is out of spec, turn the idle

adjusting screw 1/2-turn again.

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed.

Turn the ignition switch OFF. Reconnect the EVAP

purge control solenoid valve 2P connector' then do

the ECM reset Procedure.

Start the engine. ldle the engine for one minute with

heater fan switch at Hl and air conditioner on, then

check the idle speed.

ldle spaed should be:

810 t 50 rpm (in El or E Posiiion)

lf the idle speed is not within specification, see

Svmptom Chart on Page 11-84.

9.

SOLENOID VALVE

11-223

Page 496 of 2189

I

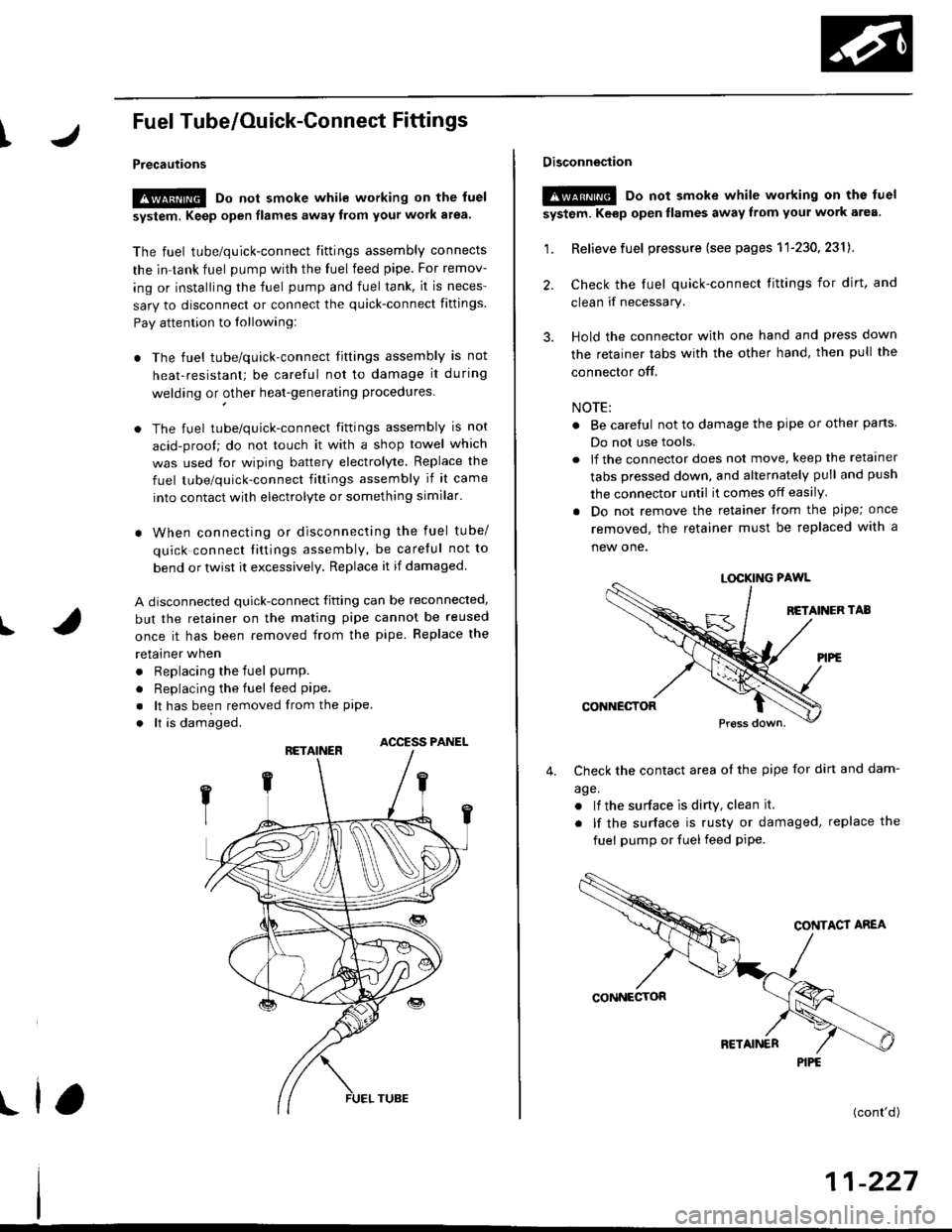

Fuel Tube/Ouick-Gonnect Fittings

Precautions

!@ Do not smoke while working on the fuel

system, Keep open flames away from your work a.ea'

The fuel tube/quick-connect fittings assembly connects

the in tank fuel pump with the fuel feed pipe. For remov-

ing or installing the fuel pump and fuel tank, it is neces-

sary to disconnect or connect the quick-connect fittings.

Pay attention to lollowing:

. The fuel tube/quick-connect fittings assembly is not

heat-resistant; be careful not to damage it during

welding or other heat-generating procedures

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. Replace the

fuel tube/quick-connect fitlings assembly if it came

into contact with electrolyte or something similar.

. When connecting or disconnecting the fuel tube/

quick connect liltings assembly, be careful not to

bend or twist it excessively. Replace it if damaged

A disconnected quick-connect fitting can be reconnecled,

but the retainer on the mating pipe cannot be reused

once it has been removed from the pipe. Replace the

retatner wnen

. Replacing the fuel pump.

. Replacing the fuel leed pipe.

. lt has been removed lrom the PiPe.. lt is damaged.

ACCESS PANEL

I

Disconnestion

!@ Do not smoke while working on the luel

system. Keep open llames away lrom youl work area.

1. Relieve fuel pressure (see pages 11'230,2311.

2. Check the tuel quick-connect tittings for dirt, and

clean if necessary.

3. Hold the connector with one hand and press down

the retainer tabs with the other hand, then pull the

connector off.

NOTE:

o Be carelul not to damage the pipe or other pans

Do not use tools.

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

. Do not remove the retainer from the pape; once

removed, the retainer must be replaced with a

new one.

LOCKING PAWL

BETAINER TAB

CONNECTOR

Check the contact area o{ the pipe for dirt and dam-

age.

. lf the surface ls dirty, clean it.

. lf the surface is rusty or damaged, replace the

fuel pump or fuel feed piPe.

4.

(cont'd)

11-227

PIPE

Page 499 of 2189

Fuel Supply System

System Description

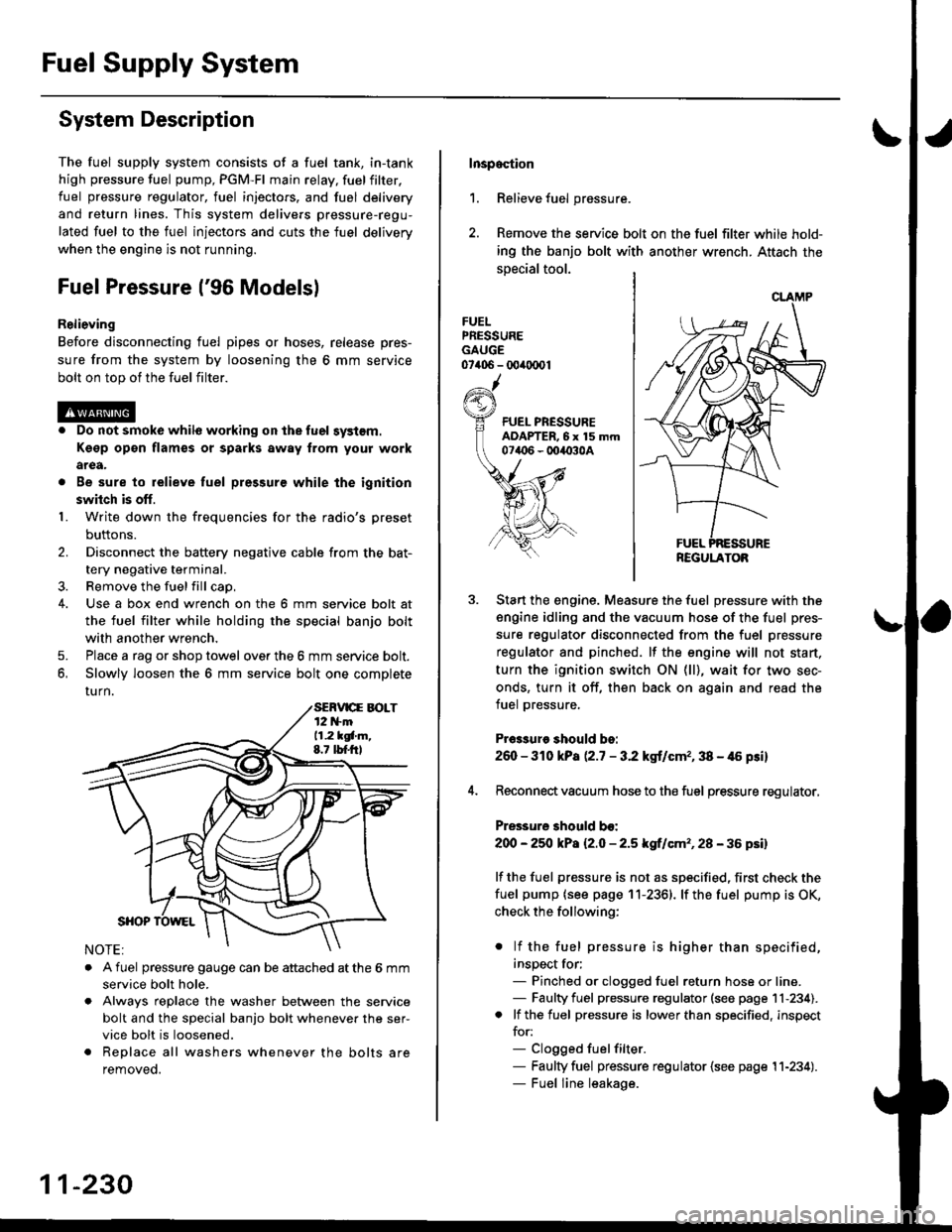

The fuel supply system consists of a fuel tank, in-tank

high pressure fuel pump, PGM-FI main relay, fuelfilter,

fuel pressure regulator, fuel injectors. and fuel delivery

and return lines. This system delivers pressure-regu-

lated fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.

Fuel Pressure l'96 Modelsl

Relieving

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 6 mm service

bolt on top of the fuel filter.

. Do not smoke whil6 working on the fuel system.

Kgsp opon flames or sparks away from youl work

area.

. Be sure to relieve fuel pressure while the ignition

switch is off.

1. Write down the frequencies for the radio's preset

buttons.

2. Disconnect the battery negative cable from the bat-

tery negative terminal.

3. Remove the fuelfill cap,

4. Use a box end wrench on the 6 mm service bolt at

the fuel filter while holding the special banjo bolt

with another wrench,

5. Place a rag or shop towel over the 6 mm service bolt.

6, Slowly loosen the 6 mm service bolt one complete

rurn.

. A fuel pressure gauge can be attached at the 6 mm

service bolt hole.

. Always reDlace the washer between the service

bolt and the special banjo bolt whenever the ser-

vice bolt is loosened.

. Replace all washers whenever the bolts are

removeo.

11-230

Inspoction

1. Relieve fuel pressure.

2. Remove the service bolt on the fuel filter while hold-

ing the banjo bolt with another wrench. Attach the

special tool.

FUELPRESSUREGAUGE07406 - 00ir0(x)1

Start the engine. Measure the fuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch ON (ll), wait for two sec-

onds, turn it off, then back on again and read the

fuel pressure.

Pr€3sure should bo:

260 - 310 kPa (2.7 - 3.2 kgt/cmr, 38 - 46 psi)

Reconnect vacuum hose to the fuel pressure regulator,

Pressure should bo:

200 - 25O kPa l2.O - 2.5 kgf/cm'�, 28 - 36 psil

lf the fuel pressure is not as specified, first check the

fuel pump {see page 11-2361. lf the fuel pump is OK,

check the following:

. lf the fuel pressure is higher than specified,

inspect for;- Pinched or clogged fuel return hose or line.- Faulty fuel pressure regulator (see page 11-234).. lf the fuel pressure is lower than specified, inspect

for:- Clogged fuelfilter.- Faulty fuel pressure regulator {see page 11-234).- Fuel line leakage.

REGULATOB

Page 521 of 2189

Emission Gontrol System

System Description

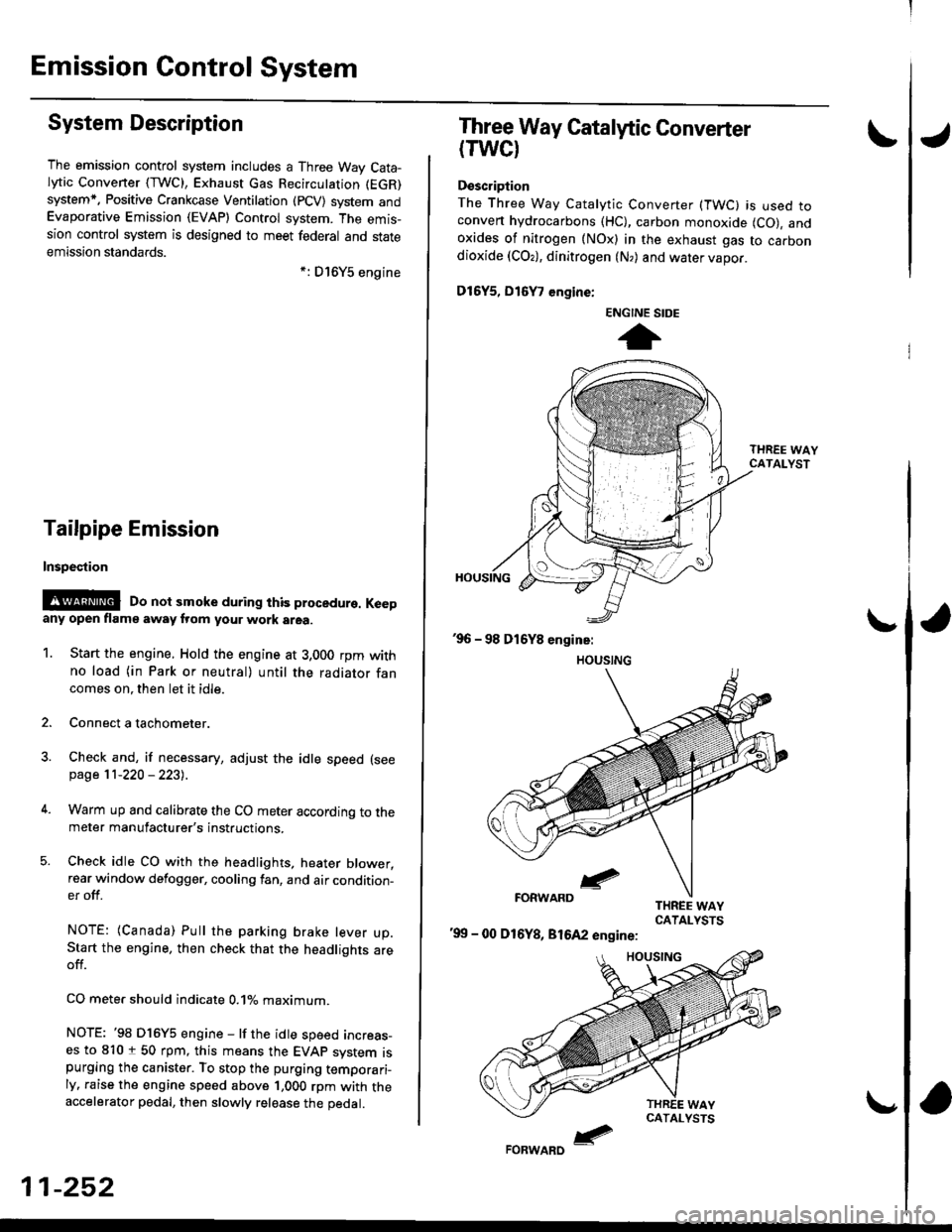

The emission control system includes a Three Way Cata-lytic Convener (TWC), Exhaust Gas Recirculation (EGR)

system,. Positive Crankcase Ventilation (pCV) system andEvaporative Emission (EVAP) Control system. The emis-sion control system is designed to meet federal and stateemission standards.*: D16Y5 engine

Tailpipe Emission

Inspestion

@@ Do not smoke during ihis procedure. Keepany open flame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm withno load (in Park or neutral) until the radiator fancomes on. then let it idle.

2. Connect a tachometer.

Check and, if necessary, adjust the idle speed (see

page 11-220 - 223).

Warm up and calibrate the CO meter according to themeter manufacturer's instructions.

Check idle CO with the headlights, heater blower,rear window defogger, cooling fan, and air condition-er off.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

CO mete. should indicate 0.1% maximum.

NOTE: '98 Dl6Y5 engine - lf the idle speed incress-es to 8101 50 rpm, this means the EVAp system ispurging the canister. To stop the purging temporari-ly. raise the engine speed above 1,000 rpm with theaccelerator pedal, then slowly release the pedal.

11-252

eFORWARD -

Three Way Catalytic Converter

(TWCI

Doscription

The Three Way Catalytic Converter (TWC) is used toconven hydrocarbons (HC), carbon monoxide (CO), andoxides of nitrogen (NOx) in the exhaust gas to carbondioxide (COr), dinitrogen (N,) and water vapor.

D15Y5, D16

, engine:

'99 - 00 D16Y8, 81642 engine:

ENGINE SIDE

t