Can HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 524 of 2189

4

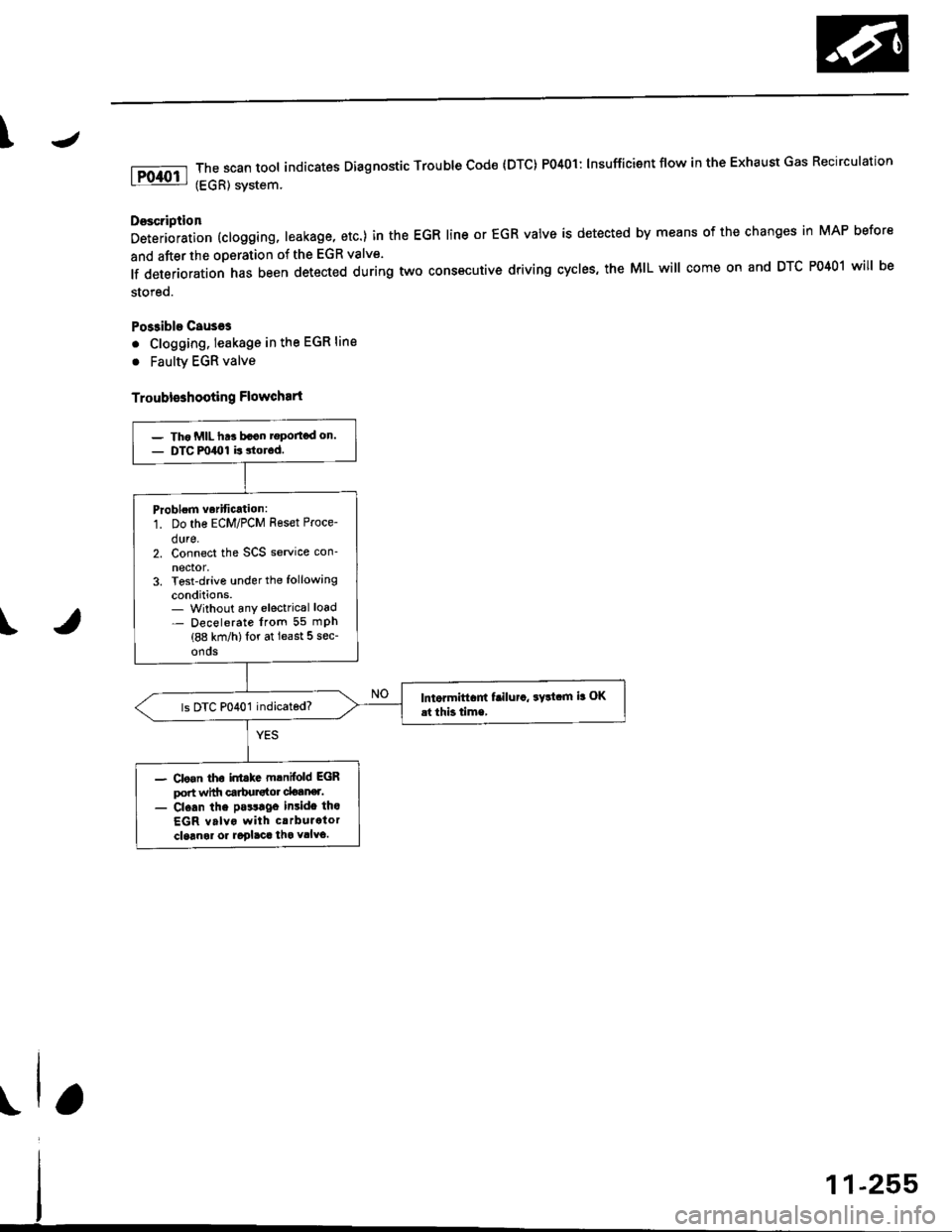

The scan tool indicates Dlagnostic Trouble cod€ {DTc} Po4ol: lnsufficient flow in the Exhaust Gas Recirculation

(EGR) svstem.

Doscription

Deterioration (clogging, leakage, etc.) in the EGR line or EGR valve is detected by means of the changes in MAP before

and after the operation of the EGR valve.

lf deterioration has been detected during two cons€cutive driving cycles, the MIL will come on and DTC P0401 will be

stored.

Po$ible Causeg

. Clogging. leakage in the EGR line

. Faulty EGR valve

Troubleshooting Flowchart

\

- Tho MIL ht! bacn rgportod on.- DTC m40l is 3torod.

Problom vorification:

1. Do the ECM/PCM Reset Proce-

dure.2. Connect the SCS service con-

nector,3. Tost-drive under the following

conditions.- Without any electrical load- Decelerate lrom 55 mPh(88 km/h)lor at least 5 sec-

onos

lntormiftam f!ilu.a, ayltam ia OK

.t thb time,

- Clo.n tho inttkc mlnifold EGRport wittr carbursto. clotner.- Cl.an the pa$lgo insido tho

EGR valvo with crrburator

cloanol or aoglaca tha vllvo.

Page 525 of 2189

Emission Control System

Exhaust Gas Recirculation (EGR) System (D16Y5 engine with GWI (cont'dl

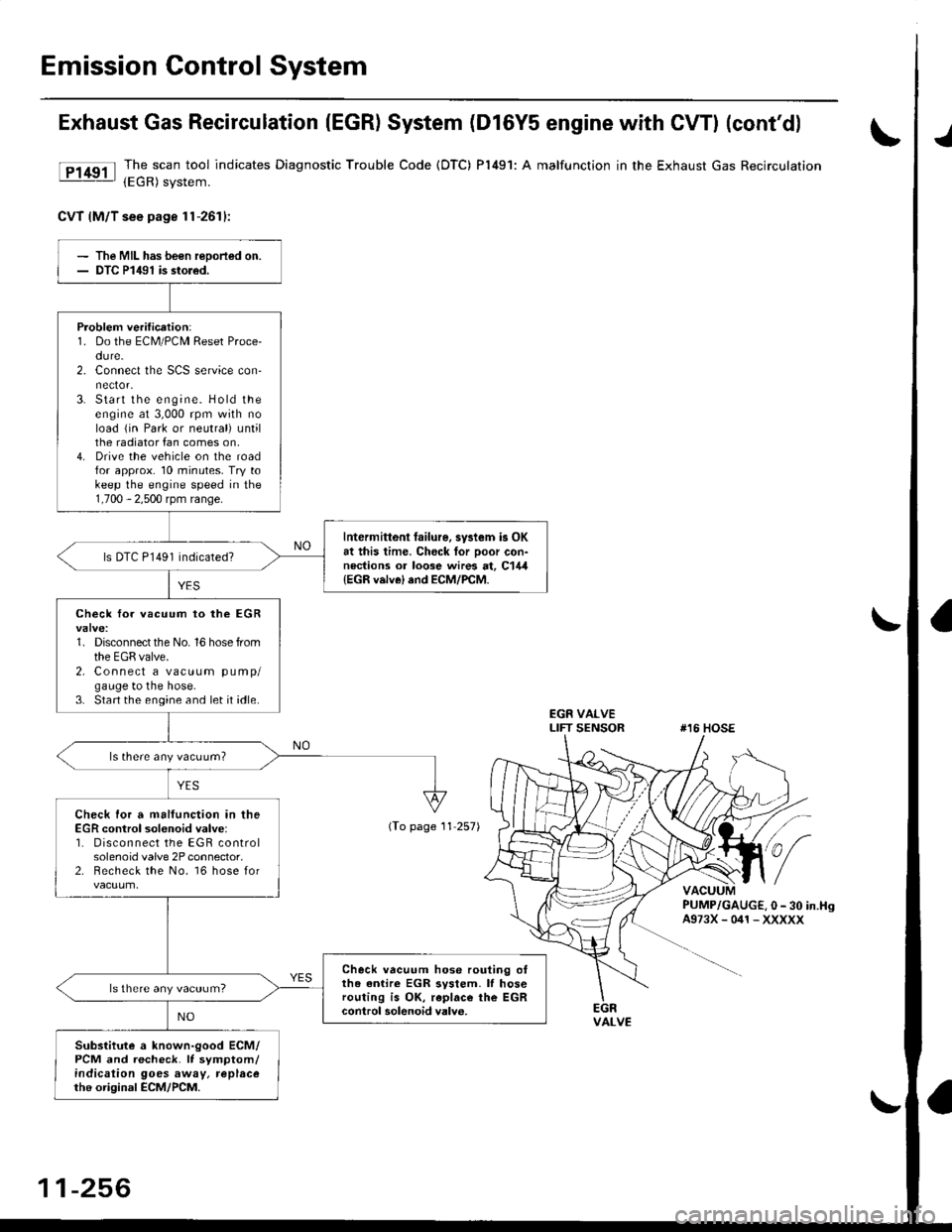

lTl49il T_he scan tool indicates Diagnostic Trouble Code (OTC) P1491: A malfunction in the Exhaust Gas Recirculation- lEgh) svstem.

CvT lM/T see page 1l-2611:

J

EGR VALVELIFT SENSOR#16 HOSE

PUMP/GAUGE,0- 30 in.HsA973X-041-XXXXX

EGRVALVE

The MIL has been reoorted on.DTC P1491 is stoled.

Problem verification:1. Do the ECM/PCM Reset Proce-du re.2. Connect the SCS service con'

3. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral) untilthe radiator fan comes on,4. Drive the vehicle on the roadfor approx. 10 minutes. Try tokeep the engine speed in the1,700 - 2,500 rpm range.

Intermittonl failure, system is OKat this time. Check for Door con-nections or loose wires at, C144{EGR velve} and ECM/PCM.

ls DTC P l49l indicated?

Check fo. vacuum to ihe EGR

1. Disconnect the No. 16 hose fromthe EGR valve.2. Connect a vacuum pump/gauge to the hose.3. Start the engine and let it idle.

ls there any vacuum?

Check tor a malfunction in theEGR control solenoid valve:'1. Disconnect the EGR controlsolenoid valve 2P connector,2. Becheck the No. 16 hose for

Check vacuum hose routing o,the entire EGR svstem. lf hoserouting is OK, replac€ the EGRcontrol solenoidvalv6.

ls there any vacuum?

Substitute a known-good ECM/PCM and recheck. It symptom/indicalion goes away, replacethe original ECM/PCM.

(To page 11 257)

11-256

Page 534 of 2189

J\

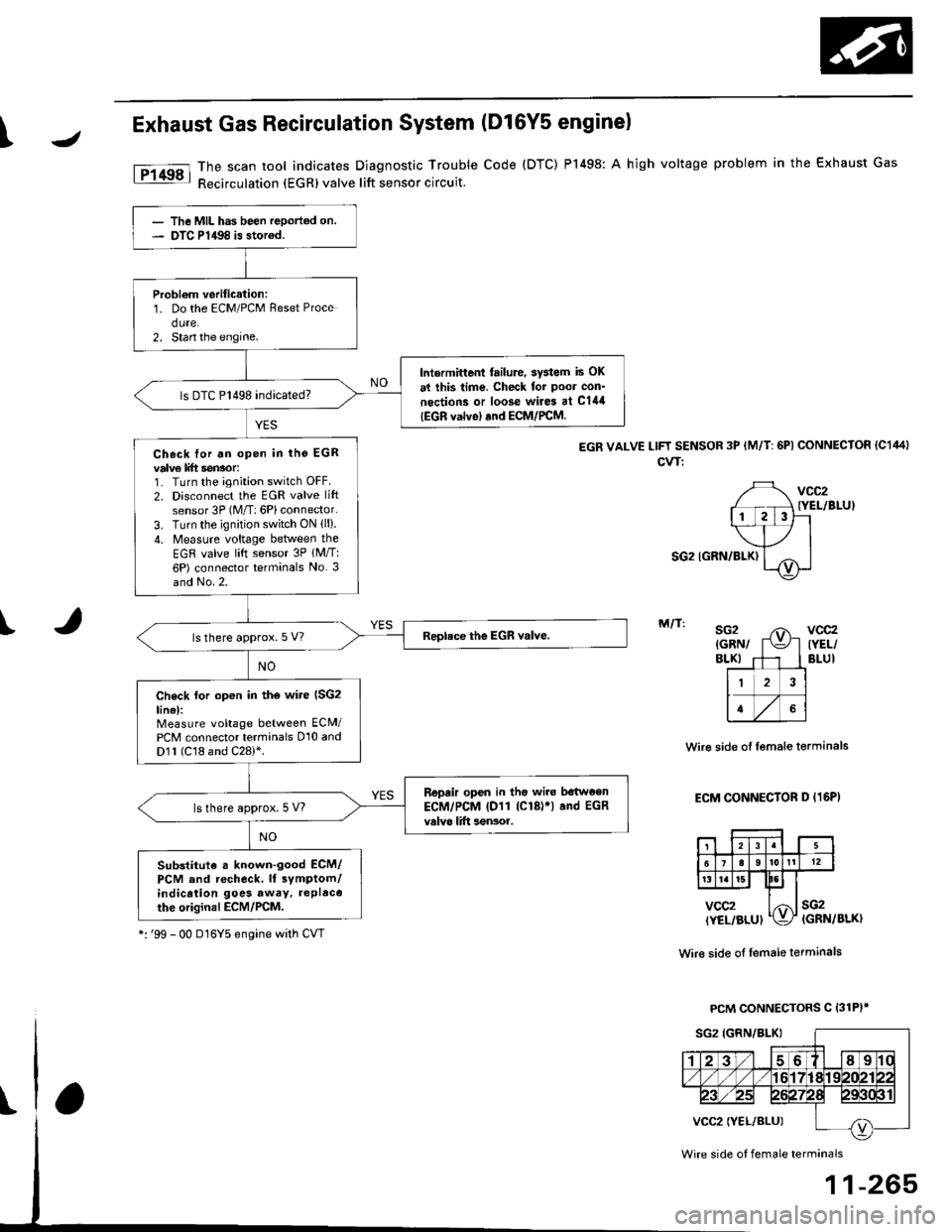

Exhaust Gas Recirculation System

The scan tool indicates Diagnostic Trouble

Recirculation (EGRlvalve lift sensor circuit.

(D16Y5 enginel

Code {DTC) P1498: A high voltage problem in the Exhaust Gas

EGR VALVE LlFf SENSOR 3P {M/T: 6Pl CONNECTOR (C1441

cvT:

vcc2{YEL/BLUI

SG2 IGRN/BLK)

IM/T:sG2{GRN/BLKI

Wir€ side ol lemale terminals

ECM CONNECTOR D (16P)

vcc2(YEL/BLUIsG2(GRN/BLK)

Wir€ side of female terminals

PCM CONNECTORS C 131P)'

Wire side oI female terminals

11-265

- The MIL has been reportod on.- DTC P1498 is storod.

Probl€m verification:1. Do the ECM/PCM Reset Proce

dure.2. Stan the engine.

Intermittent tailure, sy3lem is OK

at lhis time. Check tor poor con'

nections or loose wire3 at C144

|EGR valvel and ECM/PCM.

ls DTC P1498 indicated?

Check for an open in tho EGRvalv6 lift sen3or:1. Turn the ignition switch OFF.

2. Disconnect the EGR valve lift

sensor 3P (M/T: 6Pl connector.

3. Turn the ignition switch ON (ll).

4. Measure voltage between the

EGR valve litt sensor 3P lM/T:6P) connector terminals No. 3and No.2.

ls there approx.5 V?

Check lor op€n in th€ wire (SG2

line):Measure voltage between ECM/PCM connector terminals 010 andD1l (C18 and C28)*.

Repair open in tho wiro betwoen

ECM/PCM lDl1 (Cl8)r) and EGR

valvo lift sensor.ls there approx. 5 V?

Substitute . known-good ECM/PCM and recheck. ll symptom/indicrtion goes away, replacothe original ECM/rcM.

*:'99 - 00 D16Y5 engine with CVT

Page 536 of 2189

1\

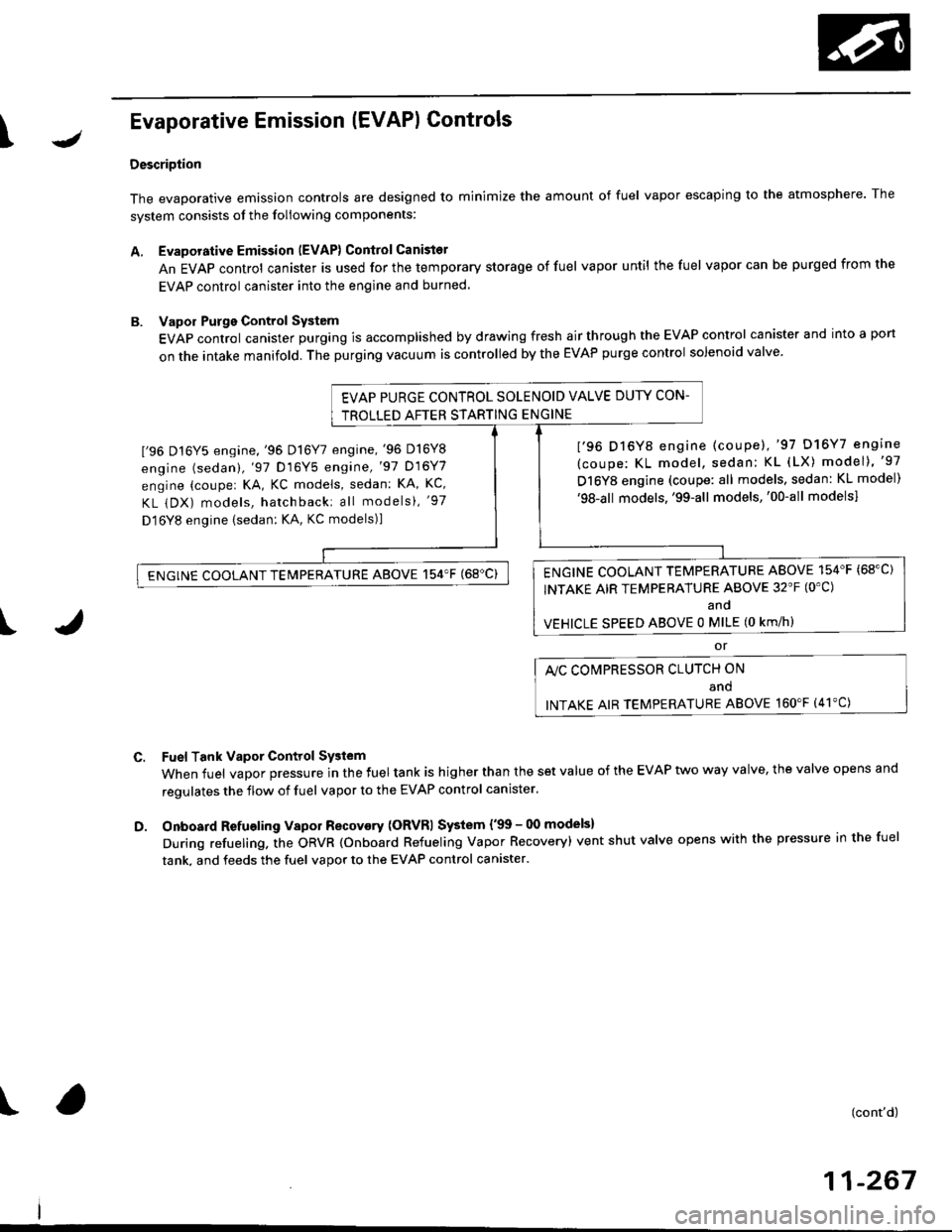

Evaporative Emission (EVAPI Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the foliowing components:

A. Evaporative Emission (EVAP) Control Canisto]

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

I'96 D16Y5 engine,'96 Dl6Y7 engine,'96 D16Y8

engine (sedan),'97 D16Y5 engine,'97 D16Y7

engine (couper KA, KC models, sedan: KA, Kc'

KL iDX) models, hatchback: all models), '97

D 16Y8 engine (sedan: KA, KC models)l

I'96 D16Y8 engine (coupe),'97 D16Y7 engine

(coupe: KL model, sedan: KL (LX) model)"97

D16Y8 engine (coupe: all models, sedan: KL model)'98-all models,'99-all models,'00-all modelsl

I

c.

D.

or

l'lc COMPRESSOR CLUTCH ON

and

INTAKE AIR TEMPERATURE ABOVE 160"F (41'C)

Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

Onboard Refueling Vapor Recovery (ORVRI System {'99 - 00 models}

During refueling. the oRVR {onboard Refueling Vapor Recovery) vent shut valve opens with the pressure in the fuel

tank. and feeds the fuel vapor to the EVAP control canister.

t(cont'd)

11-267

EVAP PURGE CONTROL SOLENOID VALVE DUTY CON-

TROLLED AFTER STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154'F {68"C)

INTAKE AIR TEMPERATURE ABOVE 32'F (O'C)

and

VEHICLE SPEED ABOVE O MILE (O KM/h}

ENGINE COOLANT TEMPERATURE ABOVE 154'F (68'C)

Page 537 of 2189

Emission Control System

Evaporative Emission IEVAPI Controls (cont'd)

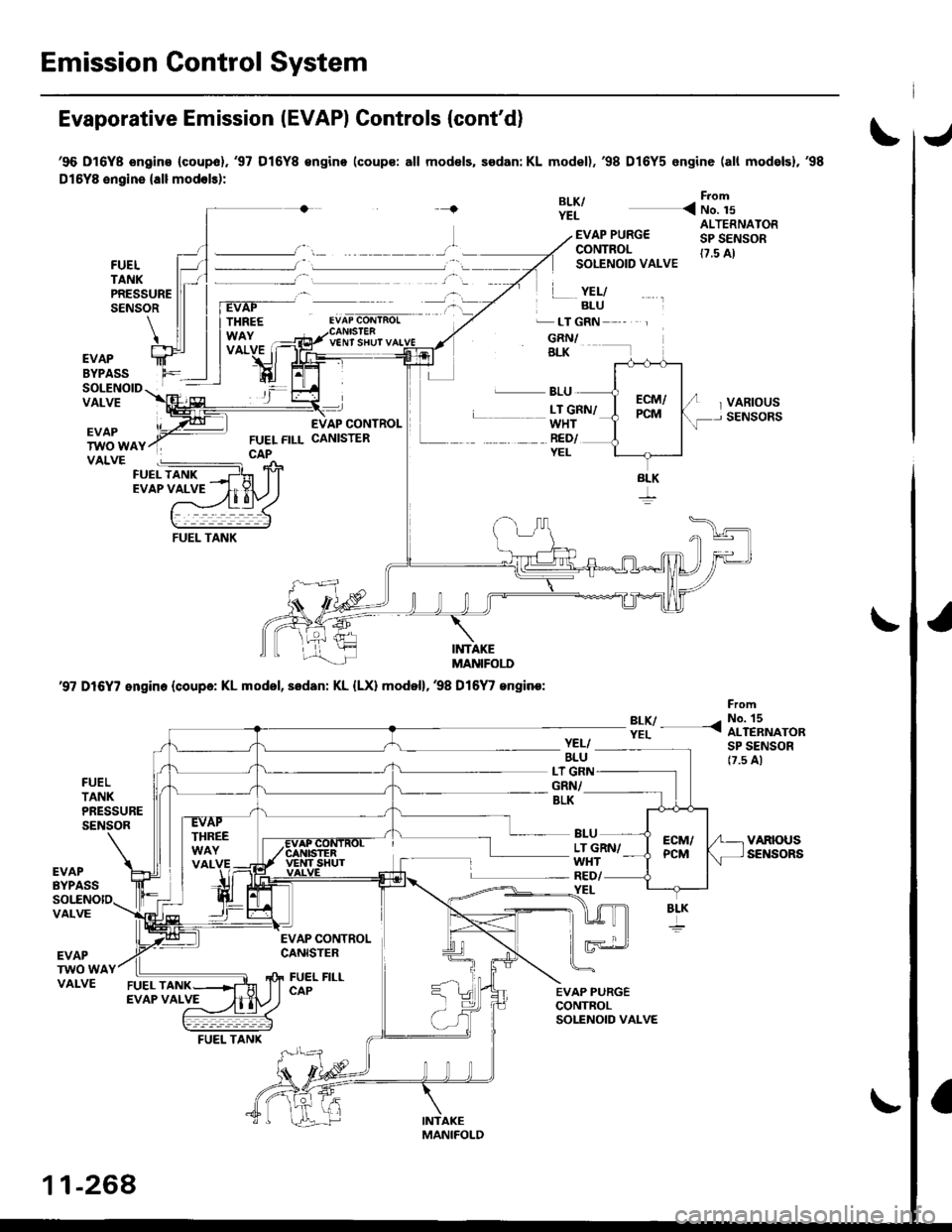

'96 D16Y8 ongins (coupol.'97 D16Y8 €ngino (coups: all mod€ls, sedan: KL model),'98 D16Y5 engine (all mod6lsl,'98

Dl5YB engine {all modols):

{BLK/YEL

From

< No. 15

FUELTANKPRESSURESENSOR

EVAP PURG€CONTROLSOLENOID VALVE

.� LT GRN

GRN/BLK

ALTERNATORSP SENSOR(7.5 A)

VARIOUSSENSORS

YEL/BLU

V€NT SHUT

EVAPBYPASSSOLENOIDVALVEL BLU

WHTRED/YEL

L __ LT GRN/

EVAPTWO WAYVALVE

INTAKEMANIFOI.I'

'97 D16Y7 engin. (coupa: KL model, sedan: KL {LX) model},38 Dl6

/ engine:

?:y- -<

FromNo. 15ALTERNATORSP SENSOR17.5 A)

FUELTANKPRESSURESENSOR

YEL/BLULT G]GRN/BLK

LT GRN/WHT

BLU

YEL

EVAPBYPASSRED/

VALVE

EVAPTWO WAVALVE

EVAP CONTROLCANISTER

FUEL FILLCAP

BLK

11-268

FUEL TANK

Page 539 of 2189

Emission Control System

Evaporative Emission (EVAPI Controls (cont'd)

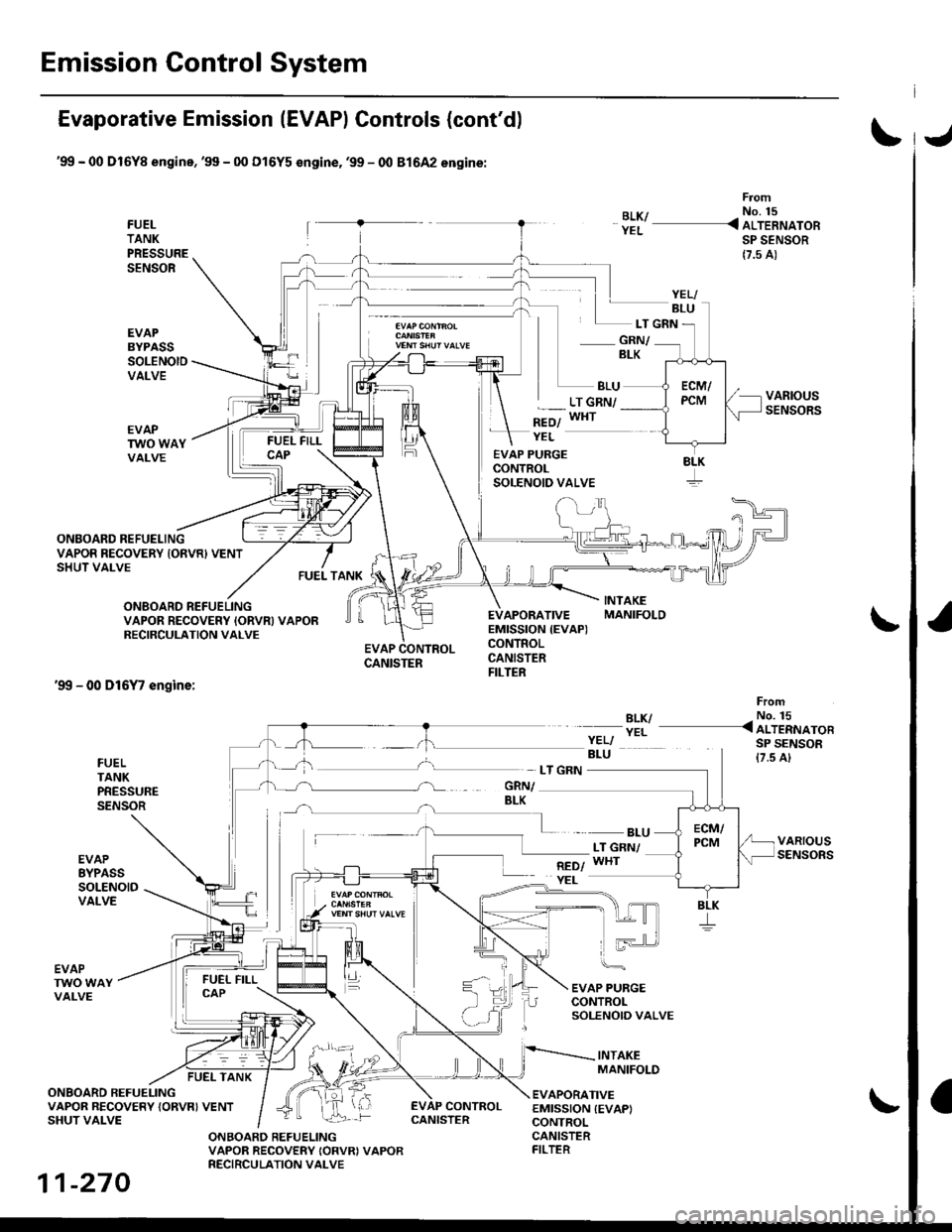

'99 - 00 Dl6Yg engine,'99 - 00 Dl6Y5 €ngine,'99 - 00 81642 engine:

FUELTANKPRESSURESENSOR

EVAPBYPASSSOLENOIDVALVE

From

BLK/ - No. 15

YEL _ ALTERNATORSP SENSOR

{7.5 A)

- GRN/BLK

BLU

*=ol

LT GRN/WHT

ONBOARD REFUELING

FUEL TANK

EVAP PURGECONTROLSOLENOID VALVE

EVAPORATIVEEMISSION {EVAP)CONTROLCANISTERFILTER

YEL

LT GRN

VAPOR RECOVERY IONVR) VENTSHUT VALVE

ONBOARD REFUELINGVAPOR RECOVERY IORVN} VAPORRECIRCULATION VALVE

'99 - 00 D16Y7 engine:

EVAP CONTROLCANISTER

BLK/YEL

FromNo. 15< ALTERNATORSP SENSOR{7.5 A}FUELTANKPRESSURESENSOR

EVAPEYPASSSOLENOIDVALVE

- BLULT GNN/WHT

EVAP PURGECONTROLSOLENOIO VALVE

INTAKEMANIFOLD

EVAPTWO WAYVALVE

FUEL TANK

ONBOARD REFUELINGVAPOR RECOVERY {ORVRI VENTSHUT VALVE

EVAPORATIVEEMISSION {EVAPICONTROL

EVAP CONTROL

ONBOARD REFUELINGVAPOR RECOVERY IORVRI VAPORRECIRCULATION VALVE

CANISTERFILTER

YELI

8LK

11-270

CANISTER

Page 540 of 2189

\J

\

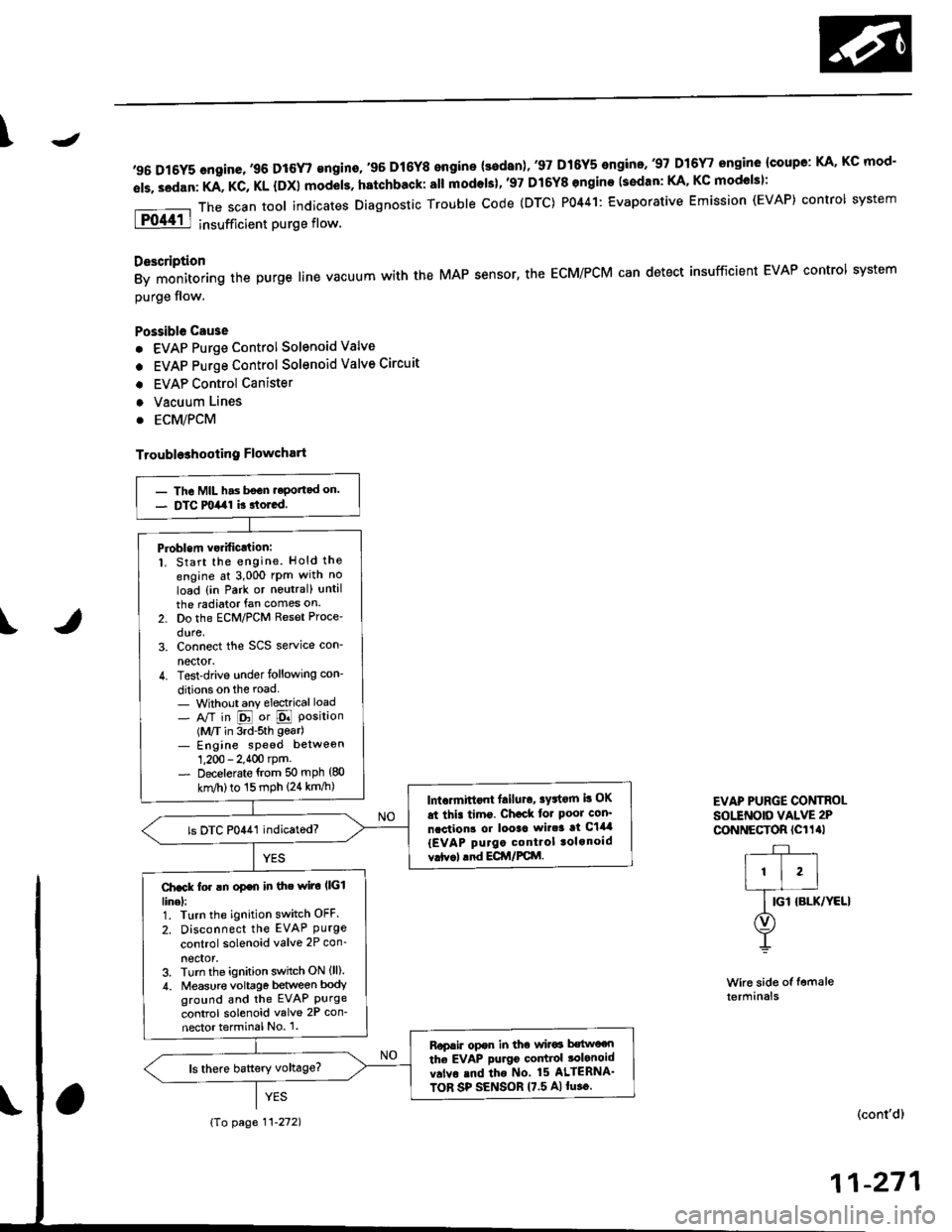

,96 D16Y5 engine,,96 D16r,gngino,,96 Dt6Y8 engine {3edan)' 37 D16Y5 engino..97 D16r, engine {coupe: KA, Kc mod-

els. sedan: KA, KC, KL {DX} models. hatchback: all modols}''97 Dl6Y8 ongine (s€dan: KA' KC mod€lsl:

The scan tool indicates Diagnostic Trouble code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the ECM/PCM can detect insufficient EVAP control system

purge flow.

Possible Cau3e

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. ECM/PCM

Troubl93hooting Flowchart

Wire side of femaleterminals

EVAP PURGE CONTROI-sottNotD vALvE 2P

CoNNECTOR (Cl1al

r-+-r

I'l'l

lG-ro.*l'rr"r

O)

Y

(cont'd)

11-271

- The MIL has bsGn.eportad on.- DTC milal k rtored.

Pioblem vsrificJtion:1. Start the engine. Hold the

engine at 3,000 rPm with no

load {in Park or noutral) until

the radiator fan comes on.

2. Do the ECM/PCM Reset Proce'

dure,3. Connect the SCS service con-

nector.4. Test-drive under following con-

ditions on the road- Without any electrical load- A/T in E or E Position(M/T in 3rd-sth gear)- Engine sPeed betweon

1,200 - 2.400 rpm.- Decelerate {rom 50 mph (80

knl/h)to 15 mph (24 km/h)lntormittont lailuro, sFtorn b OK

at thi. timo. Ch€ck tor Poor con'

ncction3 or looac wir.3 at C144

{EVAP purgo control tolonoid

vrtv.l .nd ECir/FCttl.

ls DTC P0441 indicatod?

Ch.ck fo. !n op€n in the wiro l|(illinel:1. Turn the ignition switch OFF.

2. Disconnect the EVAP Purgecontrol solenoid valve 2P con_

neclor,3. Turn the ignition switch ON (ll)

4. Measur€ voltage between bodyground and the EVAP Purgecontrol solenoid valve 2P con-

nector terminal No 1.

Rop.ir opor in tho wir6 b€two€n

the EVAP purgo codtiol tolonoid

v.lvo rnd tho No 15 ALIERNA'

TOR SP SENSOR 17.5 A)lu.o.

{To page 11-272)

Page 542 of 2189

J\

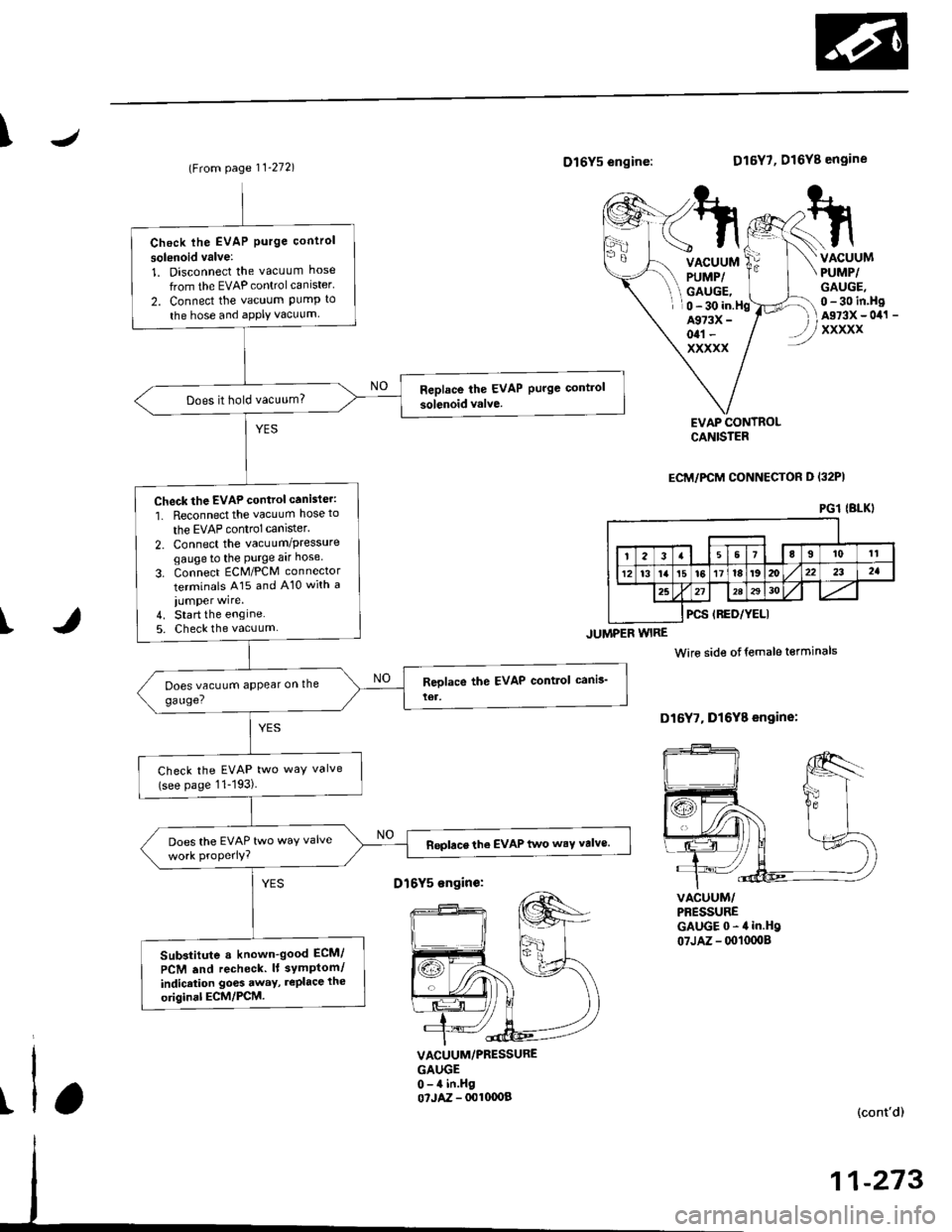

(From page 11-272)D16Y5 engine:

JUMPER WIRE

D16Y7, D16Y8 engine

VACUUMPUMP/GAUGE,

VACUUMPUMP/GAUGE,0 - 30 in.HgAs73x - 0il1 -

xxxxx

0 - 30 in.HgA973X -

otl -

xxxxx

I

EVAP CONTROLCANISTER

ECM/PCM CONNECTOH D I32PI

VACUUM/PBESSUREGAUGE0-4in.Hg07JAZ - 0010008

Wire side otfemale terminals

D16Y7, Dl6Y8 engine:

t

VACUUM/PRESSUREGAUGE0-4 in.Hgo?JAZ - 001fl)OB(cont'd)

11-273

PGl IBLKI

Check lhe EVAP Purge control

solsnoid valve:

1. Disconnect the vacuum hose

from the EVAP controlcanister'

2. Connect the vacuum PumP to

the hose and aPPIY vacuum

Does it hold vacuum?

Check the EVAP control canister:

1. Reconnect the vacuum hose to

the EVAP control canlster.

2. Connect the vacuum/Pressuregaugeto the Purge aar hose

3. Connect ECM/PCM connector

terminals A15 and A10 with a

iumper wire.4. Start the engine5. Check the vacuum

Check the EVAP two way valve(see page 11-193)

Does the EVAP two waY valveReplace the EVAP two wsY valve.

Sub3titute a known-good ECM/

PCM .nd recheck. lt symPtom/

indicrtion go6s away, rePlace the

original ECM/PCM.

D16Y5 sngin€:

Page 543 of 2189

Emission Control System

Evaporative Emission (EVAP) Gontrols (cont'd)

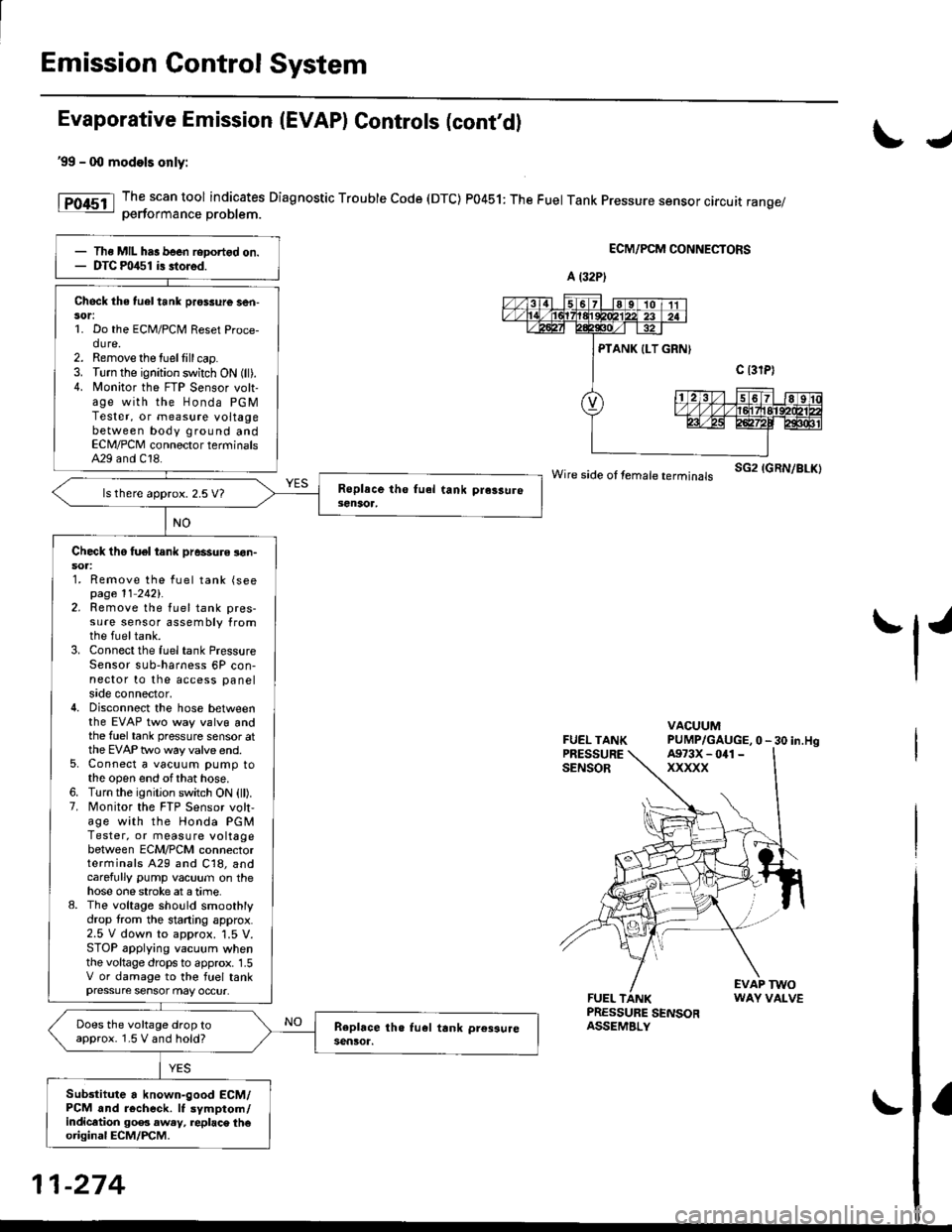

'99 - 0O models only:

The scan tool indicates Diagnostic Trouble Code (DTC) P0451: The Fuel Tank Pressure sensor circuit range/oerformance Droblem.

ECM/PCM CONNECTORS

wire side ot femare terminars sG2 IGRN/BLK)

FUEL TANKPRESSURESENSOR

VACUUMPUMP/GAUGE,0 - 30 in.Hg

FUEL TANKPRESSURE SENSORASSEMBLY

EVAP TWOWAY VALVE

IJ

tl'

Ths MIL has been reDortgd on.DTC m/$1 i3 stored.

Check the tuel tank pros3ure ser|-sor:1. Do the ECM/PCM Reset Proce-dure.2. Remove the tuellill cap.3. Turn the ignition switch ON (ll).4. N4onitor the FTP Sensor volt-age with the Honda PGMTester, or measure voltagebetween body ground andECN4/PCM connector terminalsA29 and C18.

ls there approx. 2.5 V7

Check tho tuel tank pressure !on-soa:1. Remove the fuel tank (seepage 11 2421.2. Remove the fuel tank pres-sure sensor assembly fromthe fueltank.3. Connect the fuel tank PressureSensor sub-harness 6P con-nector to the access panelside connector,4. Disconnect the hose betweenthe EVAP two way valvg andthe fuel tank pressure sensor atthe EVAP two way valve end.5. Connect a vacuum pump tothe open end ofthat hose.6. Turn the ignition switch ON (ll).7. Monitor the FTP Sensor volt,age with the Honda PGMTester, or measure voltagebetween ECM/PCM connectorterminals A29 and C18, andcarefully pump vacuum on thehose one stroke at a time.8. The voltage sho!ld smoothlydrop from the stading approx.2.5 V down to approx. '1.5 V.STOP applying vacuum whenthe voltage drops to approx. 1.5V or damage to the fuel tankpressure sensor may occur.

Does the voltage drop toapprox. 1.5 V and hold?

Sub3titute a known-good ECM/PCM and r6check. It symptom/indicltion 90e3 aw.y, replac\. th€original ECM/PCM.

A (32P)

A973X - 041 -

xxxxx

11-274

Page 546 of 2189

\

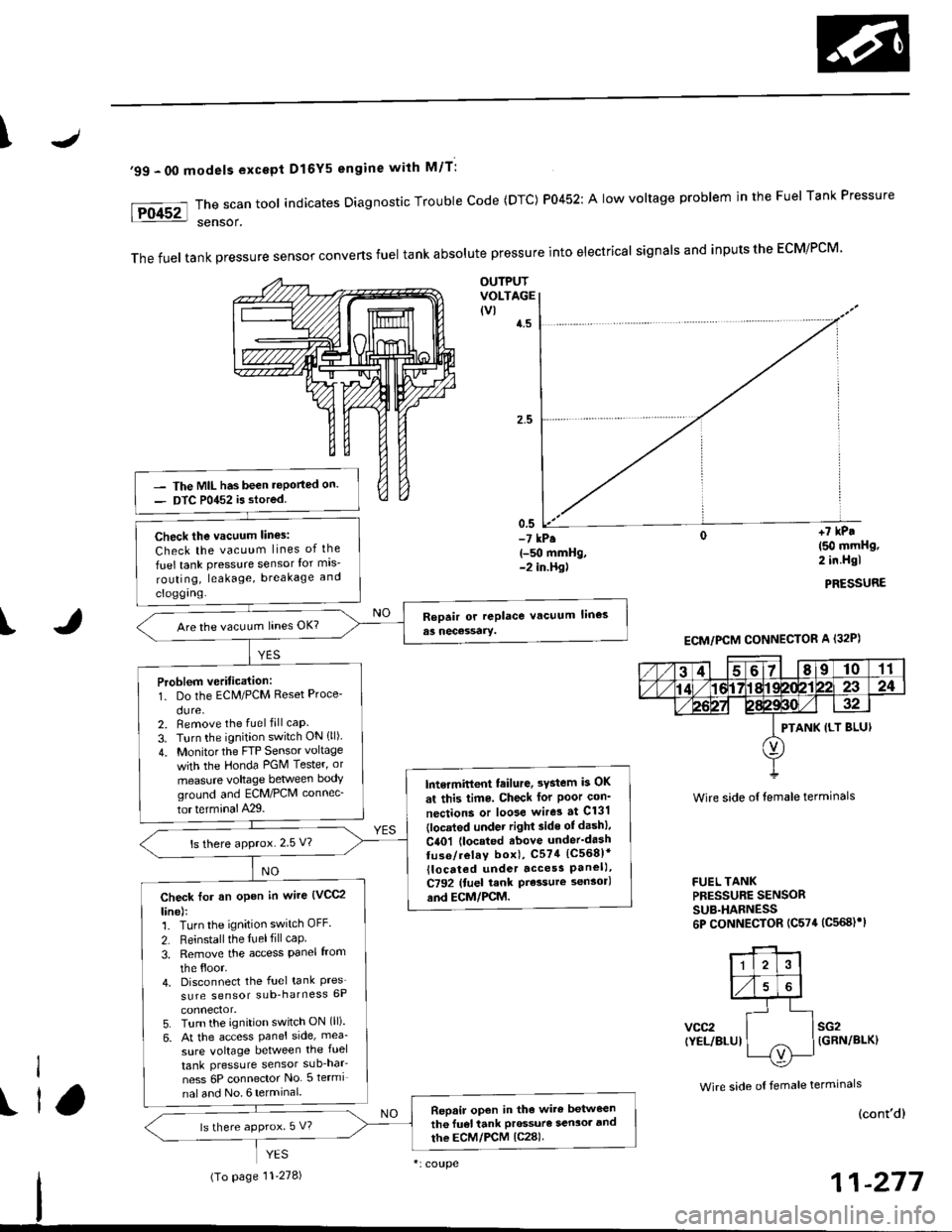

'99 - 00 models excepi Dl6Y5 engine with M/T:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensor.

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM

OUTPUTVOLTAGE(vlt.5

0.5-7 kP.(-g) mmHg,-2 in.Hgl

+7 kP.

150 mmHg,2 in.Hgl

PRESSURE

I

Wire side of lemale terminals

FUEL TANKPRESSURE SENSORSUB.HARNESS6P CONNECTOR (C574 (C568)rl

vcc2(YEL/BLUIsG2{GRN/BLK}

Wire side o{ temale terminals

The MIL has been .eported on.

DTC P0452 is stored

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor lor mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum hnes OK?

Problem veritication:1. Do the ECM/PCM Reset Proce-

du re,2. Bemove the fuel fill caP.

3. Turn the ignition switch ON {ll)

4. Monitorthe FTP Sensor voltage

with the Honda PGM Tester' or

measure voltage between body

groLrnd and ECM/PCM connec_

tor terminalA29.

lntermitlent tailure, 3Ystem b OK

at this time. Check for Poor con'

nections or loose wire3 at C131

{located under right side of dash},

C401 {located above under'dash

tuse/relay box), C574 (C568)*

llocdted under access Panel),C792 (tuel rank Prcssure sensorl

and ECM/PCM.

ls there approx.2 5 V?

Check for an open in wire {VCC2

line):1. Turn the ignition switch OFF.

2. Reinstall the ltrel fill caP

3, Remove the access Panel from

the floor.4. Disconnect the fuel tank Pres'sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll).

6. At the access Panel side, mea_

sure voltage between the fuel

tank Pressure sensor sub-nar-

ness 6P connector No 5termi

nal and No. 6 termlnal.

Repair open in tho wire between

th6 fu€l tank Prossuro sen3oa and

the ECM/PCM lc28).ls there approx 5 V?

ECM/PCM CONNECTOR A (32P)

PTANK {LT BLUI

I

ll

(To page '11-278)

(cont'd)