angle HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1125 of 2189

)

Suspension

Special Tools ............. 18-2

Component Locations

lndex ,,.............. ...... f8-3

Wheel Alignment

Caster .............. ....... 18-4

Camber .................. l8-4

Front Toe Inspection/

Adiustment ........ 18-5

Rear Toe lnspection/

Adiustment ........ 18-5

Turning Angle Inspection ................ 18-6

Wheel/Hub Inspection

Bearing End P|ay .............................. l8-7

Wheel Runout ....... 18-7

Front Suspension

Suspension Arms Replacement

('96 - 99 modelsl .......................... 18-8

Suspension Arms Replacement

('99 2D Si and Si-R models) ........ 18-9

Knuckle/Hub Replacement ............. 18-10

Lower Ball Joint Replacement ....... 18-16

Ball Joint Boot Replacement .......... 18-17

Front Damper

Removal ................. 18-17

Disassembly/1nspection .................. 18-18

Reassembly ........... 18-19

lnstallation ............. 18-19

Rear Suspension

Suspension Arms Replacement

('96 - 99 models) ....................,..... 18-21

Suspension Arms Replacement

('99 2D Si and Si-R models) ........ 1A-22

Hub Bearing Unit Replacement ...... 18-23

Upper Arm Eushing

Replacement .....18-25

Rear Damper

Removal ................. 18-26

Disassembly/|nspection ............. ..... 1A-27

Reassembly ........... 18-28

lnstallation ............. 18-29

lr

Page 1128 of 2189

Wheel Alignment

,f,

Caster

NOTE: For proper inspection/adjustment of the wheel

alignment check and adjust the following before check-

ing the alignment.

. Check that the suspension is not modified.

. Check the tire size and tire pressure.

. Check the runout of the wheels and tires.

. Check the suspension ball ioints. {Hold a wheel with

your hands and move it up and down and right and

left to check for wobbling.)

Inspection

NOTE: Use commercia lly-available computerized four

wheel alignment equipment to measure wheel align-

ment {caster. camber, toe, and turning angle). Follow

the equiDment manufacturer's instructions.

Check the caster angle.

Caster angle: 1',10' I 1'

lf out of specification, check for bent or damaged

suspensron components.

2.

1.

18-4

Camber

lnspection

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the camber angle.

Camber angle:

Front: 0'00' j 1"

Rear:-1"11"

2. lf out ol specification, check for bent or damaged

suspensron components.

Page 1129 of 2189

?

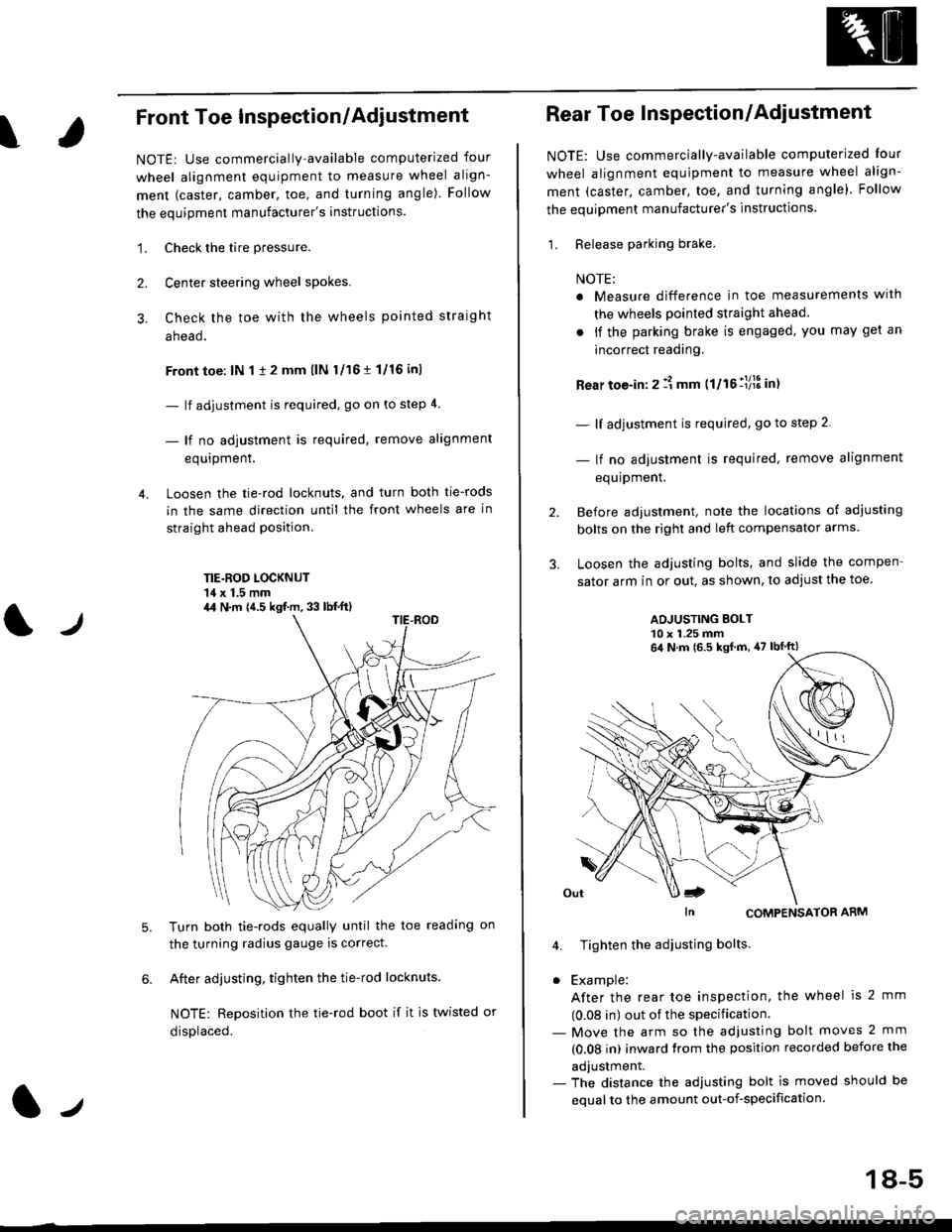

Front Toe Inspection/Adiustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the tire pressure.

Center steering wheel spokes.

Check the toe with the wheels pointed straight

a head.

Front toe: lN 1 1 2 mm llN l/16 r 1/16 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equrpmenr.

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are in

straight ahead position.

TIE.ROD LOCKNUT'14 x 1.5 mm

4.

tJ

6.

Turn both tie-rods equally until the toe readang on

the turning radius gauge is correct.

After adjusting, tighten the tie-rod locknuts.

NOTE: Reposition the tie-rod boot if it is twisted or

displaced.

4,1 N.m {4.5 kgf.m, 33 lb{.ft)

2.

Rear Toe Inspection/Adiustment

NOTE: Use commercially-available computerjzed Iour

wheel alignment equjpment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Release parking brake.

NOTE:

a Measure difference in toe measurements wlth

the wheels pointed straight ahead.

. if the parking brake is engaged, you may get an

incorrect readang,

Rear toe-in: 2 11 mm ttltollllS int

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adiusting

bolts on the right and left compensator arms

Loosen the adjusting bolts, and slide the compen

sator arm in or out. as shown, to adjust the toe

ADJUSTING BOLT10 x 1.25 mm

In CoMPENSAToR ARM

4. Tighten the adiusting bolts

. Example:

After the rear toe inspection, the wheel is 2 mm

(0.08 in) out of the specification.- Move the arm so the adjusfing bolt moves 2 mm

(0.08 in) inward trom the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

64 N.m 16.5 ksf m, 47 lbtft)

18-5

Page 1130 of 2189

Wheel Alignment

Turning Angle Inspection

NOTEr Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

'1. Turn the wheel right and left while applying the

brake, and measure the turning angle of both

wneets.

Turning angle:

lnward wheel: 39'50'

Outwald wheel (ref erencel: 33'10'

2.lf the turning angle

check for bent or

nents,

is not within the specifications,

da m aged suspension compo-

18-6

Page 1149 of 2189

T

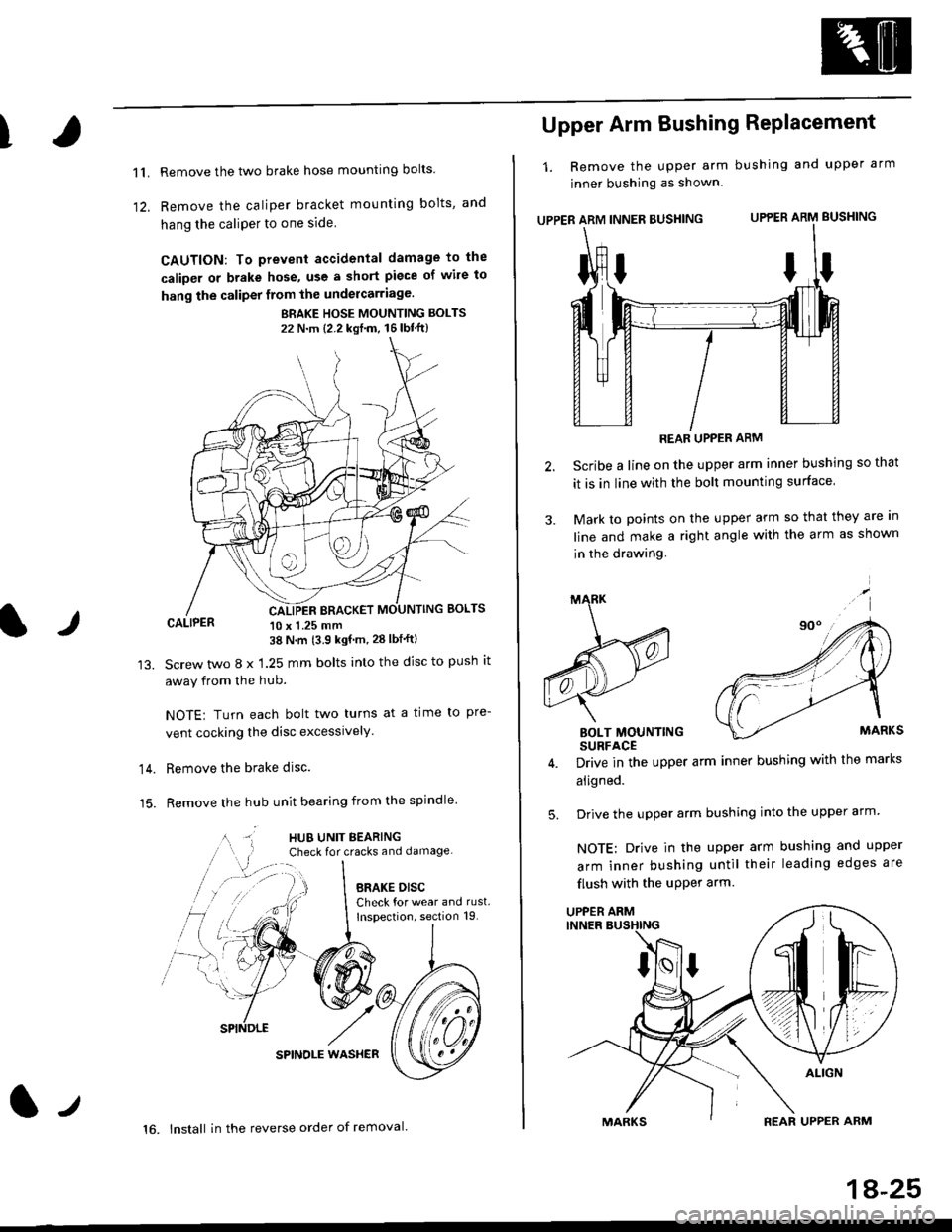

11.

1)

Remove the two brake hose mounting bolts

Remove the caliper b.acket mounting bolts, and

hang the caliPer to one side

CAUTION: To prevent accidental damage to the

caliper or brake hose, use a short piece of wile to

hang the caliper from the undercarriage.

BRAKE HOSE MOUNTING BOLTS

22 N'm {2.2 kgf'm, 16lbt"ft}

CALIPER 10 x 1.25 mm38 N'm (3.9 kgf'm, 28 lbf'ftl

Screw two 8 x 1.25 mm bolts into the disc to push it

away from the hub.

NOTE: Turn each bolt two turns at a time to pre-

vent cocking the disc excessively.

Remove the brake disc.

Remove the hub unit bearing from the spindle

SPINOLE WAS}IER

lr

14.

15.

lt

16. lnstall in the reverse order of removal.

1A-25

Upper Arm Bushing RePlacement

1. Remove the upper arm bushing and upper arm

jnner bushing as shown

UPPER ARM INNER BUSHING UPPER ARM BUSHING

REAR UPPER ARM

Scribe a line on the upper arm inner bushing so that

it is in line with the bolt mounting surface

Mark to points on the upper arm so that they are In

line and make a right angle with the arm as shown

in the drawing.

BOLT MOUNTINGSURFACE

Drive in the upper arm inner bushing with the marks

aligned.

Drive the upper arm bushing into the upper arm

NOTE: Drive in the upper arm bushing and upper

arm inner bushing until their leading edges are

flush with the uPPer arm

ttI

5.

UPPER ARM

Page 1252 of 2189

Doors

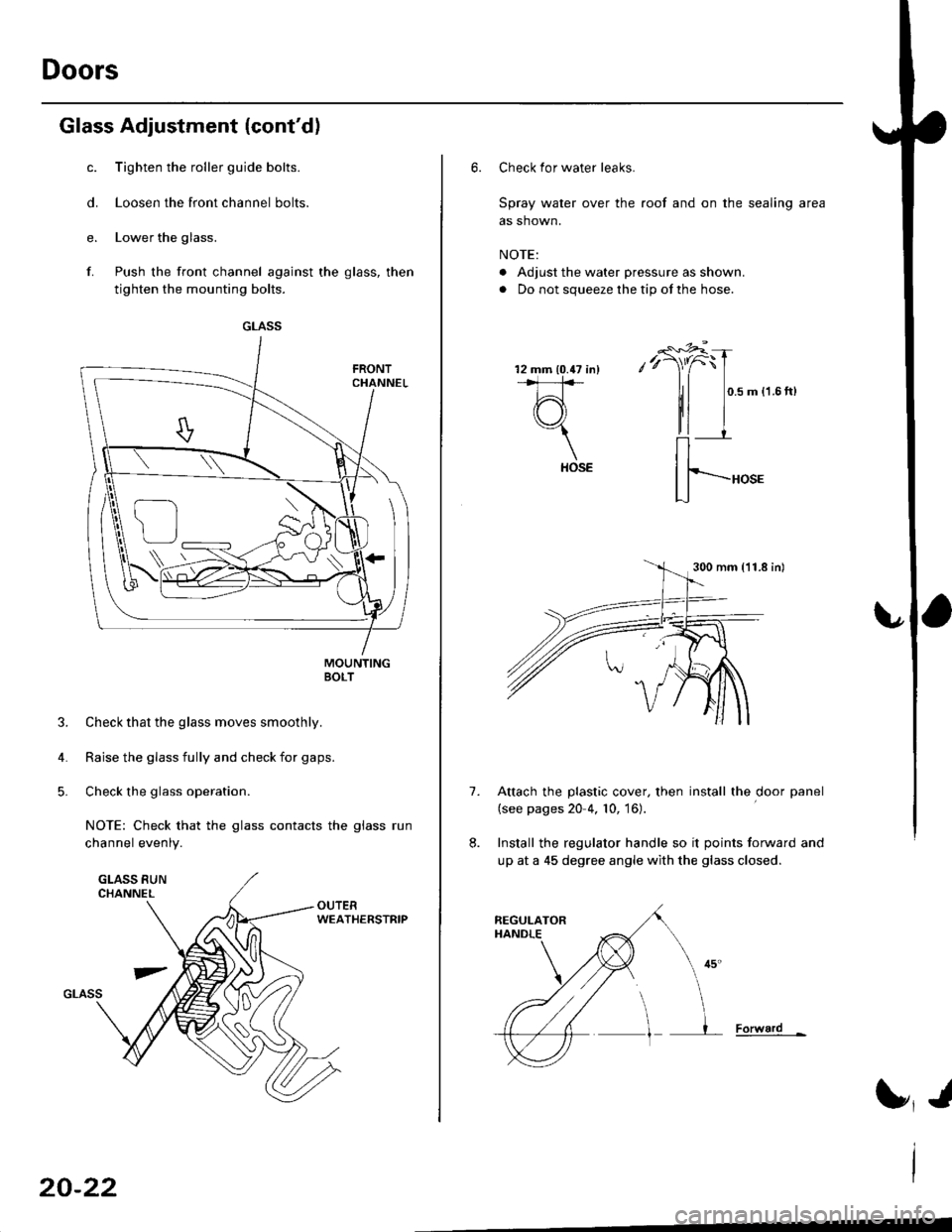

Glass Adjustment {cont'd)

c. Tighten the roller guide bolts.

d. Loosen the front channel bolts.

e. Lower the glass.

f. Push the front channel against the glass, then

tighten the mounting bolts.

MOUNTINGBOLT

3. Check that the glass moves smoothly.

4. Raise the glass fully and check for gaps.

5. Check the glass operation.

NOTE: Check that the glass contacts the glass run

channel evenly.

WEATHERSTRIP

GLASS

U

-\,

20-22

6. Check for water leaks.

Spray water over the roof and on the sealing area

as shown.

NOTE:

. Adjust the water pressure as shown.

. Do not squeeze the tip of the hose.

0.5 m {1.6ft)

HOSE

Attach the plastic cover, then install the door panel

(see pages 20 4, 10, 16).

Install the regulator handle so it points forward and

up at a 45 degree angle with the glass closed.

Forward -

1.

HOSE

300 mm {11.8 in)

Page 1261 of 2189

3

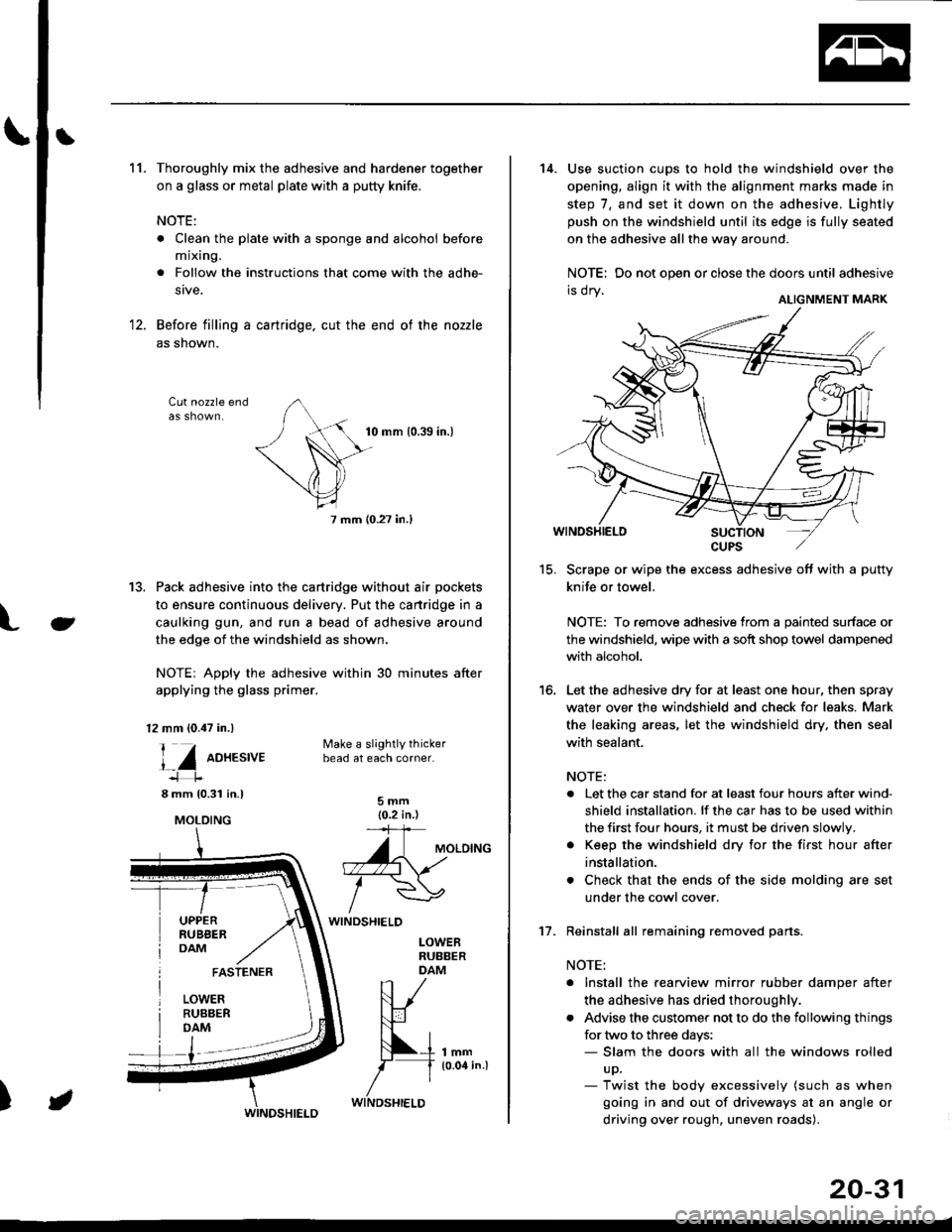

11.Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that come with the adhe-

stve.

Before filling a cartridge. cut the end of the nozzle

as shown.

Cut nozzle end

tu

10 mm 10.39 in.)

7 mm (0.27 in.l

13. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive around

the edge of the windshield as shown.

NOTE: Apply the adhesive within 30 minutes after

applying the glass primer.

12 mm (0.47 in.)

l_Z oo*.t,ut

8 mm 10.31 in.l

UPPERRUBBERDAM

Make a slightly thickerbead at each corner.

5mm(0.2 in )='+

A\uloto^o. -.\

/wWINDSHIELD

LOWEBRUBBERDAM

lmm10.04 in.l

FASTENER

LOWERRUBBERDAM

)

MOLDING

WINDSHIELD

20-31

15.

16.

14. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly

push on the windshield until its edge is fully seated

on the adhesive all the way around.

NOTE: Do not open or close the doors until adhesive

ri vI Y ALTGNMENT MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface or

the windshield, wipe with a soft shop towel dampened

with alcohol.

Let the adhesive dry for at least one hour, then spray

water over the windshield and check for leaks. Mark

the leaking areas, let the windshield dry, then seal

with sealant.

NOTE:

. Let the car stand for at least four hours after wind-

shield installation. lf the car has to be used within

the first four hours, it must be driven slowly.

. Keep the windshield dry for the first hour after

installation.

. Check that the ends of the side molding are set

under the cowl cover.

Reinstall all remaining removed parts.

NOTE:

. Install the rearview mirror rubber damper after

the adhesive has dried thoroughl',.

. Advise the customer not to do the following things

for two to three days:- Slam the doors with all the windows rolled

up.- Twist the body excessively (such as when

going in and out of driveways at an angle or

driving over rough, uneven roads).

't7.

Page 1265 of 2189

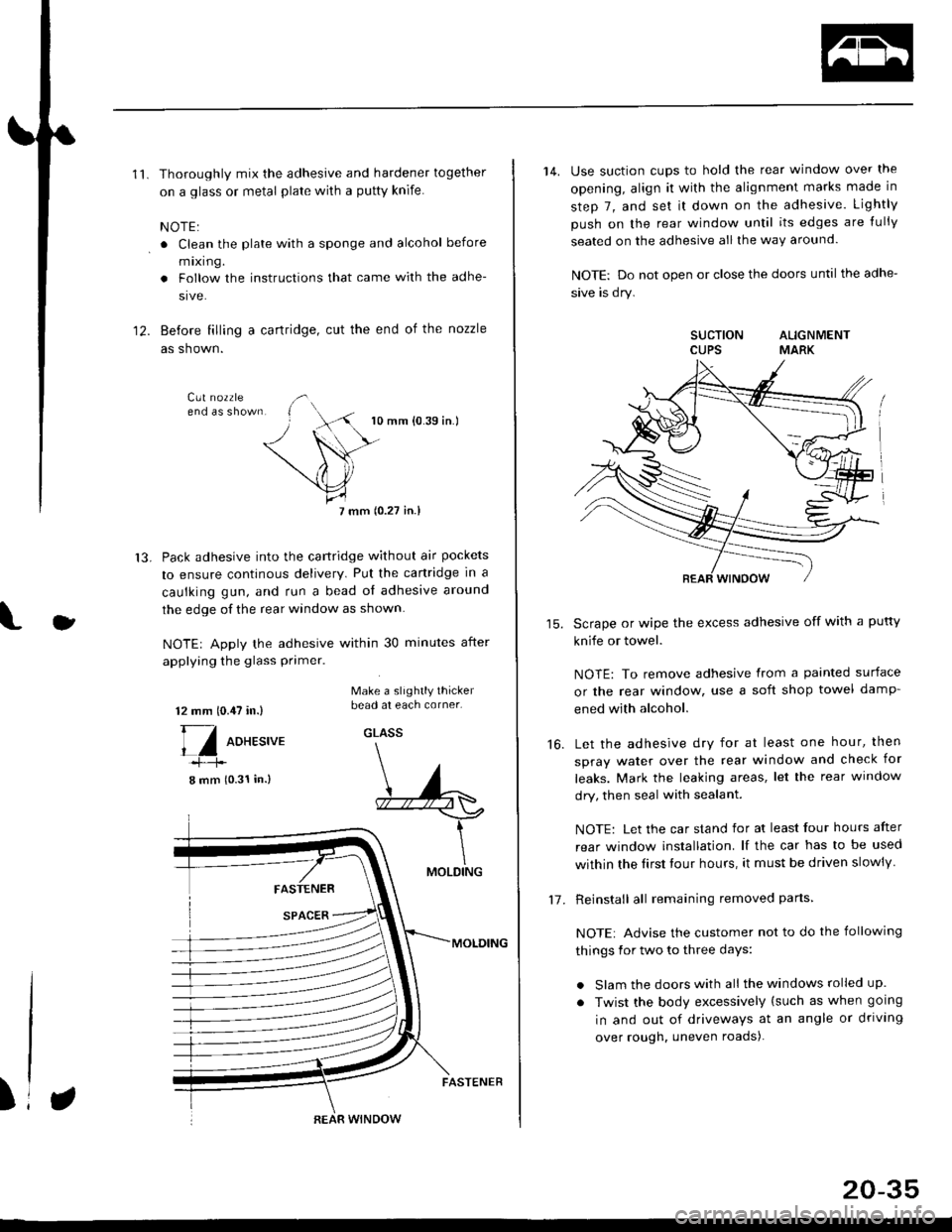

'11.Thoroughly mix the adhesive and hardener together

on a glass or metal plate wilh a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that came with the adhe-

sive.

Before filling a cartridge, cut the end of the nozzle

as shown.

10 mm {0.39 in.)

7 mm (0.27 in.l

Pack adhesive into the cartridge without air pockets

to ensure continous delivery. Put the canridge in a

caulking gun, and run a bead ol adhesive around

the edge of the rear window as shown.

NOTE| Apply the adhesive within 30 minutes after

applying the glass primer.

12.

13.

J

12 mm 10.,U in.)

[/ oo*r.,u.

8 mm (0.31 in.)

Make a slightly thickerbead at each corner.

GLASS

FASTENER

SPACER

MOLDING

MOLDING

)REAR WINDOW

FASTENER

20-35

14. Use suction cups to hold the rear window over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly

push on the rear window until its edges are {ully

seated on the adhesive all the way around.

NOTE: Do not open or close the doors until the adhe-

sive is dry.

SUCTION ALIGNMENTCUPS MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface

or the rear window, use a soft shop towel damp-

ened with alcohol.

Let the adhesive dry for at least one hour, then

spray water over the rear window and check for

leaks. Mark the leaking areas, let the rear window

dry, then seal with sealant.

NOTE: Let the car stand for at least four hours after

rear window installation. lf the car has to be used

within the Iirst tour hours, it must be driven slowly

Reinstall all remaining removed parts

NOTE: Advise the customer not to do the following

things for two to three days:

. Slam the doors with all the windows rolled up.

. Twist the body excessively (such as when going

in and out of driveways at an angle or driving

over rough. uneven roads).

16.

1-7 .

Page 1270 of 2189

Rear WindowOuarter Glass

Installation {cont'd)

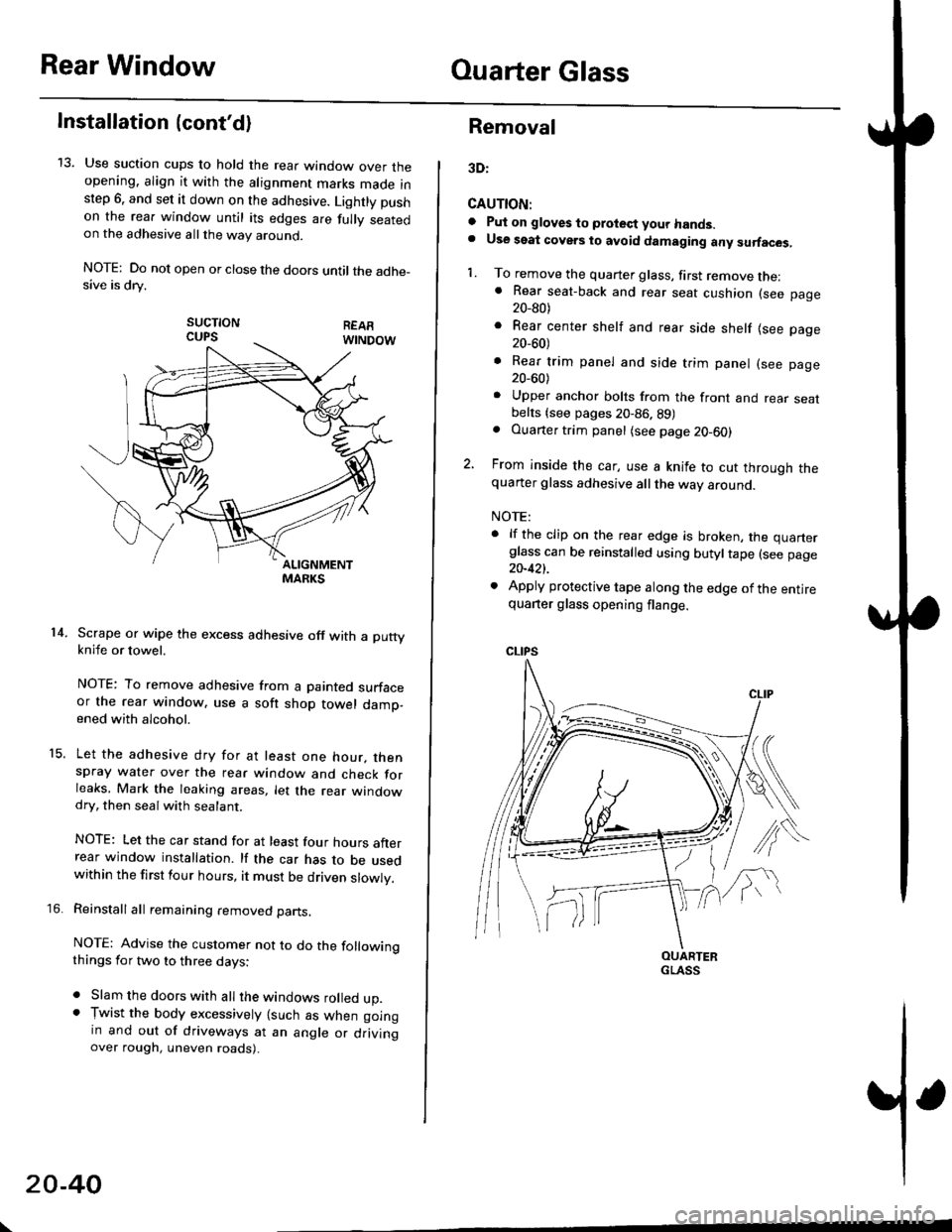

13. Use suction cups to hold the rear window over theopening. align it with the alignment marks made inslep 6. and set it down on the adhesive. Lightly pushon the rea. window until its edges are fully seatedon the adhesive allthe way around.

NOTE: Do not open or close the doors until the adhe_sive is drv.

sucTtoNCUPS

Scrape or wipe the excess adhesive off with a puttyknife or towel.

NOTE: To remove adhesive from a painted surfaceor the rear window. use a soft shop towel damp-ened with alcohol.

Let the adhesive dry for at least one hour. thenspray water over the rear window and check forleaks, Mark the leaking areas, let the rear windowdry, then seal with sealant.

NOTE: Let the car stand for at least four hours afterrear window installation. lf the car has to be usedwithin the first four hours, it must be driven slowly.

Reinstall all remaining removed parts.

NOTE: Advise the customer not to do the followingthings for two to three days:

. Slam the doors with all the windows rolled up.. Tr,vist the body excessively lsuch as when goingin and out of driveways at an angle or drivingover rough, uneven roads).

14.

15.

\

20-40

Removal

3D:

CAUTION:

a Pul on gloves to protect your hands.. Use seat covers to avoid damaging any surfaces,

1. To remove the quarter glass, first remove the:. Rear seat-back and rear seat cushion (see page20_80)

. Rear center shelf and rear side shelf lsee page20_60)

. Rear trim panel and side trim panel (see page20_60)

. Upper anchor bolts from the front and rear seatbelts {see pages 20-86. 89). Ouarter trim panel (see page20-60)

2, From inside the car, use a knife to cut through thequarter glass adhesive all the way around.

NOTE:

. lf the clip on the rear edge is broken, the quarterglass can be reinstalled using butyltape (see page20-421.

. Apply protective tape along the edge of the entirequarter glass opening flange.

OUARTERGLASS

Page 1274 of 2189

Ouarter Glass

Installation (cont'd)

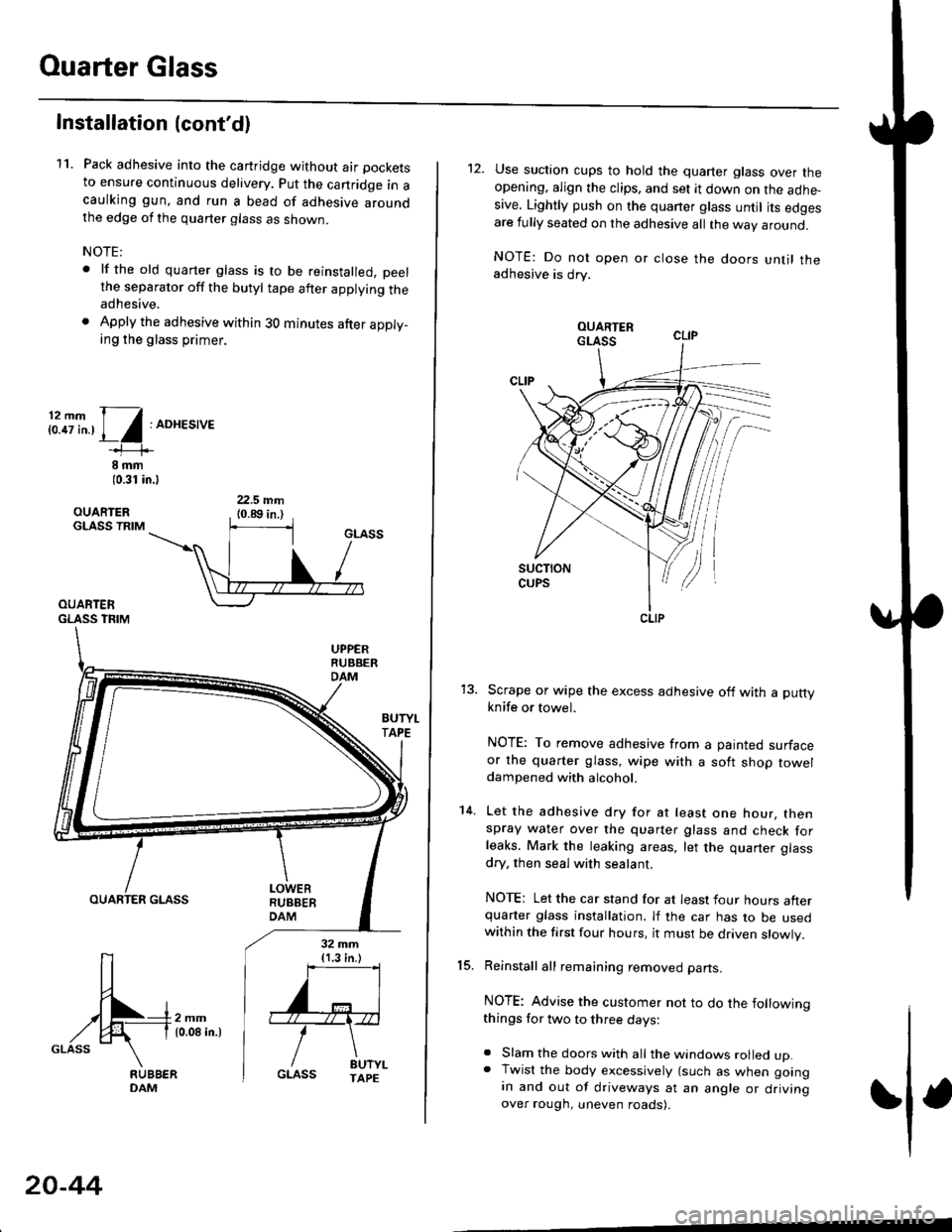

11. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. put the canridge in acaulking gun, and run a bead of adhesive aroundthe edge of the quarter glass as shown.

NOTE:

. lf the old quarter glass is to be reinstalled, peelthe separator off the butyl tape after applying theadhesive.

. Apply the adhesive within 30 minutes after apply_ing the glass primer.

i:.8i".,1/:ADHES,'E

8 rnm(0.31 in.l

OUARIERGLASS TRIM

OUARTERGLASS TFIM

BUTYI.TAPE

OUARTER GLASS

[-4m,^,GLASS \

32 mm{1.3 in.)

''='I

'"r"\

/ drt".GLASS TAPE

20-44

12. Use suction cups to hold the quarter glass over theopening, align the clips, and set it down on the adhe-sive. Lightly push on the quaner glass until its edgesare fully seated on the adhesive all the way around.

NOTE: Do not open or close the doors until theadhesive is drv.

Scrape or wipe the excess adhesive off with a puttyknife or towel.

NOTE: To remove adhesive from a painted surfaceor the quarter glass, wipe with a soft shop toweldampened with alcohol.

Let the adhesive dry for at least one hour, thenspray water over the quarter glass and check forleaks. Mark the leaking areas, let the quarter glass

dry, then seal with sealant.

NOTE: Let the car stand for at least four hours afterquarter glass installation. lf the car has to be usedwithin the first four hours, it must be driven slowly.

Reinstall all remaining removed parts.

NOTE: Advise the customer not to do the followingthings for two to three days:

. Slam the doors with all the windows rolled up.. Twist the body excessively (such as when goingan and out of driveways at an angle or drivingover rough, uneven roads).

15.

14.

CLIP