left turn HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 911 of 2189

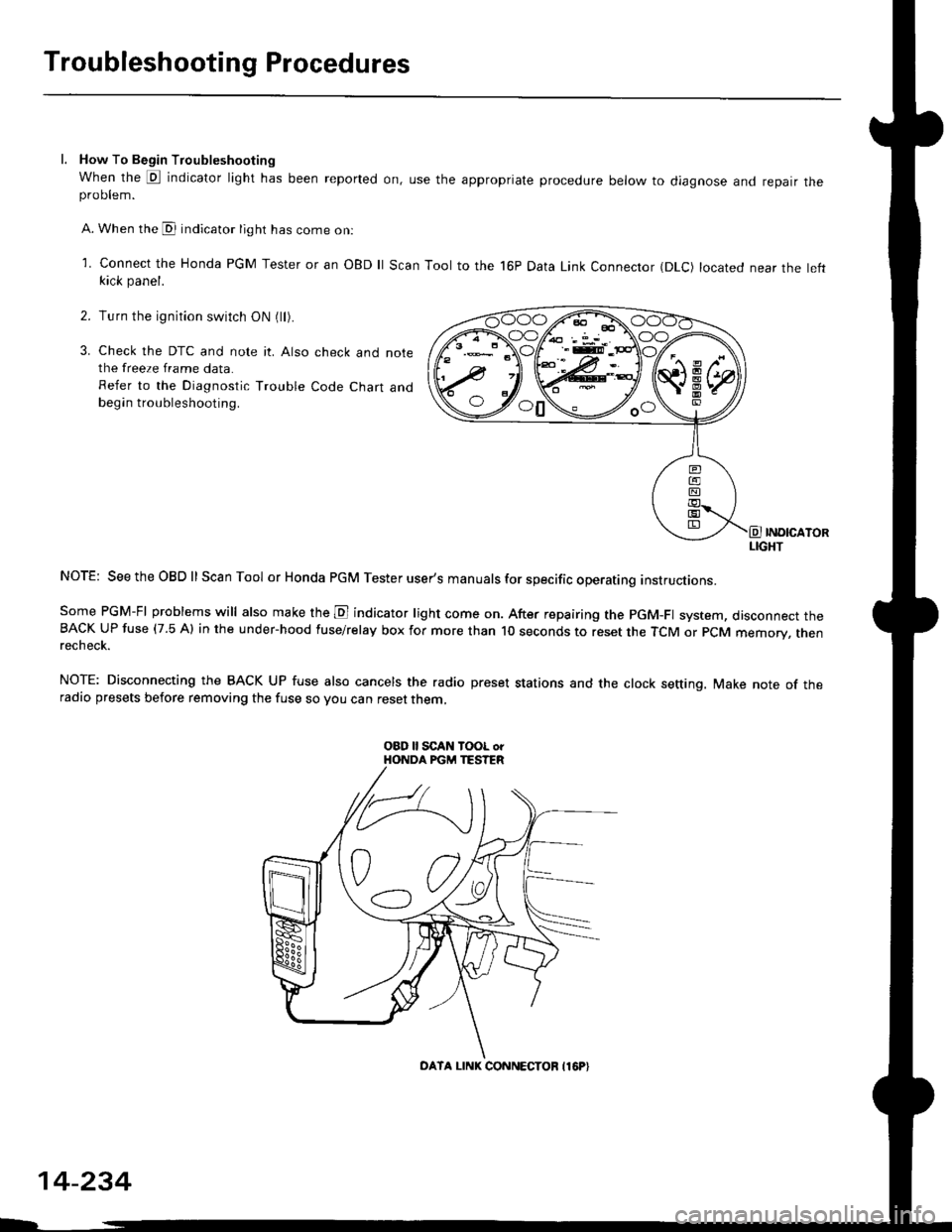

Troubleshooting Procedures

l. How To Begin Troubleshooting

When the E indicator light has been reported on, use the appropriate procedure below to diagnose and repatr theproDlem.

A. When the @ indicator light has come on:

l connect the Honda PGM Tester or an oBD ll Scan Tool to the 16P Data Link Connector (DLc) located near the leftkick panel.

Turn the ignition switch ON (ll).

Check the DTC and note it. Also check and notethe freeze frame data.

Refer to the Diagnostic Trouble Code Chart andbegin troubleshooting.

INOICATORLIGHT

NOTE: SeetheOBDll Scan Tool or Honda PGM Tester user's manuals for specific operating instructions.

Some PGM-FI problems will also make the E indicator light come on. After repairing the pGM-Fl system, disconnect theBACK UP fuse (7.5 Al in the under-hood fuse/relay box for more than l0 seconds to reset the TCM or PCM memory, rnenrecheck.

NOTE: Disconnecting the BACK UP fuse also cancels the radio preset stations and the clock setting. Make note of theradio presets before removing the fuse so you can reset them,

2.

3.

o0\e--loo

OATA LINK CONNECTOB I16P}

14-234

Page 983 of 2189

Transmission

Removal (cont'd)

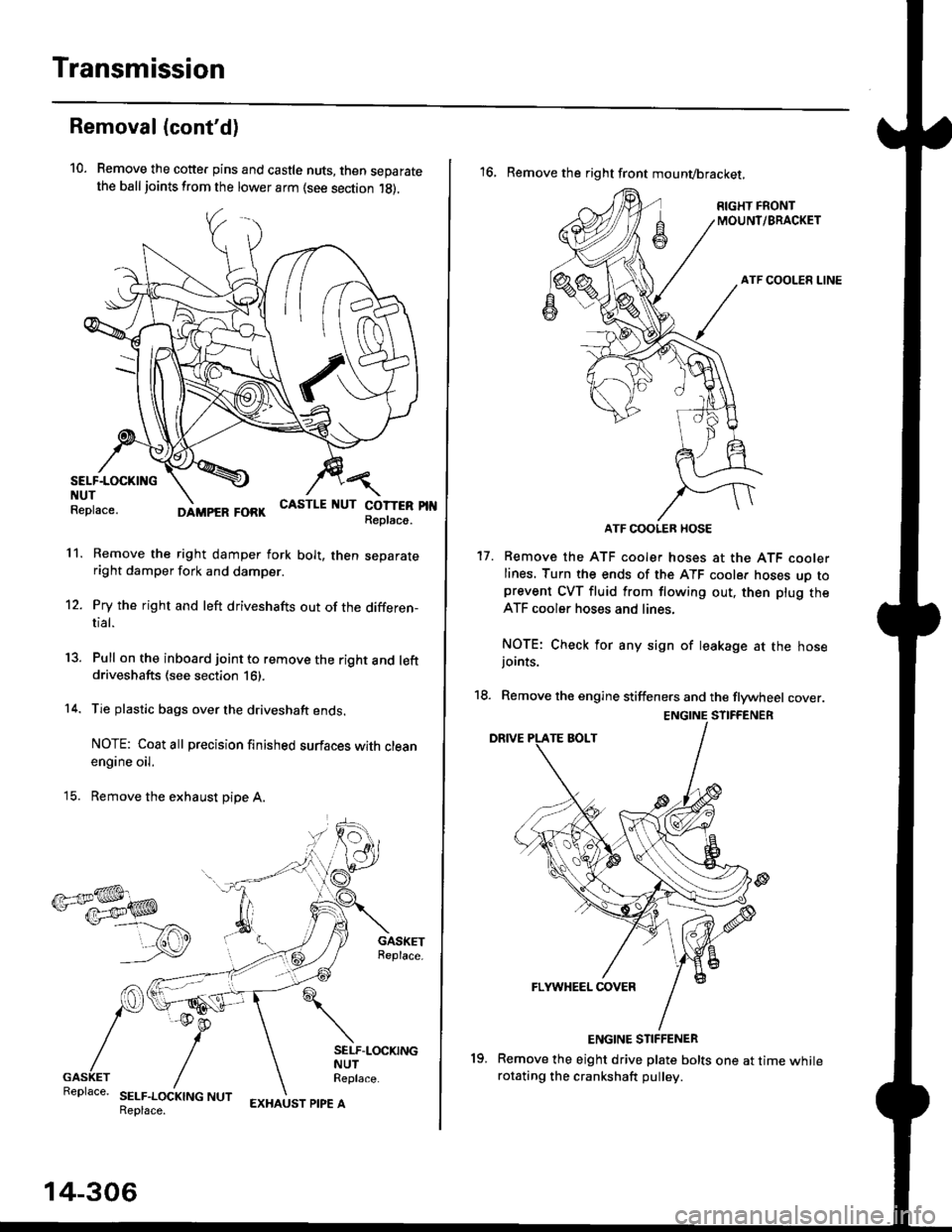

10. Remove the cotte. pins and castle nuts, then separatethe ball joints from the lower arm (see section 1g).

SELF-LOCKING -=V,

NUT \Replace. oitupea rOax

Remove the right damper fork bolt, then separateright damper fork and damper.

Pry the right and left driveshafts out of the differen-tial.

Pull on the inboard joint to remove the right and leftdriveshafts (see section 16).

Tie plastic bags over the driveshaft ends.

NOTE: Coat all precision finished surfaces with cleanengine oil.

Remove the exhaust pipe A.

/\<,\CASTLE I{UT COTTERReplac6.

't 1.

't2.

tJ.

14.

q.

SELF.LOCKINGNUTReplace.

SELF.LOCKING NUTReplace.

14-306

EXHAUST PIPE A

19.

'16, Remove the right front mounvbracket,

ATF COOLER HOSE

17. Remove the ATF cooler hoses at the ATF coolerlines. Turn the ends of the ATF cooler hoses uo toprevent CVT fluid from flowing out, then plug theATF cooler hoses and lines,

NOTE: Check for any sign of leakage at the hosejoints.

18. Remove the engine stiffeners and the flywheel cover.

Remove the eight drive plate bolts one at time whilerotating the crankshaft pullev.

ENGINE STIFFENER

Page 1026 of 2189

Transmission

17.

Installation (cont'd)

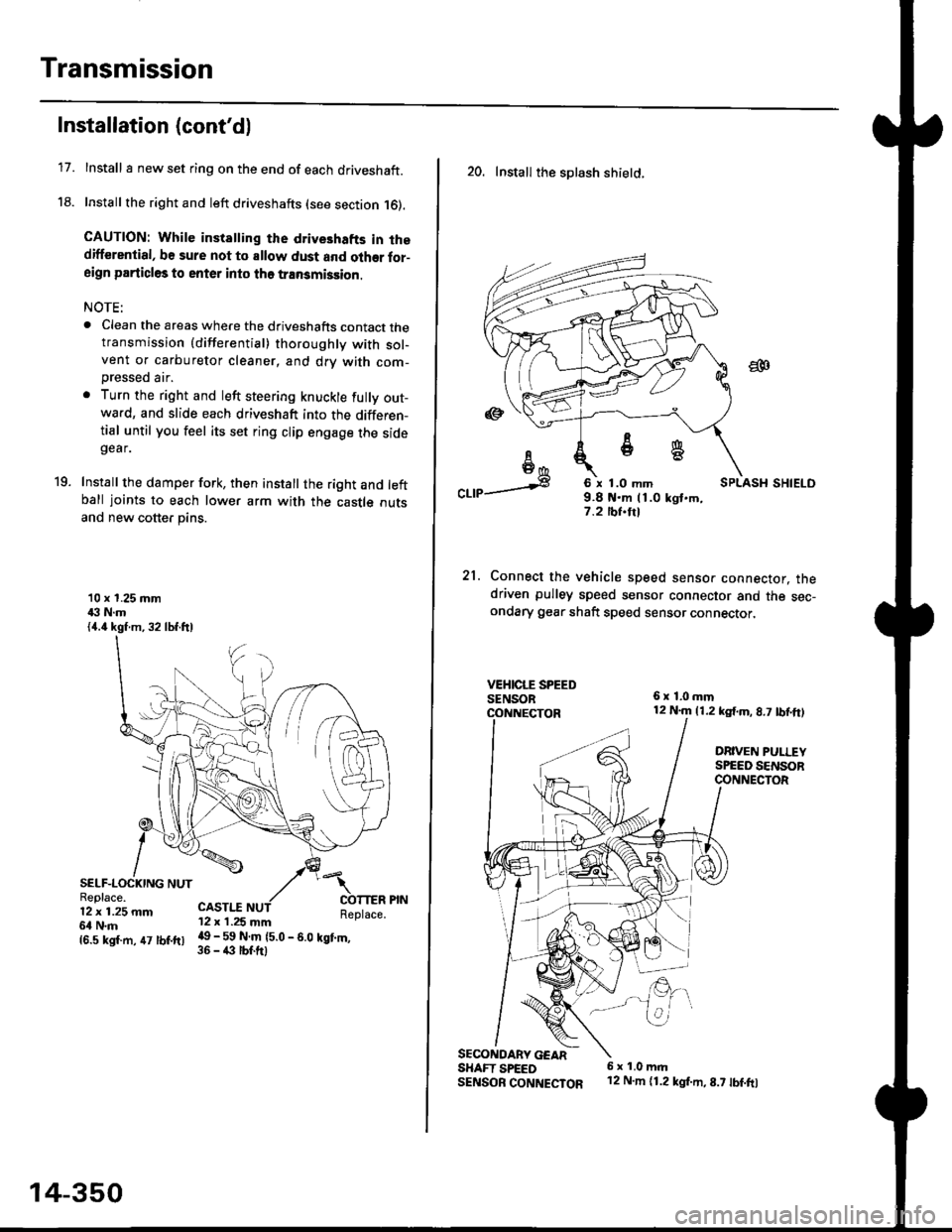

Install I new set ring on the end of each driveshaft.

Install the right and left driveshafts (see section 16).

CAUTION: While instatling the drive3hafts in thedifferential, be sure not to allow dust and olher for-aign particles to enter into tho transmission.

NOTE:

. Clean the areas where the driveshafts contact thetransmission {differential} thoroughly with sol-vent or carburetor cleaner, and drv with com-

Dressed air.

. Turn the right and left steering knuckle fully out-wa.d, and slide each driveshaft into the differen-tial until you feel its set ring clip engage the sidegear.

Install the damper fork, then install the right and leftball joints to each lower arm with the castle outsand new cotter pins.

19.

10 x 1.25 mm43 N.m{4.4 kgf.m, 32 lbf.ftl

SELF-LOCKING NUTReplace.12 x 1.25 mm6l N.m

CASTI.I'12 x 1.25 mm

{6.s ksr.m. 47 tbr.ftr l! _ ll ffiteo

- s.o tet'.,

14-350

20. Install the splash shietd.

aa

I6I6*

"a,a s

21.

SECONOARY GEARSHAFT SPEEDSENSOB CONNECTOR

6 x 1.0 mm9.8 t{.m 11.0 kgt.m,7.2 tbf.trl

Connect the vehicle speed senso. connector. thedriven pulley speed sensor connector and the sec-ondary gear shaft speed sensor connector,

6x1,0mm12 N.m {1.2 kg{.m, 8.7 tbf,ft)

DRIVEN PULLEYSPEED SENSORCONNECTOR

E.

6 x 1.0 m.rl'12 N.m {1.2 kg{.m,8.7 tbf.fo

Page 1070 of 2189

Steering Gearbox

Installation (cont'dl

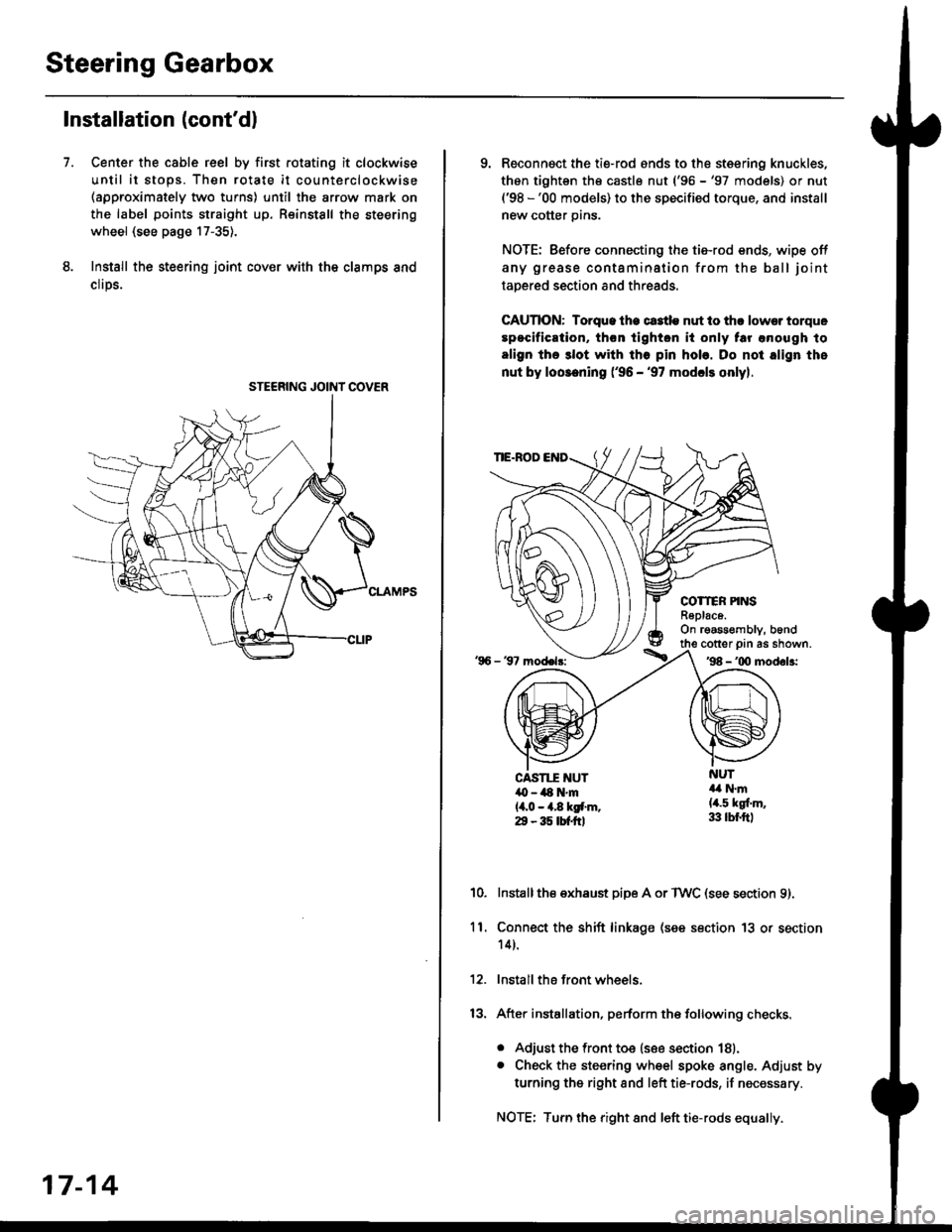

Center the cable reel by first rotating it clockwise

until it stops. Then rotate it counterclockwise(approximately two turns) until the arrow mark on

the label points straight up. Reinstall the steering

wheel (see page 17-35).

Install the steering joint cov€r with the clamps and

clrps.

7.

STEERING JOINI COVER

17-14

9. Reconnsct the ti€-rod ends to the steering knuckles,

thon tightsn th€ castle nut ('96 -'97 models) or nut('98 -'00 models) to the specified torque, and install

new cotter pins.

NOTE: Before connecting the tie-rod ends, wipe off

any grease contamination from the ball joint

tapered section and threads.

CAUTION: Torque lhe ct3tle nut to thr lowsr torque

spocification, th€n tighton it only tar anough to

align the 3lot with tho pin hob. Do not align the

nut by loosening ('96 - '97 modcls onlyl.

TIE.ROD

COTTER PINSR6plac6.On rgassombly, b6nd

'96 - 37 model3:

cotter prn as shown.'98 - '00 modol3:

NUT4a N.m(4.5 kgf.m,33 lbr.ftl

CAST1T NUT,O - ilt N'm{4,0 - 4.8 kgf.m.29 - 35 tbtftl

10.Installthe exhaust pipe A or TWC (see section 9).

Connect the shift linkage (see section 13 or section

14).

Install the front wheels.

After installation, perform the following checks.

. Adjust the front toe (see section 18).. Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

NOTE: Turn the right and left tie-rods equally.

ll.

Page 1079 of 2189

I

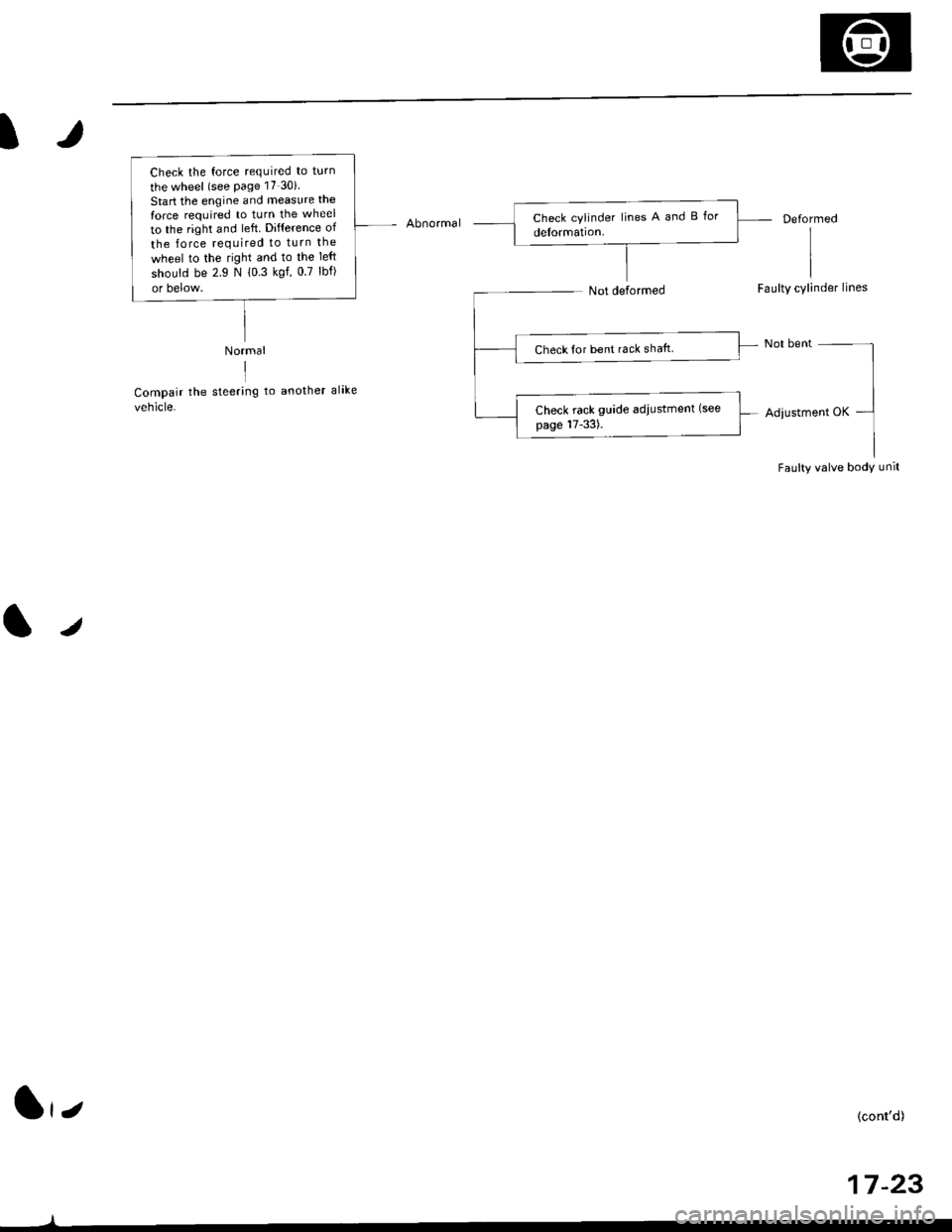

AbnormalDeformed

Faulty cylinder lines

Adiustment OK

Faulty valve body unit

Normal

IICompair the steering to another alike

vehicle.

/

Check the force required to turn

the wheel (see Page 17 30i

Start the engine and measure the

force required to turn the wheel

to the right and left. Difference of

the lorce required to turn the

wheel to the right and to the Ieft

should be 2.9 N 10 3 kgf, 0.7 lbf)

or below.

Check for bent rack shaft

Check rack guide adiustment (see

page 17-33).

(cont'd)

17 -23

1,,

Page 1082 of 2189

Troubleshooting

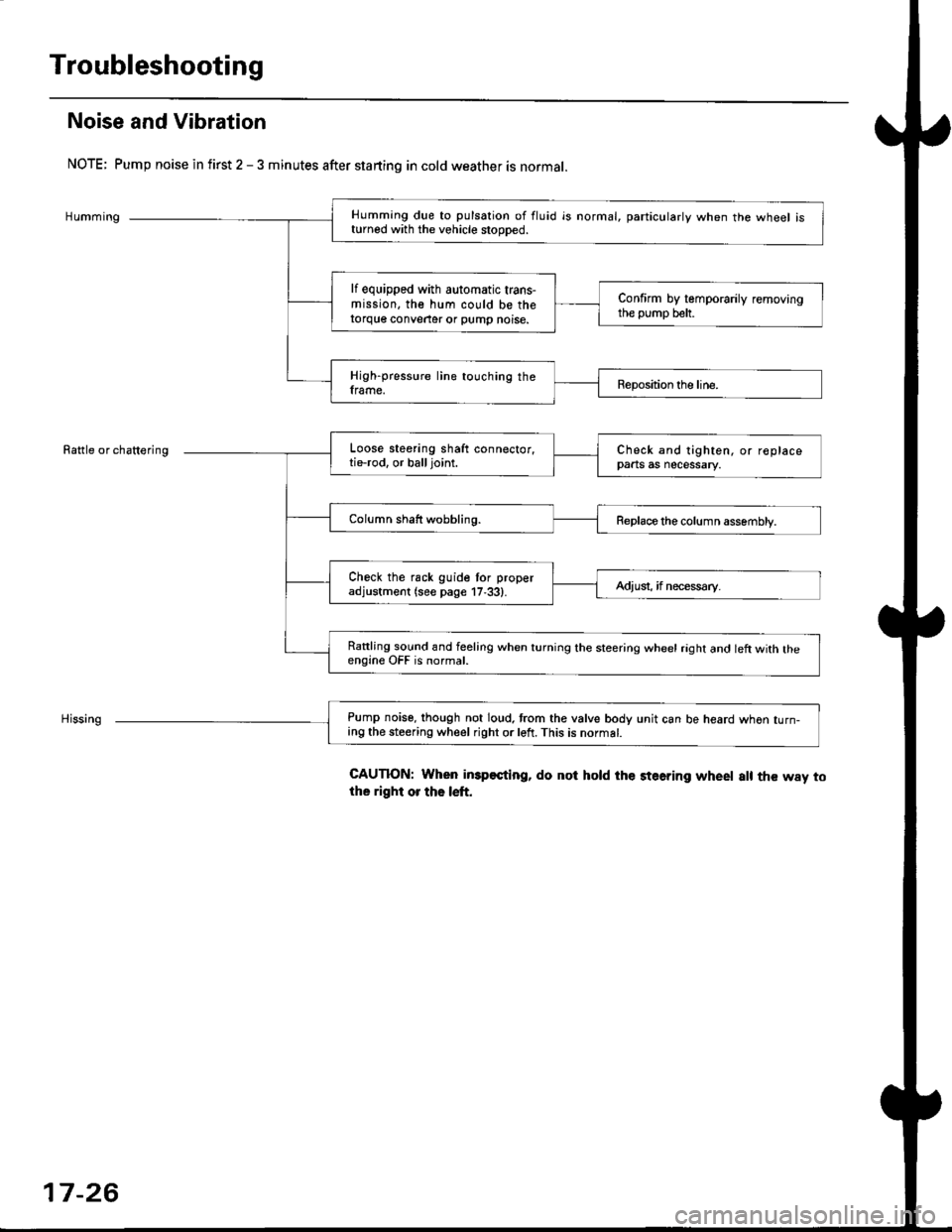

Noise and Vibration

NOTE; Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation of fluid is normal, particularlv when the wheel isturned with the vehicle stooDed.

lf equipped with automatic trans-mission, the hum could be thetorque conveater or pump noise.

Confirm by temporarily removingthe pump belt.

High-pressure line touching theframe.Reposition the line.

Loose steering shaft connector,tie-rod. or balljoint.Check and tighten, or replacepaats as necessary.

Column shaft wobbling.Replace the column assembly.

Check the rack guide tor properadjustment (see page 17,33).Adiusi, if necess€ry.

Rattling sound and feeling when turning the steering wheel raght and left with theengine OFF is normal.

Pump noise, though not loud. trom the valve body unit can be heard whon turn-ing the steering wheel right or left. This is normat.

CAUTION: When imp€sting, do not hold the steering wheet a[ the way tothe right or the left.

17-26

Page 1084 of 2189

Troubleshooting

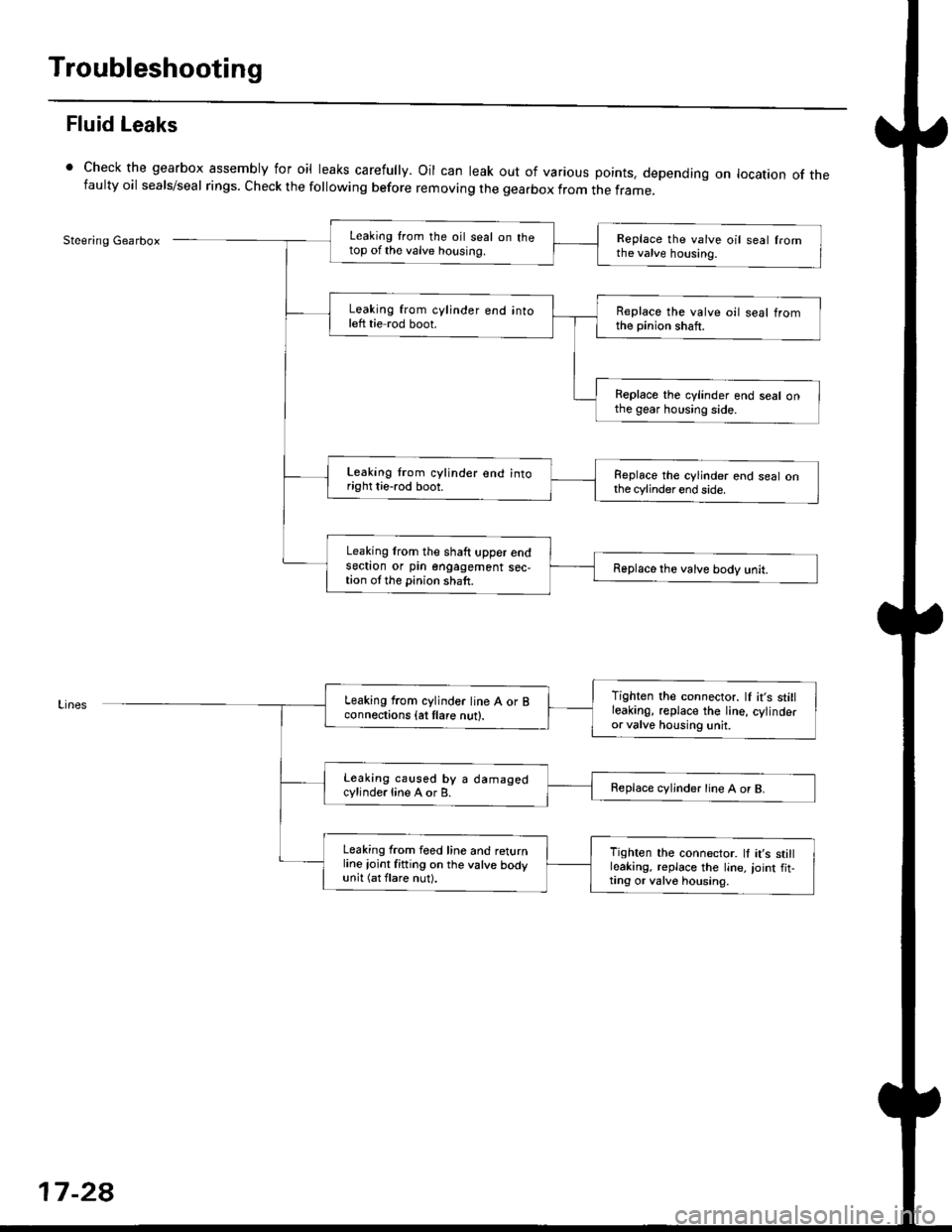

Fluid Leaks

Check the gearbox assembly for oil leaks carefully. Oil can leak out of various points. depending on location of thefaulty oil seals/seal rings. Check the following before removing the gearbox from the frame_

Steering GearboxLeaking from the oil seal on thetop of the valve housing.Replace the valve oil seal fromthe valve housing.

Leaking from cylinder end intoleft tie rod boot.Replace the valve oil seal tromthe pinion shaft.

Replace the cylinder end seal onthe gear housing side.

Leaking lrom cylinder end intoright tie-rod boot.Replace the cylinder end seal onthe cylinder end side.

Leaking lrom the shaft upper endsectron or pin engagement sec,tion ol the pinion shaft.Replace the valve body unit.

Tighten the connector. lf it's stillleakinO, replace the Iine, cylinderor valve housing unit.

Leaking from cylinder line A or Bconnections {at tlare nut}.

Leaking caused by a damagedcylinde.line A or B.Replace cvljnder line A or B.

Leaking from feed line and returnline ioint fitting on the valve bodyunit (at flare nut).

Tighten the connector. ll it's stillleaking, replace the line,,oint fit,ting or valv6 housing.

17-2a

Page 1094 of 2189

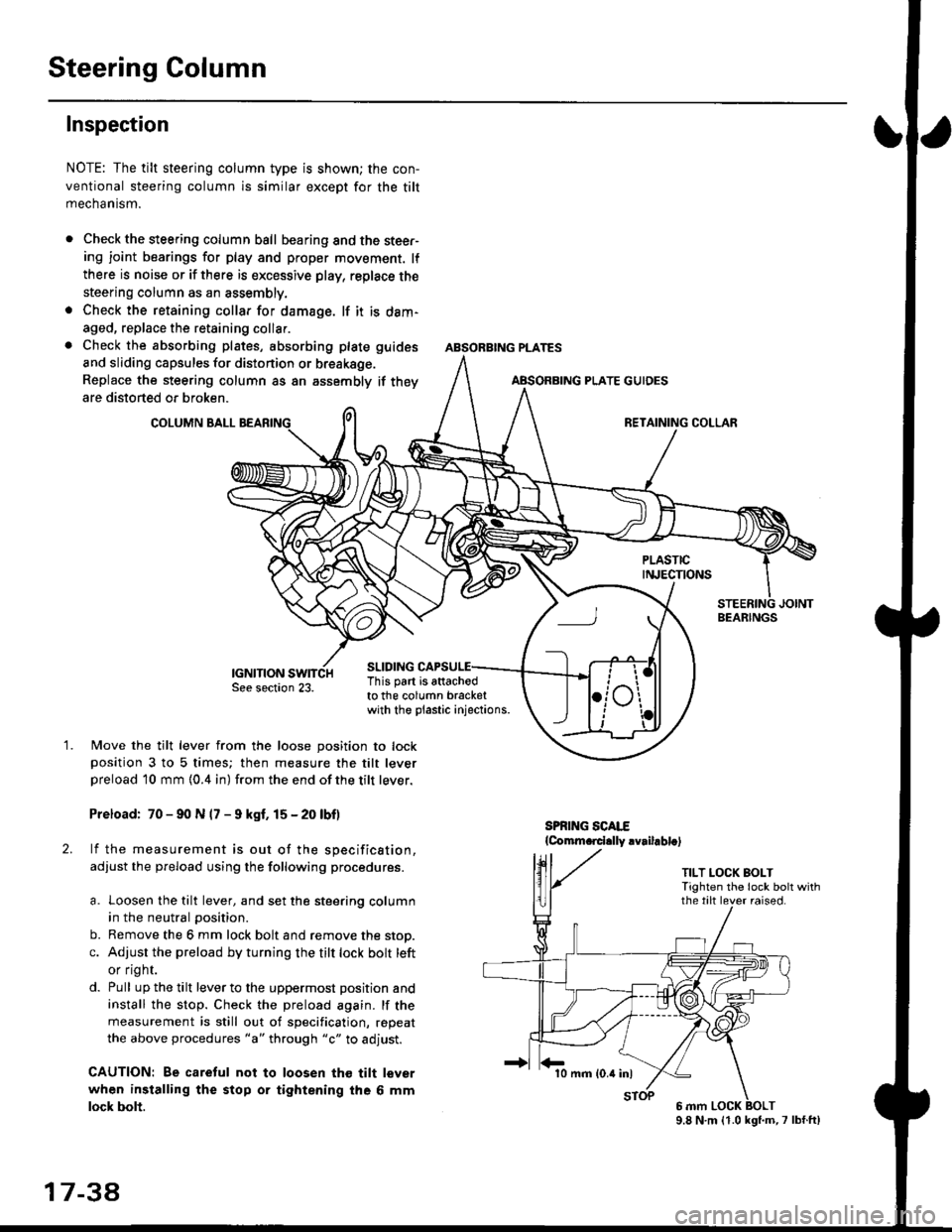

Steering Column

Inspection

NOTE: The tilt steering column type is shown; the con-

ventional steering column is similar except for the tilt

mechantsm.

Check the steering column ball bearing and the steer-ing joint bearings for play and proper movement. lf

there is noise or if there is excessive play, replace the

steering column as an assembly.

Check the retaining collar for damage. lf it is dam-

aged, replace the retaining collar.

Check the absorbing plates, absorbing plate

and sliding capsules for distonion or breakage.

Replace the steering column as an assembly

are distorted or broken.

COLUMN BALL

ABSORBING PLATE GUIDES

guides

if they

SLIDING

BEARINGS

TILT LOCK BOLTTighten the lock bolt withthe tilt lever raised.

This part is attachodto the column bracketwith the plastic injections.

1.Move the tilt lever from the loose position to lockposition 3 to 5 times; then measure the tilt leverpreload l0 mm {0.4 in) from the end ofthe tilt lever.

Preload: 70 - 90 N (7 - 9 kgf. 15 - 20 lbf)

lf the measurement is out of the specification,

adjust the pfeload using the following procedures.

a. Loosen the tilt lever, and set the steering column

in the neutral position.

b. Remove the 6 mm lock bolt and remove the stop.

c. Adjust the preload by turning the tilt lock bolt left

or flgnr.

d. Pull up the tilt lever to the uppermost position and

install the stop. Check the preload again. lf the

measurement is still out of specification, repeat

the above procedures "a" through "c" to adjust.

CAUTION: Be caretul not to loosen tho tilt lever

when installing the stop or tightening the 6 mm

lock bolt.

17 3a

10 mm (0.4 inl

9.8 N.m (1.0 kgl.m,7 lbf.ft)

Page 1104 of 2189

Steering Gearbox

Removal {cont'dl

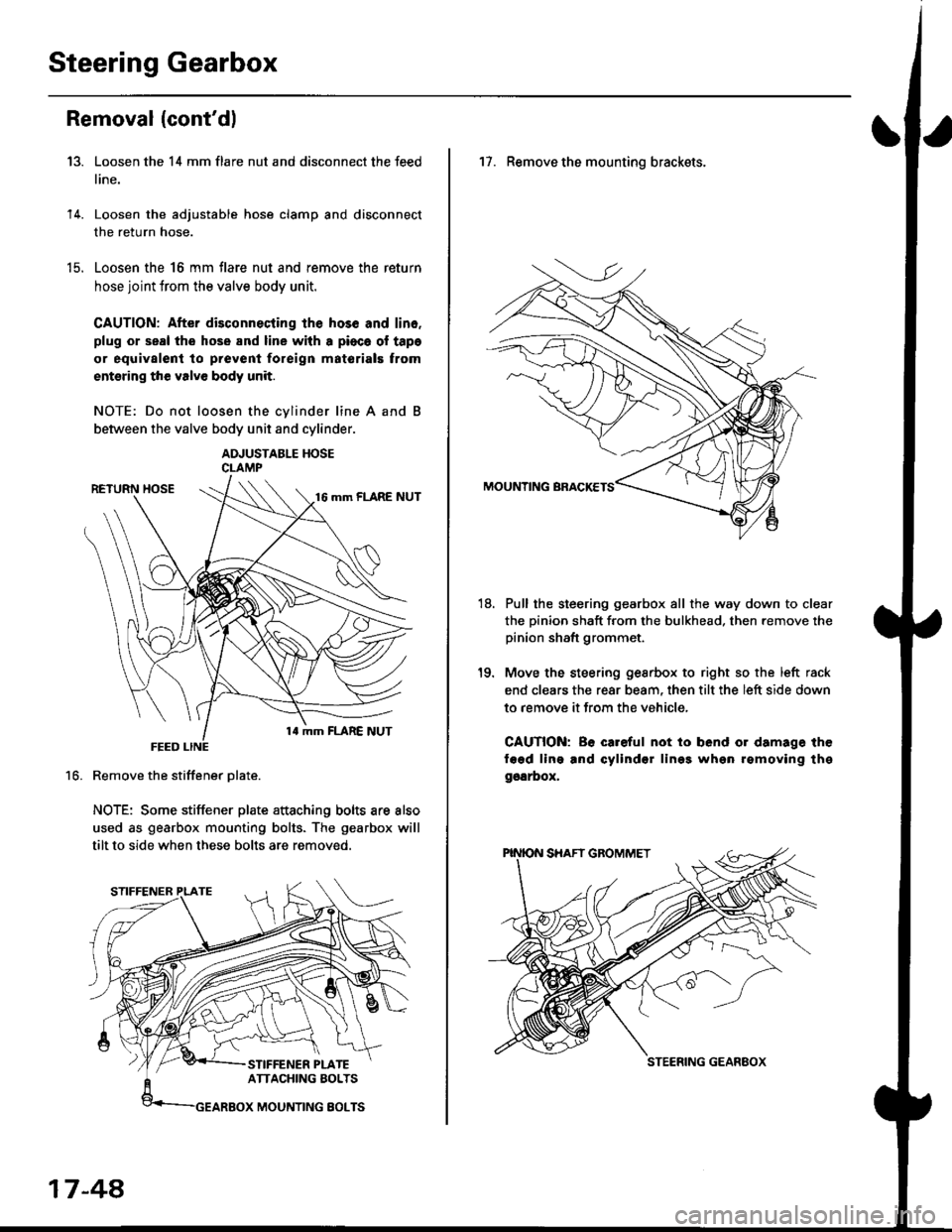

Loosen the 14 mm flare nut and disconnect the feed

line.

Loosen the adjustable hose clamp and disconnect

the return hose.

Loosen the 16 mm flare nut and remove the return

hose joint trom the valve body unit.

CAUTION: After disconnecting lhe hos6 and lin6.

plug or seal the hose and line with a pioca ol tapa

or equivalent to prevenl foreign matorials trom

entsring the valve body unit.

NOTE: Do not loosen the cvlinder line A and

between the valve body unit and cylinder.

ADJUSTABLE HOSECLAMP

Remove the stiffener Dlate.

NOTE: Some stiffener plate attaching bolts are also

used as gearbox mounting bolts. The gearbox will

tilt to side when these bolts are removed.

13.

14.

t9.

16.

17-48,

17. Remove the mounting brackets.

Pull the steering gearbox all the way down to clear

the pinion shaft from the bulkhead. then remove the

pinion shaft grommet.

Move the steering gesrbox to right so the left rack

end clears the rear beam, then tilt the left side down

to remove it from the vehicle,

CAUTION: Be careful not io bend or damage the

fagd ling and cylindsr lin99 whgn rgmoving thg

ggarbox,

18.

STEERING GEANEOX

Page 1120 of 2189

Steering Gearbox

Reassembly (cont'dl

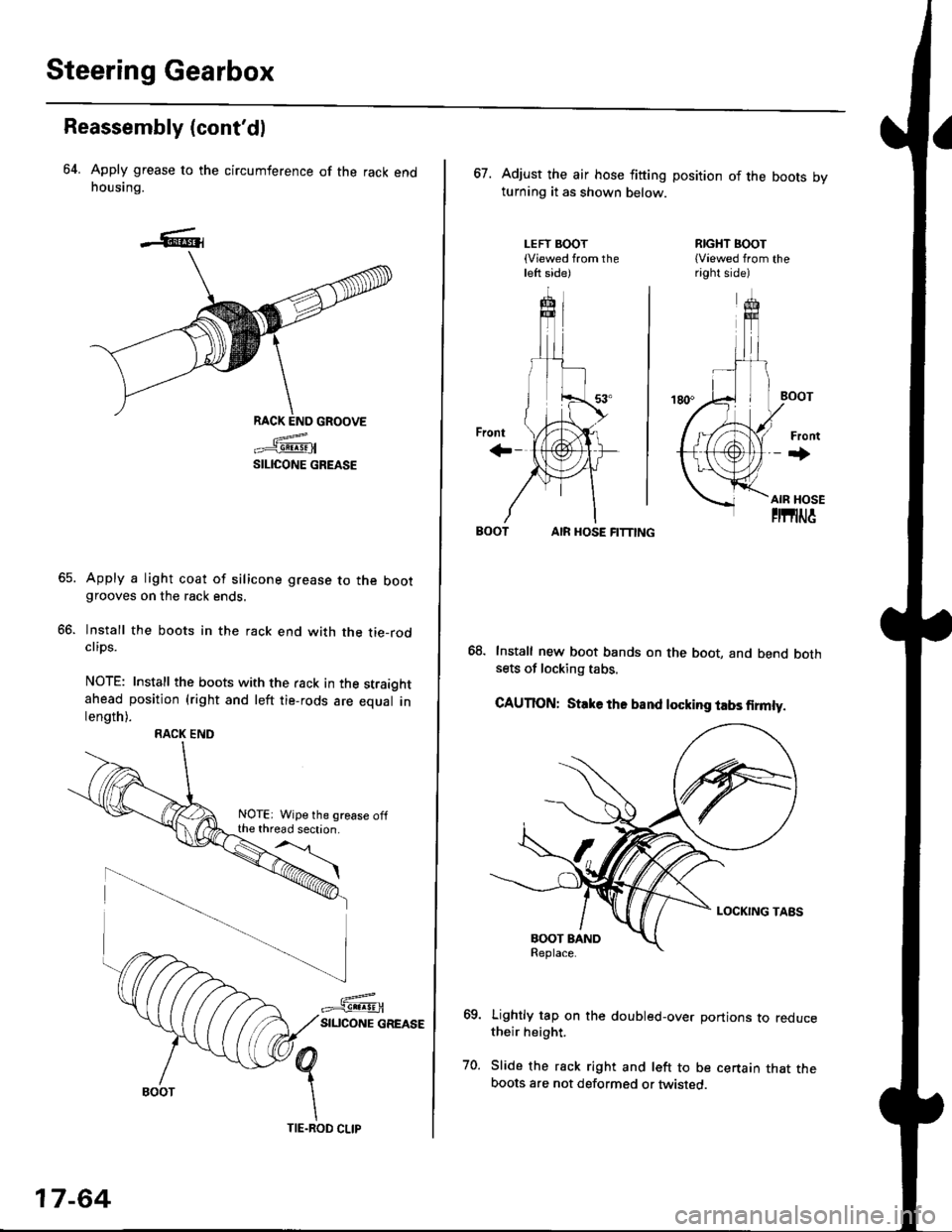

64. Apply grease to the circumference of the rack endhousing.

RACK END GROOVE

=^.#-q!:s!!H

SILICONE GREASE

Apply a light coat of silicone grease to the bootgrooves on the rack ends.

lnstall the boots in the rack end with the tie-rodclips.

NOTE: Install the boots with the rack in the straightahead position (right and left tie-rods are equal inlength).

66.

RACK END

NOTE: Wipe the grease offthe thread section.

17-64

TIE.ROD CLIP

67. Adjust the air hose fitting position of the boots bvturning it as shown below.

LEFT BOOT(Viewed from theleft side)

RIGHT BOOT{Viewed from theright side)

AIR HOSE FITTING

Install new boot bands on the boot, and bend bothsets of locking tabs.

CAUTION: Stlke ths band locking tabs firmly.

Lightly tap on the doubled-over portions to reducetheir height.

Slide the rack right and left to be certain that theboots are not deformed or twisted.