shift pin HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 624 of 2189

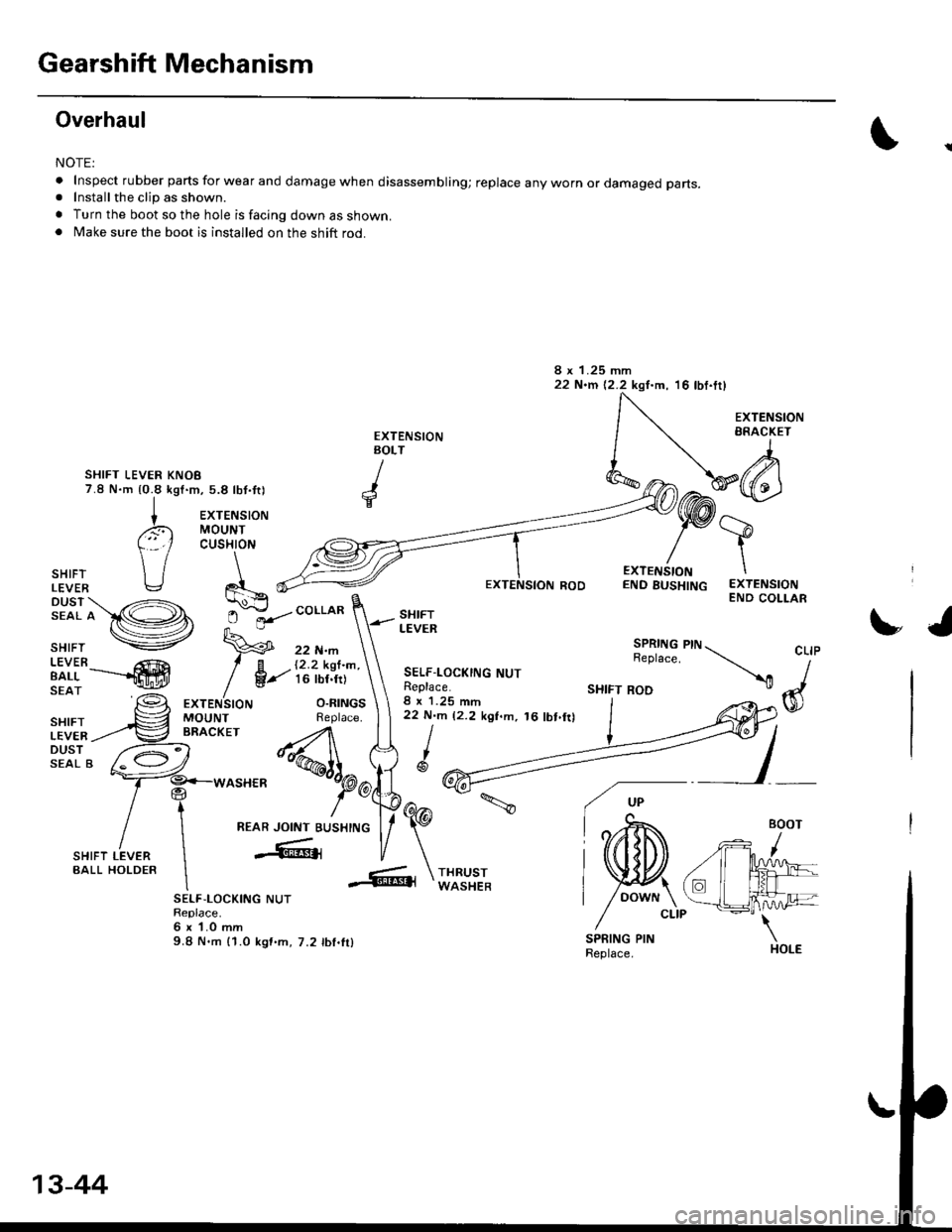

Gearshift Mechanism

Overhaul

NOTE:

.Inspectrubberpartsforwearanddamagewhendisassembling;replaceanywornordamagedparts.

. Install the clip as shown.

. Turn the boot so the hole is facing down as shown.. Make sure the boot is installed on the shift rod.

SHIFT LEVER KNOE7.8 N.m {0.8 kgf.m,5.8 lbt.tt)

EXTENSIONBOLT

)

searr'p)) p f*** \-ii,,l?'"

SHIFT -Vvvvvvvvvvvvvvvv�l tlourur Replace. | 1 22 N'm 12.2 ksf'm, 16 lbt.ftl

ii,".i'----....-.9 / g-ia',rf,',,"' sELF-LocKrNG Nur

sEAr '6 .rrr*(,o"" o-","o, ;":'i:;u --

CLIP

dul/

/,1: MOUNT

l': I cusHroN ,€\/\/-sSHIFT l / /-LEVER \, et- ffi

PY:,'\1^l lW -"or.o*Dusr .- \5".o.o)@1 -o-E "ot'o'

sHlFr \:/ Q,gD 22 N.m

IiUei__-.....p anecxer ,-/n I I I

?!il, e* ^.-.-n{wl\^fr J"r^r"

7****r

""'%ilf

t@

t1

t\sHrFT LEVER IBALL HOLDER

\

REAR JorN*lr,""17E@

_6,

L\

EXTENSION

SELF-LOCKING NUTReplace.6 x '1.0 mm9.8 N.m {1.0 kgf.m, 7.2 lbf.lr}

tJSPRING PINReplace.

-6r

16 tbf.trl

13-44

Page 632 of 2189

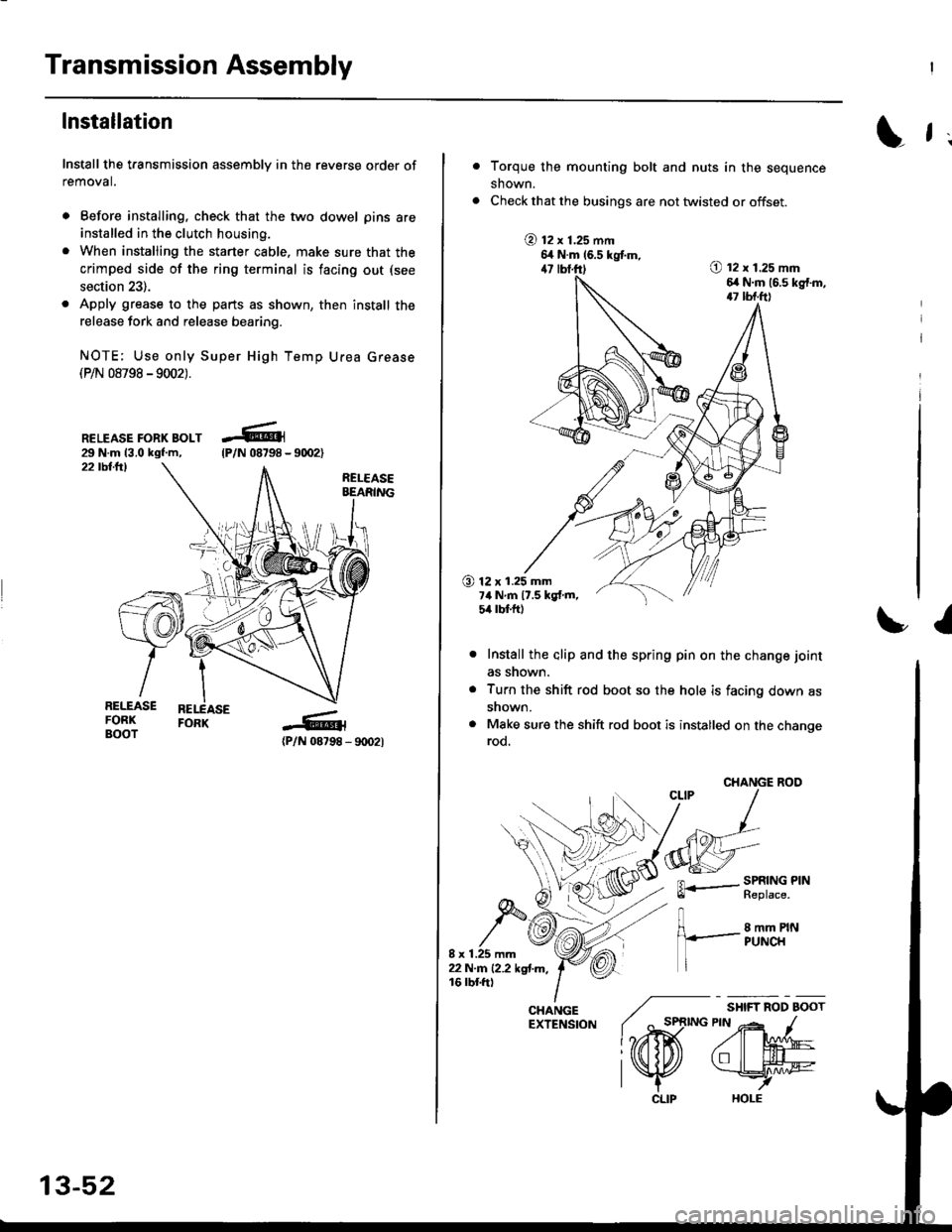

Transmission Assembly

lnstallation

Install the transmission assembly in the reverse order of

removal.

. Before installing, check that the two dowel pins are

installed in the clutch housing.

. When installing the starter cable. make sure that the

crimped side of the ring terminal is facing out (see

section 23).

. Apply grease to the parts as shown, then install the

release fork and release bearing.

NOTE; Use only Super High Temp Urea Grease(P/N 08798 -9002).

RELEASE FORK BOLT29 N.m 13.0 kgf.m,22 tbllrl

(P/N 08798 - 9rD2l

-R1

tP/N 08798 -

13-52

CLIP

L f ;

Torque the mounting bolt and nuts in the sequence

shown.

Check that the busings are not twisted or offset.

@ t2 x 1.25 mm6,t N.m 16.5 kgtm,47 lbf.ft)O t2 x 1.25 mm6,r N.m (6.s kg{.m,17 tbf.ft)

O 12 x 1.25 mm7ilNm17.5kgf.m,5it lbt ft)

I

Install the alip and the spring pin on the change joint

as snown.

Turn the shift rod boot so the hole is facing down as

snown.

Make sure the shift rod boot is installed on the changerod.

CHANGE ROO

FL.- SPRING PINll heptace,

8 mm PINPUNCH

/ "*,*

lo,iD(

CHANGE ./EXTENSfoN ( ^ st

l?rffi

l\K

Page 635 of 2189

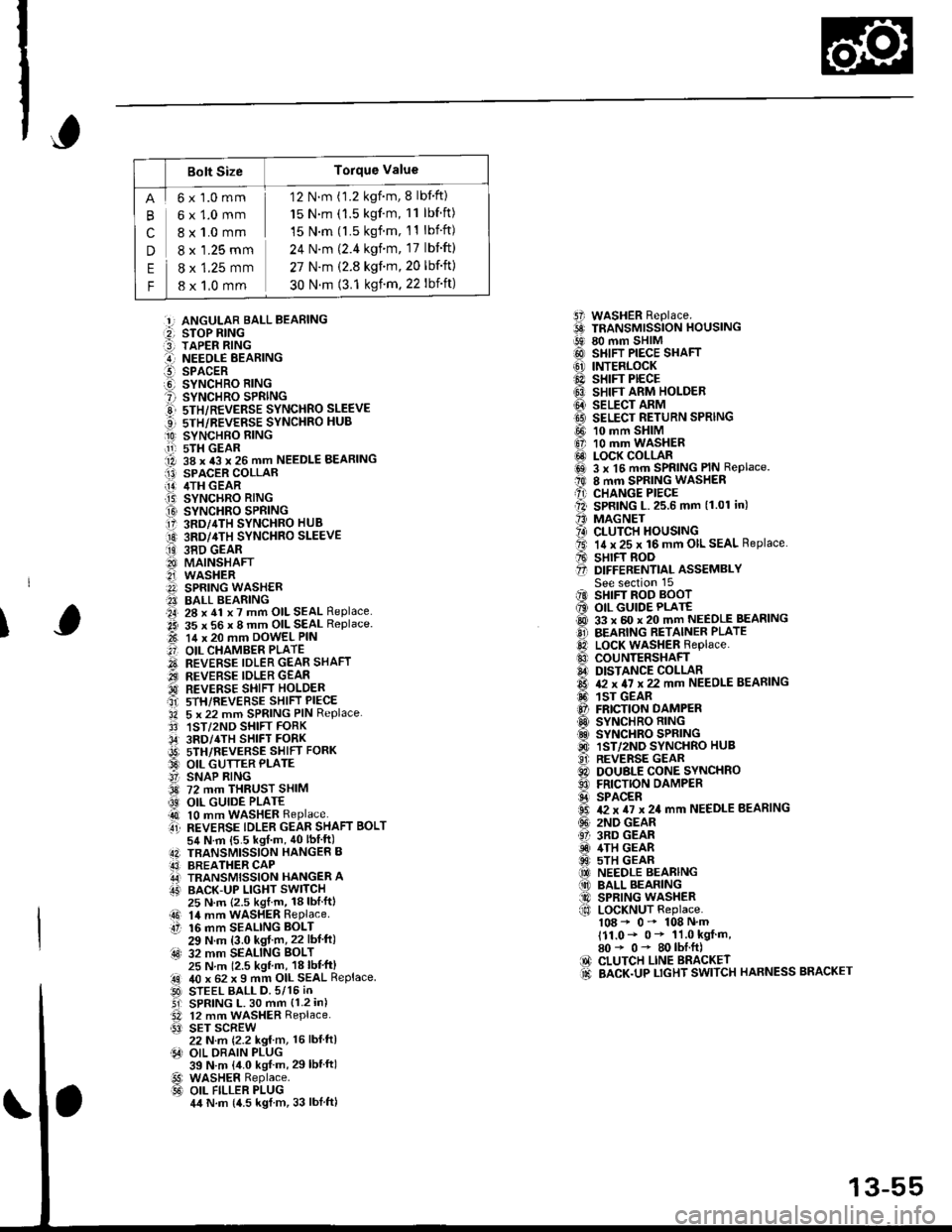

Bolt SizeTorque Value

cn

E

F

6x1.0mm

6x1.0mm

8 x 1.0 mm

8 x '1.25 mm

8 x 1.25 mm

8 x 1,0 mm

12 N.m (1.2 kgnm, 8 lbf'ft)

15 N.m (1.5 kgf'm, 11 lbf ft)

15 N.m (l.5 kgf.m, 11 lbift)

24 N'm (2.4 kgim, 17 lbift)

27 N.m (2.8 kgf.m,20 lbf'ft)

30 N.m (3.1 ksf m. 22 lbift)

5i WASHER Replace.6 TRANSMrssioN HouslNG!9 80 mm SHIM@ SHIFT PIECE SHAFT(6' INTERLOCK@ sHrFr PECE6} SHIFT ARM HOLDER@ seucr nnrvtI9 SELECT RETURN SPRING

@ 10 mm SHIM6, 10 mm WASHER@ LOCK COLLARi6sl 3 x l5 mm SPRING PIN Replace.t0 8 mm SPRING WASHERA) CHANGE PIECEll SPRING L.25.6 mm (1.01 in)'' MAGNET?4) CLUTCH HOUSINGta. 14 x 25 x 16 mm OIL SEAL Replace.A sHrFT BooO D|FFERENT|aL ASSEMBLYSee section 15iIO SHIFT ROD BOOT6 OIL GUIDE PLATE@ 33 x 60 x 20 mm NEEDLE BEASINGO BEARING RETAINER PLATElD LocK WASHER Replace..0 couNTERSHAFIA DISTANCE COLLAR6 & x 4I x 22 mm NEEDLE BEARING6. 1sr GEAR@ FRICTION DAMPERO SYNCHRO RING.d SYNCHRO SPRING@ 1ST/2ND SYNCHRO HUB..9i. REVERSE GEARC) DOUBLE CONE SYNCHROO FRICTION DAMPERS SPACER6 T2 x TI x 24 mm NEEDLE BEARING(!' 2ND GEAR61 3RD GEARiD 4TH GEAR@ 5TH GEAR(O NEEDLE BEARING(10 BALL BEARING@ SPRING WASHERf,o LoCKNUT Replace.108 - 0- 108 N'm111.0- 0* 11.0 kgf m,80* 0- 80lbI.ft)IO CLUTCH LINE BRACKET.d BACK.UP LTGHT SWITCH HARNESS BRACKET

:!, ANGULAR BALL BEABING:2, STOP RING:3] TAPER RING..-I NEEOLE BEARINGl!-- SPACERO SYNCHRO RING? SYNCHRO SPRINGE 5TH/REVERSE SYNCHRO SLEEVE...] sTH/REVERSE SYNCHRO HUB

O SYNCHBO EING.11-r sTH GEAR1A 38 x 43 x 26 mm NEEDLE BEARINGI13) SPACER COLLAR[!] /ITH GEAR.T5) SYNCHRO RING

O SYNCHRO SPRING17 3RD/4TH SYNCHRO HUB

O 3RD/4TH sYNcHRo SLEEVE

ii9 38D GEAR8I MAINSHAFT2i WASHERA SPRING WASH€R?I BALL BEARING.a4, 28 x 41 x 7 mm OIL SEAL Replace..2i 35 x 56 x 8 mm OIL SEAL Replace.t-t 14 x 20 mm DowEL PIN

.'] OIL CHAMBER PLATE

O REVERSE IDLER GEAR SHAFT.iI.., REVERSE IDLER GEAR'd REVERSE SHIFI HOLDERait srH/REVERSE sHIFT PIECE'34 5 x 22 mm SPRING PIN Replace.3' 1ST/2ND SHIFT FORK,34' 3RD/4TH SHIFT FORKi9t) srH/nevense sstrr ronx33 OIL GUTTER PLATE!' SNAP RING3d 72 mm THRUST SHIM

@ OIL GUIDE PLATE4t 10 mm WASHER Replaceti REVERSE TDLER GEAR SHAFT BoLT54 N.m {5.5 kgf m, 40lbIft)4N TBANSMISSION HANGER B43] BREATHER CAPA,J TRANSMISSION HANGER AIT' BACK-UP LIGHT SWITCH

I

25 N.m {2.5 kgl.m, 18lblftl14 mm WASHER RePlaceaO 14 mmtt 16 mm16 mm SEALING BOLT29 N.m (3.0 kgf m,22 lbf ft):4s) 32 mm SEALING BoLT25 N m 12.5 kgl m, 18 lbl'ft)40 x 62 x I mm OIL SEAL ReplaceSTEEL BALL D.5/15 iNSPRING L. 30 mm {1.2 in)12 mm WASHER Replace.SET SCREW22 N.m {2.2 kg{ m, 16 lbl ftlOIL DRAIN PLUG39 N.m {4.0 kgf m, 29lbtftlWASHER Replace.OIL FILLER PLUG4,t N.m {4.5 kgl m, 33 lblftl

.!rl00

@l

13-55

Page 637 of 2189

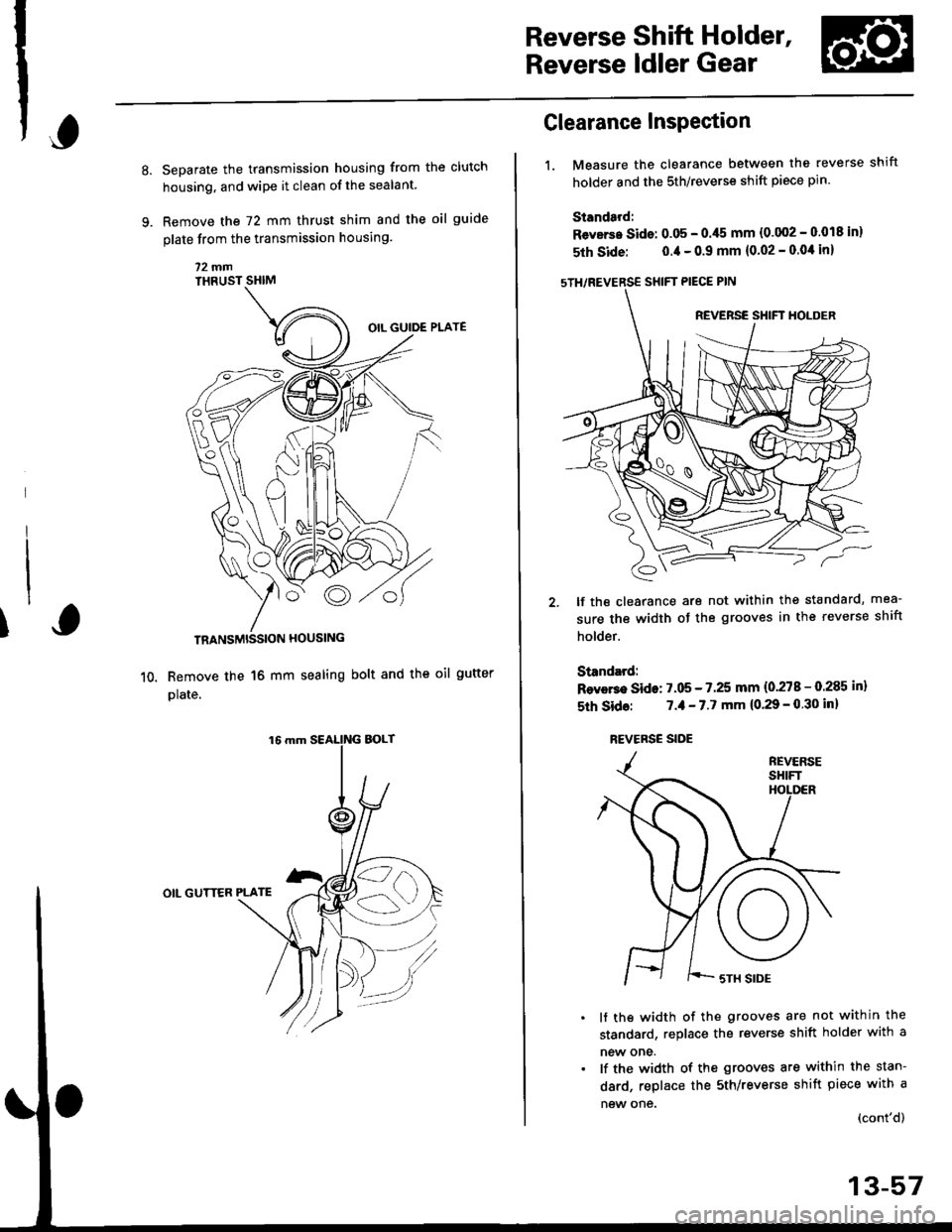

Reverse Shift Holder,

Reverse ldler Gear

Separate the transmission housing from the clutch

housing, and wipe it clean of the sealant.

Remove the 72 mm thrust shim and the oil guide

plate from the transmission housing

72fifiTHRUST SHIM

TRANSMISSION HOUSING

Remove the 16 mm sealing bolt and the oll gutter

plate.

OIL GUTTER PLATE

fi

1.

Clearance Inspection

Measure the clearance between the reverse shift

holder and the 5th/reverse shift piece pin

Standard:

Revsrs. Sids: 0.05 - 0./t5 mm {0'002 - 0.018 in}

5th Side: 0.4 - 0.9 mm (0.02 - 0.0'l in)

sTH/REVERSE SHIFT PIECE PIN

lf the clearance are not within the standard, mea-

sure the width of the grooves in the reverse shift

holder.

Standard:

Rsvers€ Side: 7.05 - 7.25 mm (0'278 - 0.285 in)

5th Sid6: 7.,1- 7.7 mm (0.29 - 0 30 inl

REVERSE SIDE

lf ths width of the grooves are not within the

standard, replace the reverse shift holder with a

new one.

lf the width of the grooves are within the stan-

dard, replace the sth/reverse shift piece with a

new one {cont'd)

13-57

Page 645 of 2189

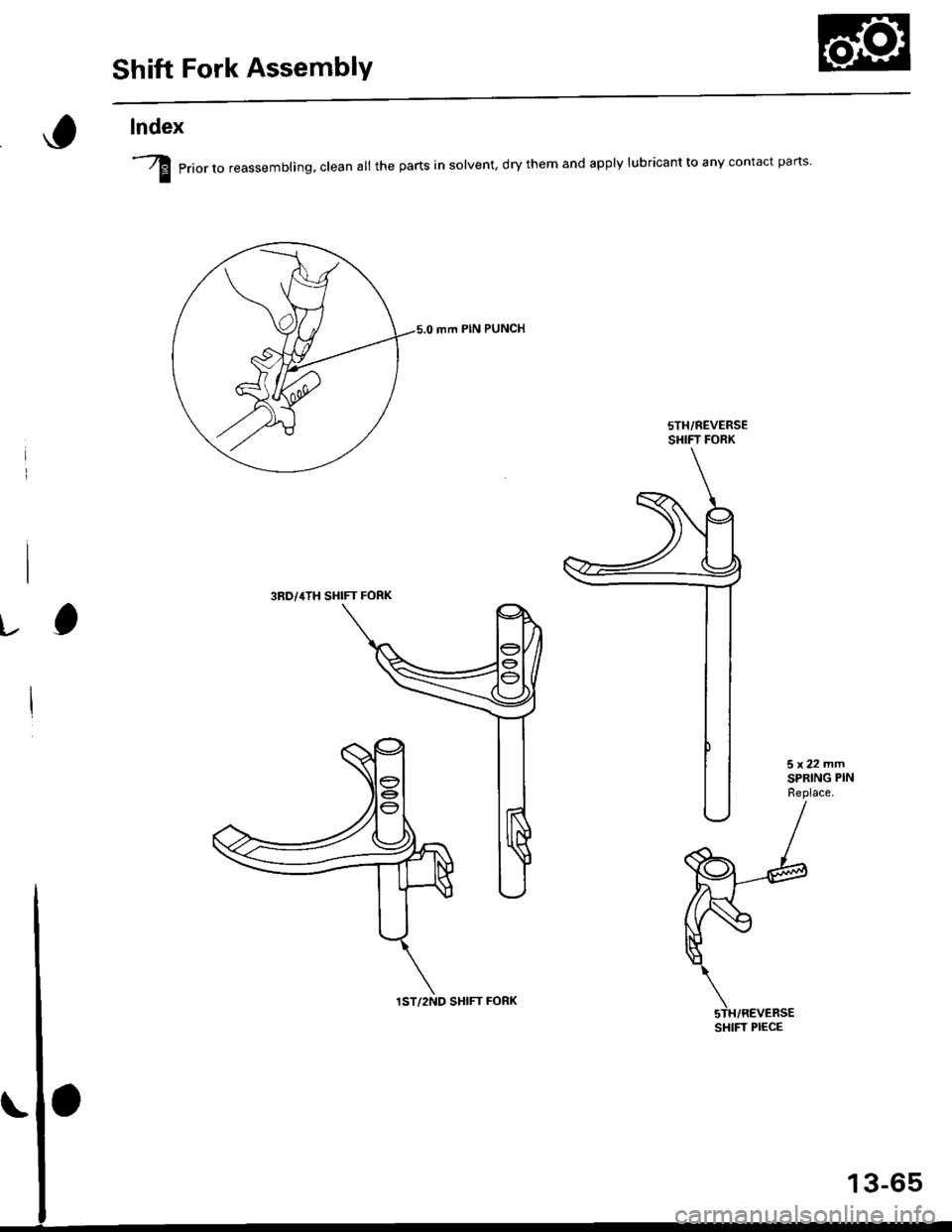

Shift Fork AssemblY

lndex

-A erior ro reassemblinq. clean all the parts in solvent, dry them and apply lubricant to any contact pans

I

mm PIN PUNCH

sTH/REVERSESI{IFT FORK

3RD/4TH SHIFT FORK

Page 677 of 2189

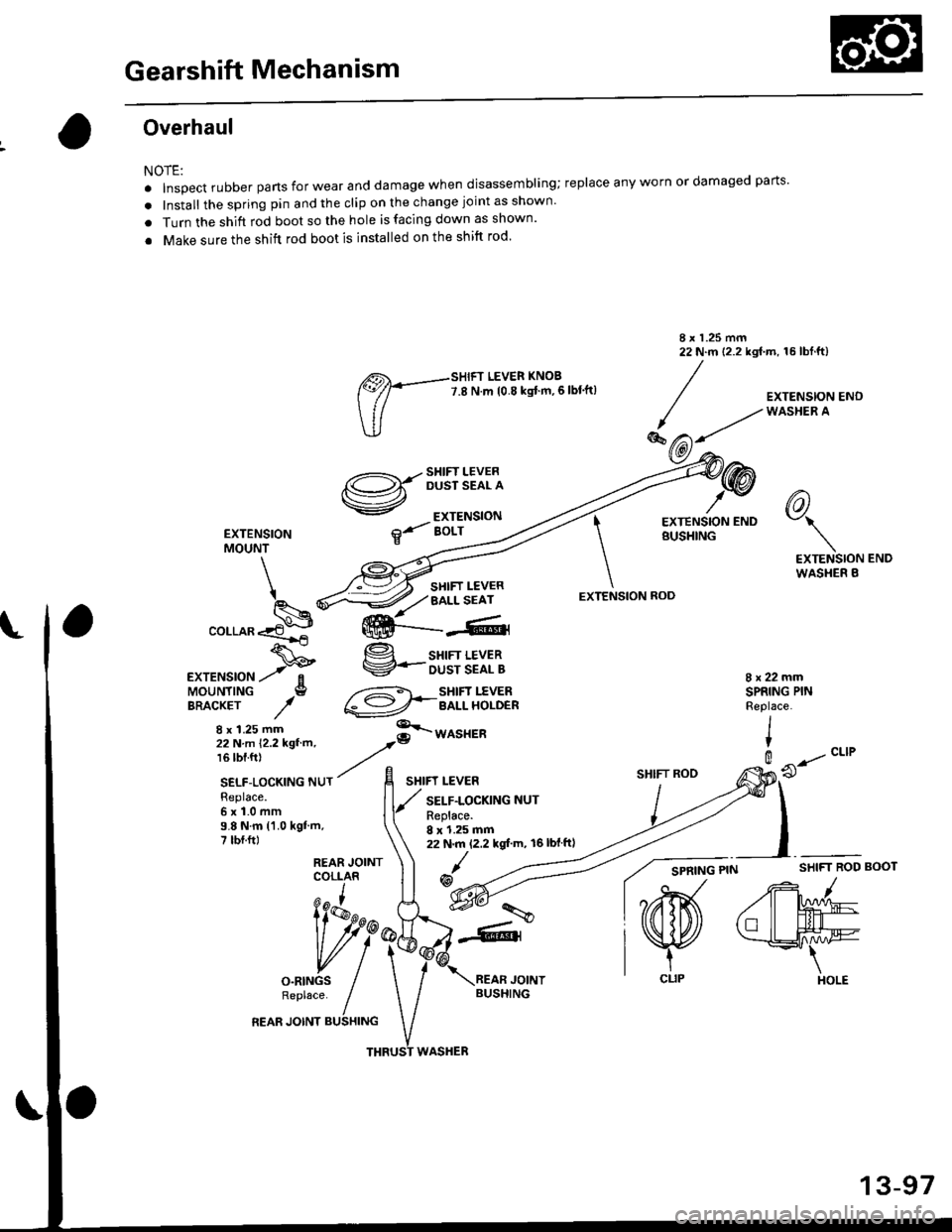

Gearshift Mechanism

Overhaul

NOTE:

. Inspect rubber parts for wear and damage when disassembling;

. Install the spring pin and the clip on the change joint as shown'

. Turn the shift rod boot so the hole is facing down as shown'

. Make sure the shift rod boot is installed on the shift rod'

reDlace any worn or damaged Parts.

I x 1.25 mm22 N.m 12.2 kgf.m, 16 lbf.ft)

ffi-:t't:il1ii51i?"'*,

TU

/g3i'51!Exii

V ExrENsroN

EXTENSfON ilr'eol.T

EXTENSION ENDBUSHING

hV\

EXTENSIONWASI{ER B

MOUNT -_.--_-_---

@2'

--1'>=2 -:liT.i'ff"

.o,-.o*&--ffi{---*,

v/,,/ BALL SEAT

8 x 1.25 mm22 N.m 12.2 kgf'm, 16lblftl

,@

EXTENSION ROD

SHIFT ROD

SPRING

END

BOOT

N: g sHrFr LEvER

.*rr"r,o"-tf V-oiliiSi[a

MOUNTING I --::=t SHIFT I"EVERBRAcxEr / €9-l--enr xoloen

8 x 1.2s mm :-,rro""a,ii-ri- ri.z rsr.-, -.Q u

16 tbf.ft) ,,,.

,rar-aoa*,"o "u, / E ,",t.ruaa

Replace.6x1.0mm9.8 N.m ('1.0 kgt'm,7 tbr.ftt

8x22mmSPRING PINReplace.

IIt

@CLIP

9.a-"t't

PIN SHIFT ROD/

ZW

€lt#-,\

HOLE

13-97

Page 681 of 2189

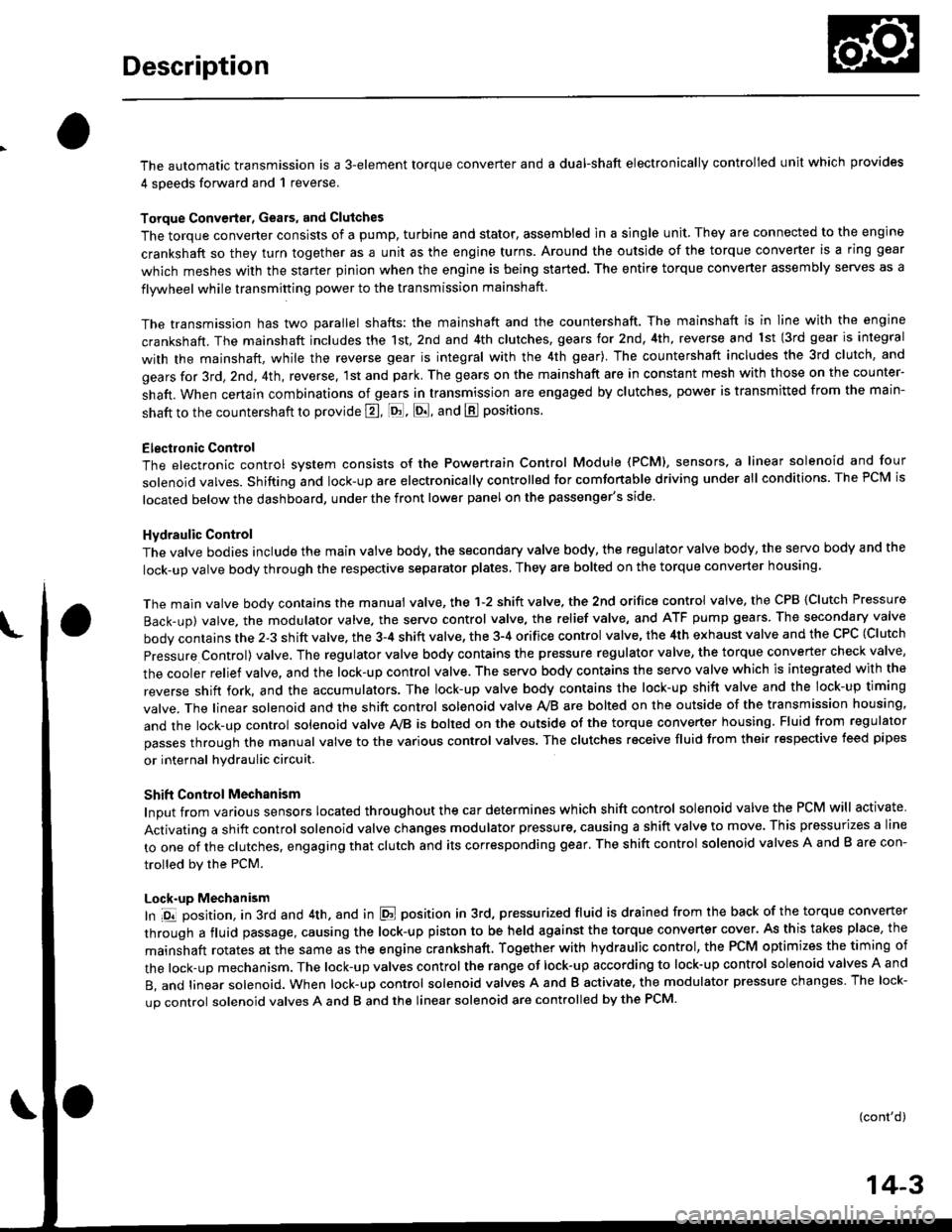

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3

Page 682 of 2189

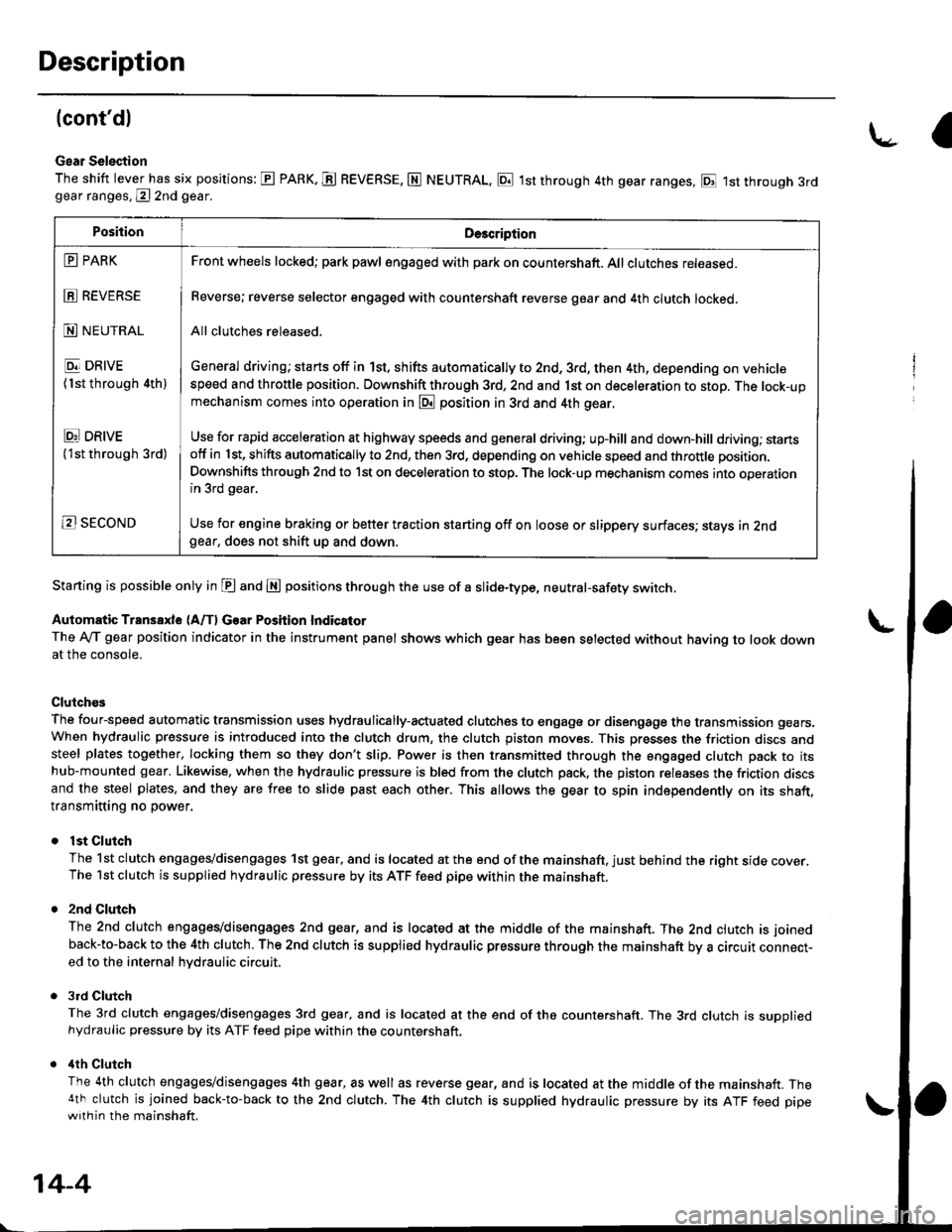

Description

(cont'dl

Gear Selection

The shift lever has six positions: E PARK. E REVERSE, N NEUTRAL, E 1st through 4th gear ranges, E 1st through 3rdgear ranges, @ 2nd gear.

Starting is possible only in E and E positions through the use of a slide-type, neutral-safety switch.

Automatic Transaxle (A/f, Gear Position Indicator

The Ay'T gear position indicator in the instrument panel shows which gear has been selected without having to look downat the console.

Clutch€s

The four-speed automatic transmission uses hydraulically-actuated clutches to engage or disengage the transmission gears.When hydraulic pressure is introduced into the clutch drum, the clutch piston moves. This presses the friction discs andsteel plates together, locking them so they don't slip. Power is then transmitted through the engaged clutch pack to itshub-mounted gear. Likewise, when the hydraulic pressure is bled from the clutch pack, the piston releases the friction discsand the steel plates, and they are free to slide past each other. This allows the gear to spin independently on its shaft,transmitting no power.

lst Clutch

The 1st clutch engages/disengages 1st gear, and is located at the end of the mainshaft, just behind the right sroe cover.The 1st clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

2nd Clulch

The 2nd clutch engagegdisengages 2nd gear, and is located at the middle of the mainshaft. The 2nd clutch is joined

back-to-back to the 4th clutch. The 2nd clutch is supplied hydraulic pressure through the mainshaft by a circutr connect-ed to the internal hvdraulic circuit,

3rd Clutch

The 3rd clutch engages/disengages 3rd gear, and is located at the end of the countershaft. The 3rd clutch is suooliedhydraulic pressure by its ATF feed pipe within the countershaft.

ilth Clutch

The 4th clutch engages/disengages 4th gear, as well as reverse gear, and is located at the middle of the mainshaft. The4th clutch is joined back-to-back to the 2nd clutch. The 4th clutch is supplied hydraulic pressure by its ATF feed pipewith in the mainshaft.

\-a

PositionDe3cription

E PARK

E REVERSE

N NEUTRAL

E DRIVE

{1st through 4th)

Ei DRtvE('lst through 3rd)

B SECOND

Front wheels locked; park pawl engaged with pa* on countershaft. All clutches released.

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

All clutches released.

General driving; starts off in 1st, shifts automatically to 2nd, 3rd, then 4th, depending on vehiclespeed and throttle position. Downshift through 3rd, 2nd and 1st on deceleration to stop. The lock-upmechanism comes into operation in @ position in 3rd and 4th gear.

Use for rapid acceleration at highway speeds and general driving; up-hill and down,hill dfiving; stansotf in 1st, shifts automatically to 2nd, then 3rd, depending on vehicle speed and throttle position.

Downshifts through 2nd to lst on deceleration to stop. The lock-up mechanism comes into operationin 3rd gear,

Use for engine braking or better traction starting off on loose or slippery surfaces; stays in 2ndgear, does not shift up and down.

14-4

Page 790 of 2189

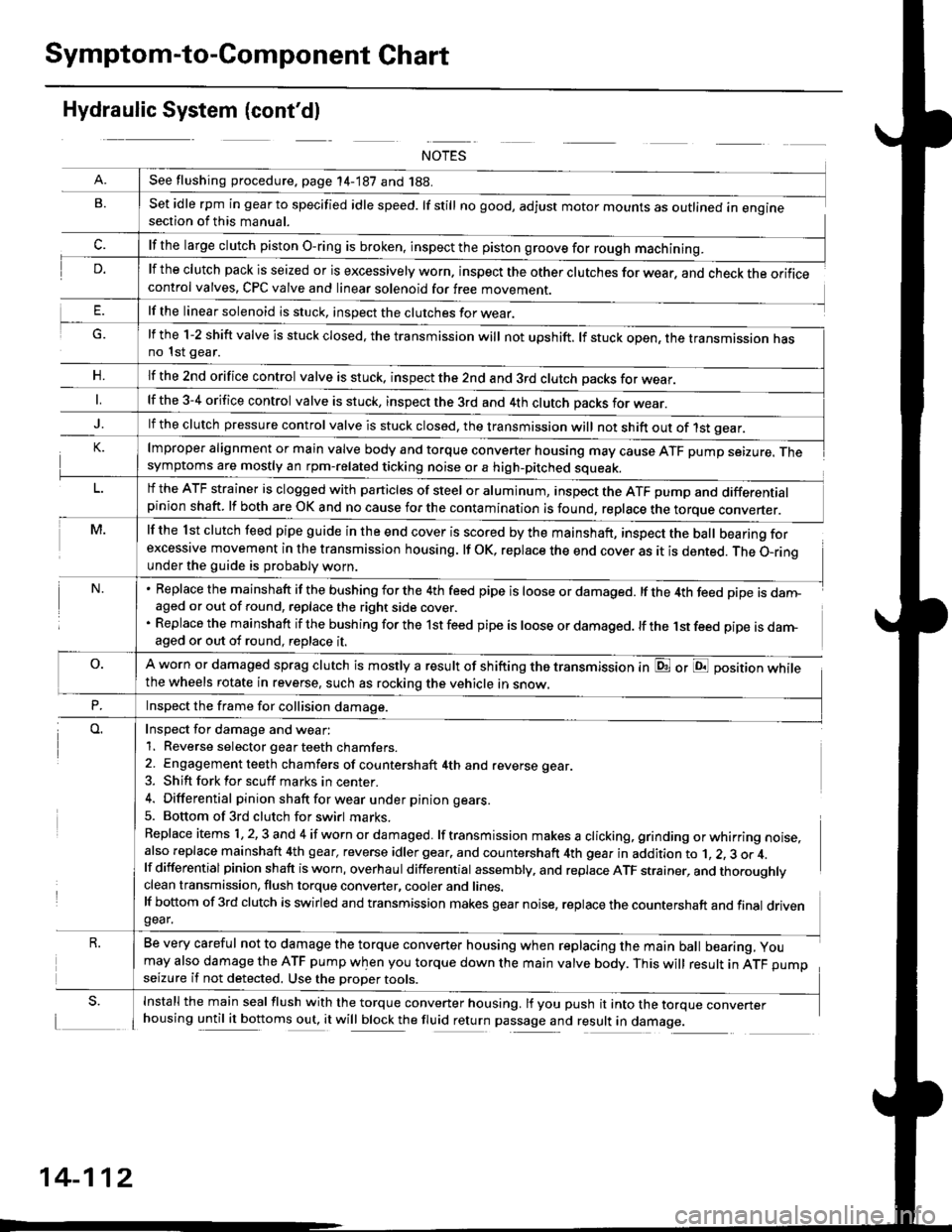

Symptom-to-Component Chart

Hydraulic System (cont'dl

G.

n,

set idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

lf the clutch pack is seized or is excessively worn. inspect the other clutches for wear, and check the orificecontrol valves, CPC valve and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lmproper alignment or main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

lf the l st clutch feed pipe guide in the end cover is scored by the mainshaft, inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged. lf the 4th feed pipe is danFaged or out of round, replace the right side cover.

Replace the mainshaft if the bushing for the 1st feed pipe is loose or damaged. lf the 1st feed pipe is darn-aged or out of round, replace it.

A worn or damaged sprag clutch is mostly a result of shifting the transmission inthe wheels rotate in reverse, such as rocking the vehicle in snow.

or E position while

Inspect for damage and wear:

1. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear u nder pin ion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1,2,3 and 4 if worn or damaged. lf transmission makes a clicking, grinding orwhirring noise,also replace mainshaft 4th gear, reverse idler gear. and countershaft 4th gear in addition to 1, 2, 3 or 4.lf differential pinion shaft is worn, overhaul differential assembly, and replace ATF strainer, and thoroughlyclean transmission, flush torque converter, cooler and lines.lf bottom of 3rd clutch is swirled and transmission makes gear noise, replace the countershaft and final drivengear.

Be very careful not to damage the torque converter housing when replacing the main ball bearing, you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the oroper roors.

Install the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

See flushing procedure, page 14-187 and 188.

lf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

lf the l-2 shift valve is stuck closed, the transmission will not upshift. lf stuck open, the transmission hasno 1st gear.

lf the znd orifice control valve is stuck. inspect the 2nd and 3rd clutch oacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch oacks for wear.

lf the clutch pressure control valve is stuck closed, the transmission will not shift out of 1st gear.

lf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Inspect the frame for collision damage.

14-112

Page 794 of 2189

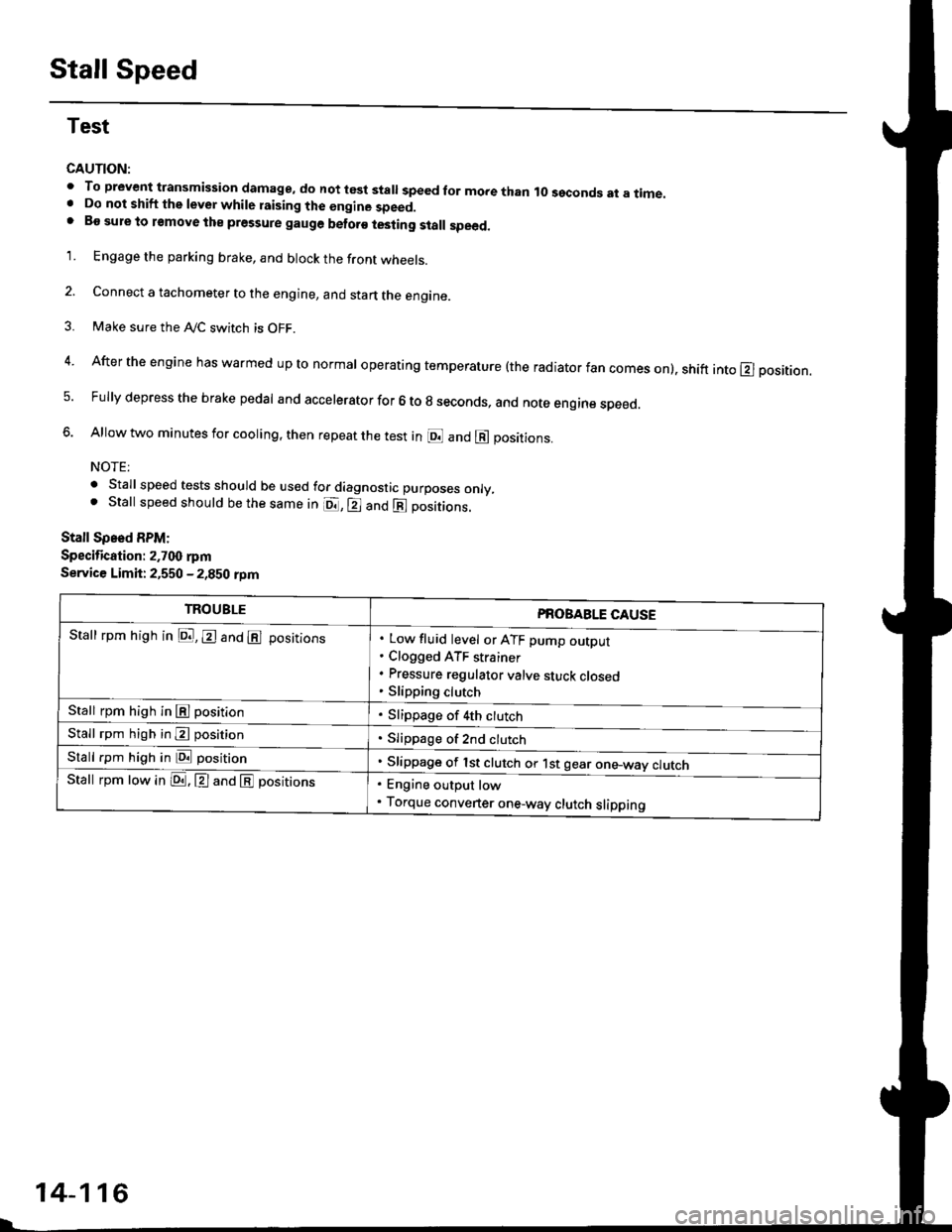

Stall Speed

Test

CAUTION:

. To prev€nt transmission damage, do not t6st stall speed for more than ro sgconds at a time.. Do not shift the levor while raising the engine speed.. Bo sule lo remove the pressure gauge betoro testing stall speed.

'1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the Ay'C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on). shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to g seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in @ and @ positions.

NOTE:

. Stall speed tests should be used for diagnostic purposes only,. Stall speed should be the same in o., E and E positions.

Stall Spsed RPM:

Specification: 2.700 rpm

Service Limit: 2,550 - 2,850 rDm

TROUBLEPROBABLE CAUSE

. Low fluid level or ATF pump outDur. Clogged ATF strainer. Pressure regulator valve sluck closeo. Slipping clutch

. Slippage of 4th ctutch

. Slippage of 2nd clutch

. Slippage of lst clut"tr or. t"t g""io*-*"y "lut"h

Stall rpm high in D., E and E positions

Stall rpm high in El position

Stall rpm high in E posirion

Stall rpm high in E position

Stall rpm low in LDa . El and E positrons. Engine output low. Torque converter one-way clutch slipping

14-116