srs harness HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1549 of 2189

t

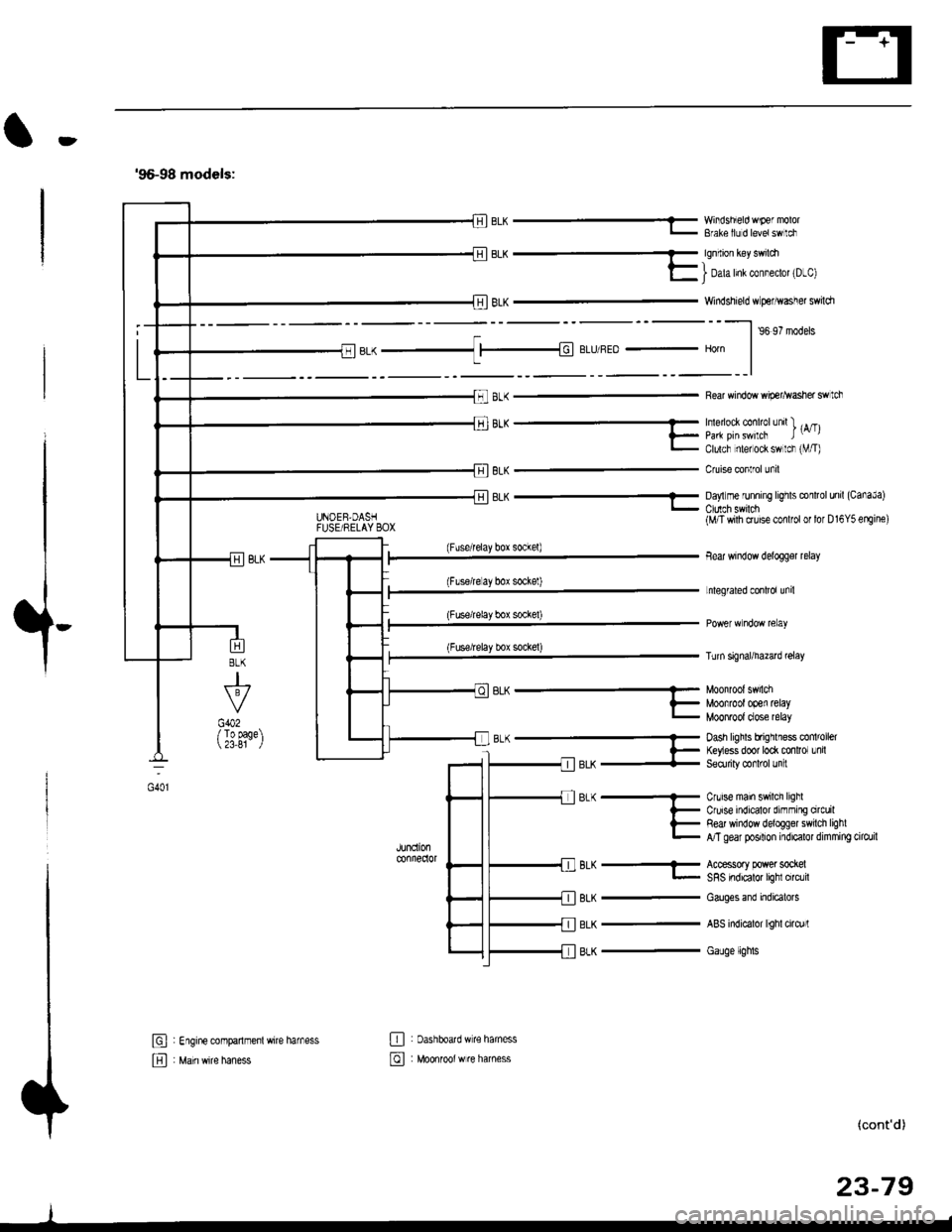

'96-98 models:

BLK -..1 |-|d BLIJ/REo - Horn

8LK

J

G402/ To page 23,81

6L^ --...........-- Munn'un' 5.nLi

?_ Moofrootooen retayL MOOnTOOI dose relay

B-(- Dash hghls bfrqrlless co 'oel

l- ftyess door to* mnlror Lnil-llerX + Seorriry @rl'ol Jn :

JUndonconnedor

BLK

BLK

BLK

Cnrise main swilch lighlCruise indicalor dirnming orcuilRed window deloggel swilch lighlA/T gear posilion indicalor dimming cilo./il

Accessory power sockelSRS indicalor lighl circlil

Cauges end indicatols

ABS indicalor lighl cirq)rl

Gauge lights

El : Engine companmenl wire harness

E , M"in *it" h"n"..

E : oashboatd w€ haness

@ : Moonrool w re harness

UNOEB,DASHFUSE/RELAY BOX

EL^ - YY'iisnEo 'F€ "'v'u'- Bfale llJ d levetswlci

qq.-_

E I Dah Inl col"eclot 'D-cl

Windshield w perhvasher swildr

--l ,o ,? '.da.

Rear window wip€r^vasher swtch

'''"_- -- , rA/Tll_ paa pirswilcF t-,l- Clulcf nlel ock sw lcr rVT)

Cruise conlrol unil

8LK - Da,'lm€ runnrng lrghts conltol unil (CanaJa)

(Fuserelay box sockel)

(Flserelay bor sockel)

(Fuse/relay box socke0

(Fuse/relay box sockel)

BLK-

(M/T wilh cruise conlfol or lor D16Y5 erEine)

Bear window delogger relay

Lnlegrated conlrol unil

Turn signal/hazad @lay

(cont'd)

23-79

oot

Page 1550 of 2189

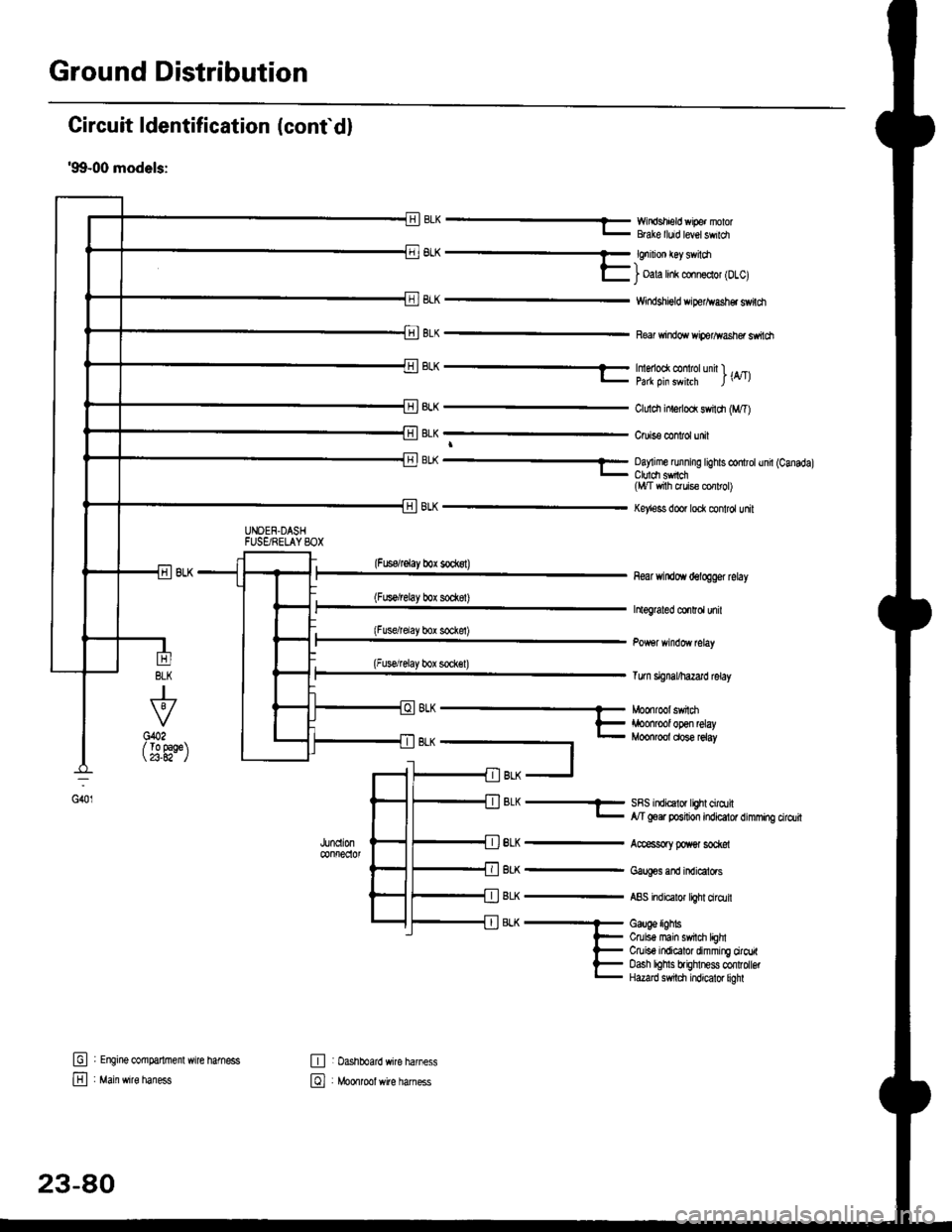

Ground Distribution

Circuit ldentification (conf d)

'99-00 models:

EWir'rdshield wipe. nolorBGke lluid level swildl

6L^ -- €nrnon €y sv loa-)l- i oala hnk conn€clol lDlcl

8LK

BLK

Windshigld dper^vash€r switdt

Re windo wiperlflasher ssitch

BLK

J

To 9aqe23.A2-

tr

E

UNOEN.DASHFUSgRELAYSOX

-r^ -..-- tmenoo( @ rotunn l ._.l- pa* oin swhrh l\4tl

ClLrldr inlerlod swildr (M,T)

Cruis€ confol unit

BL( ---- Oay me running tights controtund (Canadal_ Ctuldt sfich(l,t/T vrith ruis€ cor rol)

Key'ess door lock control unit

(Fuserelay box sockst)

(Fus€/relay box sod(8t)

(Fusdrelay bor sockel)

(Fuserelay box sock€l)

8LK

BLK

BLK

BLK

8LK

near windoYr delogger rclay

htograted co.Ird unil

Tum signal/hazard lelay

SRS indicalor lighl cirqtil,y'T goer position indicator dimming cirdlit

Accessory poxer sod@l

Gaug€s and indicators

ABS indicalor light ciro.lil

Gauge lighbCruis€ main swil$ lEhlCruiso indicator dimming ciroritoash lohls brighlness confolbtHazard s$tdl indicator liohl

G401

(

oh --- Moonroot swnm

t- iroonrool open relay- Moonroot dose reiay

t

fil BLK -J

: Engine @mparlrnenl wire hamess

: Main wire haness

,JUncll0n@nfreclol

E : Dashboard wire harness

El , Mo*tool *ite har"..

23-80

Page 1559 of 2189

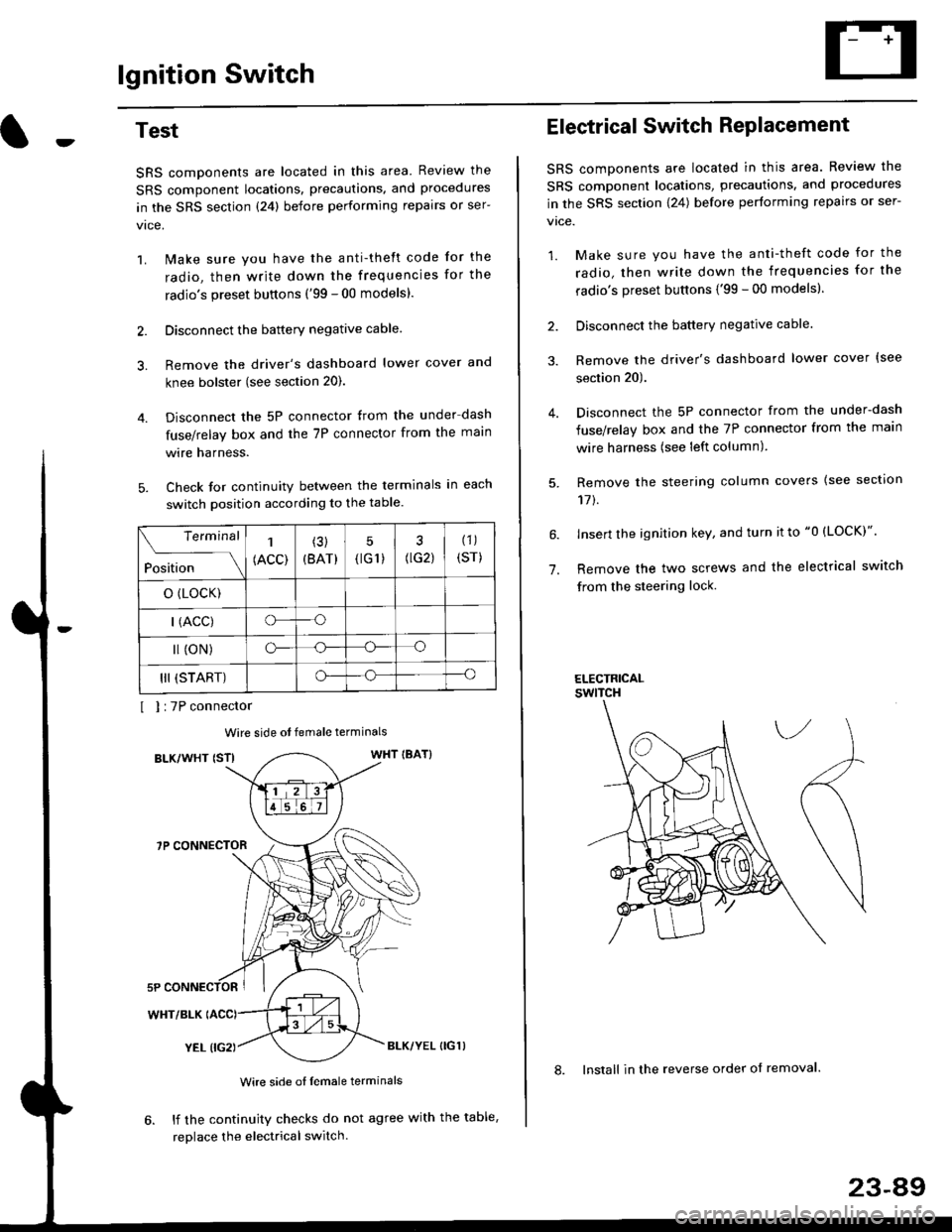

lgnition Switch

4.

Test

SRS components are located in this area Review the

SRS component locations. precautions. and procedures

in the SRS section {24} before performing repairs or ser-

1. i/ake sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons ('99 - 00 models).

2. Disconnect the battery negative cable.

3. Remove the driver's dashboard lower cover and

knee bolster (see section 20).

Disconnect the 5P connector from the under dash

fuse/relay box and the 7P connector from the main

wire harness.

Check for continuity between the terminals in each

switch position according to the table.

I I :7P connector

Wire side ot female terminals

BLK/WHT {STIWHT IBAT}

7P CONNECTOR

WHT/BLK

YEL (IG2}BLK/YEL {IG1)

Wire side of female terminals

6. lf the continuity checks do not agree with the table,

replace the electrical switch.

Terminal

Position

1

(ACC)

(3)

(BAT)

5

{tG1) G2)

(1)

(sr)

o (LocK)

| (ACC)o--o

l (oN)o-o

III (START)o--o

1.

Electrical Switch RePlacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section \24) belore performing repairs or ser-

vtce.

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons {'99 - 00 modelsl.

2. Disconnect the battery negatlve cable.

3. Remove the driver's dashboard lower cover {see

section 20).

Disconnect the 5P connector from the under-dash

fuse/relay box and the 7P connector from the main

wire harness (see left column).

Remove the steering column covers {see section

11t.

lnsert the ignition key, and turn it to "0 {LOCK)".

Remove the two screws and the electrical switch

from the steering lock.

ELECTRICALswtTcH

8. Install in the reverse order of removal.

23-a9

Page 1560 of 2189

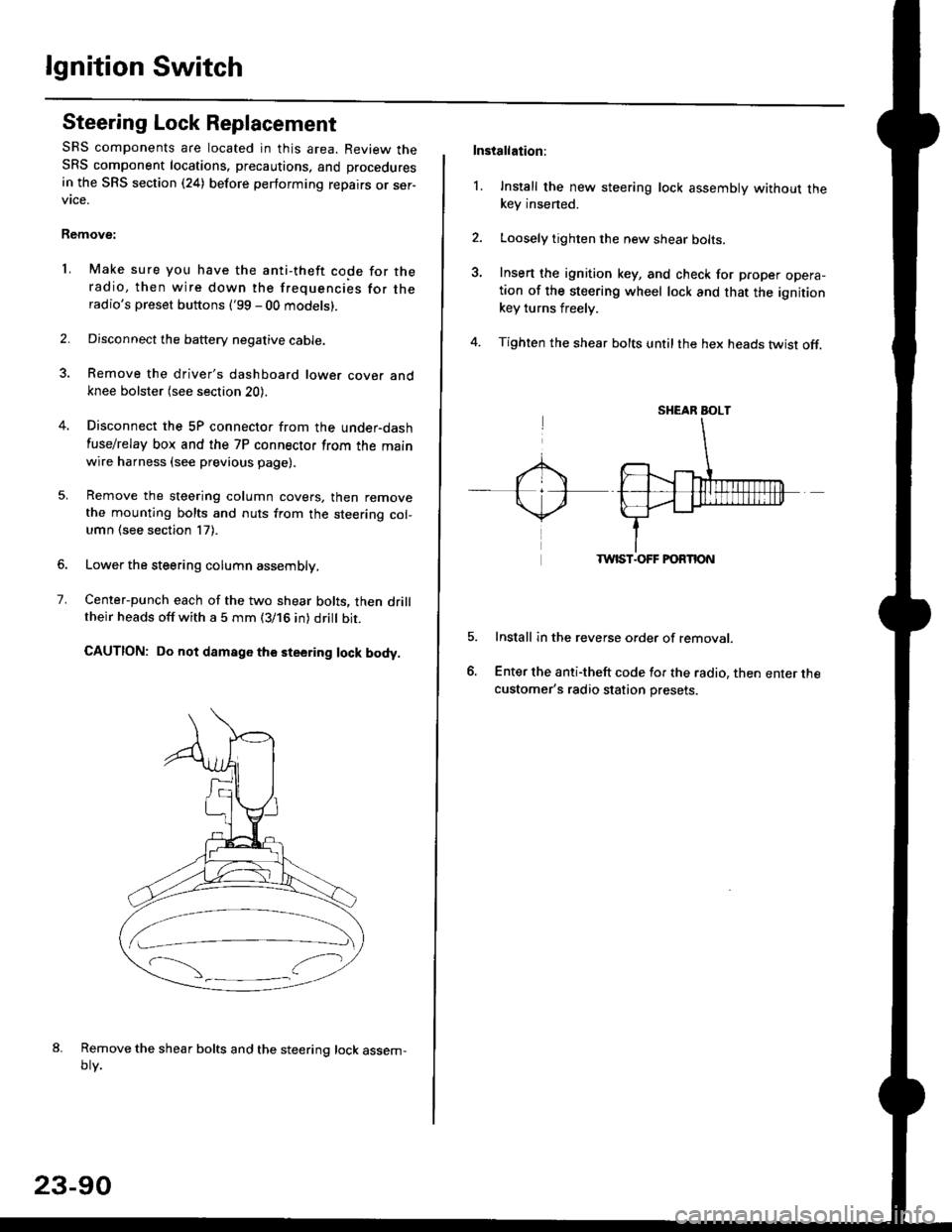

lgnition Switch

Steering Lock Replacement

SRS components are located in this area. Review theSRS component locations. precautions, and procedures

in the SRS section (24) before performing repairs or ser-vtce.

Remove:

LMake sure you have the anti-theft code for theradio, then wire down the frequencies for theradio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable.

Remove the driver's dashboard lower cover andknee bolster (see section 20).

Disconnect the 5P connector from the under-dash

fuse/relay box and the 7P connector from the mainwire harness (see previous page).

Remove the steering column covers, then removethe mounting bolts and nuts from the steering col-umn (see section l7).

Lower the steering column assembly,

Center-punch each of the two shear bolts, then drilltheir heads off with a 5 mm (3/16 in) dritt bit.

CAUTION: Do not damago the steering lock body.

Remove the shear bolts and the steering lock assem,oty.

2.

1.

23-90

Installation:

l. Install the new steering lock assembly without thekey insened.

Loosely tighten the new shear bolts-

Insert the ignition key, and check for proper opera-tion of the steering wheel lock and that the ignitionkey turns freely.

Tighten the shear bolts untilthe hex heads twist off.

TWIST.OFF FORTION

Install in the reverse order of removar.

Enter the anti-theft code for the radio, then enter thecustomer's radio station presets.

sr{€aR SroLT

Page 1669 of 2189

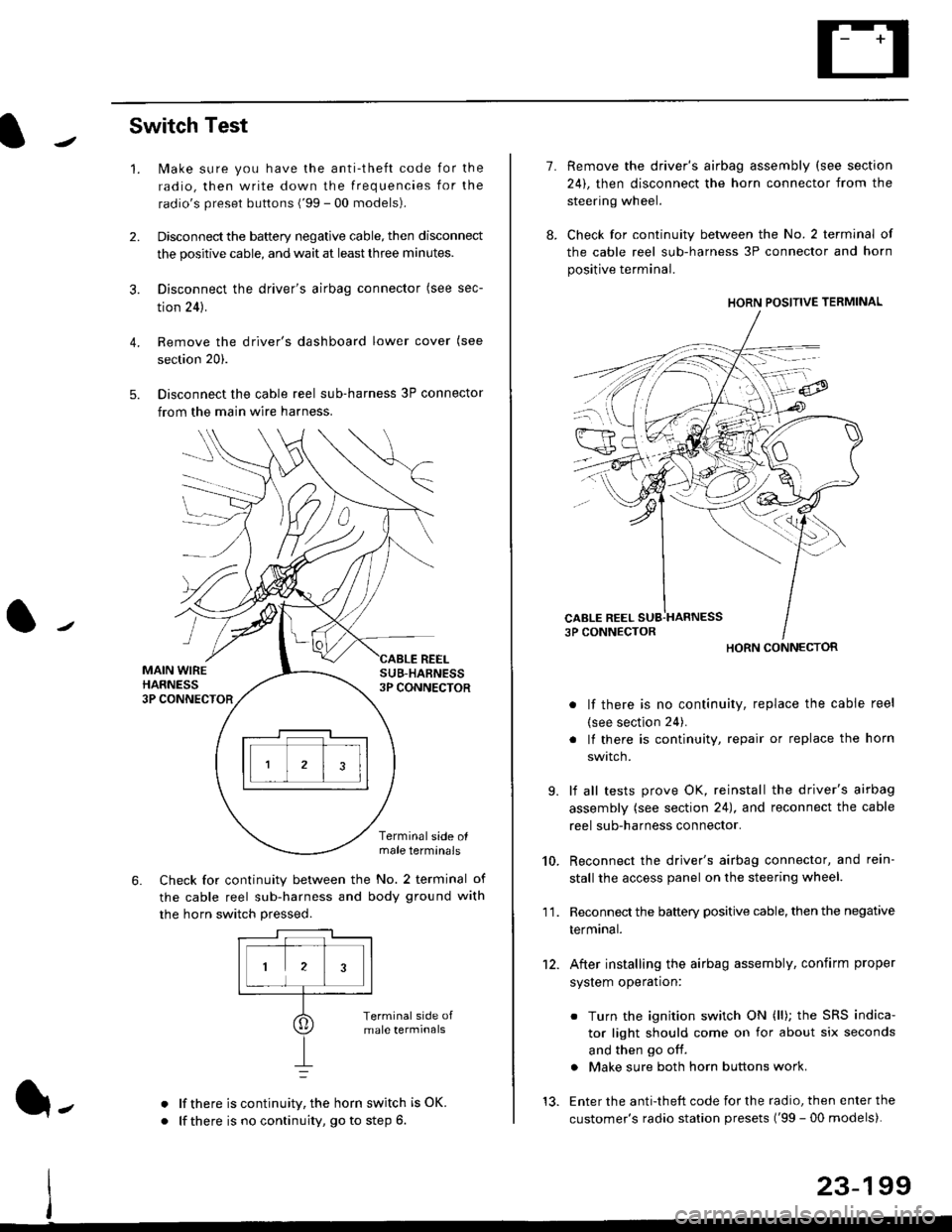

Switch Test

lMake sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable, then disconnect

the positive cable, and wait at least three minutes.

Disconnect the driver's airbag connector (see sec-

tion 24).

Remove the driver's dashboard lower cover (see

section 20).

Disconnect the cable reel sub-harness 3P connector

from the main wire harness.

2.

3.

4.

5.

1.

MAIN WIREHARNESS3P CONNECTOR

SUB-HABNESS3P CONNECTOR

REEL

6.

Terminalside olmale terminals

Check for continuity between the No. 2 terminal of

the cable reel sub-harness and body ground with

the horn switch pressed.

alf there is continuity, the horn switch is OK.

lf there is no continuity, go to step 6l-

-\

1.

8.

10.

'I 1.

9.

Remove the driver's airbag assembly (see section

24), then disconnect the horn connector from the

steering wheel.

Check for continuity between the No. 2 terminal of

the cable reel sub-harness 3P connector and horn

positive terminal.

lf there is no continuity, replace the cable reel

(see section 24).

lf there is continuity, repair or replace the horn

swtlcn,

lf all tests prove OK, reinstall the driver's airbag

assembly (see section 24), and reconnect the cable

reel sub-harness connector.

Reconnect the driver's airbag connector, and rein-

stall the access panel on the steering wheel.

Reconnect the battery positive cable, then the negative

termtnar.

After installing the airbag assembly, confirm proper

system operation:

12.

Turn the ignition switch ON (ll); the SRS indica-

tor light should come on for about six seconds

and then go off.

Make sure both horn buttons work.

13. Enter the anti-theft code for the radio, then enter the

customer's radio station presets ('99 - 00 models).

HORN CONNECTOR

23-199

Page 1715 of 2189

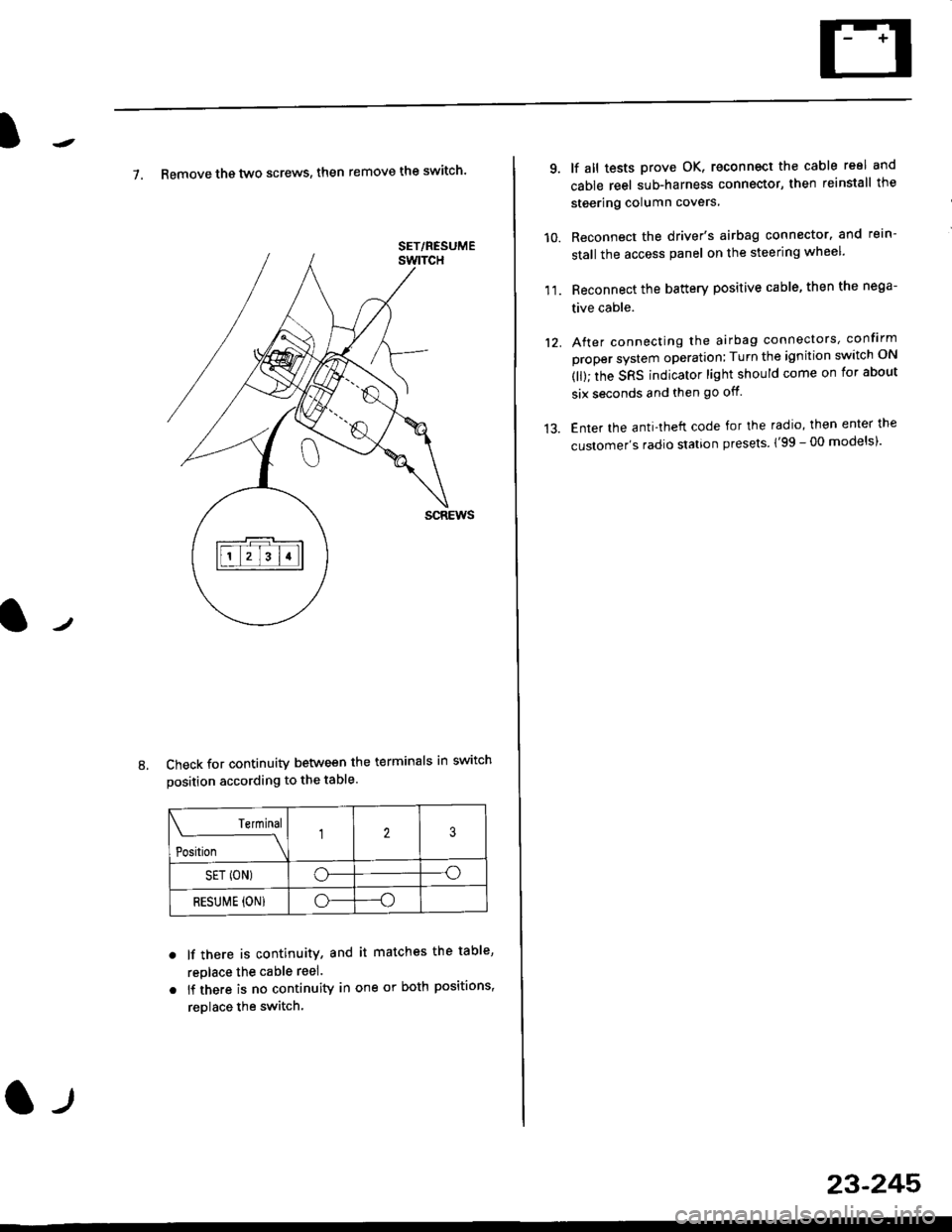

7. Remove th€ two screws, then remove the switch'

Check for continuity between the terminals in switch

position according to the table.

Terminal

t"-"t*

-\23

SET (ON)o--o

RESUI\4E {ON}o----o

lf there is continuity, and it matches the table,

replace the cable reel.

lf there is no continuity in one or both positions,

reDlace the switch.

8.

SET/NESUME

l-l

23-245

11.

q

10.

12.

lf all tests prove OK, reconnect the cable reel and

cable reel sub-harness connector, then reinstall the

steering column covers

Reconnect the driver's airbag connector. and rein-

stall the access panel on the steering wheel.

Reconnect the battery positive cable, then the nega-

tive cable.

After connecting the airbag connectors, confirm

proper system operation; Turn the ignition switch ON

(ll); the SRS indicator light should come on for about

six seconds and then go off.

Enter the anti-theft code for the radio, then enter the

customer's radio station presels {'99 -00 models)'

Page 1741 of 2189

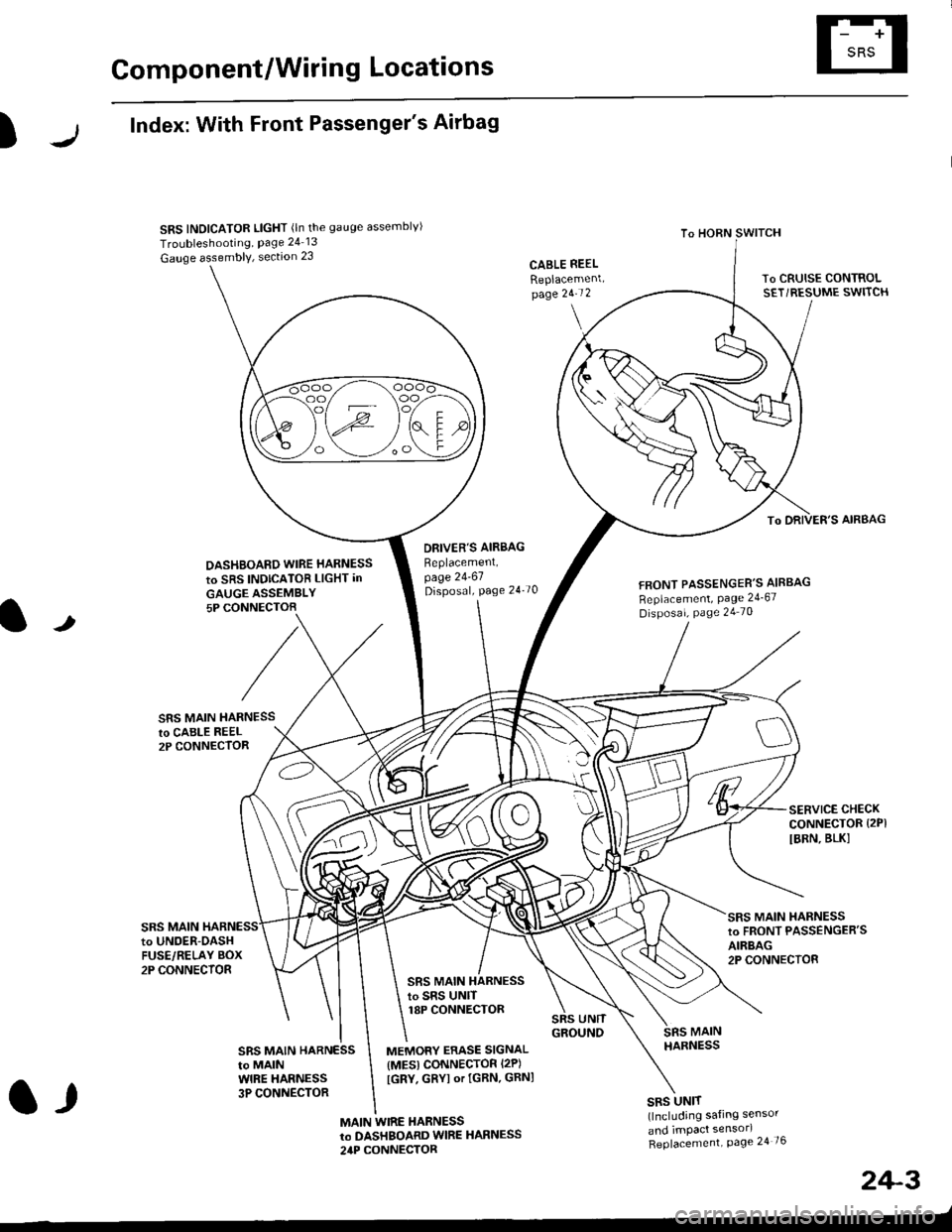

Component/Wiring Locations

)

Index: With Front Passenger's Airbag

SRS INDICATOR LIGHT (ln the gauge assemblvl

Troubleshooting, Page 24 13

Gauge assembly, section 23CABLE REEL

Replacemenlpage 2!-t 2

To HORN SWITCH

SRS UNIT(lncluding safing sensor

and imPact sensorl

Replacement Page 24 76

To DRIVER'S AIRBAG

DASHBOARD WIRE HARNESS

to SRS INDICATOB LIGHT in

GAUGE ASSEMBLY5P CONNECTOB

DBIVER'S AIRBAG

Beplacement,page 24-61Disposal, page 24 70FRONT PASSENGER'S AIBBAG

Replacement, Page 24_67

Disposal, Page 24 70

t

SRS MAIN HARNESSto CABI-E RE€L2P CONNECTOR

SRS MAIN

SERVICE CHECKCONNECTOR {2PI

IBRN, BLK]

to UNOER-OASHFUSE/RELAY BOX2P CONNECTOR

SRS MAIN HARNESSto FRONT PASSENGER'SAIRBAG2P CONNECTOB

SRS MAIN HARNESSto SRS UNITr8P CONNECTOR

SBS MAIN HARNESSto MAINWIRE HARNESS3P CONNECTOR

MEMORY ERASE SIGNAL(MES) CONNECTOR I2P)

[GRY, GRYI or IGRN. GRNI

MAIN WIRE HARNESSto DASHBOARD WIRE HARNESS

24P CONNECTOR

2+3

t,

Page 1742 of 2189

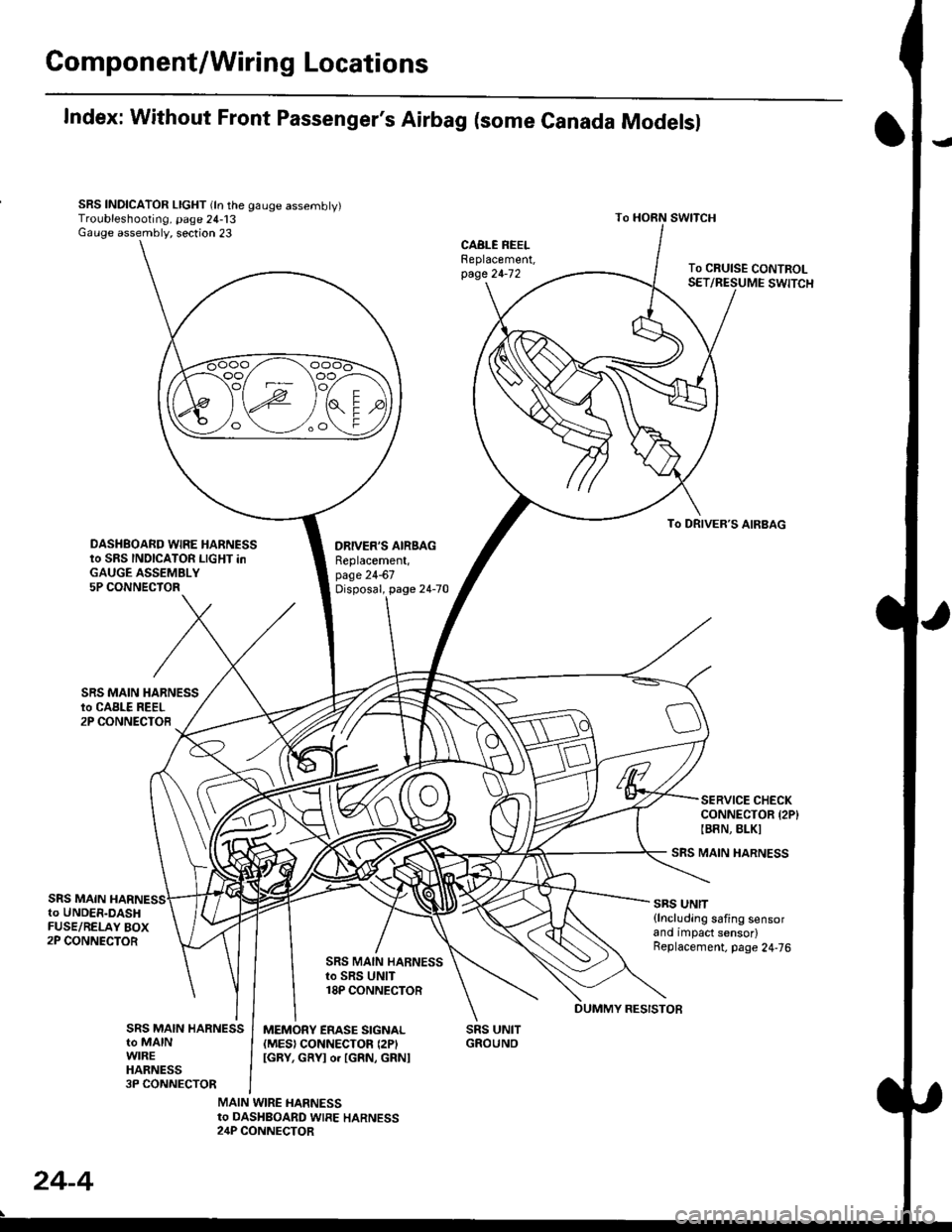

Gomponent/Wiring Locations

Index: Without Front Passenger's Airbag (some Canada Modelsl

SRS INDICATOR LIGHT (ln the gauge assembly)Troubleshooting, page 24-13Gauge assembly, section 23

DRIVER'S AIRSAGReplacement,page 24-67Disposal, page 24-70

SRS UNITGROUNO

To HORN SWITCH

SRS MAIN HARNESS

SRS UNIT{lncluding safing sensorand impact sensor)Replacement. page 24,76

To CRUISE CONTROLSET/RESUME SWITCH

oo/ \oo

To DRIVER,S AIRBAG

DASHBOARD WIRE HARNESSto SRS INDICATOR LIGHT inGAUGE ASSEMBLY5P CONNECTOR

SERVICE CHECKCONNECTOR {2P}IB8N, BLKI

SRS MAINto UNDER-DASHFUSE/RELAY BOX2P CONNECTOR

SRS MAIN HARNESSto SRS UNIT18P CONNECTOR

SRS MAIN HARNESSto MAINWIREHARNESS3P CONNECTOR

MEMORY ERASE SIGNAL(MES) CONNECTON (2P'

IGRY, GRYI o. IGRN, GRNI

MAIN WIRE HARNESSto DASHBOARD WIRE HARNESS24P CONNECTOR

24-4

DUMMY RESISTOB

Page 1746 of 2189

Precautions/Procedu res

SRS Unit Precautions

Take extra care when painting or doing body work inthe area below the dashboard. Avoid direct exDosureof the SRS unit or wiring to heat guns, welding. orsprayang equipment.

Disconnect the airbag connector(s) before discon-necting SRS harness connectors (see page24-1|1J.

After any degree of frontal body damage, or after acollision without airbag deployment, inspect the SRSunit for physical damage. lf it is dented. cracked, ordeformed, replace it.

Be sure the SRS unit is installed securely.

Do not disassemble the SRS unit.

Store the SRS unit in a cool (less than about 104.F/40"C) and dry (less than 80% humidity, no moisture)place. Do not spill water or oil on the SRS unit, andkeep it away from dust.

During installation or replacement, be careful not tobump (impact wrench, hammer, etc.) the area aroundthe SRS unit. The airbag(s) could accidentally deptoyand cause damage or injury.

24-8

Inspection After Deployment

After a collision ln which the airbag(s) was (were)

deployed, replace the SRS unit, and inspect the following:

1. Inspect all the SRS wire harnesses. Replace. don,trepair, any damaged harnesses.

2. Inspect the cable reel for heat damage. lf there is anydamage, replace the cable reel.

3. After the vehicle is completely repaired, turn theignition switch on. lf the SRS indicator light comeson for about six seconds and then goes off. the SRSsystem is OK. lf the indicator light does not functionproperly, go to SRS Troubleshooting.

Page 1747 of 2189

)

Wiring Precautions

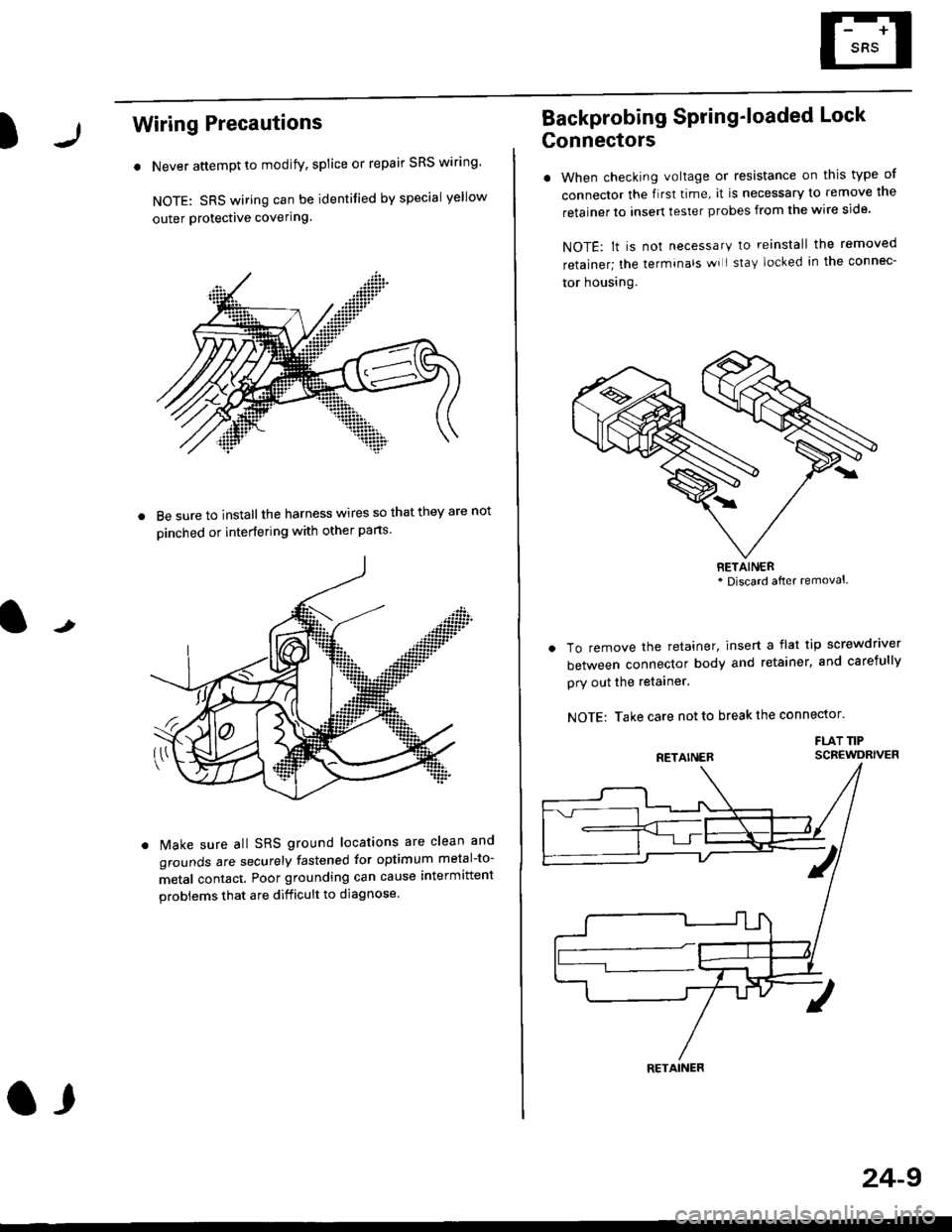

. Never attempt to modify, splice or repair SRS wiring'

NOTE: SRS wiring can be identified by special yellow

outer Protective covering.

8e sure to install the harness wires so that they are not

oinched or interfering with other parts.

t

Make sure all SRS ground locations are clean and

grounds are securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.

a,

24-9

Backprobing Spring'loaded Lock

Gonnectors

. When checking voltage or resistance on this type of

connector the flrst time, it is necessary to remove lne

retainer to insert tester probes from the wire side.

NOTE: lt is not necessary to reinstall the removed

retainer; the terminals wi I stay locked in the connec-

tor housrng.

To remove the retainer, insert a flat tip screwdriver

between connector body and retainer, and carefully

pry out the retainer.

NOTE: Take care not to break the connector.

FLAT TIPSCBEWDRIVER

RETAINER* Discard after removal.

RETAINER