tools HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 166 of 2189

VTEC Rocker Arms

4.

Inspection Using Special Tools (cont,dl

Loosen the valve on the regulator and apply thespecified air pressure.

Specified Air Pressuro:

250 kPa {2.5 kgtlcm,, 36 psil- 490 kPa {5.0 kgtcm,, 7t psil

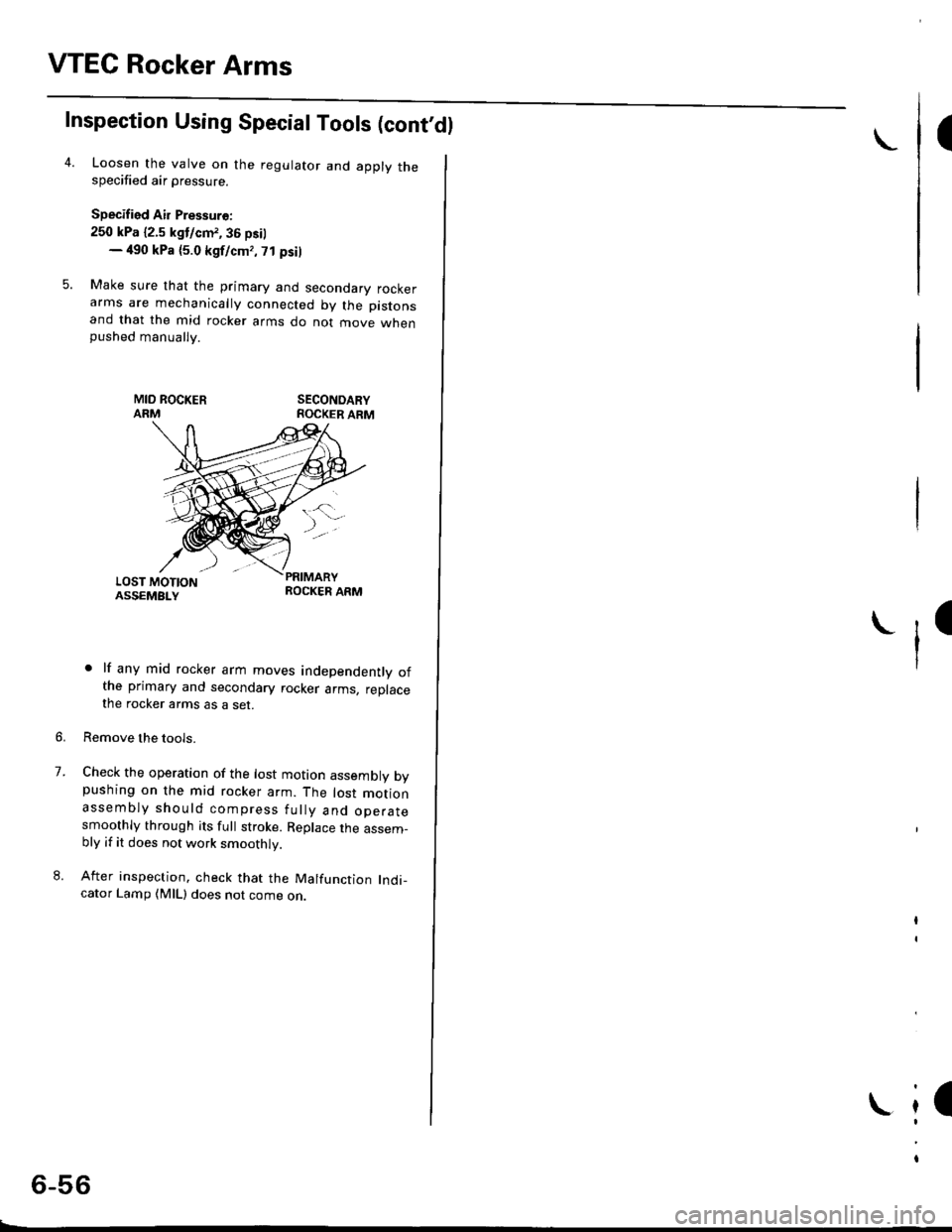

Make sure that the primary and secondary rockerarms are mechanically connected by the pistonsand that the mid rocker arms do no. move wnenpushed manually.

SECONDARYROCKER ARM

. lf any mid rocker arm moves independently ofthe primary and secondary rocker arms, replacethe rocker arms as a set.

Remove the tools.

Check the operation of the lost motion assembly bypushing on the mid rocker arm. The lost motionassembly should compress fully and operatesmoothly through its full stroke. Replace the assem_bly if it does not work smoothly.

After inspection. check that the Malfunction Indi_cator Lamp {MlL) does not come on.

7.

6-56

I

ll

;l

Page 198 of 2189

Engine Block

Speciaf Tools ..........." 7-2

lllustlated Index ...................."..'.......... 7-3

Flywheel and Drive Plate

Repf acement """'.' 7-7

Connecting Rod and Crankshaft

End Play ..........."....7-8

Main Bearings

Clearance ............... 7-9

Selection ................7-10

Connecting Rod Bearings

clearance ....'.......... 7-11

Selection ................ 7-11

Pistons and Crankshaft

Removaf ................. 7 -12

Crankshaft

Inspection ."".........7-14

Pistons

Inspection ......"'.....7-15

fnstaffation .............7-23

Cylinder Block

lnspec'tion ..............7-16

Bore Honing ..........7-17

Piston Pins

Removal ...,...........'.7-17

lnstallation .............7-18

Inspection .'............7-19

Connecting Rods

Selection ................7-18

Piston Rings

End Gap ..........".."' 7'2O

Repfacement .........7-2O

Ring-to-Groove Clearance ...........'.'. 7 -21

Afignment .......""'.. 7'21

Crankshaft Oil Seal

fnstaffation .............7-22

Crankshaft

fnstaffation ..-.-..'.".' 7'23

Oil Pan

lnstallation .............7-26

Oil Seals

fnstaffation ....""""' 7-29

r-f

Page 199 of 2189

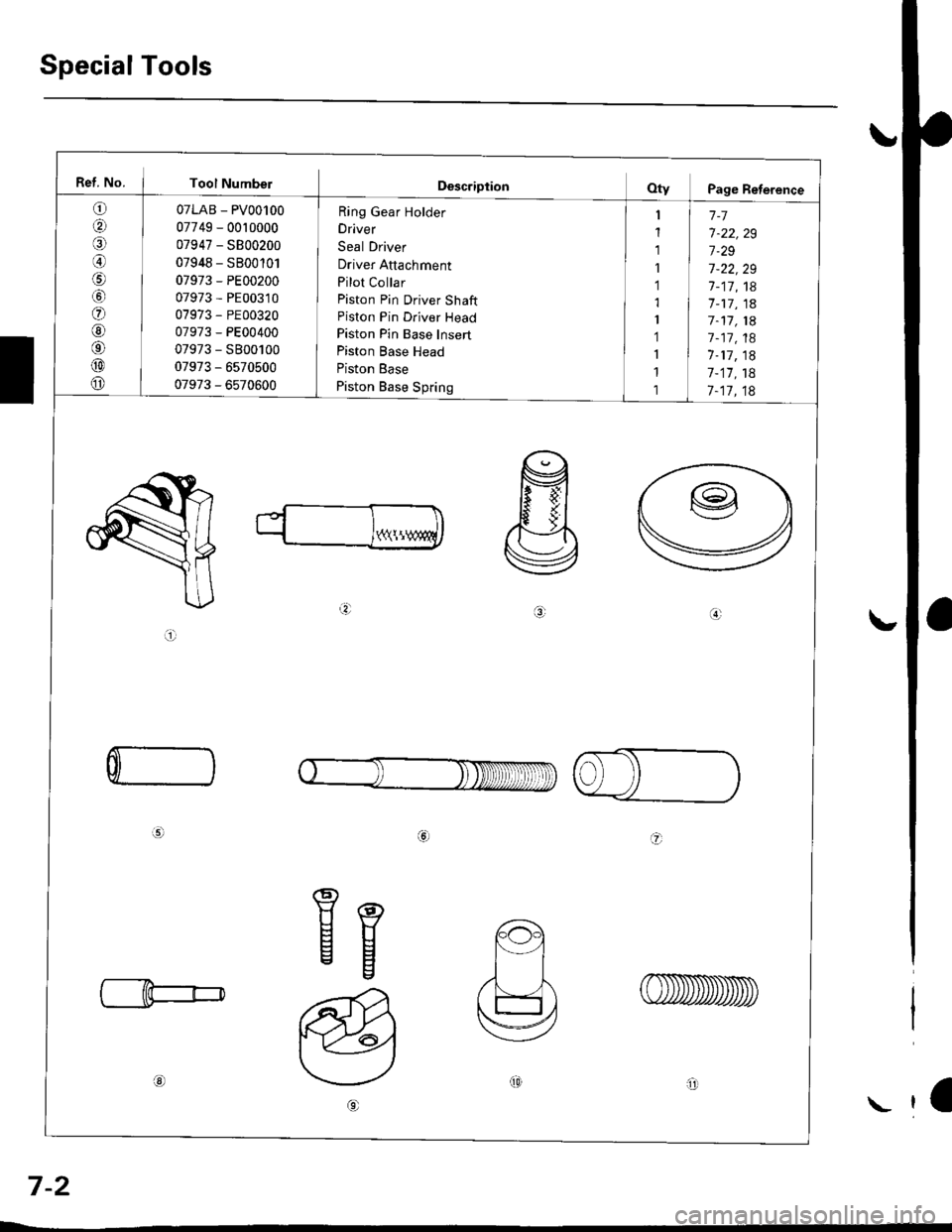

Special Tools

Ref. No. I Tool Numbel

o

aal

@

o

@6'

@

o

07LAB - PV00100

07749 - 0010000

07947 - SB00200

07948 - SB00'101

07973 - PE00200

07973 - PE00310

07973 - PE00320

07973 - PE00400

07973 - S800100

07973 - 6s70500

07973 - 6570600

Ring Gear Holder

Driver

Seal Driver

Driver Attachment

Pilot Collar

Piston Pin Driver Shaft

Piston Pin Driver Head

Piston Pin Base Insert

Piston Base Head

Piston Base

Piston Base Spring

1-7

7-22,29

7.29

7-22,29

7-17,18'7 -17, 1a

7-11, 1A

7 -17, 18

1-17, 18

7-17,18

7-17,18

Y(\!

a.:

ai

C

a

Eg

ot0arll

a

7-2

\

Page 214 of 2189

Cylinder BlockPiston Pins

Bore Honing

1.Measure cylinder bores as shown on page 7-16. lf the

block is to be reused, hone the cylinders and remea-

sure the bores.

Hone cylinder bores with honing oil 8nd a fine (400

grit) stone in a 60 degree cross-hatch pattern.

NOTE:

. Use only a rigid hone with 400 grit or finer stone

such as Sunnen, Ammco, or equivalent.

. Do not use stones lhat are worn or broken.

When honing is complete, thoroughly clean the

engine block of all metal particles. Wash the cylin-

der bores with hot soapY water, then dry and oil

immediately to prevent rusting.

NOTE: Never use solvent. it will only redistribute the

grit on the cylinder walls.

lf scoring or scratches are still present in cylinder

bores after honing to the service limit, rebore the

cylinder block.

NOTE: Some light vertical scoring and scratching is

acceptable if it is not deep enough to catch your fin-

gernail and does not run the full length of the bore.

CYLINOES BLOCK

CYLINDER

NOTE:

. After honing, clean the cylinder thoroughly with

soapy warer.

. Onlv a scored or scratched cylinder bore must be

noneo.

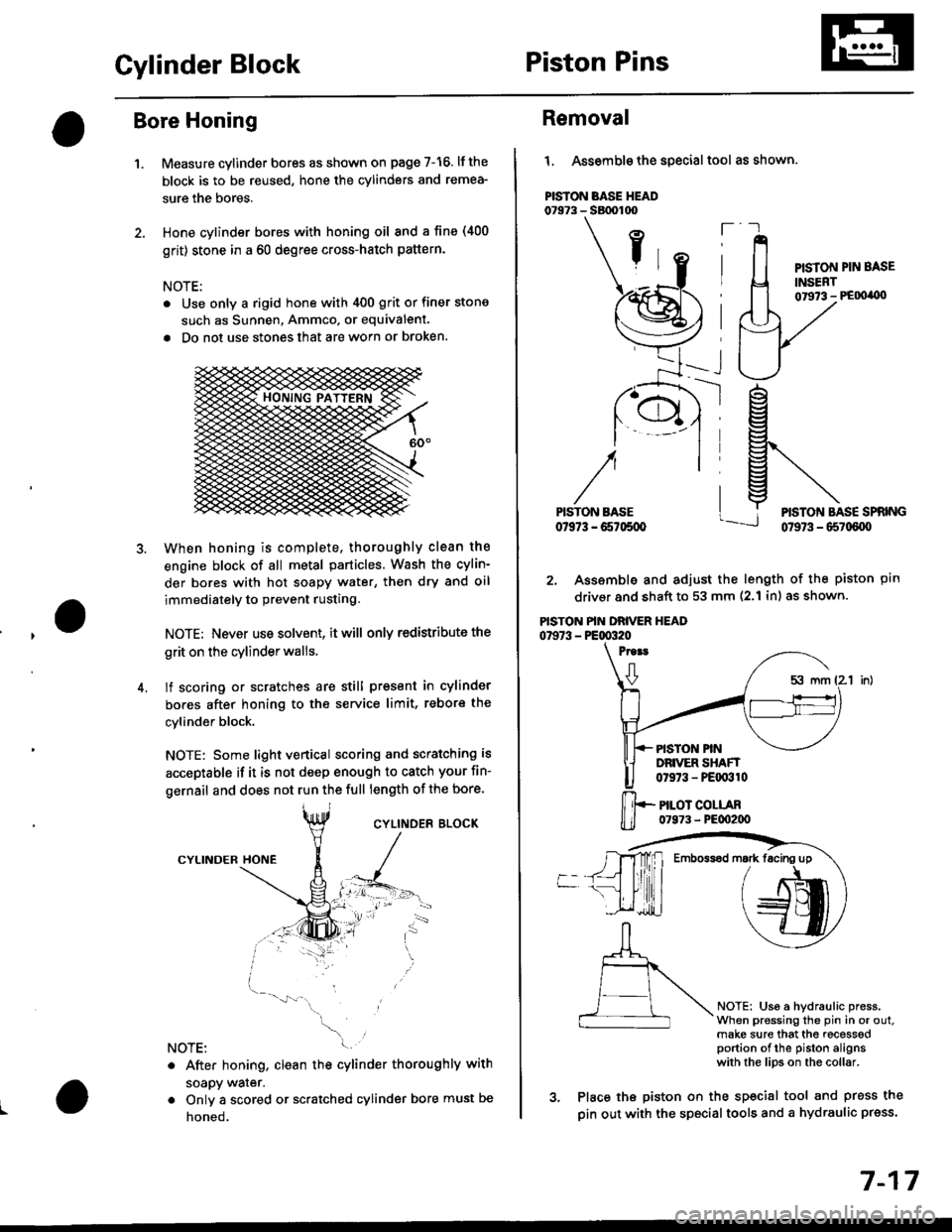

Removal

l. Assemble the special tool as shown.

PISTON BASE HEAD07973 - SBtx)too

ft

PISTON PIN BASE

INSERT01973 - PE00'0)

ptn

NOTEi Us6 a hydraulic press.When pressing the pin in or out.make sure that the recesssdportion of the piston alignswith the lips on the collar.

rg

g\

lj*N*,""

2. Assemble and adjust the length of the piston

driver and shaft to 53 mm (2.1 inl as shown.

PISTON PIN DRIVER HEAD07973 - PE00320

Proat

0

PISTON PINDRIVER SHAFT0t973 - PEqr310

PILOT COLLAR07973 - PE00200

3. Place the piston on the sp€cial tool and press the

pin out with the special tools and a hydraulic press.

Emboss6d mark facing up

7-17

Page 219 of 2189

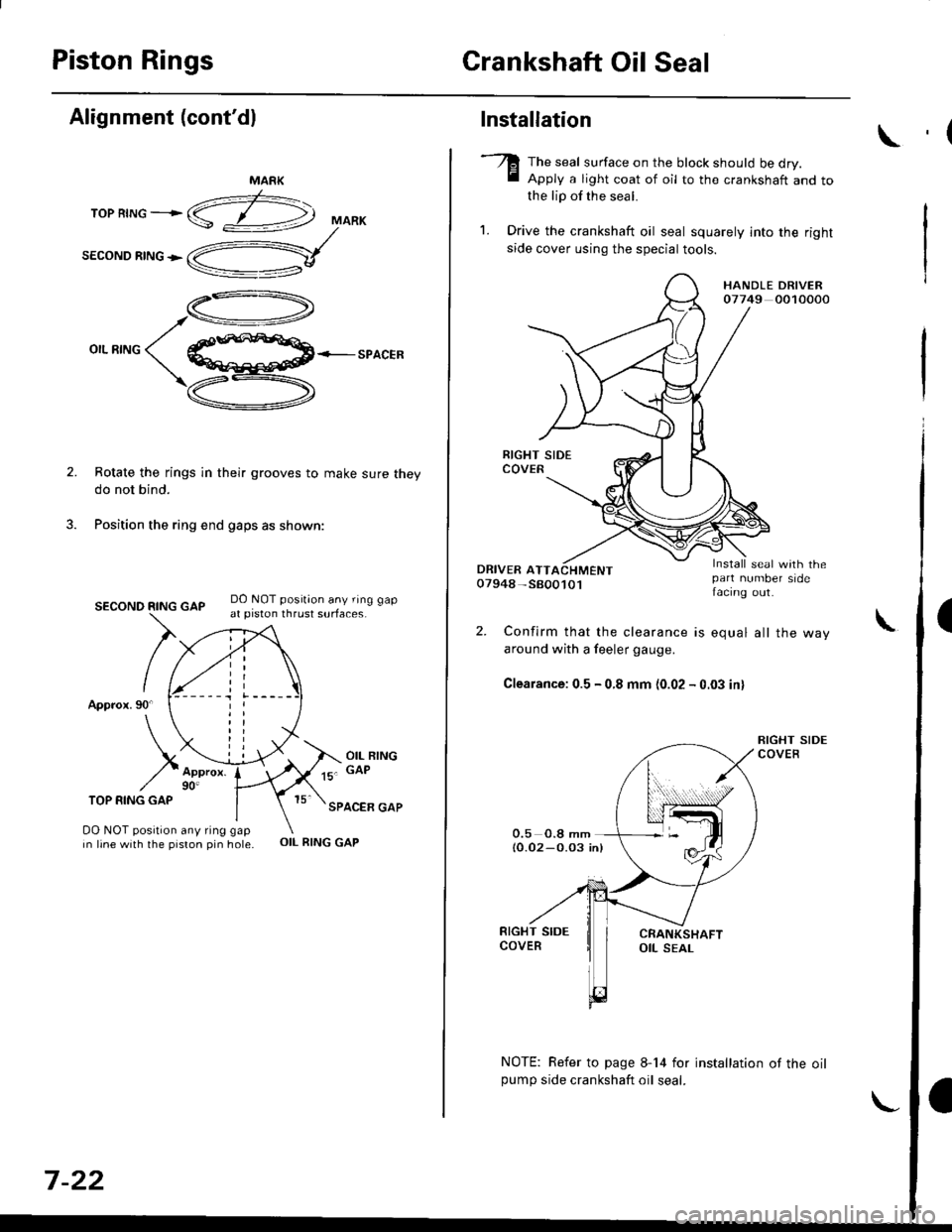

Piston RingsCrankshaft Oil Seal

Alignment (cont'dl

TOP RING ---.>

SECOND RING >

MARK

,a-)

/\_4

o,.r^o( qffi<--sPACER

\Z-.

v

Rotate the rings in their grooves to make sure theydo not bind.

Position the ring end gaps as shown:

DO NOT position any ring gapat piston thrust surfaces.

DO NOT position any ring gapin line with the piston pin hole.OIL RING GAP

SECOND RING GAP

Approx.90

TOP RING GAP

7-22

Installation

The seal surface on the block should be dry.Apply a light coat of oil to the c.ankshaft and tothe lip of the seal.

1. Drive the crankshaft oil seal squarely into the right

side cover using the special tools.

HANDLE DRIVER07749 0010000

seal with thepan number sidefacing out.

Confirm that the clearance is equal all the way

around with a feeler gauge.

Clearance:0.5 - 0.8 mm (0.02 - 0.03 inl

NOTE: Refer to page 8-14 for installation of the oilpumo side crankshaft oil seal.

,(

\

Page 227 of 2189

Engine Lubrication

SpecialTools .......... "'.""".8'2

lllustrated Index ........... .'..' 8-3

Engine Oil

Inspection .....'......"....."'. 8-6

Replacement........'......".'.'..."...."......" 8-7

OilFilter

Rep1acement...............".'...'..'.....'.'...". 8-8

Oil Pressure

Testing '.....' 8-9

OilJet (B16A2 engine)

Inspection ...'.'......"...."'..8-10

OilPump

overhaul.'... .....'...'..'."""' 8-11

Removal/lnspection/lnstallation ..'.... 8-1 3

Page 228 of 2189

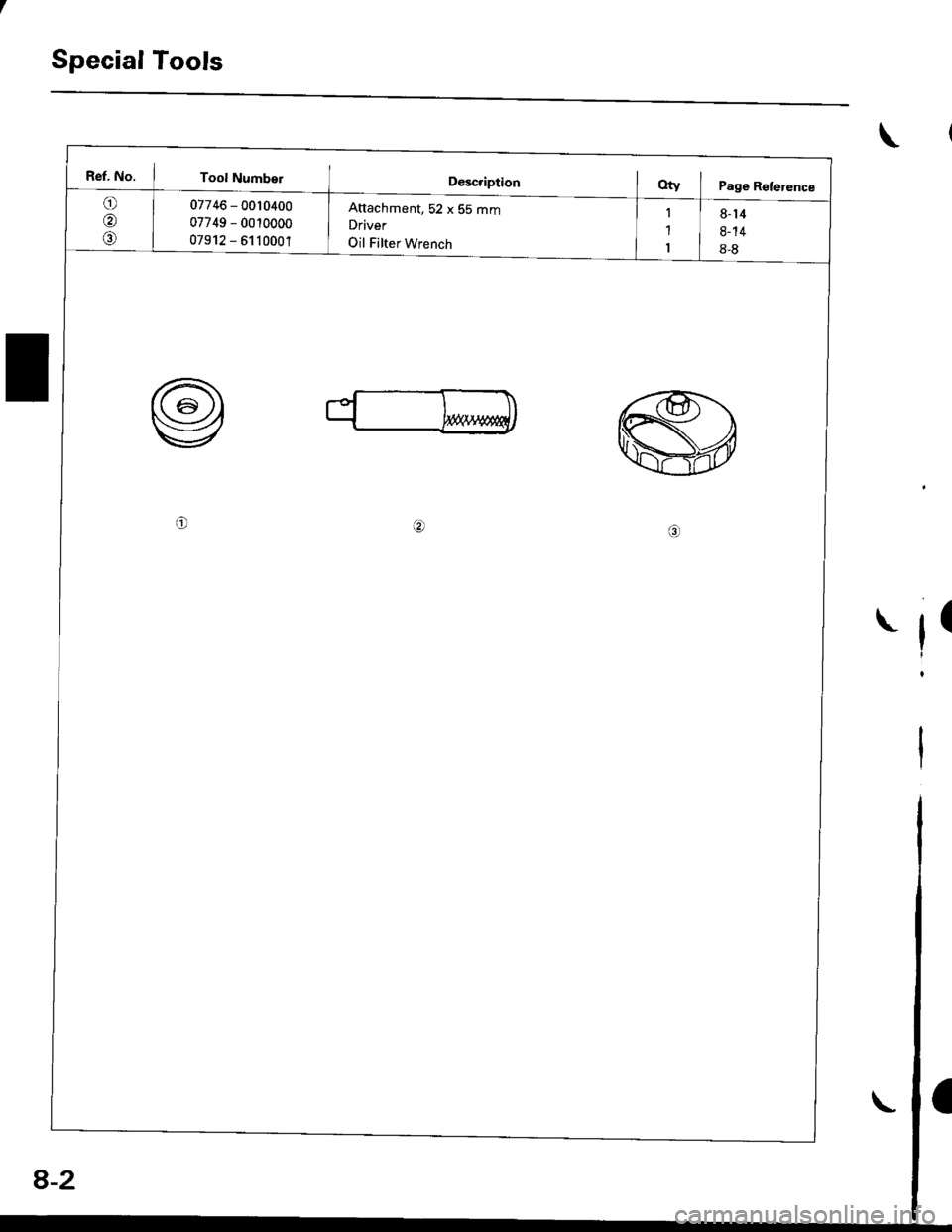

Special Tools

Ref. No. I Toot Number

07746 - 0010400

07749 - 0010000

07912 - 6110001

Attachment, 52 x 55 mmDriver

Oil Filter Wrench

o6\,6

\

ll

a

8-2

\

Page 271 of 2189

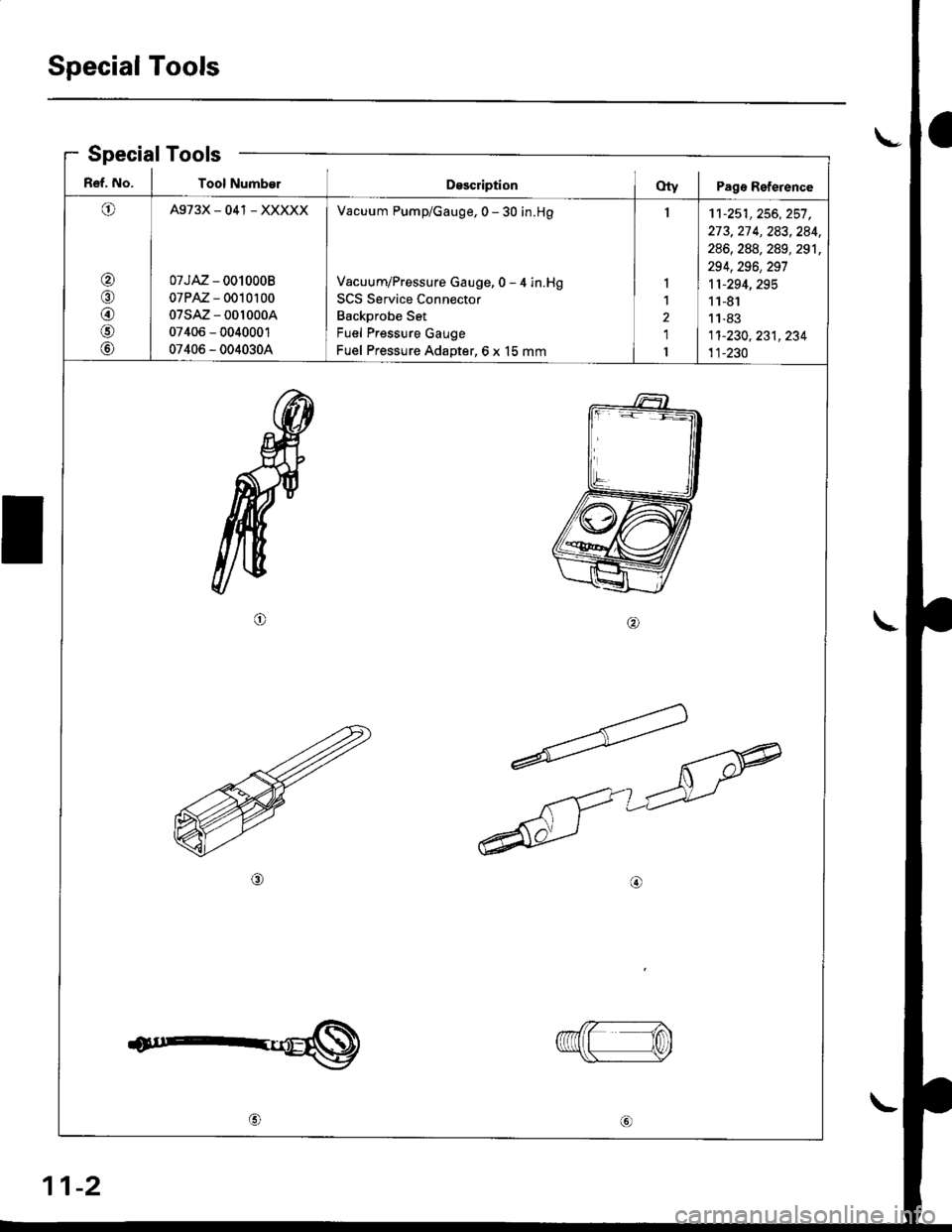

Special Tools

a\-Special Tools

R€f. No. I Tool NumberDsscriptionOty I Pagr Reference

O

@/n

@

@

@

A973X_041 _ XXXXX

07JAZ - 0010008

07PAZ - 0010100

07sAz - 001000A

07406 - 0040001

07406 - 0040304

Vacuum Pump/Gauge, 0 - 30 in.H9

Vacuum/Pressure Gauge, 0 - 4 in.Hg

SCS Service Connector

Backprobe Set

Fuel Pressure Gauge

Fuel Pressure Adapter,6 x 15 mm

I

I

1

2

1

I

11-251,256, 257 ,273,27 4, 283,284,

286, 288, 289, 291,

294,296,297

11-294,295

11-81

11-83

1'�t-230, 231, 234

11-230

ta

1n\Y

11-2

Page 496 of 2189

I

Fuel Tube/Ouick-Gonnect Fittings

Precautions

!@ Do not smoke while working on the fuel

system, Keep open flames away from your work a.ea'

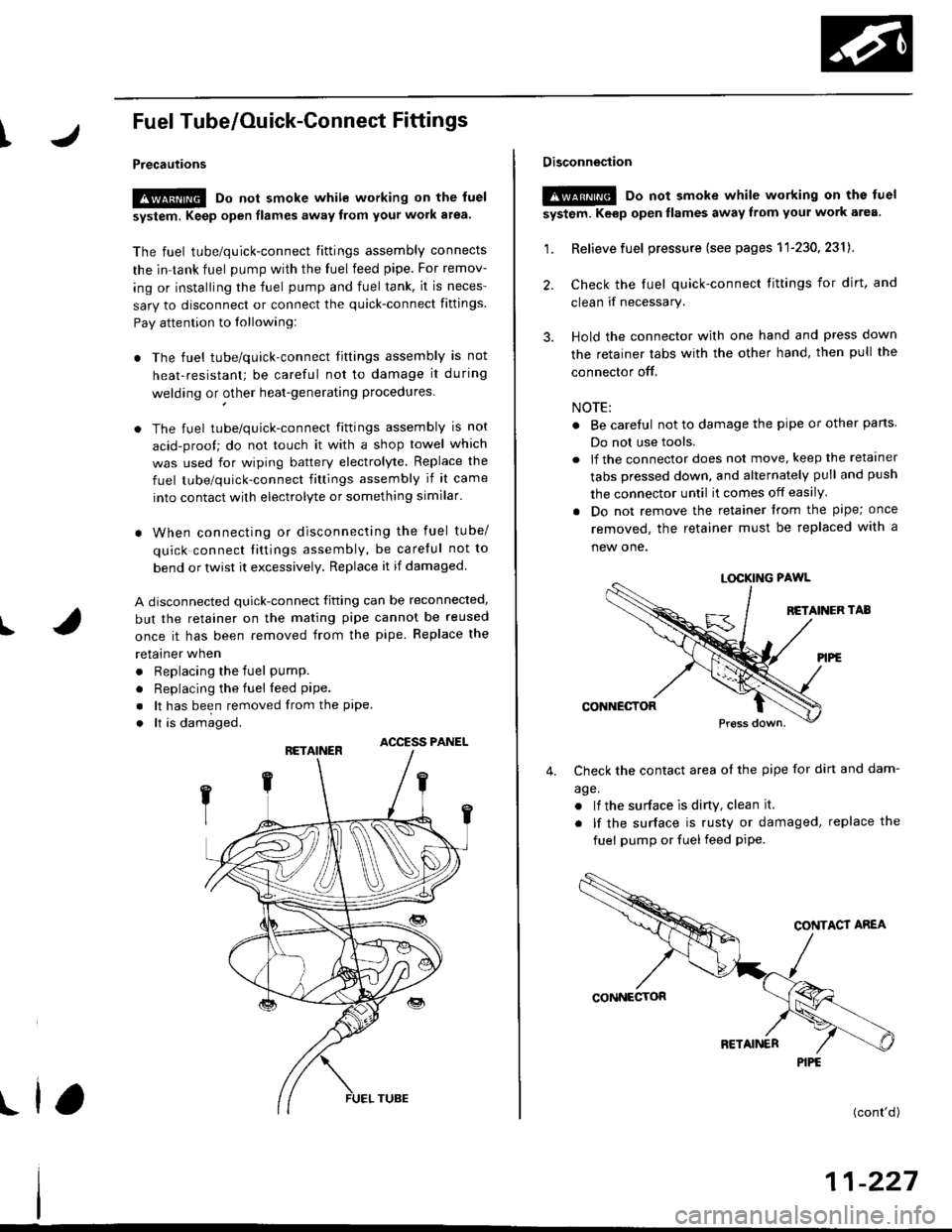

The fuel tube/quick-connect fittings assembly connects

the in tank fuel pump with the fuel feed pipe. For remov-

ing or installing the fuel pump and fuel tank, it is neces-

sary to disconnect or connect the quick-connect fittings.

Pay attention to lollowing:

. The fuel tube/quick-connect fittings assembly is not

heat-resistant; be careful not to damage it during

welding or other heat-generating procedures

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. Replace the

fuel tube/quick-connect fitlings assembly if it came

into contact with electrolyte or something similar.

. When connecting or disconnecting the fuel tube/

quick connect liltings assembly, be careful not to

bend or twist it excessively. Replace it if damaged

A disconnected quick-connect fitting can be reconnecled,

but the retainer on the mating pipe cannot be reused

once it has been removed from the pipe. Replace the

retatner wnen

. Replacing the fuel pump.

. Replacing the fuel leed pipe.

. lt has been removed lrom the PiPe.. lt is damaged.

ACCESS PANEL

I

Disconnestion

!@ Do not smoke while working on the luel

system. Keep open llames away lrom youl work area.

1. Relieve fuel pressure (see pages 11'230,2311.

2. Check the tuel quick-connect tittings for dirt, and

clean if necessary.

3. Hold the connector with one hand and press down

the retainer tabs with the other hand, then pull the

connector off.

NOTE:

o Be carelul not to damage the pipe or other pans

Do not use tools.

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

. Do not remove the retainer from the pape; once

removed, the retainer must be replaced with a

new one.

LOCKING PAWL

BETAINER TAB

CONNECTOR

Check the contact area o{ the pipe for dirt and dam-

age.

. lf the surface ls dirty, clean it.

. lf the surface is rusty or damaged, replace the

fuel pump or fuel feed piPe.

4.

(cont'd)

11-227

PIPE

Page 500 of 2189

tJFuel Pressure {'97 and later Models)

ReliGving

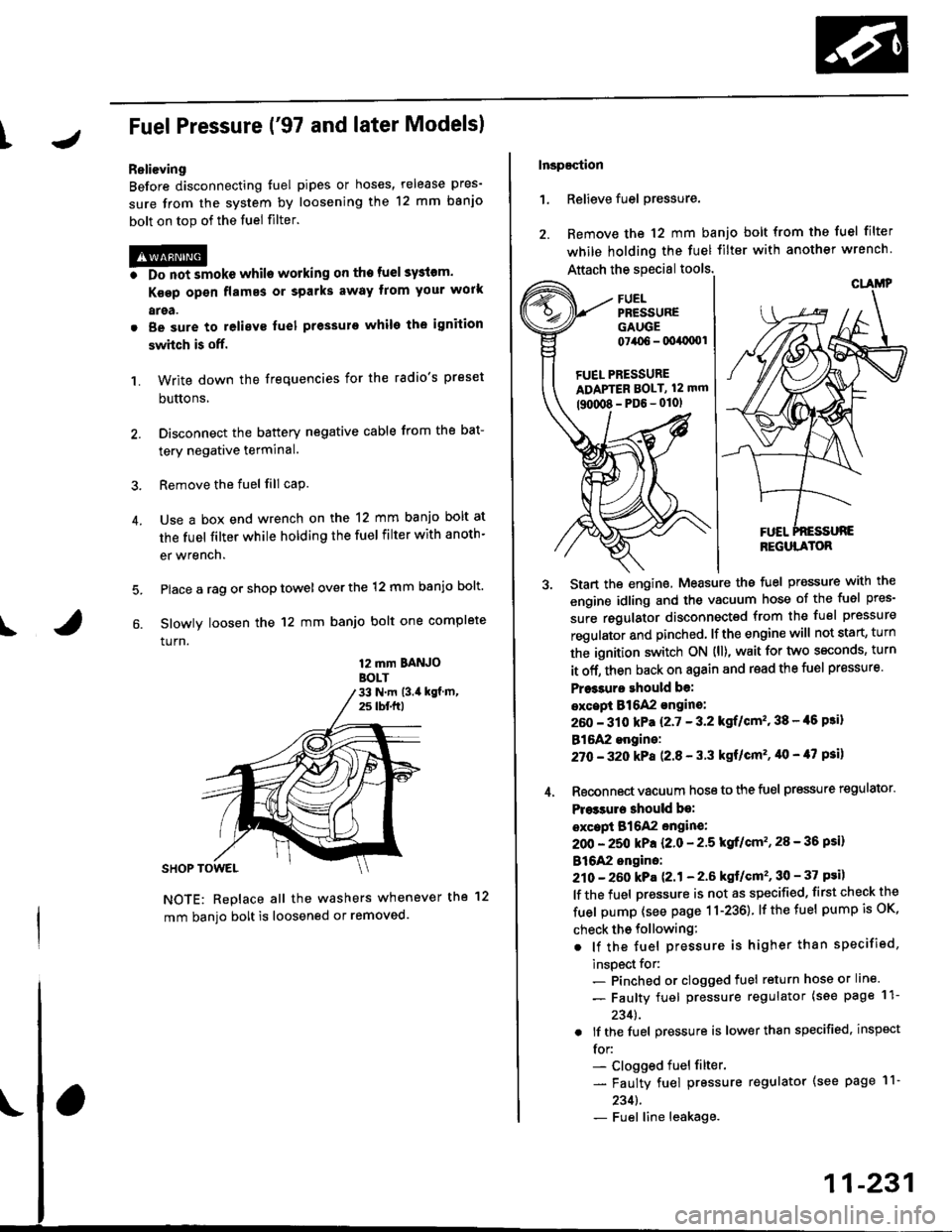

Before disconnecting tuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on top of the fuel filter.

@o Do not smoke whilo working on the fuel sy3lom.

Ksgp op€n flames or sparks away tlom Your work

arga.

. Be sure to relieve fuel pressule while the ignition

swhch is off.

1. Write down the frequencies for the radio's preset

buttons,

2. Disconnect the battery negative cable from the bat-

tery negative terminal.

3. Remove the fuel fill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with anoth-

er wrench.

Place a rag or shop towel over the 12 mm banio bolt.

Slowly loosen the 12 mm banjo bolt one complete

turn.

4.

I

12 mm BAtt OBOLT33 N.m (3.i1 kgf m,25 tbf.f0

NOTE: Replace all the washers whenever the 12

mm banio bolt is loosened or removed.

Inspaqtion

1. Relieve fuel pressure.

2. Remove the 12 mm banjo bolt from the fuel filter

while holding the fuel Jilter with another wrench

Attach the special tools.

3. Start the enginethe fuel Pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched lfthe engine will not start, turn

the ignition switch ON {ll), wait for two seconds, turn

it off, then back on again and read the fuel pressure'

Pr$3uro ehould be:

excepi 816A2 sngine:

260 - 310 kPa {2'7 - 3.2 kgf/cm" 38 - {6 Fi}

B16A2 engine:

27O -32O kPa P.8 - 3'3 kgf/cm'�, '10 - 47 psi)

4. Reconnect vacuum hoso to the fuel pressure regulator'

Pre33ure 3hould be:

except B16A2 engin€:

2OO - 250 kPa {2.0 - 2'5 kgf/cm'�, 28 - 36 psi)

B16A2 engino:

210 - 260 kPa 121 - 2.6 ksf/cm'�, 30 - 37 psi)

lf the fuel pressure is not as specified, first check the

fuel pump (see page 11-236) lfthetuel pumpisoK,

check tho following:

. lf the fuel pressure is higher than specified,

inspect for:- Pinched or clogged fuel return hose or line.

- Faulty fuel pressure regulator (see page 11-

2341.

. lf the fuel pressure is lower than specified, inspect

for:- Clogged fuel filter.

- Faulty fuel pressure regulator (see page l1-

2341.- Fuel line leakage.

FUEL PRESSUREADAPTER BOLT, 12 mm

tguxt8-PD6-0101

CLAMP

REGULATOR

11-231