Front end HONDA CIVIC 1996 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1027 of 2189

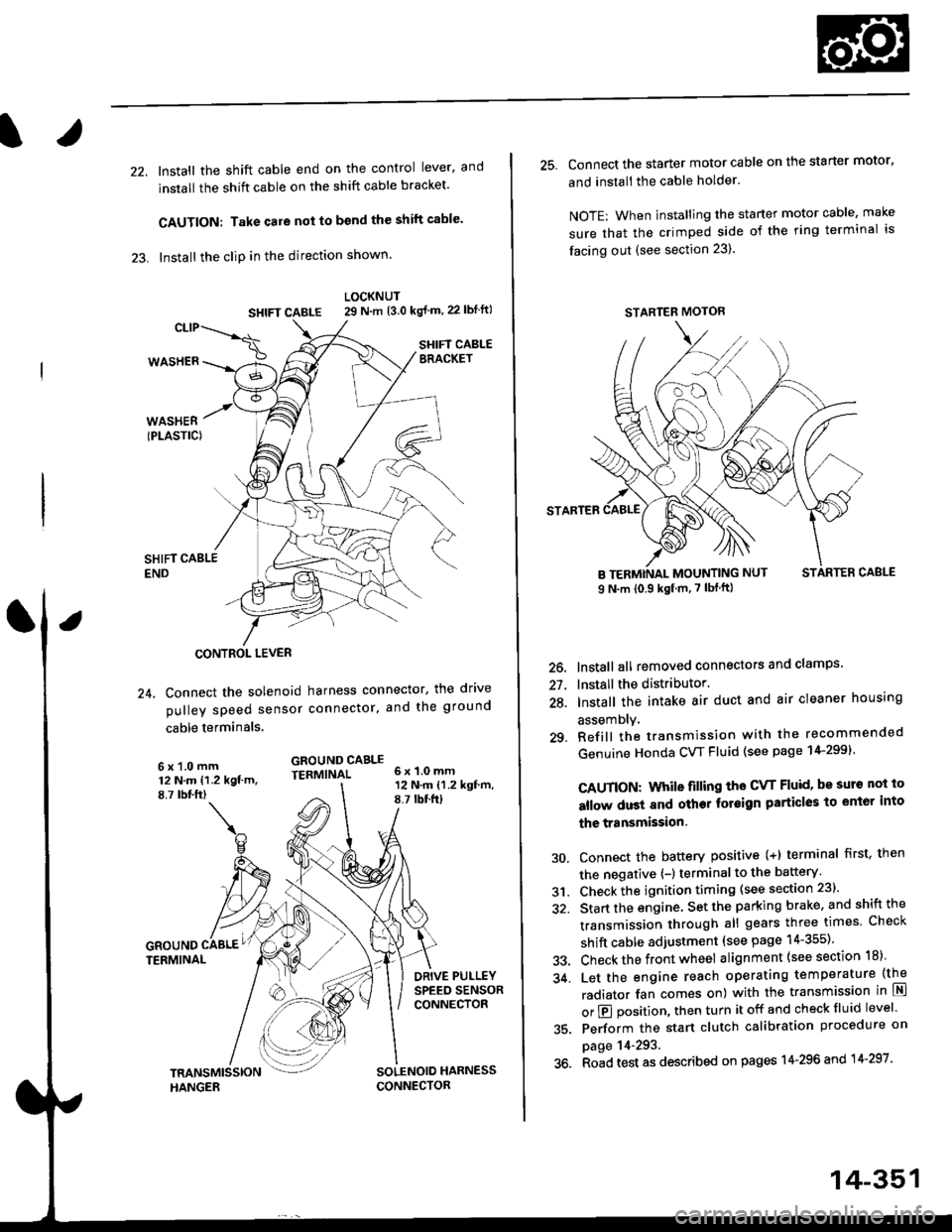

22. Install the shift cable end on the control lever, and

install the shift cable on the shift cable bracket'

CAUTION: Take care not to bend the shift cable'

23. lnstall the clip in the direction shown.

LOCKNUT

SHIFI CABLE 29 N m {3.0 kg{ m, 22lblftl

SHIFT CABLEERACKET

WASHERIPLASTIC)

CONTROL LEVER

24, Connect the solenoid harness connector. the drive

pulley speed sensor connector. and the ground

cable terminals.

6x1.0mm12 N.m {1.2 kgf.m.8,7 rbtft)

GROUND CABLETERMINAL 6x1.0mm

GROUNDTERMINAL

12 N.m {1.2 kgf'm,8.7lbtfrl

DRIVE PULLEYSPEED SENSORCONNECTOR

SOLENOID HARNESS

CONNECTOR

25. Connect the starter motor cable on the starter motor.

and install the cable holder.

NOTE: When installing the staner motor cable. make

sure that the crimped side of the ring terminal is

facing out (see section 23).

STARTEB

BMOUNTING NUT

9 N.m (0.9 kgf m,7 lbf ft)

26. Install all removed connectors and clamps'

27. Install the distributor.

28. Install the intake air duct and air cleaner housing

29.

assemDly.

Refill the transmission with the recommended

Genuine Honda CVT Fluid (see page 14-2991

CAUTION: While filling the CvT Fluid, bs surs not io

allow dust and other fotoign particles to entor into

the transmission.

Connect the battery positive (+) terminal first, then

the negative (-l terminal to the battery'

Check the ignition timing (see section 23).

Start the engine. Set the parking brake, and shift the

transmission through all gears three times Check

shift cable adjustment (see page 14-355).

Check the front wheel alignment (see section 18)

Let the engine reach operating temperature (the

radiator fan comes on) with the transmission in lXl

or E position, then turn it off and check fluid level'

Perform the start clutch calibration procedure on

page 14-293.

Road test as described on pages 14-296 and 14-297

30.

31.

34.

36.

STARTER MOTOR

14-351

Page 1030 of 2189

Shift Cable

RemovaUlnstallation

@ Make sure lifts, iacks and safety stands are

placed properly (see seqtion 11,

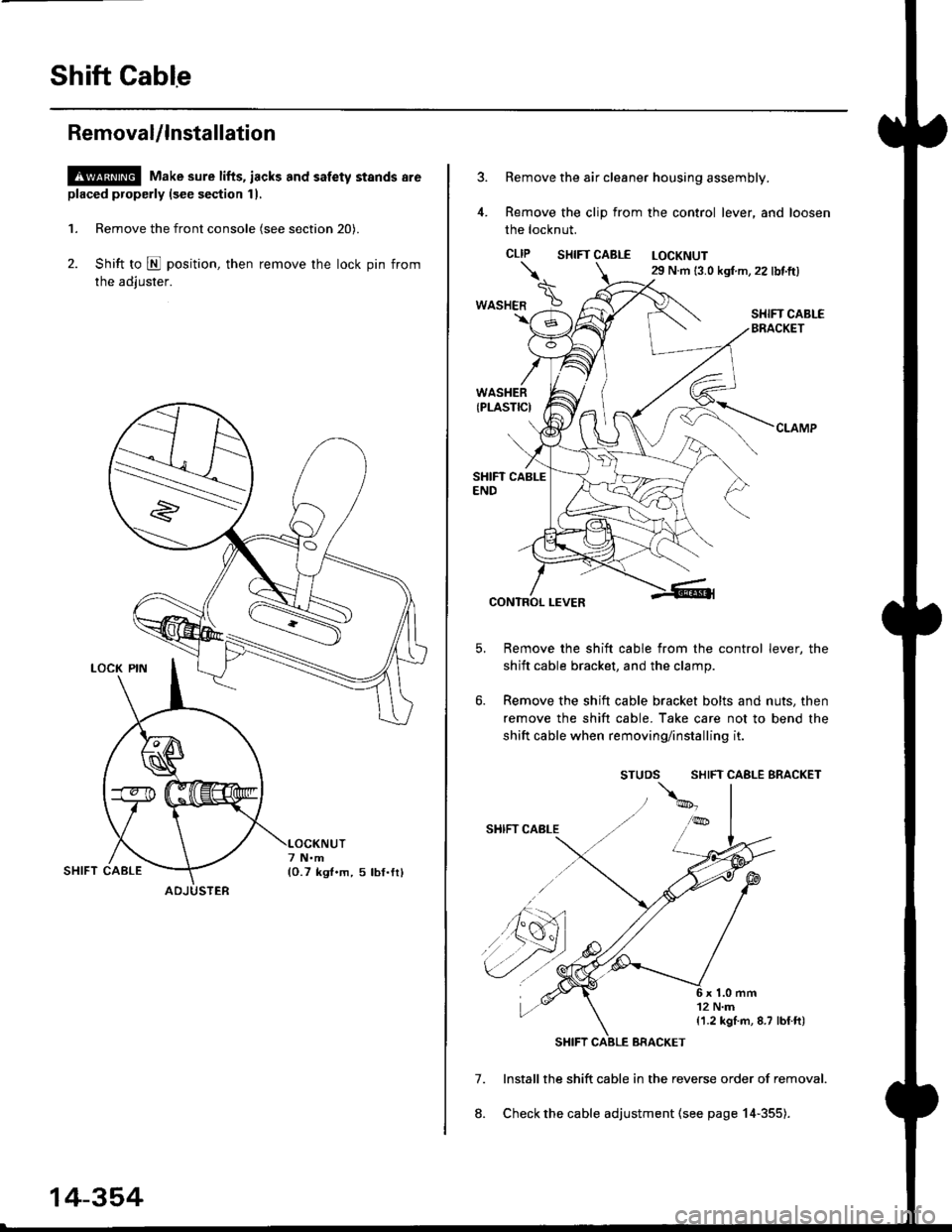

1. Remove the front console (see section 20).

2. Shift to E position, then remove the lock pin from

the adiuster.

ADJUSTER

14-354

Remove the air cleaner housing assembly.

Remove the clip from the control lever, and loosen

the locknut.

CLIP SHTFT CABLE LOCKNUT29 N.m 13.0 kgf m,22 lbf.ft)

SHIFT CABI-EBRACKET

7.

8.

CONTROL LEVER

Remove the shift cable from the control lever, the

shift cable bracket, and the clamp.

Remove the shift cable bracket bolts and nuts, then

remove the shift cable. Take care not to bend the

shift cable when removing/installing it.

SHIFT CABLE BRACKET

lnstall the shift cable in the reverse order of removal.

Check the cable adjustment (see page 14-355).

\.

*o"ra" \

{1.2 kgI m, 8.7 lblft)

Page 1037 of 2189

Driveshafts

Removal (cont'd)

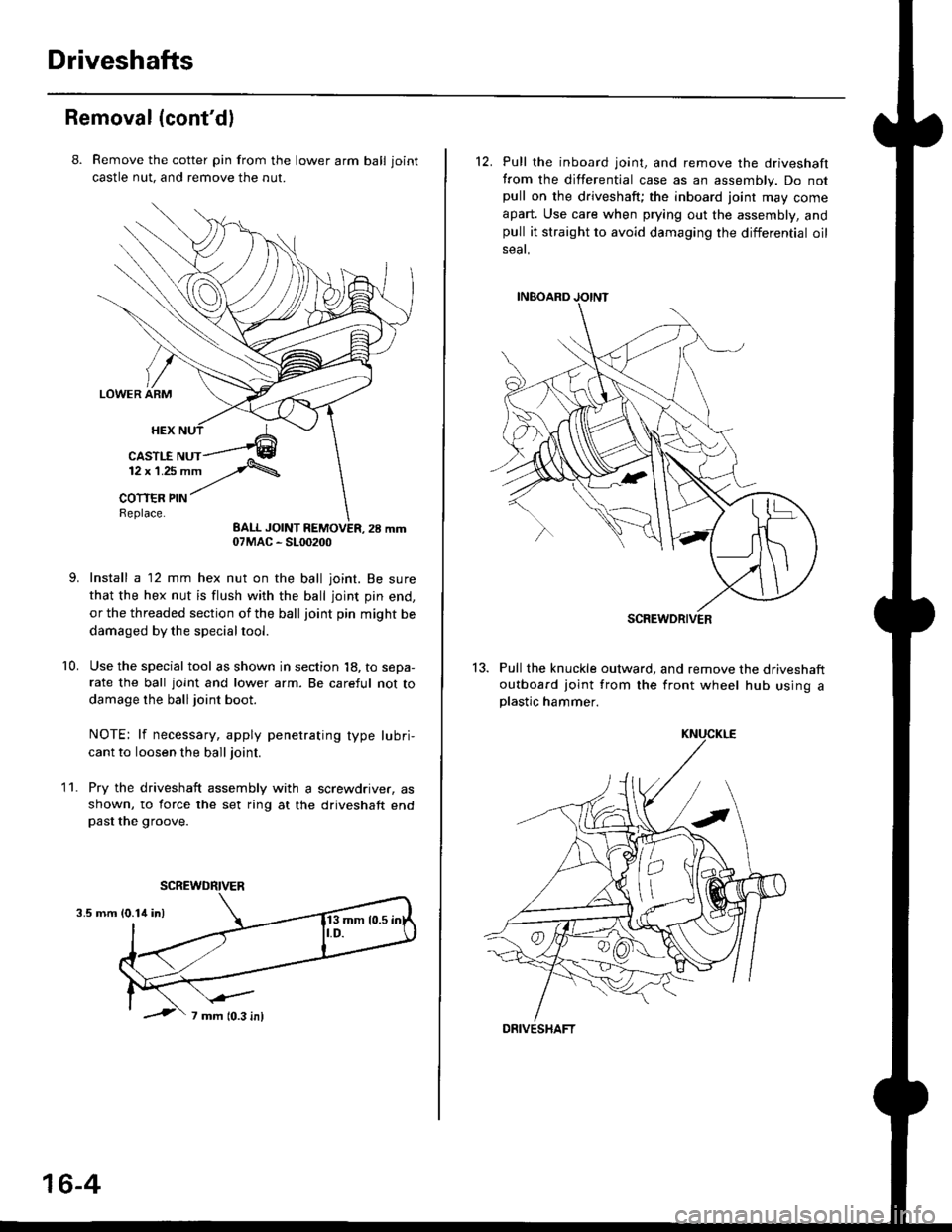

8. Remove the cotter pin from the lawer arm ball joint

castle nut. and remove the nut.

Install a 12 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end,

or the threaded section of the ball joint pin might be

damaged by the special tool.

Use the special tool as shown in section 18, to sepa-

rate the ball joint and lower arm. Be careful not to

damage the ball joint boot.

NOTE: lf necessary, apply penetrating type lubri,

cant to loosen the ball joint.

Pry the driveshaft assembly with a screwdriver, as

shown, to force the set ring at the driveshaft endpast the groove.

10.

11.

3.5 mm

07MAC - SL00200

SCREWDRIVER

16-4

12. Pull the inboard joint, and remove the driveshaft

from the differential case as an assembly. Do notpull on the driveshaft; the inboard joint may come

apart. Use care when prying out the assembly, andpull it straight to avoid damaging the differential oil

seat.

13. Pull the knuckle outward, and remove the driveshaft

outboard joint from the front wheel hub using aplastic hammer.

SCREWDRIVER

DRIVESHAFT

Page 1046 of 2189

l.

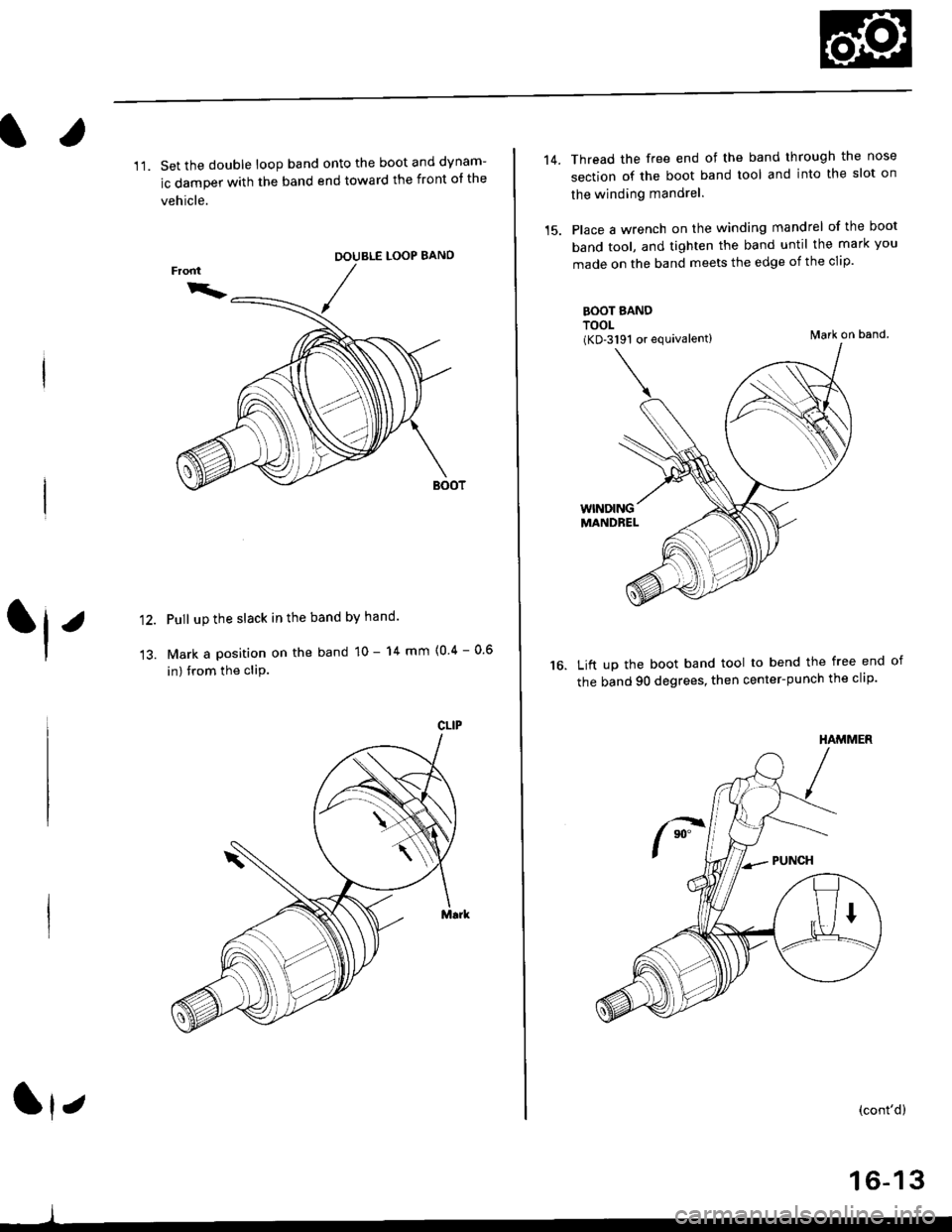

11. Set the double loop band onto the boot and dynam-

ic damper with the band end toward the front ot the

vehicle.

LOOP BANO

Pull up the slack in the band bY hand

Mark a position on the band 10 - 14 mm {0 4 - 0 6

in) from the cliP.

DOUBLE

,

1')

13.

CLIP

Ip

14.

15.

Thread the free end of the band through the nose

section of the boot band tool and into the slot on

the winding mandrel.

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the mark you

made on the band meets the edge of the clip.

Mark on band.

Lift up the boot band tool to bend the free end

the band 90 degrees, then center-punch the clip'16.

(cont'd)

16-13

(KD-3191 or equivalent)

HAMMER

Page 1052 of 2189

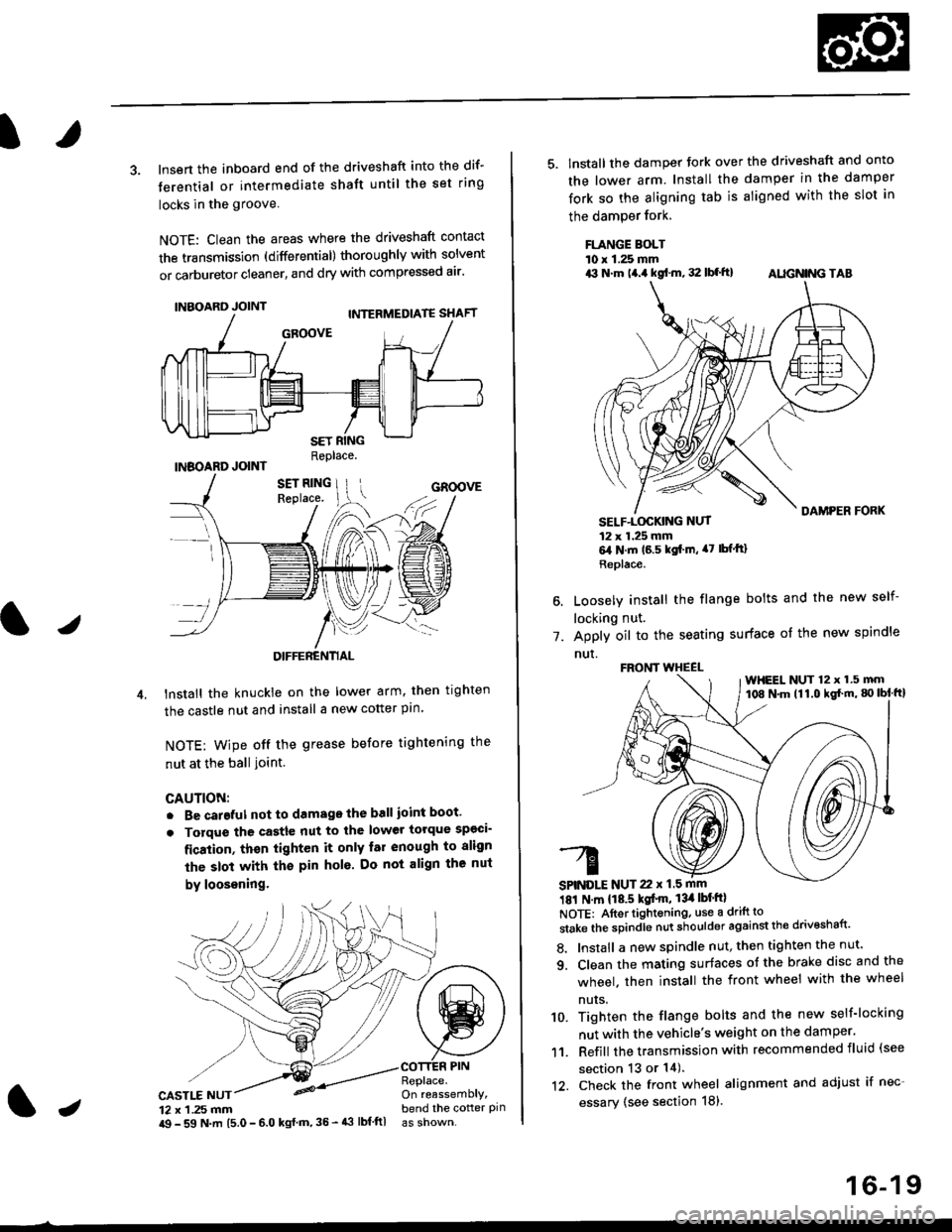

3. lnsert the inboard end of the driveshaft into the dif-

terential or intermediate shaft until the set ring

locks in the groove

NOTE: Clean the areas where the driveshaft contact

the transmission (differential) thoroughly with solvent

or carburetor cleaner, and dry with compressed air'

INBOARD JOINT

INBOARD JOINTReplace.

GROOVE

an

DIFFERENTIAL

lnstall the knuckie on the lower arm. then trghten

the castle nut and install a new cotter pin

NOTE: wipe off the grease before tightening the

nut at the ball ioint.

CAUTION:

. Be careful not to damago the ball ioint boot'

. Torque the castle nut to the lower torque sp€ci-

fication, thsn tighten it only far enough to align

the slot with th€ pin hol6. Do not align the nut

by loosening.

CASTLE NUT12 x 1 .25 mm

COTTER PINReplace.On reassemblY,bend the cotter pinJi$ - 59 N.m 15.0 - 6.0 kgl m,35 - 43 lbf ftl

16-19

5. lnstall the damper tork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damPer fork.

FLANGE BOLTl0 r 1.25 mmrit N.m t4.a kgf.m, 32 lbf.ft) AIIGN|NG TAB

1.

SELF-LOGKING NUT12 x 1.25 mm6,1N.m 16.5 kgi.m, a7 lbfftl

Replace.

Loosely install the flange bolts and the new self-

locking nut.

Apply oil to the seating surface of the new spindle

nut.

181 N m 118.5 kgt'm, 13il lbt'ftl

NOTE: Aftortightening, use a drift to

stake the spindle nut shoulder against the drivoshaft'

8. Install a new spindle nut, then tighten the nut'

9. Clean the mating surfaces ot the brake disc and the

wheel. then install the front wheel with the wheel

nuts.

10. Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

11. Refill the transmission with recommended fluid (see

section 13 or 14).'t2. Check the front wheel alignment and adjust if nec-

essary (see section 18),

FRONT WHEEL

SPINDLE NUT 22 x 1.5 mm

WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgl'm, g) lbl ftl

Page 1058 of 2189

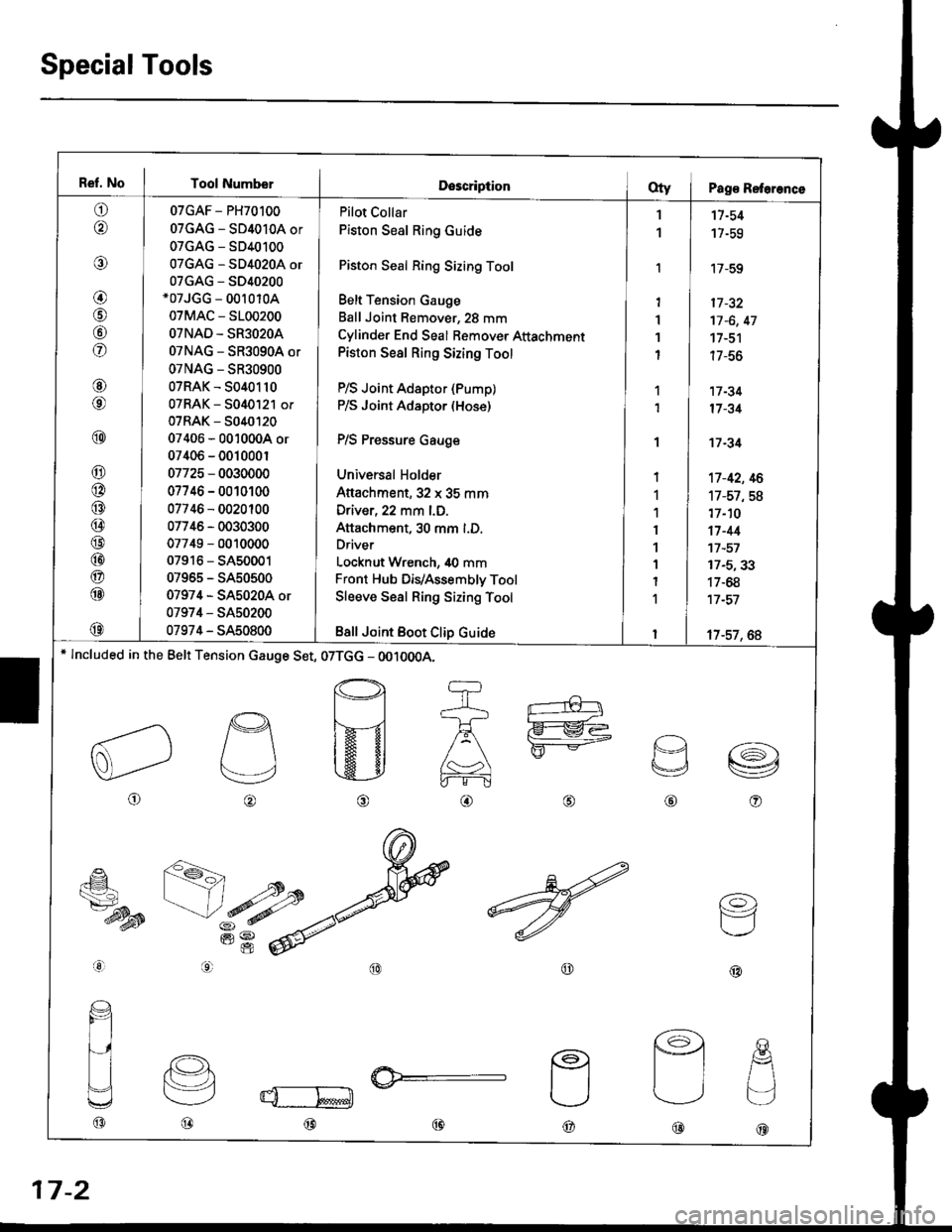

Ref. No I Tool NumberDescriptionOty I Pag€ Reterence

o

@

@

@

@

fof

@

@

@

@

@

@

@

@

@

@

@

@

@

07GAF - PH70100

07GAG - SD4010A or

07GAG - SD40100

07GAG - SD4020A or

07GAG - S040200*07JGG - 00r 010A

07MAC - 5100200

OTNAD - SR3O2OA

07NAG - SR3090A or

07NAG - SR30900

07RAK - 5040110

07RAK - 5040121 or

07RAK - 5040t20

07406 - 0010004 or

07406 - 001000r

07725 - 0030000

07746 - 0010100

07746 - 0020100

07746 - 0030300

07749 - 0010000

07916 - SA50001

07965 - SA50500

07974 - SA5020A or

07974 - SA50200

07974 - SA50800

Pilot Collar

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Belt Tension Gauge

Ball Joint Remover, 28 mm

Cylinder End Seal Bemover Attachment

Piston Seal Ring Sizing Tool

P/S Joint Adaptor (Pump)

P/S Joint Adaptor (Hose)

P/S Pressure Gauge

Universal Holder

Attachment,32 x 35 mm

Driver, 22 mm l.D.

Attachment, 30 mm l.D.

Driver

Locknut Wrench, 40 mm

Front Hub DiVAssembly Tool

Sleeve Seal Ring Sizing Tool

Bsll Joint Boot Clip Guide

1

1

'I

1'I

1

I

1

1

I

1

1

I

1

1

I

1

I

11-54

17-59

'17-59

17 -32

17 -6, 47

17-51

| /-ao

17 -34

17 -31

't7 -34

't7-42, 16

17-57,58

17-10

17-44't7 -57

17-5,33

17-68

17 -57

17-57, 6A* lncluded in the Belt Tension cauge Set, 07TGG - OO10OOA.

o

p

v

@o

€_

ts7-dysB

aal

@@

(o)

F=1

@@@

@@@

17-2

Page 1060 of 2189

Inspection and Adjustment

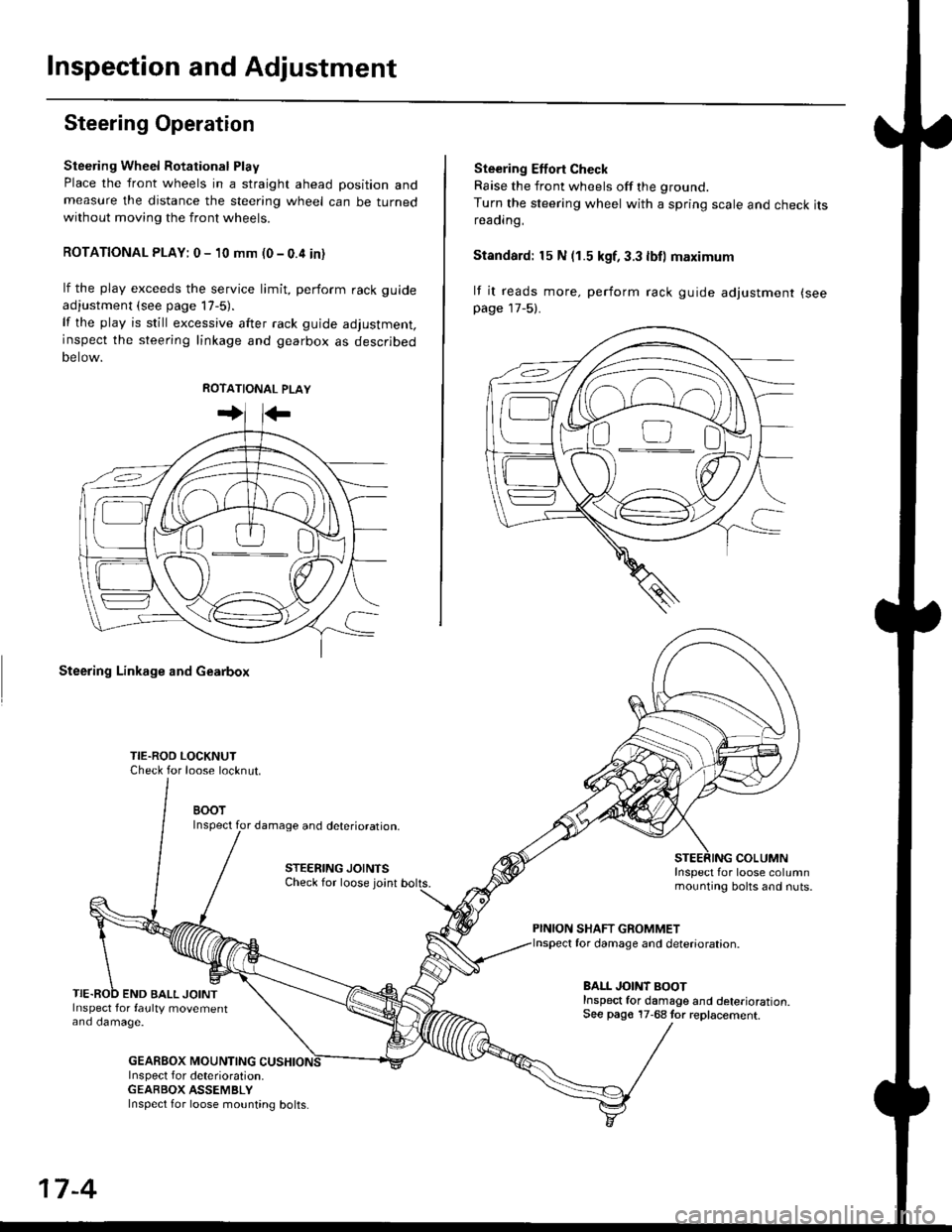

Steering Operation

Steering Wheel Rotational Play

Place the front wheels in a straight ahead position andmeasure the distance the steering wheel can be turnedwithout moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm (0 - 0.4 in)

lf the play exceeds the service limit, perform rack guide

adjustment (see page lT-5).

lf the play is still excessive after rack guide adjustment,inspect the steering linkage and gearbox as descrjbed

Detow.

Steering Linkage and Gearbox

TIE.ROO LOCKNUTCheck for loose locknut.

BOOTInspect for damage and deterioration.

STEERING JOINTSCheck for loose joint

END BALL JOINTInspect for faulty movementano oamage.

GEABBOX MOUNTINGInspect f or deterioration.GEABBOX ASSEMBLY

Ste€ring Effort Check

Raise the front wheels off the ground.

Turn the steering wheel with a spring scale and check itsreaorng,

Standard: 15 N (1.5 kgf, 3.3 lbll maximum

lf it reads more. perform rack guide adjustment (see

page 17-5).

COLUMNInspect for loose columnmounting bolts and nuts.

PINION SHAFT GROMMETfor damage and deterioration.

BALL JOINT BOOTInspect for damage and deterioration.See pago 17-68 tor replacement.

ao-\---------U

17-4

Inspect for loose mounting bolts.

Page 1069 of 2189

)

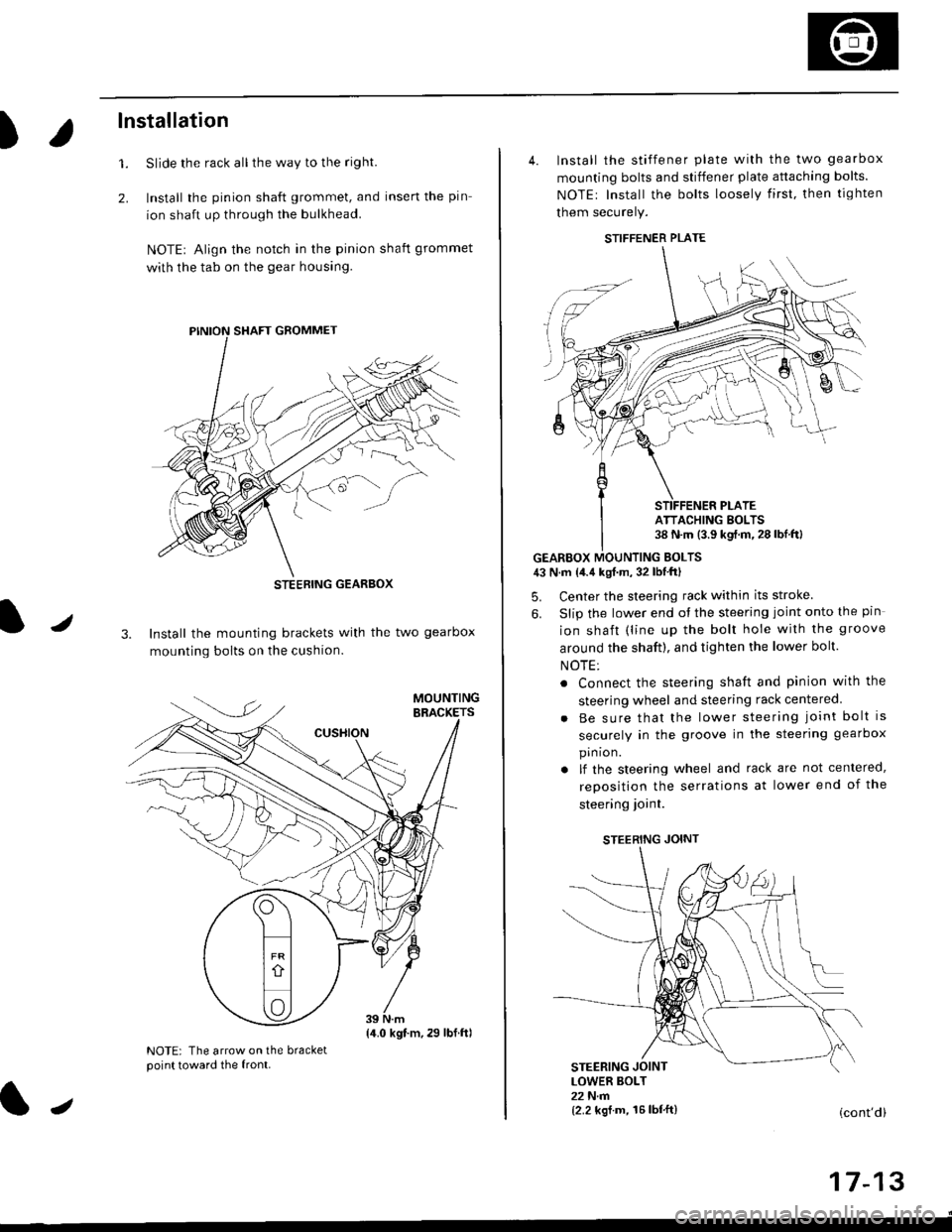

lnstallation

Slide the rack all the way to the righl

Install the pinion shaft grommet, and insert the pin

ion shaft up through the bulkhead.

NOTE| Align the notch in the pinion shaft grommet

with the tab on the gear housing.

1.

2.

J3. Install the mounting brackets with the two gearbox

mounting bolts on the cushion.

NOTE: The arrow on the bracketpoint toward the front.

STEEBING GEARBOX

{4.0 kgt.m,29 lbf.ftl

J

4. Install the stiffener plate with the two gearbox

mounting bolts and stiffener plate attaching bolts.

NOTEr Install the bolts loosely first. then tighten

them securely.

GEARBOX MOUNTING EOLTS43 N.m {4.4 kgf.m, 32 lbf'ftl

5. Center the steering rack within its stroke

6. Slip the lower end ot the steering joint onto the pin

ion shaft (line up the bolt hole with the groove

around the shaft), and tighten the lower bolt.

NOTE:

. Connect the steering shaft and pinion with the

steering wheel and steering rack centered

Be sure that the lower steering joint bolt is

securely in the groove in the steering gearbox

pin ion.

lf the steering wheel and rack are not centered,

reposition the serrations at lower end of the

steering ioint.

STEERING JOINT

STEERING JOINTLOWER BOLT22 N.m{2.2 kgf.m, 16lbf'ft}(cont'd)

I t- t5

STIFFENER PLATE

ATTACHING BOLTS38 N.m (3.9 kgf.m.28lbf.ftl

Page 1070 of 2189

Steering Gearbox

Installation (cont'dl

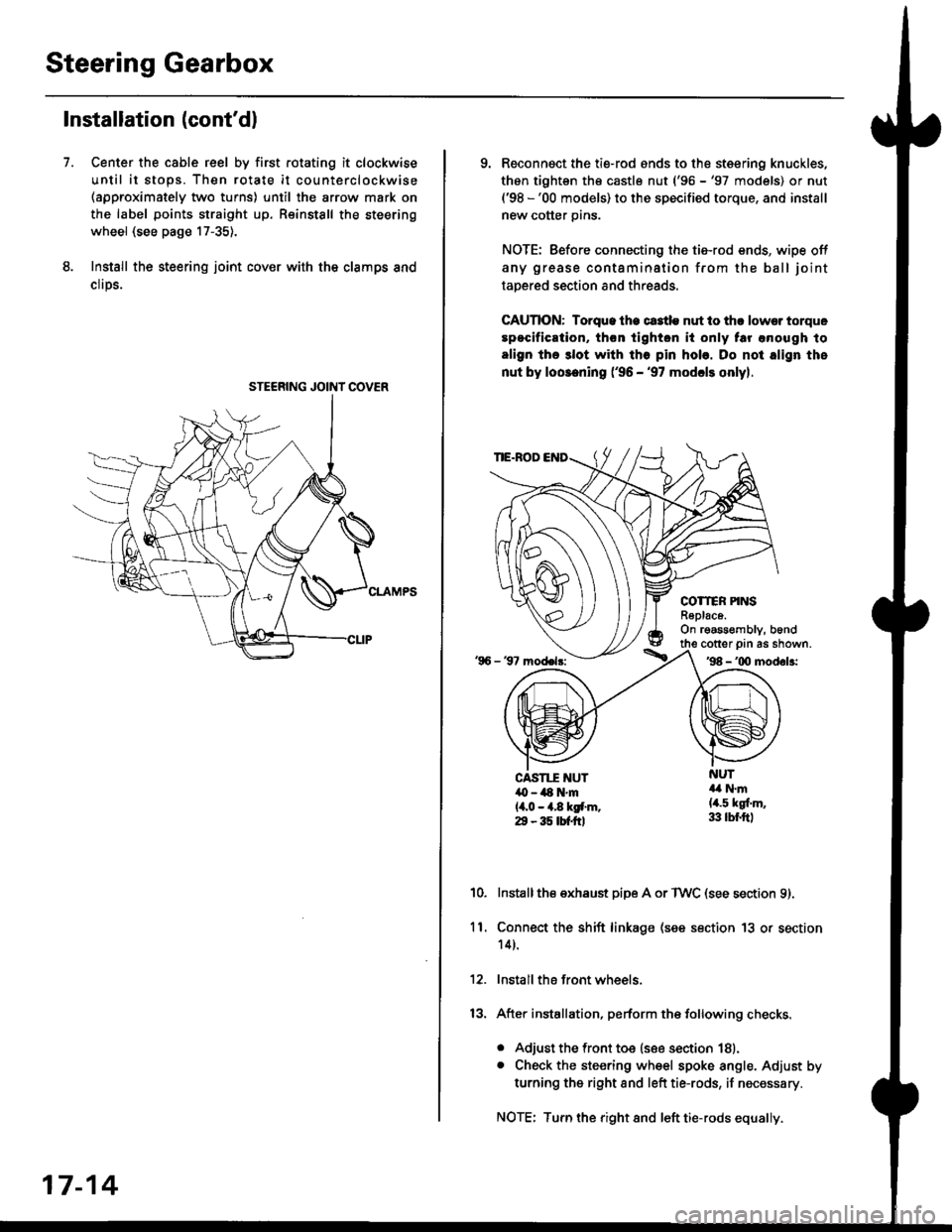

Center the cable reel by first rotating it clockwise

until it stops. Then rotate it counterclockwise(approximately two turns) until the arrow mark on

the label points straight up. Reinstall the steering

wheel (see page 17-35).

Install the steering joint cov€r with the clamps and

clrps.

7.

STEERING JOINI COVER

17-14

9. Reconnsct the ti€-rod ends to the steering knuckles,

thon tightsn th€ castle nut ('96 -'97 models) or nut('98 -'00 models) to the specified torque, and install

new cotter pins.

NOTE: Before connecting the tie-rod ends, wipe off

any grease contamination from the ball joint

tapered section and threads.

CAUTION: Torque lhe ct3tle nut to thr lowsr torque

spocification, th€n tighton it only tar anough to

align the 3lot with tho pin hob. Do not align the

nut by loosening ('96 - '97 modcls onlyl.

TIE.ROD

COTTER PINSR6plac6.On rgassombly, b6nd

'96 - 37 model3:

cotter prn as shown.'98 - '00 modol3:

NUT4a N.m(4.5 kgf.m,33 lbr.ftl

CAST1T NUT,O - ilt N'm{4,0 - 4.8 kgf.m.29 - 35 tbtftl

10.Installthe exhaust pipe A or TWC (see section 9).

Connect the shift linkage (see section 13 or section

14).

Install the front wheels.

After installation, perform the following checks.

. Adjust the front toe (see section 18).. Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

NOTE: Turn the right and left tie-rods equally.

ll.

Page 1103 of 2189

Steering Gearbox

)

Removal

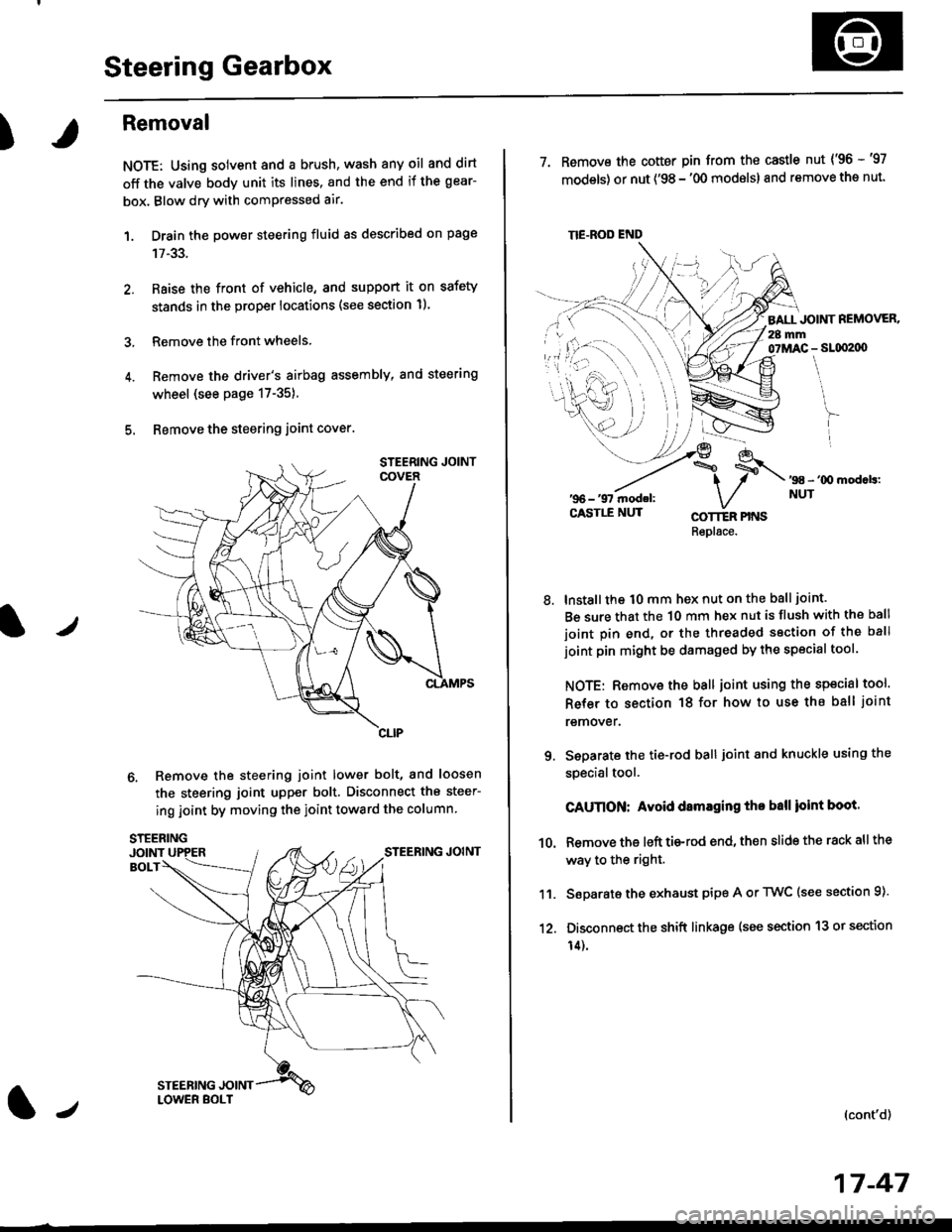

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit its lines. and the end if the gear-

box. Blow dry with comPressed air.

1. Drain the power steering fluid as described on page

2. Raise the front of vehicle, and support it on safety

stands in the proper locations (see section 11.

3, Remove the front wheels.

4. Remove the driver's airbag assembly, and steering

wheel (see page 17-35)

5. Bemove the steering joint cover.

6. Remove the steering joint lower bolt, and loosen

the steering joint upper bolt. Disconnect the steer-

ing joint by moving the ioint toward the column

tJ

17-47

TIE.ROD END

7. Remove the cotter pin from the castle nut {'96 -'97

models) or nut ('98 - '00 modslsl and remove the nut.

BALL JOINT REMOVER.28 mm07MAC - SLqI2|X)

'98 - '00 mod.b:NUT

8.

COTTER PINSRepl6ce.

lnstall the t0 mm hex nut on the ball joint.

Be sure that the 10 mm hex nut is flush with the ball

joint pin end, or the threaded section of the ball

joint pin might be damaged by the special tool.

NOTE: Remove the ball joint using the special tool.

Refer to section 18 for how to use ths ball joint

remover.

Seoarate the tie-rod ball joint and knuckle using the

specialtool.

CAUnON: Avoid damaging tho ball ioint boot.

Remove the left tie-rod end, then slide the rack all the

way to the right.

Separate the exhaust pipe A or TWC (see section 9).

Disconnect the shift linkage (see section 13 or section

14).

(cont'd)

9.

10.

11.

12.