Right air HONDA CIVIC 1996 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1120 of 2189

Steering Gearbox

Reassembly (cont'dl

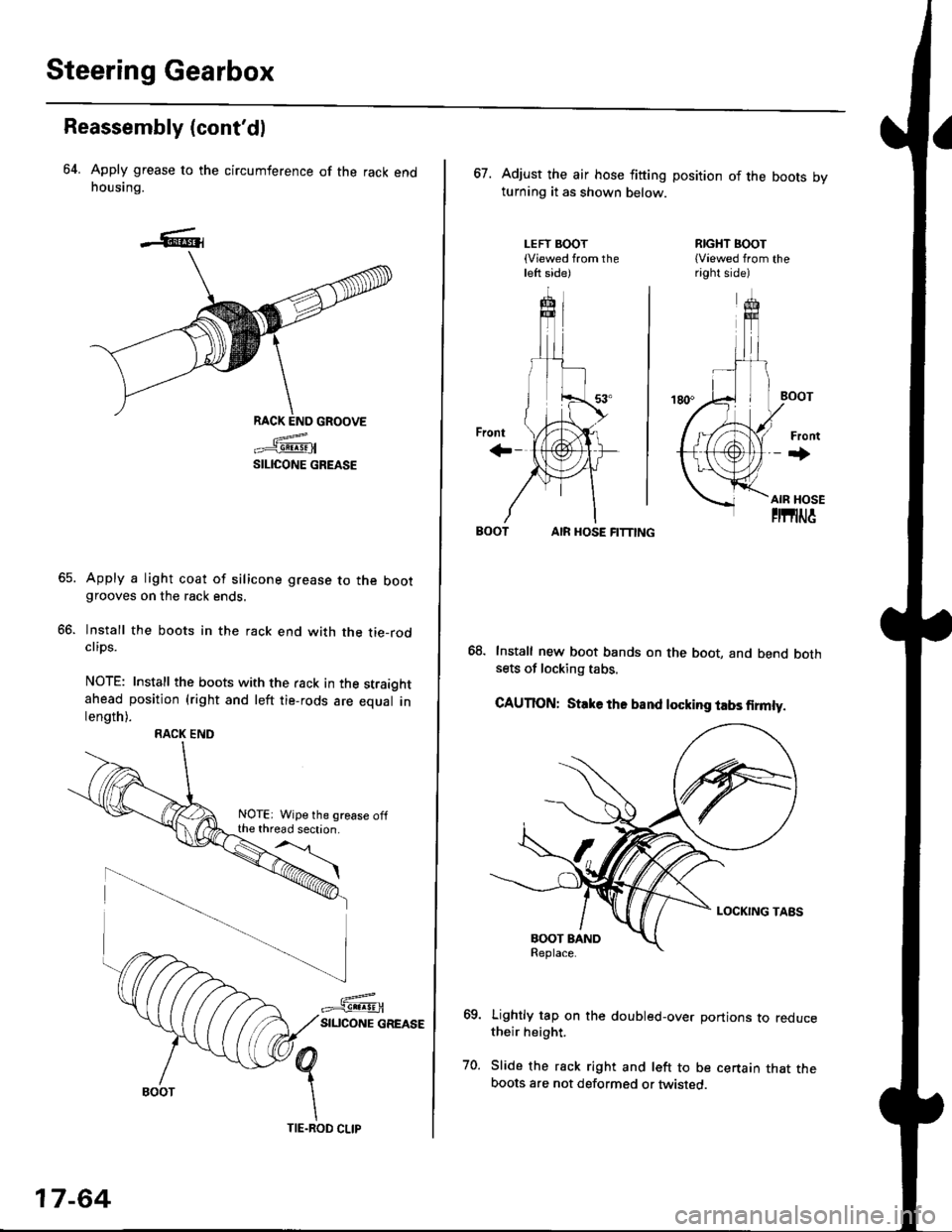

64. Apply grease to the circumference of the rack endhousing.

RACK END GROOVE

=^.#-q!:s!!H

SILICONE GREASE

Apply a light coat of silicone grease to the bootgrooves on the rack ends.

lnstall the boots in the rack end with the tie-rodclips.

NOTE: Install the boots with the rack in the straightahead position (right and left tie-rods are equal inlength).

66.

RACK END

NOTE: Wipe the grease offthe thread section.

17-64

TIE.ROD CLIP

67. Adjust the air hose fitting position of the boots bvturning it as shown below.

LEFT BOOT(Viewed from theleft side)

RIGHT BOOT{Viewed from theright side)

AIR HOSE FITTING

Install new boot bands on the boot, and bend bothsets of locking tabs.

CAUTION: Stlke ths band locking tabs firmly.

Lightly tap on the doubled-over portions to reducetheir height.

Slide the rack right and left to be certain that theboots are not deformed or twisted.

Page 1121 of 2189

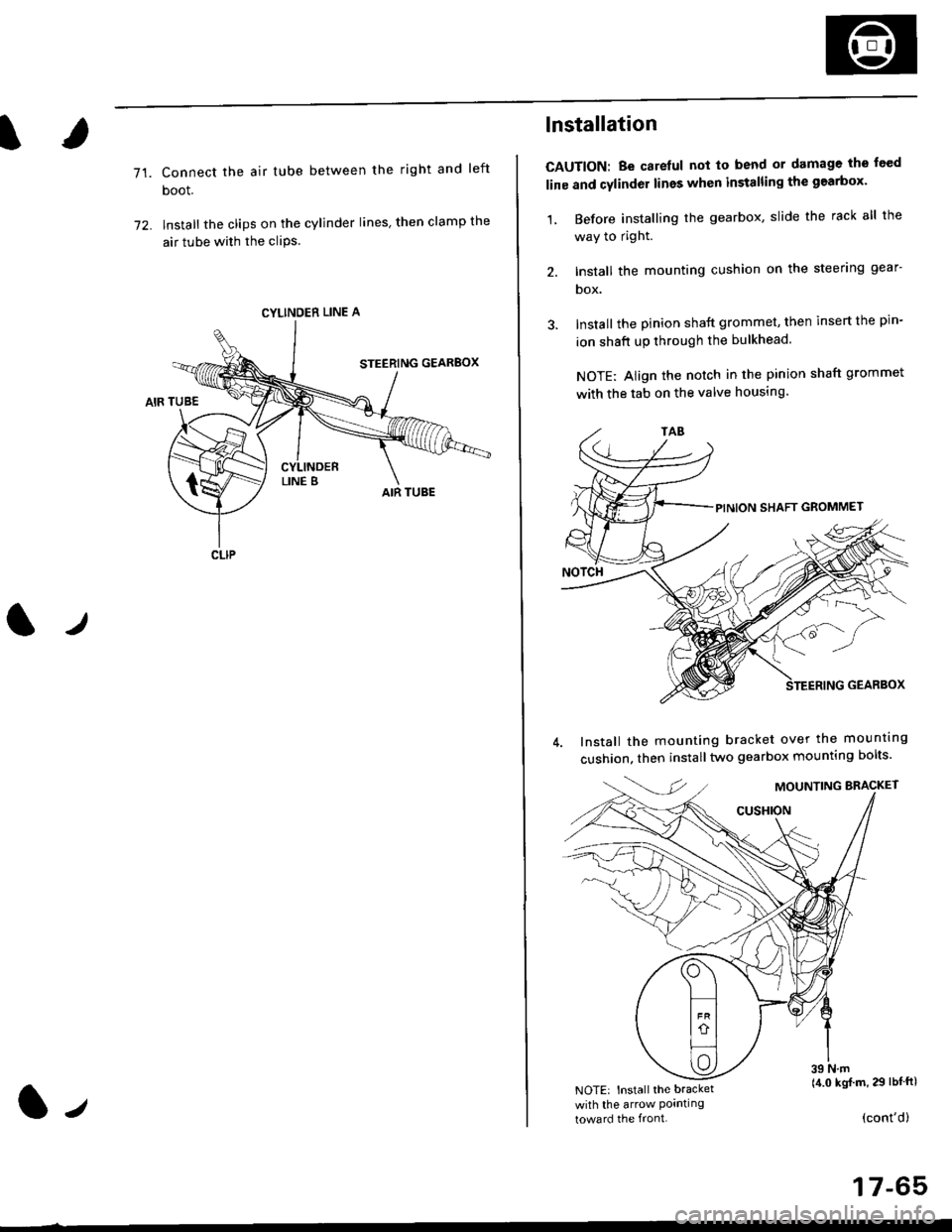

71.Connect the air tube between the right and left

boot.

lnstall the clips on the cylinder lines' then clamp the

air tube with the cliPs.

l./

CYLINDER LINE A

CLIP

l-,

lnstallation

CAUTION: Be carelul not to bend or damage the feed

line and cylinder lines when installing the gearbox'

1, Before installing the gearbox, slide the rack all the

way to right.

2. Install the mounting cushion on the steering gear-

DOX.

Install the pinion shaft grommet, then insert the pin-

ion shaft up through the bulkhead.

NOTE: Align the notch in the pinion shaft grommet

with the tab on the valve housing.

Install the mounting bracket over the mounttng

cushion, then installtwo gearbox mounting bolts'

MOUNTING BRACKET

cusHroN

39 N.m(4.0 kgj m, 29 lbtftlNOTE: Install the bracket

with the arrow Pornllngtoward the front.(cont'd)

17-65

Page 1123 of 2189

)

1?

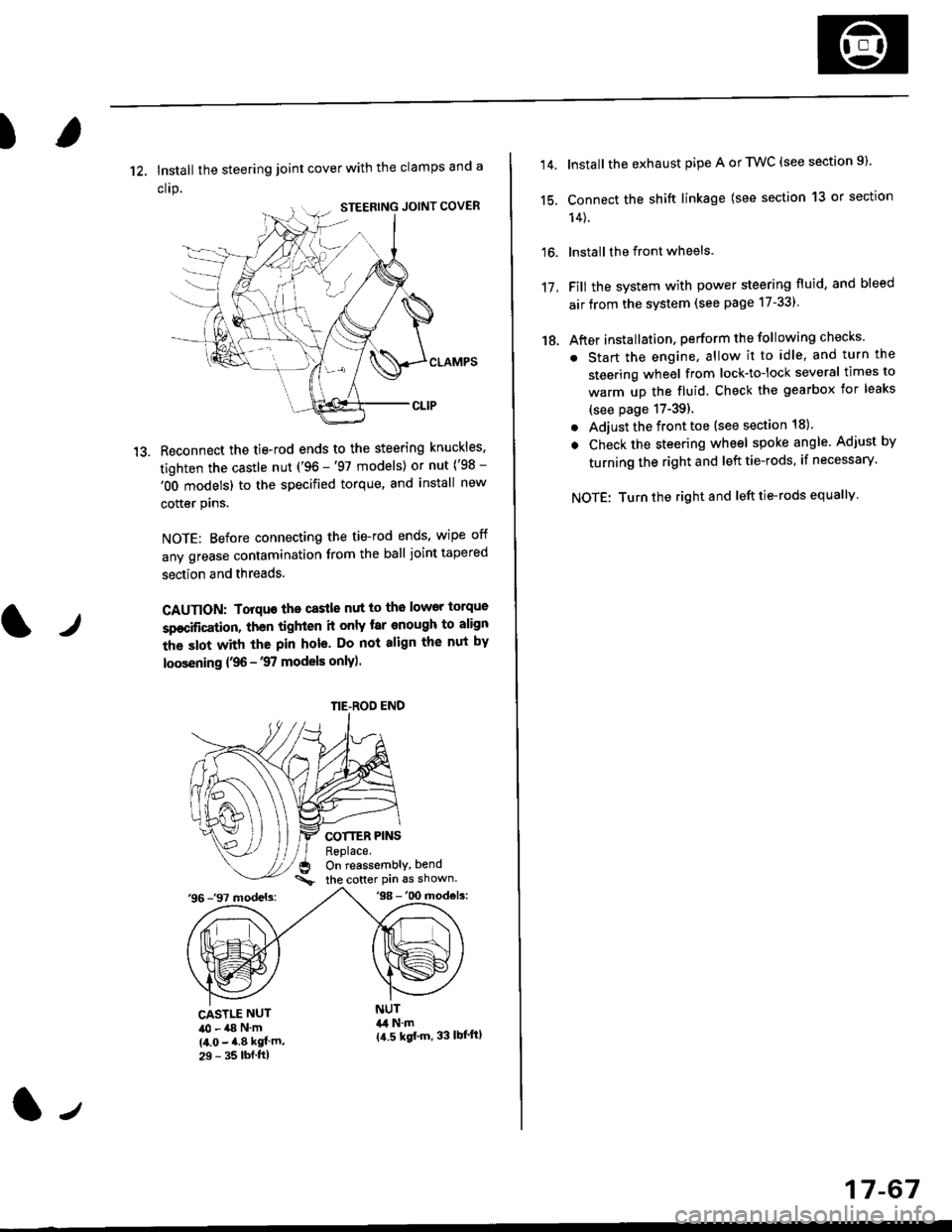

12, Install the steering joint cover with the clamps and a

clrp.

Reconnect the tie-rod ends to the steering knuckles,

tighten the castle nut ('96 -'97 models) or nut ('98 -

'OO models) to the specified torque, and install new

cotter plns.

NOTE: Before connecting the tie-rod ends, wipe off

any grease contamination from the ball joint tapered

section and threads.

CAUTION: Torquo the castle nut to the lower torque

sp€cification, then tighten it only tar enough to align

the slot with the pin hole. Do not align the nut by

loosening {,96 -'97 models only).

COTTER PINSReplace.On reassembly, bend

the cotter Pin 6s shown.'96 -'97 models:'98 -'00 mod€ls:

tr

CASTLE NUT40 - a8 N'm(4.0 - 4.8 kgf'm,29 - 35 lbf.ftl

NUT&l N.m{a.5 kgf'm, 33 lbl'ftl

NE-ROD END

(l-,

17-67

14.

15.

16.

17.

18.

Install the exhaust pipe A or TWC (see section 9).

Connect the shift linkage (see section 13 or section

14).

lnstall the front wheels

Fill the system with power steering fluid, and bleed

air from the system (see page 17-331

After installation, perform the following checks

. Start the engine, allow it to idle, and turn the

steering wheel from lock-tolock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-39).

. Adjust the front toe (see section 18).

. Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

NOTE: Turn the right and left tie-rods equallv

Page 1161 of 2189

I

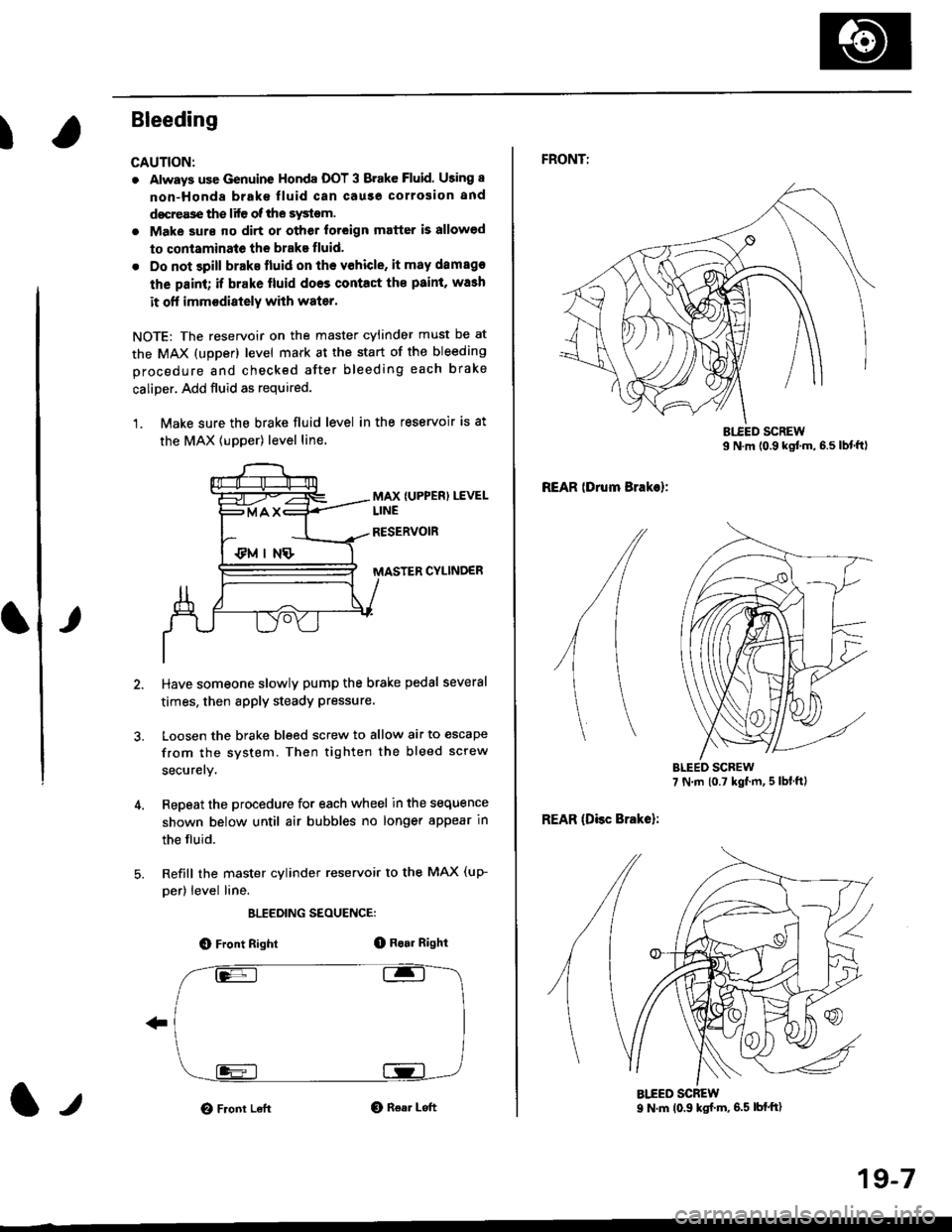

Bleeding

CAUTION:

. Always use Genuine Honda DOT 3 Brake Fluid. Using 8

non-Honda brak€ fluid can cause corrosion and

docrea3e the life of the system.

. Make surs ||o dirt or other foteign matter is allowed

to contaminate the brake fluid,

. Do not spill brake lluid on the vehicle, it may damago

the paint; if brake lluid doos contac{ the paint, wash

it ofl imm€diately with water.

NOTE: The reservoir on the master cylinder must be at

the MAX (upper) level mark at the start of the bleeding

procedure and checked after bleeding each brake

caliper. Add fluid as required.

1. Make sure the brake fluid level in the reservoir is at

the MAX lupper) level line.

MAX {UPPER) LEVEL

CYLINDER

Have someone slowly pump the brake pedsl several

times, then apply steady Pressure.

Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

Repeat the procedure for each wheel in the sequence

shown below until air bubbles no longer appear in

the fluid.

Refill the master cylinder reservoir to the MAX (up-

per) level line.

ELEEDING SEOUENCE:

O Front Right(D Bo.r Right

O Front LeftO Rear Left1,,

19-7

FRONTT

REAR lDrum Brakel:

REAR (Disc Brake):

AIEED SCREW9 N.m (0.9 ksf m, 6.5 lbf'ft)

Page 1189 of 2189

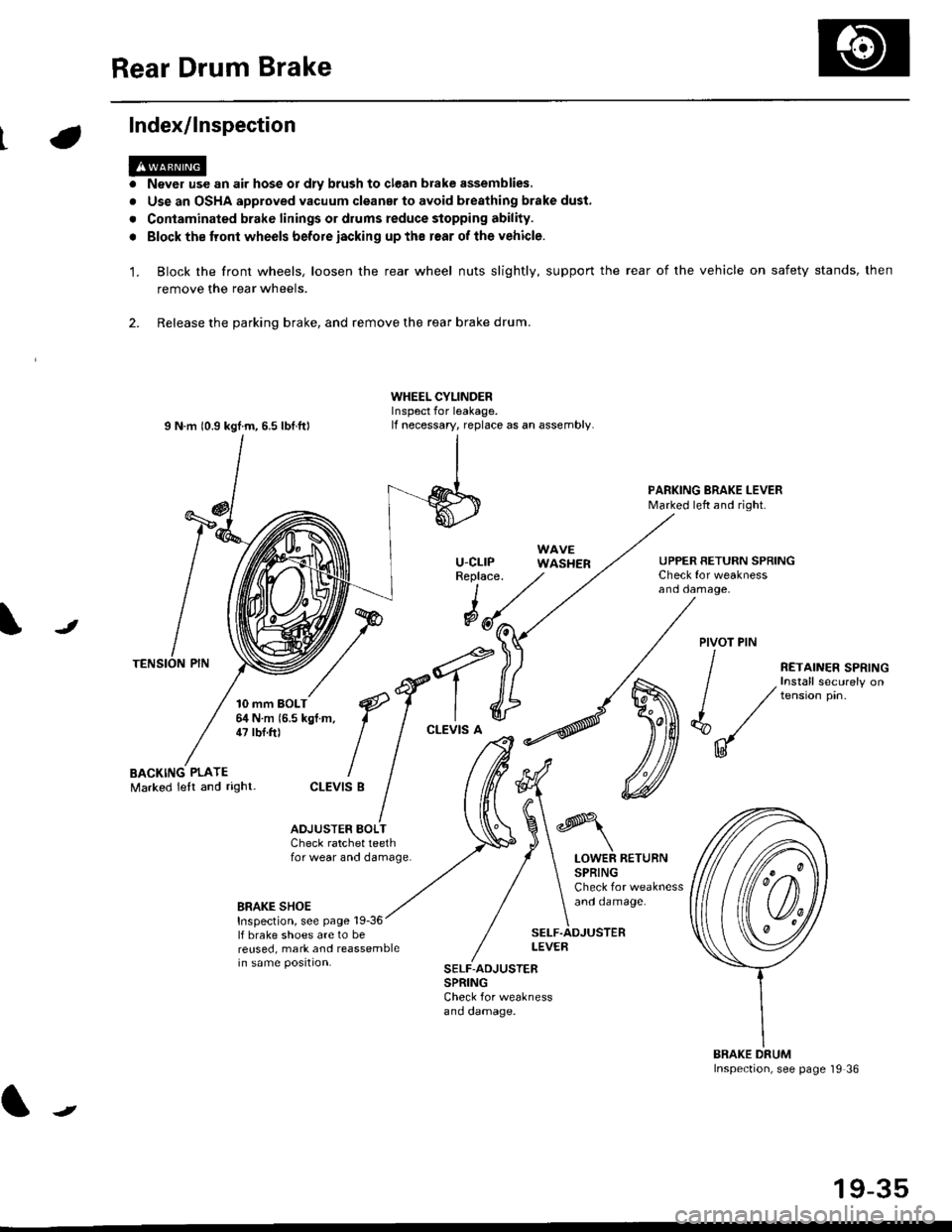

Rear Drum Brake

Index/lnspection

'1.

a

a

Never use an air hose or dly brush to clean brake assemblies,

Use an OSHA approved vacuum cleanar to avoid breathing brake dust,

Contaminated brake linings or drums reduce stopping ability.

Block the tront wheels before iacking up ths r€ar of lhe vehicle.

Block the front wheels, loosen the rear wheel nuts slightly, support the rear of the vehicle on safety stands, then

remove the rear wheels.

2. Release the parking brake, and remove the rear brake drum.

I N m 10.9 kgtm, 6.5 lbf.ftl

TENSION PIN

10 mm BOLT6,1N m 15.5 kgf m,47 tbf.ft)

WHEEL CYLINDERInspect for leakage.lf necessary, replace as an assembly.

u-cLrPReplace.

WAVEWASHER

PARKING BRAKE LEVERMarked left and right.

Check for weaknessano oamage,

UPPER RETURN SPRING

I

@JPIVOT PIN

BACKING PLATEMarked lelt and right-

/

€f-l.^

I I

*'t")

ctEv'sB

/ (t

/ ,.ro,".r r.*,"n

/ , Install securely on

| / tension pin.

d"/

IU

ADJUSTER BOI-TCheck ratchet teethfor wear and damage.LOWER RETURNSPRINGCheck for weaknessand oamage.BRAKE SHOEInspection, see page 19-36lf brake shoes are to bereused, mark and reassemblein same position.

SELF.ADJUSTERLEVEB

SELF-ADJUSTERSPRINGCheck for weaknessano oamage.

BRAKE DRUMInspection, see page '19 36

t

19-35

Page 1217 of 2189

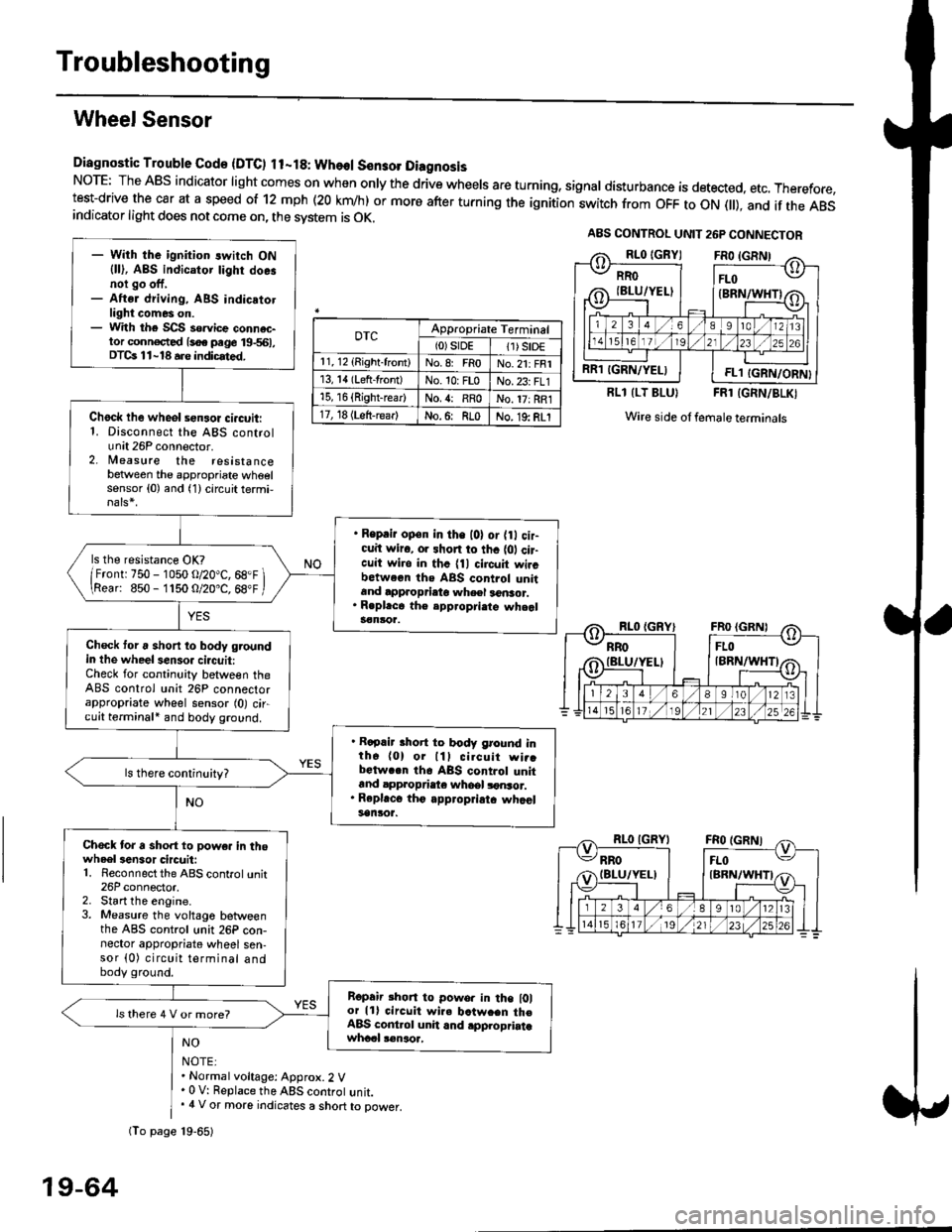

Troubleshooting

Wheel Sensor

Diagnostic Trouble Gode {DTC) ll-18: Wheol S€n3ol DiagnosisNoTE: The ABS indicator light comes on when only the drive wheels are turning, signal disturbance is detected, etc. Therefore,test-drive the car at a speed of 12 mph (20 krn/h) or more after turning the ignition:witch from OFF to ON fll), and if the ABSindicator light does not come on, the svstem is OK.

0TcAppropriate Terminal(0)srDE11) SrD€r 1, 12 (Right-front)No.8: FRoNo.21: FRI13, 14 (Left-front)No. 10: FLoNo.23: FL115, 16 {Right-rear)No. {: RRoNo. 17: RRl17, 18 (Left-rear)No.6: RLoNo. 19: RLI

RLl (LT BLU}FRl (GRN/BLKI

Wire side ol female terminals

NO

NOTE:. Normal voltage: Approx.2 V' 0 V: Replace the ABS controt unit.. 4 V or more indicates a short to power.

A8S CONTROL UNIT 26P CONNECTOR

RRO

IBLU/YELI

RR1 IGRN/YELIFL1 IGRN/ORN}

- With the ignition switch ON{ll), ABS indicator tighr doe.noi go off,- Aftsr driving, ABS indicatotlight comes on.- With the SCS so.vice connac-tor conn€c,ted {soe pege 19-561,DTCs 11-18 a.e indicrted.

Chock lhe wheol sensor ci.cuit:1. Disconnect the ABS controlunit 26P connector.2. lleasure the resistancebetween the appropriate wheelsensor (0) and (1) circuit termi,

. Reprir op€n in the l0l or {0 cir-cuit wiro, or shon to thc {01 cir-cuit wi.o in thc {11 circuit wircbctween ths ABS control unitand approprieto wheel a6nsor.. R.pl.ce th€ epp.opri.te wheal3€nloa.

ls the resistance OK?

/Frontr 750 - 1050 o/20"C, 68.F \\Rear: 850- 1150 O/20.C, 68"F /

Check toru short to body groundin the wheel senso. circuit:Check for continuity between theABS control unit 26P connectorappropriate wheel sensor (0) circuit terminali and body ground.

. Rapair short to body ground inth6 (0) or lll cilcuit wi..bctwa.n th6 ABS control unitand appropdaie whoel lonsor.. Rep|'c6 tho appropriatc whcelsanlor.

Chock tor a sho.t to powe. in thowheel3en3or circuit:1. Reconnect the ABS control unit26P connector,2. Start the engine.3. Measure the voltage betweenthe ABS control unit 26P con-nector appropriate wheel sen-sor (0) circuit terminal andbody ground.

Ropair rhon to powo. in the l0lor lll circuit wire batw.en th€ABS cont.ol unit and .pplopriatawhccl !€naoa,

ls there 4 V or more?

fio page 19-65)

19-64

Page 1229 of 2189

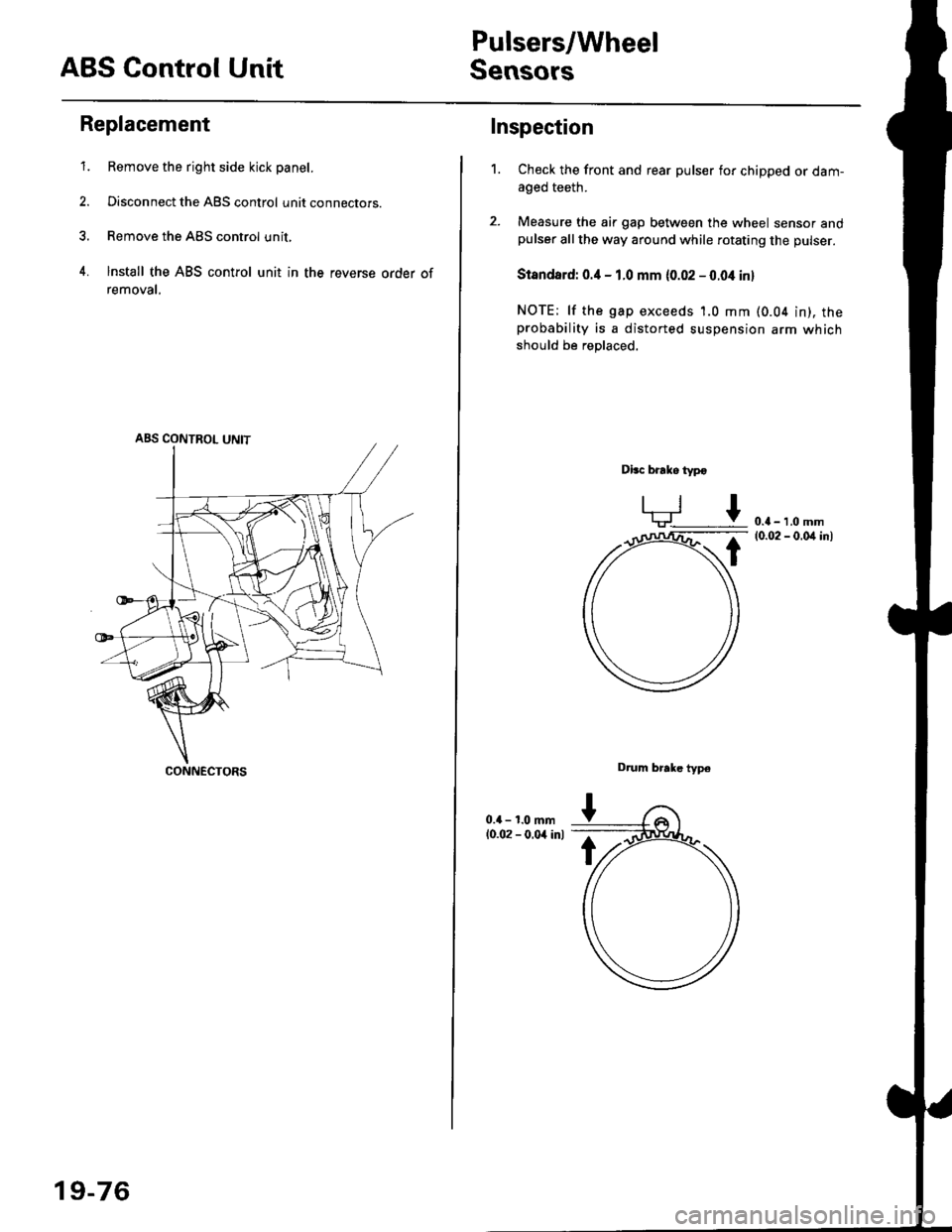

ABS Control Unit

Pulsers/Wheel

Sensors

Replacement

1. Remove the right side kick panel.

2. Disconnect the ABS control unit connecrors.

3. Remove the ABS control unit,

4. lnstall the ABS control unit in the reverse order of

removal,

CONNECTORS

19-76

Inspection

Check the front and rear pulser for chipped or dam-aged teeth.

Measure the air gap between the wheel sensor andpulser all the way around while rotating the pulser.

Slandard: 0.4 - 1.0 mm (0.02 - 0.04 in,

NOTE; lf the gap exceeds 1.0 mm (0.04 in), theprobability is a distorted suspension arm which

should be replaced.

Dbc brake typo

0.{ - 1.0 mm(0.02 - 0.04 in)

Drum brake typ6

1.

Page 1299 of 2189

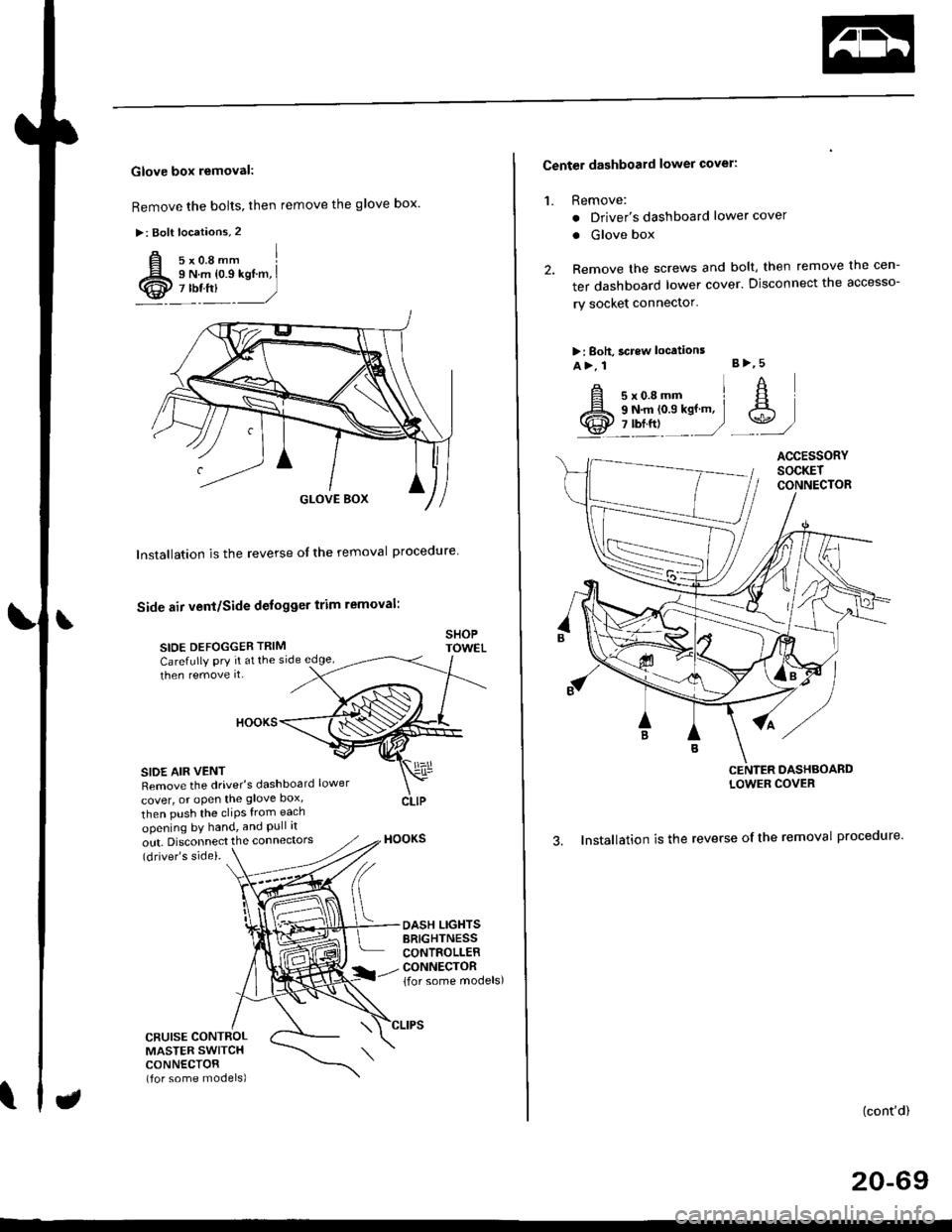

Glove box removal:

Remove the bolts, then remove the glove box.

>: Bolt locations,2

Installation is the reverse of the removal proceoure

Side air vent/Side defogger trim removal:

SIOE DEFOGGER TRIMSHOPTOWET_Carefully PrY rt at the

then remove it,side edge,

SIDE AIR VENTRemove the driver's dashboard lower

cover, or oPen the glove Dox,

HOOKS

then push the cliPs from each

opening by hand, and Pull it

out. Disconnect the connedors(driver's side).

HOOKS

DASH LIGHTSBRIGHTNESSCONTROLLERCONNECTOR{for some models)

CFUISE CONTROLMASTER SWITCHCONNECTOR(for some models)

Center dashboard lower covel:

1. Remove:

. Driver's dashboard lower cover

. Glove box

2. Remove the screws and bolt, then remove the cen-

ter dashboard lower cover. Disconnect the accesso-

ry socket connector'

>i Boh, screw locations

a>, 1 B>'5

A s*o.e-- I A

@;*;ry'-1'-.J _e)

3. Installation is the reverse of the removal proceoure'

(cont'd)

20-69

LOWER COVER

Page 1410 of 2189

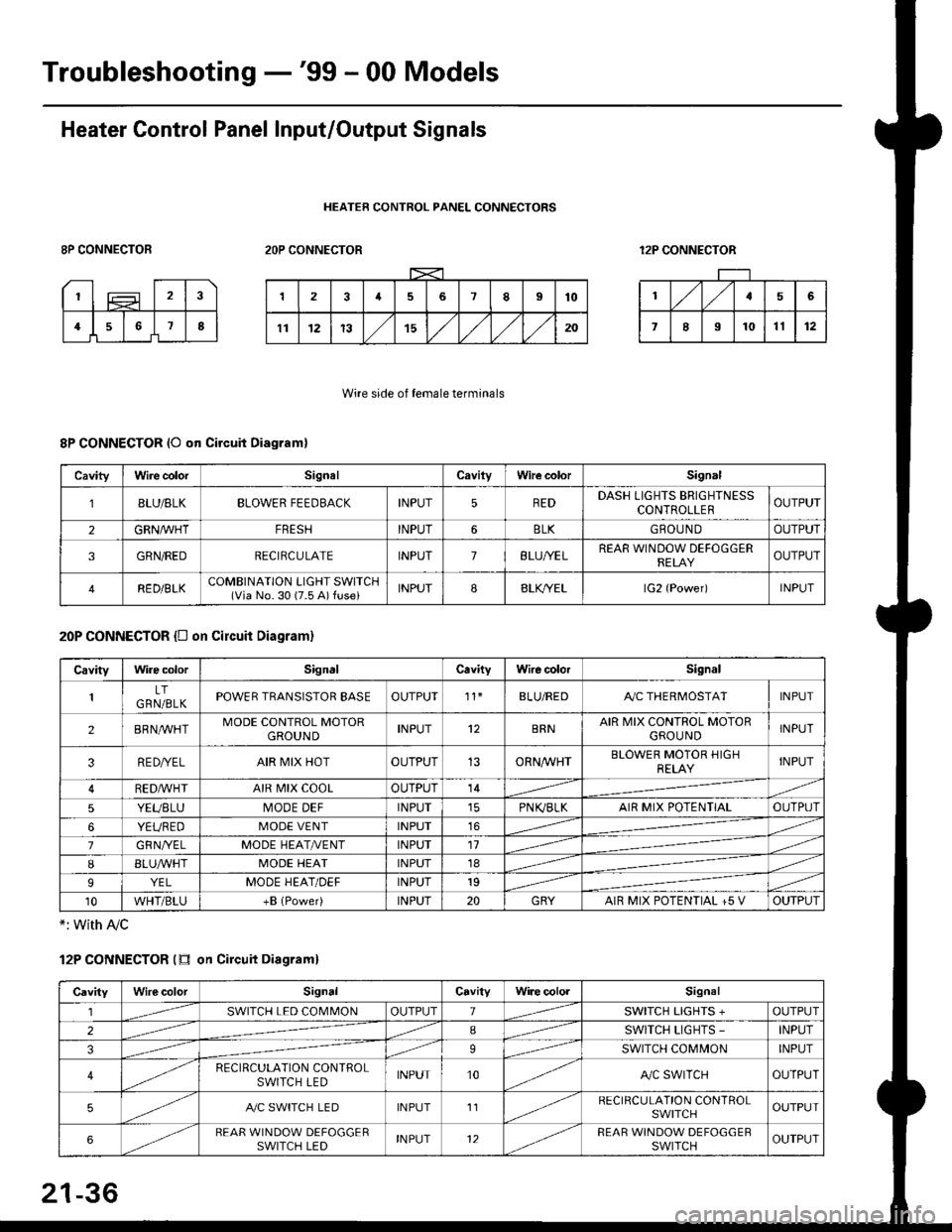

Troubleshooting -'99 - 00 Models

Heater Control Panel Input/Output Signals

HEATER CONTROL PANEL CONNECTORS

8P CONNECTOR2OP CONNECTOR12P CONNECTOR

Wire side of female terminals

8P CONNECTOR (O qn Circuit Diagram)

20P CONNECTOR {D on circuit Diagram}

*: with Ay'c

12P CONNECTOR (tr on Circuit Diagraml

CavityWire colorSignalCavilyWhe colorSignal

BLU/8LKBLOWER FEEDBACKINPUT5REDDASH LIGHTS BRIGHTNESSCONTROLLEROUTPUT

2GRN/lVHTFRESHINPUT6BLKGBOU N DOUTPUT

3GRN/REDRECIRCULATEINPUT7BLU/YELREAR WINDOW DEFOGGERRELAYOUTPUT

4RED/BLKCOMBINATION LIGHT SWITCH(Via No. 30 (7.5 A) fuse)INPUT88LfiELlG2 {Power)INPUT

CavityWire colorSignalCavityWire colorSignal

LTGRN/BLKPOWER TRANSISTOR EASEOUTPUT't1BLU/REDAy'C THERMOSTATINPUT

2BRNMHTMODE CONTROL MOTORGROUNDINPUT12BRNAIR MIX CONTROL MOTORGROU NDINPUT

3RE D/YELAIR MIX HOTOUTPUT13ORNAA/HTBLOWER MOTOR HIGHRELAYINPUT

RED,ryvHIAIR MIX COOLOUTPUT14

5YEUBLUMODE DEFINPUTPN K,/BLKAIR MIX POTENTIALOUTPUT

6YEUREDMODE VENTINPUT16

7GRNI/ELMODE HEAT/r'ENTINPUT11

IBLUAVHTMODE HEATINPUT18

9YELMODE HEAT/DEFINPUT19

10WHT/BLU+B (Power)INPUT20GRYAIR MIX POTENTIAL +5 VOUTPUT

CavityWilecolorSignalCavityWi.e cololSignal

lSWITCH LED COMMONOUTPUT1SWITCH LIGHTS +OUTPUT

2ISWITCH LIGHTS -INPUT

39SWITCH COMMONINPUT

4RECIRCULATION CONTROLSWITCH LEDINPUT10A,/C SWITCHOUTPUT

5A./C SWITCH LEDINPUT11RECIRCULATION CONTROLSWITCHOUTPUT

6REAR WINDOW DEFOGGERSWITCH LEDINPUT12REAR WINDOW DEFOGGEBSWITCHOUTPUT

21-36

Page 1417 of 2189

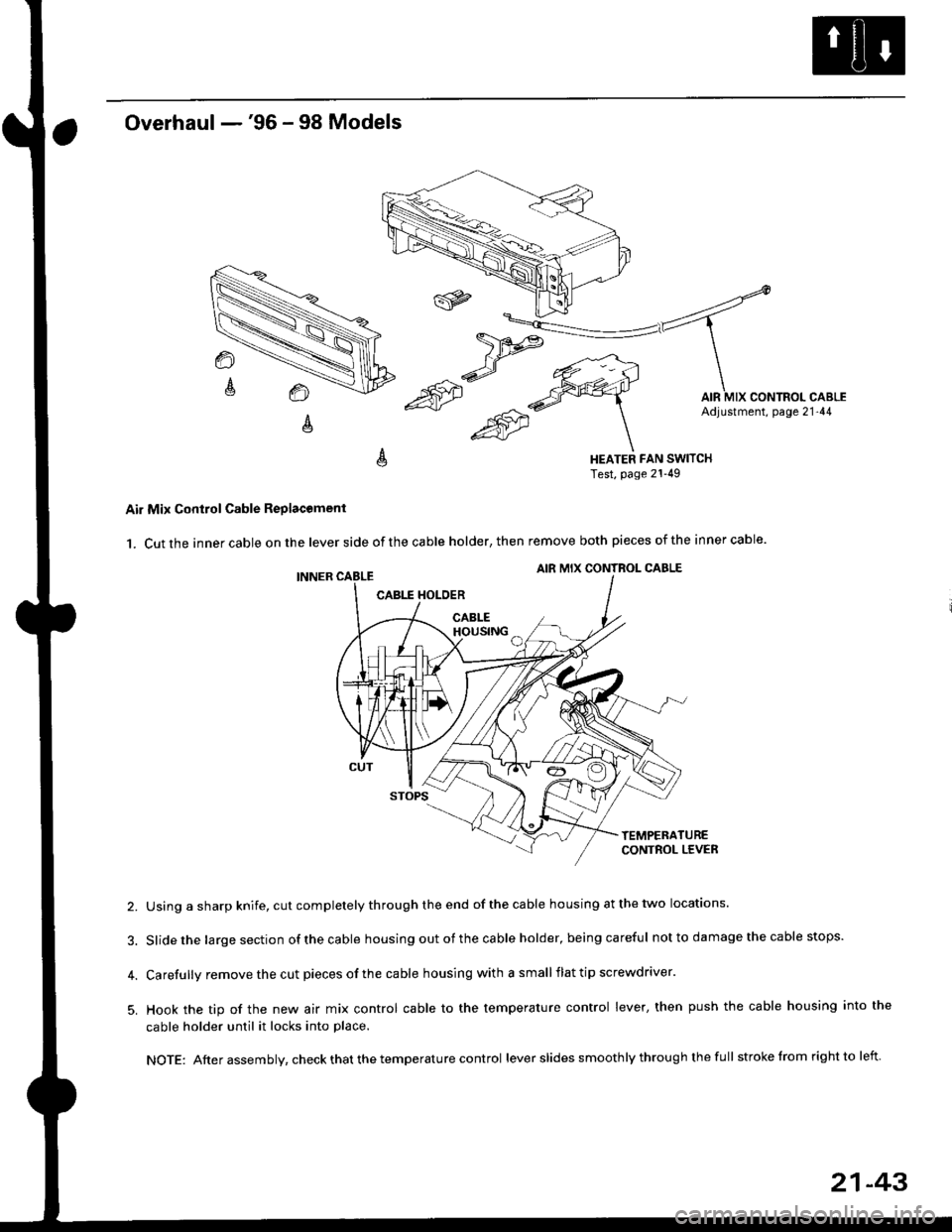

Overhaul -'96 - 98 Models

HEATER FAN SWITCHTest, page 21-49

Air Mix Control Cable Replacomenl

1. Cut the inner cable on the lever side of the cable holder, then remove both pieces of the inner cable.

2. Using a sharp knife, cut completely through the end of the cable housing at the two locations.

3. Slidethe largesection ofthecable housing outofthe cable holder, being careful not to da mage the cable stops.

4. Carefully remove the cut pieces of the cable housing with a small flat tip screwdriver.

5. Hook the tip of the new air mix control cable to the temperature control lever, then push the cable housing into the

cable holder until it locks into place.

NOTE: After assembly, check that the temperature control lever slides smoothly through the full stroke lrom right to left.

21-43