Cam HONDA CIVIC 1996 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1101 of 2189

I

8.

9.

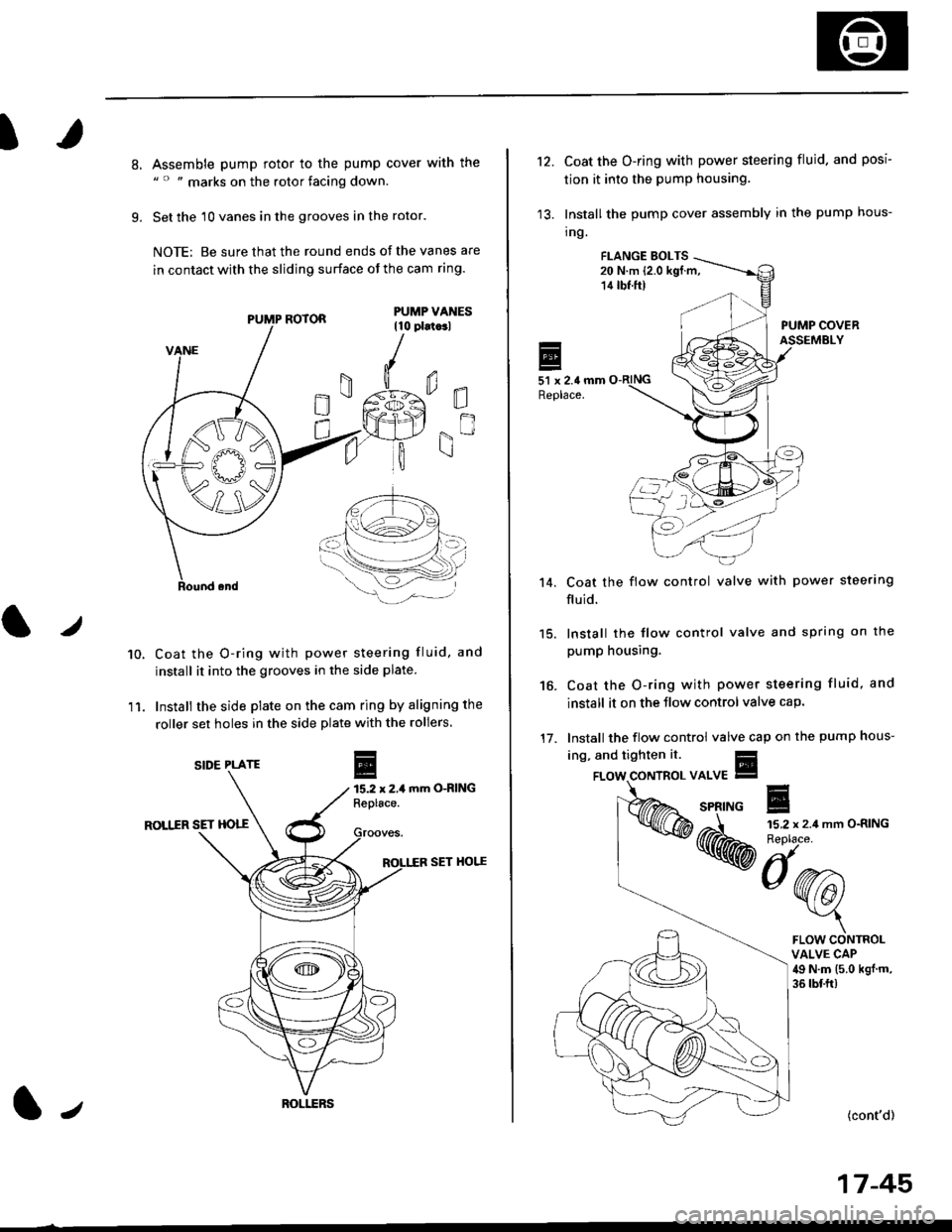

Assemble pump rotor to the pump cover with the" " " marks on the rotor facing down.

Set the 10 vanes in the grooves in the rotor.

NOTE: Be sure that the round ends ot the vanes are

in contact with the sliding surface of the cam ring.

Coat the O-ring with power steering fluid, and

install it into the grooves in the side plate.

Install the side plate on the cam ring by aligning the

roller set holes in the side plate with the rollers.

mm O-RING

ROLIIR SET HOTT

SET HOI.^E

0E

gn

10.

11.

r

E15.2 x 2,1Replace.

PUMP ROTOR

SIDE PLATE

ROI.I.ERSl,

't2.Coat the O-ring with power steering fluid. and posi

tion it into the pump housing.

Install the pump cover assembly in the pump hous-

tng.

FI.ANGE EOLTS20 N.m (2.0 kgf.m,14 tbf.ft)

PUMP COVERASSEMBLY

51 x 2.4 mmReplace.

Coat the flow control valve with power steerlng

fluid.

15. lnstall the flow control valve and spring on the

pump housing.

Coat the O-ring with power steering fluid, and

install it on the Jlow control valve cap.

Install the flow control valve cap on the pump hous-

't 4.

16.

17.

ing, and tighten it.

{cont'd)

17-45

FLOW CONTROLVALVE CAP49 N.m (5.0 kgj m,

36 tbf.ft)

Page 1125 of 2189

)

Suspension

Special Tools ............. 18-2

Component Locations

lndex ,,.............. ...... f8-3

Wheel Alignment

Caster .............. ....... 18-4

Camber .................. l8-4

Front Toe Inspection/

Adiustment ........ 18-5

Rear Toe lnspection/

Adiustment ........ 18-5

Turning Angle Inspection ................ 18-6

Wheel/Hub Inspection

Bearing End P|ay .............................. l8-7

Wheel Runout ....... 18-7

Front Suspension

Suspension Arms Replacement

('96 - 99 modelsl .......................... 18-8

Suspension Arms Replacement

('99 2D Si and Si-R models) ........ 18-9

Knuckle/Hub Replacement ............. 18-10

Lower Ball Joint Replacement ....... 18-16

Ball Joint Boot Replacement .......... 18-17

Front Damper

Removal ................. 18-17

Disassembly/1nspection .................. 18-18

Reassembly ........... 18-19

lnstallation ............. 18-19

Rear Suspension

Suspension Arms Replacement

('96 - 99 models) ....................,..... 18-21

Suspension Arms Replacement

('99 2D Si and Si-R models) ........ 1A-22

Hub Bearing Unit Replacement ...... 18-23

Upper Arm Eushing

Replacement .....18-25

Rear Damper

Removal ................. 18-26

Disassembly/|nspection ............. ..... 1A-27

Reassembly ........... 18-28

lnstallation ............. 18-29

lr

Page 1128 of 2189

Wheel Alignment

,f,

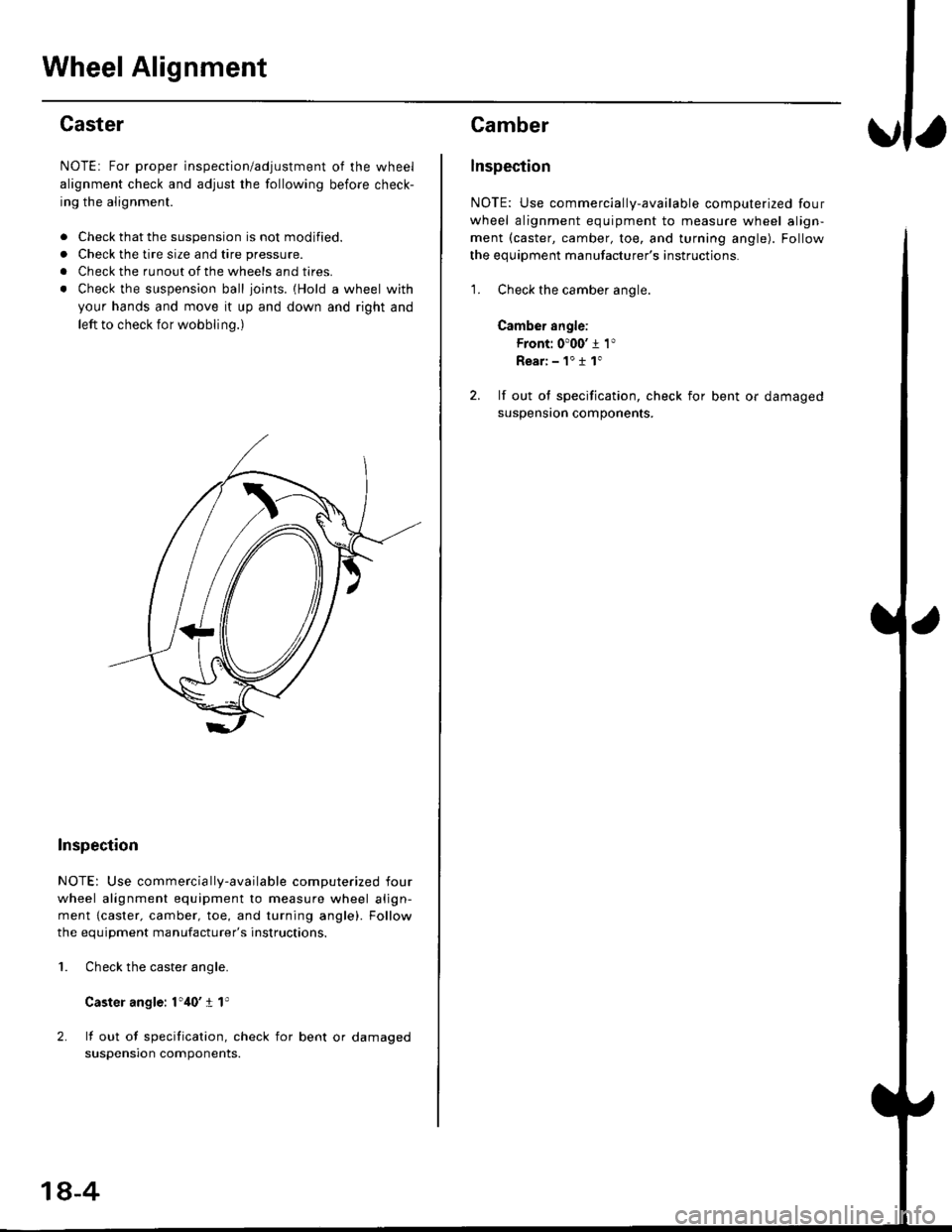

Caster

NOTE: For proper inspection/adjustment of the wheel

alignment check and adjust the following before check-

ing the alignment.

. Check that the suspension is not modified.

. Check the tire size and tire pressure.

. Check the runout of the wheels and tires.

. Check the suspension ball ioints. {Hold a wheel with

your hands and move it up and down and right and

left to check for wobbling.)

Inspection

NOTE: Use commercia lly-available computerized four

wheel alignment equipment to measure wheel align-

ment {caster. camber, toe, and turning angle). Follow

the equiDment manufacturer's instructions.

Check the caster angle.

Caster angle: 1',10' I 1'

lf out of specification, check for bent or damaged

suspensron components.

2.

1.

18-4

Camber

lnspection

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the camber angle.

Camber angle:

Front: 0'00' j 1"

Rear:-1"11"

2. lf out ol specification, check for bent or damaged

suspensron components.

Page 1129 of 2189

?

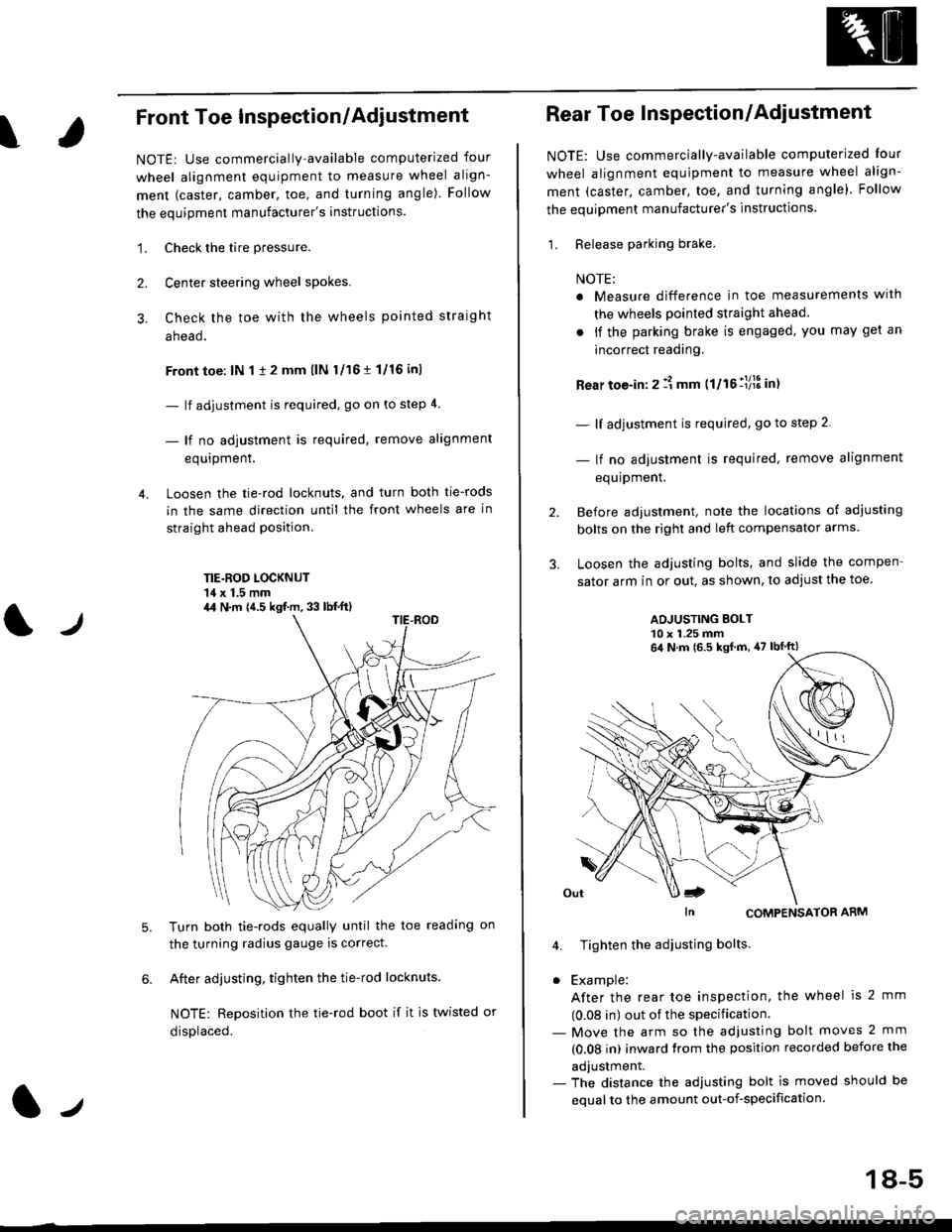

Front Toe Inspection/Adiustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the tire pressure.

Center steering wheel spokes.

Check the toe with the wheels pointed straight

a head.

Front toe: lN 1 1 2 mm llN l/16 r 1/16 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equrpmenr.

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are in

straight ahead position.

TIE.ROD LOCKNUT'14 x 1.5 mm

4.

tJ

6.

Turn both tie-rods equally until the toe readang on

the turning radius gauge is correct.

After adjusting, tighten the tie-rod locknuts.

NOTE: Reposition the tie-rod boot if it is twisted or

displaced.

4,1 N.m {4.5 kgf.m, 33 lb{.ft)

2.

Rear Toe Inspection/Adiustment

NOTE: Use commercially-available computerjzed Iour

wheel alignment equjpment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Release parking brake.

NOTE:

a Measure difference in toe measurements wlth

the wheels pointed straight ahead.

. if the parking brake is engaged, you may get an

incorrect readang,

Rear toe-in: 2 11 mm ttltollllS int

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adiusting

bolts on the right and left compensator arms

Loosen the adjusting bolts, and slide the compen

sator arm in or out. as shown, to adjust the toe

ADJUSTING BOLT10 x 1.25 mm

In CoMPENSAToR ARM

4. Tighten the adiusting bolts

. Example:

After the rear toe inspection, the wheel is 2 mm

(0.08 in) out of the specification.- Move the arm so the adjusfing bolt moves 2 mm

(0.08 in) inward trom the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

64 N.m 16.5 ksf m, 47 lbtft)

18-5

Page 1130 of 2189

Wheel Alignment

Turning Angle Inspection

NOTEr Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

'1. Turn the wheel right and left while applying the

brake, and measure the turning angle of both

wneets.

Turning angle:

lnward wheel: 39'50'

Outwald wheel (ref erencel: 33'10'

2.lf the turning angle

check for bent or

nents,

is not within the specifications,

da m aged suspension compo-

18-6

Page 1183 of 2189

\

13.

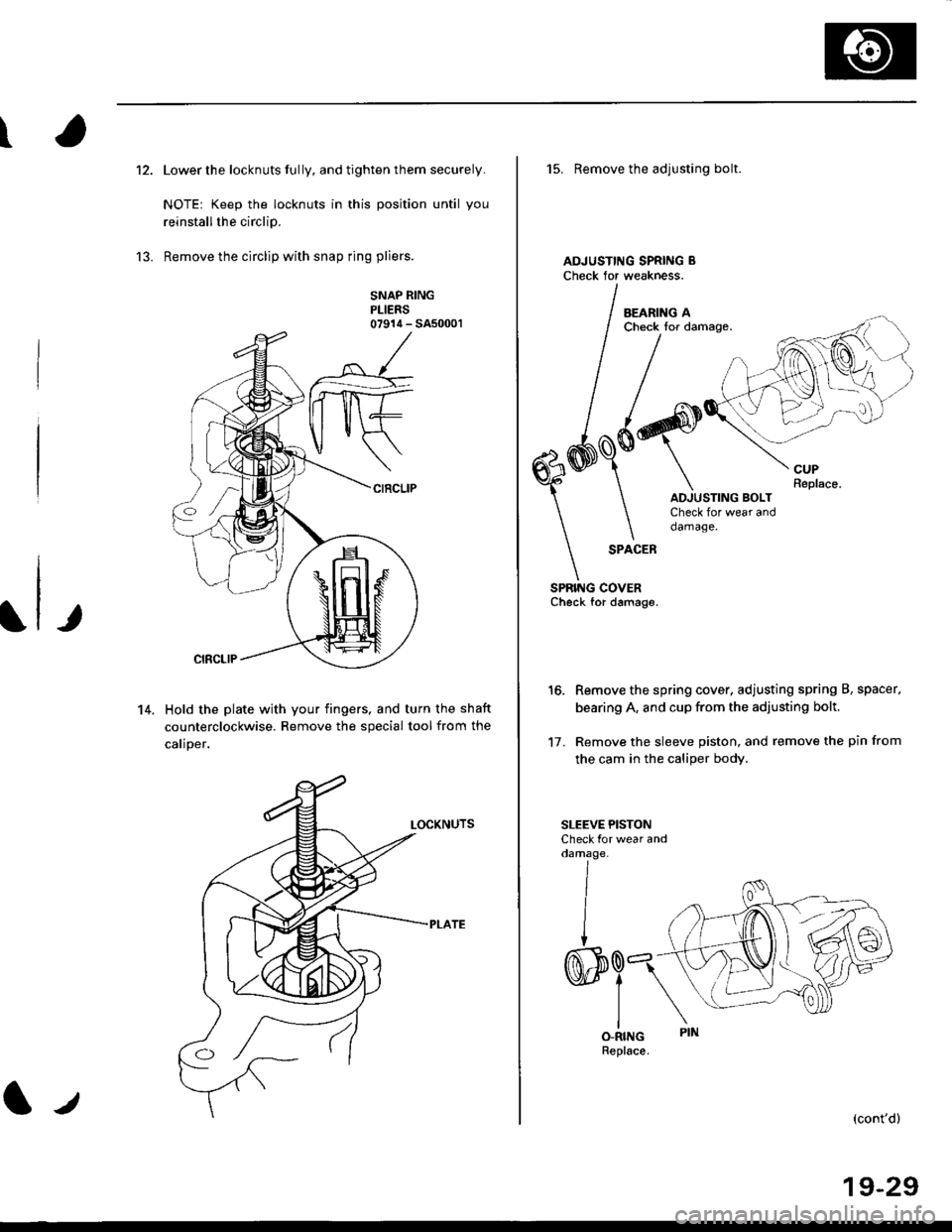

Lower the locknuts fully, and tighten them securely.

NOTE: Keep the locknuts in this position until you

reinstallthe circlip.

Remove the circlip with snap ring pliers.

SNAP RINGPLIERS07914 - SA50001

't 4.Hold the plate with your fingers, and turn the shaft

counterclockwise. Remove the special tool from the

calioer.

LOCKNUTS

l./

15. Remove the adjusting bolt.

Remove the spring cover, adjusting spring B, spacer,

bearing A, and cup from the adjusting bolt.

Remove the sleeve piston, and remove the pin from

the cam in the caliper body.

'17 .

SLEEVE PISTONCheck lor wear anddamage,

i

I

I

6-50-awl \

IO-RIITGRepl6ce.

(cont'd)

19-29

Page 1184 of 2189

Rear Brake Galiper

Disassembly (cont'dl

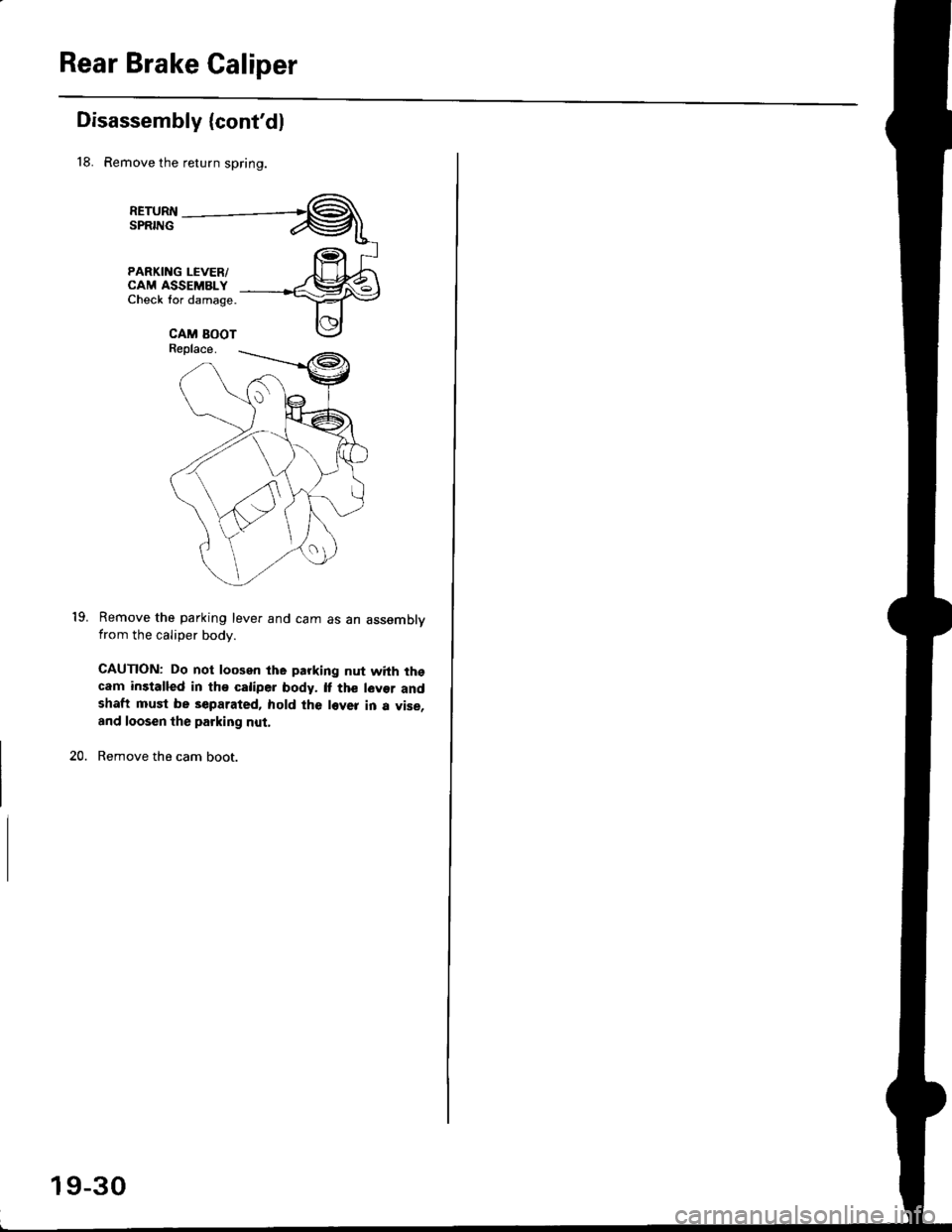

18. Remove the return spring.

PARKING LEVER/CAM ASSEMBLYCheck lor damage.

Remove the parking lever and cam as an assemblvfrom the caliper body.

CAUTION: Do not loosen the parking nut with thecam inslalled in the caliper body, lf the leyer andshaft must be separated, hold the lever in a vise,and loosen the parking nut,

Remove the cam boot.

RETURNSPRING

19.

19-30

Page 1186 of 2189

Rear Brake Caliper

Reassembly (cont'dl

L

PARKING NUT28 N.m (2.8 kgt m,20 rbr.trt

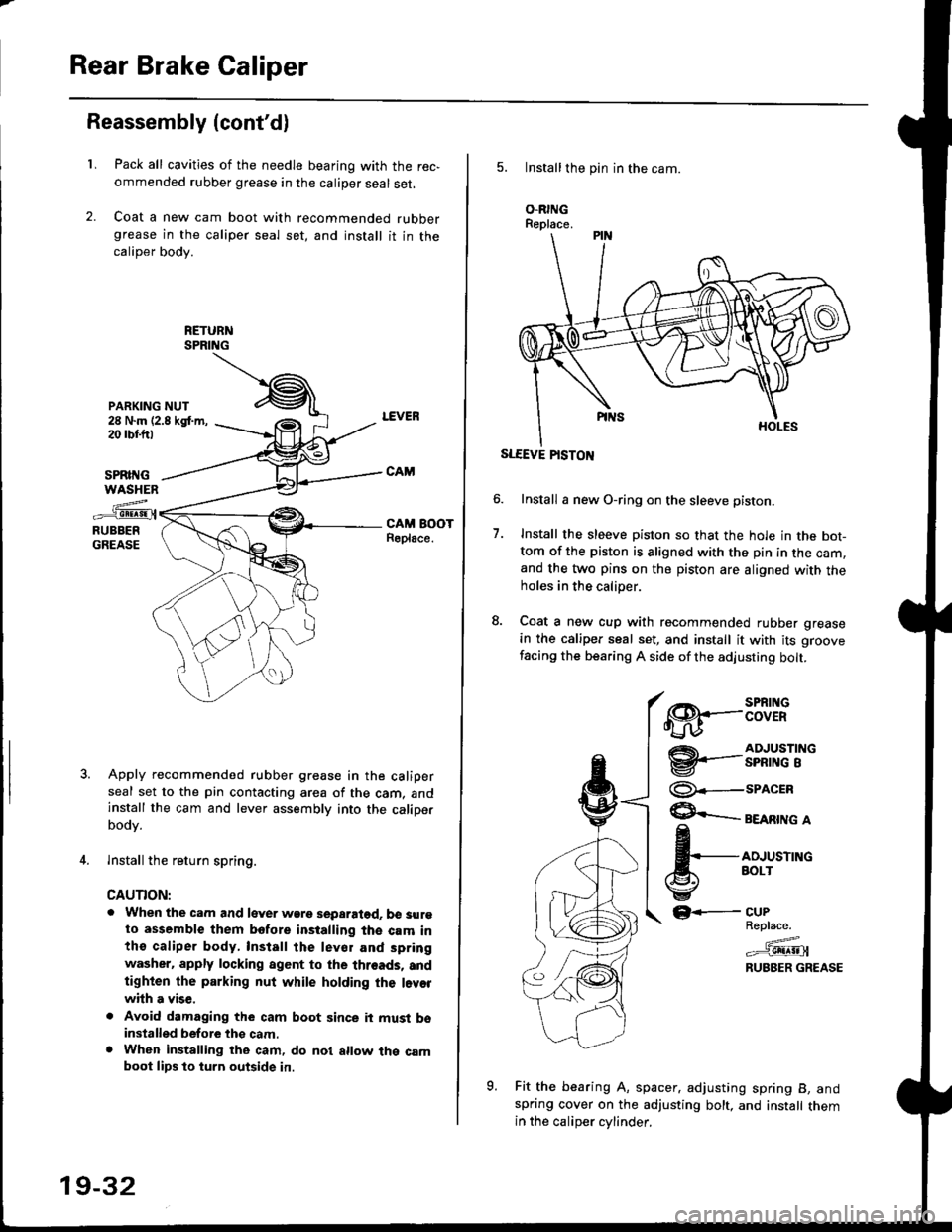

Pack all cavities of the needle bearing with the rec,

ommended rubber grease in the caliper seal set,

Coat a new cam boot with recommended rubbergrease in the caliper seal set, and install it in thecaliper body.

SPRII{GWASHEN

z..-_e!!!9!.{RUBBERGREASE

Apply recommended rubber grease in the caliperseal set to the pin contacting area of the cam, andinstall the cam and lever assembly into the caliperbodv.

lnstall the return spring.

CAUTION:

. When the cam and lever wgre separatod. b€ surgto assemble them bofore installing the cam inthe caliper body, Install the lev€r and spring

washer. apply locking agent to the threads, andtighten the parking nut while holding the l.vorwhh a vise,

. Avoid damaging the cam boot since it must bsinstalled before thg cam.. When installing the cam, do nol allow the camboot lips lo turn outside in.

19-32

5. Installthe pin in the cam.

O.RINGReplace.

SLEEVE PISTON

Install a new O-ring on the sleeve pisron.

Install the sleeve piston so that the hole in the bot-tom of the piston is aligned with the pin in the cam,and the two pins on the piston are aligned with theholes in the calioer.

Coat a new cup with recommended rubber grease

in the caliper seal set, and install it with its groove

facing the bearing A side of the adjusting bolt.

7.

€8.--:BTif

@'-.-3nfi""'i"

@--seacrn

$ eeenrne a

fi,*,*^"

GF-

Fit the bearing A, spacer. adjusting spring B, andspring cover on the adjusting bolt, and install themin the caliDer cvlinder.

CUPReplace.

=^.#-g!!!!!Jl

RUBBER GREASE

o

Page 1208 of 2189

tJ

t\

Kickback

1. The motor operates when the ABS is functioning, and the fluid in the reservoir is forced out to the master cylinder

causing kickback at the brake pedal.

2. TheABScontrol unit operates the solenoid valve when the brake pedal is released afterthe initial diagnosis Youmay

hear the faint solenoid valve operation sound at this time. but it is normal.

Pump Motor

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the faint operation sound

at this time. but it is normal.

Brake Fluid Replacament/Air Blsading

1. Brake fluid replacement and air bleeding procedures are the same as for conventional brakes

Troubleshooting

1. The troubleshooting flowcharts explain the procedures on the assumption that the cause of the problem is still pre-

sent and the ABS indicator light is still on.

Note that troubleshooting following the flowchart when the ABS indicator light does not come on can result in incor-

rect judgment.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

self,diagnosis is made at various times such as the initial diagnosis, except ABS control. during ABS control, during

acceleraiion, during the specified vehicle speed, etc. Therefore, the symptom cannot be checked unless the check

conditions match with the problem conditions

3. When the ABS indicator light does not come on during the test drive, but the troubleshooting is performed based on

the DTC, check for the loose connectors. poor contact of the terminals, etc, before troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the car. Be sure that the ABS indicator light does not come on.

5. The connector illustrations show the female connectors with a single outline and the male connectors with a double

ouflrne.

6. The connector terminal cavities containing female terminals are always numbered by looking at the connector from

the wire side. and the cavities containing male terminals are always numbered by looking at the connector from the

terminal side.

r'

19-55

Page 1265 of 2189

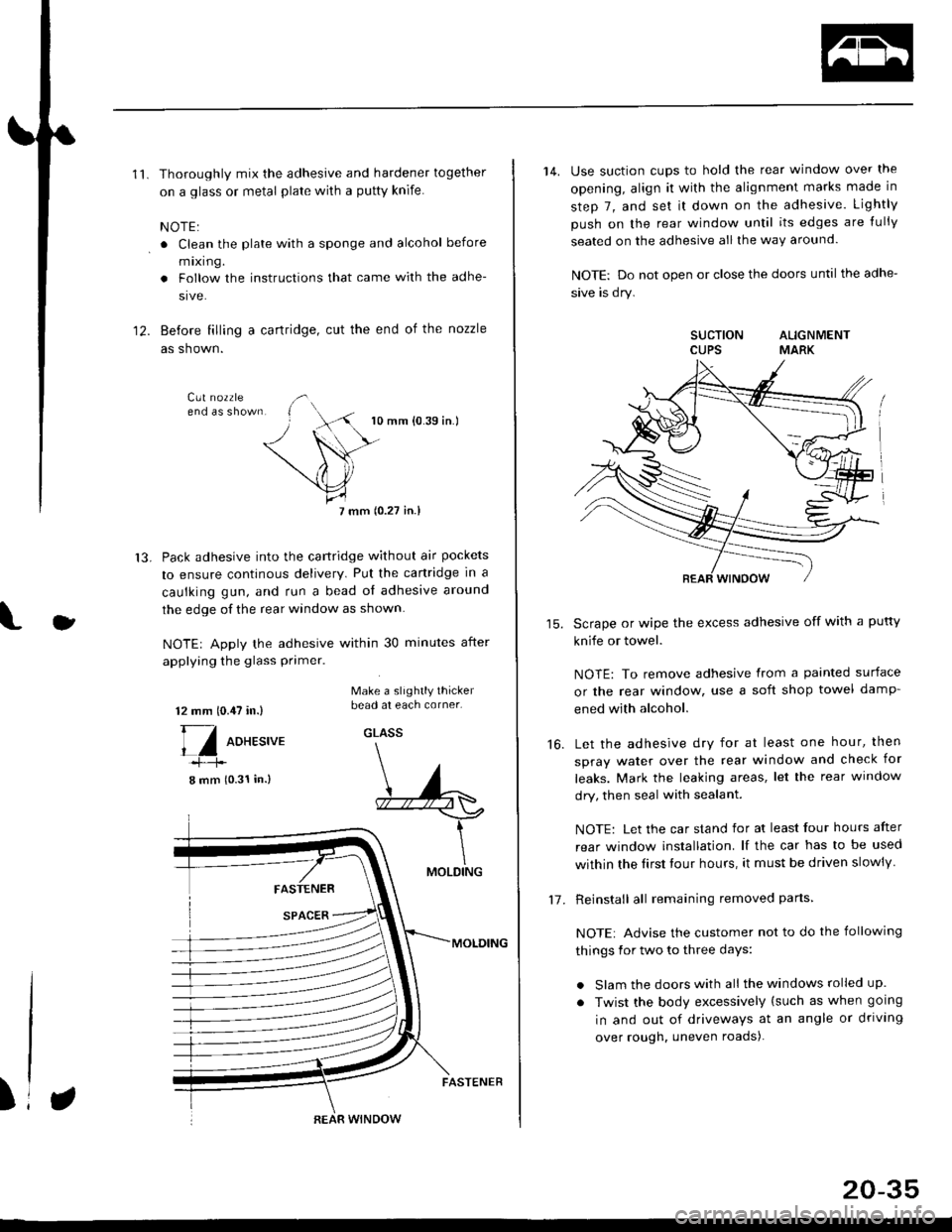

'11.Thoroughly mix the adhesive and hardener together

on a glass or metal plate wilh a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that came with the adhe-

sive.

Before filling a cartridge, cut the end of the nozzle

as shown.

10 mm {0.39 in.)

7 mm (0.27 in.l

Pack adhesive into the cartridge without air pockets

to ensure continous delivery. Put the canridge in a

caulking gun, and run a bead ol adhesive around

the edge of the rear window as shown.

NOTE| Apply the adhesive within 30 minutes after

applying the glass primer.

12.

13.

J

12 mm 10.,U in.)

[/ oo*r.,u.

8 mm (0.31 in.)

Make a slightly thickerbead at each corner.

GLASS

FASTENER

SPACER

MOLDING

MOLDING

)REAR WINDOW

FASTENER

20-35

14. Use suction cups to hold the rear window over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly

push on the rear window until its edges are {ully

seated on the adhesive all the way around.

NOTE: Do not open or close the doors until the adhe-

sive is dry.

SUCTION ALIGNMENTCUPS MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface

or the rear window, use a soft shop towel damp-

ened with alcohol.

Let the adhesive dry for at least one hour, then

spray water over the rear window and check for

leaks. Mark the leaking areas, let the rear window

dry, then seal with sealant.

NOTE: Let the car stand for at least four hours after

rear window installation. lf the car has to be used

within the Iirst tour hours, it must be driven slowly

Reinstall all remaining removed parts

NOTE: Advise the customer not to do the following

things for two to three days:

. Slam the doors with all the windows rolled up.

. Twist the body excessively (such as when going

in and out of driveways at an angle or driving

over rough. uneven roads).

16.

1-7 .