Hydraulic HONDA CIVIC 1996 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 894 of 2189

Description

Hydraulic Flow (cont'd)

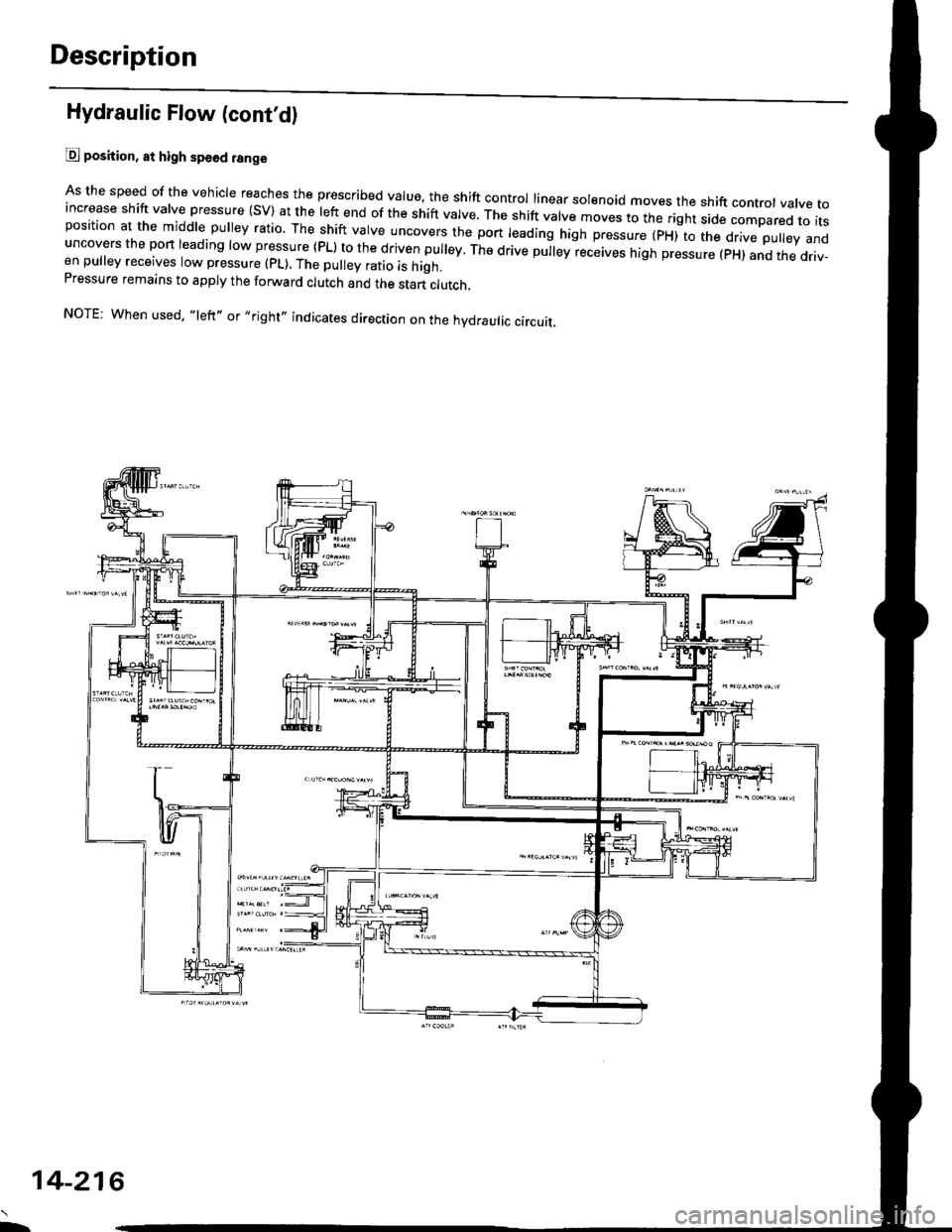

@ position, at high spe6d range

As the speed of the vehicle reaches the prescribed value, the shift control linear sol€noid moves the shift contror vatve toincrease shift valve pressure (SV) at the left end of the shift valve. ttre srrit vatve moves to the right side compared to itsposition at the middle pulley ratio. The shift valve uncovers the port leading high pressure (pxito ttre d.ve puley anduncovers the port leading low pressure (PL) to the driven pulley. The drive pu|ey receives high pressure (pH) and the driv-en pulley receives low pressure (pL). The pulley ratio is high.Pressure remains to apply the forward clutch and the start clutch,

NOTE: When used, "left,, or,,right" indicates direction on the hydraulic circuit.

L

14-216

Page 895 of 2189

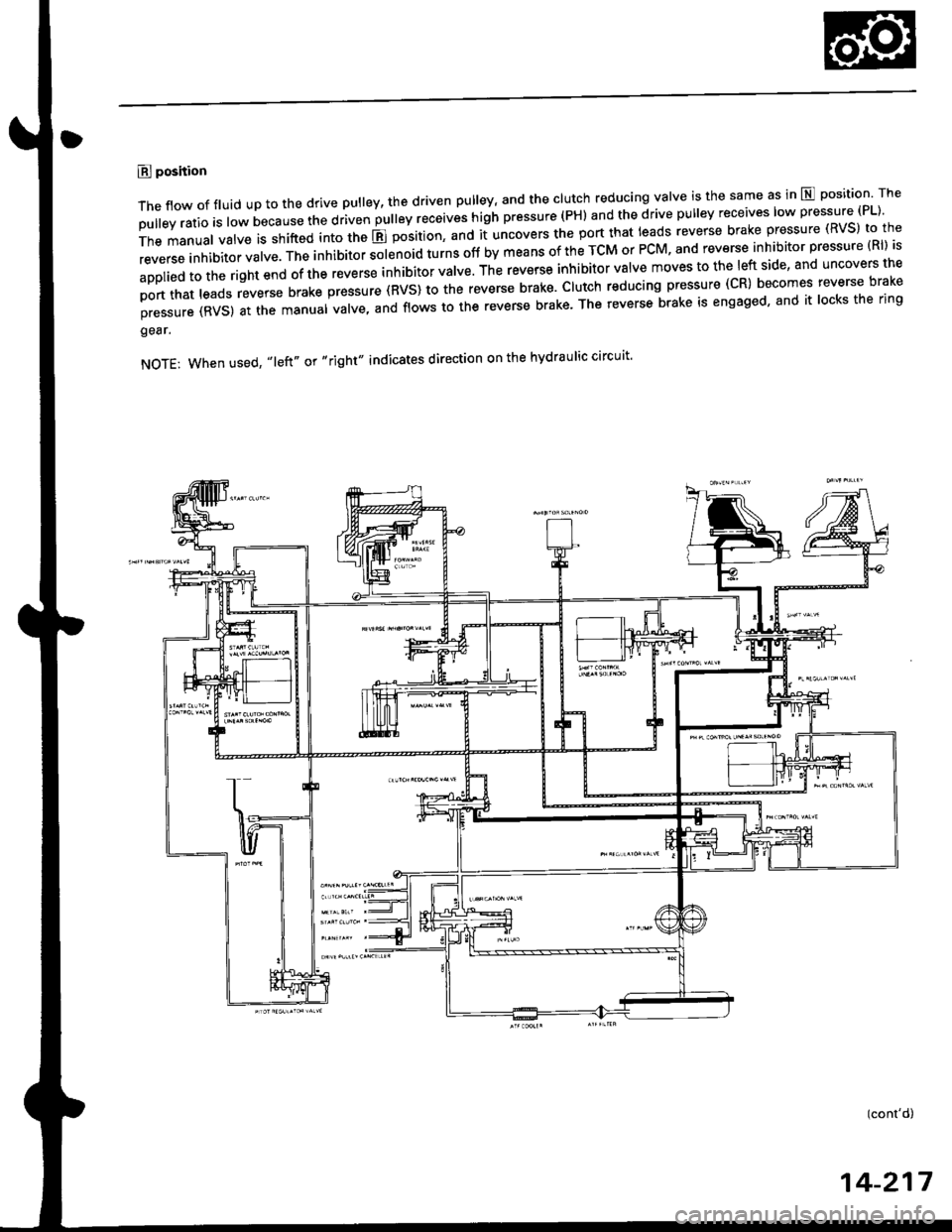

E position

The flow of fluid up to the drive pulley, the driven pulley' and the clutch reducing valve is the same as in E position The

pulley ratio is low b"car"" tt " o riu",i'prti"vi"""v"" t'igtr pressure.(pH) and the drive pulley receives low pressure {PL).

The manual valve is shifted into the B position, and it uncovers the port that leads reverse brake pressure (RVS) to the

reverse inhibitor valve. The inhibitoi Jenoid turns off by means of the TcM or PcM, and reverse inhibitor pressure (Rl) is

appliedtotherightendofthe,"u",""int,iui.o,u,|ve.Thereverseinhibitorva|vemovestothe|eftside,anduncoversthe

port that leads reverse brake pr"a"ur" tivst,o,he reverse brake. clutch reducing pressure (cR) becomes reverse brake

pressure (RVS) at the manuat *r"-, "nJ tro*" to the reverse brake. The reverse brake is engaged, and it locks the ring

gear.

NOTE: When used, "|eft" or "right" indicates direction on the hydraulic circuit'

(cont'd)

14-217

Page 896 of 2189

Description

Hydraulic Flow (cont'dl

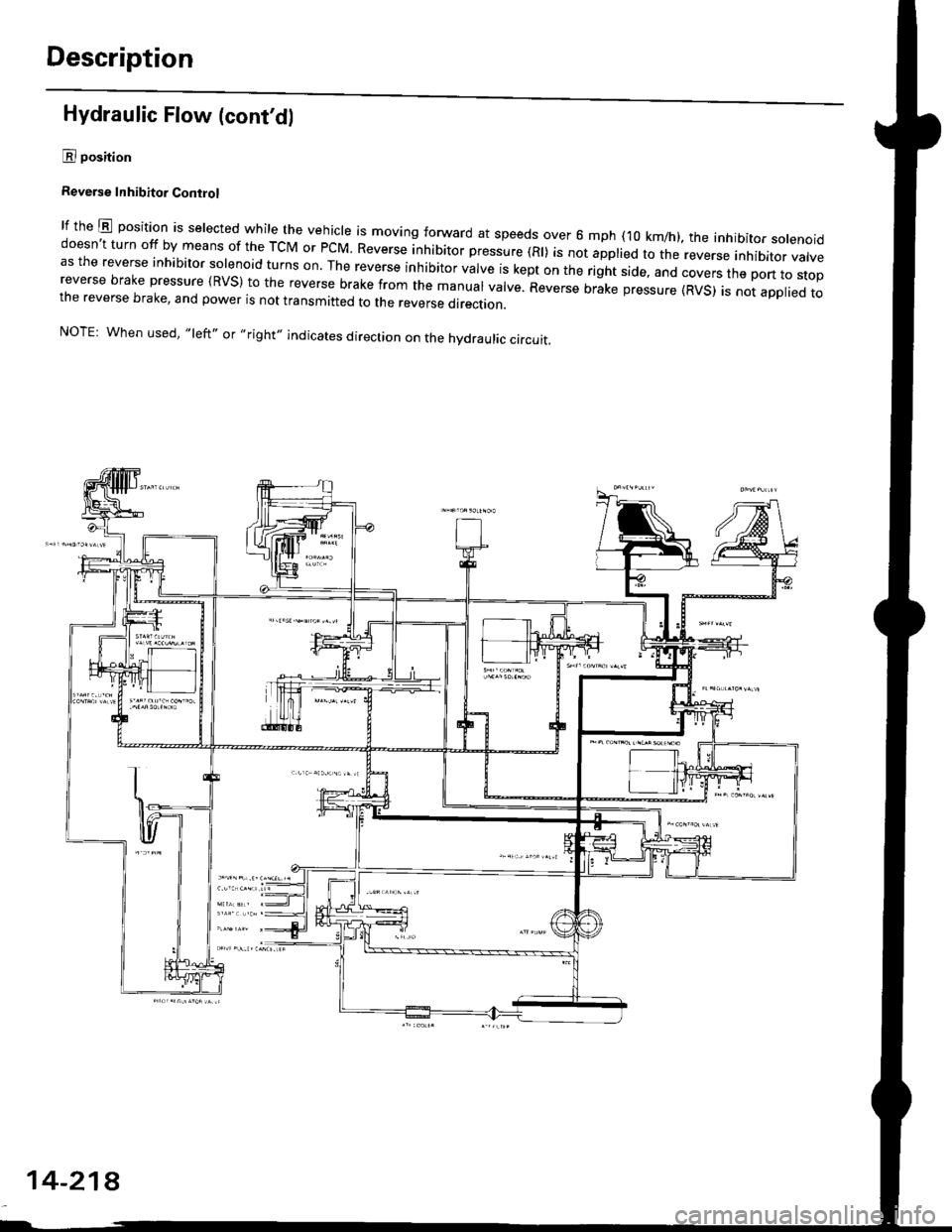

E position

Reverse Inhibitor Conirol

lf the E position is selected while the veiicle is moving forward at speeds over 6 mph (10 km/h), the inhibitor solenoiddoesn't turn off by means of the TcM or PCM Reverse inhibitor pressure (Rl) is not applied to the reverse inhibitor valveas the reverse inhibitor solenoid turns on. The reverse inhibitor valve is kept on the right side, and covers the pon ro sropreverse brake pressure {RVS} to the reverse brake from the manual valve. Reverse brike pressure (RVs) i; not appried tothe reverse brake, and power is not transmitted to the reverse direction.

NOTE: When used, "left,' or,,right,, indicates direction on the hydraulic circuit.

14-218

Page 897 of 2189

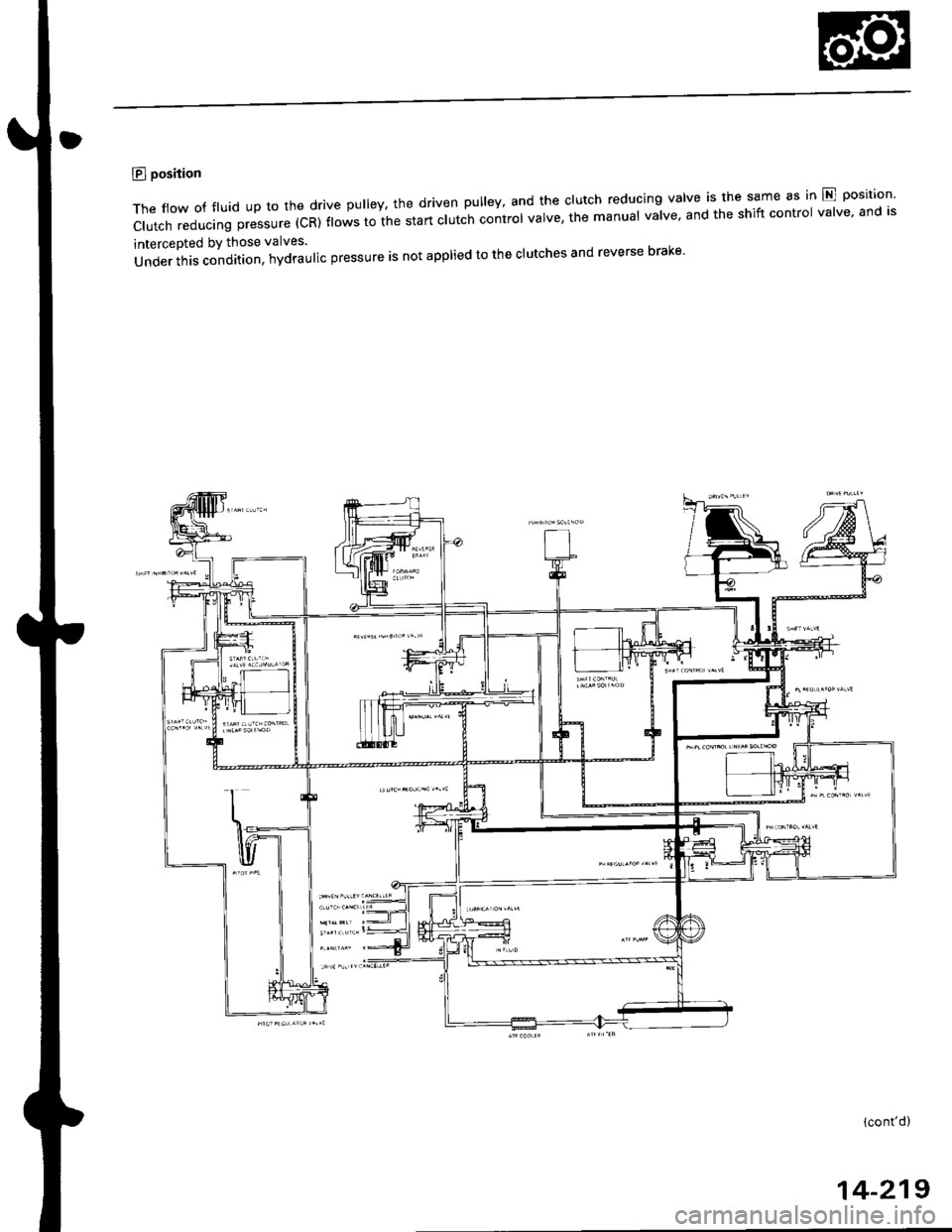

E position

The flow of fluid up to the drive pulley, the driven pulley' and the clutch reducing valve is the same as in E position'

Clutch reducing pressure (CR) t'"*" i" ii" start clut;h control valve, the manual valve, and the shift control valve' and is

intercepted bY those valves.

Under ihis condition, hydraulic pressure is not applied to the clutches and reverse braKe'

fr - --l

4t1.1 , 1'rltll

(cont'd)

14-219

Page 898 of 2189

Description

Hydraulic Flow (cont'd)

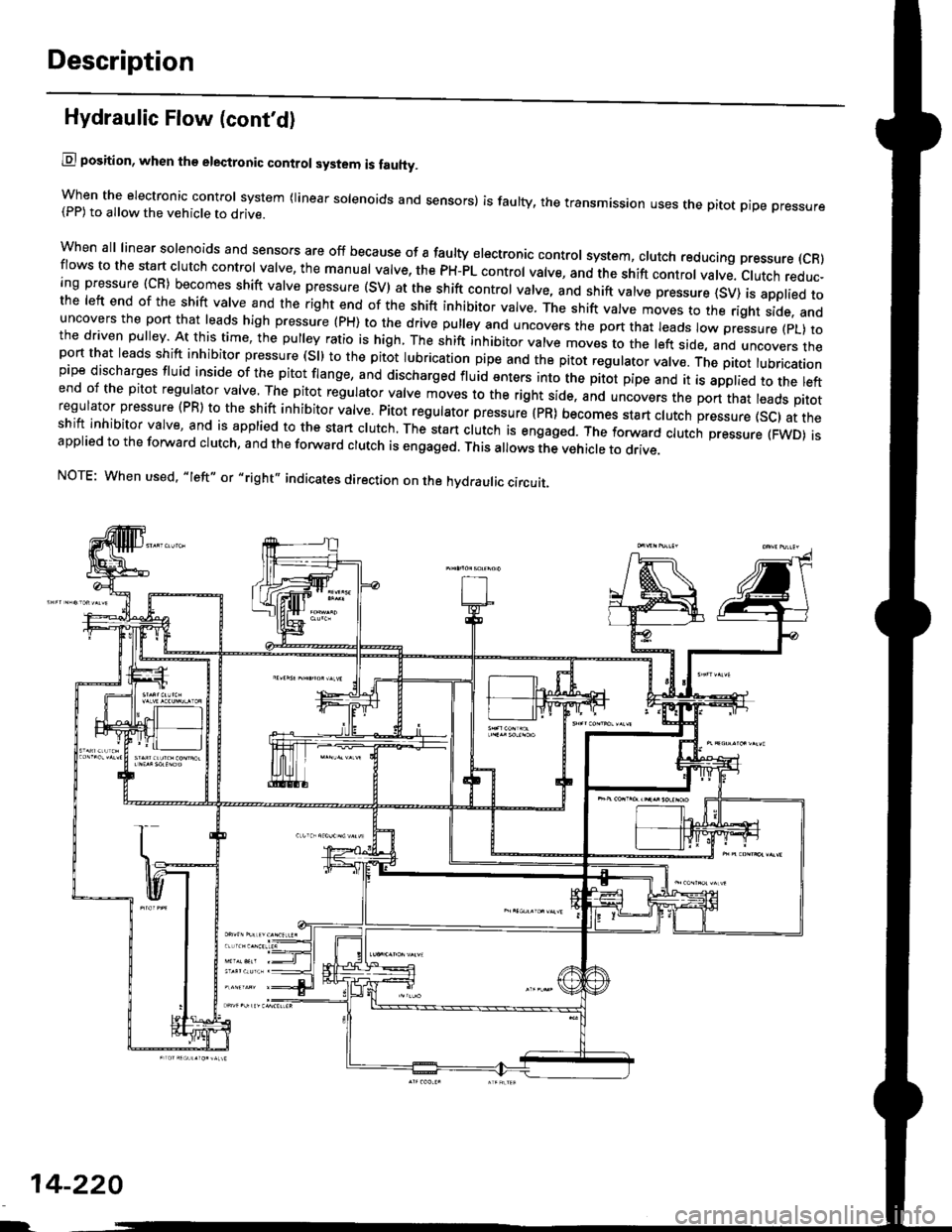

lll position, when th€ electronic control system is fauhy.

when the electronic control svstem (linear solenoids and sensors) is faulty, the transmission uses the pitot pipe pressure(PP) to 311o- rh" u"hicle to drive.

when all linear solenoids and sensors are off because of a faulty electronrc control system, clutch reducing pressure (cR)flows to the start clutch control valve, the manual valve, the PH-PL control valve, and the shift control valve. clutch reduc-ing pressure (cR) becomes shift varve pressure (sV) at the shift contror varve, and shift varve pressure {sv) is appried tothe left end of the shift valve and the right end of the shift inhibitor valve. The shift valve moves to the right side. anduncovers the pon that leads high pressure (PH) to the drive pulley and uncovers the po.t tlr"t r""1" ro,,"-pressure (pL) tothe driven pulley At this time, the pulley ratio is high, The shift inhibitor valve moves to the left side, and uncovers theport that leads shift inhibitor pressure (Sll to the pitot lubrication pipe and the pitot regulator valve. tne prtot lubricationpipe discharges fluid inside of the pitot flange, and discharged fluid enters into the pitot pipe and it is applied to the leftend of the pitot regulator valve. The pitot regulator valve moves lo the right side, and uncovers the port that leads pitotregulator pressure (PR) to the shift inhibitor valve. Pitot regulator pressure {pR) becomes start clutch pressure {sc1 at theshift inhibitor valve, and is applied to the stan clutch. The stan clutch rs engaged. The forward clutch pressure (FWD) isapplied to the forward crutch, and the forward crutch is engaged. This alows the vehicre to drive.

NOTE: When used. "|eft" or ,,right', indicates direction on the hydraulic circuit.

14-220

I.

Page 899 of 2189

![HONDA CIVIC 1996 6.G Repair Manual E] position, when the elestronic Gontrol system is faulty

The flow of tluid up to the drive pulley, the driven pulley and the start clutch is the same as in El position

The manual valve is shifted i HONDA CIVIC 1996 6.G Repair Manual E] position, when the elestronic Gontrol system is faulty

The flow of tluid up to the drive pulley, the driven pulley and the start clutch is the same as in El position

The manual valve is shifted i](/img/13/6068/w960_6068-898.png)

E] position, when the elestronic Gontrol system is faulty'

The flow of tluid up to the drive pulley, the driven pulley' and the start clutch is the same as in El position

The manual valve is shifted into the lE position' and it uncovers the port that leads reverse brake pressure {RVS} to the

reverse inhibitor valve. Reverse ,"nlu-i,"ip*r""i" (Rl) is applied to.the right end of the reverse inhibitor valve because of

afaultyinhibitorsolenoid.The'"t'",""inftiUito'valvemovestotheleftside'anduncoverstheportthatleadsreverse

brake pressure {RVS) to the ,"u"r." ir"t"- cru,ch reducing pressure (cR) becomes reverse brake pressure (RVS) at the

manual valve, and,lows to the ,e

"rs" lr"re. ttre reverse brake is engaged and locks the ring gear' This allows the vehi-

cle to drive in reverse.

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit'

14-221

Page 971 of 2189

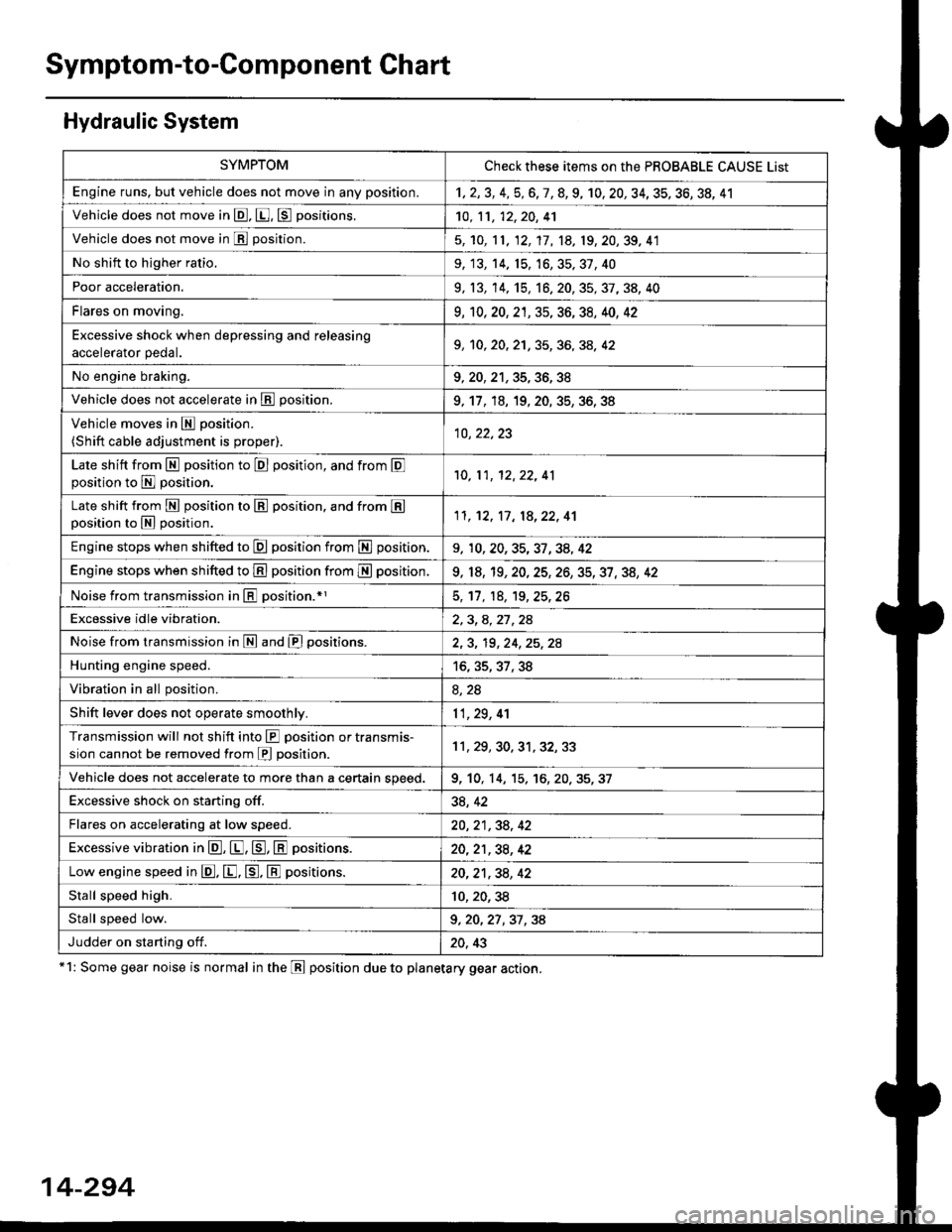

Symptom-to-Component Chart

Hydraulic System

*1: Some gear noise is normal in the Lll position due to planetary gear action.

14-294

SYMPTOMCheck these items on the PBOBABLE CAUSE List

Engine runs, but vehicle does not move in any position.'t,2,3,4,5,6,7,8,9, 10, 20, 34, 35, 36, 38, 41

Vehicle does not move in @, [. p positions.10,11, 12, 20, 41

Vehicle does not move in E position.5, 'to, 11, 12, 17, 1A, 19, 20,39, 41

No shift to higher ratio,9, 13, 14. 15, 16,35,37,40

Poor acceleration.9, 13,'�t4,'t5,16. 20, 35, 37, 38, 40

Flares on moving.9,'t0, 20, 2't, 35, 36, 38, 40, 42

Excessive shock when depressing and releasing.^^alA/.r^r ^A.1. I9, 10, 20, 2'1, 35, 36, 3A, 42

No engine braking.9,20,21,35,36,38

Vehicle does not accelerate in lll position.9, 17, 18, 19, 20. 35, 36, 38

Vehicle moves in E position.

(Shift cable adjustment is proper).10, 22,23

Late shift from N position to E position, and from Eposition to E position.'10,11, 12,22, 41

Late shift from E position to E position. and from Eposition to N position.1l,'t2, 17, 18,22, 41

Engine stops when shifted to E position from E position.9, 10,20,35,37,34, 42

Engine stops when shifted to E position from I position.9, 18, 19,20,25,26,35,37,38, 42

Noise from transmission in @ position.rl5, 17, 18, 't9,25,26

Excessive idle vibration.2,3,4,21,24

Noise from transmission in @ and @ positions.2,3, 19,24,25,2A

Hunting engine speed.16, 35, 37, 38

Vibration in all position.8, 2a

Shift lever does not operate smoothly.11,29, 4'l

Transmission will not shift into lll position or transmis-

sion cannot be removed from E position.11 , 29, 30, 31, 32,33

Vehicle does not accelerate to more than a certain speed.9, 10, 14, 15,'t6,20,35,37

Excessive shock on starting off.38, 42

Flares on accelerating at low speed.20, 21 ,38, 42

Excessive vibration in E, E, tr, E positions.20,21,38, 42

Low engine speed in E. E. tr. E positions.20,21,38,42

Stall speed high.10,20,38

Stall speed low.9, 20, 27 ,37 , 38

Judder on starting off.20, 43

Page 1072 of 2189

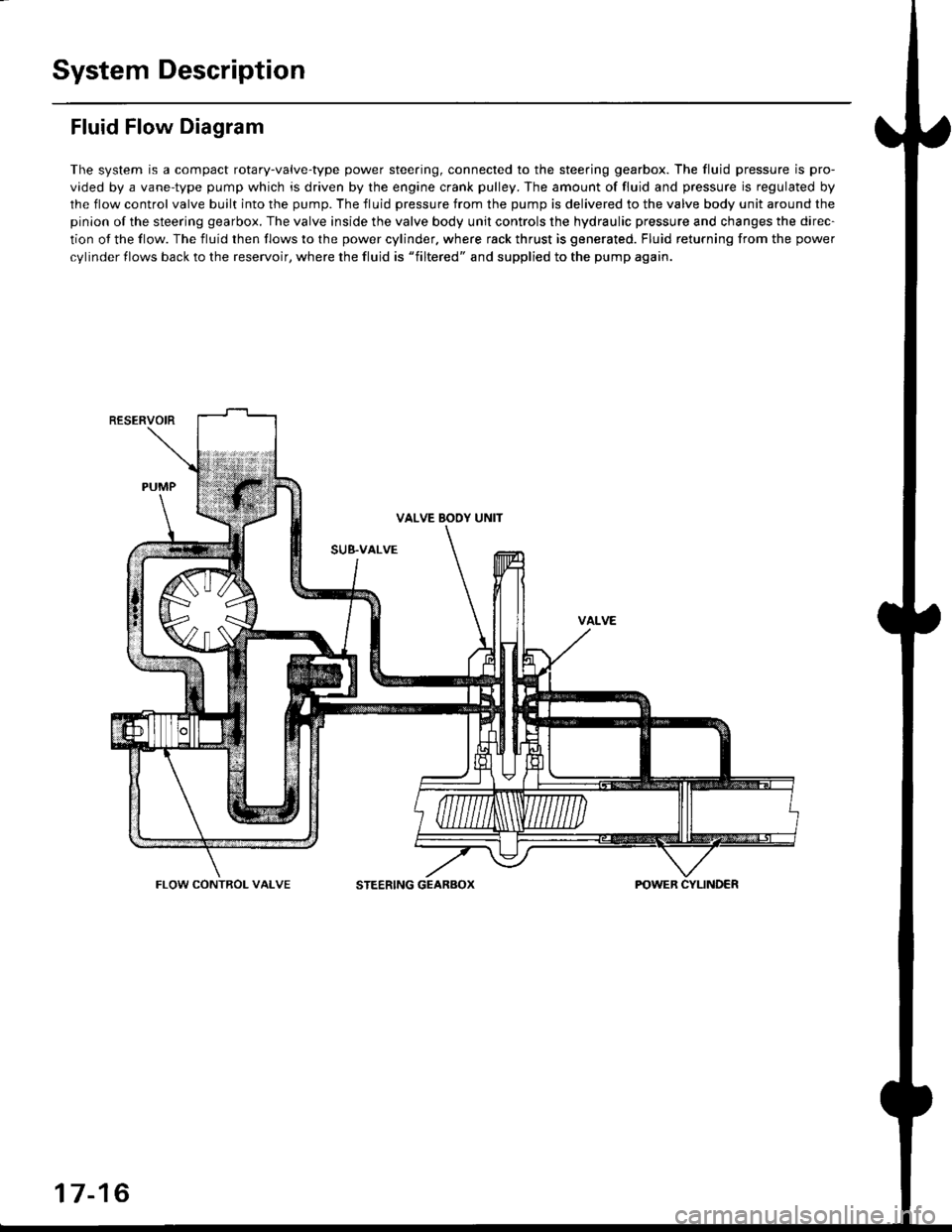

System Description

Fluid Flow Diagram

The system is a compact rotary-valve-type power steering, connected to the steering gearbox. The fluid pressure is pro-

vided by a vane-type pump which is driven by the engine crank pulley. The amount of fluid and pressure is regulated by

the flow control valve built into the pump. The fluid pressure from the pump is delivered to the valve body unit around the

pinion of the steering gearbox. The valve inside the valve body unit controls the hydraulic pressure and changes the direc-

tion of the flow. The fluid then flows to the power cylinder. where rack thrust is generated. Fluid returning from the power

cylinder flows back to the reservoir, where the fluid is "filtered" and supplied to the pump again.

RESERVOIR

VALVE BOOY UNIT

SUB.VALVE

FLOW CONTROL VALVESTEERING GEARBOX

17-16

Page 1073 of 2189

)

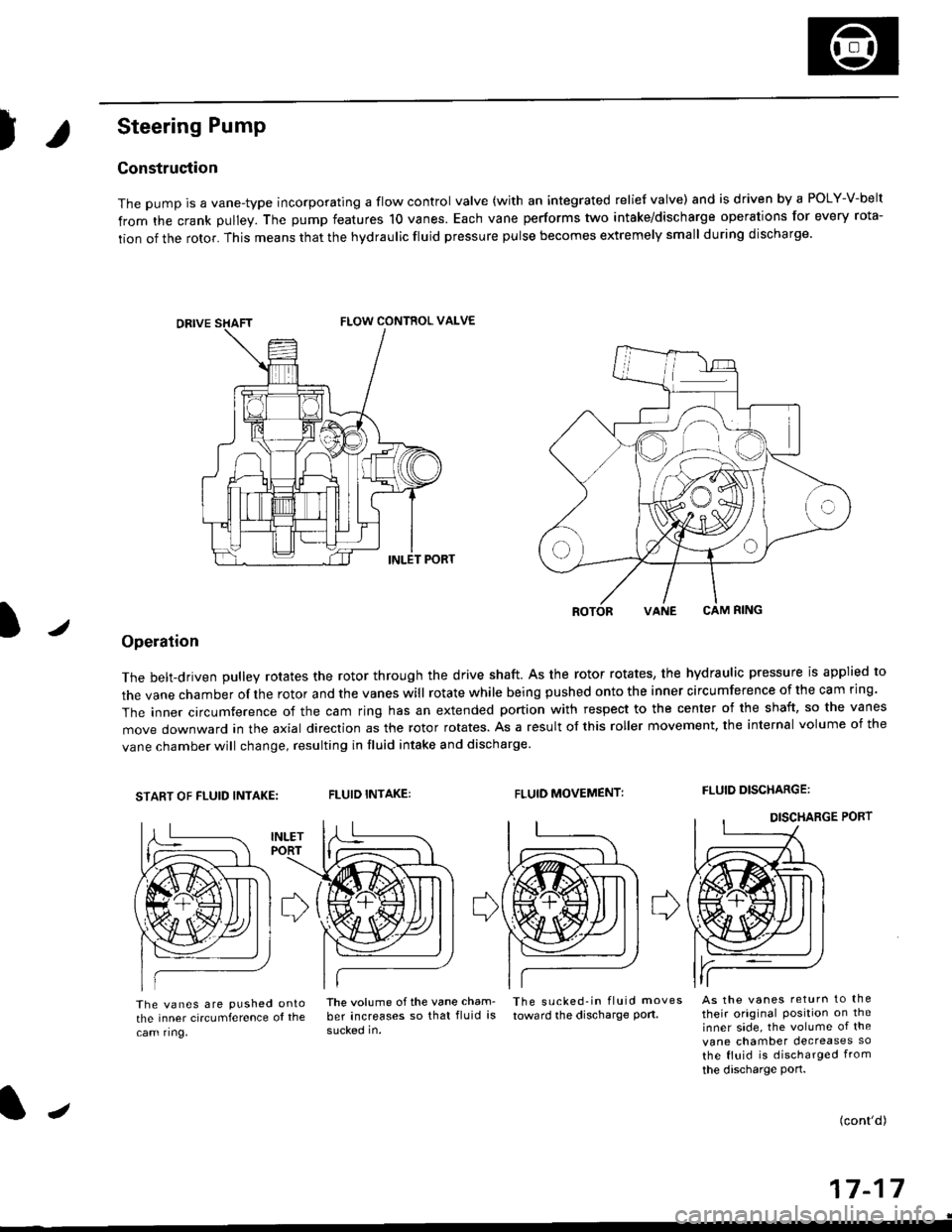

Steering Pump

Construction

The pump is a vane-type incorporating a flow control valve (with an integrated relief valve) and is driven by a POLY-V-belt

from the crank pulley. The pump features 10 vanes. Each vane performs two intake/discharge operations for every rota-

tion of the rotor. This means that the hydraulic fluid pressure pulse becomes extremely small during discharge.

/

ROTORVANE CAM RING

Operation

The belt-driven pulley rotates the rotor through the drive shaft. As the rotor rotates, the hydraulic pressure is applied to

the vane chamber of rhe rotor and the vanes will rotate while being pushed onto the inner circumference of the cam ring.

The inner circumference of the cam ring has an extended portion with respect to the center of the shaft, so the vanes

move downward in the axial direction as the rotor rotates. As a result of this roller movement. the internal volume of the

vane chamber will change, resulting in fluid intake and discharge

START OF FLUID INTAKE:FLUID INTAKE:FLUID MOVEMENT:FLUID DISCHARGE:

The vanes are pushed ontothe inner circumference ol the

cam ring,

lhe volume ofthe vane cham- The sucked-in fluid moves

ber increases so that fluid is toward the discharge port.

sucked in.

As the vanes return to the

their original Position on theinner side, the volume of the

vane chamber decreases so

the fluid is discharged from

the discharge port.

(cont'd)

a-t 4-I I- | t

FLOW CONTROL VALVE

J

Page 1076 of 2189

System Description

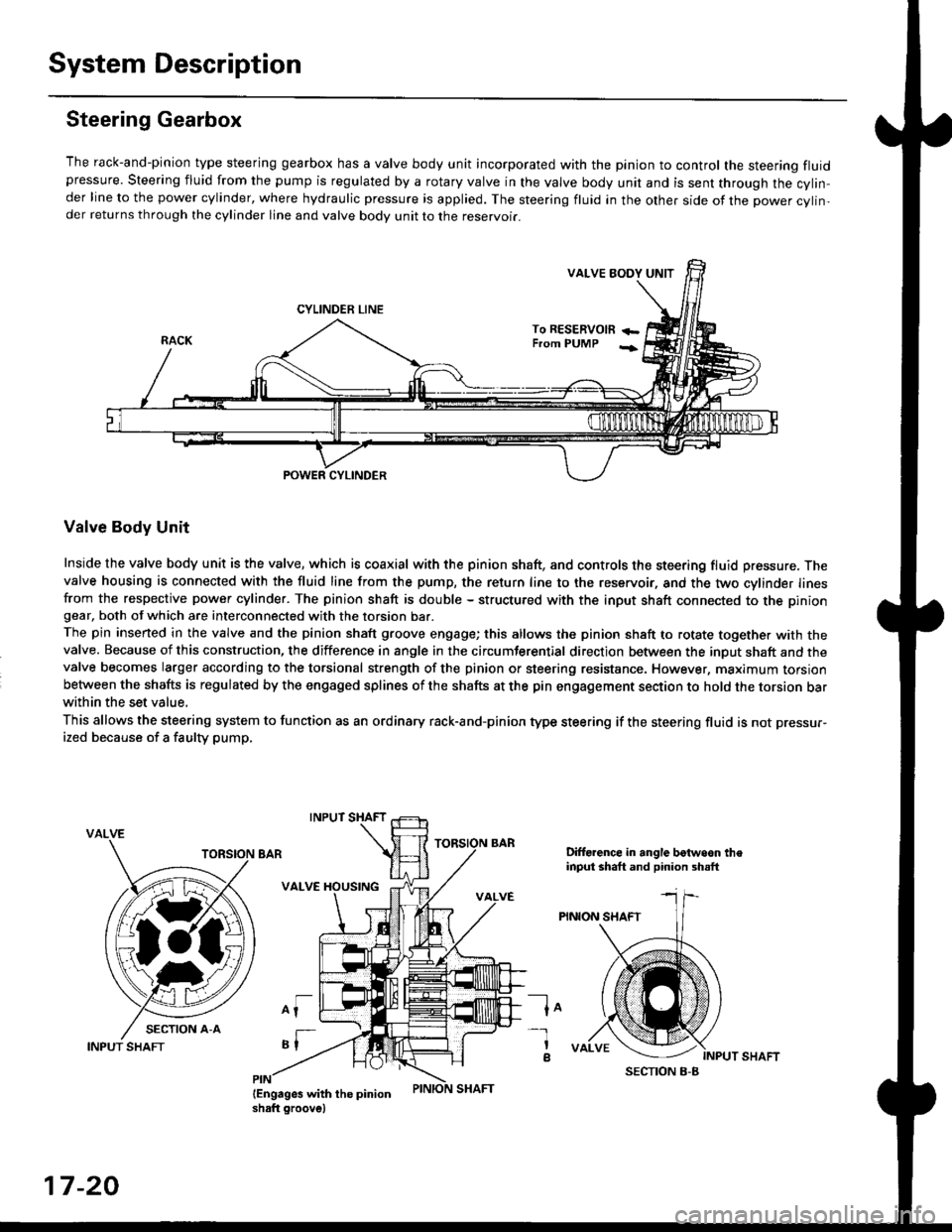

Steering Gearbox

The rack-and-pinion type steering gearbox has a valve body unit incorporated with the pinion to control the steering fluidpressure. Steering fluid from the pump is regulated by a rotary valve in the valve body unit and is sent through the cylin,der line to the power cylinder, where hydraulic pressure is applied. The steering fluid in the other side of the power cylin,der returns through the cylinder line and valve body unit to the reservoii.

VALVE EODY UNIT

CYLINDER LINE

To RESERVOm +-From PUMP -;

POWER CYLINDER

Valve Body Unit

Inside the valve body unit is the valve, which is coaxial with the pinion shaft, and controls the steering fluid pressure. Thevalve housing is connected with the fluid line from the pump, the return line to the reservoir, and the two cylinder linesfrom the respective power cylinder. The pinion shaft is double - structured with the input shaft connected to the piniongear, both of which are interconnected with the torsion bar.

The pin inserted in the valve and the pinion shaft groove engage; this allows the pinion shaft to rotate together with thevalve. Because of this construction, the difference in angle in the circumferential direction between the input shaft and thevalve becomes larger according to the torsional strength of the pinion or steering resistance. However, maximum torsionbetween the shafts is regulated by the engaged splines of the shafts at the pin engagement section to hold the torsion barwithin the set value,

This allows the steering system to function as an ordinary rack-and-pinion type steering if the steering fluid is not pressur-

ized because of a faulty pump,

VALVE

Difforence in angle botwoon theinput shaft and pinion shsft

PINION SHAFT

lo

INPUT SHAFT

-l

a

17-20

INPUT SHAFT