Hydraulic HONDA CIVIC 1996 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1110 of 2189

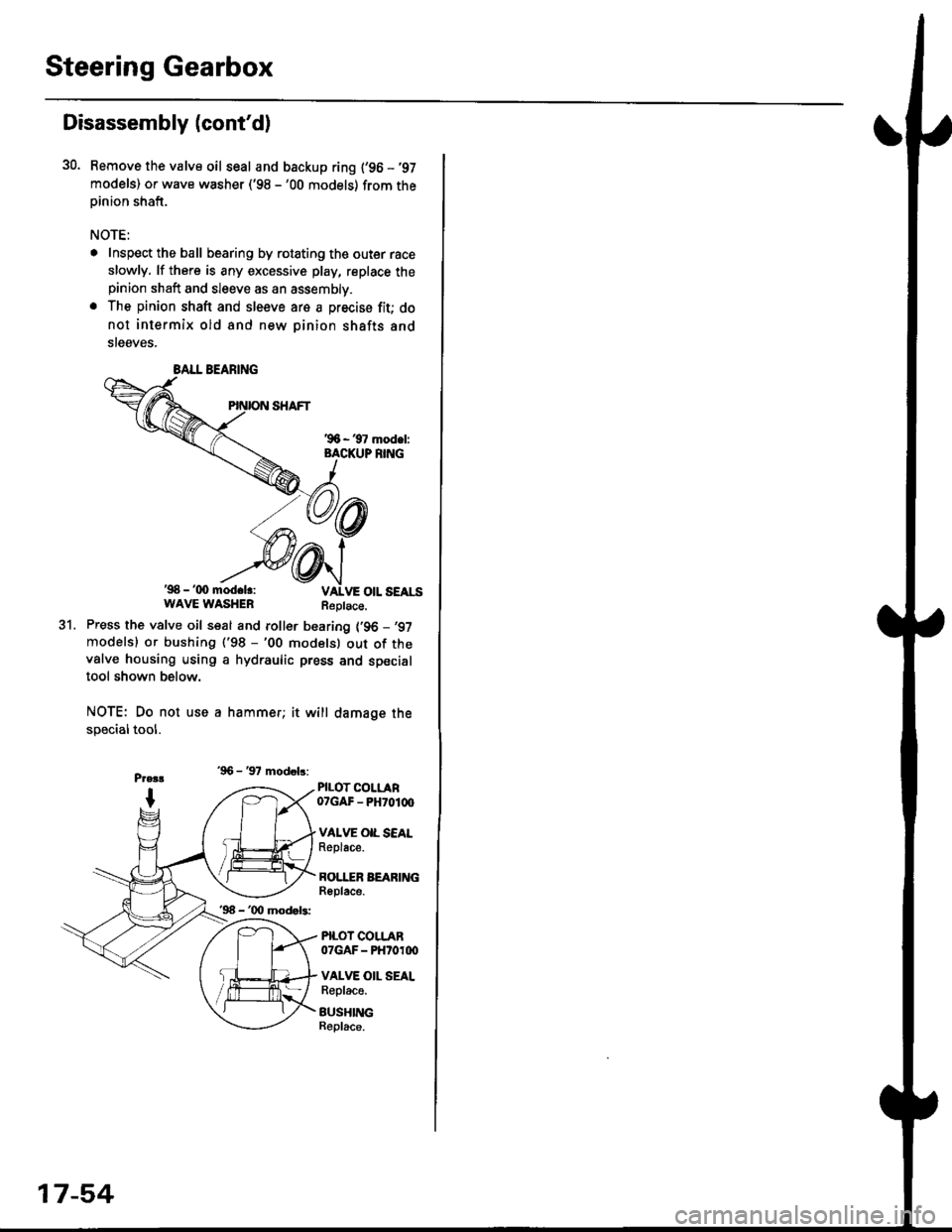

Steering Gearbox

Disassembly (cont'd)

30. Bemove the valve oil seal and backup ring {'96 -'97

models) or wave washer ('98 -'00 models) from theoinion shaft.

NOTE:

. Inspect the ball bearing by rotating the outer race

slowly. lf there is any excessive play, replace thepinion shaft and sleeve as an assembly.

. The pinion shaft and sleeve are a precise fit; do

not intermix old and new pinion shafts and

steeves.

'98 - '(x) mod.lr:WAVE WASHERReplace.

31.Press the valve oil seal and roller bearing {'96 -,97

modelsl or bushing ('98 -'00 modelsl out of thevalve housing using a hydraulic press and specialtool shown below.

NOTE: Do not use a hammer; it will damage the

specialtool.

'96 - '97 modob:

PILOT COLLAR07GAF - PH70100

VAI.VE OIL SEALReplace.

BOI.I"ER BEARINGReplace.

PILOT COLLAR07GAF - PHtoroo

VALVE OII. SEALReplace.

BUSHINGBeplace.

BALL BEARING

'96 - '00 mod.b:

17-54

Page 1113 of 2189

I

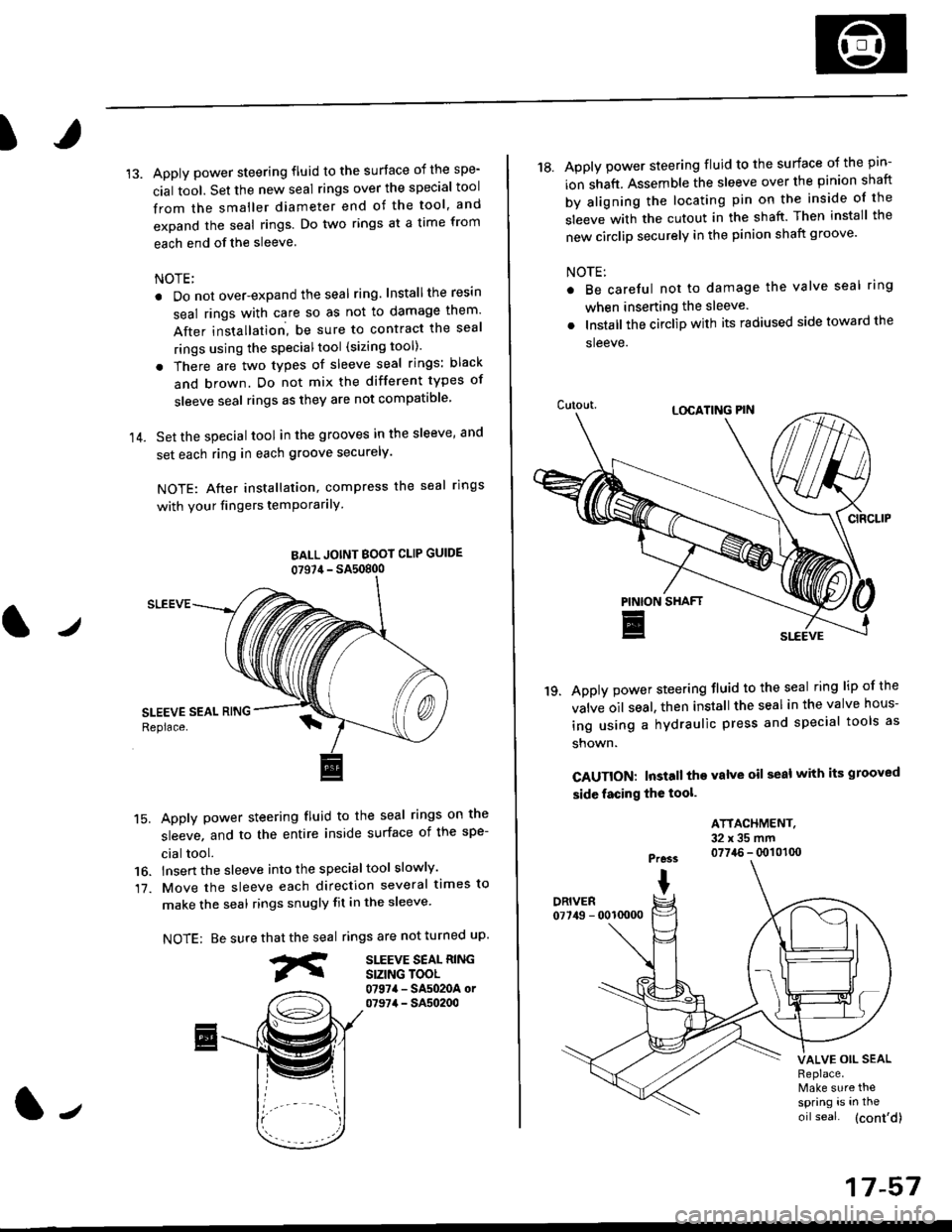

14.

Apply power steering fluid to the surface of the spe-

cial tool. Set the new seal rings over the special tool

from the smaller diameter end of the tool, and

expand the seal rings. Do two rings at a time from

each end of the sleeve.

NOTE;

. Do not over-expand the seal ring. Installthe resin

seal rings with care so as not to damage them'

After installation, be sure to contract the seal

rings using the specialtool (sizing tool).

. There are two types of sleeve seal rings: black

and brown. Do not mix the different types of

sleeve seal rings as they are not compatible

Set the special tool in the grooves in the sleeve, and

set each ring in each groove securely.

NOTE: After installation, compress the seal rings

with your fingers temPorarilY

BALL JOINT BOOI CLIP GUIDE

07S7,1- SA50800

SLEEVE

15. Apply power steering fluid to the seal rings on the

sleeve, and to the entire inside surface of the spe-

cial tool.

16. lnsert the sleeve into the specialtool slowly'

17. Move the sleeve each direction several times to

make the seal rings snugly fit in the sleeve'

NOTE: Be surerings are not turned uP.

SITEVE SEAL RINGSIZING TOOL0797a - SA5020A or07974 - SA50200

that the seal

fr

J

17-57

18. Apply power steering fluid to the surface o{ the pin-

ion shaft. Assemble the sleeve over the pinion shaft

by aligning the locating pin on the inside of the

sleeve with the cutout in the shaft. Then install the

new circlip securely in the pinion shaft groove'

NOTE:

Be careful not to damage the valve seal ring

when inserting the sleeve.

Installthe circlip with its radiused side toward the

sleeve.

Apply power steering fluid to the seal ring lip of the

valve oil seal. then install the seal in the valve hous-

ing using a hydraulic press and special tools as

shown.

CAUTION: Install the valve oil seal with its grooved

side facing the tool.

'19.

ATTACHMENT.32x35mm0774.6 - q)101(x)Pre3s

IDRIVER07749 - 0010000

VALVE OIL SEALReplace.Make sure thespring is in the

oil seal. (cont'd)

Page 1114 of 2189

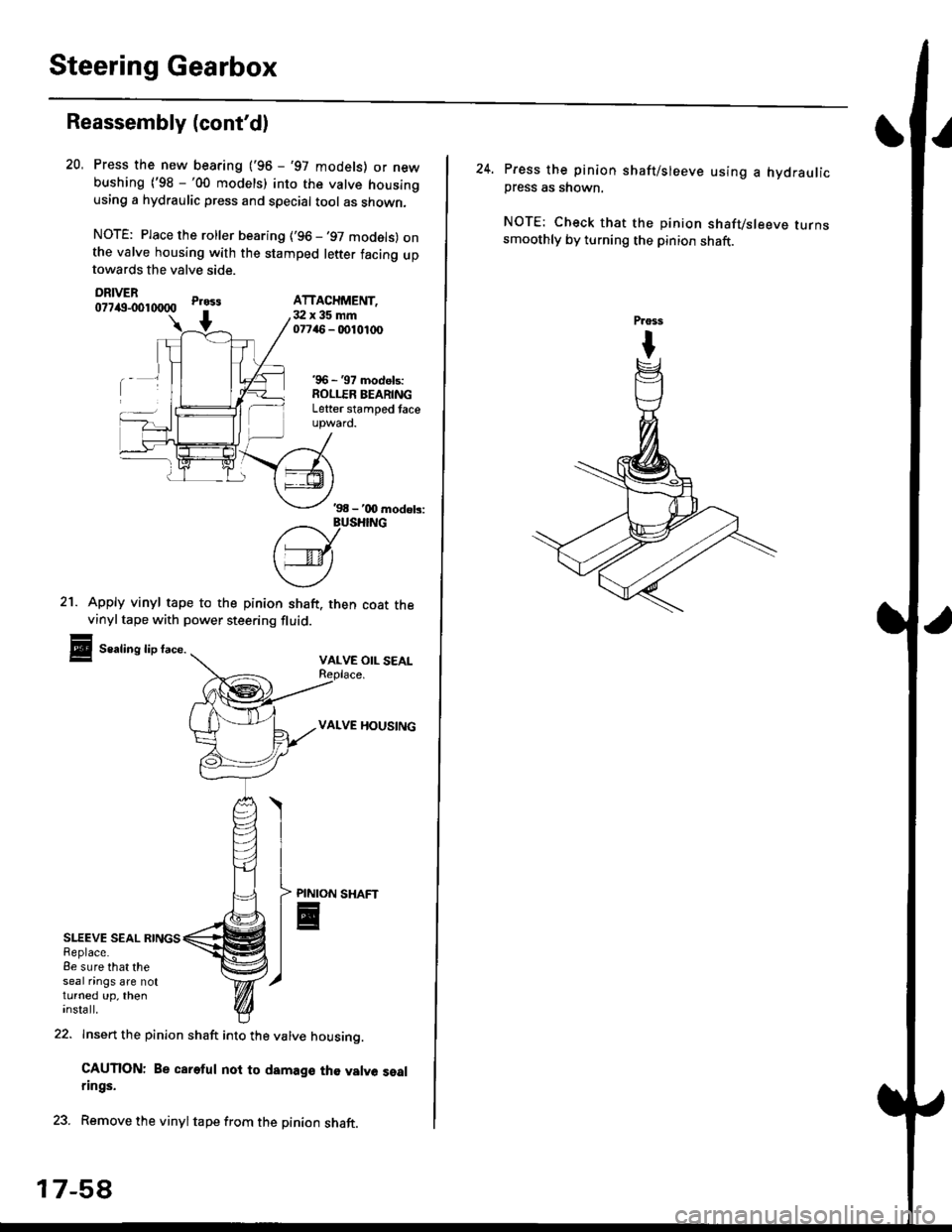

Steering Gearbox

Reassembly (cont'd)

SLEEVE SEAL RINGSReplace.8e sure that theseal nngs are notturned up, theninsta ll.

21. Apply vinyl tape to the pinion shaft. then coat thevinyltape with power steering fluid.

Sealing lip face.VALVE OIL SEAL

VALVE HOUSING

Press the new bearing ('96 - '97 models) or newbushing ('98 -'00 models) into the valve housingusing a hydraulic press and special tool as shown,

NOTE: Place the roller bearing ('96 -'97 models) onthe valve housing with the stamped letter facing uptowards the valve side.

DRIVER077itg-001tXlOO

22. Insert the pinion shaft into the valve housino.

CAUTION: Be careful noi to damage th€ valve sealrings.

23. Remove the vinyltape from the pinion shaft.

20.

Pr033

+3:Ix35mm07746 - 0010,t(x)

'96 - '97 models:ROLLER BEARINGLetter stamped taceupward.

ATTACHMENT,

'98 - '00 modob:

?/_vusHrNG

['---v-lt

\4)

PINION

E

17-5A

24. Press the pinion shaft/sleeve using a hydraulicpress as shown.

NOTE: Check that the pinion shafvsleeve turnssmoothly by turning the pinion shaft.

Page 1138 of 2189

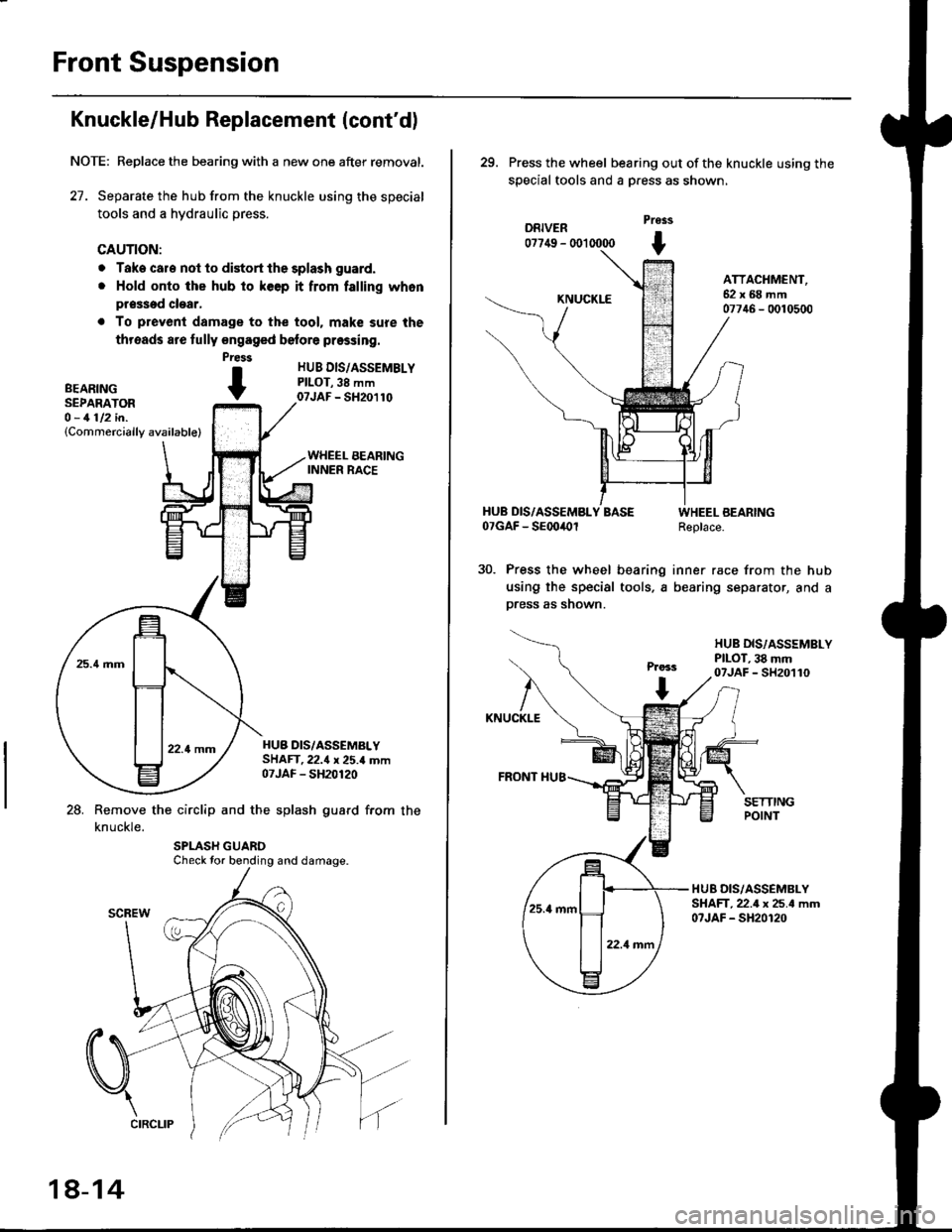

Front Suspension

Knuckle/Hub Replacement (cont'dl

NOTE: Replace the bearing with a new one after removal.

27. Separate the hub from the knuckle using the special

tools and a hydraulic press.

CAUTION:

o Take cale not to distort the splash guard.

. Hold onto the hub to keep it from falling whon

pr$sed clear,

. To prevenl damage to the tool. mak€ sure the

threads are fully engaged belore pressing.

HUB DIS/ASSEMBLYPILOT,38 mm07JAF - SH20110

HUB DIS/ASSEMALYSHAFT.22.{ x 25.4 mm07JAF - SH20120

28. Remove the circlip and the splash guard from the

knuckle.

Press

BEARTNG tSEPARATOR -O - 1112 in.(Commercially available)

Check tor bending and damage.

18-14

29. Press the wheel bearing out ofthe knuckle using the

special tools and a Dress as shown,

DRIVER07749 - (X)l 0000

Pross

t

KNUCKLE

ATTACHMENT,62x68mm07746 - 0010500

HUB DIS/ASSEMBLY BASE07GAF - SEoo4Ol

Press the wheel bearing

using the special tools, a

press as shown.

WHEEL BEARINGReplace.

inner race from the hub

bearing separator, and a

HUB DIS,/ASSSMBLYPILOT, 38 mm07JAF - SH20110

KNUCKLE

FRONT I{U8

HUB DIS/ASSEMBLYSHAFT,22.4 x 25.4 mm07JAF - SH20120

Page 1139 of 2189

I

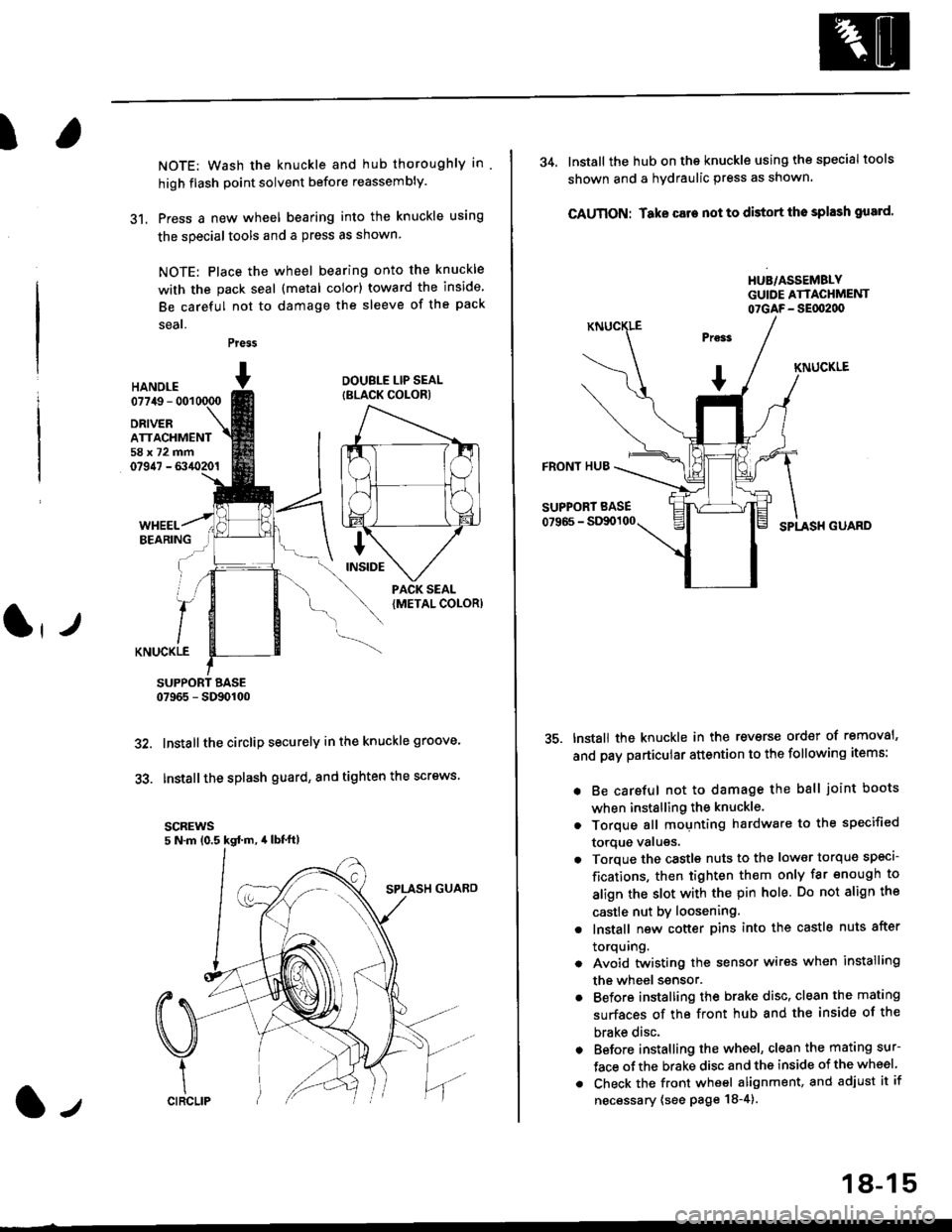

NOTE: Wash the knuckle and hub thoroughly in

high flash point solvent before reassembly.

31. Press a new wheel bearing into the knuckle using

the specialtools and a press as shown

NOTE: Place the wheel bearing onto the knuckle

with the pack seal (metal color) toward the inside

Be careful not to damage the sleeve of the pack

seal.

Press

HANOI.E07749 - 001

DRIVERATTACHMENT58x72mm07947 - 6340201

DOUBLE LIP SEAL

{BLACK COLOR)

KNUCKLE

SUPPORT BASE07965 - SD90100

Installthe circlip securely in the knuckle groove'

Installthe splash guard, and tighten the screws.

scREws5 N.m (0.5 kgd m, 4lbt'ft)

32.

33.

l-,

18-15

34. lnstall the hub on the knuckle using the specialtools

shown and a hydraulic press as shown.

CAUTION: Take care not to distort tho splash gusrd'

HUB/ASSEMBLYGUIDE ATTACHMENT07GAF- SEflt2d)

KNUCKLE

FRONT HUB

SUPPORT BASE

07966 - StXx)100SPLASH GUARD

tnstall the knuckle in the reverse order of removal'

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle.

. Torque all mounting hardware to the specified

torque valugs.

. Torque the castls nuts to the low€r torque specl-

fications, then tighten them only far enough to

align the slot with the pin hole. Do not align the

castle nut by loosening.

. lnstall new cotter pins into the castle nuts after

torquing.

. Avoid twistin0 the sensor wires when installing

the wheel ssnsor.

. Before installing the brake disc, clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the wheel, clean the mating sur-

face ofthe brake disc and the inside of the wheel

. Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

Page 1201 of 2189

Anti-lock Brake System {ABS)

Operation (cont'dl

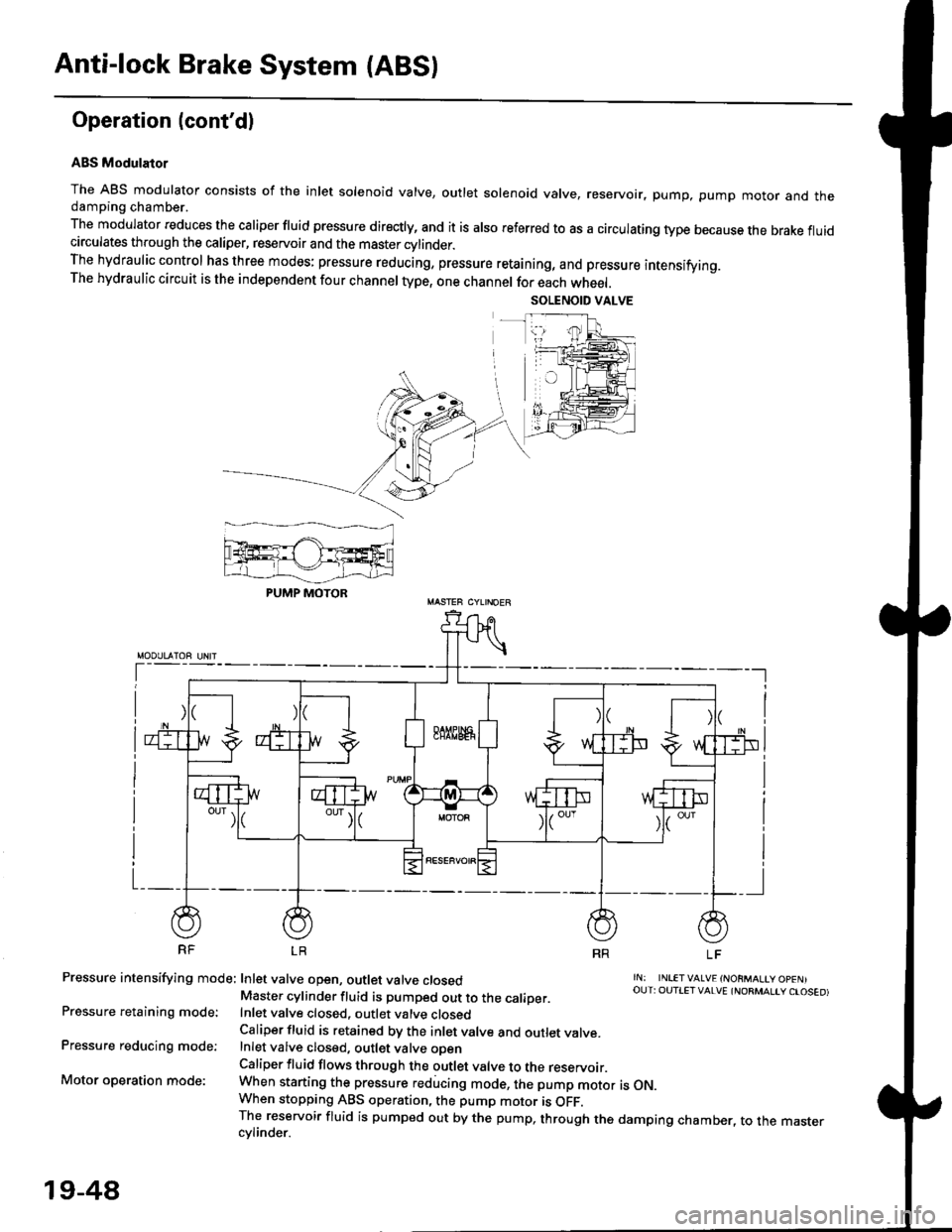

ABS Modulator

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and thedamping chamber.

The modulator reduces the caliper fluid pressure directly, and it is also referred to as a circulating type because the brake fluidcirculates through the caliper, reservoir and the master cylinder.The hydraulic control has three modes: pressure reducing, pressure retaining, and pressure intensifying.The hydraulic circuit is the independent four channel type, one channel for each wheel.

RF LR

Pressure intensifying mode: Inlet valve open, outlet valve closed

Pressure retaining mode:

Pressure reducing mode:

Motor operation mode:

rN: INLETVALVE {NORMALtY OpENIOUT: OUTIET VALVE {NORMALIY CTOSED)Master cylinder fluid is pumped out to the caliDer.Inlet valve closed, outlet valve closedCaliper fluid is retained by the inlet valve and outlet valve.Inlet valve closed, outlet valve oDenCaliper fluid flows through the outlet valve to the reservoir.When starting the pressure reducing mode, the pump motor is ON.When stopping ABS operation, the pump motor is OFF.The reservoir fluid is pumped out by the pump, through the damping chamber, to the mastercvlinder.

PUMP MOTOR

19-48

Page 1945 of 2189

- How the Circuit Works

The anti-lock brake system (ABS) prevents locking

of the wheels as a result of heavy braking and/or

poor lraction. A vehicle with locked wheels cannot

be steered. The anti-lock brake system controls the

application of the brakes, allowing the driver to

maintain control of the steering.

Under anti-lock conditions, the antilock brake

system (ABS) modulates the pressure of the brake

tluid to each brake caliper. This system is a four

channel system: the pressure at each caliper is

controlled independently of the pressure al any

other caliper. Whenever a wheel is likely to lock

dunng braking, the anti-lock brake system

modulates the brake oressure at that wheel. When

the brake pressure is reduced to the point where

there is no longer any possibility of wheel locking,

the system returns to the conventional braking

system mode of operation.

Battery voltage is applied at all times through fuse

63 to the ABS control unit. When the ignition switch

is in ON (ll), battery voltage is supplied to the

control unit through fuse 16. The control unit is case

grounded. Inputs are received from the brake switch

and the individual wheel sensors located at each

wheel. The ABS control unit uses these inputs to

control the modulator solenoid unit. The solenoids

adjust the hydraulic pressure applied to each

calioer.

The ABS control unit has a self-diagnosis function.

When the control unit detects a fault, it turns on the"ABS" indicator and disables the anti-lock brake

system. lf the fault is not in the conventional braking

system, the brakes will continue to operate normally

but without the anti-lock feature.

Refer to the Service Manual (Section '19,

Anti-Lock Brake System) for specific tests or

troubleshooting procedures.

44-3