rpm HONDA CIVIC 1996 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 553 of 2189

Emission Control System

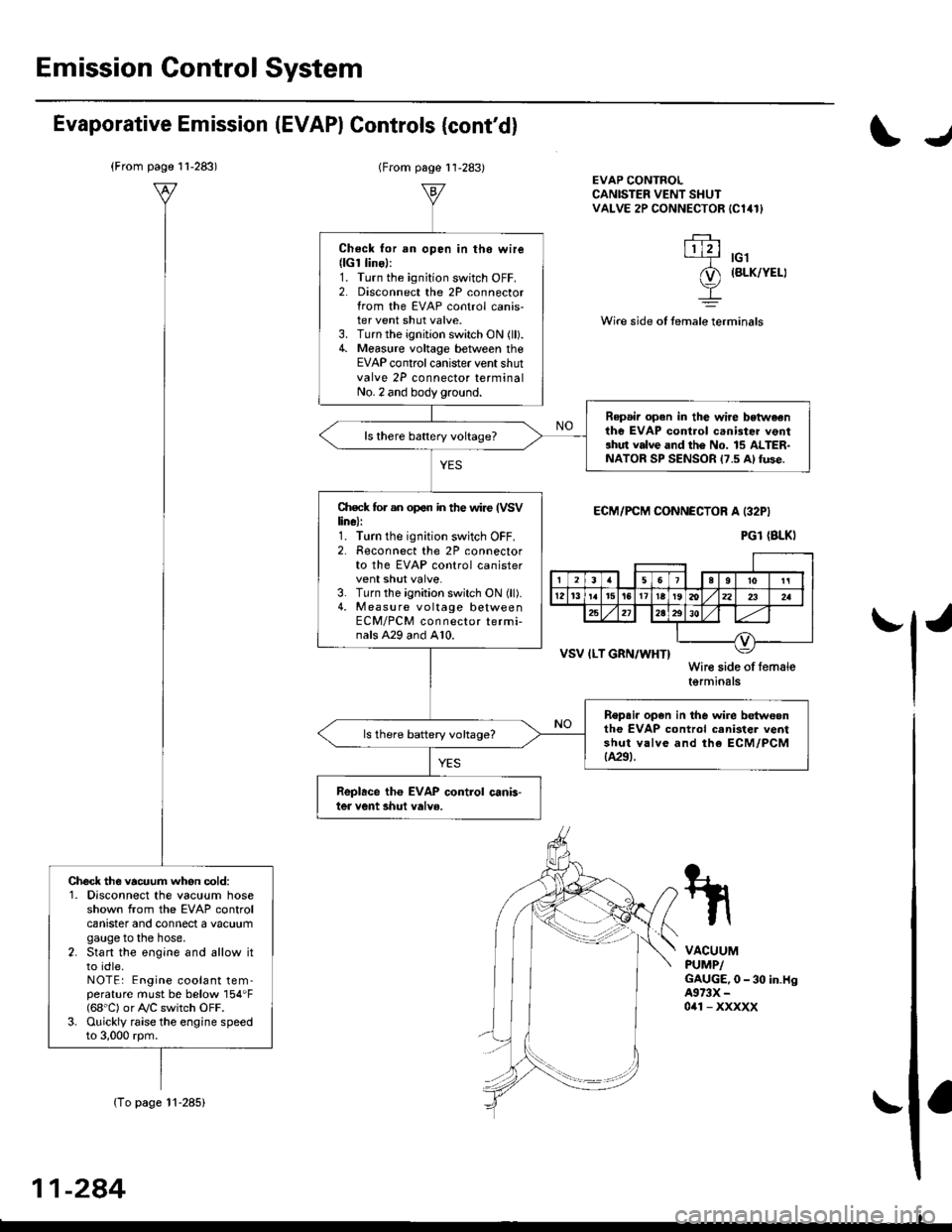

Evaporative Emission (EVAPI Controls (cont'dl

1

EVAP CONTROLCANISTER VENT SHUTVALVE 2P CONNECTOR IC141}

lltrt+ rcl

o) (8LK/YErl

I

temale terminalsWire side ot

ECM/PCM CONNECTOR A (32PI

VSV ILT GRN/WHT}

'l'

Wiro side of lemaletgrminals

VACUUMPUMP/GAUGE,0 - 30 in.Hg4973X -

041 - XXXXX

(From page 1l-283)

{To page 1l-285}

Check the vacuum whon cold:1. Disconnect the vacuum hoseshown from the EVAP controlcanrster and connect a vacuumgauge to the hose,2. Start the engine and allow itto idle.NOTE: Engine coolant tem-perature must be below 154oF(68'C) or lVC switch OFF.3. Ouickly raise the engine speedto 3,000 rpm.

(From page l1-283)

Check for an open in tho wire(lGl line):1. Turn the ignition switch OFF.2. Disconnect the 2P connectorlrom the EVAP control canis-ter vent shut valve.3. Turn the ignition switch ON (ll).4. Measure voltage between theEVAP controlcanister vent shutvalve 2P connector terminalNo. 2 and body ground.

Repair open in the wire betwe€nthe EVAP control c.ni3tei ventshut valve and th6 No. 15 ALTER-NATOR SP SENSOR 17.5 Al fuse.

Cfisck tor an opon in the wire (VSVline):1. Turn the ignition switch OFF.2. Beconnect the 2P connectorto the EVAP control canistervent shut valve.3. Turn the ignition switch ON (ll).4. Measure voltage betweenECM/PCM connector termi-nals A29 and Al0.

Rep.ir open in the wire betwoonthe EVAP control canister ventshut valve and th€ ECM/PCMtA29t.

ls there battery voltage?

Replace th6 EVAP control canis-ter vent 3hut valve.

PGT (BLKI

:lI23l'ltl'l lelsl ro Ir I1213t6€lnltlr@/lzzl zs f il

25

11-284

Page 554 of 2189

\

\

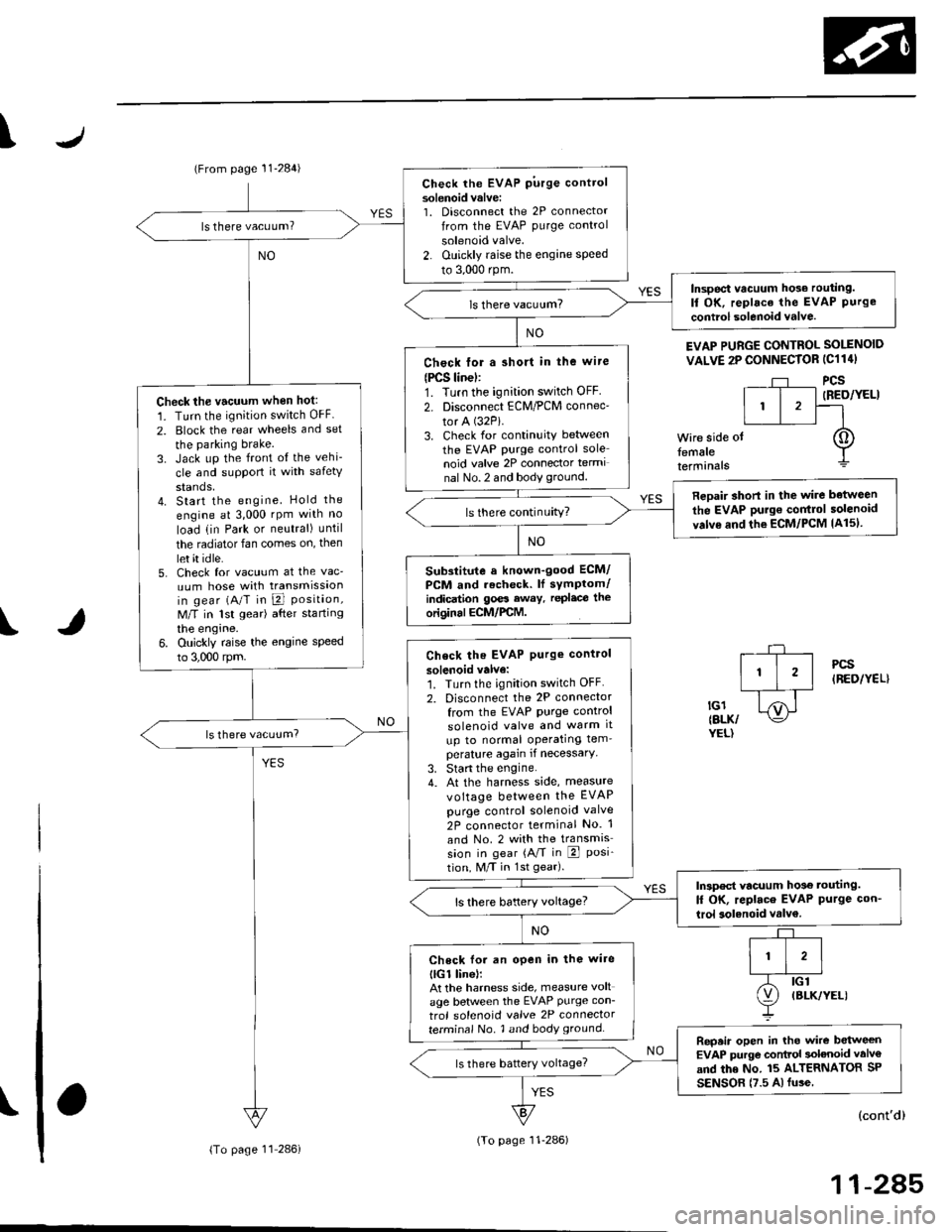

(From page 11-284)

\(cont'd)

11-285

EVAP PURGE CONTROL SOI.INOID

VALVE 2P CONNECTOR IC114I

Wire side otfemaleterminals

?,

I,l,lil?"",,,u

EL,TWYEL)

Check the EVAP pirrge controlsolenoid valvei1. Disconnect the 2P connector

lrom the EVAP purge control

solenoid valve.

2. Ouickly raise the engine speed

to 3,000 rpm.

ls there vacuum?

InsDect vacuum ho56 routing.ll OK, replace the EVAP Purgecontrol solenoid valve.

Chock for a short in the wire(PCS linel:1. Turn the ignition switch OFF

2. Disconnect ECM/PCM connec'

tor A (32Pi.

3. Check for continuity between

the EVAP PUrge control sole

noid valve 2P connector termi

nal No.2 and body ground.

Check the vacuum when hot:

1. Turn the ignition switch OFF

2. Block the rear wheels and set

the parking brake.3. Jack up the front o{ the vehi-

cle and support it with safety

stands,4. Start the engine. Hold the

engine al 3,000 rpm wlth no

load (in Park or neutral) until

the radiator fan comes on, then

let it idle.5, Check for vacuum at the vac-

uum hose with transmissaonin gear (A/T in B Position,M/T in lst gear) after starting

the engrne.6. Ouickly raise the engine speed

to 3,000 rpm.

Reoair short in the wire botween

the EVAP purg€ cor|t]ol solenoid

valve and the ECM/pcM lA15l.ls there continuity?

Substitute a known-good ECM/

PCM and recheck. lf sYmPtom/indication goes eway. repl.c€ the

original ECM/PCM.

Check the EVAP Purg€ control

solenoid valve:1. Turn the ignition switch OFF

2. Disconnect the 2P connector

from the EVAP Purge control

solenoid valve and warm lt

up to normal operating tem_perature again if necessary

3. Stan the engine.4. At the harness side, measure

voltage between the EVAP

Purge control solenoid valve

2P connector terminal No. 1

and No. 2 with the transmission in gear (A,/T in E Posi-tion, M/T in 1st gear).

In3pect vacuum ho3€ touting.

ll OK, replace EVAP Purge con-

lrol aolenoid vtlv€.

Check lo. an open in the wire

llGl linel:At the harness side, measure volt

age between the EVAP Purge con-

trol solenoid valve 2P connectorterminal No. 1 and body groundRepeir open in tho wire between

EVAP purge conttol solenoid valv€

and the No. 15 ALTERNATOR SP

SENSOR (7.5 A fu3e

IBLK/YELI

lTo page 11 286i(To page 11-286)

Page 558 of 2189

\

EVAP CONTROLCANISTER VENT SHUTVALVE 2P CONNECTOR IC141I

Wire side of temale terminals

ECM,/PCM CONNECTORS

tG1IBLK/WHT}

A973X -

0/r1 - XXXXX

Wire side of femaletermrnats

\

?,T-t

fl

VACUUMPUMP/GAUGE, 0 -30 in.Hg

\(cont'd)

11-289

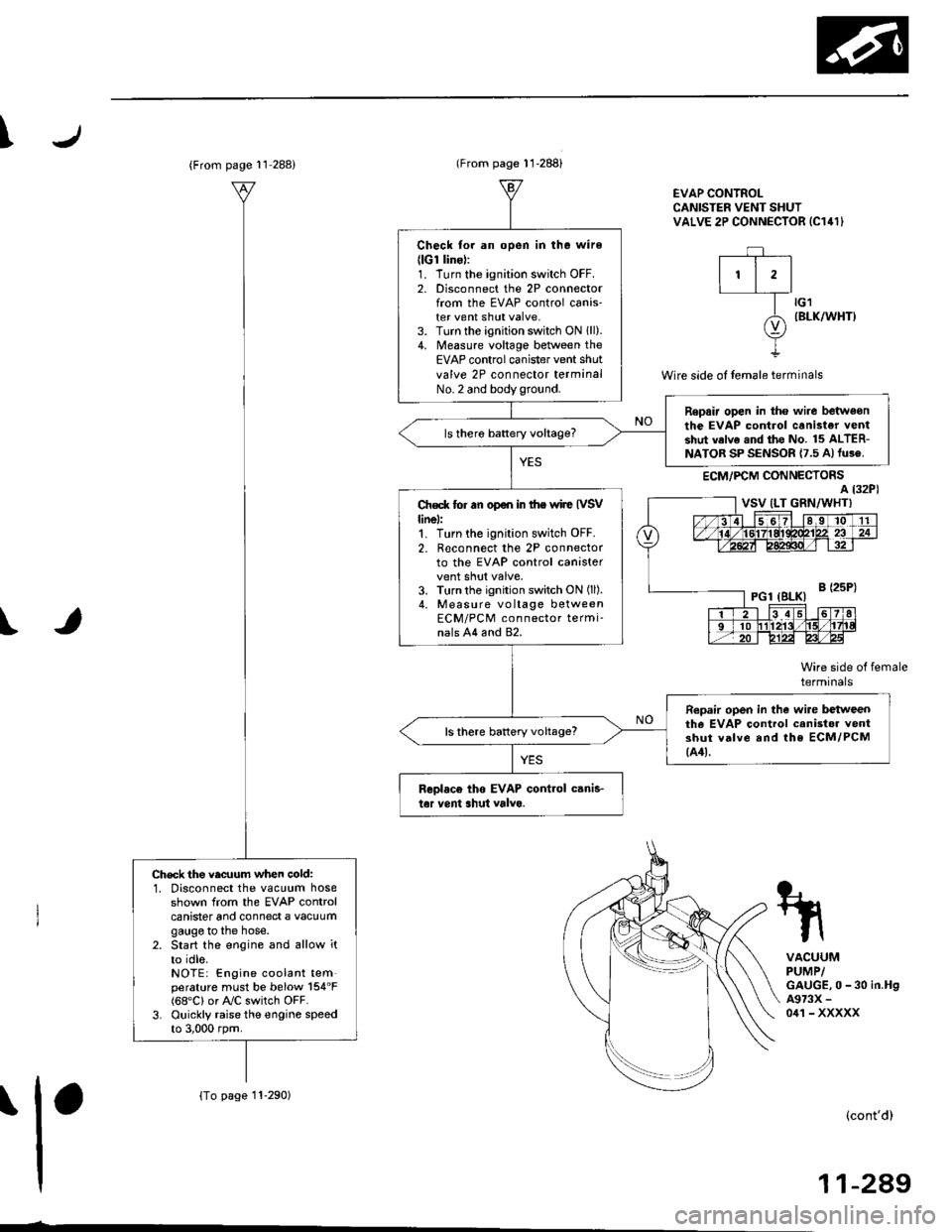

{From page l1 288}

{To page 11-290)

Ch€ck the vac[um when cold:1, Disconnect the vacuum hoseshown from the EVAP controlcanister and connect a vacuumgauge to the hose.2. Start the engine and allow it

to idle.NOTEi Engine coolant temperature must be below 154"F(68'C) or Ay'C switch OFF.3. Ouickly raise the engine speedto 3,000 rpm.

(From page 11-288)

Check for an open in tha wire(lGt linol:1. Turn the ignition switch OFF.2. Disconnect the 2P connectorfrom the EVAP control canis-ter vent shut valve.3. Turn the ignition switch ON lll).4. Measure voltage between theEVAP control canister vent shut

valve 2P connector terminalNo.2 and bodyground.

Repair open in the wire betweenthe EVAP control canister ventshut valve .nd the No. 15 ALTER-NATOR SP SENSOR {7.5 A)fu3e.

ls there battery voltage?

Ch€d( for an op€n in the wiie IVSVlinel:1. Turn the ignition switch OFF.

2. R€connect the 2P connectorto the EVAP control canistervent shut valve,3. Turn the ignition switch ON (ll).

4. Measure vo ltage betweenECM/PCM connector termi-nals A4 and 82.

Repair open in the wire bctweenthe EVAP control canistor ventshut valve and lhe ECM/PCM{44t.

ls there battery voltage?

Rcolaco tho EVAP control canis.t6r vent shut valvo.

a t32P)

-

Page 559 of 2189

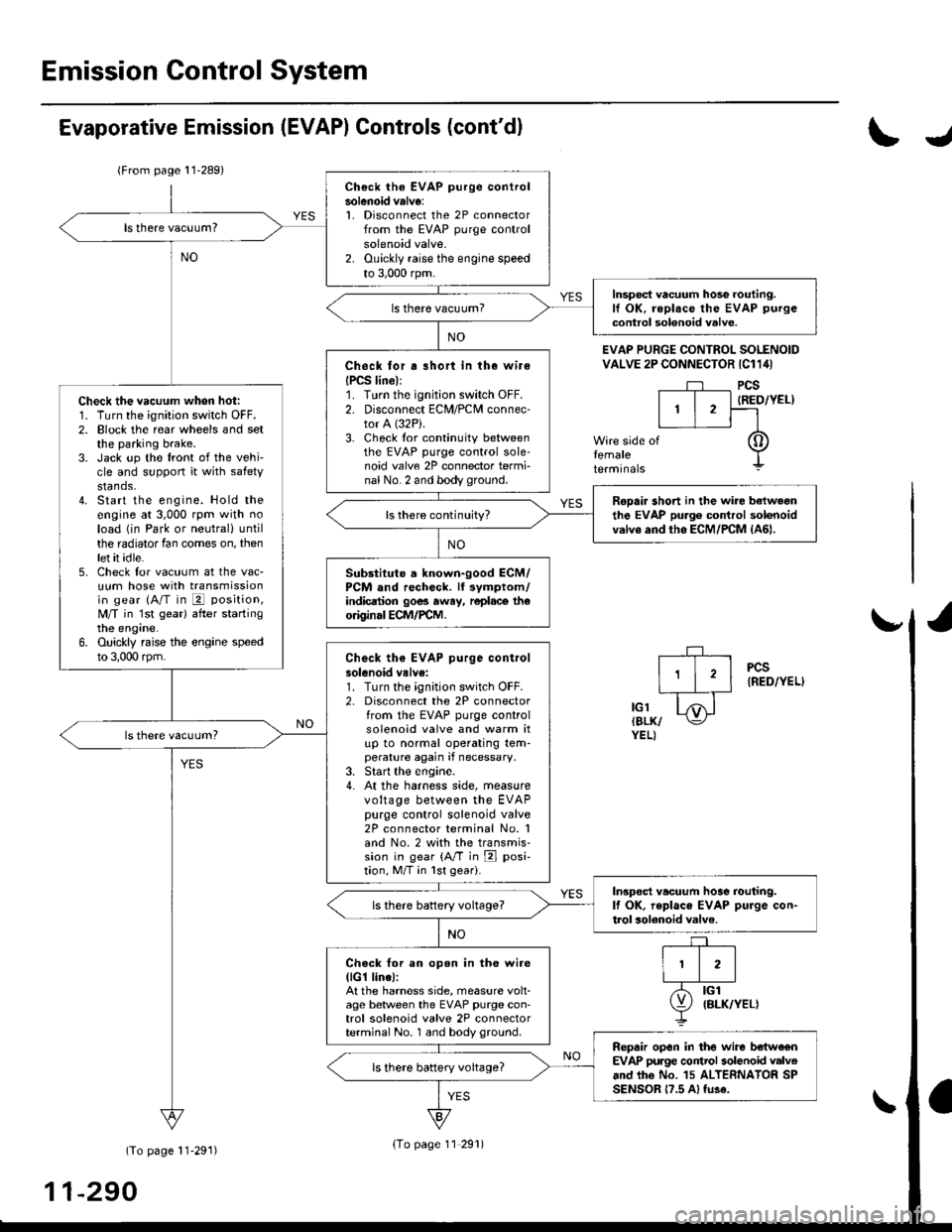

Emission Control System

Ch€ck the EVAP purge controlsolenoid valv6:1. Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve.2. Ouickly raise the engine speedto 3,000 rpm.

Insped vacuum hose routing.lf OK. roplace the EVAP purge

control solonoid valve.

Chock tor r short in the wir€

{PCS line):1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connec-tor A (32P).

3- Check tor continuity betweenthe EVAP purge control sole-noid valve 2P connector termi-nal No. 2 and body ground.

Check the vacuum when hot:1. Turn the ignition switch OFF.2. Block the rear wheels and setthe parking brake.3. Jack up the lront of the vehi-cle and support it with safetystands.4. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali until

the radiator fan comes on, thenlet it idle.5. Check for vacuum at the vac-uum hose with transmissionin gear (A/T in E position,

lvl/T in 1st gear) after startingthe engine.6. Ouickly raise the engine speedto 3,000 rpm.

Rooair shoft in the wire belwegnthe EVAP pulg6 control solenoidvalvs and tho ECM/PCM {A61.ls there continuity?

Substitute a known-good ECM/PCM and rech6ck. lt 3ymptom/indicrtion 90e3 rway, r6plac6 th€o.iginal ECM/FCM.

Check th€ EVAP purge controlsolenoid valve:1. Turn the;gnition switch OFF.2. Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve and warm itup to normal operating tem-perature again if necessary.3. Start the engine.4- At the harness side, measurevoltage between the EVAPpurge control solenoid valve2P connector terminal No. 1and No.2 with the transmis-sion in gear {A/T in E posi-tion, M/T in lst geari.

In3pect vacuum hoae routing.lf OK, repl.ce EVAP purge con-trol solonoid valve.ls there battery voltage?

Chock for an open in the wire(lG1 lina):At the harnoss side, measure volt-age beNveen the EVAP purge con-trol solenoid valve 2P connectorterminal No. 1 and body ground.

Repair open in the wire b€lwe€nEVAP purge contrl 3olenoid valv6and lhe No. 15 ALTERNATOR SPSENSOR 17.5 A, fu3e.

ls there battery voltage?

Evaporative Emission (EVAPI Controls (cont'dl

(From page 11-289)

(To page 11-291)

11-290

IJ

EVAP PURGE CONTROL SOLENOIDVALVE 2P CONNECTOR IC114I

PCS

IRED/YEL)

temaletermrnars

of

PCS(RED/YEL)

tGlIBLK/YEL)

{To page 11 291)

Page 787 of 2189

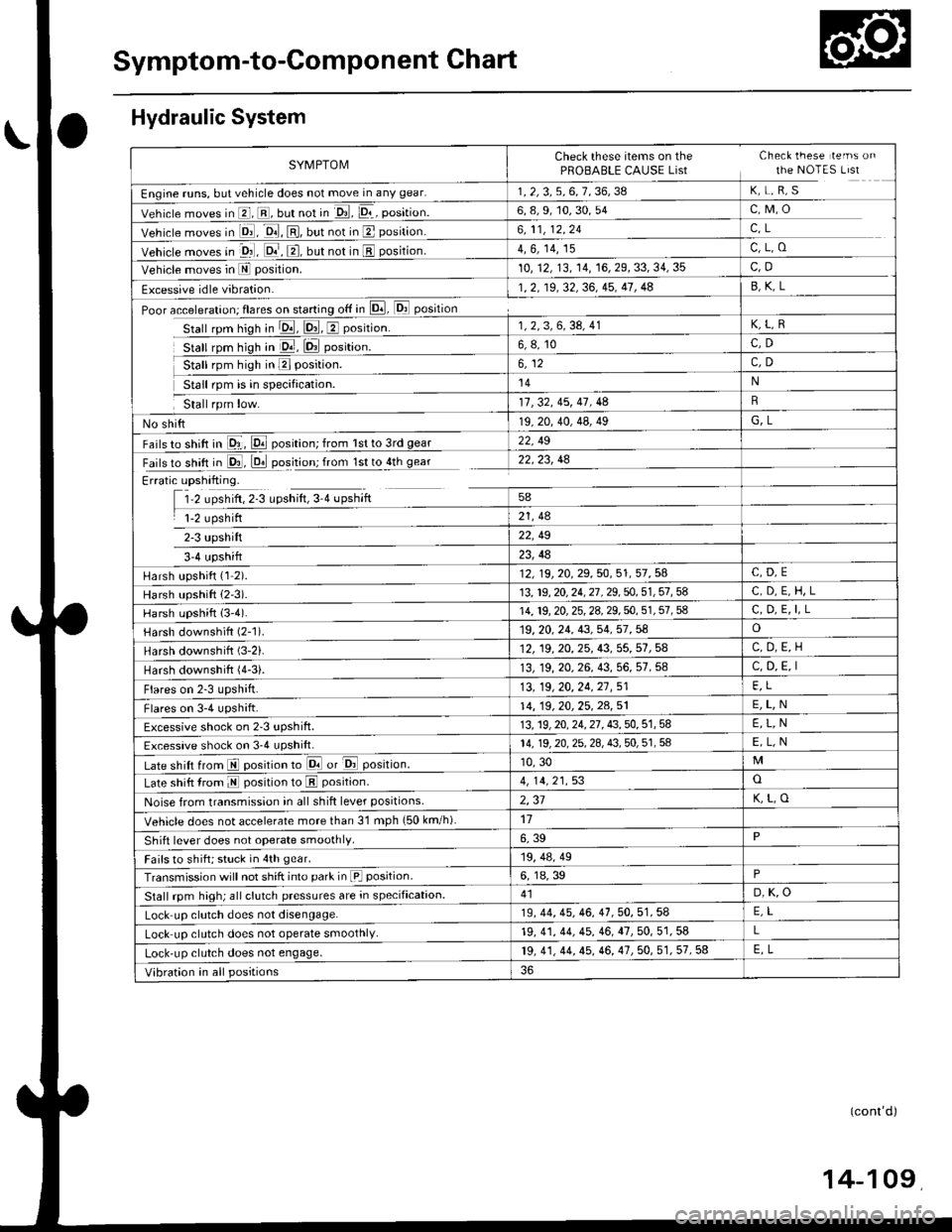

Symptom-to-Component Chart

Hydraulic System

SYMPTOMCheck these items on the Check lhese lems on

PROBABLE CAUSE List the NOTES LIst

Engine runs, but vehicle does not move in any gear.1.2,3,5,6,7.36,38 K, L, R, S

Vehicle moves in E, E, but not in lrl, pr-, position.6, 8, 9, 10, 30, 54c,M,o

Vehicle moves in Dl, E, El,lut not in E position.6,11,12.24C,L

Vehicle moves in -o1], @, @, Uut not in E position.4, 6, 14, 15c,L,o

Vehicle moves in E position.10, 12, 13,14, 16, 29, 33, 34, 35C,D

Excessive idle vibration.1.2, 19,32,36, 45, 41, 4a

Poor acceleration; flares on starting otf in E, [Dl] position

Stall rpm hiqh in !!1, p!1, E position.1,2,3,6,34, 41K,L,R

stall rom hioh in D.r, lD,l oosition.6. 8. 10C,D

5t"[ rprn rsn ^ a"t"t-at6,12C,D

14N

11 , 32. 45, 41 , 48

No shift19,20, 40, 48, 49G,L

Fails to shift in 81, pll position; from lst to 3rd gear22, 49

Fails to shift in 03, D. oosition; from lstto4th qear22.23, 48

Erratic upshifting.

1'2 upshift, 2-3 upshift, 3-4 upshift

1-2 upshift

3'4 upshift

58

21, 48

22, t9

23,la

Harsh upshift {1 2).12, 19, 20, 29. 50, 51, 57. 54

Harsh upshift (2'3).13, 19, 20, 24, 27 , 29, 50. 51 , 51 , 58C,D,E,H,L

Harsh upshift (3'4).14, 19, 20, 25, 28, 29. 50, 51 , 51 , IC, D, E, I,L

Harsh downshift (2-1)19, 20. 24, 43, 54, 57 , 58o

Harsh downshift (3-2).12, 19, 20,25, 43, 55, 57,5AC,D,E,H

Harsh downshift (4-3).13, 19, 20, 26, 43, 56, 57, 58C, D, E, I

Flares on 2-3 upshift.13, 19,20,24.21,51FI

Flares on 3-4 upshift.14, 19 . 20, 25. 24, 51E,L,N

Excessive shock on 2-3 uPshift.13. 19, 20, 24, 27 . 43. 50. 51 , 58E,L,N

Excessive shock on 3-4 uPshift.14, 19, 20, 25. 2A, 8, 50, 51 , 58E,L,N

Late shift from El position to Lq! or &l position.10, 30

Late shift from E position to E position.4, 14, 21,53o

Noise from transmission in all shift lever positions2,31K,L,O

Vehicle does not acceletate more than 31 mph {50 km/h)17

shift lever does not operate smoothly.6, 39P

Fails to shift; stuck in 4th gear.19, 48, 49

Transmission will not shift into park in [a] position6, 18, 39

Stall rpm high; all clutch pressures are in specification.41D,K,O

Lock up clutch does not disengage.19, 44, 45, 46. 41,50,51.54

Lock up clutch does not operate smoothly.19, 41, 44, 45, 46, 47, 50, 51, 58L

Lock-up clutch does not engage.19, 41, 4t, 15, 46, 41 ,50, 51, 57, 58FI

Vibration in all positions

(cont'd)

Page 789 of 2189

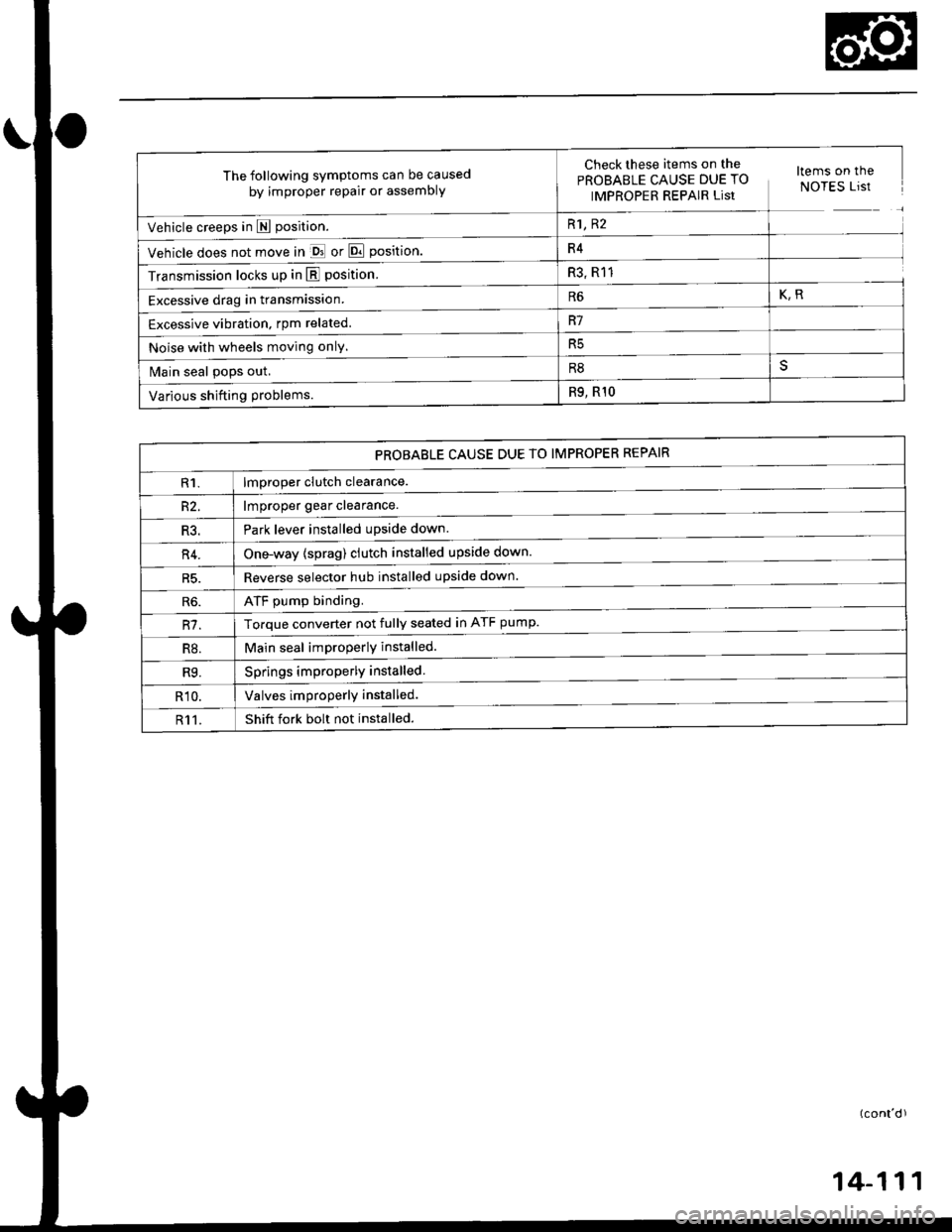

The following symptoms can be caused

by improper repair or assembly

Check these items,on th€^ ltems on thePROBABLE CAUSE DUE TO NOTES ListIMPROPER REPAIR List

Vehicle creeps in N position.R1, R2

Vehicle does not move in &l or Pll position.R4

Transmission locks up in E position.R3, R11

Excessive drag in transmission.R6K,R

Excessive vibration, rpm related.R7

Noise with wheels moving onlY.R5

Main seal pops out.R8

Various shifting problems.R9, RlO

PROBABLE CAUSE DUE TO IMPROPER REPAIR

lmproper clutch clearance.

lmproper gear clearance.

Park lever installed upside down.

one-way {sprag) clutch installed upside down.

Reverse selector hub installed upside down.

ATF pump binding.

Torque converter not fully seated in ATF pump.

Main seal improperly installed.

Springs improperly installed.

Valves improperly installed.

Shift fork bolt not installed.

14-11

Page 790 of 2189

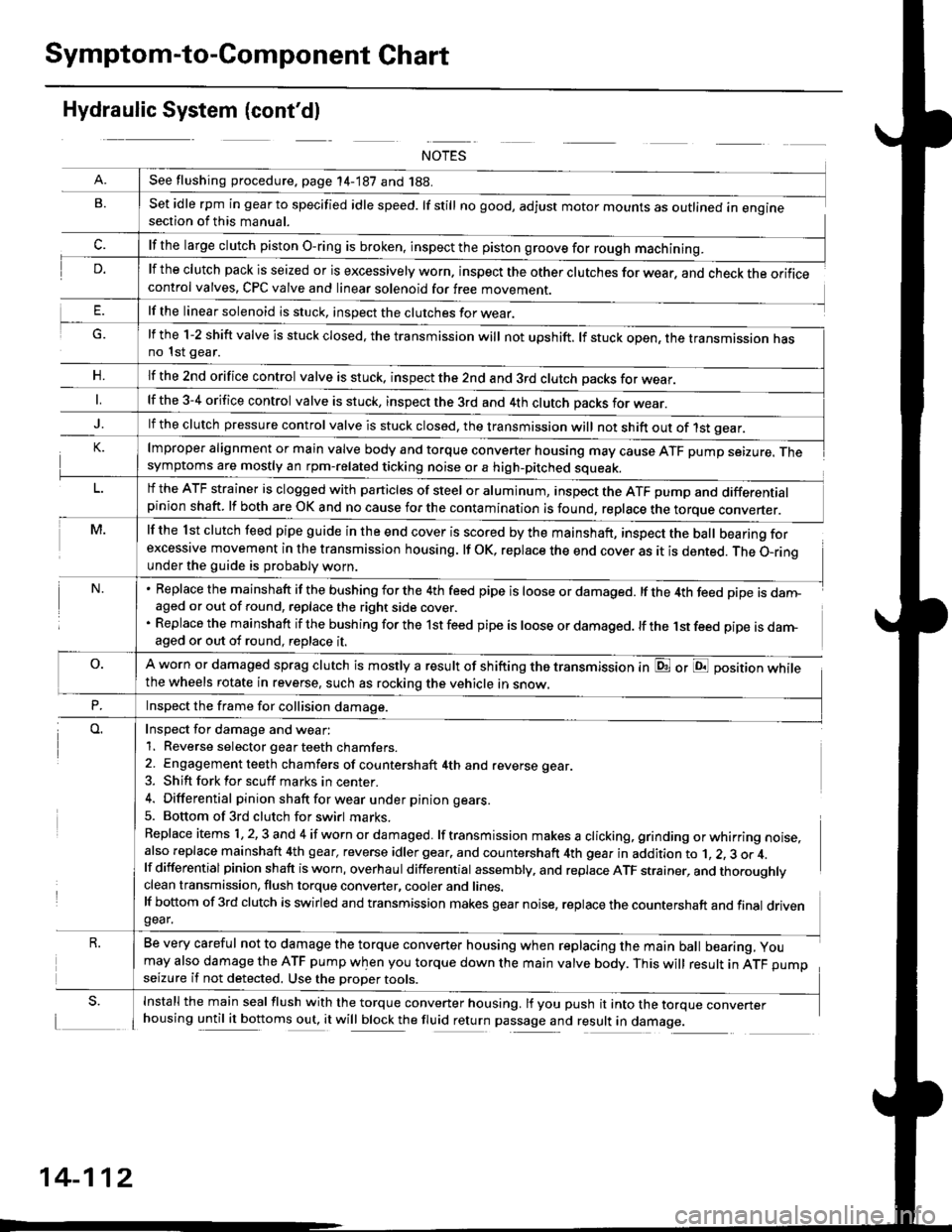

Symptom-to-Component Chart

Hydraulic System (cont'dl

G.

n,

set idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

lf the clutch pack is seized or is excessively worn. inspect the other clutches for wear, and check the orificecontrol valves, CPC valve and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lmproper alignment or main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

lf the l st clutch feed pipe guide in the end cover is scored by the mainshaft, inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged. lf the 4th feed pipe is danFaged or out of round, replace the right side cover.

Replace the mainshaft if the bushing for the 1st feed pipe is loose or damaged. lf the 1st feed pipe is darn-aged or out of round, replace it.

A worn or damaged sprag clutch is mostly a result of shifting the transmission inthe wheels rotate in reverse, such as rocking the vehicle in snow.

or E position while

Inspect for damage and wear:

1. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear u nder pin ion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1,2,3 and 4 if worn or damaged. lf transmission makes a clicking, grinding orwhirring noise,also replace mainshaft 4th gear, reverse idler gear. and countershaft 4th gear in addition to 1, 2, 3 or 4.lf differential pinion shaft is worn, overhaul differential assembly, and replace ATF strainer, and thoroughlyclean transmission, flush torque converter, cooler and lines.lf bottom of 3rd clutch is swirled and transmission makes gear noise, replace the countershaft and final drivengear.

Be very careful not to damage the torque converter housing when replacing the main ball bearing, you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the oroper roors.

Install the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

See flushing procedure, page 14-187 and 188.

lf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

lf the l-2 shift valve is stuck closed, the transmission will not upshift. lf stuck open, the transmission hasno 1st gear.

lf the znd orifice control valve is stuck. inspect the 2nd and 3rd clutch oacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch oacks for wear.

lf the clutch pressure control valve is stuck closed, the transmission will not shift out of 1st gear.

lf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Inspect the frame for collision damage.

14-112

Page 794 of 2189

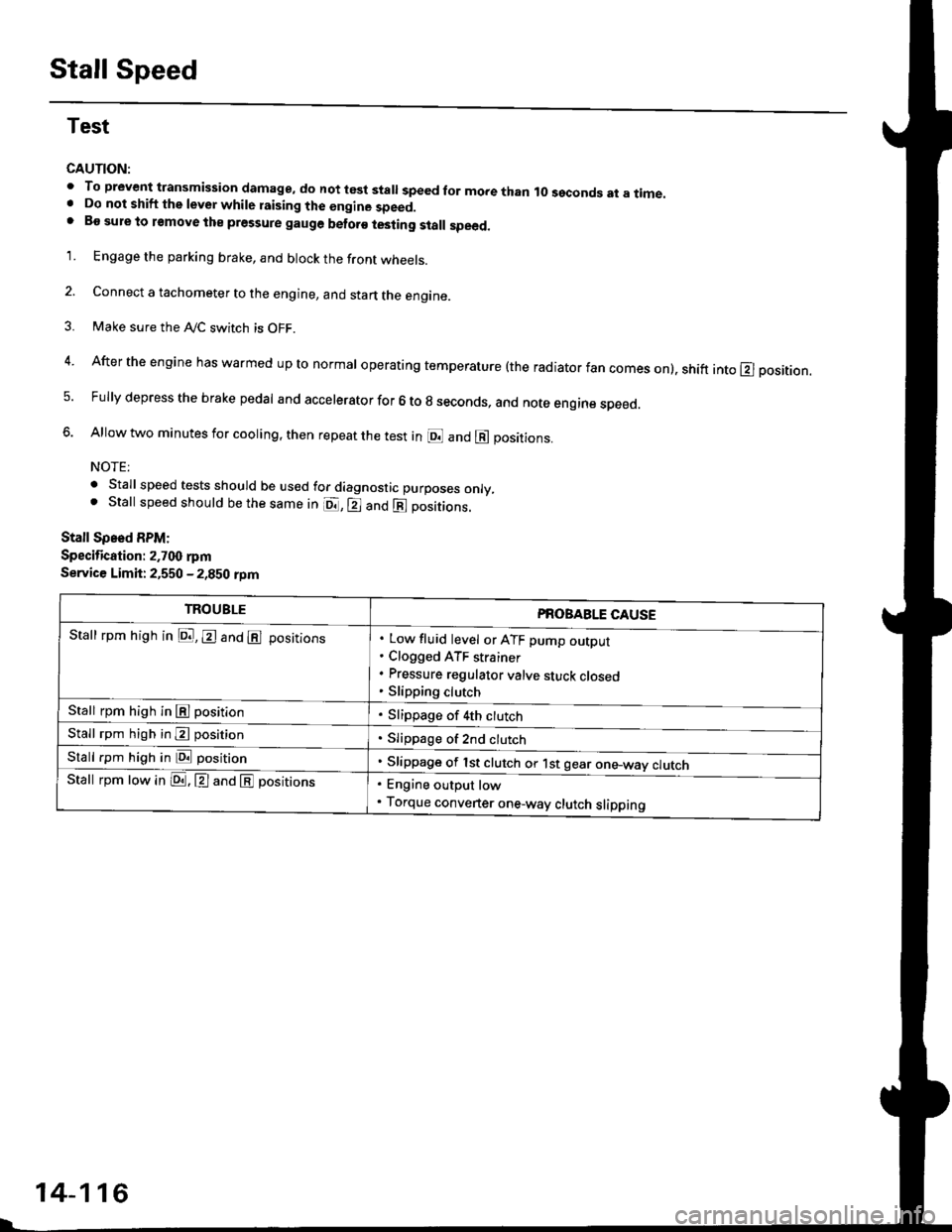

Stall Speed

Test

CAUTION:

. To prev€nt transmission damage, do not t6st stall speed for more than ro sgconds at a time.. Do not shift the levor while raising the engine speed.. Bo sule lo remove the pressure gauge betoro testing stall speed.

'1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the Ay'C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on). shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to g seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in @ and @ positions.

NOTE:

. Stall speed tests should be used for diagnostic purposes only,. Stall speed should be the same in o., E and E positions.

Stall Spsed RPM:

Specification: 2.700 rpm

Service Limit: 2,550 - 2,850 rDm

TROUBLEPROBABLE CAUSE

. Low fluid level or ATF pump outDur. Clogged ATF strainer. Pressure regulator valve sluck closeo. Slipping clutch

. Slippage of 4th ctutch

. Slippage of 2nd clutch

. Slippage of lst clut"tr or. t"t g""io*-*"y "lut"h

Stall rpm high in D., E and E positions

Stall rpm high in El position

Stall rpm high in E posirion

Stall rpm high in E position

Stall rpm low in LDa . El and E positrons. Engine output low. Torque converter one-way clutch slipping

14-116

Page 798 of 2189

Pressure Testing

(cont'd)

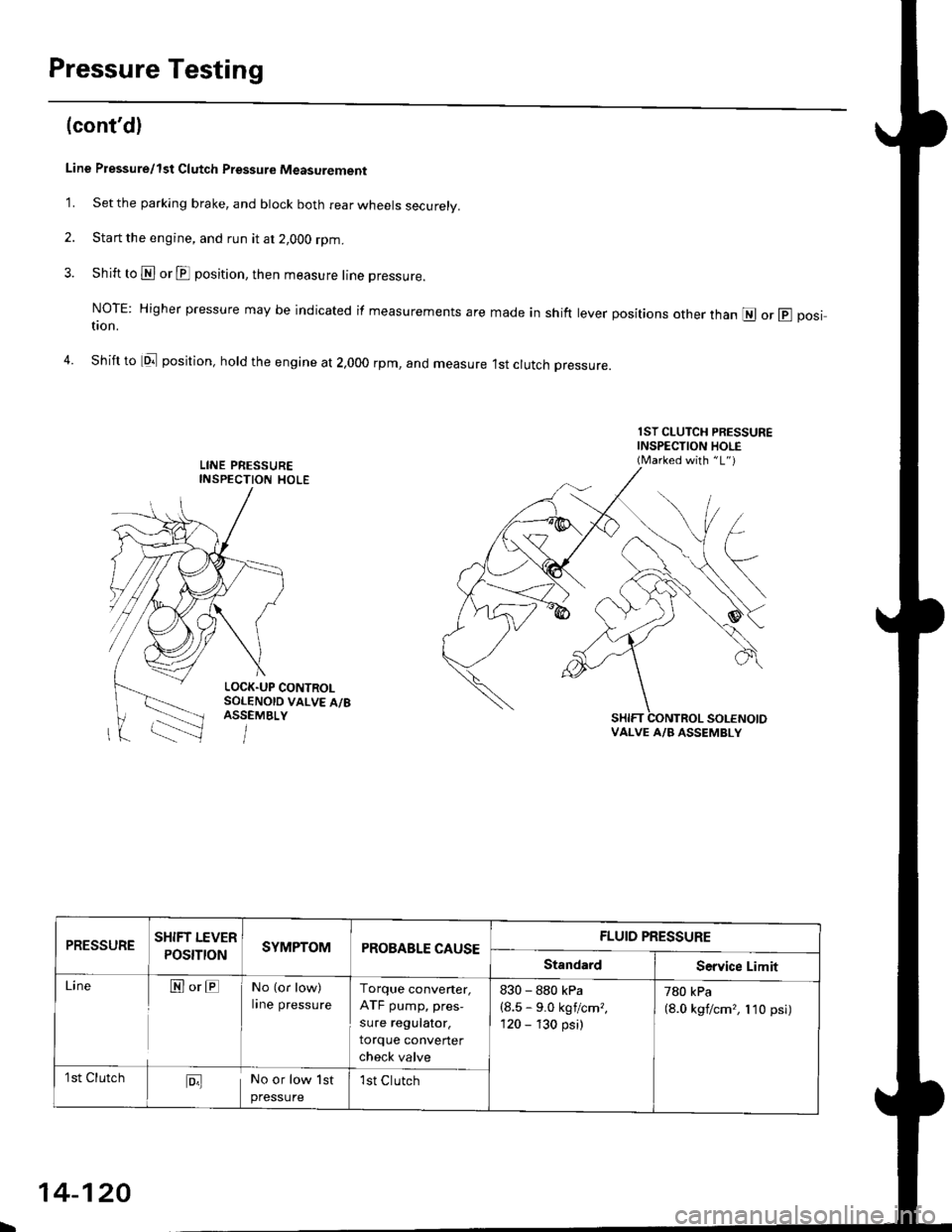

Line Pressure/1st Clutch Pressurc Measurement

1. Set the parking brake, and btock both rear wheels securely.

2. Start the engine, and run it at 2,OOO rpm.

3. Shift to N or E position, then measure line pressure.

NoTE: Higher pressure may be indicated if measurements are made in shift lever positions other than @ or @ positron.

4. Shift to tq;l position, hold the engine at 2,000 rpm, and measure 1st crutch pressure.

1ST CLUTCH PRESSUREINSPECTION HOLE(Marked with "1")

LOCK.UP CONTROLSOLENOID VALVE A/8ASSEMBLY

VALVE A/B ASSEMBLY

PRESSURESHIFT LEVER

POS|TtONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandardService Limit

LineN orENo (or low)

lrne pressureTorque converter,

ATF pump, pres-

sure regutator.

torque converter

check valve

830 - 880 kPa

{8.5 - 9.0 kgf/cm?,

120 - 130 psi)

780 kPa(8.0 kgf/cm'�, 110 psi)

1st ClutchD;lNo or low 1st

pressure

1st Clutch

\

14-120

Page 799 of 2189

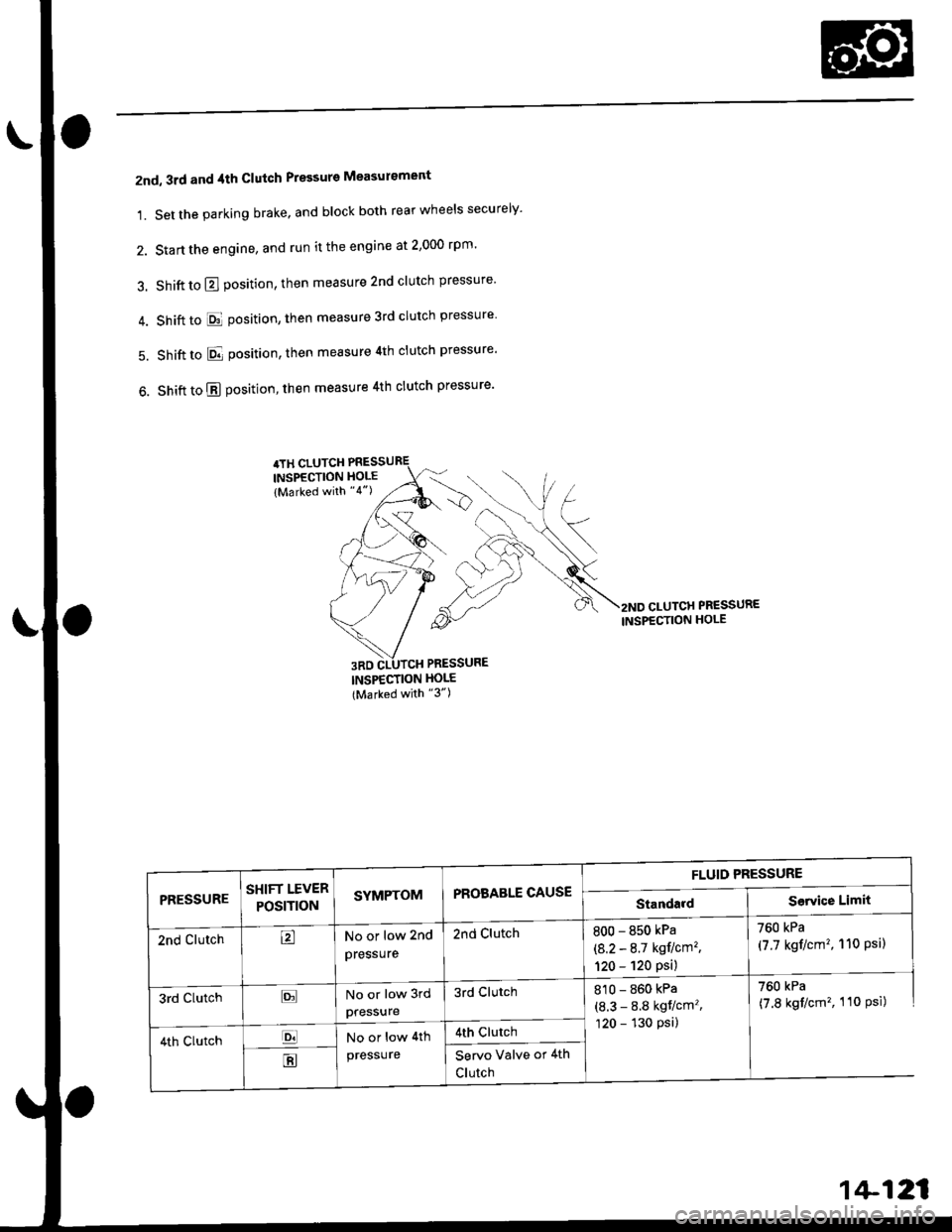

2nd, 3rd and 4th Clutch Pressure Measurement

1. Set the parking brake, and block both rear wheels securely'

2. Start the engine, and run it the engine at 2,000 rpm'

3. Shift to E position, then measure 2nd clutch pressure

4. Shiftto El position, then measure3rd clutch pressure

5. Shift to E position, then measure 4th clutch pressure'

6. Shift to E position, then measure 4th clutch pressure'

INSPECTION HOI'E(Marked with "3")

2ND CLUTCH PR€SSURE

INSPECTION HOLE

FLUID PRESSURE

standard I sorviqe LimitPRESSURESHIFT LEVER

POStT|()NSYMPTOMPROBABLE CAUSE

2nd ClutchtrNo or low 2nd

pressure

2nd Clutch800 - 850 kPa

(8.2 - 8.7 kgflcm'�,

120 - 120 psi)

760 kPa

(7.7 kgf/cm'�, 110 Psil

3rd ClutchtrNo or low 3rd

pressure

3rd Clutch8'�10 - 860 kPa

(8.3 - 8.8 kgt/cm',

120 - 130 psi)

760 kPa

(7.8 kgt/cm', 110 Psi)

4th clutchp.lNo or low 4th

presSure

4th clurch

EServo Valve or 4th

Clutch

1+121