tools HONDA CIVIC 1996 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1028 of 2189

Transmission

Gooler Flushing

@ To prevent iniury to face and eyes, alwayswear safety glasses or a tace shield when using thetransmission flusher.

NOTE: This procedure should be performed before rein-stalling the transmission.

'1. Check the tools and hoses for wear and cracks before

using. lf wear or cracks are found, reDlace the hoses

before using.

4.

Using the measuring cup. fill the tank with 2,1 ounces(approximately 2/3 full) of biodegradable flushingfluid (J35944 - 20). Do not substitute with any otherfluid. Follow the handling procedure on the fluidcontatner.

Secure the flusher filler cap, and pressurize the tankwith compressed air to between 5S0 - 829 kpa (5.6 -

8.45 kgf/cm'�, 80 - 120 psi).

NOTE: The air line should be equipped with a watertrap to ensure a dry air system,

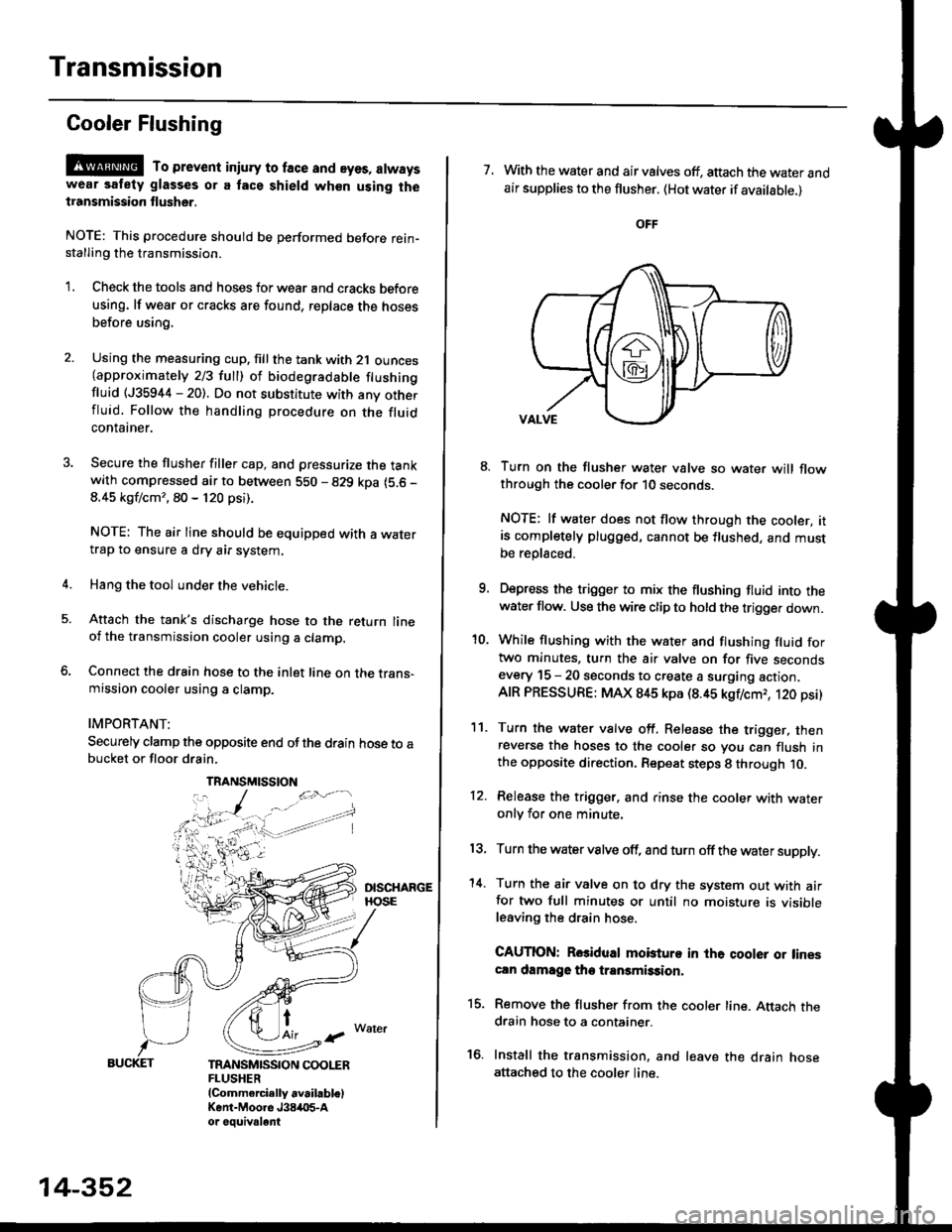

Hang the tool under the vehicle.

Attach the tank's discharge hose to the return lineoi the transmission cooler using a clamp.

Connect the drain hose to the inlet line on the trans-mission cooler using a clamp.

IMPORTANT:

Securely clamp the opposite end ofthe drain hose to abucket or floor drain,

t

TRANSMISSION COOLERFLUSHER{Commercially available)Kent-Moore J384O5-Aor oouivalent

TRANSMISSION

14-352

7. With the water and air valves off, attach the water andair supplies to the flusher. (Hot water if available.)

8. Turn on the flusher water valve so water will flowthrough the cooler for 10 seconds.

NOTE: lf water does not flow through the cooler, itis completely plugged, cannot be flushed, and mustbe replsced.

9. Depress the trigger to mix the flushing fluid into thewater flow. Use the wire clip to hold the trigger down.

'10. While flushing with the water and flushing fluid fortwo minutes. turn the air valve on for five secondsevery 15 - 20 seconds to create a surging action.AIR PRESSURE: MAX 845 kpa (8.45 kgflcmr, 120 psi)

11. Turn the water valve off. Release the trigger, thenreverse the hoses to the cooler so you can flush inthe opposite direction. Repeat steps 8 through 10.

12. Release the trigger. and rinse the cooler with wateronly for one minute.

13, Turn the water valve off, and turn off the water supply.

'14. Turn the air valve on to dry the system out with airfor two full minutes or until no moisture is visibleleaving the drain hose.

CAUTION: Rosidual mobturo in the qooler or linescln damage the transmission,

15. Remove the flusher from the cooler line. Attach thedrain hose to a container.

16. Install the transmission. and leave the drain hoseattached to the cooler line.

Page 1035 of 2189

Special Tools

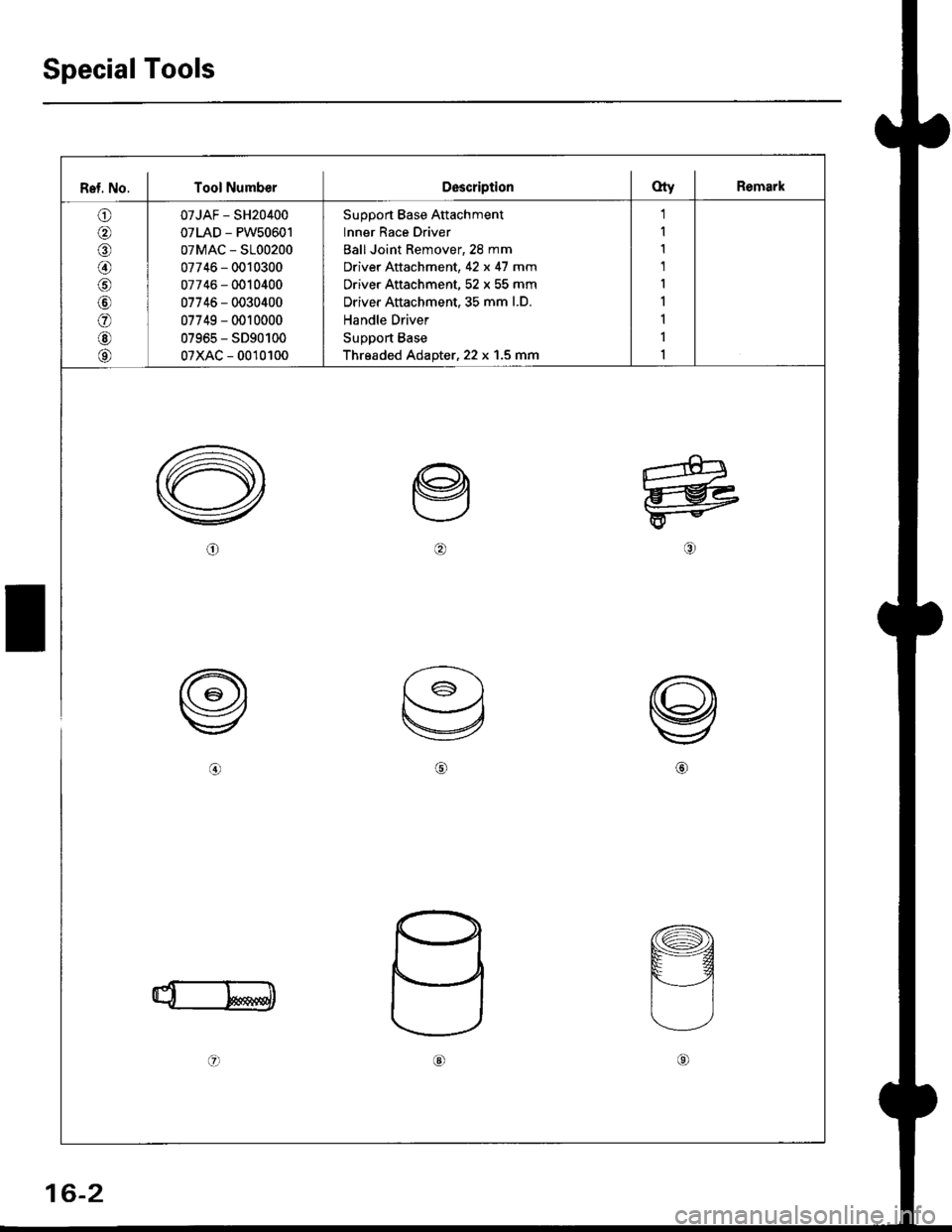

Ref. No. I Tool NumberDescriptionOty I Remark

o

@,a

\9'

o

@

@

07JAF - SH20400

07LAD - PW50601

07MAC - S100200

07746 - 0010300

07746 - 0010400

07746 - 0030400

07749 - 0010000

07965 - SD90100

07xAc - 0010100

Support Base Attachment

Inner Race Driver

Ball Joint Remover, 28 mm

Driver Attachment, 42 x 47 mm

Driver Attachment, 52 x 55 mm

Driver Attachment, 35 mm l.D.

Handle Driver

Support Base

Threaded Adapter, 22 x 1.5 mm

1

1

1

1

I

I

1

I

1

@e

@

&

w

@

@

c

6

@

'

lo,

c[G)

8-)

ge

l..---,l

G)

16-2

Page 1054 of 2189

Disassembly

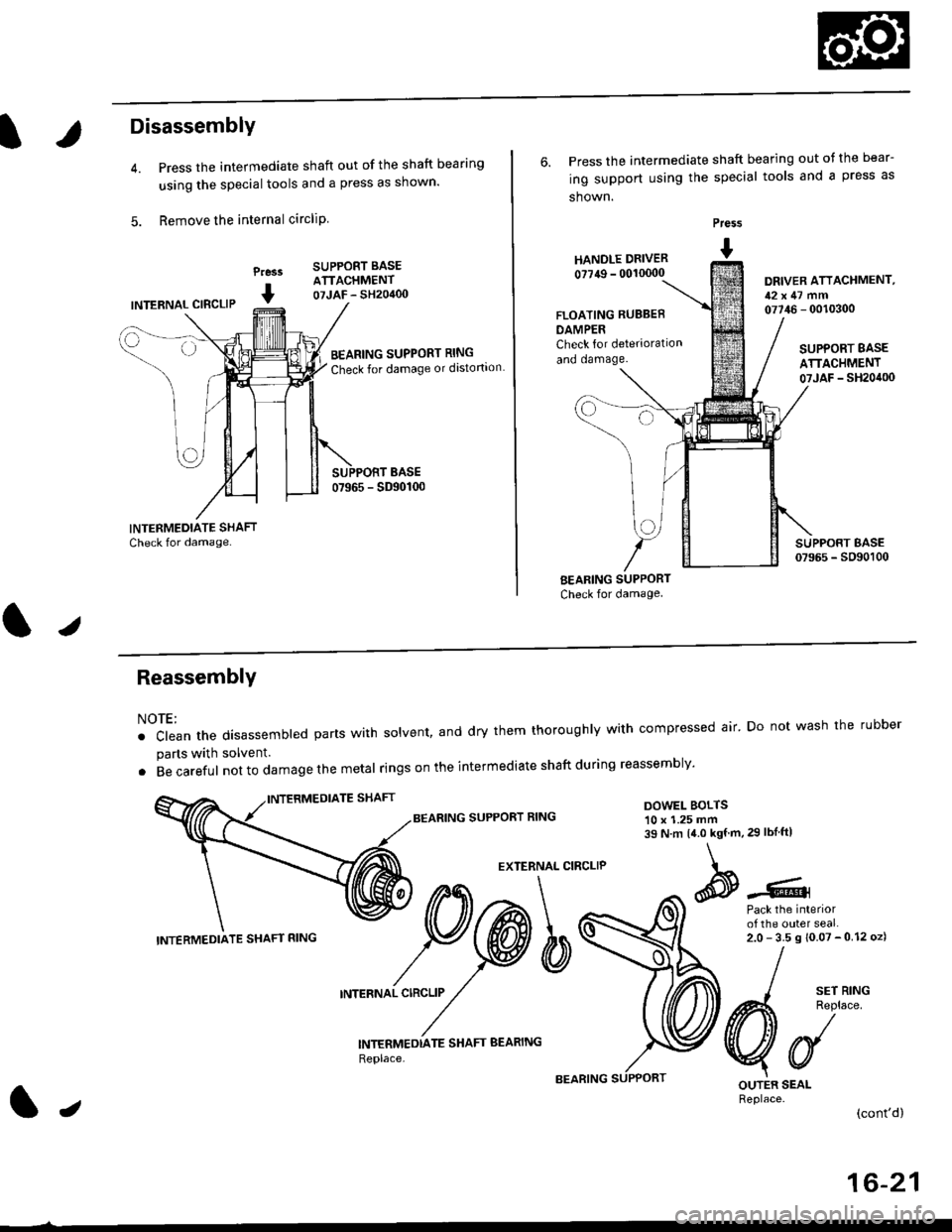

Press the intermediate shaft out of the shaft bearing

using the special tools and a press as shown.

Remove the internal circliP

Press

I

SUPPORT BASEATTACHMENT07JAF - SH20400INTERNAL CIBCLIP

BEARING SUPPORT RING

Check for damage or distortion

6. Press the intermediate shaft bearing out ot the bear-

ing support using the special tools and a press as

shown.

HANOLE DRIVER

0?749 - 00'�10000

Press

I

DRIVER ATTACHMENT,12x47 mm07746 - 0010300FLOATING RUBBEB

DAMPERCheck for deterioration

and oamage.SUPPORT BASE

ATTACHMENT07JAF _ SH20it00

BEARING SUPPORT

Check for damage

I sErR'NG

A4 Reolace

VUOUTER SEALReplace.(cont'd)

ReassemblY

NOTE:

. clean the disassembted parts with solvent, and dry them thoroughly with compressed air' Do not wash the rubber

parts with solvent.

. Becareful not to da mage the metal ringson the intermediate shaftduring reassembly'

BEARING SUPPORT RINGDOWEL BOLTS10 x 1.25 mm39 N.m 14.0 kgf.m,29 lbIftl

EXTERNAL CIRCLIP

Pack the interiorof the outer seal.2.0-35s10.07-012oz)

INTERNAL CIRCLIP

INTERMEDTATE SHAFT BEARING

Replace,

INTERMEDIATE SHAFT RING

lJ

16-21

Page 1055 of 2189

lntermediate Shaft

Reassembly (cont'd)

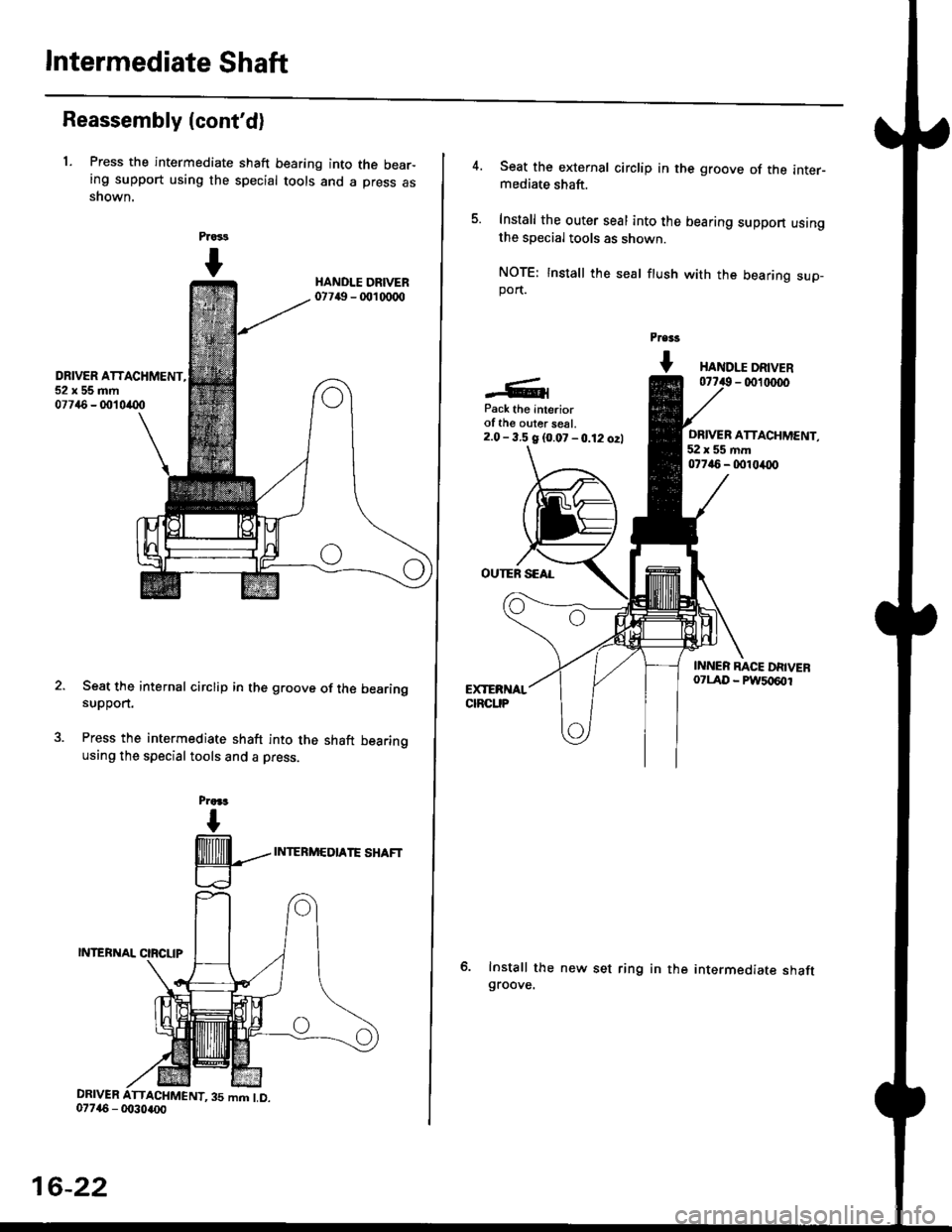

1. Press the intermediate shaft bearing into the bear-ing support using the special tools and a press asshown.

Prass

I

DRIVER ATTACHMENT,52x55mm07746 - 001 0(X)

Seat the internal circlip in the groove of the bearingsuppon.

Press the intermediate shaft into the shaft bearingusing the special tools and a press.

Praa.r

I

@---

LJ

INTERMEDIATE SHAFT

DRIVER ATTACHMENT,35 mm LD.

16-22

Seat the external circlip in the groove of the inter-mediate shaft.

Install the outer seal into the bearing support usingthe special tools as shown.

NOTE: Install the seal ftush with the bearing sup-port.

Pre$

t HANDr.r DRTVER- 0011r(x)0

Pack the Interiorof the ouler seal.2.0- 3.5 g {0.07 -0.12 ozl

OUTEN SEAL

Install the new set ringgroove.

ORIVER ATTACHMENT,52x55mm077i16 - 0010/O0

in the intermediate shaft

Page 1057 of 2189

l.

t

Steering

Speciaf Tools ....."'.....17-2

Manual Steering

Component Locations

lndex ................ ....... 17-3

Inspection and Adiustment

Steering Operation "'......"............... 17-4

Rack Guide Adiustment ................... 17-5

*Steering Wheel

(See power steering section)

*Steering Column

(See power steering sectionl

Steering Gearbox

Removal ................. 17-5

Disassembly ......."" 17-7

ReassemblY ..'......... 17-9

lnstallation ............. 17-13

Power Steering

Component Locations

lndex "......."..... """' 17-15

System DescriPtion

Fluid Flow Diagram .........""............. 17'16

Steering Pump ............'... "........"'...-- 17 -17

Steering Gearbox .".................'...'.'.' 17-20

Troubleshooting

Generaf Troubleshooting ..........--.... 17'22

Noise and Vibration ......................... 17 -26

Ffuid Leaks .............17-28

Inspection and Adiustment

Steering Operation'......."'........'...... 1 7-30

Power Assist Check

With Vehicle Parked .."................ 17-30

Steering Linkage and Gearbox ....." 17-31

Pump Beft ...--.""".. 17-32

Rack Guide Adiustment .'.......'.......'. 17'33

Fluid Replacement .....'.."................. 17-33

Pump Pressure Check .............'....-. " 17 -34

'Steering Wheel

Removal .."'........'... 17-35

lnstallation ............. 17-35

Disassembly/Reassembly ......'.....'.' 17-36

*Steering Column

Removal/lnstallation ....'........... ---.... 17'37

lnspection .............. 17'38

Power Steering Hoses, Lines

Fluid Leakage Inspeetion ............'.... 17-39

Replacement ......".. 17-39

Power Steering PumP

Removal/lnstallation .'.'..'..'............. 17-40

Disassembly ".........17-41

fnspection .......---'." 17'42

Reassembly ..'.........17-44

Steering Gearbox

Removal ....'........."' 17'47

DisassemblY ..........' 17-49

Reassembly '........... 17-55

lnstallation ............. 17-65

Ball Joint Boot Replacement .......'.. 17-68

Ir/

lp

Page 1066 of 2189

Steering Gearbox

Reassembly (cont'dl

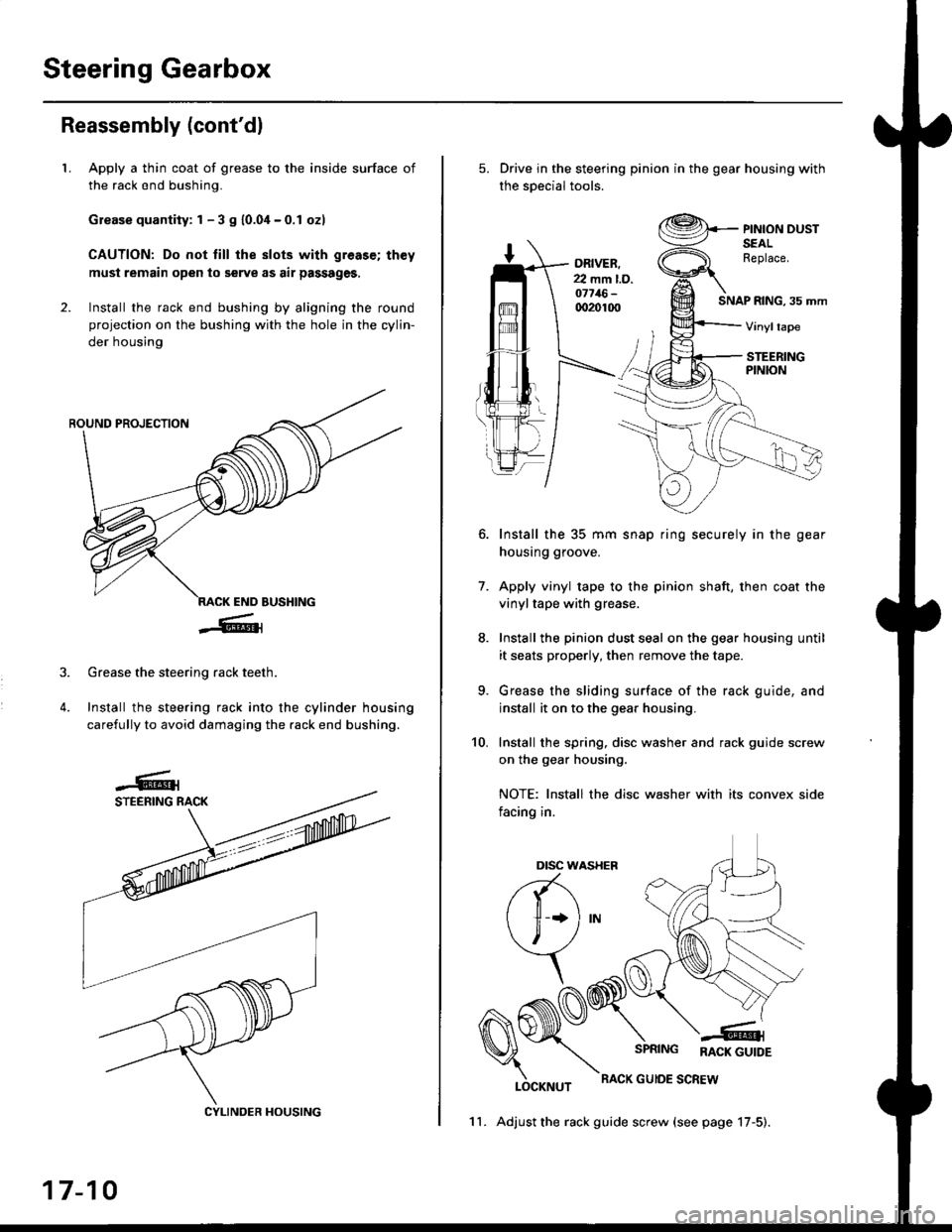

LApply a thin coat of grease to the inside surface of

the rack end bushing.

Grease quantity: 1 - 3 S 10.04-0.1 ozl

CAUTION: Do not till the slots with greas€; th€y

must remain open to serve as air passages,

Install the rack end bushing by aligning the round

projection on the bushing with the hole in the cylin-

der housing

4.

Grease the steering rack teeth.

Install the steering rack into the cylinder housing

carefully to avoid damaging the rack end bushing.

CYLINDER HOUSING

17-10

11. Adjust the rack guide screw (see page 17-5).

Drive in the steering pinion in the gear housing with

the soecial tools.

ORIVER.22 mm l.D.o7716-qr20100SNAP RING, 35 mm

PINION DUSTSEALReplace.

Vinyltape

STEERINGPINION

7.

Install the 35 mm snap ring securely in the gear

housing groove.

Apply vinyl tape to the pinion shaft, then coat the

vinyltape with grease.

Install the pinion dust seal on the gear housing until

it seats properly, then remove the tape.

Grease the sliding surface of the rack guide, and

install it on to the gear housing.

Install the spring, disc washer and rack guide screw

on the gear housing.

NOTE: Install the disc washer with its convex side

facing in.

LOCKNUT

SPRING RACK GUTDE

RACK GUIOE SCREW

10.

Dtsc w,

a(-\

l1 *l

\, ,/

\

Page 1111 of 2189

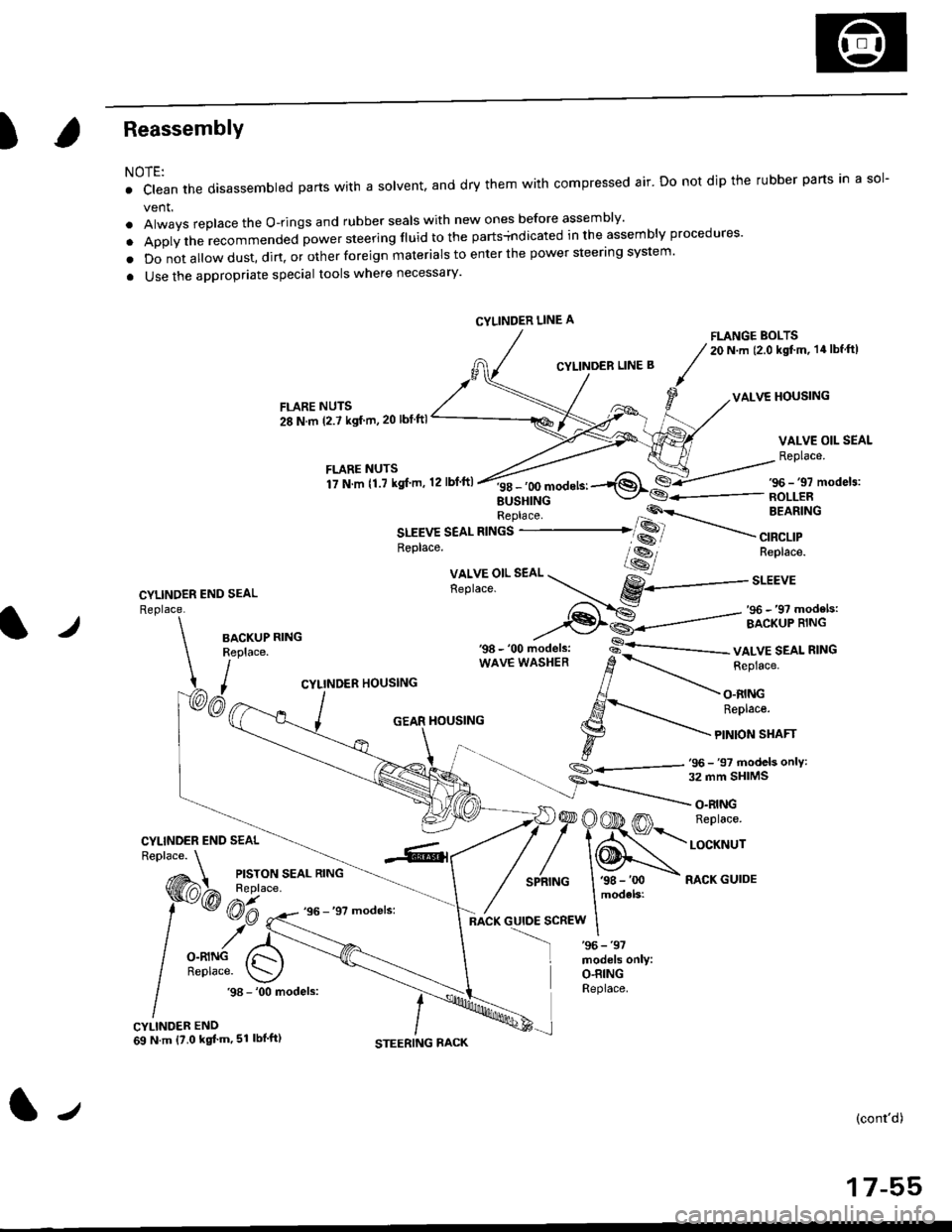

)Reassembly

NOTE:

. clean the disassembled parts wrth a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly'

. Apply the recommended power steering fluid to the parts+ndicated in the assembly procedures'

o Do not a||ow dust, dirt, or other foreign materials to enter the power steering system.

a Use the appropriate special tools where necessary'

FLANGE BOLTS20 N.m (2.0 kgt'm, 14lbf ftl

CYLINDER LINE B

VALVE HOUSINGFLARE NUTS

28 N.m (2.7 ksf m,20 lbf ftl

VALVE OIL SEAL

Replace.

CYLINDER END SEAL

Replace.

f itllTllli".",'r'o,.n,ft

''*^'*-1$*€-/s6-,,mode,3:

EUSHINGReplace 'P'\-- BEARING

SLEEVE SEAL RINGS ..-------......�� SS

.----

",a"a,,

*---

--,

Replace. lss-, Replace.

Xll,Y5"l'.

"o. --r...- gY------..r.u,

,-f-..-S: _ ,96 _,9? models:

--€l€--------=- ircriip'ii.rt'-l./BACKUPReplace.

I,

wAvE wAsHER d

-.-.-r_ i"pru"".

CYLINDER HOUSING // -\-

, AJ - O.RING

/ ,S-'..- ReDtace.

_ j GEAR HouslNG l.g --'\-

\- t F

tonsrnrr

.,_- s

- 'oo ,,iod"t., -s-'--------- vALvE SEAL R'NG

S_.<---,tj- 97 models onlY:

CYLINDER END SEAL

)@OOD m n"prac".

/'\N,."._nrNG I '98 - 'oo - RACK GUIDE

models:

:scREw I

O.RINGReplace..98 - '00 models:

CYLINDER END69 N.m {?.0 kgt'm,51 lbl'ft)

(cont'd)

17-55

CYLINDER LINE A

tJ

Page 1113 of 2189

I

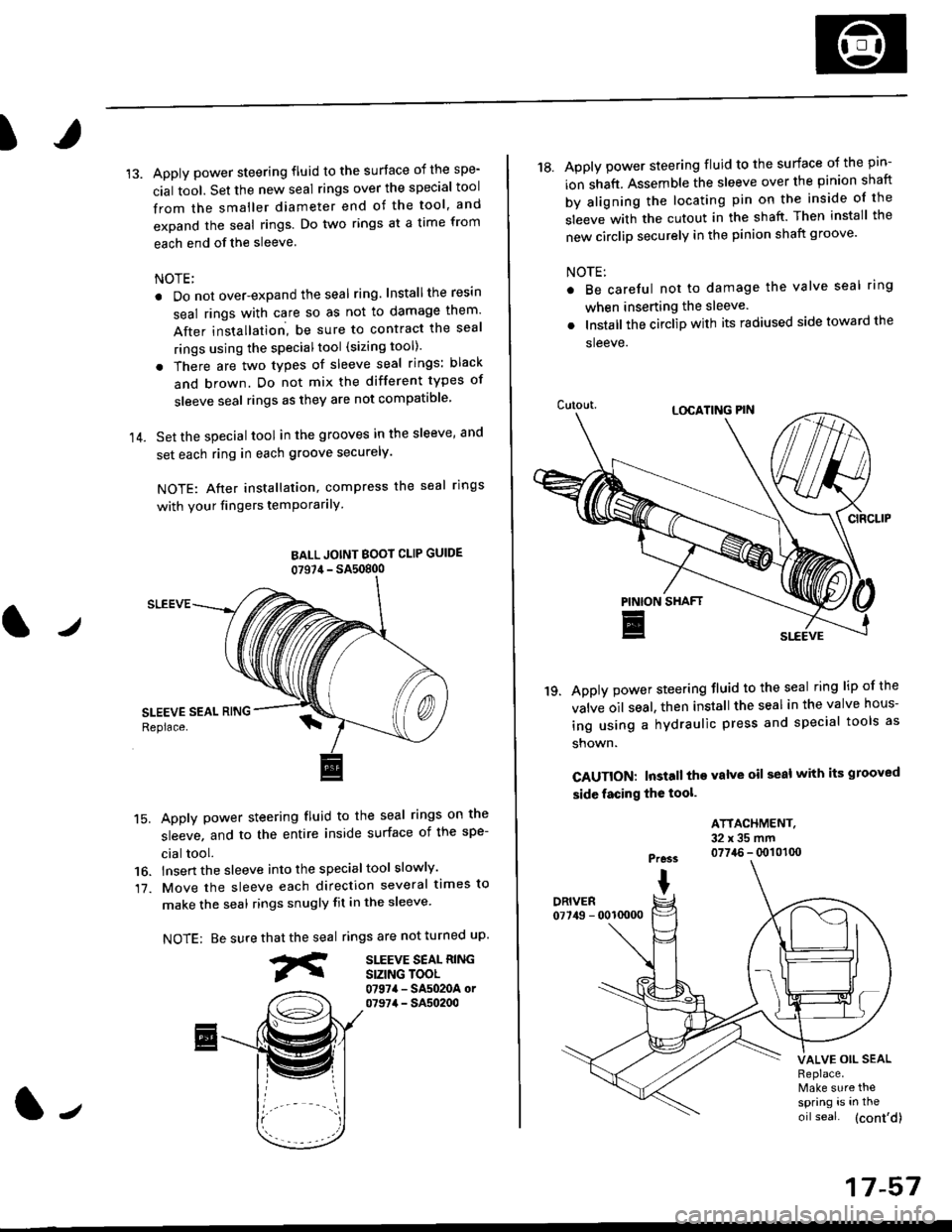

14.

Apply power steering fluid to the surface of the spe-

cial tool. Set the new seal rings over the special tool

from the smaller diameter end of the tool, and

expand the seal rings. Do two rings at a time from

each end of the sleeve.

NOTE;

. Do not over-expand the seal ring. Installthe resin

seal rings with care so as not to damage them'

After installation, be sure to contract the seal

rings using the specialtool (sizing tool).

. There are two types of sleeve seal rings: black

and brown. Do not mix the different types of

sleeve seal rings as they are not compatible

Set the special tool in the grooves in the sleeve, and

set each ring in each groove securely.

NOTE: After installation, compress the seal rings

with your fingers temPorarilY

BALL JOINT BOOI CLIP GUIDE

07S7,1- SA50800

SLEEVE

15. Apply power steering fluid to the seal rings on the

sleeve, and to the entire inside surface of the spe-

cial tool.

16. lnsert the sleeve into the specialtool slowly'

17. Move the sleeve each direction several times to

make the seal rings snugly fit in the sleeve'

NOTE: Be surerings are not turned uP.

SITEVE SEAL RINGSIZING TOOL0797a - SA5020A or07974 - SA50200

that the seal

fr

J

17-57

18. Apply power steering fluid to the surface o{ the pin-

ion shaft. Assemble the sleeve over the pinion shaft

by aligning the locating pin on the inside of the

sleeve with the cutout in the shaft. Then install the

new circlip securely in the pinion shaft groove'

NOTE:

Be careful not to damage the valve seal ring

when inserting the sleeve.

Installthe circlip with its radiused side toward the

sleeve.

Apply power steering fluid to the seal ring lip of the

valve oil seal. then install the seal in the valve hous-

ing using a hydraulic press and special tools as

shown.

CAUTION: Install the valve oil seal with its grooved

side facing the tool.

'19.

ATTACHMENT.32x35mm0774.6 - q)101(x)Pre3s

IDRIVER07749 - 0010000

VALVE OIL SEALReplace.Make sure thespring is in the

oil seal. (cont'd)

Page 1125 of 2189

)

Suspension

Special Tools ............. 18-2

Component Locations

lndex ,,.............. ...... f8-3

Wheel Alignment

Caster .............. ....... 18-4

Camber .................. l8-4

Front Toe Inspection/

Adiustment ........ 18-5

Rear Toe lnspection/

Adiustment ........ 18-5

Turning Angle Inspection ................ 18-6

Wheel/Hub Inspection

Bearing End P|ay .............................. l8-7

Wheel Runout ....... 18-7

Front Suspension

Suspension Arms Replacement

('96 - 99 modelsl .......................... 18-8

Suspension Arms Replacement

('99 2D Si and Si-R models) ........ 18-9

Knuckle/Hub Replacement ............. 18-10

Lower Ball Joint Replacement ....... 18-16

Ball Joint Boot Replacement .......... 18-17

Front Damper

Removal ................. 18-17

Disassembly/1nspection .................. 18-18

Reassembly ........... 18-19

lnstallation ............. 18-19

Rear Suspension

Suspension Arms Replacement

('96 - 99 models) ....................,..... 18-21

Suspension Arms Replacement

('99 2D Si and Si-R models) ........ 1A-22

Hub Bearing Unit Replacement ...... 18-23

Upper Arm Eushing

Replacement .....18-25

Rear Damper

Removal ................. 18-26

Disassembly/|nspection ............. ..... 1A-27

Reassembly ........... 18-28

lnstallation ............. 18-29

lr

Page 1126 of 2189

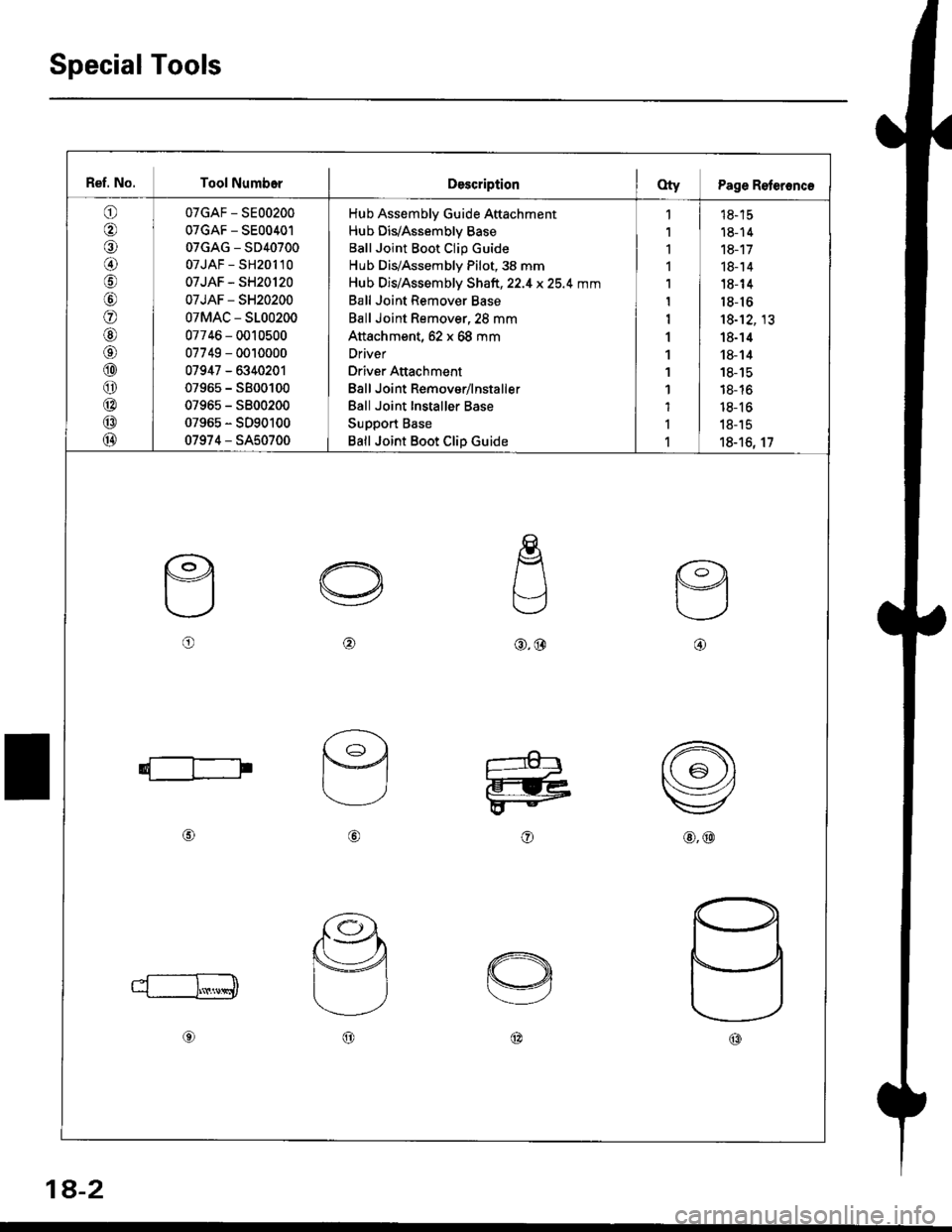

Special Tools

Ref. No. Tool NumborDescriptionOty Page Reteronc€

o

€)

@

\9

o

@aa\

@

o

@

@

@

07GAF - SE00200

07GAF - SE00401

07GAG - SD40700

07JAF - SH201 l0

07JAF - SH20120

07JAF - SH20200

07MAC - S100200

07746 - 0010500

07749 - 0010000

07947 - 6340201

07965 - SB00100

07965 - 5800200

07965 - SD90100

07974 - SA50700

Hub Assembly Guide Attachment

Hub DivAssembly Base

Ball Joint Boot Clip Guide

Hub Dis/Assembly Pilot, 38 mm

Hub Dis/Assembly Shaft,22.4 x25.4 mm

Ball Joint Remover Base

Ball Joint Remover,2S mm

Attachment, 62 x 68 mm

Driver

Driver Attachment

Eall Joint Remover/lnstaller

Ball Joint Installer Base

Support Base

Ball Joint Boot Clip Guide

,|

1

1

1

1

1

1

1

1

1

1

1

I

1

td- tc

18- 14

18-17

18- 14

18- 14

18-16

18-12, 13

18-14

18- 14

18- 15

18- 16

18- 16

18-15

18-16, 17

o@@.@@

@

o@

1a-2