Hydraulic HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 56 of 2189

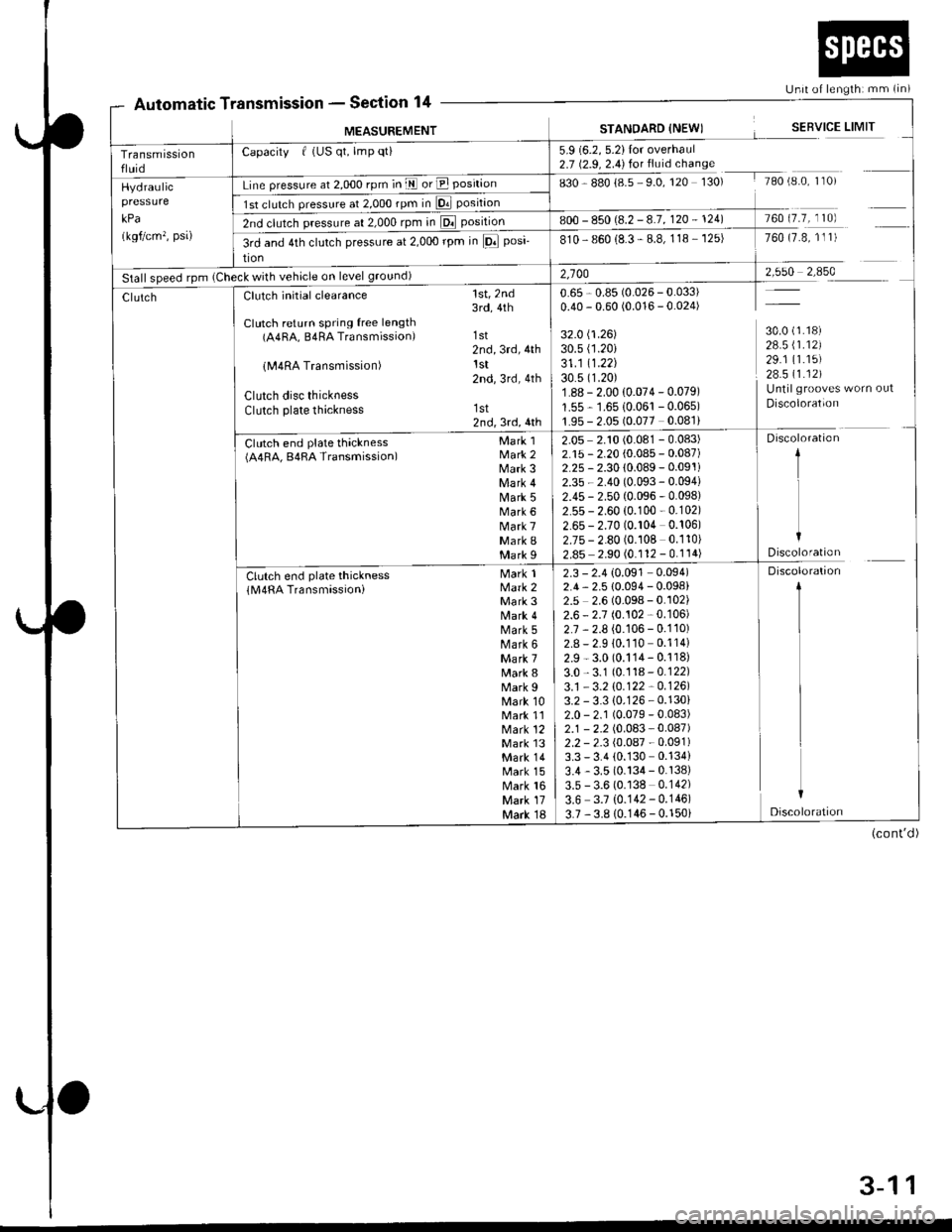

Automatic TtssronSection 14Unit of lengthi mm (in)

fansmtssron -

MEASUREMENTSTANOARD {NEWISERVICE LIMIT

Transmissionfluid

Capacity f (US qt, lmp qti5.9 (6.2, 5.2)Ior overhaul2.7 (2.9, 2.4) for fluid chanse

sgO g8ol85 SO,rzO rSO, rAo,e'0 I 0,Hydraulic

kPa

(kgf/cm'�, psa)

Line pressure at 2,000 rpm in E or E position

1st clulch pressure al 2,O0Orpmin D. position

2nd clutch pressure at 2,000 rpm in El position800 - 850 (8.2 -8.7, 120 - 124)760 (7.7, 110)

3rd and 4th clutch pressure at 2,000 rpm in lFl posi-

tion

810- 860 (8.3 - 8.8, 118 - 125)760 (7.8, 1l 1)

Stall speed rpm (Check with vehicle on level ground)2,10028 1_ ffi9

30.0 (1.18)

28.5 \1.12)29.1 (1.15)

28.511.121Untilgrooves worn out

Discoloration

ClutchClutch initial clearance

Clutch return spring free length(A4RA, B4RA Transmission)

lM4RA Transmission)

Clutch disc thicknessClutch plate thickness

Ctr t"h ""d pl"t" thl"t**(A4RA, B4RA Transmission)

1st,2nd3rd,4th

1st2nd,3rd,4thlst2nd,3rd,4th

1st2nd,3rd,4th

Mark 1Mark 2Mark 3Mark 4Mark 5Mark 6Mark 7Mark IMark I

M"*lMark 2Mark 3Mark 4Mark 5Mark 6Mark 7Mark 8Mark 9Mark 10Mark 11Mark 12Mark l3Mark 14Mark 15Mark 16Mark 17Mark 18

Clutch end plate thickness(M4RA Transmassioni

0.65 , 0.85 (0.026 - 0.033)0.40 - 0.60 (0.016 - 0.024)

32.0 (1.26)

30.s (1.20i

31 .1 11.22130.5 (1.20)

1.88 - 2.00 {0.074 - 0.079)

1.55 - 1.6510.061 -0.065)

1.95 - 2.05 (0.077 0.081)

2.05 2.10 (0.081 - 0.083)2.15 - 2.20 (0.085 - 0.087)2.25 - 2.30 {0.089 - 0.091i

2.35 - 2.40 (0.093 - 0.094)

2.45 - 2.50 (0.096 - 0.098)2.55 - 2.60 (0.100 - 0.102)

2.65 - 2.70 (0.104 0.106)2.75 - 2.80 (0.108 0.110)

2.85 2.90 (0.112 - 0.114)

Discoloration

1

I

IDiscoloration

2.3 - 2.4 {0.091 0.094)2.4, 2.5 {0.094 - 0.098)2.5 2.6 (0.098 - 0.102)2.6 - 2.7 (0.102 - 0.106)

2.7 , 2.8 (0.106 - 0.110)2.8 - 2.9 10.110 0.114)

2.9 - 3.0 (0.114- 0.118)

3.0,3.1 (0.118-0.122)

3.1 - 3.2 \O.122 -0.1261

3.2 - 3.3 {0.126 - 0.130}2.0 - 2.1 (0.079 - 0.083)2.1 - 2.2 (0.083 - 0.087)2.2 - 2.3 (0.087 - 0.091)3.3 - 3.4 (0.130 0.134)

3.4 - 3.5 (0.134 - 0.138)3.5 - 3.6 (0.138 0.142)

3.6 3.7 {0.142- 0.146)

3.7 ,3.8 10.146 - 0.150i

Discoloration

1

I

I

L

I

Discoloration

(cont'd)

3-11

Page 59 of 2189

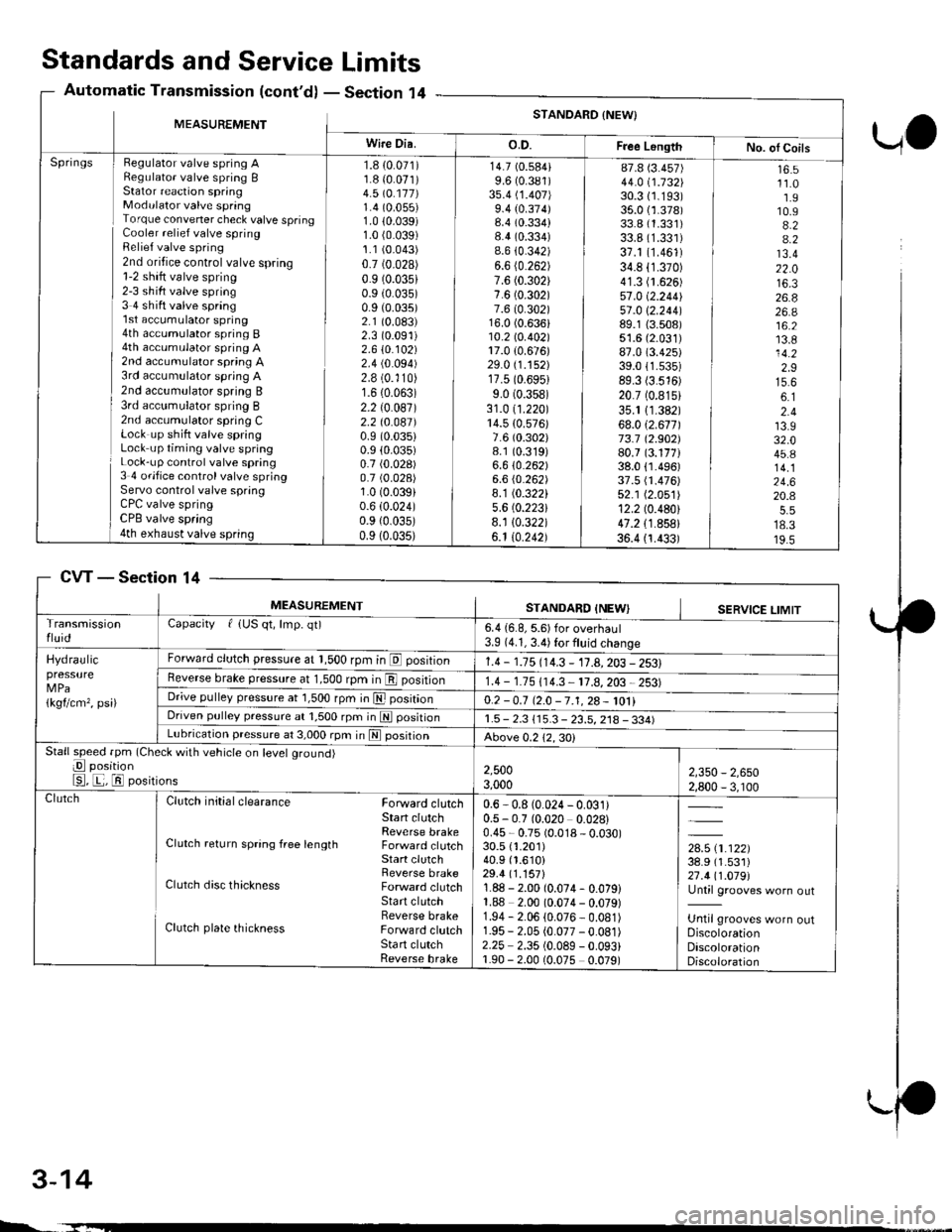

Standards and ServiceLimits

Section '14Automatic Transmission (cont'd)

UO

MEASUREMENTSTANDARD {NEW}

Wire Dia.o.D.Free LongthNo. ol CoilsHegulator valve spring ARegulato. valve spring BStator reaction springModulator valve springTorque convener check valve springCooler relief valve springRelief valve spring2nd oritice control valve spring1-2 shift valve spring2-3 sh ift valve spring3 4 shift valve spring'l st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd acc!mulator spring B2nd accumulator spring CLock up shift valve springLock up timing valve springLock-up control valve spring3 4 ofifice control valve springServo control valve springCPC valve springCPB valve spring4th exhaust valve spring

Springs1.8 {0.071)1.8 {0.071)4.5 \O.117)1.4 (0.055)

1.0 10.039)1.0 (0.039)

1.1 (0.043)

0.7 (0.028)

0.9 (0.035)

0.9 (0.035)

0.9 (0.035)

2.1 (0.083)

2.3 (0.091)

2.610.102)2.4 (0.094)

2.8 (0.'110)

1.6 (0.063)

2.2 (0.087)

2.2 t0.041)0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.7 (0.028)

1.0 (0.039)

0.6 (0.024)

0.9 {0.035)0.9 (0.035)

14.7 (0.584)

9.6 (0.381)

3s.4 (1.407)

9.4 (0.374)8.4 (0.334)

8.4 (0.334)

8.6 {0.342)6.6 (0.262)

7.6 (0.302)

7.6 (0.302)

7.6 (0.302)16.0 (0.636)10.2lo.402l17.0 {0.676)29.0 (1.152)

17.5 (0.6951

9.0 (0.358)

31.0 (1.220)

14.5 {0.576)7.6 (0.302)

8.1 (0.319)

6.610.262)6.6 (0.262)

8.1 (0.322)

5.6 (0.2231

8.1 10.322)6.1 10.242)

87.8 (3.457)

44.0 i.732l'30.3 (1.193)

35.0 {1.378)33.8 (1.331)

33.8 (1.331)

37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57.0 (2.2441

51 .0 \2.244189.1 {3.508)51.6 (2.031)

87.0 (3.425)

39.011.535)89.3 (3.516)

20.7 (0.815)

35.1 11.382)68.012.671173.7 12.902)80.7 (3.177)38.0 {1.496)37.5 fi.476)52.1 (2.051)

12.2 (0.480)

47.2 {1.858}36.4 {1.433)

16.511.01.910.94.24.213.422.016.326.826.a16.213.814.22.915.66.12.413.932.045.814.124.620.4

18.319.5

CVTSection 14

3-14

MEASUREMENTSTANDARD INEWISERVICE LIMITTransmissionfluidCapacity f {US qt, lmp. qt)6.4 {6.8, 5.6) for overhaul3.9 (4.1, 3.4) for fluid change

Hydraulicpressure

1kgflcm,, psi)

Forward clutch pressure at 1,500 rpm in E position1.4 - 1.15 114.3 - 11.A,203 - 2531Reverse brake pressure at 1,500 rpm in E position1.4 - 1.75 (14.3 11.8,203 2531Dr;ve pulley pressure at 1,500 rpm in E posrtrono.2 -0.7 12.0 -7.1,28- 1011Driven pulley pressure at 1,500 rpm in N positionr.5 - 2.3 115.3 - 23.5, 218 - 334)Lubrication pressure at 3,000 rpm in E posrtronAbove 0.212,30)Stall speed fpm (Check with vehicle on level ground)

E position

E, E, El positions2,5003,0002,350 - 2,6502,800 - 3, r00ClutchClutch initial clearance Forward clutchStart clutchReverse brakeClutch return spring free length Forward clutchStart clutchReverse brakeClutch disc thickness Forward clutchStart clutchReverse brakeClutch plate thickness Forward clutchSta rt clutchReverse brake

0.6 - 0.8 (0.024 - 0.031)0.5 - 0.7 (0.020 0.028)0.45 - 0.75 (0.018 - 0.030)30.5 {1.201)40.9 (1.610)

29.4 (1.157)

1.88 - 2.00 (0.074- 0.079)1.88 2.00 (0.074 - 0.079)1.94 - 2.06 (0.076 - 0.081)1.95 - 2.05 (0.077 -0.081)

2.25 2.35 (0.089 - 0.093)1.90 - 2.00 (0.075 0.079)

,*x.ar}38.9 (1.531)

27.411.019l'Until grooves worn out

Until grooves worn outDiscolorationDiscolorationDiscoloration

L.

Page 66 of 2189

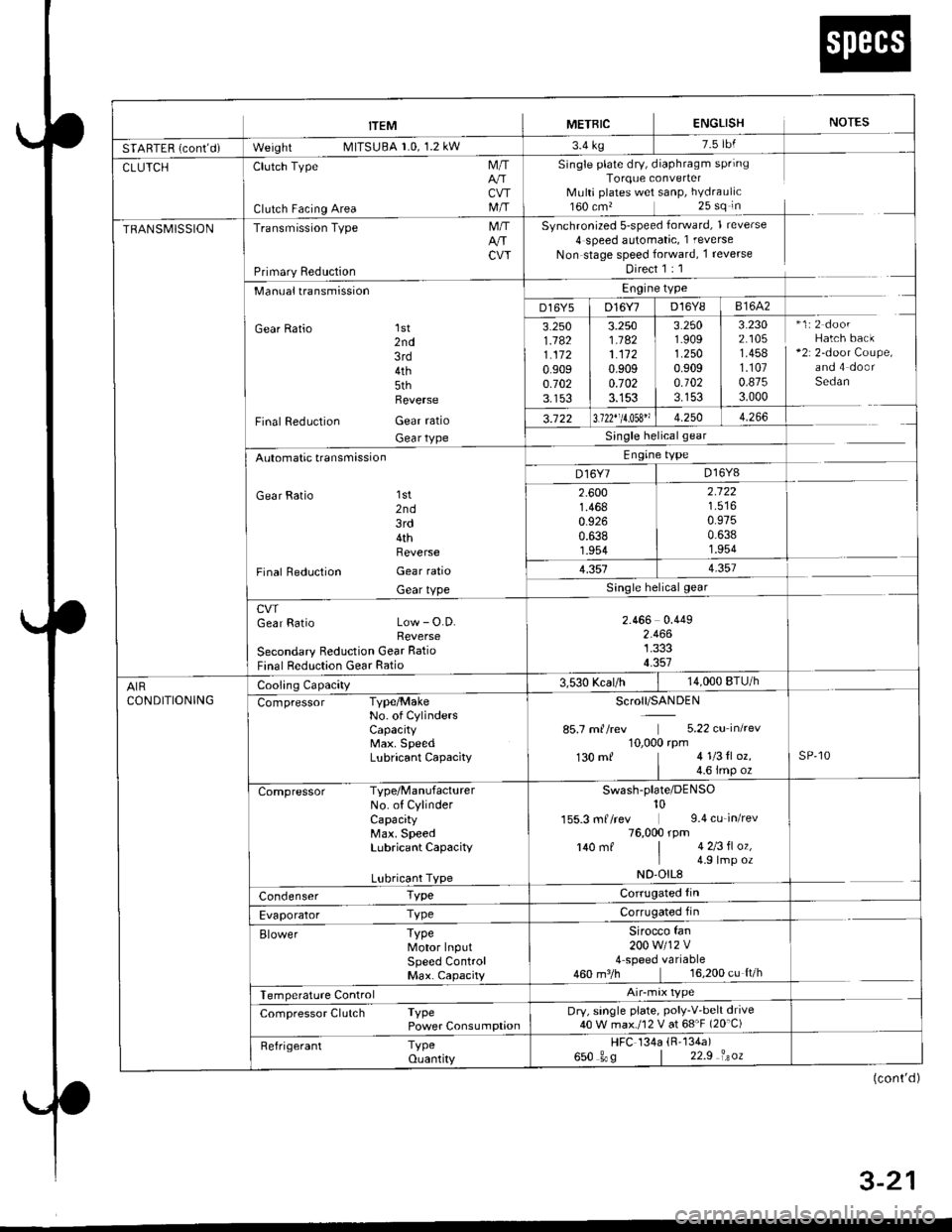

trEM I merntc ENGLISH NorEs

SfAnff n i*nt-i- W"'gf,t MllSUBA r.u, l.z kw r'4 rg

CLUTCHClutch Type

Clutch Facing Area

M/T

CVTM/T

Single plate dry, diaphragm springTorque converterMulti plates wet sanP, hYdraulic160 cm,25 sq in

Synchronized 5-speed forward, 1 reverse

4 speed automatic, 1 reverse

Non stage speed forward, 1 reverse

Direct 1 : 1

TRANSMISSIONTransmission Type

Primary Reduction

M/TArrCW

Manualtransmission

Gear Ratio 1st2nd3rd4th5thReverse

Final Reduction Gear ratio

Gear tYPe

Engine type

D16Y5 | D16Y7 D16Y8 I 81642

3.2501.1821.1120.9090.7023.153

3.2501.1821.1120.9090.7023.153

3.2501.9091.2500.9090.1023.153

3.2302.1051.4581.1070.8753.000

*1:2 doorHatch back+2r 2-door Coupe,and 4 doorSedan

3.122 13.122"11.053" 1 4.250 | 4.266

Single helicalgear

Engine type

D16Y7 | D16Y8Automatic transmission

Gear Ratio 'lst

2nd3rd4thReverse

Final Reduction Gear ratio

Gear tYPe

2.6001.4680.9260.6381.954

2.122

0.9750.6381.954

1.3514.357

cwGear Ratio Low - O.D.Reverse

Secondary Reduction Gear Ratio

Final Reduction Gear Ratio

2.466 0.4492.4661.3334.357

AIRCONDITIONING

Cooling Capacity3,530 Kcal/h14,000 BTU/h

Compressor Type/MakeNo. of CYlindersCaPacitYMax. SpeedLubricant CaPacitY

Scroll/SANDEN

85.7 m//rev 5.22 cu inkev10,000 rpm130 mf 41l3tl oz.

| 4.6 imp ozsP,10

Compressor Type/ManufacturerNo. of CylinderCapacityMax. SpeedLubricant CaPacitY

Lubricant TYPe

Swash-plate/DENso10155.3 mf /rev 9.4 cu_in/rev76,000 rpm140 mf | 4 2l3fl oz,I 4 9lmp ozND'OIL8

Condenser TypeCorrugated fin

Evaporator TyPeCorrugated fin

Elower TyPeMotor InputSPeed ControlMax. CaPacity

Sirocco fan200w112v4 speed variable460 m3/h 16,200 cu ft/h

Temperature Control

Compressor Clutch TyPePower ConsumPtionDry, single plate, PolY-V'belt drive40 W max./12 V at 68'F (20'C)

Refrigerant TyPeouantity

HFC 134a (R'134a)

650 gos | 22.9 isoz

(cont'd )

4 . J-Z I

Page 67 of 2189

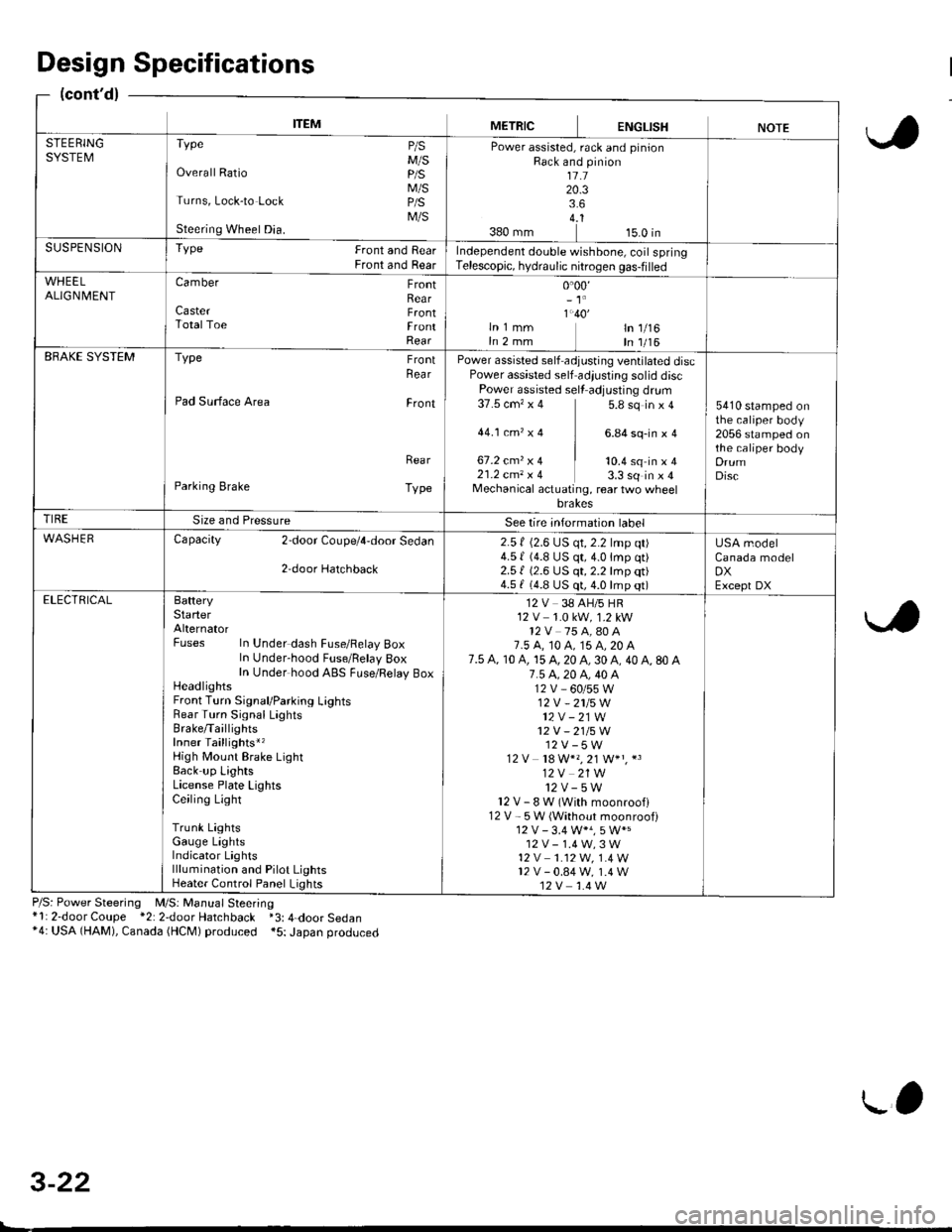

ITEMMETRICENGLISHNOTESTEERINGSYSTEMTvpe P/sM/SOverall Ratio p/S

M/STurns, Lock-to Lock p/S

M/SSteering Wheel Dia.

Power assisted, rack and pinionRack and pinion1l.120.33.64..1380 mm 15.0 inSUSPENSIONTYPe Front and RearFront and RearIndependent double wishbone, coil springTelescopic, hydraulic nitrogen gas-filled

WHEELALIGN| 4ENTCamber FrontRearCaster F.ontTotalToe FrontRear

0.00,- 't'

1.40'ln 1 mm ln 1/16In 2 mm In 1/16EBAKE SYSTEMType FrontRea r

Pad Surface Area Front

Rea r

Parking Brake Type

Power assisted self adjusting ventilated discPower assisted self adiustjng solid discPower assisted sell adjusting dr!m37.5 cm'�x 4 5.8 sq in x 4

44.1ctn,x4 ] 6.84sq-inxa

67.2 cmz x 4 | to.+ sq in ' I21.2 cm, x 4 3.3 sq in x 4Mechanical actuating, rear two wheelbrakes

5410 stamped onthe caliper body2056 stamped onthe caliper bodyDrumDisc

TIRESize and PressureSee lire intormation label

WASHERCapacity 2door Coupe/4,door Sedan

2,door Hatchback

2.5 f (2.6 LJS qt, 2.2 lmp qt)4.5 | (4.8 US qt,4.0lmp qt)2.51 (2.6 US qt, 2.2 lmp qt)4.5 f (4.8 US qt, 4.0 lmp qt)

USA modelCanada modelDXExcept DXELECTRICALBafteryStarterAlternatorFuses In Under dash Fuse/Felay BoxIn Under-hood Fuse/Belay 8oxIn Under hood ABS FLrse/Relay BoxHeadlightsFront Turn Signal/Parking LightsRear Turn Signal LaghtsBrake/TaillightsInner Taillights*,High Mount Brake LightBack up LightsLicense Plate LightsCeiling Light

Trunk LightsGauge LightsIndicator Lightslllumination and Pilot LightsHeater Control Panel Lights

12 V 38 AH/5 HR12 V 1.0 kW, 1.2 kW12V 75 A,80 A7.5 A, t0 A, 15 A, 20 A7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A, 80 A7.5 4.20 A, 40 A12V_60/55W12V -2115W

12V - 21W12V - 21/5W12V-5W12 V 18 W*" 21 W+" *3

12V 21W12v-5wl2V-8W(Withmoonroofl12 V - 5W (Without moonroof)

12V-1.4W,3W't2 v 1.12W. 1.4 W12v-0.84w, 1.4 W12V 1.4 W

Design Specifications

(cont'd)

P/S: Power Steering M/S: Manual Steering*l: 2-door Coupe *2: 2door Hatchback *3: 4-door Sedan*4: USA (HAM), Canada (HCM) produced *5: Japan produced

3-22

L'

Page 214 of 2189

Cylinder BlockPiston Pins

Bore Honing

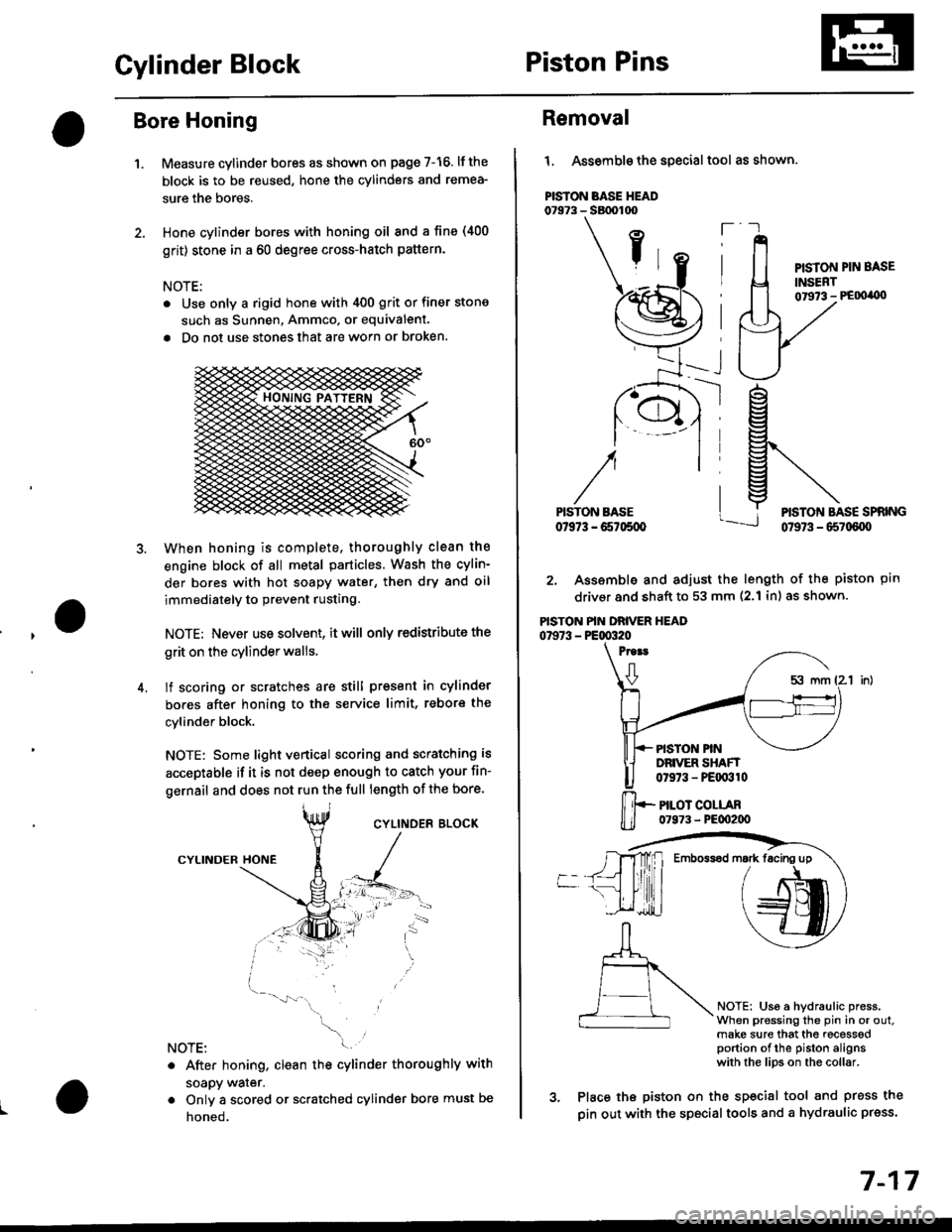

1.Measure cylinder bores as shown on page 7-16. lf the

block is to be reused, hone the cylinders and remea-

sure the bores.

Hone cylinder bores with honing oil 8nd a fine (400

grit) stone in a 60 degree cross-hatch pattern.

NOTE:

. Use only a rigid hone with 400 grit or finer stone

such as Sunnen, Ammco, or equivalent.

. Do not use stones lhat are worn or broken.

When honing is complete, thoroughly clean the

engine block of all metal particles. Wash the cylin-

der bores with hot soapY water, then dry and oil

immediately to prevent rusting.

NOTE: Never use solvent. it will only redistribute the

grit on the cylinder walls.

lf scoring or scratches are still present in cylinder

bores after honing to the service limit, rebore the

cylinder block.

NOTE: Some light vertical scoring and scratching is

acceptable if it is not deep enough to catch your fin-

gernail and does not run the full length of the bore.

CYLINOES BLOCK

CYLINDER

NOTE:

. After honing, clean the cylinder thoroughly with

soapy warer.

. Onlv a scored or scratched cylinder bore must be

noneo.

Removal

l. Assemble the special tool as shown.

PISTON BASE HEAD07973 - SBtx)too

ft

PISTON PIN BASE

INSERT01973 - PE00'0)

ptn

NOTEi Us6 a hydraulic press.When pressing the pin in or out.make sure that the recesssdportion of the piston alignswith the lips on the collar.

rg

g\

lj*N*,""

2. Assemble and adjust the length of the piston

driver and shaft to 53 mm (2.1 inl as shown.

PISTON PIN DRIVER HEAD07973 - PE00320

Proat

0

PISTON PINDRIVER SHAFT0t973 - PEqr310

PILOT COLLAR07973 - PE00200

3. Place the piston on the sp€cial tool and press the

pin out with the special tools and a hydraulic press.

Emboss6d mark facing up

7-17

Page 215 of 2189

Connecting RodsPiston Pins

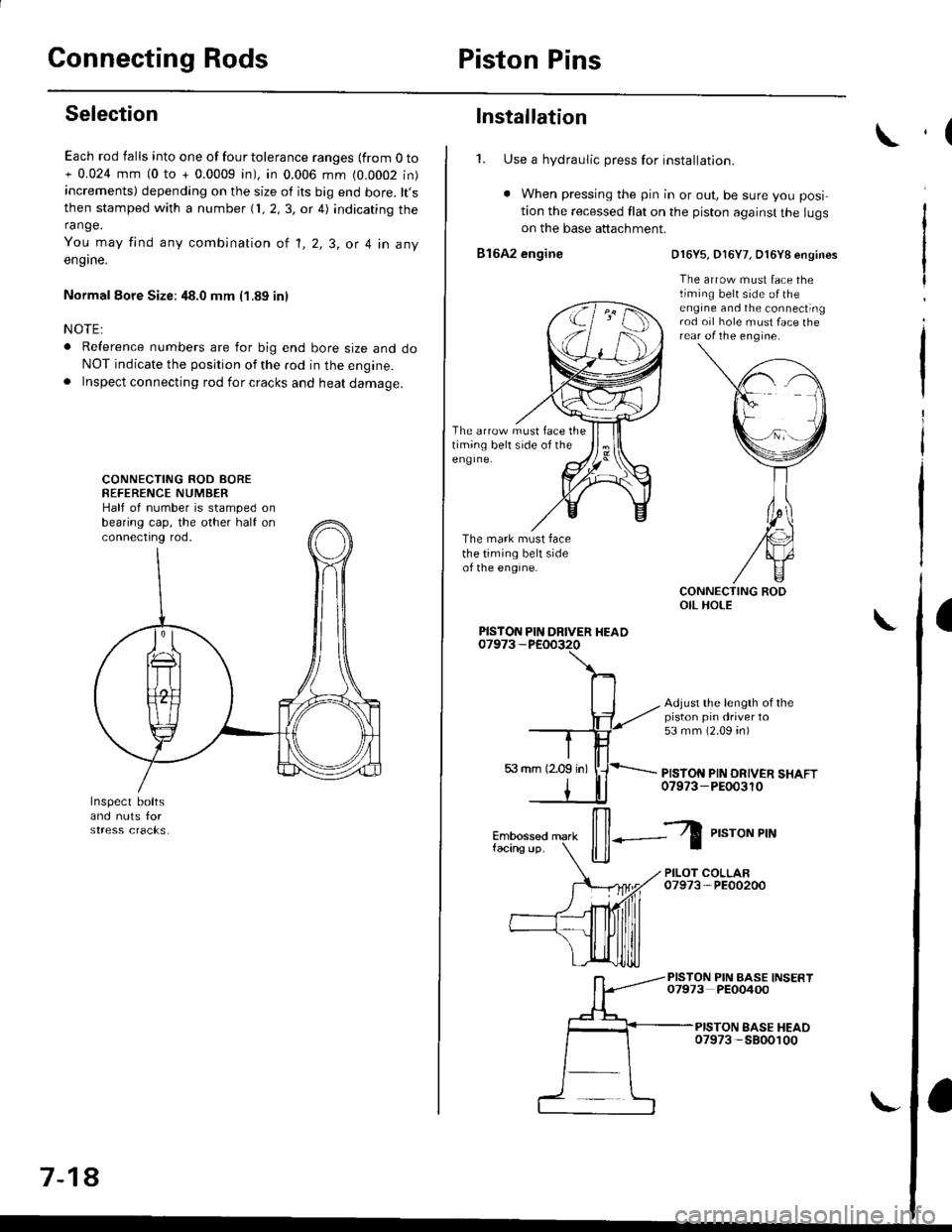

Selection

Each rod falls into one of four tolerance ranges {from O to+ 0.024 mm (0 to + 0.0009 in), in 0.006 mm (0.0002 in)increments) depending on the size of its big end bore. lt,sthen stamped with a number {1, 2,3, or 4) indicating therange.

You may find any combination ot l, 2, 3, or 4 in any

engrne.

Normal Eore Size: 48.0 mm (1.89 in)

NOTE:

o Reference numbers are for big end bore size and doNOT indicate the position of the rod in the engine.. Inspect connecting rod for cracks and heat damage.

CONNECTING ROD AOREREFERENCE NUMBERHalf of number is stamped onbearing cap, the other half onconnectrng rod.

7-18

Installation

1. Use a hydraulic press for installation.

. When pressing the pin in or out, be sure you posi

tion the recessed flat on the piston against the lugson the base attachment.

816A2 engine

The arrow must face thetiming belt side of theeng Ine.

The mark must facethe timing belt sideof the engine.

D16Y5, D16Y7, O16Y8 engines

The arrow must face thetiming belt side o{ theengine and the connectingrod oil hole must face therear of the engine.

Adjust the length of thepiston pin driver to53 mm (2.09 4n)

PISTON PIN DRIVER SHAFT07973-PEOo3r0

PISTON PIN DRIVER HEAD

il--Z

P,"roNPrN

PILOT COLLAR07973-PE00200

PISTON PIN BASE INSERT07973 PEO0400

PISTON EASE HEAO07973 -5800100

,(

a

Page 570 of 2189

lllustrated Index

\

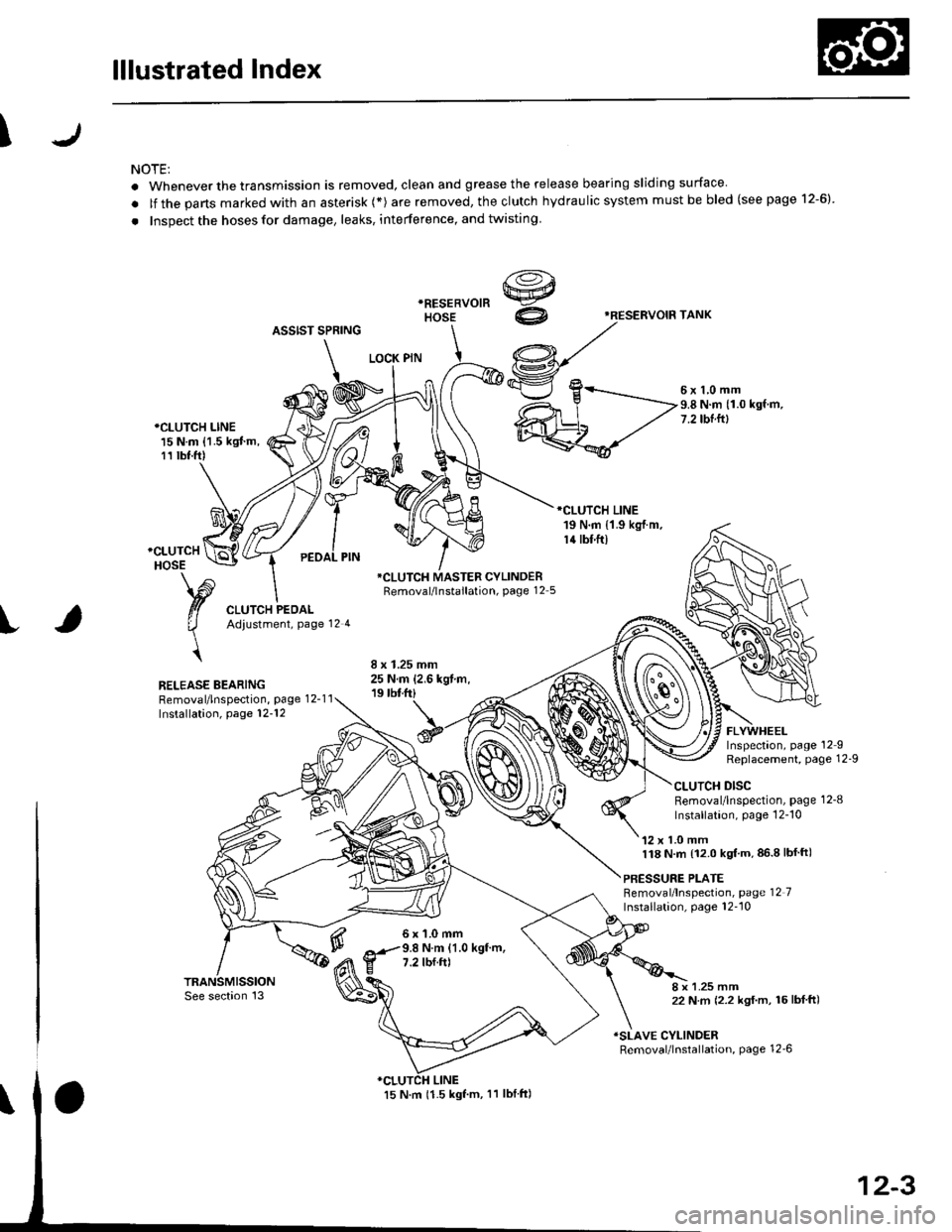

NOTE:

. Whenever the transmission is removed, clean and grease the release bearing sliding surface

. lf the parts marked with an asterisk (*) are removed, the clutch hydraulic system mustbe bled (seepage 12-6)

. Inspect the hoses for damage, leaks, interference, and twisting

'RESERVOIF TANK

ASSIST SPRING

LOCK PIN

5x1,0mm9.8 N.m (1.0 kgf.m,7.2 tbtftl*CLUTCH LINE15 N.m {1.5 kgJ m,11 tbt.ft)

RELEASE BEARINGRemoval/lnspection, page 12-1 1Installation, page 12-'12

*CLUTCH MASTER CYLINDERRemoval/lnstallation, page 12 5

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbf.ft)

FLYWHEELInspectaon, page 12IReplacement, Page 12-9

CLUTCH DISCRemoval/lnspection, page 1 2-8

lnstallation, page 12-'10

'12 x 1.0 mm118 N.m {12.0 kgt'm,86.8lbfft)

PBESSURE PLATEBemoval/lnspection, page 12 7Installation, page 12''10

8 x 1.25 mm22 N m (2.2 kgf.m, 16lbf ft)

ISLAVE CYLINDERRemoval/lnstallation, page 12_6

12-3

Page 572 of 2189

Glutch Master Gylinder

IRemovaUlnstallation

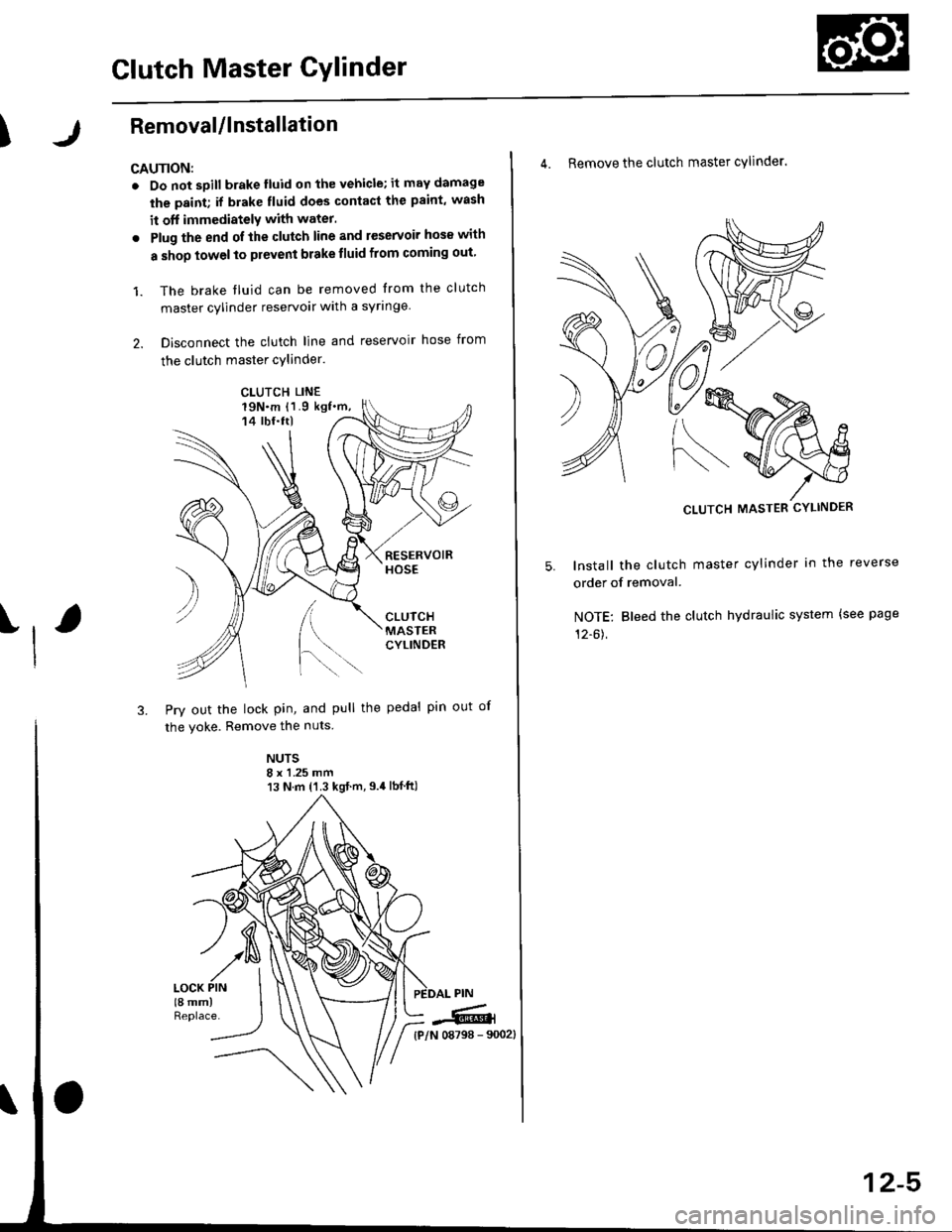

CAU'NON:

. Do not sDill brake lluid onthevehicle;it may damage

the paint; if brake fluid does contact the paint, wash

it off immediatelY with water.

. Plug the end ofthe clutch line and reservoir hos€ with

a shop towelto prevent brake tluid from coming out

1. The brake tluid can be removed from the clutch

master cylinder reservoir with a syringe

2. Disconnect the clutch line and reservoir hose from

the clutch master cylinder.

19N.m 11.9 kgf.m,14 tbf.ttl

[.

3. Pry out the lock pin, and pull the pedal pin out

the yoke. Remove the nuts

NUTS8 x 1 .25 mm13 N.m {'1.3 kgt.m,9.4lbf ft)

)

of

CLUTCH LINE

iffi,

4. Remove the clutch master cylinder.

CLUTCH MASTER CYLINDER

lnstall the clutch master cylinder in the reverse

order of removal.

NOTE: Bleed the clutch hydraulic system {see page

12-61,

12-5

Page 573 of 2189

Slave Gylinder

Removal/lnstallation

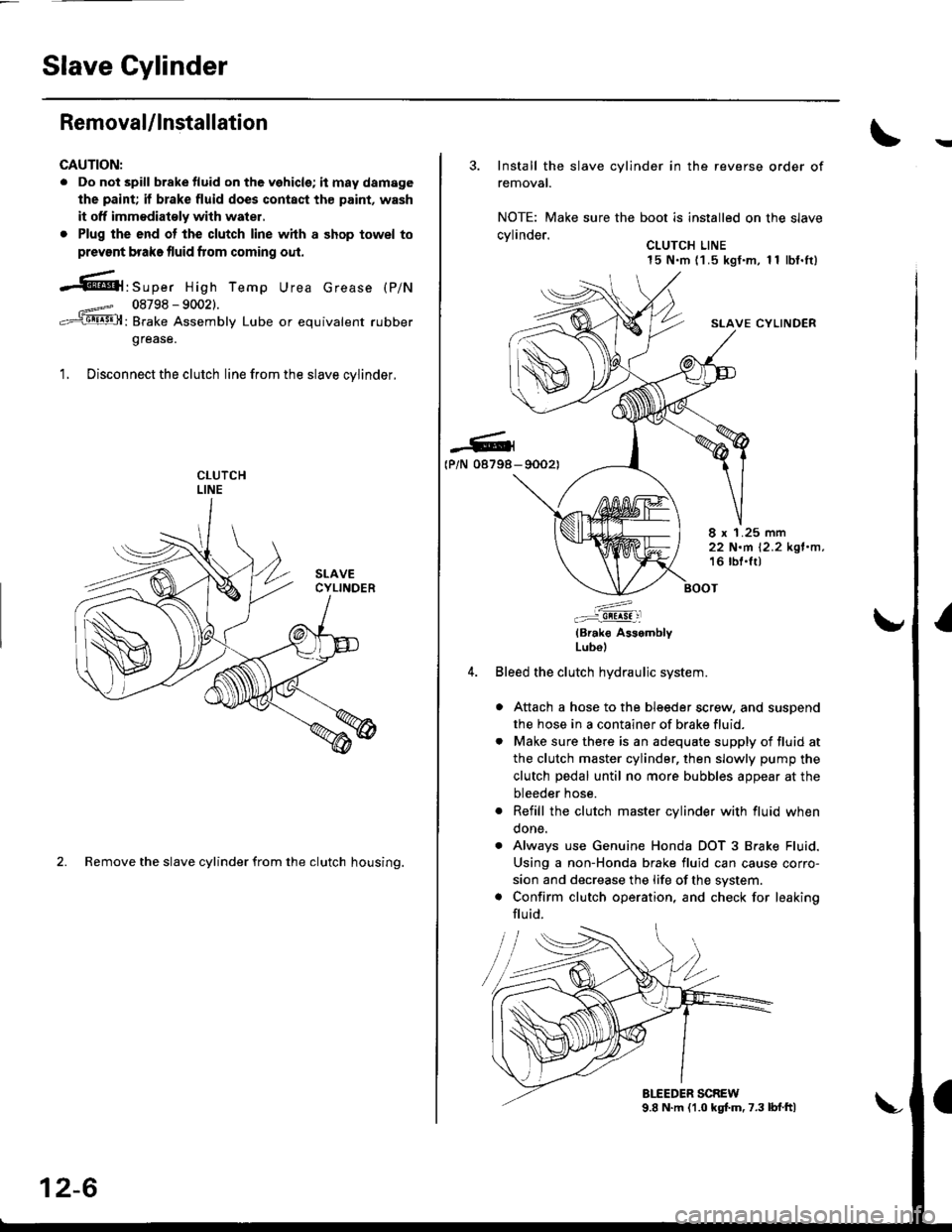

CAUTION:

. Do not spill brake tluid on the vehicle; it may damage

the paint; if brake fluid does contact th€ paint, wash

it off immodiatoly with water,

. Plug the end ot the clutch line with a shop towel to

prevsnt brake fluid from coming oul.

-61'srp", High Temp Urea crease (p/N

08798 - 90021.

: Brake Assembly Lube or equivalent rubber

grease.

1. Disconnect the clutch line from the slave cvlinder.

2. Remove the slave cylinder from the clutch housing.

12-6

3. Install the slave cylinder in the reverse order of

removal.

NOTE: Make sure the boot is installed on the slave

cvlinder.. CLUTCH LINE15 N.m (1 .5 kgf.m, 1 1 lbf.It)

SLAVE CYLINDER

-G4(P/N 08798- 90021

8 x 1.25 mm22 N.m 12.2 kgl.n,16 lbl.lt)

:^..:i!!!!! :l

(Brak€ AssemblyLubol

Bleed the clutch hydraulic system.

a Attach a hose to the bleeder screw, and suspend

the hose in a container of brake fluid.

. Make sure there is an adequate supply of fluid at

the clutch master cylinder, then slowly pump the

clutch pedal until no more bubbles appear at the

bleeder hose.

. Refill the clutch master cylinder with fluid when

done.

. Always use Genuine Honda DOT 3 Brake Fluid.

Using a non-Honda brake fluid can cause corro-

sion and decrease the life of the system.

. Confirm clutch operation, and check for leaking

flu id.

Page 679 of 2189

Automatic Transmission

Special Tools ......... .....'."".'-.-.' 14'2

Description .,....................-...... 14-3

power Flow ......,................. 14"6

Elestronic Control System .... . ................'..'.'.. 14-13

Hvdraulic Control .....'......" 1'l-19

Hydraulic F|ow...... .'.'.".'....11-21

Lock-up System '............ ... t/t'33

Electrical System

Component Locations....,.............'......'.............'.,. 14'39

PCM Circuit Diagram

lA/T Control Syst€m: '96 - 98 Models) .........'.. 1/t-40

PCM Tarminal Volt8ge/Measuring Condhions

{'96 - 98 ModeblA/T Control System ............

PCM Circuit Disgram(A/T Conlrol System: '99 - 00 Modsls) '..........' 14-44

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)A/T Control System ...

Troubleshooting Proceduros ....

Symptom-to-ComPonent Chari

Efectricaf SFiem - '96 - 98 Models '..-.-..."'.'..11-52

Eloqtrical System -'99 - 00 Modols ... .........". 1+54

EleclricatTroubl$hooting ('96 - 98 Models)

Valve Body

Repair .................... ........'.... 14-139

Valve

Assembly

ATF Pump

1,1-1i10

Inspection ...........'.......... 14-141

Main Valvs Body

Disass€mbf y/lnspoction/R.sssembly .'.'.'.'.. -. -. 1 1-1 12

Secondsry Valve BodY

Disa$embfy/lnspoction/Rsassembly ......'.'.'.'. 11-111

Regulator Valve Body

Disa$embly/lnspoction/Rea3sembly ..........'... 14-1{5

Servo Body

Disassombly/lnsp€ction/Reassembly .".'........ 14-146

Lock-up Valv6 Body

Dis$s.mbf y/ln3poction/Rea$embly .'.. -. -..'.'.' 1 1-1 17

Mainsh!ft

Dkassembly/lnep€ction Reassembly ..'...'........ 14'148

Inspoction .............'..........'. l it-149

Countsrshaft

Disa$embly/lnspeqtion/Rea3sembly .......'...'.. 1a-l51

Dba$ombly/Re$s.mblY11-152

til-46

I rl-48

Troubleshooting Flowcharts

Electrical Troubleshooting ('9!t - 00 Models)

Troublsshooting Flowchart3

Lock-up Control Solenoid vslvo A/B AssemblY

RePlacoment

Shift Cont.ol Solenoid Valve A/B A3sembly

Inspestion

Ona-way Clutch

Disassembh/lrupoction/Rca$embly .. "'........ l4-155

Clutch

lllustlttcd Ind.x {A48A, B4RA Transmlssion) ..' 14-156

tustr.tod Index (MrnA Transmi$ionl ............ til-158

...................... 14-153

L

14-56

1+81'

14-105

1+105

Replacoment ......

Mainshaft/Countorshaft Spo€d Sonsors

Replacemsnt ......'."'........... lit'108

Hydraulic System

Symptom-to-Componeni Chart

Hydraulic Sydemr+109

t4-113

1+116

11-117

Rea$emblY

14-106 Difforrr ial

llhdraied Index........ t4-156

B.ckhrh ln3poction. 14-167

Boaring Roplacemont..-..........11-167

..... 14-108 Diftrrsniial Carrior Repl8cemeni .'.-.............'...' lil-168

Oil Sall Romovalt4-t 59

Oil Soal ln3tallstion/Sidc Clearance'......'.....'... 1'l'169

Torqua Convertcr Housing Boarings

Mlin3haft Besring/Oil Scal Roplac.ment ."..'.. lil-172

Counio6hatt Betring R.plscem.nt ..'...... ....... 14-173

Test.....,......14-106

14-107

14-160

11-162

11-171

11-175

Replacement

Test .....,.,..........

Road Te3t

Linear Solenoid AsssmblY

Stall Speed

lllustrated Indax

Transmission/End Cover'. ....

Transmission Hou3ing,.............'.'......'....""..-.-.. 11-128

Torque Conve.ter Housing/Valvo Body ........... 14-130

End Cover

14-itB Park Stop

1+119 In3pection/Adiustmsnt...'......'.'............'...."""'14-175

Transmbgion

Reassombly

11-122 Torquo Convertet/Drivr Plsie ............'.'............'.. . l4-182

Transmission

11.726 Inrtallation

Tranlmission Housing Boarings

Msinsh.ft /CounteEhaft Bearings

B!pltcomgnt

Rcvo.3s ldlor Gear

lnrtallation

Cooler Flushing ..

Shift Cabls

Test

Fluid Level

Checkin9 .........."..'.'.....

Changing

Pressure Testing

Transmission

Transmission

Rgmoval ..

lil-176

.'..........'.'.'..... 1'l-183

.... lil-187

11-132Adiustmont

RemovaUlnttallation1,1-190

lit-191Transmisgion Housing

Removal ... '.'...... ......'..... 14-l3il

Tolque Convgrter Housing/valvs Body

Rsmoval .........,...... ............. 14-136

Valve CaDs

Description .......'................. t 4'138

Shift lndicator Panel

Adiu3tmant ..'.................. 14-192

ATF Coolor Hoses

Connection ..,............,.,....... l'l-192

Shift Lever .,........