Powertrain control module HONDA CIVIC 1997 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 377 of 2189

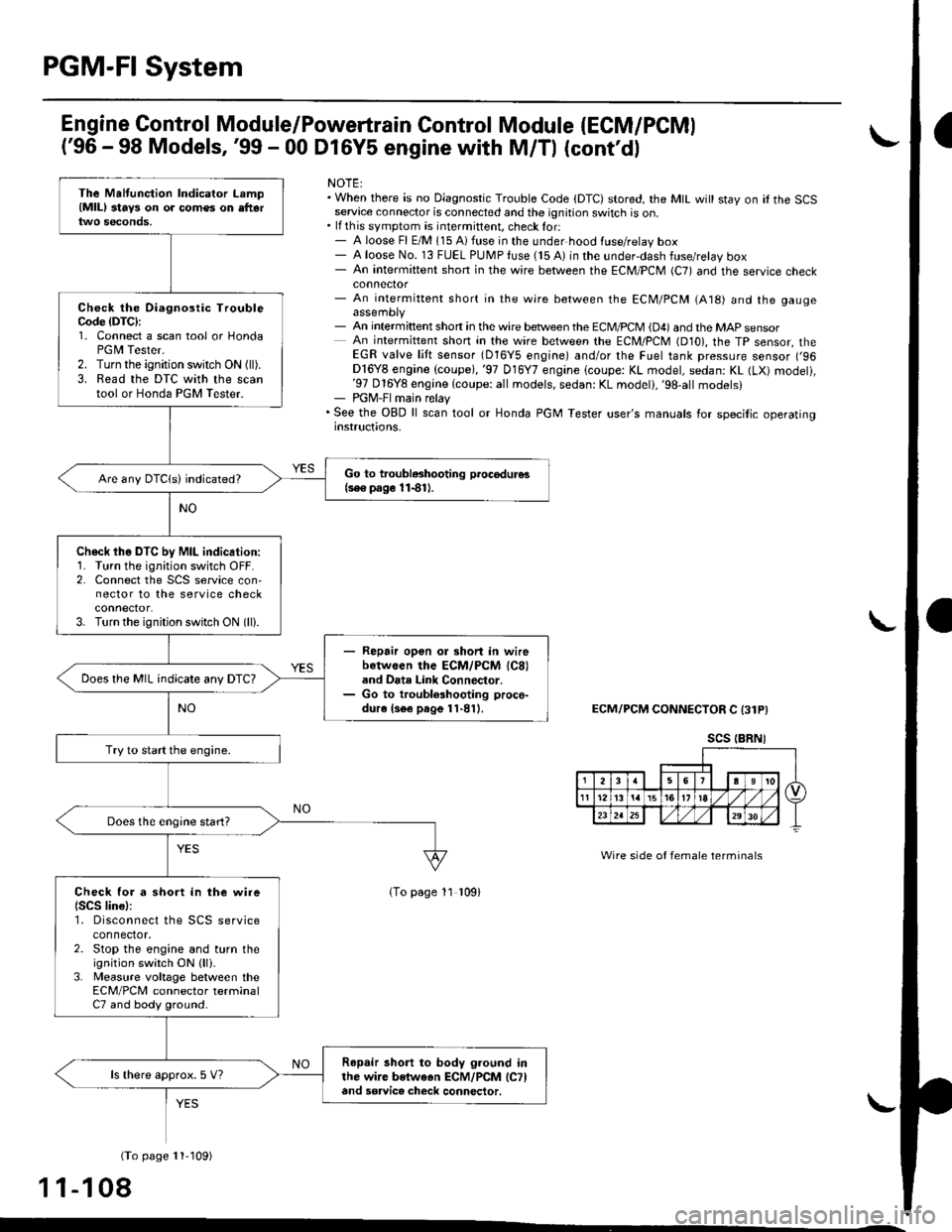

PGM-FI System

Engine Control Module/Powertrain Control Module (ECM/PCMI

('96 - 98 Models,'99 - 00 Dl6Y5 engine with M/Tl (cont'd)

NOTE:. When there is oo Diagnostic Trouble Code (DTC) stored, the MtL wi

stay on if the SCSservace connector is connected and the ignition switch is on,. lf this symptom is intermittent, checklor:- A loose Fl E/M 115 A) fuse in the under hood luse/relay box- A loose No. 13 FUEL PUMP fuse (15 A) in the underdash fuse/relay box- An intermittent shon in the wire between the ECM/PCM (C7) and the service cnecKconnector- An intermittent short in the wire between the ECM/PCM (A18) and the gaugeassembly- An intermittent shon in the wire between the ECM/PCM {D4) and the MAp sensorAn intermittent short in the wire between the ECM/PCM (D10), the Tp sensor, theEGR valve l:ft sensor (D16Y5 engine) and/or the Fuel tank pressure sensor (,96Dl6Y8 engine (coupe), '97 016Y7 engine (coupe: KL model, sedan: KL (LX) modeli,'97 016Y8 engine {coupe: all models, sedan: KL modeti,'98,all models}- PGM-FImain relay. See the OBD ll scan tool or Honda PGM Tester user's manuals lor specitic operatinginstructions.

ECM/PCM CONNECTOR C 13lPI

Wire side of female terminals

(To page 11 109)

(To page 11,109)

11-108

The Maltunction Indicator Lamp(MlLl stays on o. comes on eftartwo s€conds,

Check the Oiagnoslic TroubleCode {DTC}I1. Connect a scan tool or HondaPGM Tester.2. Turn the ignition switch ON (ll).

3. Read the DTC with the scantool or Honda PGM Tester.

Go to troubleshooting p.oc€dur€s(se€ pago 11{11.Are any DTC{s) indicated?

Check the DTC by MIL indication:1. Turn the ignition switch OFF.2. Connect the SCS service con,nector to the service checkconnector.3. Turn the ignition switch ON (lli.

Repair opon ol short in wirebotwoen the ECM/PCM (C8)

and Data Link Connector.Go to troublelhooting proce-dure ls6e page 11-811.

Does the MIL indicate any DTC?

Try to start the engine.

Does the engine start?

Check for a short in the wire(SCS lin€l:1. Disconnect the SCS serviceconnector.2. Stop the engine and turn theignition switch ON {lli.3. Measure voltage between theECM/PCM connector terminalC7 and body ground.

Ropair short to body Iround inthe wire betweon ECM/PCM lCTland sorvice check connector.

ls there approx. 5 V?

scs tBRNI

Page 379 of 2189

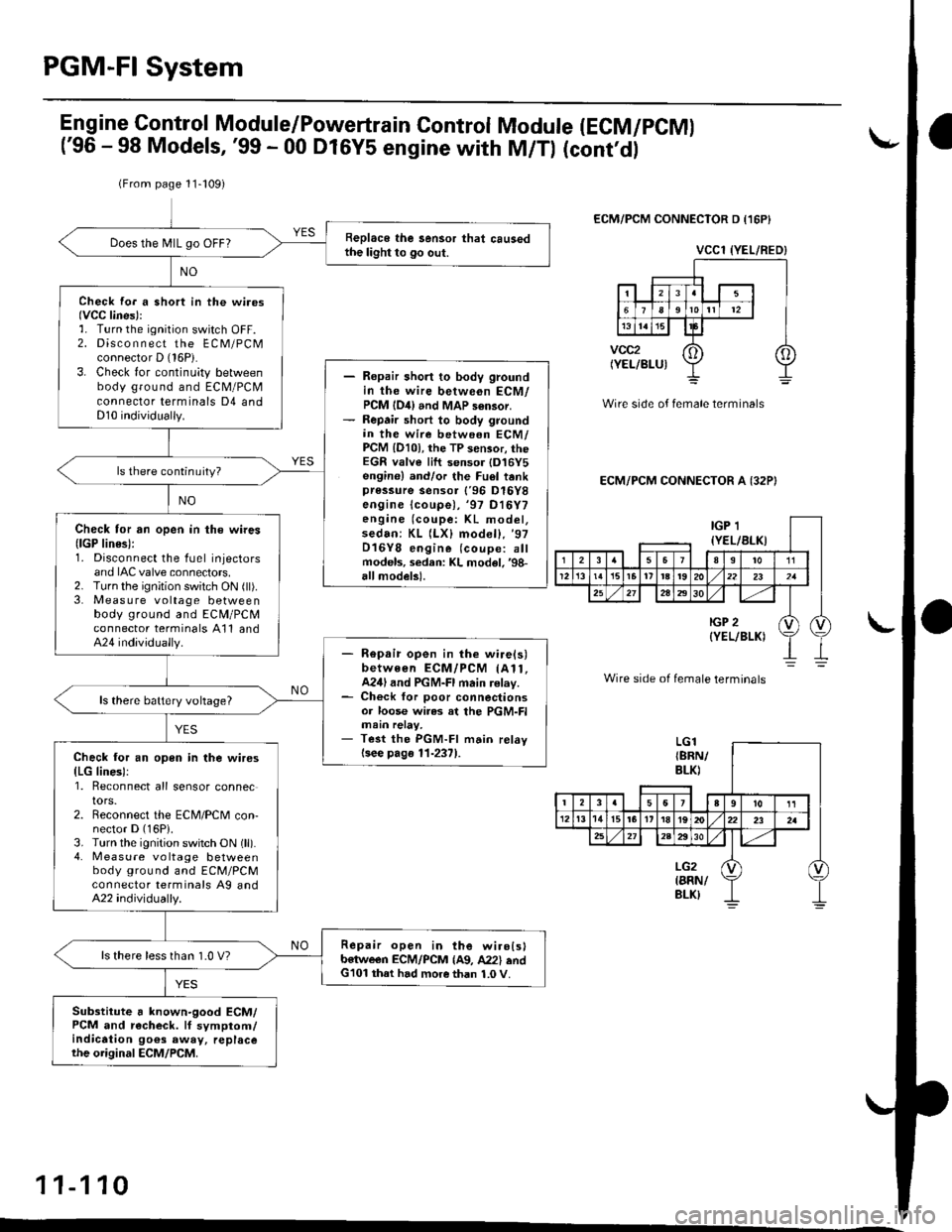

PGM-FI System

(From page 11-109)

Replace the sensor that causedthe light to go out.Does the N4lL go OFF?

Check fo. a short in the wi.os(VCC lines):':. Turn the ignition switch OFF.2. Disco n n ect the ECM/PCMconnector D (16P).

3. Check for continuity betweenbody ground and ECM/PCMconnector terminals D4 andD10 individually.

Ropair short to body groundin the wire betweon ECM/PCM {O4) and MAP s6n3or.Repair short to body groundin the wire between ECM/PCM lD10l, the TP sensor, theEGR valve lift sensor {D16Y5engine) and/or the Fuel tankpressure sensor {'96 Dl6Ygengine lcoupe),'97 D16Y7engine (coupe: KL model,sedan: KL (LXl model), '97

D16Y8 engine (coupe: allmodels, sedan: KL model. €8-allmodelsl.

ls there continuity?

Check tor rn open in the wires(lGP lines):1. Disconnect the fuel injectorsand IAC valve connectors,2. Turn the ignition switch ON (ll).3. Meas u re voltage betweenbody ground and ECM/PCMconnector terminals A11 and424 indivjdually.- Repair open in the wirels)between ECM/PCM (A11,A24land PGM-Fl main relay.- Check for poor connectionsor loose wiras at the PGM-FImain relay,- Test the PGM-FI mdin relavlsee pag6 11-237).

ls there battery vohage?

Check for an open in the wires(LG line3):1. Reconnect all sensor connectors.2. Reconnect the ECM/PCM con-nector D (16P).

3. Turn the ignition switch ON (ll).4. Measure vo ltage betweenbody ground and ECM/PCMconnector terminals Ag andA22 individually.

Repair open in the wirolglb€twe€n ECM/PCM {A9, A22} andG101 that had more than 1.0 V.

ls there less than 1.0 V?

Substitute 6 known-good ECM/PCM and r€check. lf symptom/indication 9o€s away, replacethe original ECM/PCM.

Engine Control Module/Powertrain Control Module (ECM/pCMl

('96 - 98 Models, '99 - 00 D16Y5 engine with M/Tl (cont,dl

ECM/PCM CONNECTOR D {16P}

Wire side of female terminals

ECM/PCM CONNECTOR A (32P}

Wire side of female terminals

11-110

LG1

VCCl {YEL/RED}

IGP 1{YEL/BLKI

2I11

1213l5t6Itt8t9202321

25272a2930

IGP 2(YEL/BLKIv) (l

{8RN/BLK)

I258tol1'12tt11t5l617t8t920232a

2A2330

LG2{8RN/8LK}

Page 380 of 2189

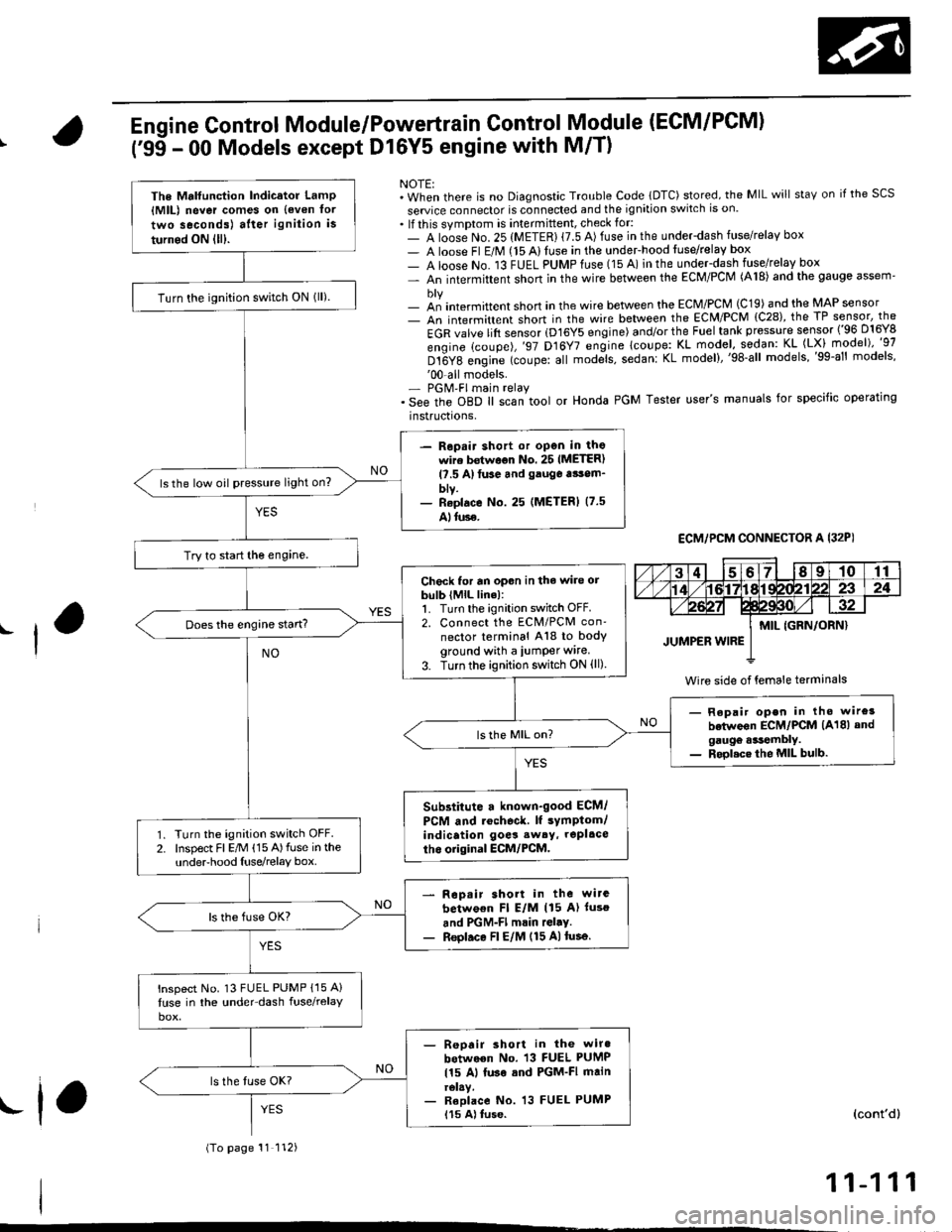

Engine Control Module/Powertrain Control Module (ECM/PCM)

('95 - 00 Models except Dl6Y5 engine with M/T)

NOTE:. When there is no Diagnostic Trouble Code lDTC) stored, the MIL will staY on if the SCS

seruice connector is connected and the ignition switch is on.. lf this symptom is intermittent, check for:- A loose No. 25 (METER) {7.5 A) fuse in the underdash fuse/relay box- A loose Fl E/M (15 Alluse in the undeFhood fuse/relay box- A loose No. 13 FUEL PUMPfuse (15 A) in the under-dash fuse/relay box- An intermittent shon in the wire between the ECM/PCM (A18) and the gauge assem'

- an intermittent short in the wire between the ECM/PCM (C19) and the MAP sensor- An intermittent short in the wire between the ECM/PCM {C28), the TP sensor, the

EGR valve lift sensor (D16Y5 engine) and/or the Fuel tank pressure sensor ('96 D16Y8

engine (coupe),'97 D16Y7 engine lcoupe: KL model, sodan: KL (LX) model)"g7

Dt6Y8 engine (coupe: all mod;ls, sedanl KL model),'98-all models,'99-al' models''00-all models.- PGM'FI main relay. See the oBD ll scan tool or Honda PGM Tester user's manuals for specific operating

instructrons,

ECM,/PCM CONNECTOR A I32PI

Wire side of {emale terminals

The Mrlfunction Indicator LamP{MlL) never comes on {even tor

two seconds) after ignition is

turned ON lll).

Turn the ignition switch ON lll).

- Repair shott or open in thowire bstwoon No. 25 IMETER)l?.5 A)tuse and gauga tsom_blv.- Reolace No. 25 (METERI (7.5

Alluse.

ls the low oil pressure light on?

Try to start the engine.

Check for an opon in the wire orbulb (MlL line):1. Turn the ignition switch OFF.2. Connect the ECM/PCM con'

nector terminal A18 to bodyground with a iumper wire.

3. Turn the ignition switch ON (ll)

Does the engine start?

- Repair open in tho wire3

betwoon ECM/PCM (A18) andgaugo .*tembly.- Rool.ce the MIL bulb.

Substitute a known-good ECM/

PCM and rochoc&. lf sYmptom/indication goes sw6y, repl.ce

tho original ECM/PCM.Turn the ignition switch OFF.Inspect Fl E/M (15 A)fuse in theunderhood Iuse/relay box.

Rop.ir short in the wirc

betwo€n Fl E/M (15 A) luso

and PGM-Fl mrin rGl.y.Reol.ce Fl E/M (15 A)tusa.

lnspect No. 13 FUEL PUMP {15 A}

luse in the under-dash fuse/relay

- Reoair short in the wiro

between No. 13 FUEL PUMP

115 Al luse sod PGM-FI mainrelay.- Reolace No. 13 FUEL PUMP115 A) tuse.

(To page 11 112)

(cont'd)

11-111

.f,

Page 381 of 2189

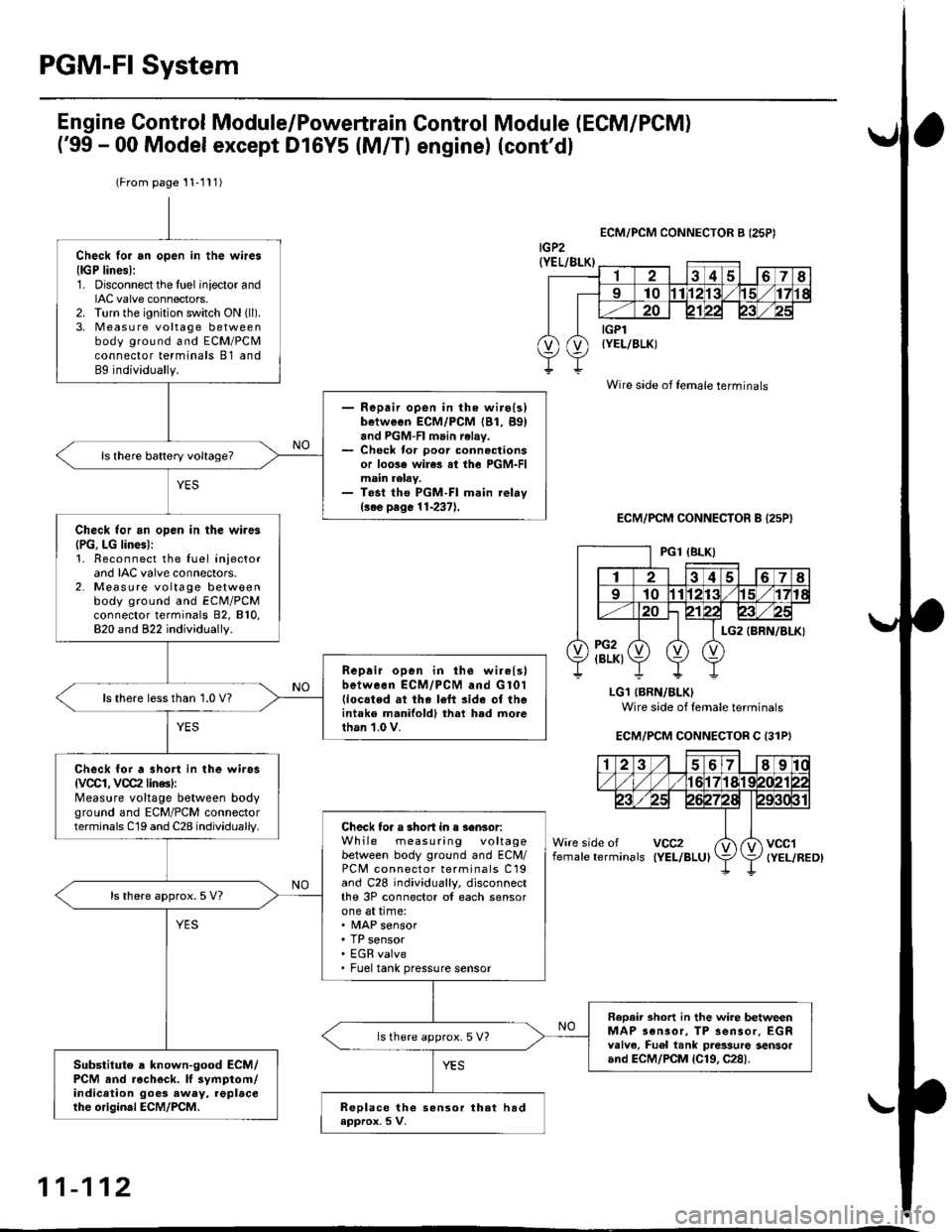

PGM-FI System

(From page'11-111)

Check loi an open in the wires(lGP linesl:1. Disconnect the lueliniector andIAC valve connectors.2. Turn the ignition switch ON (ll).

3, Measu re voltage betweenbody ground and ECM/PCMconnector terminals 81 andBg individually.

- Repair open in the wiro(3)between ECM/PCM lBl, B9land PGM-Fl main relay.- Check tor poor connectionsor loose wires al the PGM-FImain relav.- Test tho PGM-FI main rehy(3.e page 11-237).

ls there battery voltage?

Check tor an open in the wires(PG, LG lines):1. Reconnect the fuel iniectorand IAC valve connectors.2. Measure voltage betweenbody ground and ECM/PCMconnector terminals 82, 810,820 and 822 individually.

Repair open in the wirels)between ECM/PCM and G 101llocated ai the l6ft side of thointaks m.nifoldl thrt h.d morethan 1.0 V.

ls there lessthan 1.0 V?

Check for a short in the wires

{VCCI, VCC2 lin6s}:Measure voltage between bodyground and ECM/PCM connectorterminals C19 and C28 individually.Check toa a 3hort in s 3ensor:While measuring voltagebetween body ground and ECM/PC[/t connector terminals C19and C28 individually, disconnectthe 3P connector of each sensorone at time:. MAP sensor. TP sensor. EGR valve. Fueltank pressure sensor

ls there approx.5 V?

Reoair short in lhe wire betwe.enMAP 3ansor, TP sensor, EGRvalve, Fuel tank pres3ure 3ensorand ECM/PCM {Cl9, C28).

ls there approx. 5 V?

Substiiute a known-good ECM/PCM and racheck. ll symptom/indicetion goes eway, replaceth6 original ECM/PCM.Replace tho sansor that had.pprox. 5 V.

Engine Control Module/Powertrain

('99 - 00 Model except Dl6Y5 (M/Tl

Module (ECM/PCM)

(cont'd)

Control

engine)

ECM/PCM CONNECTOR B {25P)

LG1 (BRN/BLKI

Wire side of female terminals

ECM/PCM CONNECTOR C (31P)

female terminalsvcc2IYEL/BLUIvccl{YEL/RED)

Wire side of female terminals

11-112

Page 383 of 2189

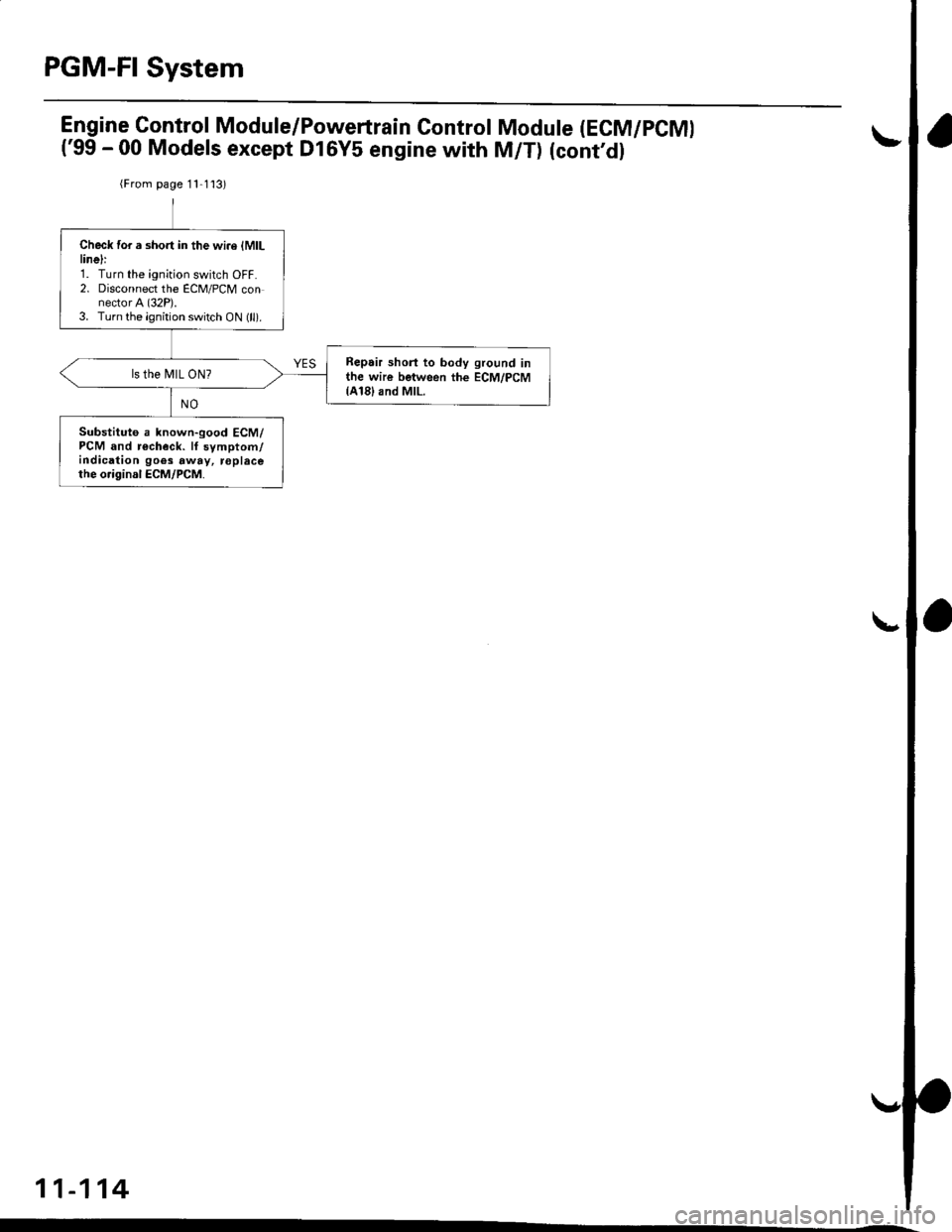

PGM-FI System

Engine Gontrol Module/Powertrain Control

('99 - 00 Models except Dl6Y5 engine with

Module (ECM/PCMI

M/T) (cont'dl

{From page 11 1 l3)

Check for a short in the wi.e lMlLlinelr1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM connector A (32P).3. Turn the ignition switch ON (ll).

Repair shorl to body ground inthe wire between the ECM/PCM{A18}and MlL.

ls the MIL ON?

Substituto a known-good ECM/PCM and r€check. lf symptom/indication goes away, roplacethe o.iginal ECM/PCM.

11-114

Page 681 of 2189

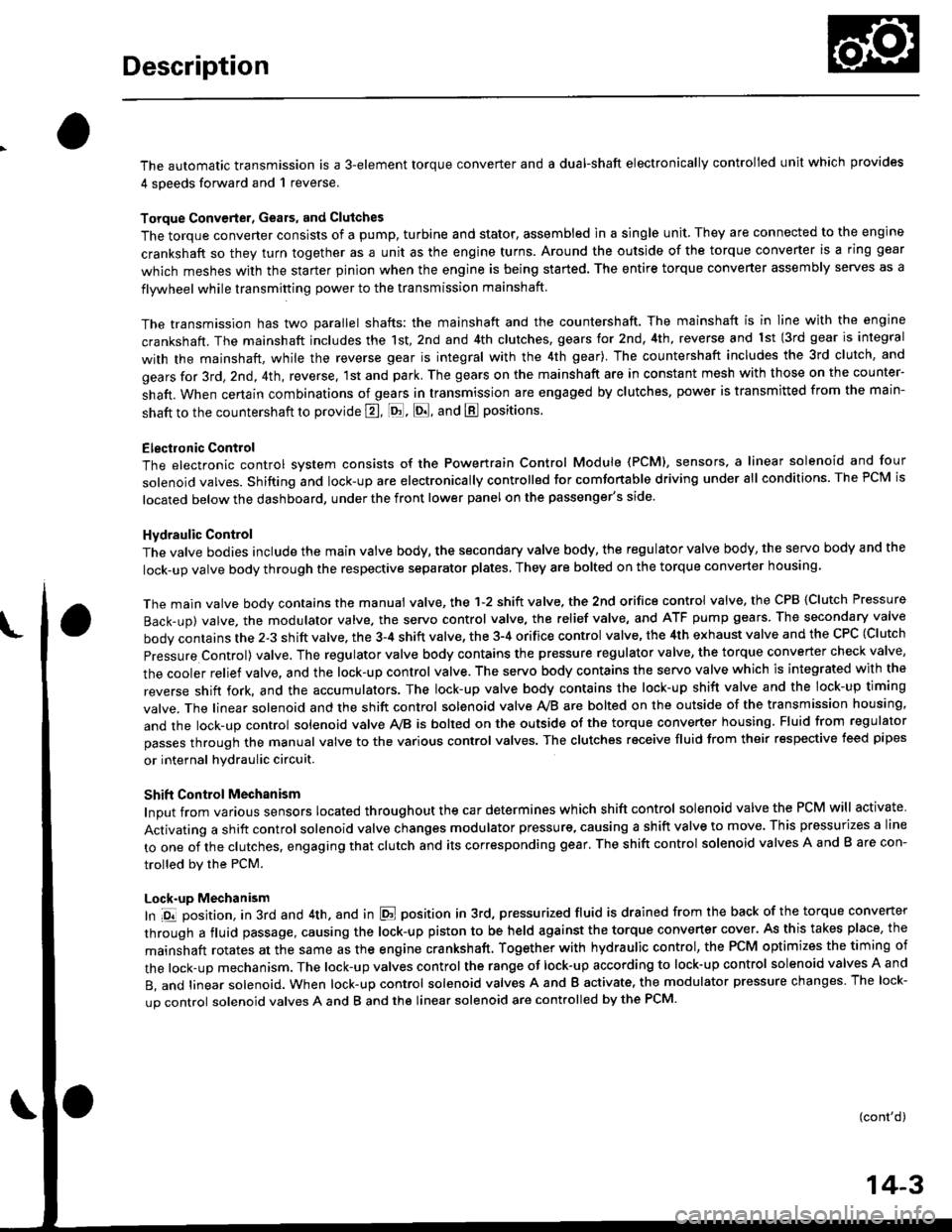

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3

Page 691 of 2189

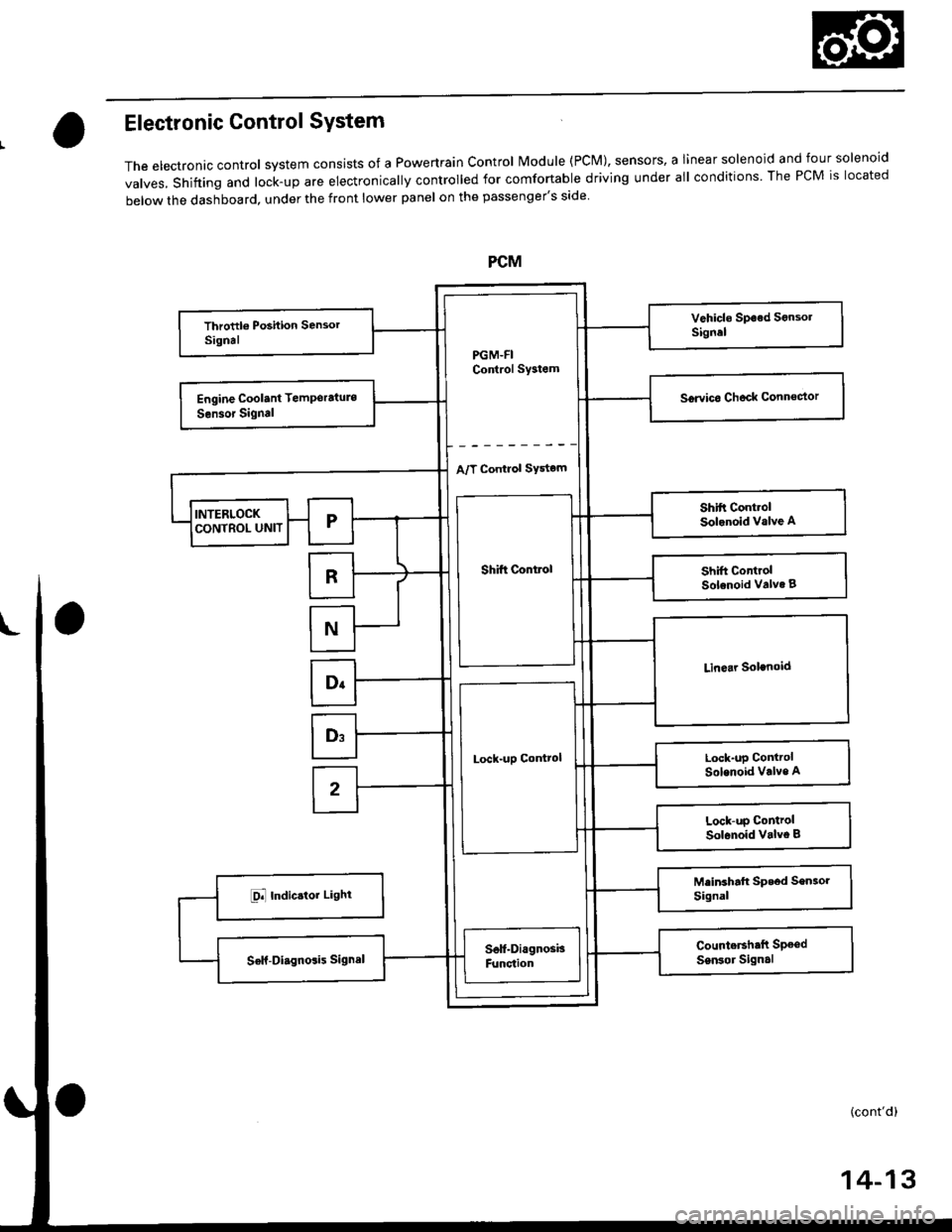

Electronic Control SYstem

The electronac controt system consrsts of a Powertrain control Module (PcM), sensors, a Iinear solenoid and four solenoid

valves, shifting and lock-up are electronically controlled for comfortable driving under all conditions The PCM is located

below the dashboard, under the front lower panel on the passenger's side

PGM-FIControl Sy3tem

A/T Control SYstom

Shift Control

Lock-uD Control

14-13

Page 717 of 2189

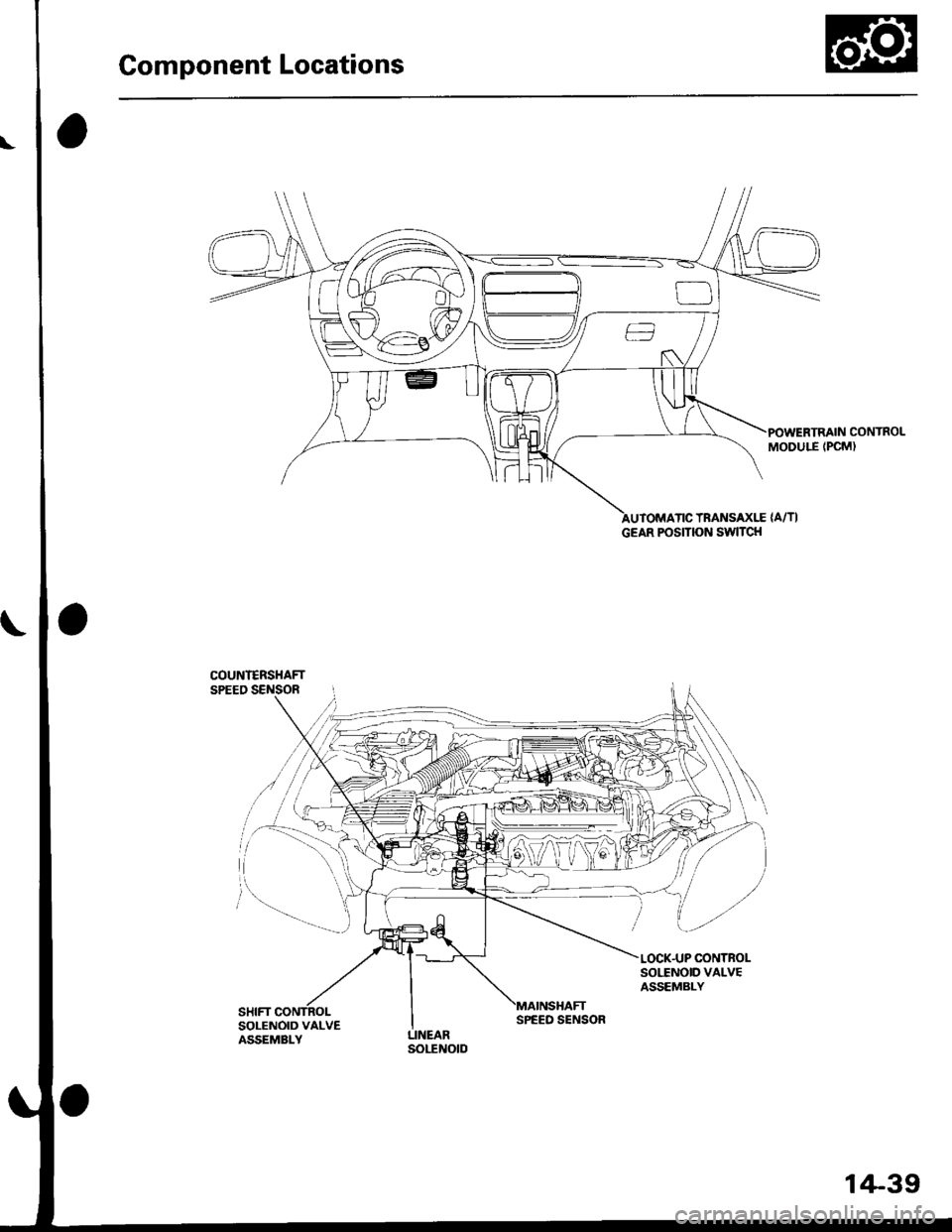

Component Locations

POWERTRAIN CONTROLMODULE (PCM)

TRANSAXLE {A/TI

COUNI€RSHAFTSPEED SENSOR

SOI,TNOID VALVEASSEMBLY

SOLENOID VALVEASSEMBLY

GEAR POSITION SWITCH

SPEED SENSOR

1+39

Page 873 of 2189

Description

The Continuously Variable Transmission (CVT) is an electronically controlled automatic transmission with drive and driv

en Oullevs, and a steel belt. The CVT provides non stage speeds forward and one reverse. The entire unit is positioned in

line with the engine.

Transmission

Around the outside of the flywheel is a ring gear which meshes with the starter pinion when the engine is being staned.

The transmission has four parallel shafts: the input shaft, the drive pulley shaft. the driven pulley shaft, and the secondary

gear shaft. The input shaft is in line with the engine crankshaft. The drive pulley shaft and the driven pulley shaft consist of

movable and fixed face pulleys. Both pulleys are linked by the steel belt.

The input shaft includes the sun gear. The drive pulley shaft includes the forward clutch which mounts the carrier assem-

bly on the forward clutch drum. The carrier assembly includes the pinion gears which mesh with the sun gear and the ring

gear. The ring gear has a hub-mounted reverse brake disc.

The driven pulley shaft includes the start clutch and the secondary drive gear which is integral with the park gear' The sec-

ondary gear shaft is positioned between the secondary drive gear and the final driven gear. The secondary gear shaft

includes the secondary driven gear which serves to change the rotation direction. because the drive pulley shaft and the

driven oullev shaft rotate the same direction. When certain combinations of planetary gears in the transmission are

engaged by the clutches and the reverse brake, power is transmitted from the drive pulley shaft to the driven pulley shaft

to provide E, E, E, and El.

Electronic Control'96 - 98 Models:

The electronic control system consists of the Transmission Control Module (TCM), sensors, three linear solenoids, and a

inhibitor solenoid. Shifting is electronically controlled under all conditions'

The TCM is located below the dashboard, behind the kick panel on the driver's side.'99 - 00 Models:

The electronic control svstem consists of a Powertrain Control Module (PCM), sensors, three linear solenoids and an

inhibitor solenoid. Shifting is electronically controlled under all conditions. A Grade Logic Control System to control shift-

ing in E position while the vehicle is ascending or descending a slope.

The PCM is located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the Pressure Low (PL) reguiator valve body, the shift valve

body, the start clutch control valve body, and the secondary valve body. They are positioned on the lower part of the

transmission housing.

The main valve body contains the Pressure High (PH) control valve, the lubrication valve, and the pitot regulator valve.

The secondary valve body contains the PH regulator valve, the clutch reducing valve, the start clutch valve accumulator,

and the shift inhibitor valve. The PL regulator valve body contains the PL regulator valve and the PH-PL control valve

which is ioined to the PH,PL control linear solenoid. The inhibitor solenoid valve is bolted on the PL regulator valve body.

The shift valve body contains the shift valve and the shift control valve. which is joined to the shift control linear solenoid.

The start clutch control valve body contains the start clutch control valve, which is joined to the start clutch control linear

solenoid. The linear solenoids and the inhibitor solenoid are controlled by the TCM or PCM. The manual valve body which

contains the manual valve and the reverse inhibitor valve, is bolted on the intermediate housing.

The ATF pump assembly is located on the transmission housing, and is linked with the input shaft by the sprockets and

the sprocket chain. The pulleys and the clutch receive fluid from their respective feed pipes, and the reverse brake receives

fluid from internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which linear solenoid the TCM or PCM will activate.

Activating the shift control linear solenoid changes the shift control valve pressure, causing the shift valve to move. This

pressurizes the drive pulley pressure to the drive pulley and the driven pulley pressure to the driven pulley and changes

their effective pulley ratio. Activating the start clutch control linear solenoid moves the start clutch control valve. The start

clutch control valve uncovers the port, providing pressure to the start clutch to engage it(cont'd)

14-195

,!

Page 883 of 2189

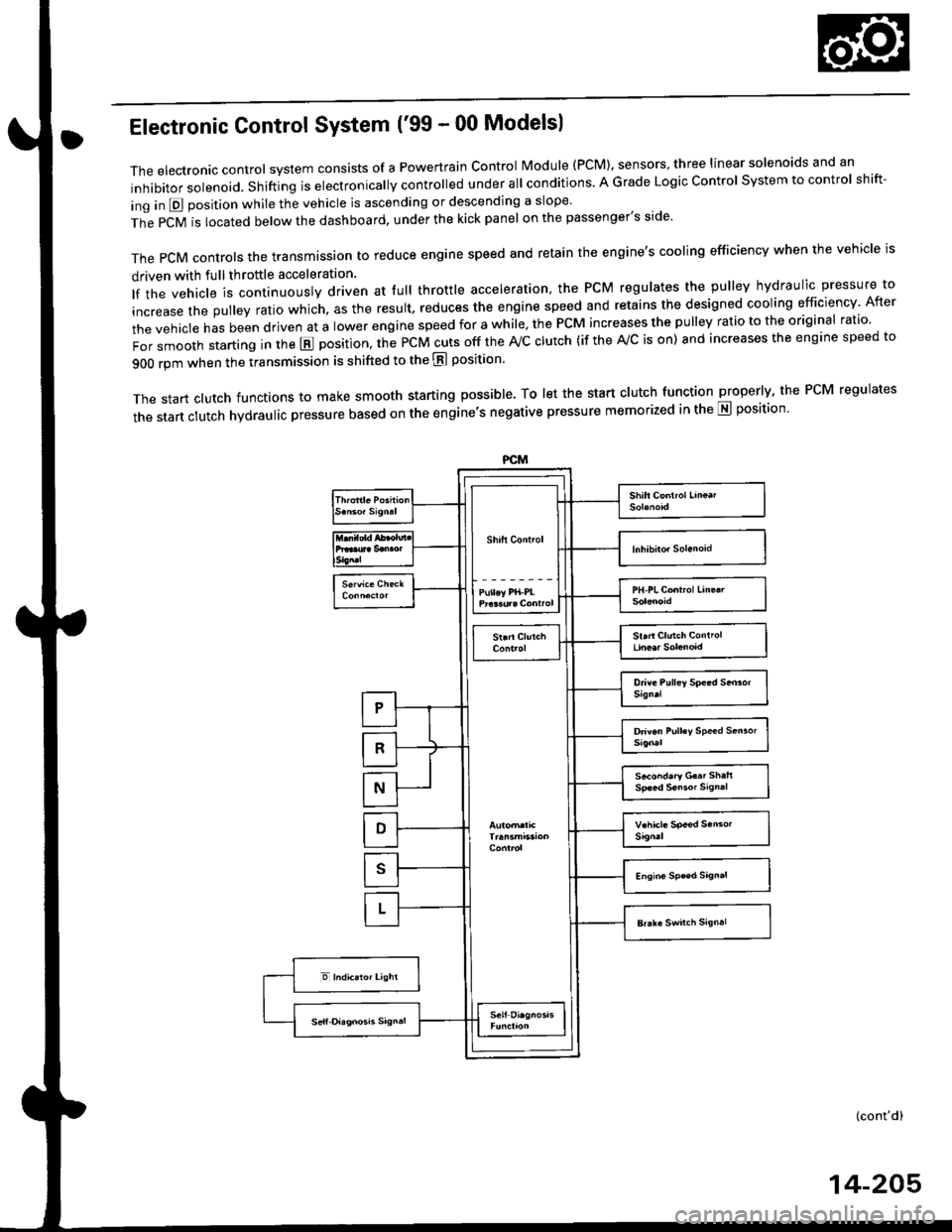

Electronic Gontrol System ('99 - 00 Modelsl

The electronic controt system conststs of a Powertrain control Module (PCM). sensors, three linear solenoids and an

inhibitor solenoid. shifting is electronically controlled under all conditions A Grade Logic control system to control shift-

ing in E position while the vehicle is ascending or descending a slope'

fn"pCVirlocatedbelowthedashboard,underthekickpanelonthepassenger'sside'

The pCM controls the transmassion to reduce engine speed and retain the engine's cooling efficiency when the vehicle is

driven with full throftle acceleration

lf the vehicle is continuously driven at lull throttle acceleration, the PCM regulates the pulley hydraulic pressure to

increase the pulley ratio which. as the result, reduces the engine speed and retains the designed cooling efficiency After

the vehicle has been driven at a lower engine speed for a while, the PCM increases the pulley ratio to the original ratio'

i"i ".nl",rr starting in the E position, the PcM cuts off the ,Vc clutch (if the A/c is on) and increases the engine speed to

900 rpm when the transmission is shifted to the E position'

The start clutch functions to make smooth starting possible. To let the start clutch function properly, the PcM regulates

the start clutch hydraulic pressure based on the engine's negative pressure memorized in the E position'

FCM

s*o.d.ry G..t Sh.h

(cont'd)

14-205