d16 HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 544 of 2189

\J

Fuel Tank Pro3sure sensor 196 D16Y8 engine (coupe).'97 D15Y7 engine {coupe: KL model, sedan: KL (LX) modeu,'97

D16Y8 engine (coupe: all models, sedan: KL model, '98-all models) '99 - 00 D16Y5 engine with M/Tl:

\

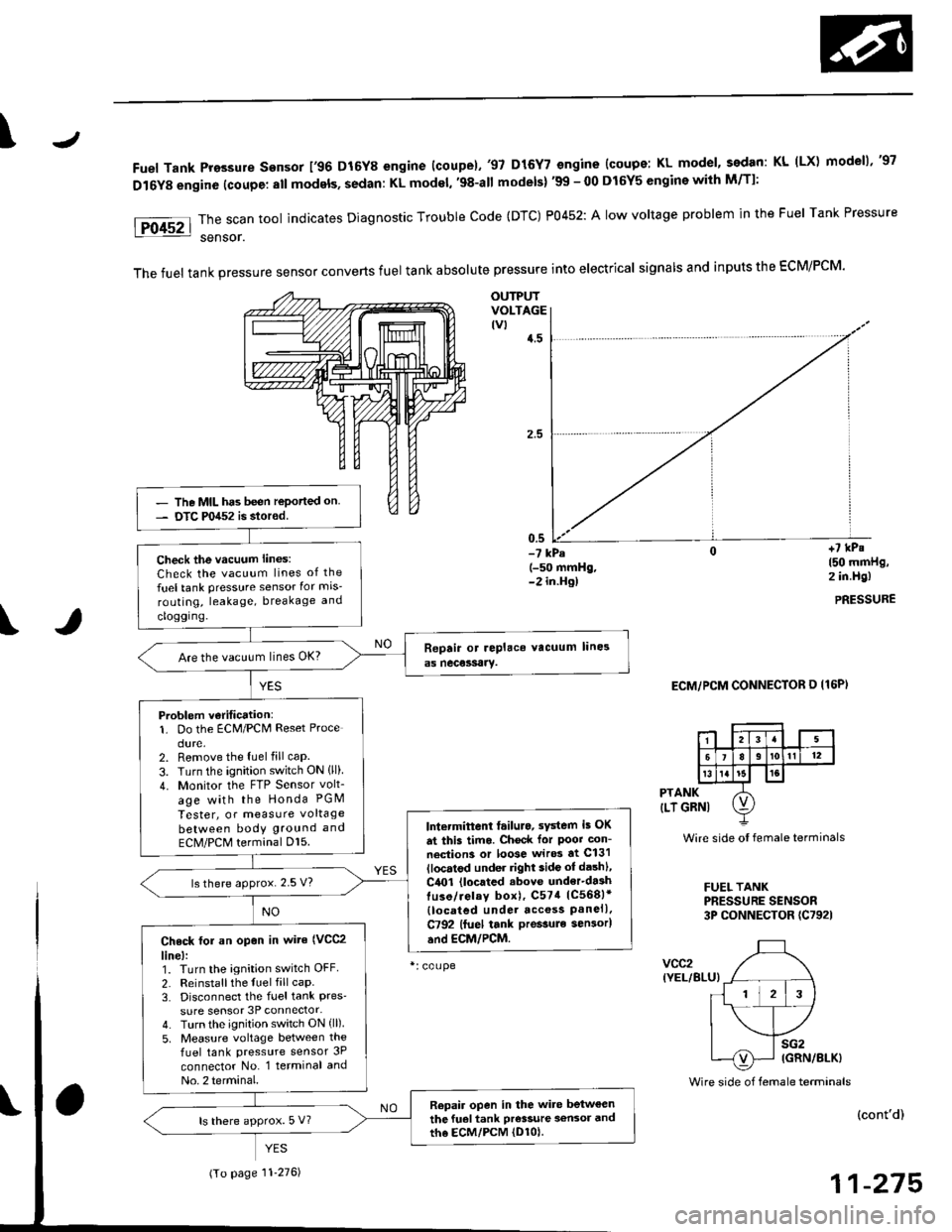

PTANK

{LT GRNI

vcc2(YEL/BLU}

Wire side oI female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR (C7921

sG2IGRN/8LK)

Foc2l::il":"toolindicatesDiagnosticTroublecode(DTc)P0452:A|owvo|tageprob|emintheFue|TankPressure

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the EcM/PCM.

OUTPUTVOLTAGEtvt4.5

-? kPa(-50 mmHg,-2 in.Hg)

ECM/PCM CONNECTOR O I16P)

Wire side of female terminals

+7 kPs150 mmHg,2 in.Hg)

PRESSURE

(cont'd)

11-275

- The MIL has been reported on- DTC P0452 is stored.

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor for mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum lines OK?

Problem v€ritication:1. Do the ECM/PCM Reset Proce

dure.2. Remove the luel fill caP.

3. Turn the ignition switch ON lll)4. Monitor the FTP Sensor volt_

age with the Honda PGM

Tester, or measure voltage

between bodY ground and

ECM/PCM terminal Dl5.lntermittent tailuro, sYstem i5 OK

dt this timo. Chock for Poot con-

neciion3 or loose wir* at C131

llocatod under right side ot dashl,

C4O1 (located .bove under'da3htuso/ielay box), C574 1C568)*

{located under acc€ss Panell.C792 lfuel tank pressule sen3or)

and EcM/PCM.

ls there approx. 2.5 V?

Check tol an op€n in wite (VCC2

line):1. Turn the ignition switch OFF

2. Reinstallthe fuel fill caP.3. Disconnect the fuel tank Pres'sure sensor 3P connector-4. Turn the ignition switch ON (ll)

5, Measure voltage between the

fuel tank pressure sensor 3P

connector No. l terminal and

No. 2 terminal.

Repair open in the wite betweenthe fuel tank Pr€s3ure a€n3or andth6 EcM/PcM (D1ol.ls there approx. 5 V?

(To page 11'276)

Page 548 of 2189

\

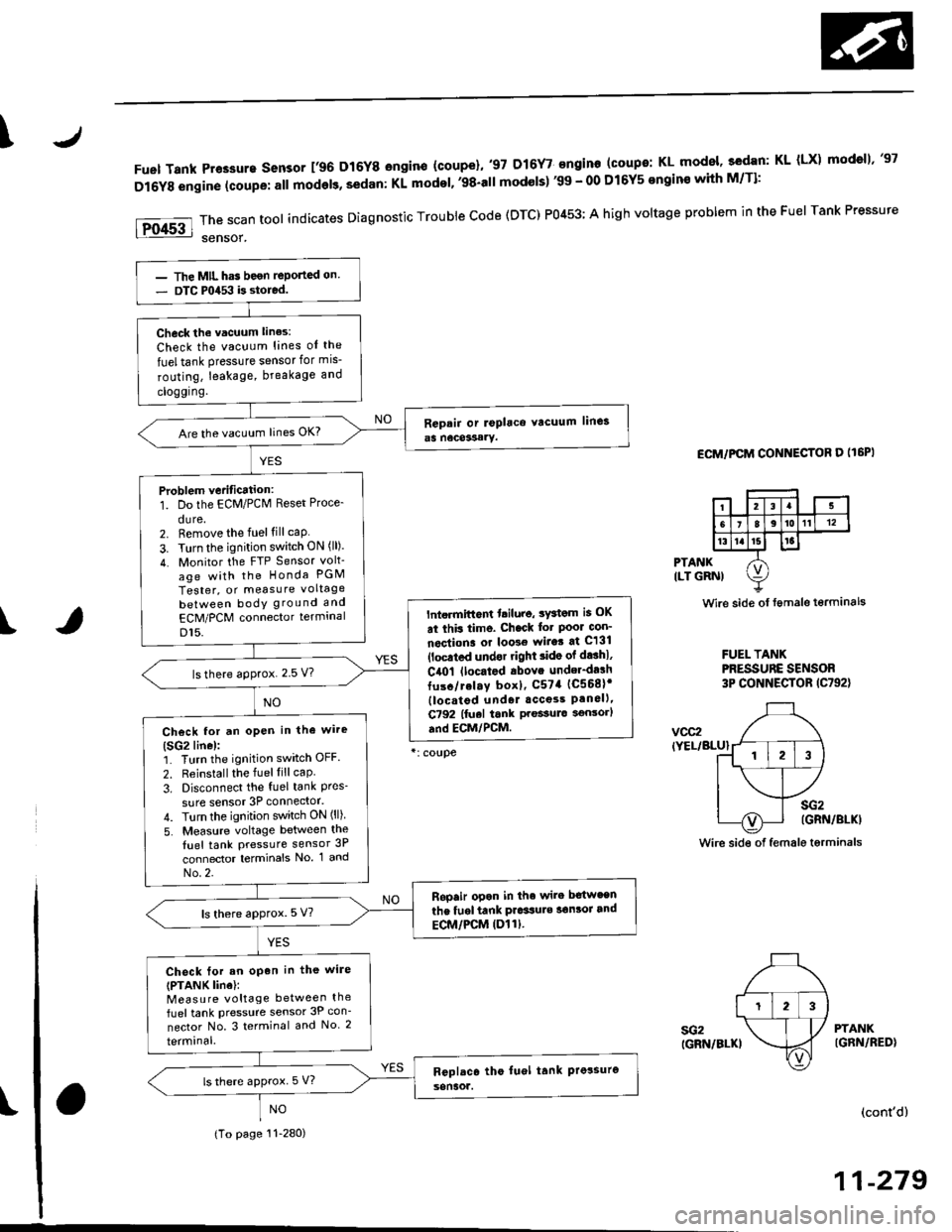

Fue| Tank Pr€ssure sensor 196 Dr6Y8 engine (coupe},,97 D16Y7 angino (coupo: KL mode|' 3edan: KL (Lxl modg||',97

Dl6Y8 engine (coupe: all modeb, sedan: Ki model.'98'all modols) 39 - 0O Dl6Y5 ongins with M/Tl:

rFoG'l::;Jl"too|indicatesDiagnosticTroub|ecode(oTc)P0453;Ahighvo|tageprob|emintheFue|TankPressure

ECM/PCM CONNECTOR D Il6PI

PTANKILT GRNI

\

Wire side of tgmale torminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR (C792)

vcc2(YEL/BLU}

sG2(GRN/BLKI

Wire sid€ of female terminals

I

sG2IGRN/BLKI

PTANKIGBN/RED}

(cont'd)

11-279

The MIL has beon reponed on

DTC P0453 b stored.

Check the vacuum lines:

Check the vacuum lines oI the

fueltank pressure sensor for mis-

routing, leakage, breakage and

clogging.

Are the vacuum lines OK?

Problem verification:1. Do the ECM/PCM Reset Proce-

dure.2. Femove the fuel fill cap

3. Turn the ignition switch oN (ll).

4. Monitor the FTP Sensor volt-

age with the Honda PGM

Tester, or measure voltage

between bodY ground and

ECM/PCM connector termrnal

D15.

lntormittont t iluro, 3Ystem is OK

at this time. Check lot Poor con_

noctiona or loo3e wirat at C131

{loc.ted undor right 3id6 of d8hl,

CaOl llocatod rbov. under-dalh

fus6/relay boxl, C574 (C568lr

llocatod und6l accoss Pan6ll,C792 lfuel tank Preasulo aonlorl

end ECM/PCM.

ls there approx. 2 5 V?

Check for an oPen in the wire(SG2line):1. Turn the ignition switch OFF.

2. Reinstall the fuellill cap

3. Disconnect the fuel tank Pres-sure sensor 3P connector.

4. Turn the ignition switch ON (ll)

5. Measure voltage between the

fuel tank Pressure sensor 3P

connector terminals No. 1 and

No.2.

Ropair opon in the wira b€tw€sn

the fuel tank prasure sonlor and

ECM/PCM (Dl1).ls there aPProx. 5 V?

Check for an open in the wire(PTANK line):Measure voltage between the

fueltank Pressure sensor 3P con-

nector No. 3 terminal and No. 2

termrnal,

ls there approx. 5 V?

*: coupe

{To page 11-280)

Page 552 of 2189

\

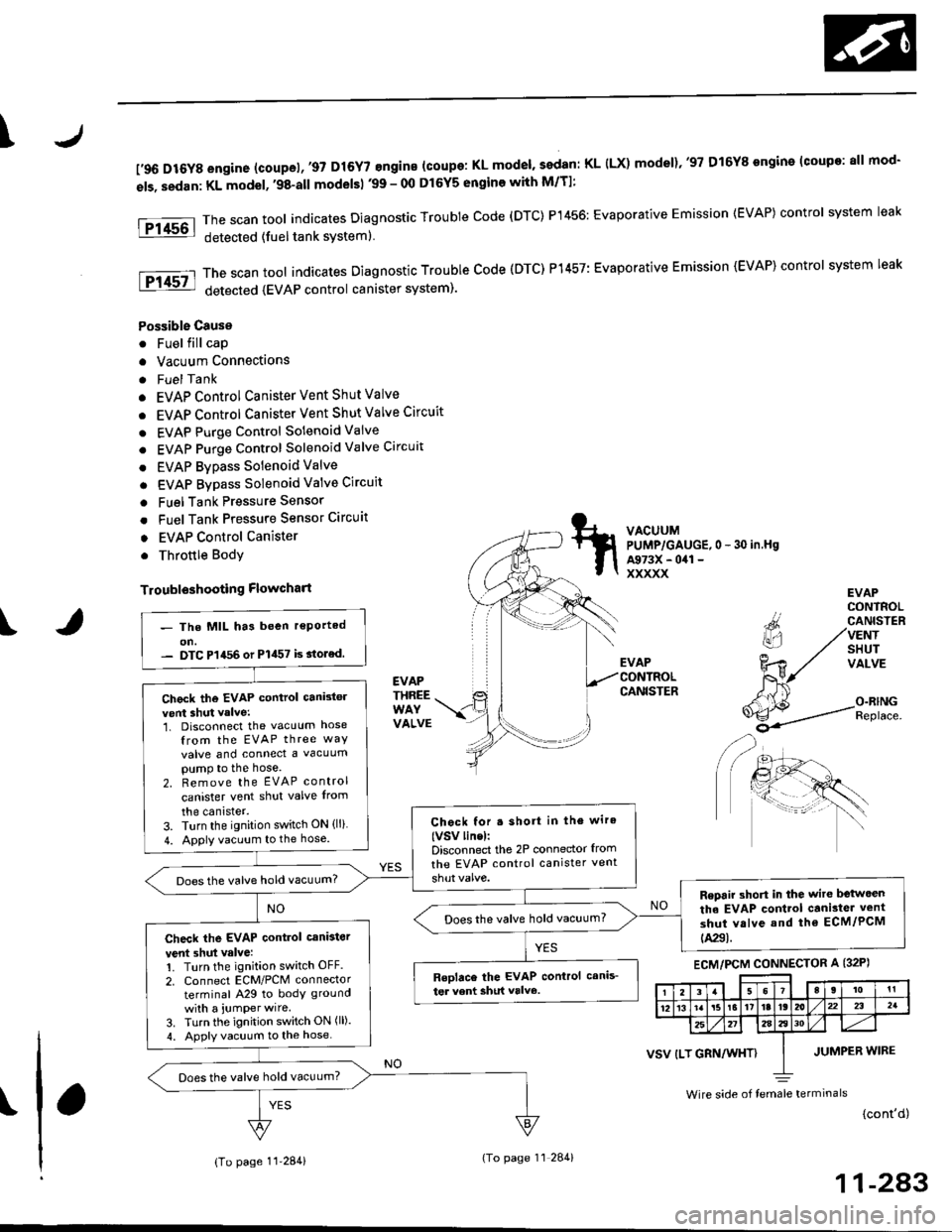

t,96 D16Y8 engine (coup6l,'9? Dl6Y7 engine (coupe: KL model, sedan: KL (LX) model)"g7 Dl6Y8 ongine (coupe: all mod-

els, sedan: KL model,'98-8ll modelsl 39 - 00 Dl5Y5 engine with M/Tl:

The scan tool indicates Diagnostic Trouble code (DTc) P1456: Evaporative Emission (EVAP) control system leak

detected (fuel tank sYsteml

The scan tool indicates Diagnostic Trouble Code (DTC) P1457: Evaporative Emission (EVAP) control system leak

detected (EVAP control canister system).

Fr4t6l

fF14s7

Possible Causs

. Fuel fill cap

. Vacuum Connections

. Fuel Tank

. EVAP Control Canister Vent Shut Valve

. EVAP Control Canister Vent Shut Valve Circuit

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Bypass Solenoid Valve

. EVAP Bypass Solenoid Valve Circuit

. Fuel Tank Pressure Sensor

. Fuel Tank Pressure Sensor Circuit

. EVAP Control Canister

. Throttle Body

Troublsshooting Flowchart

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X - 041 -

xxxxx

I

EVAPCONTROL

.4, cANrsrER

re ./ VALVE

{S----r*::n

\(cont'd)

- The MIL ha3 been rePofted

on.- DTC P1456 or P1457 is stored.

Check the EVAP control canbtol

vent shut valve:1. Disconnect the vacuum hose

Irom the EVAP three waY

valve and connect a vacuurnpump to the hose.

2. Remove the EVAP control

canister vent shut valve Irofi

the canrster.3. Turn the ignition switch ON (lli

4. Apply vacuum to the hose.

Chock for . shon in the wire(VSv linel:Disconnect the 2P connector {rom

the EVAP control canister vent

Does the valve hold vacuum?

Repair short in the wir€ betwcen

the EVAP control canister vent

shut v.lve and tho ECM/PCM

tA29|.

Does the valve hold vacuum?

Check the EVAP control canister

vent shui valve:1. Turn the ignition switch OFF.

2. Connect ECM/PCM connectorterminal A29 to body ground

with a iumPer wire.

3. Turn the ignition switch ON (ll).

4. Applyvacuum to the hose

Reohce the EVAP control canis-

ter vent shttt valve.

Does the valve hold vacuum?

ECM/PCM CONNECTOR A {32P)

37I9t01t't2t3t5t6ItItt9202a2a

25aA

ILT GRN/W{T) I JUMPER WIRE

Wire side of femll terminals

(To page 11-284i(To page 11 284)

11-283

Page 563 of 2189

Emission Control System

Evaporative Emission (EVAPI Controls (cont'd)

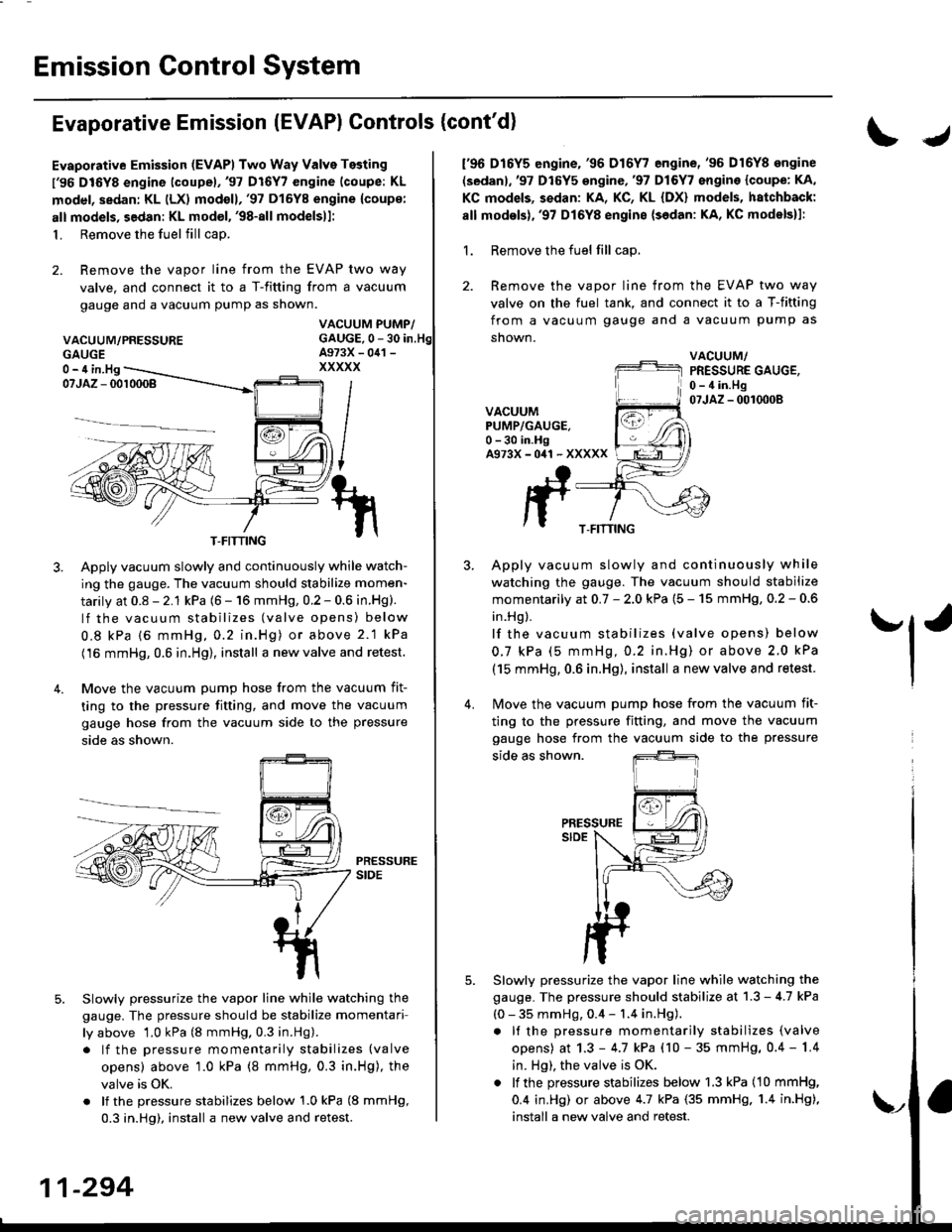

Evaporative Emission (EVAPI Two Way Valve Testing

l'96 DIGYS engine lcoupel,'97 Dl6Y7 engine (coupe: KL

model, sedan: KL (LX) modoll,'97 Dl6Y8 engine {coup€:

alt models, sedan: KL model, '98-all modelsll:

1. Remove the fuel fill cap.

2. Remove the vapor line from the EVAP two way

valve. and connect it to a T-fitting from a vacuum

gauge and a vacuum pump as shown.

VACUUM/PRESSURE

IJ

f96 D16Y5 engine,'96 D16Y7 engine,'96 D16Y8 ongine

(sedanl,'97 D16Y5 engine,'97 Dl6Y7 engine {coupe: KA,

KC models, sedan: KA, KC, KL {DX} models, hatchback:

all modsls),'97 D16Y8 engine {sedan: KA, KC models}l:

1. Remove the fuel fill cap,

2. Remove the vapor line from the EVAP two way

valve on the fuel tank, and connect it to a T-fitting

from a vacuum gauge and a vacuum pump as

snown.

VACUUM/PRESSURE GAUGE,0 - 4 in.Hg07JAZ - 0010008VACUUMPUMP/GAUGE.0 -30 in.HgA973X-041 -XXXXX

Apply vacuum slowly and continuously while watch-

ing the gauge. The vacuum should stabilize momen-

tarily at 0.8 - 2.1 kPa (6 - 16 mmHg, 0.2 - 0.6 in.Hg).

lf the vacuum stabilizes (valve opens) below

0.8 kPa {6 mmHg, 0.2 in.Hg) or above 2.1 kPa

(16 mmHg, 0.6 in.Hg), install a new valve and retest.

Move the vacuum pump hose from the vacuum fit-

ting to the pressure fitting, and move the vacuum

gauge hose from the vacuum side to the pressure

side as shown.

Slowlv pressurize the vapor line while watching the

gauge. The pressure should be stabilize momentari

ly above 1.0 kPa (8 mmHg. 0.3 in.Hg).

. lf the pressure momentarily stabilizes (valve

opens) above '1.0 kPa (8 mmHg, 0.3 in.Hg), the

valve is OK.

. lf the pressure stabilizes below 1.0 kPa (8 mmHg,

0.3 in.Hg), install a new valve and retest.

Apply vacuum slowly and continuously while

watching the gauge. The vacuum should stabilize

momentarily at 0.7 - 2.0 kPa (5 - 15 mmHg, 0.2 - 0.6

in.Hg ).

lf the vacuum stabilizes (valve opens) below

0.7 kPa (5 mmHg,0.2 in.Hg) or above 2.0 kPa

(15 mmHg, 0.6 in.Hg), install a new valve and retest.

Move the vacuum pump hose from the vacuum fit-

'l'

4.

5.

ting to the pressure fitting, and move the

gauge hose from the vacuum side to the

side as shown.

PRESSURESIDE

Slowly pressurize the vapor line while watching the

gauge. The pressure should stabilize at 1.3 - 4.7 kPa

(0 - 35 mmHg, 0.4 - 1.4 in.Hg).

. It the pressure momentarily stabilizes (valve

opens) at 1.3 - 4.7 kPa (10 - 35 mmHg, 0.4 - 1.4

in. Hg), the valve is OK.

. lf the pressure stabilizes below 1.3 kPa (10 mmHg,

0.4 in.Hg) or above 4.7 kPa (35 mmHg. 1.4 in.Hg),

install a new valve and retest.

vacuum

pressure

GAUGE0- 4 in.Hg

T-FITTINGT-FITTING

11-294

\,

Page 586 of 2189

Transmission Assembly

Removal (cont'dl

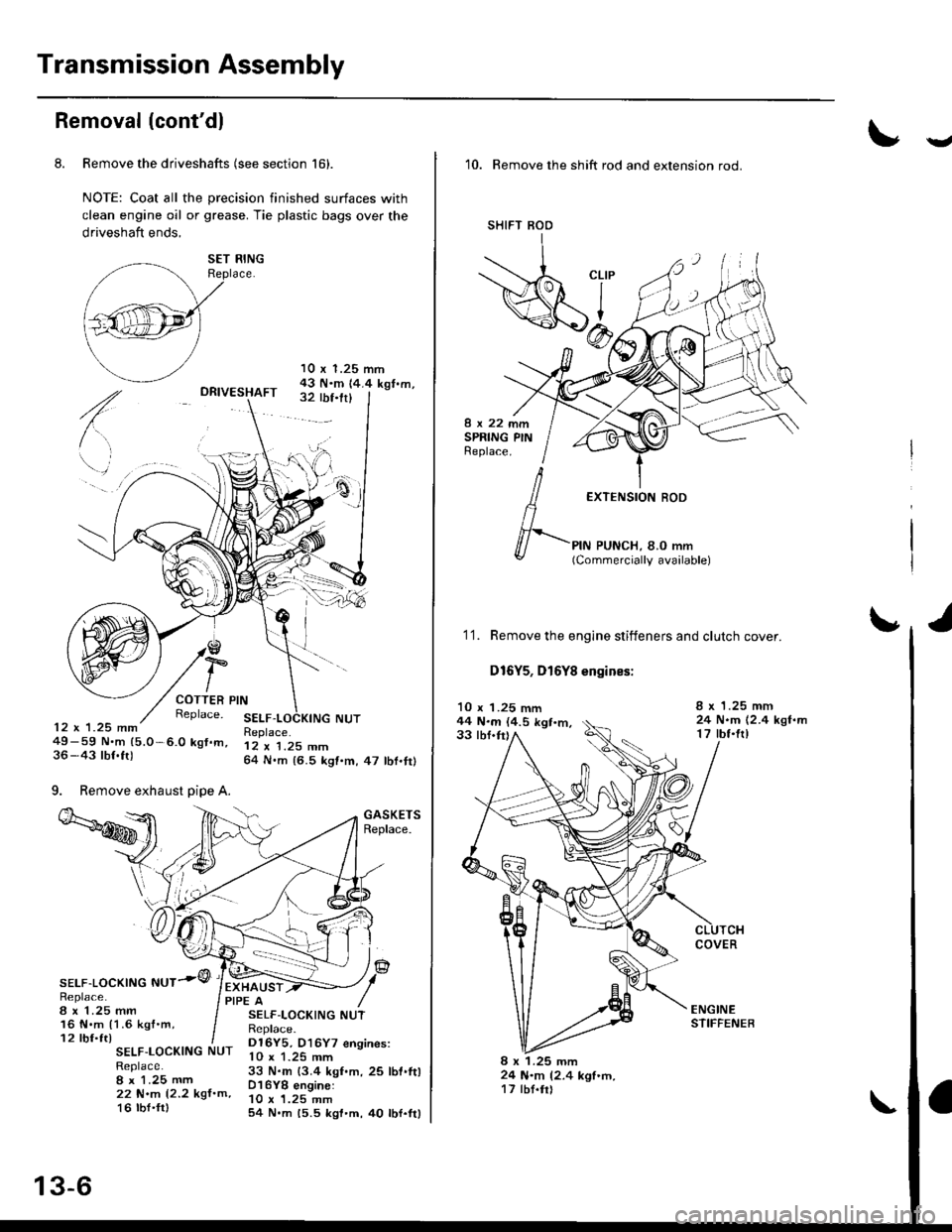

8. Remove the driveshafts (see section 161.

NOTE: Coat all the precision finished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends,

DRIVESHAFT

10 x 1.25 mrn43 N.m 14.4 kgt.m,32 rbf.frl

COTTER PINReplace. SELF12 x 1.25 mm49-59 N.m (5.0 -6.0 kgt.m,36-43 lbf.ft)

9. Remove exhaust pipe A.

Replace.12 x 1.25 mm64 N.m {6.5 kgt.m,47 lbf.tr)

GASKETSReplace.

IF\sELF-LocKtNG NUT.''1/Replace.8 x 1.25 mm16 N.m {1.6 kgf'm,12 tbf.ft)

EXHAUSTPIPE A

SELF-LOCKING NUTReplace.I x 1.25 mm22 N.m (2.2 kgf.m,16 tbt'fr)

SELF-LOCKING NUTReplace.D16Y5, D16Y7 engines:

33 N.m {3.4 kgf.m,25 lbt.ft)D16YB engine:10 x 1.25 mm54 N.m 15.5 kgl'm,40 lbf.ttl

SET RING

13-6

v'10. Remove the shift rod and extension rod.

SI'IIFT BOD

8x22mmSPRING PINReplace.

EXTENSION ROD

PIN PUNCH, 8.O mm(Commercially available)f-

'1'1. Remove the engine stiffeners and clutch cover.

D16Y5, D16Y8 engines:

10 x 1.25 mm44 N.m (4.5 kgt.m,33 tbf.tr)

I x 1.25 mm24 N.m (2.4 kgf.m17 lbt.frl

COVER

8 x 1.25 mm24 N.m 12.4 kgf'tn,17 tbt.tr)

Page 587 of 2189

12.

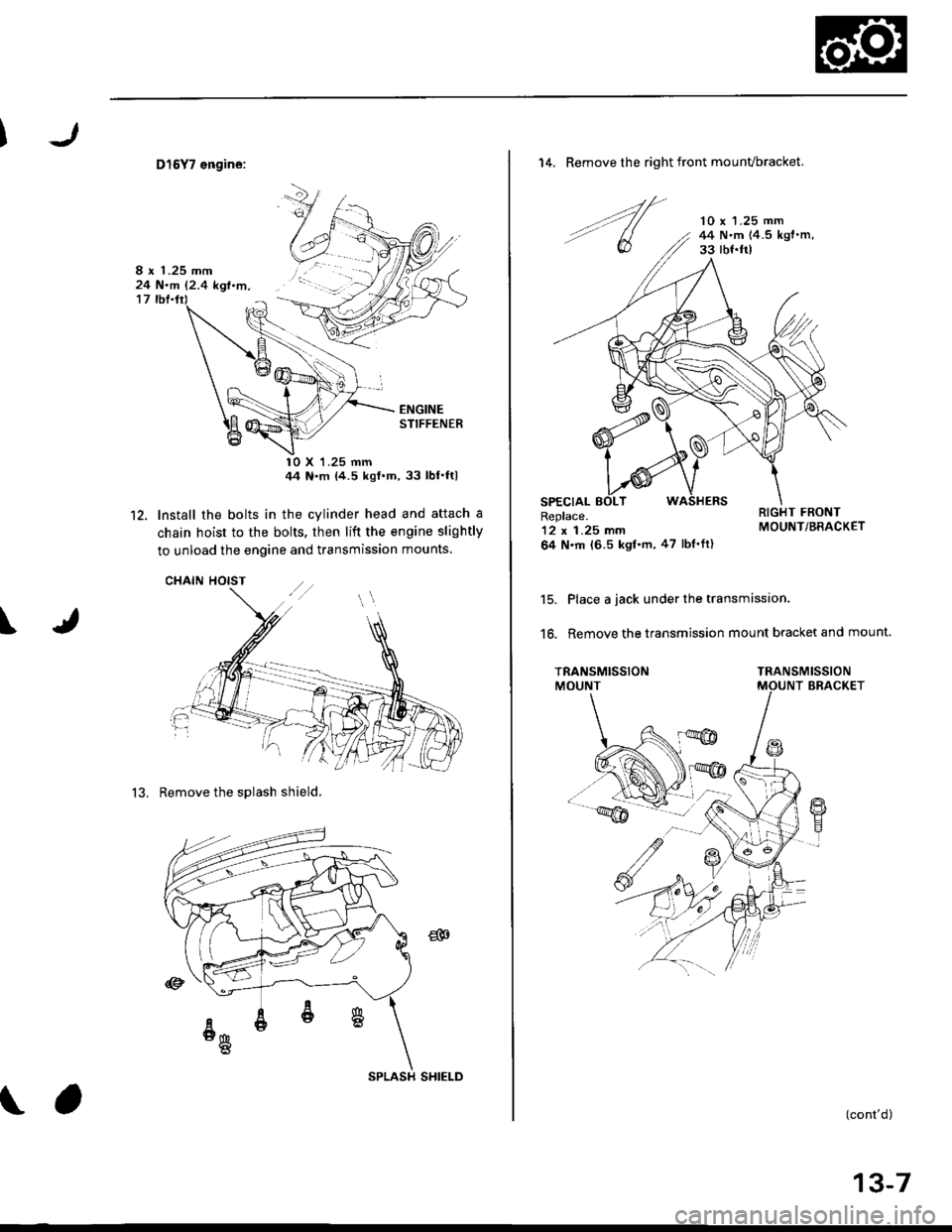

D16Y7 engine:

ENGINESTIFFENER

10 X 1.25 mmIt4 N'm (4.5 kqf'm,33 lbf'ltl

Install the bolts in the cylinder head and attach a

chain hoist to the bolts, then lift the engine slightly

to unload the engine and transmission mounts.

CHAIN HOIST

13. Remove the sDlash shield,

\

8 x 1.25 mm24 N.m {2.4 kgl.m,

SPLASH SHIELD

14. Remove the right front mounvbracket.

'lO x 'l.25 mm44 N'm (4.5 kgl.m,33 rbf.frl

Replace.12 x 1.25 mm

64 N.m t6.5 kgf.m,47 lbf'ft)

Place a jack under the transmission.

Remove the transmission mount bracket and mount.16.

TRANSMISSIONMOUNTTRANSMISSIONBRACKET

(cont'd)

13-7

Page 591 of 2189

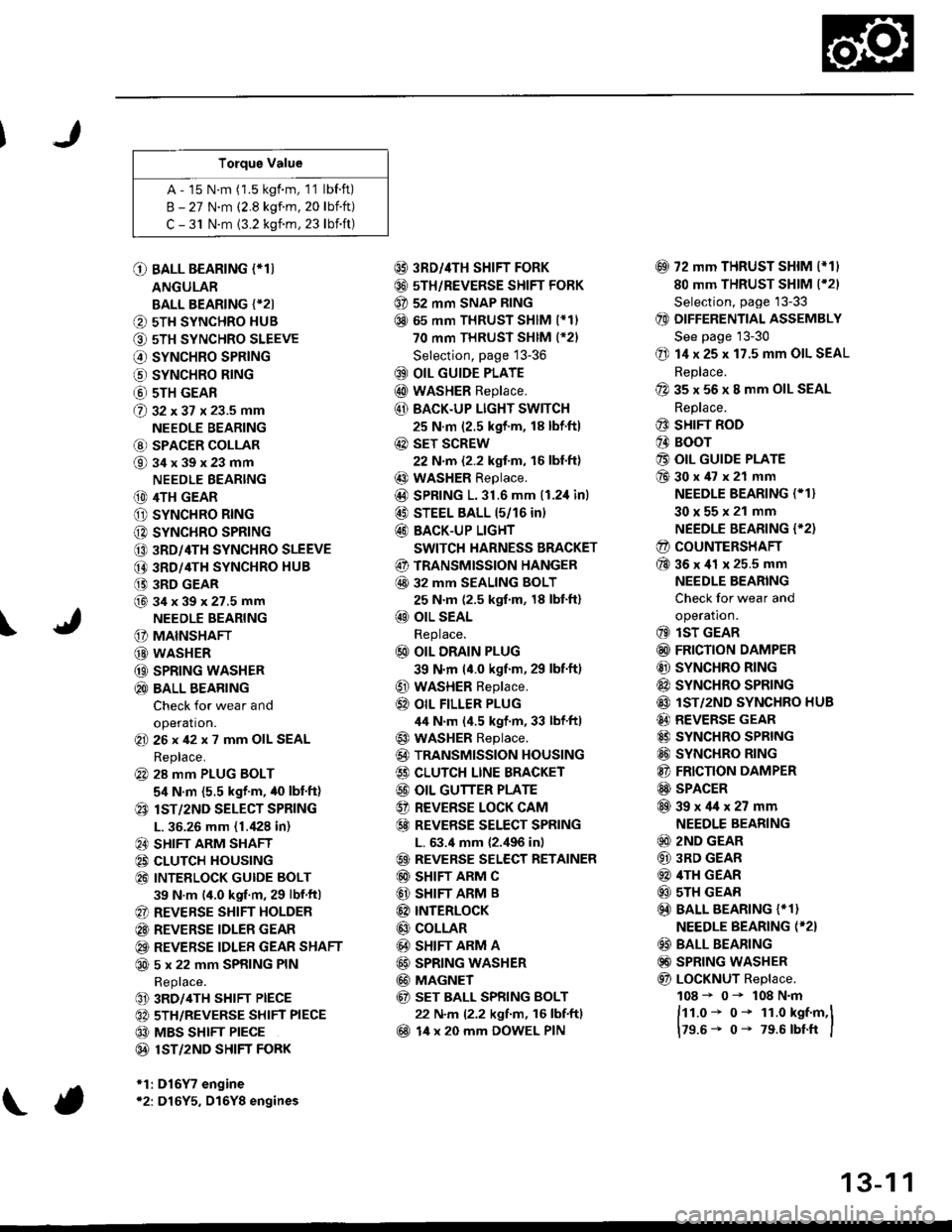

Torque Value

A - 15 N.m (1.5 kgf.m, 1'1 lbf.ft)

B - 27 N.m (2.8 kgf.m. 20 lbift)

C - 31 N.m {3.2 kgnm, 23 lbift)

\

O BALL BEARING (*T)

ANGULAR

BALL BEARING {*2I

O 5TH SYNCHRO HUB

O 5TH SYNCHRO SLEEVE

€) SYNCHRO SPRING

o SYNCHRO B|NG

@ 5TH GEAR

@ gz xgt x 23.5 mm

NEEDLE BEARING

@ SPACER COLLAR

@34x39x23mm

NEEDLE BEARING

(D 4TH GEAR

O SYNCHRO RING

C) SYNCHRO SPRING

CO 3RD/4TH SYNCHRO SLEEVE

@ 3RD/4TH SYNCHRO HUB

(} 3RD GEAR

@34x39x27.5mmNEEDLE BEARING

G) MAINSHAFT

G) WASHER

@ SPRING WASHER

@ BALL BEARING

Check for wear and

operation.(E 26x42x7 mm OIL SEAL

Replace.

@ 28 mm PLUG BOLT

5,1 N.m {5.5 kgf'm, /t0 lbt'ft)

@ lsT/zND SELECT SPRING

L. 36.26 mm (1./P8 in)

@ SHIFT ARM SHAFT

@ CLUTCH HOUSING

@ INTEELOCK GUIDE BOLT

39 N.m (4.0 kgf.m, 29 lbf.ftl

@ REVERSE SHIFT HOLDER

@ REVERSE IDLER GEAR

@ REVERSE IDLER GEAR SHAFT

@ 5 x 22 mm SPRING PIN

Replace.

@ 3RD/4TH SHIFT PIECE

@ 5TH/REVERSE SHIFT PIECE

@ MBS SHIFT PIECE

@ 1ST/2ND SHIFI FORK

*1:D16Y7 engine*2: D16Y5, D16Y8 engines

@ 3RD//|TH SHIFT FORK

@ 5TH/REVERSE SHIFT FORK

@ 52 mm SNAP RING

@ 65 mm THRUST SHIM (*11

70 mm THRUST SHIM (*21

Selection, page 13-36

@ OIL GUIDE PLATE

@ wASHER Replace.

@ BACK.UP LIGHT SWITCH

25 N.m (2.5 kgf'm, 18 lbf'ft)

@ sET SCREW

22 N.m {2.2 kgf.m, 16 lbl.ft}

@ WASHER Replace.

@D SPRING 1.31.6 mm (1.2,1inl

@ STEEL BALL 15/16 in)

@ BACK-UP LIGHT

SWITCH HARNESS BRACKET

@ TRANSMISSION HANGER

@ 32 MM SEALING BOLT

25 N.m (2.5 kgf.m, 18 lbt'ft)

@ OIL SEAL

Replace.

@ OIL DRAIN PLUG

39 N.m (4.0 kgf.m, 29 lbf.ft)

@ WASHER Replace.

@} OIL FILLER PLUG

44 N.m (4.5 kgf.m, 33 lbf'ftl

@ WASHER Replace.

@) TRANSMISSION HOUSING

€) CLUTCH LINE BRACKET

@ OIL GUTTER PLATE

@ REVERSE LOCK CAM

@ REVEBSE SELECT SPRING

L. 63.4 mm {2.,196 in)

@ REVERSE SELECT RETAINER

@ SHIFT ARM C

@ SHIFT ARM B

@ INTERLoCK

@ COLLAR

@ SHIFT ARM A

@ SPRING WASHER

@ MAGNET

@ sET BALL SPRING BOLT

22 N.m (2.2 kgf.m, 16 lbf.ftl

@ 14 x 20 mm DOWEL PIN

@ 72 mm THRUST SHIM l*11

80 mm THRUST SHIM (*21

Selection, page '13-33

@ DIFFERENTIAL ASSEMBLY

See page 13-30

@ 14 x 25 x 17.5 mm OIL SEAL

Replace.

@ 35 x 56 x 8 mm OIL SEAL

Replace.

@ SHIFT ROD

@ BOOr

@ OIL GUIDE PLATE

@30x47x21 mm

NEEDLE BEARING (* 1}

30x55x21 mm

NEEDLE BEARING {'2)

@ COUNTERSHAFT

@36x41 x 25.5 mm

NEEDLE BEARING

Check for wear and

operatron.

@ lsT GEAR

@ FRICTION DAMPER

@ SYNCHRO RING

@ SYNCHRO SPRTNG

@ lST/2ND SYNCHRO HUB

@ REVERSE GEAR

@ SYNCHRO SPRING

@ SYNCHRO RING

@ FRICTION DAMPER

@ SPACER

@39x4lx27mm

NEEDLE BEARING

@ 2ND GEAR

@ 3RD GEAR

@ 4TH GEAR

@ sTH GEAR

@) BALL BEARING {* 1}

NEEDLE BEARING (*2}

@ BALL BEARING

@) SPRING WASHER

@ LoCKNUT Replace.

108 - 0- 108 N.m

ftt.o* o- 1r.o kst.m,l

179.6- 0- 79.6 rbtft I

13-1 1

Page 595 of 2189

Mainshaft Assembly

I

lndex

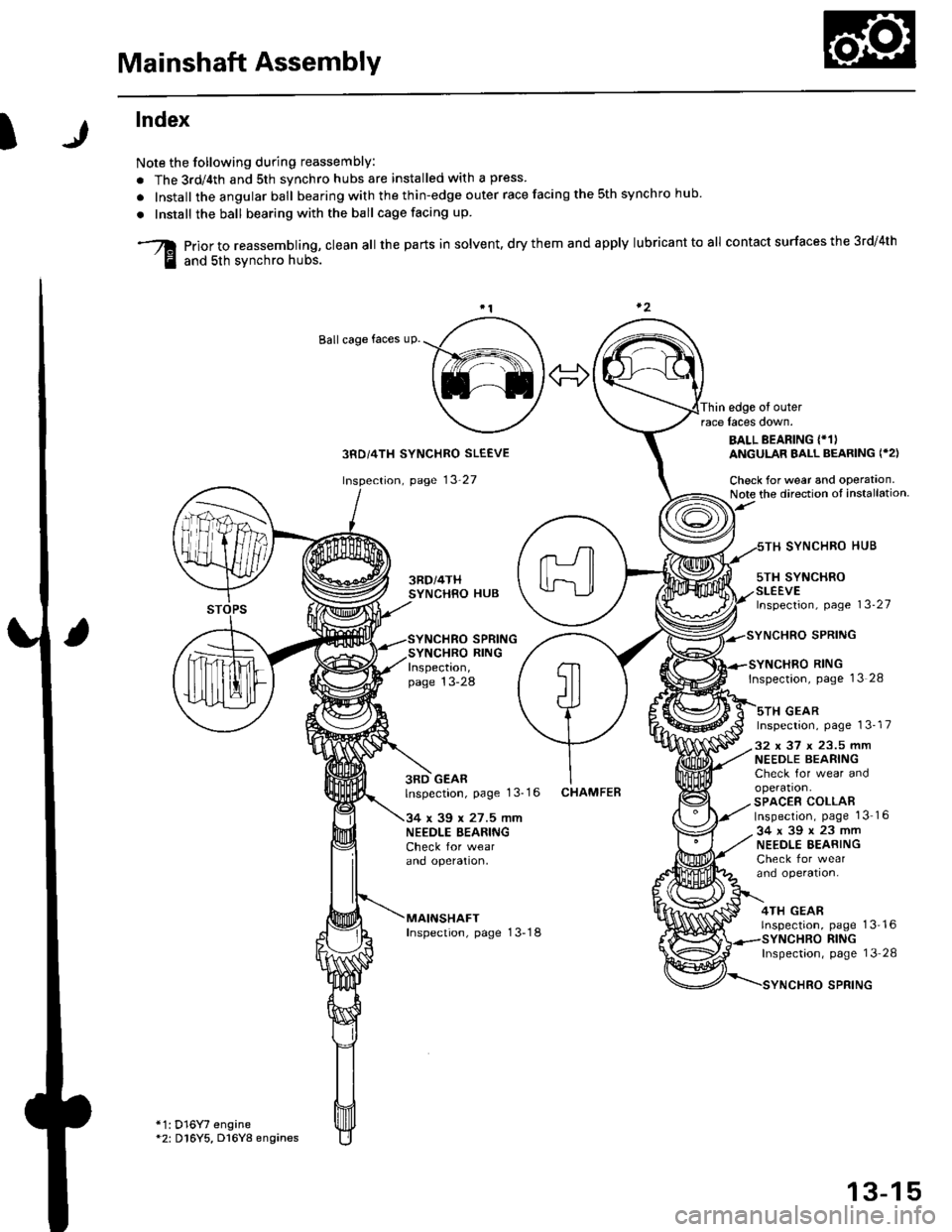

Note the following during reassembly:

. The 3rd/4th and sth svnchro hubs are installed with a press

. Install the angular ball bearing with the thin-edge outer race facing the sth synchro hub

. Install the ball bearing with the ball cage facing up

prior to reassembling, clean all the parts in solvent, dry them and apply lubricant to all contact surfaces the 3rd/4th

and sth svnchro hubs.

Ballcage faces uP.

Thin edge of outerrace laces down.

3RD/4TH SYNCHRO SLEEVE

page 13'27

SYNCHRO SPRINGSYNCHRO RINGInspection,page 13-28

BALL BEARING {*1)ANGULAR BALL BEARING ('2)

Check for wear and operataon.Note the direction ot installation

5TH SYNCHROSLEEVElnspection, page 13-27

SYNCHRO HUB

SYNCHRO RINGInspection, pase 13 28

sTH GEARInspection, page 13-17

3RD GEARlnspection, page 1 3-1 6

34 x 39 x 27.5 mmNEEDLE BEARINGCheck for wearano opetaflon,

MAINSHAFTInspection, page 13-18

CHAMFEB

32 x 37 x 23.5 mmNEEDLE BEARINGCheck for wear andoperation.SPACER COLLABInspection, page 1316

34x39x23mmNEEDLE EEARINGCheck for wearand operation,

4TH GEARrnspeclron,

*1: D16Y7 engine*2: D16Y5, D16Y8 engines

page 13'16RINGInspectaon, page 13 28

SPRING

13-15

Page 599 of 2189

I

)r'

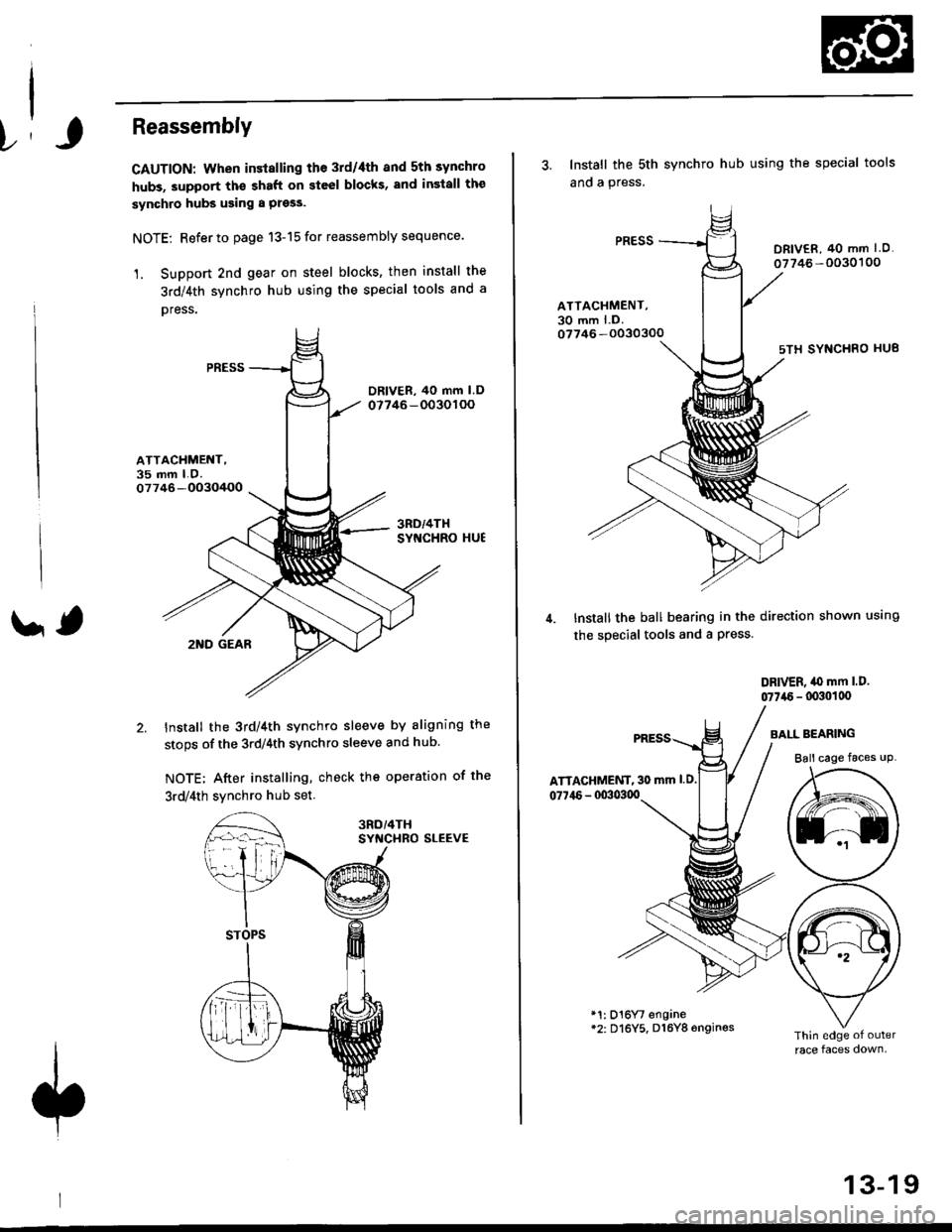

Reassembly

CAUTION: When installing the 3rd/4th and 5th synchro

hubs, support th€ shaft on steel blocks, and insiall the

synchro hubs using a press.

NOTE: Refer to page 13-15 for reassembly sequence.

1. Support 2nd gear on steel blocks' then install the

3rd/4th synchro hub using the special tools and a

oress.

ATTACHMENT,35 mm LO.07746-OO3O/+OO

' ,2I{D GEAR

Install the 3rd/4th synchro sleeve by aligning the

stops of the 3rdl4th synchro sleeve and hub.

NOTE; After installing, check the operation of the

3rd/4th svnchro hub set

SYf{CHRO SLEEVE

3. Install the sth

ano a press.

synchro hub using the special tools

DRIV€R, 40 mm I O.

07746 -0030'�100

ATTACHMENT,30 mm l.D.07746 -O030300

sTH SYNCHRO HU8

Install the ball bearing in the direction shown using

the special tools and a Press.

DRIVER, iO mm l.D.

07746 - lxxlollx'

ATTAGHMENT, 30 mm l.D.

077i16 - 00303qt

BAI-L BEARING

Ball cage faces uP

*1: D16Yt engane*2: Dl6Y5, D16Y8 6ngines

13-19

Page 600 of 2189

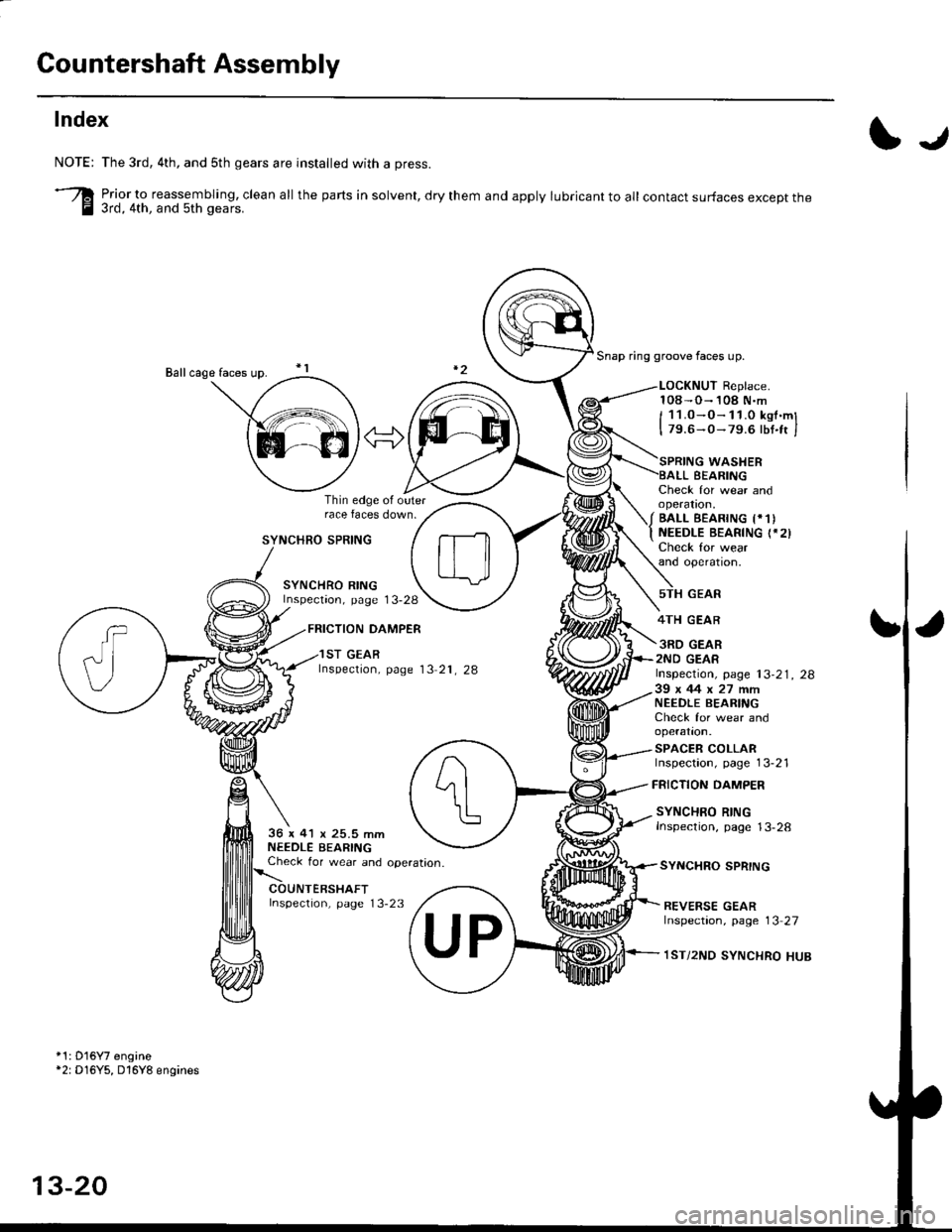

Countershaft Assembly

Index

I.r

NOTE:

-re

The 3rd, 4th, and sth gears are installed with a press.

Prior_to reassembling, clean all the parts in solvent, dry them and apply lubricant to all contact surfaces except the3rd, 4th, and 5th gears.

Snap ring groove faces up.

LOCKNUT Replace.108-O- 108 N.m

I 11.0-O-11.0 kst.ml

I 79.6-0- 79.6 lbt.ft I

SYNCHRO SPRING

SYNCHRO RINGInspectaon, page 13-28

FRICTION DAMPER

Thin edge ol outerrace faces down.

Check for wear andoperatron,

/ BALL EEAR|NG t*1)

t NEEDLE BEARTNG (.2)

Check for wearand operatron,

WASHERBEARING

GEAR

4TH GEAR

3RD GEAR2ND GEAR

FRICTION DAMPER

SYNCHRO SPRING

SYNCHRO RINGInspection, page 13-2836 x 41 x 25.5 mmNEEDLE BEARINGCheck for wear and operataon.

Inspection, page 13-23

1ST GEARlnspection, page 13 21, 28lnspection, page 13-21, 2839x44x27m�mNEEDLE BEARIfI'GCheck for wear andoperation.

SPACER COLLARInspection, page 13-21

REVERSE GEARlnspection, page 13 27

1ST/2ND SYNCHRO HUB

*1: D'16Y7 engine*2: D16Y5, D16Y8 engines

13-20