Face HONDA CIVIC 1997 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 243 of 2189

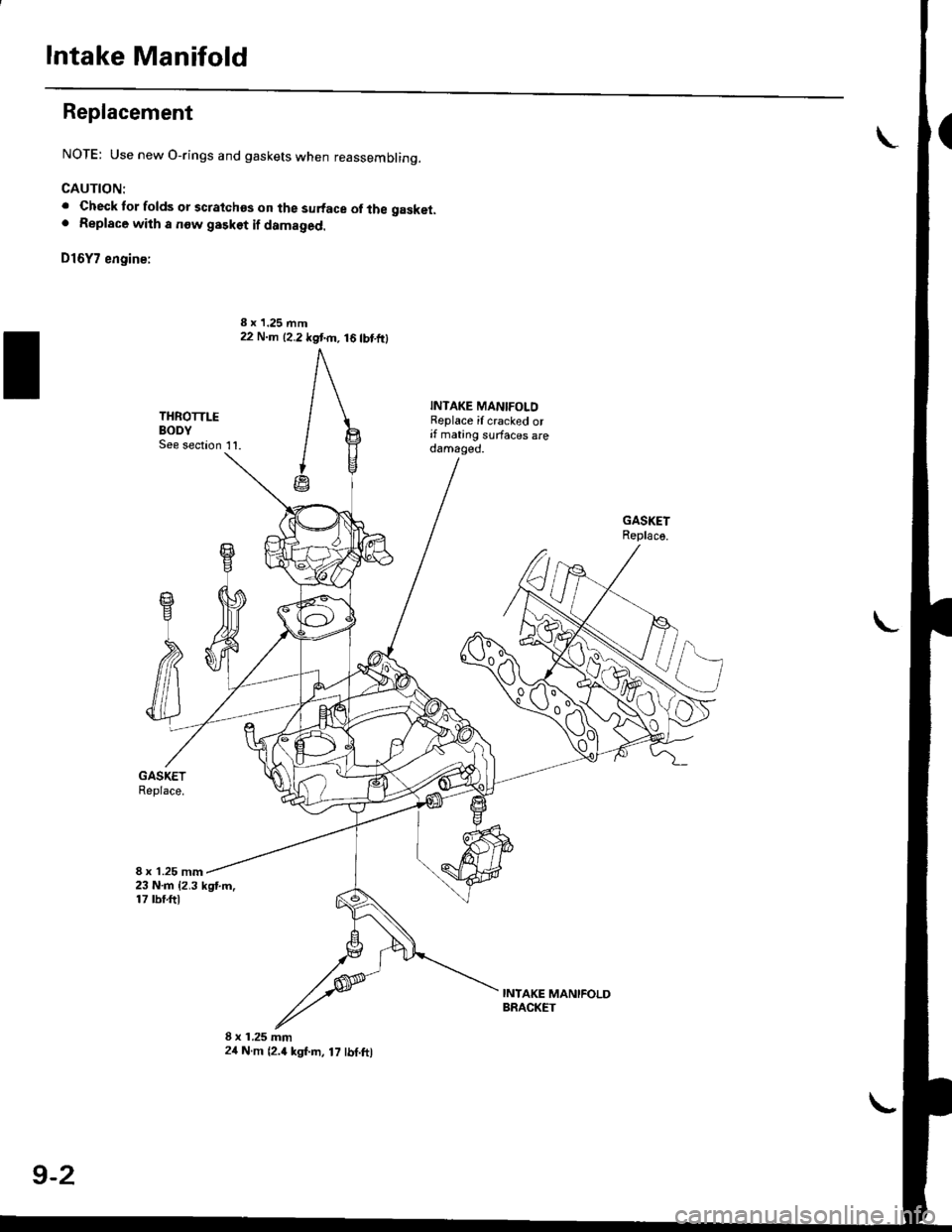

Intake Manifold

Replacement

NOTE: Use new O-rings and gaskets when reassemblinq.

CAUTION:

. Check tor folds or scratchos on the surface of tbe gasket.. Replace with a now gasket if damaged.

D16Y7 engine:

8 x 1.25 mm22 N.m 12.2 kgtm, 16 tbtftl

INTAKE MANIFOLDReplace if cracked orif mating surfaces aredamaged.

8 x 1.25 mm23 N.m {2,3 kgt m.17 rbf.ftl

INTAKE MANIFOLDBRACKET

8 x 1.25 mm24 N.m {2.4 kgf.m, 17 tbf.ftl

9-2

Page 244 of 2189

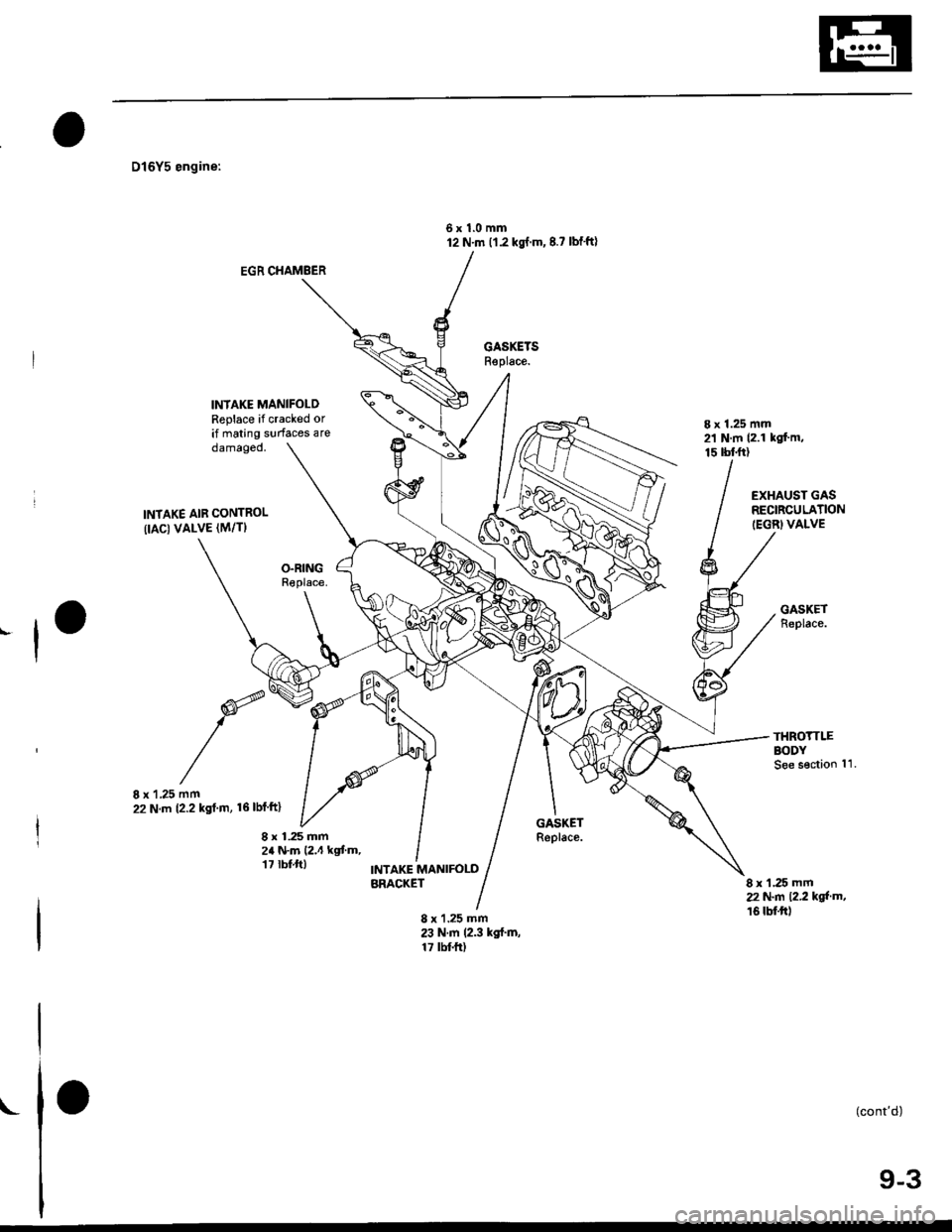

D16Y5 engine:

6x1.0mm12 N'm (1.2 kgl.m,8.? lbf'ft)

EGR CHAMBER

INIAKE MANIFOLDReplace if cracked orif mating surfaces are8 x 1.25 mm21 N m (2.1 kgf.m,15 tbtft)damageo,

INTAKE AIB CONTROL(IAC) VALVE (M/TI

8 x'1,25 mm22 N.m (2.2 kst m, 16lblftl

8 r 1.25 mm2a N.m (2.4 kgt m,17 rbt.ft)

EXHAUST GASRECIRCULATION(EGRIVALVE

8 x 1,25 mm22 N.n 12.2 kol'm,16 tbftr)

INTAKE MANIFOLDBRACKET

8 x 1.25 mm23 N.m 12.3 kgf'm,17 tbt fr)

(cont'd)I

9-3

Page 245 of 2189

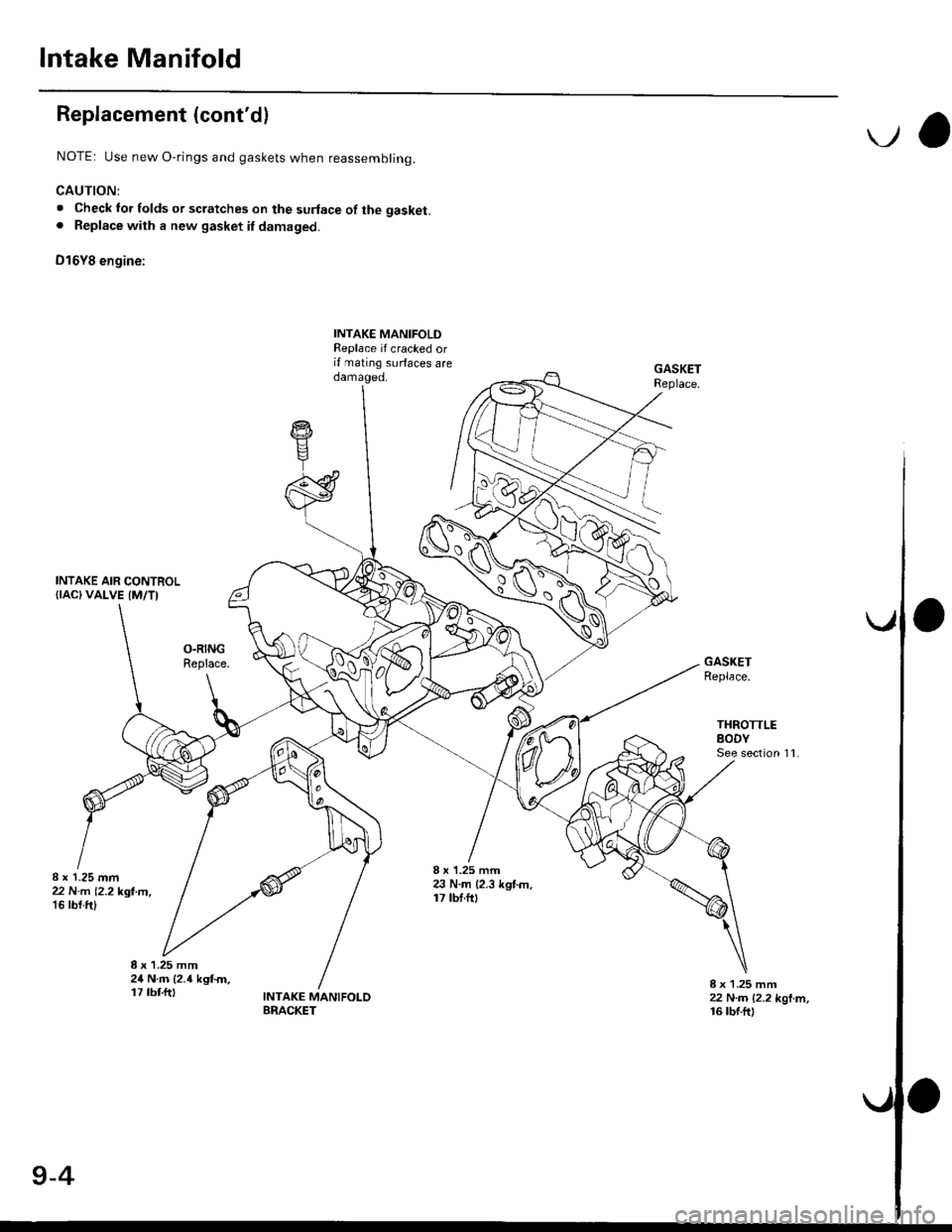

lntake Manifold

Replacement (cont'dl

NOTE: Use new O,rings and gaskets when reassembling.

CAUTION:

. Check lor folds or scratches on the surface of the gasket.. Replace with a new gasket il damaged.

D16Y8 engine:

INTAKE MANIFOLDReplace if cracked orif mating surfaces areoamageo,

INTAKE AIR CONTROL{ract vAt_vE {M/Tl

GASKETReplace.

8 x 1.25 mm24 N.m {2.{ kgtm.17 tbtftt

THROTTLEBODY

8 x 1.25 mm22 N.rn |.2.2 kgl.rn,16 tbtft)INTAKE MANIFOLDBRACKET

9-4

Page 246 of 2189

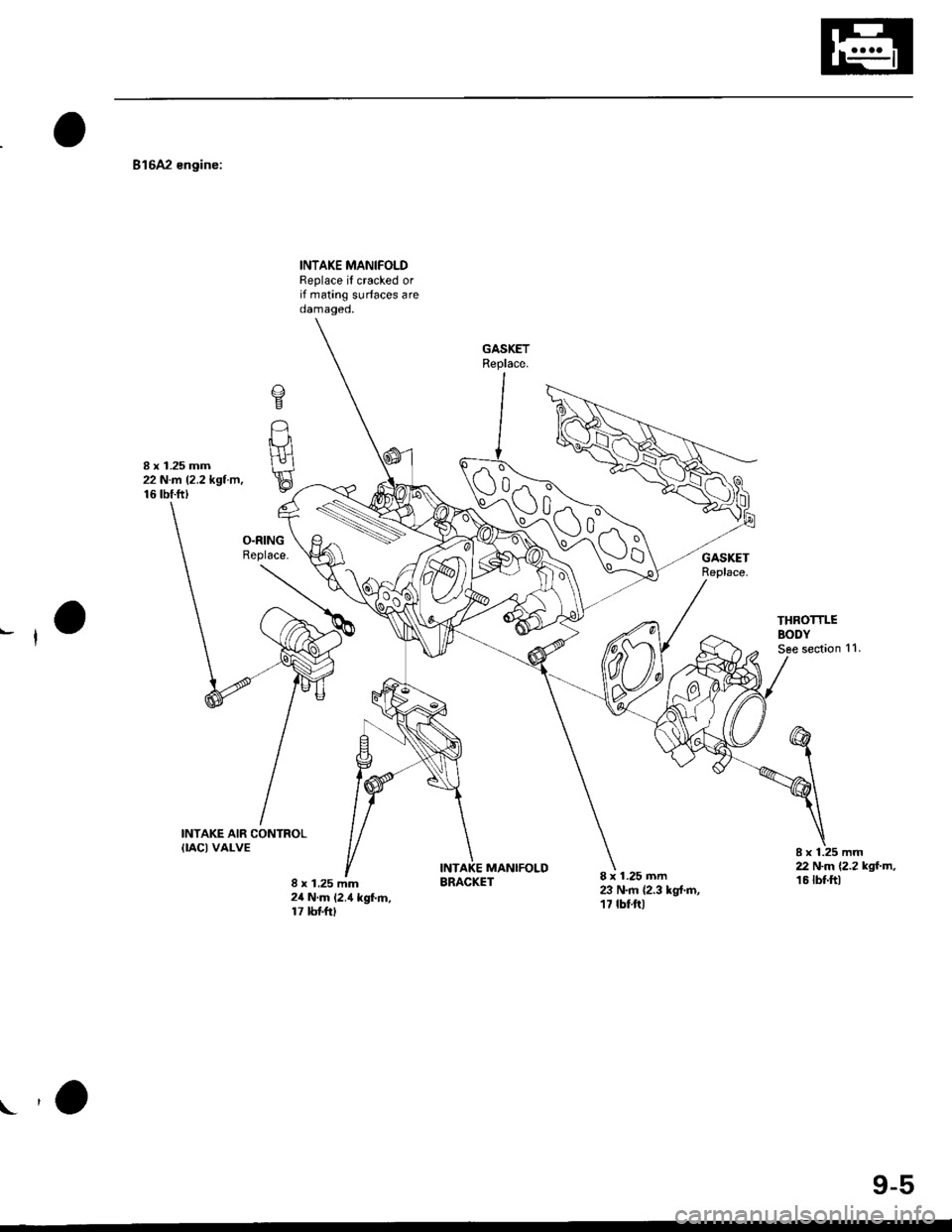

816A2 engine:

INTAKE MANIFOLDReplace if cracked orif mating surfaces areoamageo,

8 x 1.25 mm22 N.rA 12.2 kgl.trr,16 tbtftt

o

t_-lUH

E

INTAKE AIR CONTROLIIACI VALVE

8 x 1.25 mm24 N.m 12.4 kgf.m,17 tbtftl

8 x 1.25 mm23 N.m {2.3 kg{.m,17 tbt.ftl

Al N-m 12.2 kgt.m,16 tbt.ftlMANIFOLDBRACKET

n ""\--

VlCd>-^

M\G

yo

9-5

Page 247 of 2189

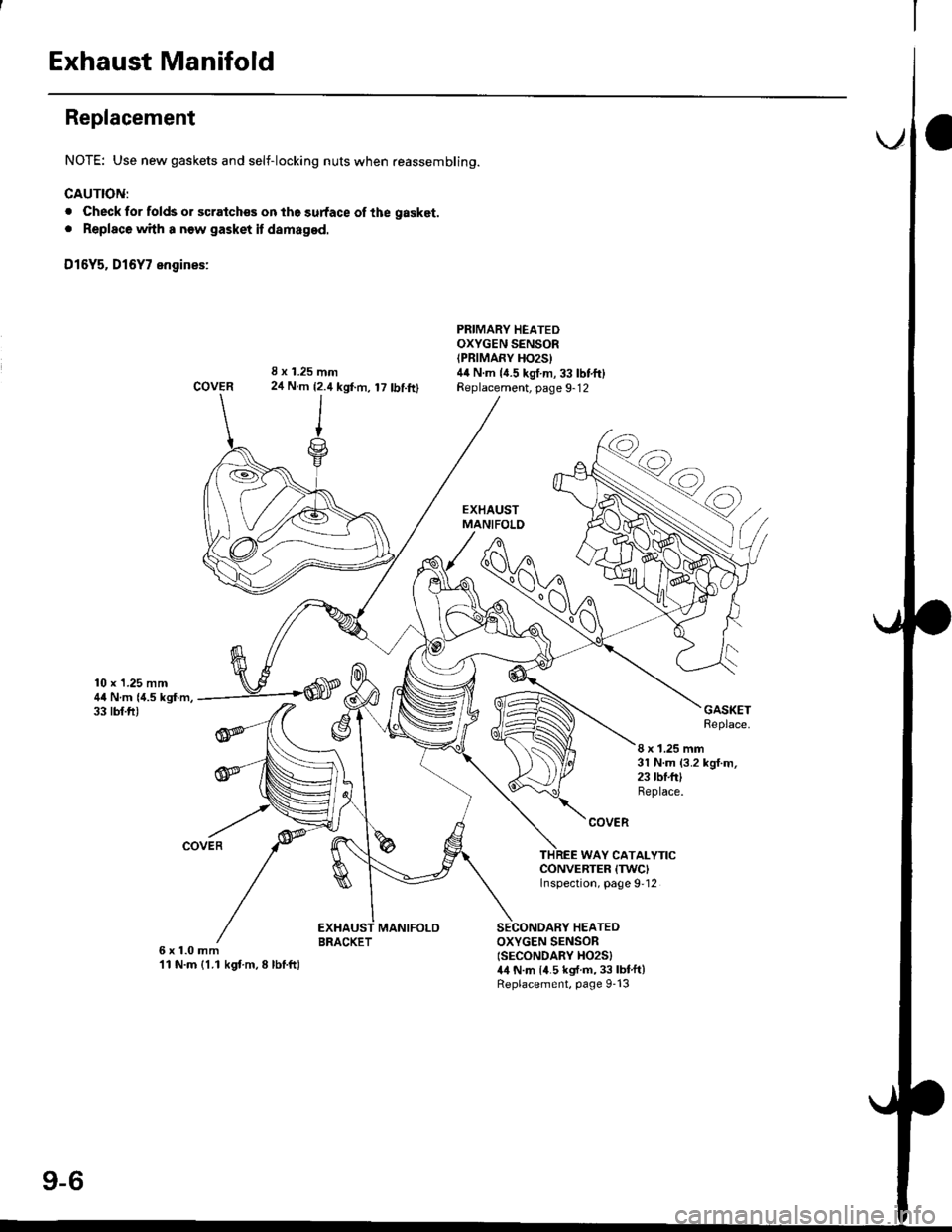

Exhaust Manifold

Replacement

NOTE: Use new gaskets and self-locking nuts when reassembling.

CAUTION:

. Check for folds or scratch€s on the surface of the gasket.

. Replace with a new gasket it damaged.

D16Y5. D16Y7 engines:

I x 1.25 mm24 N.m {2.4 kgt.m, 17 tbtft}

MANIFOLDBRACKET

PRIMARY HEATEDOXYGEN SENSORIPRIMAFY HO2SI44 N.m {4.5 kgf m, 33 lbtft)Replacement, page 9-12

GASKETReplace.

I x 1.25 mm31 N.m (3.2 kgf.m,23 tbf.ft)Beplace.

WAY CATALYTICCONVERTER {TWCIlnspection, page 9'12

6x1.0mm11 N.m {1.1 kgt m,8 lbf.ft)

SECONDARY HEATEDOXYGEN SENSOR(SECONDARY HO2S}44 N.m 14.5 kgf.m,33 lbf.ft)Replacement, page 9-13

9-6

Page 249 of 2189

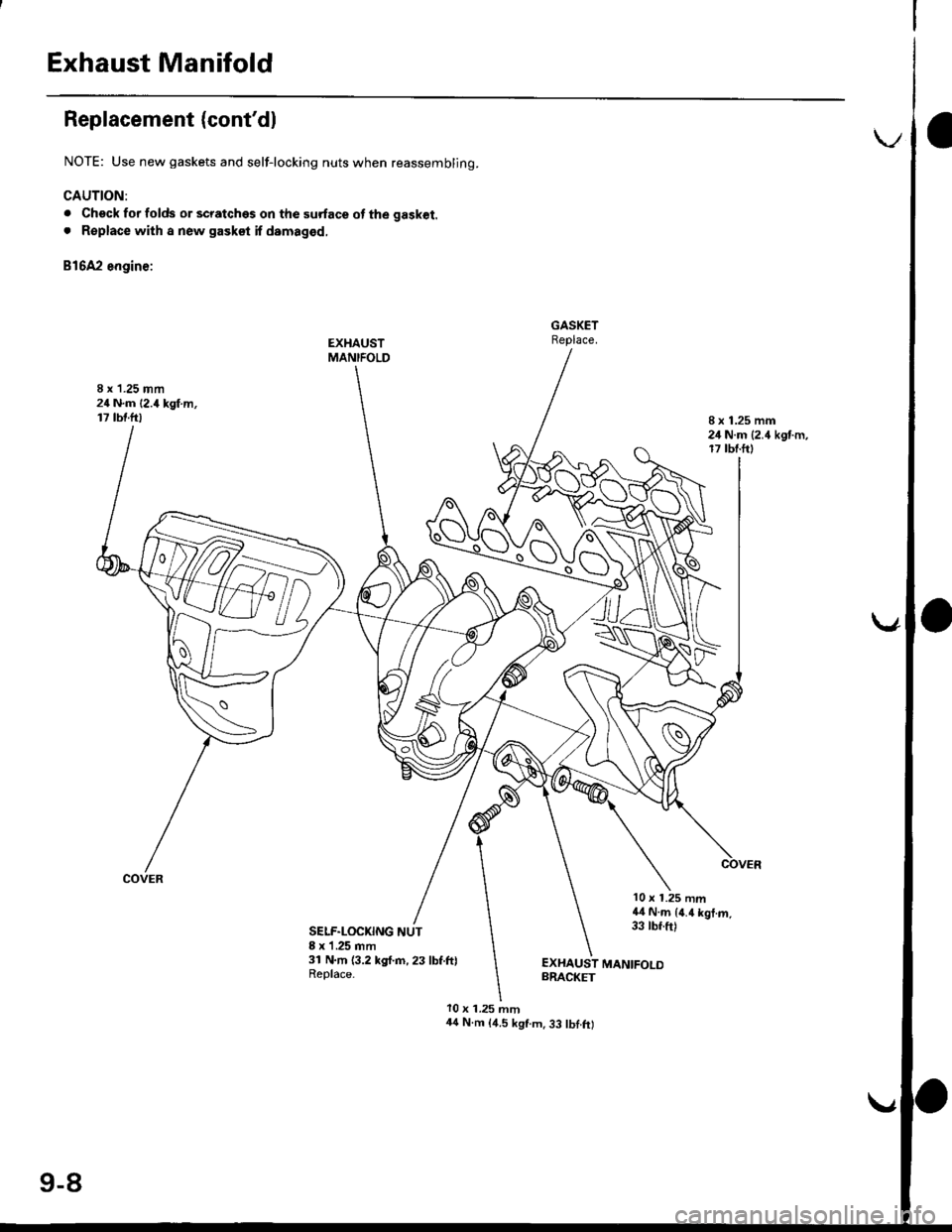

Exhaust Manifold

Replacement (cont'dl

NOTE: Use new gaskets and self-locking nuts when reassembljng.

CAUTION:

. Check for folds or scratches on the surface ot the gask€t.

. R€place with a new gaskot if damagod,

B16A2 engine:

GASKETReplace.

10 x 1.25 mm44 N.m {4.4 kgt.m,33 tbl.ft)SELF.LOCKING NUT8 x 1 .25 mm31 N.m (3.2 kg{.m, 23 lbf.ft)Replace-EXHAUST MANIFOLDBRACKET

10 x 1.25 mm4{ N.m (4.5 kgf.m. 33 tbt.fil

9-8

Page 267 of 2189

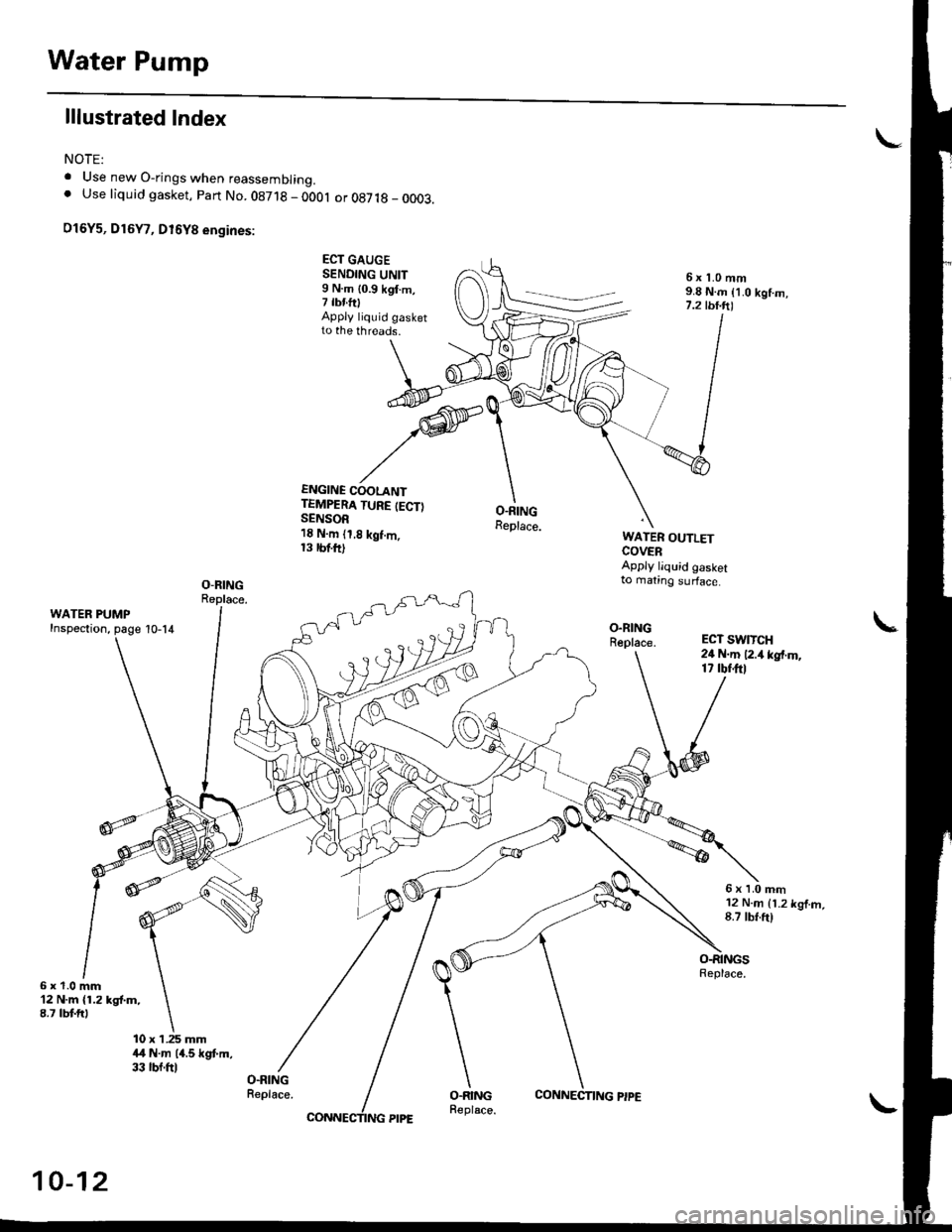

Water Pump

lllustrated Index

NOTE:

. Use new O-rings when reassembrrng.. Use liquid gasket, Part No. 08718 - 0OOl or 087 t8 _ 0003.

O16Y5, D16Y7, D16Y8 engines:

ECT GAUGESENDING UNIT9 N.m {0.9 kgI.m,7 tbnftlApply liquid gasketto the threads.

ENGINE COOLANTTEMPERA TURE (ECT)SENSOR1E N.m (1,8 kgf.m,13 rbttt)

6x 1.0 mm9.8 N.m {1.0 kgf.m,7.2 tbt.ft'|

O.RINGReplace.WATER OUTLETCOVERApply liquid gasketto mating surface.

ECT SW1TCH24 N.m 12.4 kgf.m,17 rbf.ftl

6xl.0mm12 N.m {1.2 kgf.m,8.7 tbf.ft)

6x1.0mm'12 N.m {1.2 kgt m,8.7 lbt fr)

10 x 1.25 mmitl N.m 14.5 kgt m,33 rbf.ftlO.RINGReplace.

10-12

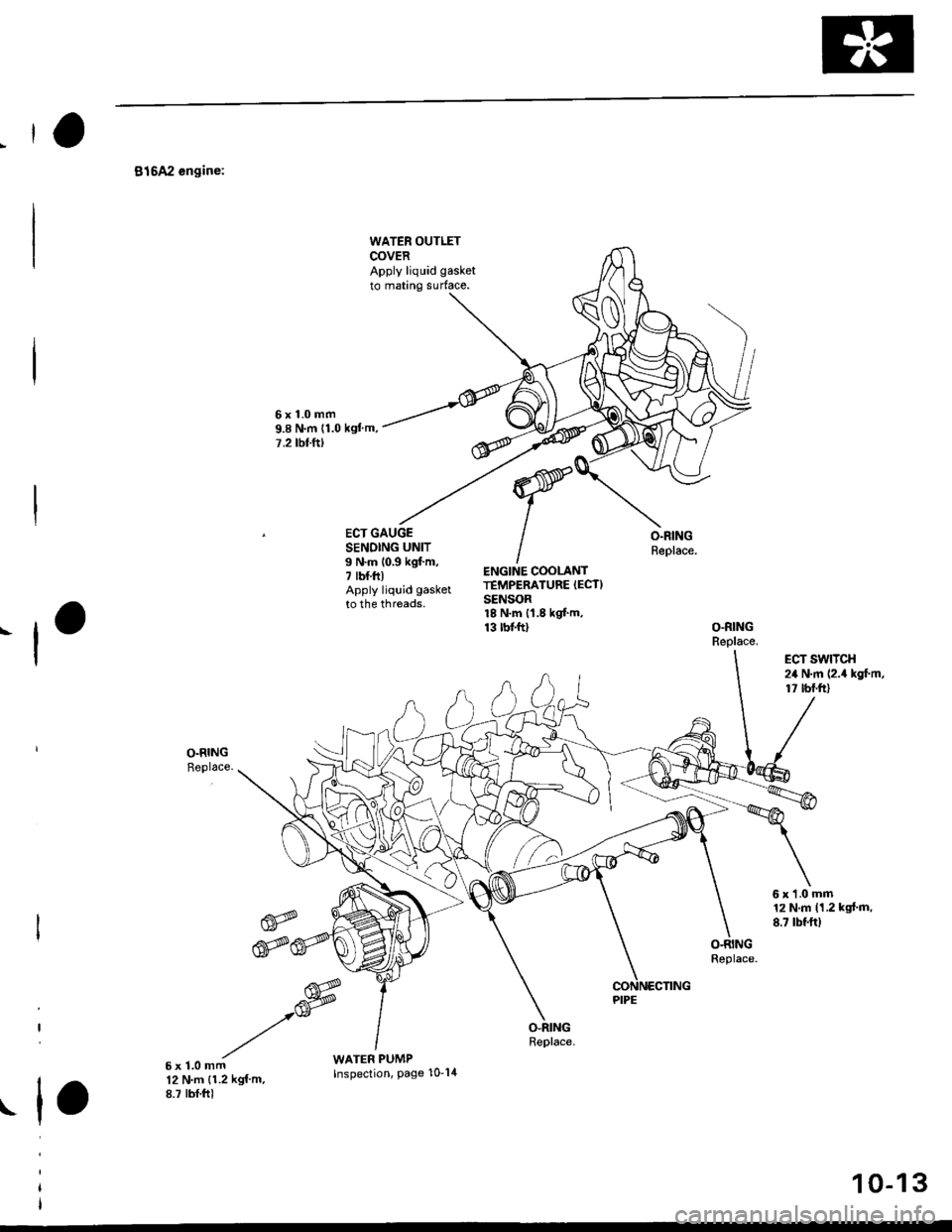

Page 268 of 2189

815A2 engine:

WATER OUTLETCOVERApply liquid gasket

to mating surface.

6x1.0mm9.8 N.m {1.0 kgl'm,7,2 tbl.ftt

ECT GAUGESENDING UNIT9 N.m (0,9 kgf.m,7 rbf.ft)Apply liquid gasket

to the threads.

rENGINE COOLANTTEMPERATURE (ECT)

SENSOR18 N.m {1.8 kgf.m,13 tbtftl

6x1.0mm12 N.m (1,2 kgd m,

8.7 tbf.ftl

16@

aY@

t"S X 1.0 Mrf WATEN PUMP

iiil:i'iij rnr.., Inspection, pase 10'1'r

8.7 tbf.ftl

\lo

10-13

Page 269 of 2189

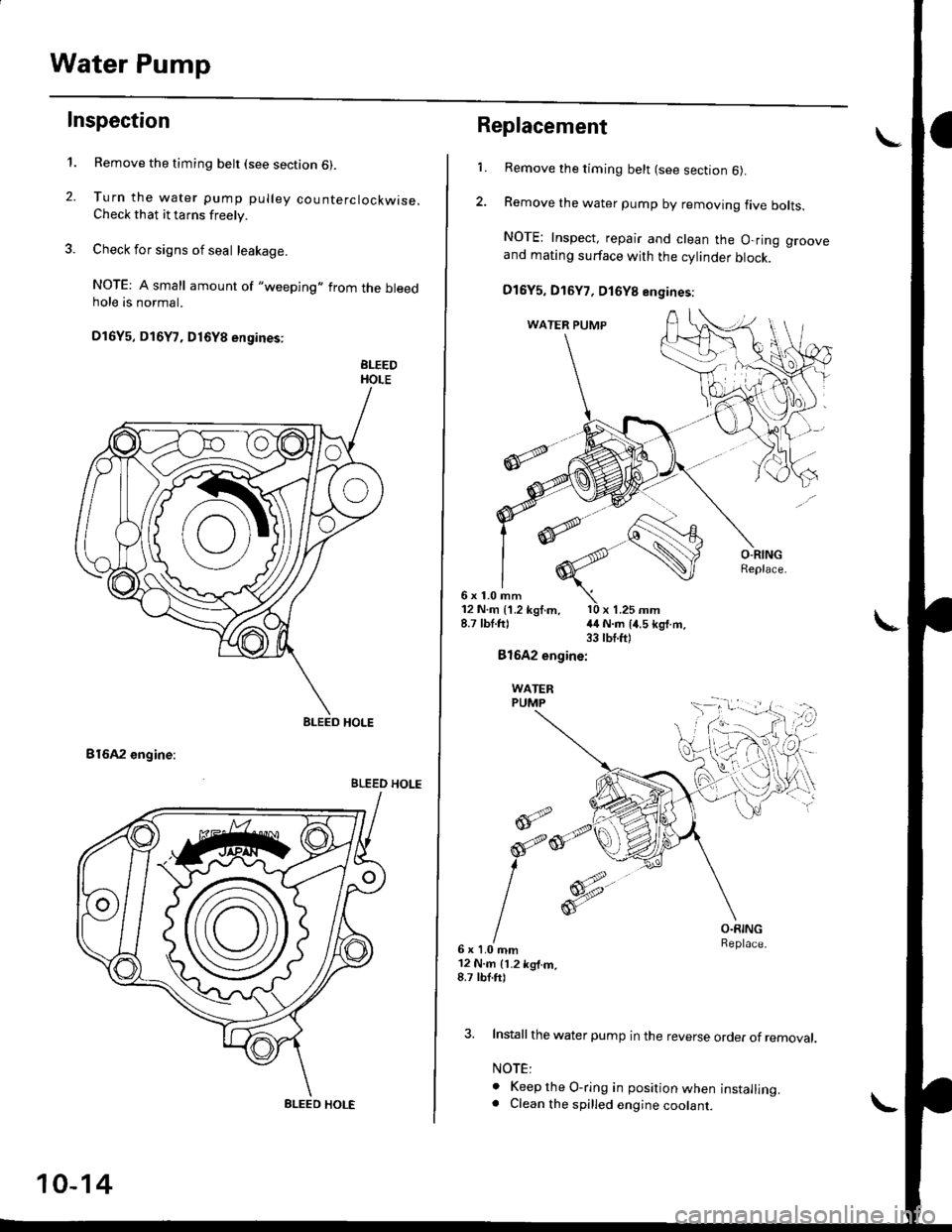

Water Pump

Inspection

't.

2.

Remove the timing belt (see section 6).

Turn the water pump pulley counterclockwise.Check that it tarns freely.

Check for signs of seal leakage.

NOTE: A small amount of "weeping,,from the bleedhole is normal.

Dl6Y5, Dl6Y7, D16Y8 engines:

BLEEDHOLE

B16A2 engine:

BLEED HOLE

BLEED HOLE

BLEED HOLE

10-14

Replacement

6x1.0mm

1.Remove the timing belt (see section 6).

Remove the water pump by removing five bolts.

NOTE: Inspect, repair and clean the O-ring grooveand mating surface with the cylinder block.

D16Y5, D16Y7, D16Y8 engines:

12 N.m {1.2 kgf.m, l0 x 1.25 mm8.7 lbt.ft) {4 N.m 14.5 kg{.m.33 tbt.ft)

Bl642 engine:

WATERPUMP

@;2

6x1.0mm12 N.m 11.2 kg{.m,8.7 tbf.ft)

O.RINGReplace.

3. Install the water pump in the reverse order of removal.

NOTE:

o Keep the O-ring in position when installing.. Clean the spilled engine coolant.

d

orp,

I

Page 496 of 2189

I

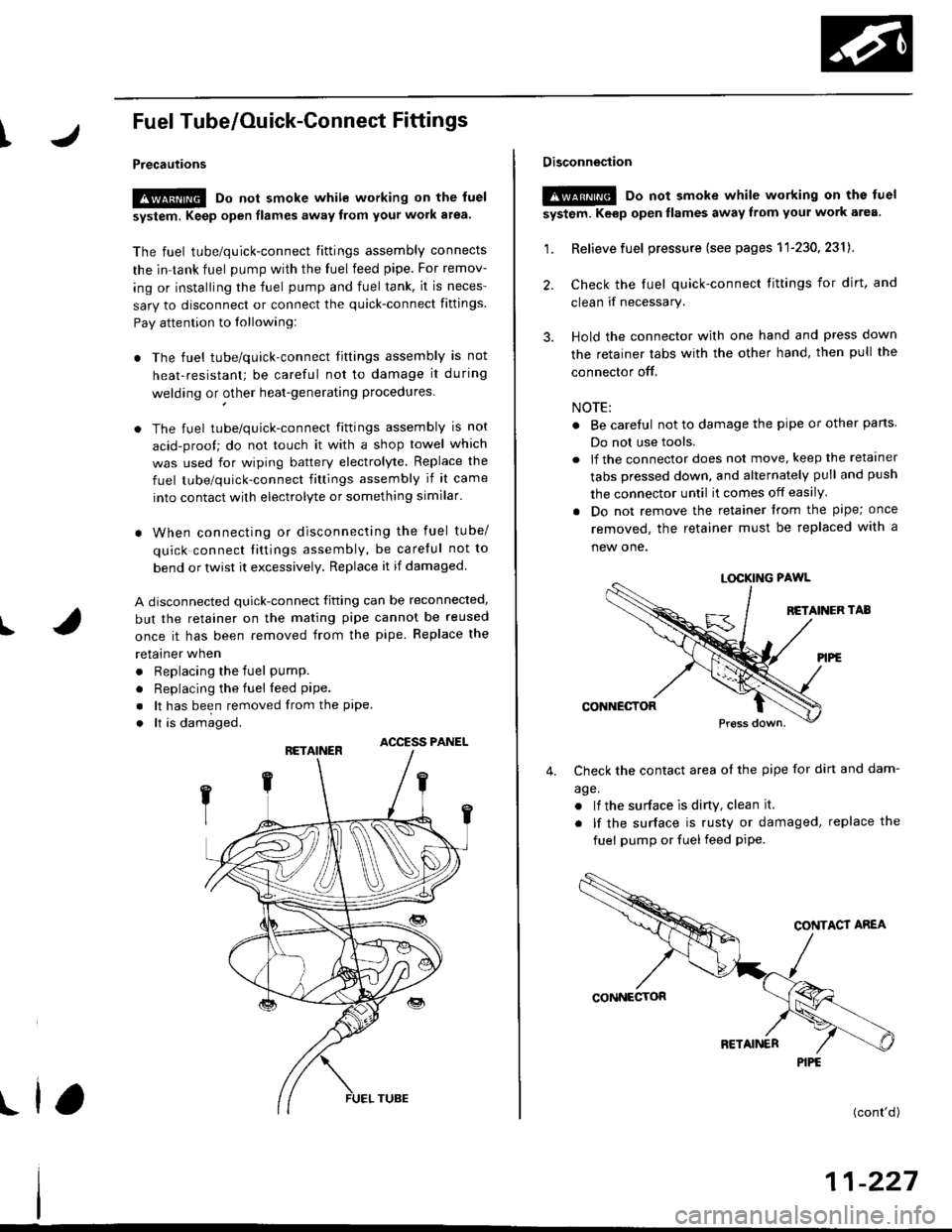

Fuel Tube/Ouick-Gonnect Fittings

Precautions

!@ Do not smoke while working on the fuel

system, Keep open flames away from your work a.ea'

The fuel tube/quick-connect fittings assembly connects

the in tank fuel pump with the fuel feed pipe. For remov-

ing or installing the fuel pump and fuel tank, it is neces-

sary to disconnect or connect the quick-connect fittings.

Pay attention to lollowing:

. The fuel tube/quick-connect fittings assembly is not

heat-resistant; be careful not to damage it during

welding or other heat-generating procedures

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. Replace the

fuel tube/quick-connect fitlings assembly if it came

into contact with electrolyte or something similar.

. When connecting or disconnecting the fuel tube/

quick connect liltings assembly, be careful not to

bend or twist it excessively. Replace it if damaged

A disconnected quick-connect fitting can be reconnecled,

but the retainer on the mating pipe cannot be reused

once it has been removed from the pipe. Replace the

retatner wnen

. Replacing the fuel pump.

. Replacing the fuel leed pipe.

. lt has been removed lrom the PiPe.. lt is damaged.

ACCESS PANEL

I

Disconnestion

!@ Do not smoke while working on the luel

system. Keep open llames away lrom youl work area.

1. Relieve fuel pressure (see pages 11'230,2311.

2. Check the tuel quick-connect tittings for dirt, and

clean if necessary.

3. Hold the connector with one hand and press down

the retainer tabs with the other hand, then pull the

connector off.

NOTE:

o Be carelul not to damage the pipe or other pans

Do not use tools.

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

. Do not remove the retainer from the pape; once

removed, the retainer must be replaced with a

new one.

LOCKING PAWL

BETAINER TAB

CONNECTOR

Check the contact area o{ the pipe for dirt and dam-

age.

. lf the surface ls dirty, clean it.

. lf the surface is rusty or damaged, replace the

fuel pump or fuel feed piPe.

4.

(cont'd)

11-227

PIPE