Face HONDA CIVIC 1997 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 570 of 2189

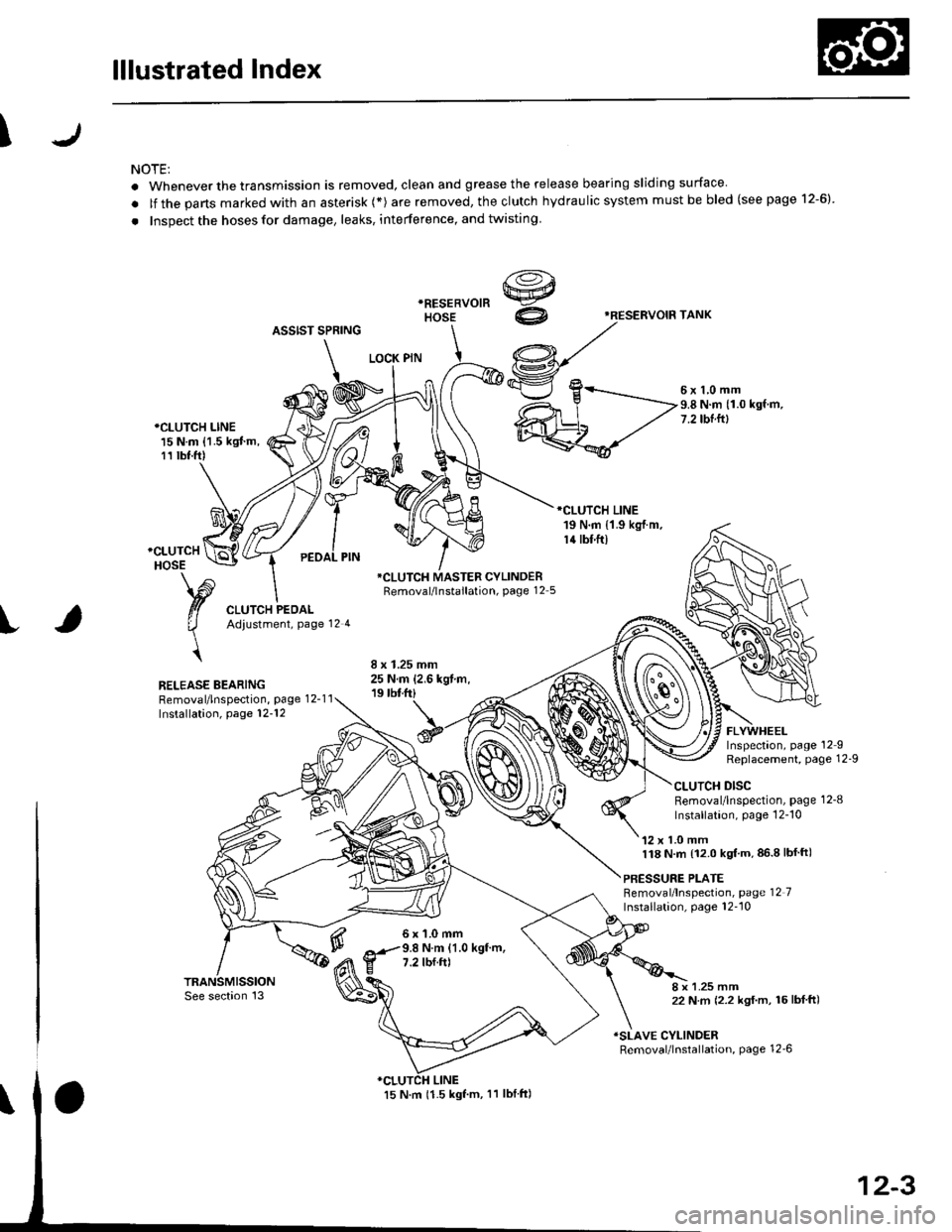

lllustrated Index

\

NOTE:

. Whenever the transmission is removed, clean and grease the release bearing sliding surface

. lf the parts marked with an asterisk (*) are removed, the clutch hydraulic system mustbe bled (seepage 12-6)

. Inspect the hoses for damage, leaks, interference, and twisting

'RESERVOIF TANK

ASSIST SPRING

LOCK PIN

5x1,0mm9.8 N.m (1.0 kgf.m,7.2 tbtftl*CLUTCH LINE15 N.m {1.5 kgJ m,11 tbt.ft)

RELEASE BEARINGRemoval/lnspection, page 12-1 1Installation, page 12-'12

*CLUTCH MASTER CYLINDERRemoval/lnstallation, page 12 5

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbf.ft)

FLYWHEELInspectaon, page 12IReplacement, Page 12-9

CLUTCH DISCRemoval/lnspection, page 1 2-8

lnstallation, page 12-'10

'12 x 1.0 mm118 N.m {12.0 kgt'm,86.8lbfft)

PBESSURE PLATEBemoval/lnspection, page 12 7Installation, page 12''10

8 x 1.25 mm22 N m (2.2 kgf.m, 16lbf ft)

ISLAVE CYLINDERRemoval/lnstallation, page 12_6

12-3

Page 574 of 2189

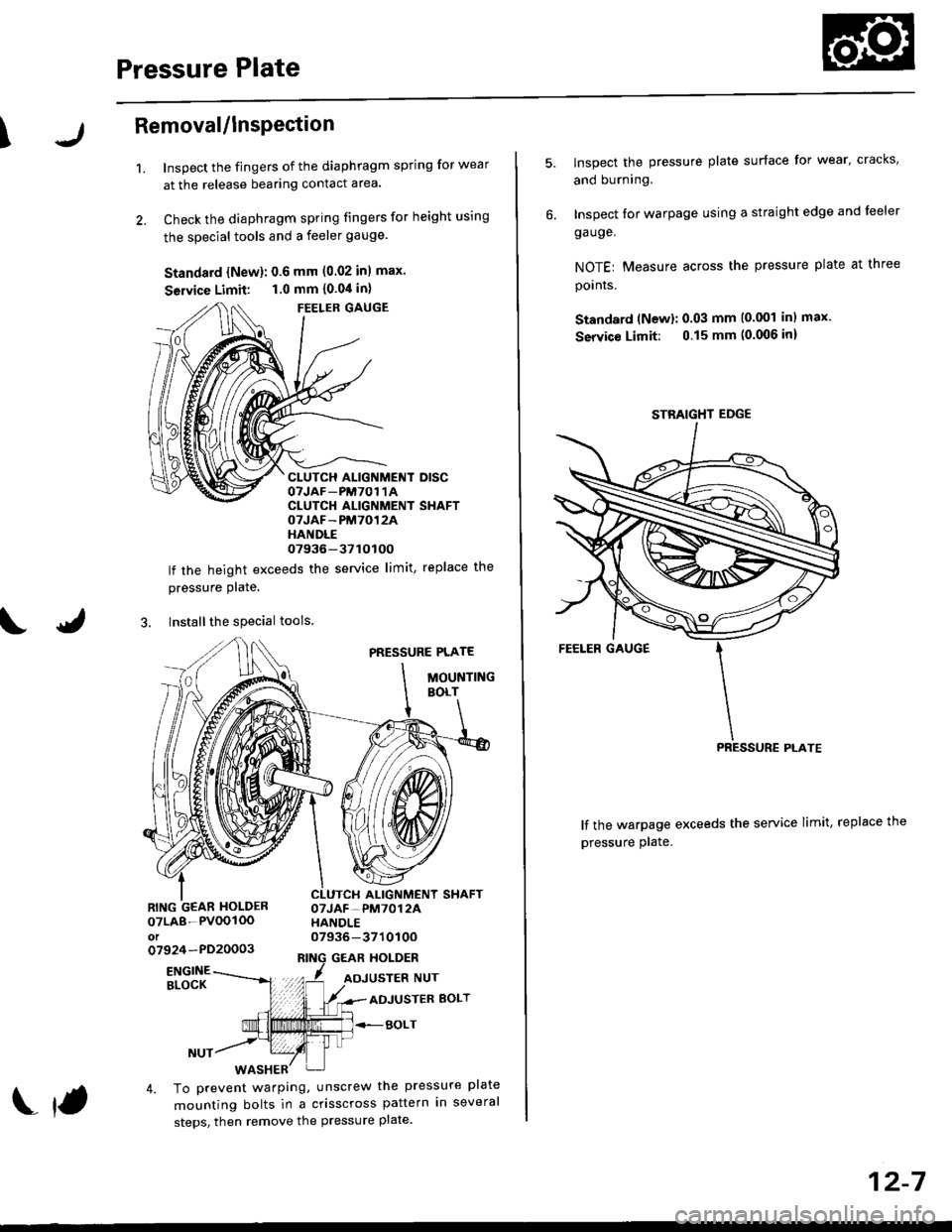

Pressure Plate

\Removal/lnsPection

1.Inspect the fingers of the diaphragm spring for wear

at the release bearing contact area.

Check the diaphragm spring fingers for height using

the special tools and a feeler gauge.

Standard {New}: 0.6 mm (0.02 inl max.

Seruice Limit: 1.0 mm {0.04 in}

FEELER GAUGE

CLUTCH ALIGNMENT DISCOTJAF_PM7O1 1ACLUTCH ALIGNMENT SHAFTOTJAF-PM7012AHANDLE07936-37tOtOO

lf the height exceeds the service limit, replace the

pressure Plate.

3. Installthe special tools

PRESSURE PLATE

MOUNTINGBOLT

ALIGNMENT SHAFTOTJAF-PM7012AHANDLE07936-371010Oo7924-PD20003GEAR HOLDER

07LA8-PVOOIOOot

ENGINEBLOCKADJUSTER BOLT

BOLT

4. To prevent warping, unscrew the pressure plate

mounting bolts in a crisscross pattern in several

steps, then remove the pressure plate.

f

12-7

lnspect the pressure plate surface for wear' cracks,

and burning.

Inspect for warpage using a straight edge and leeler

ga uge.

NOTEr Measure across the pressure plate at three

pornrs.

Standard (Newl: 0.03 mm (0.001 inl max.

Service Limit: 0.15 mm (0.006 inl

lf the warpage exceeds the service limit, replace the

pressure plate.

STBAIGHT EDGE

Page 575 of 2189

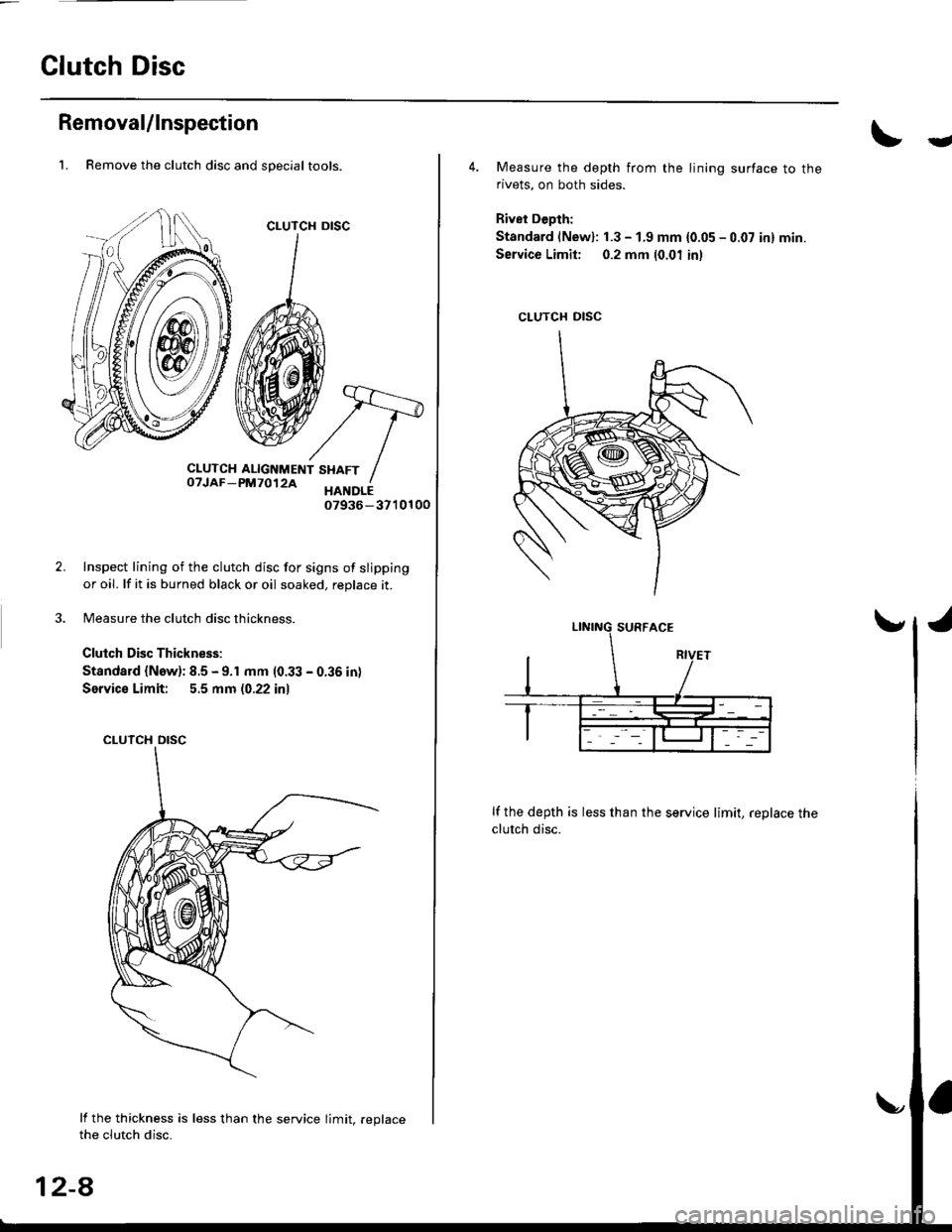

Clutch Disc

RemovaUlnspection

2.

'1. Remove the clutch disc and special tools.

CLUTCH

CLUTCH ALIGNMENT SHAFToTJAF-pM7012A xltori07936-3710100

Inspect lining of the clutch disc for signs of slipping

or oil. lf it is burned black or oil soaked, replace it.

Measure the clutch disc thickness.

Clulch Disc Thickness:

Standard (Now): 8.5 - 9.1 mm (0.33 - 0.36 in)

Servic€ Limit: 5.5 mm (0.22 inl

CLUTCH

lf the thickness is less than the service limit. .eolacethe clutch disc.

12-8

U

4. Measure the depth from the lining surface to therivets, on both sides.

Rivet Depth:

Standard lNewl: 1.3 - 1.9 mm {0.05 - 0.07 in} min.

Service Limit: 0.2 mm (0.01 in)

lf the depth is less than the service limit, replace the

clutch disc.

CLUTCH DISC

Page 576 of 2189

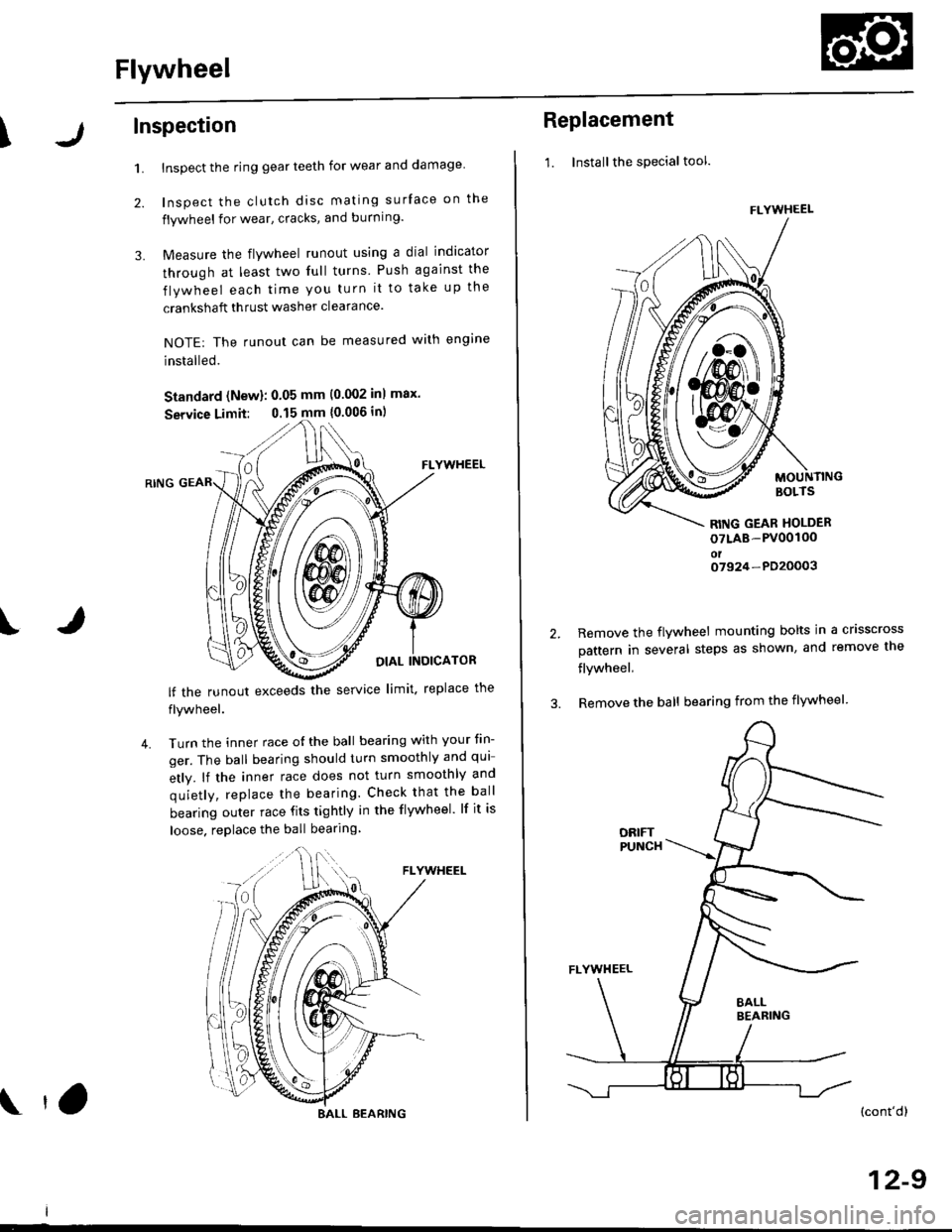

Flywheel

\Inspection

1.

2.

3.

Inspect the ring gear teeth for wear and damage

Inspect the clutch disc mating surface on the

flywheel for wear, cracks, and burning.

Measure the flywheel runout using a dial indicator

through at least two full turns Push against the

flywheel each time you turn it to take up the

crankshaft thrust washer clearance.

NOTE: The runout can be measured with engine

installed.

Standard (New): 0.05 mm (0.002 inl max.

Service Limit: 0.15 mm {0.006 in)

FLYWHEEL

OIAL INOICATOR

FLYWHEEL

lf the runout exceeds the service limit. replace the

flywheel.

Turn the inner race o{ the ball bearing with your tin-

ger. The ball bearing should turn smoothly and qui

etly. lf the inner race does not turn smoothly and

quietly, replace the bearing. Check that the ball

bearing outer race fits tightly in the flywheel. lf it is

loose. replace the ball bearing

IJ

4.

BALL BEARING tO

Replacement

1. Installthe special tool.

MOUNTINGBOLTS

RITIG GEAR HOLDER

oTLAB-PV00100oto7924-PD20003

2.Remove the flywheel mounting bolts in a crisscross

pattern in several steps as shown, and remove the

flywheel,

Remove the ball bearing from the flywheel

(cont'dl

12-9

FLYWHEEL

t\

m\J

Page 585 of 2189

Transmission Assembly

I

Removal

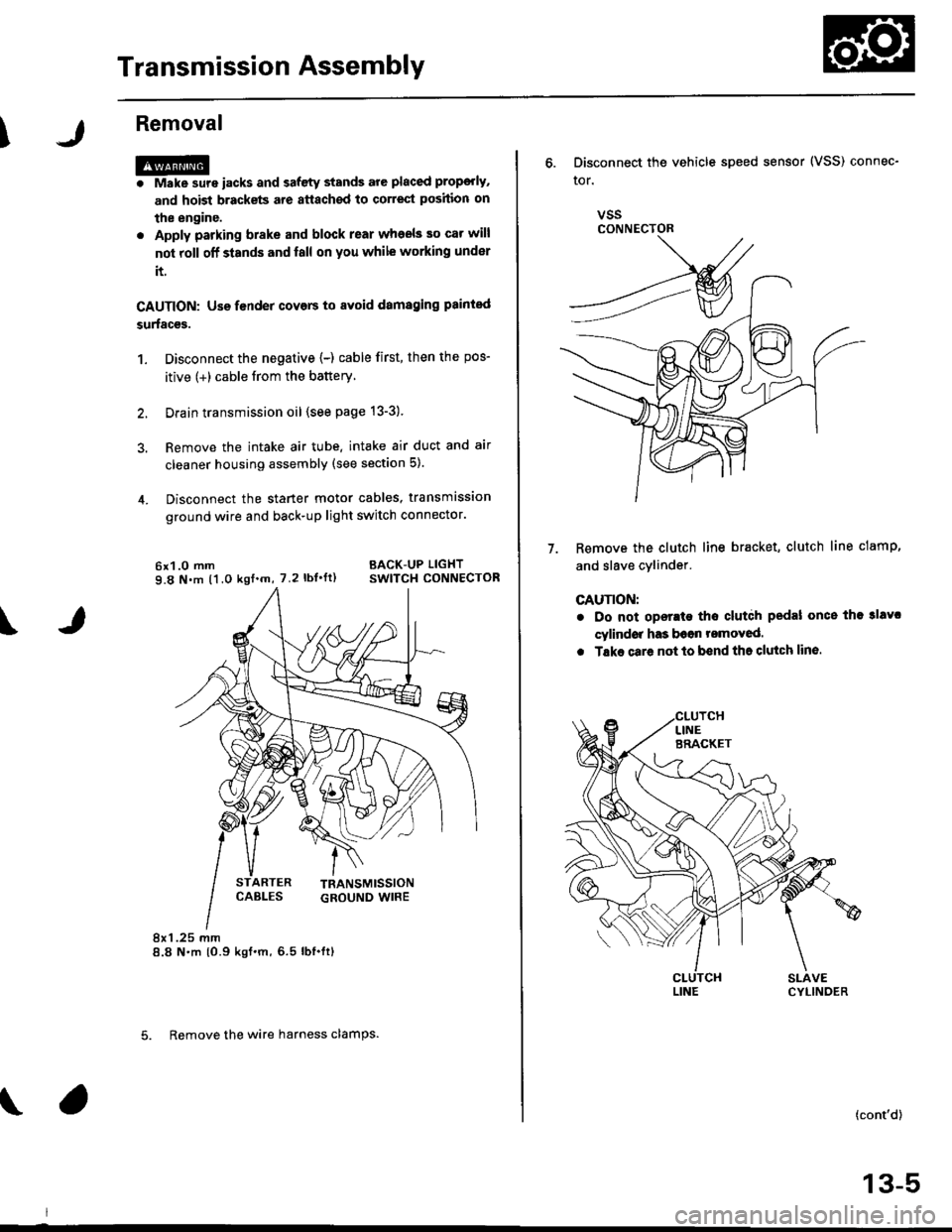

@. Make sure iacks and safety stands are placed prop€dy,

and hoist brackets are atlach€d to correct position on

the enginc.

. Apply parking brake and block rear whosls so car will

nol roll olf stands and lall on you while working under

it.

CAUTION: Use fender covers to svoid damaging painted

surfaces.

1. Disconnect the negative {-) cable first, then the pos-

itive (+) cable from the battery'

Drain transmission oil {see page 13-3).

Remove the intake air tube. intake air duct and air

cleaner housing assembly (see section 5).

Disconnect the starter motor cables, transmission

ground wire and back-up light switch connector.

6x1.0 mm BACK-UP LIGHT

9.8 N.m (1.0 ksf.m, 7.2 lbI.ft) swlTcH CoNNECTOR

8x 1 .25 mm8.8 N.m {0.9 kgt.m,6.5 lbf.ftl

\

ARTER

5. Remove the wire harness clamps.

vssCONNECTOR

6. Disconnect the vehicle speed sensor (VSS) connec-

ror.

Remove the clutch line bracket, clutch line clamp,

and slave cvlinder.

CAUTION:

. Do not opsr.te tho clutdh pedal once the 3lavc

cylindor has b6on romoved.

. Tske care not to bend tha clutch lin6.

7.

(cont'd)

13-5

Page 586 of 2189

Transmission Assembly

Removal (cont'dl

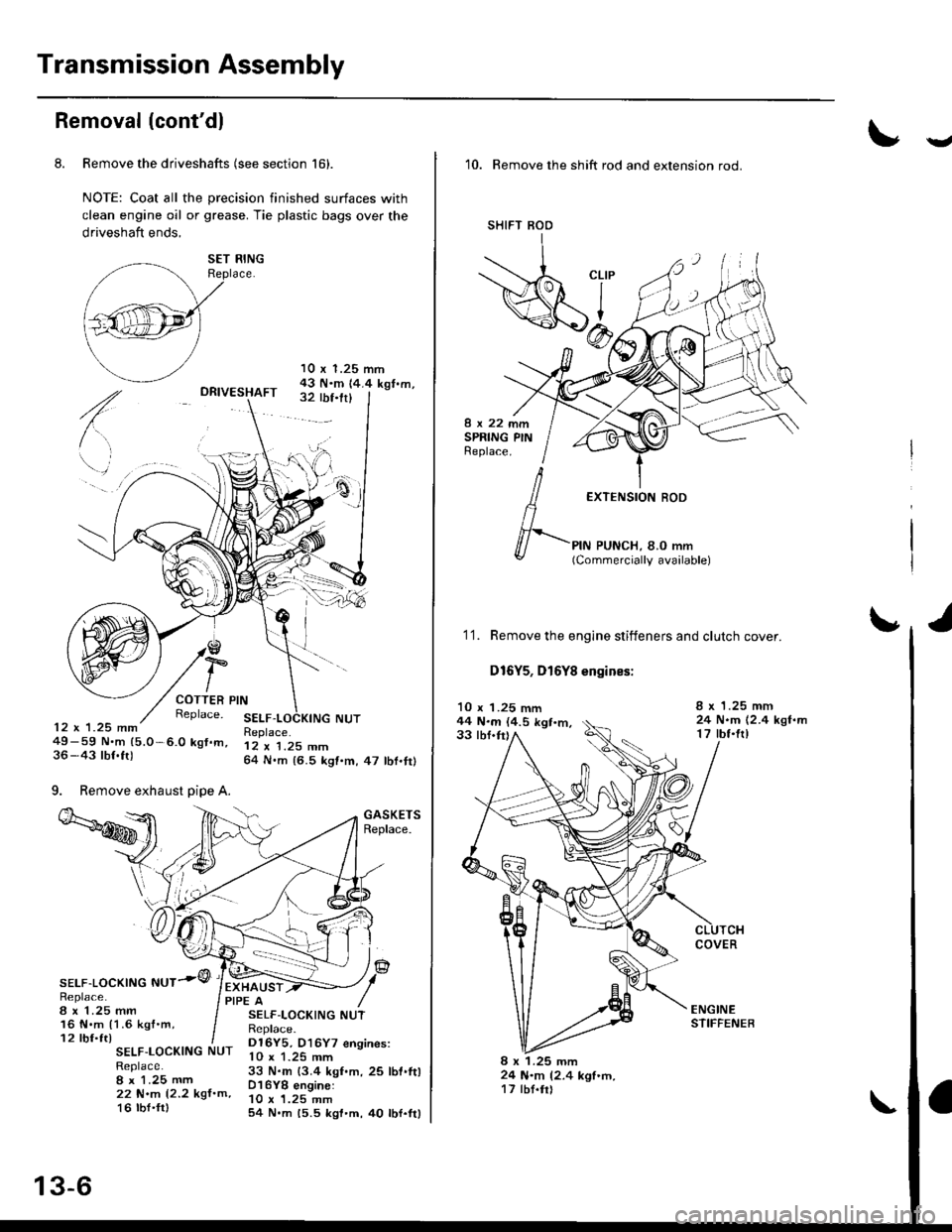

8. Remove the driveshafts (see section 161.

NOTE: Coat all the precision finished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends,

DRIVESHAFT

10 x 1.25 mrn43 N.m 14.4 kgt.m,32 rbf.frl

COTTER PINReplace. SELF12 x 1.25 mm49-59 N.m (5.0 -6.0 kgt.m,36-43 lbf.ft)

9. Remove exhaust pipe A.

Replace.12 x 1.25 mm64 N.m {6.5 kgt.m,47 lbf.tr)

GASKETSReplace.

IF\sELF-LocKtNG NUT.''1/Replace.8 x 1.25 mm16 N.m {1.6 kgf'm,12 tbf.ft)

EXHAUSTPIPE A

SELF-LOCKING NUTReplace.I x 1.25 mm22 N.m (2.2 kgf.m,16 tbt'fr)

SELF-LOCKING NUTReplace.D16Y5, D16Y7 engines:

33 N.m {3.4 kgf.m,25 lbt.ft)D16YB engine:10 x 1.25 mm54 N.m 15.5 kgl'm,40 lbf.ttl

SET RING

13-6

v'10. Remove the shift rod and extension rod.

SI'IIFT BOD

8x22mmSPRING PINReplace.

EXTENSION ROD

PIN PUNCH, 8.O mm(Commercially available)f-

'1'1. Remove the engine stiffeners and clutch cover.

D16Y5, D16Y8 engines:

10 x 1.25 mm44 N.m (4.5 kgt.m,33 tbf.tr)

I x 1.25 mm24 N.m (2.4 kgf.m17 lbt.frl

COVER

8 x 1.25 mm24 N.m 12.4 kgf'tn,17 tbt.tr)

Page 595 of 2189

Mainshaft Assembly

I

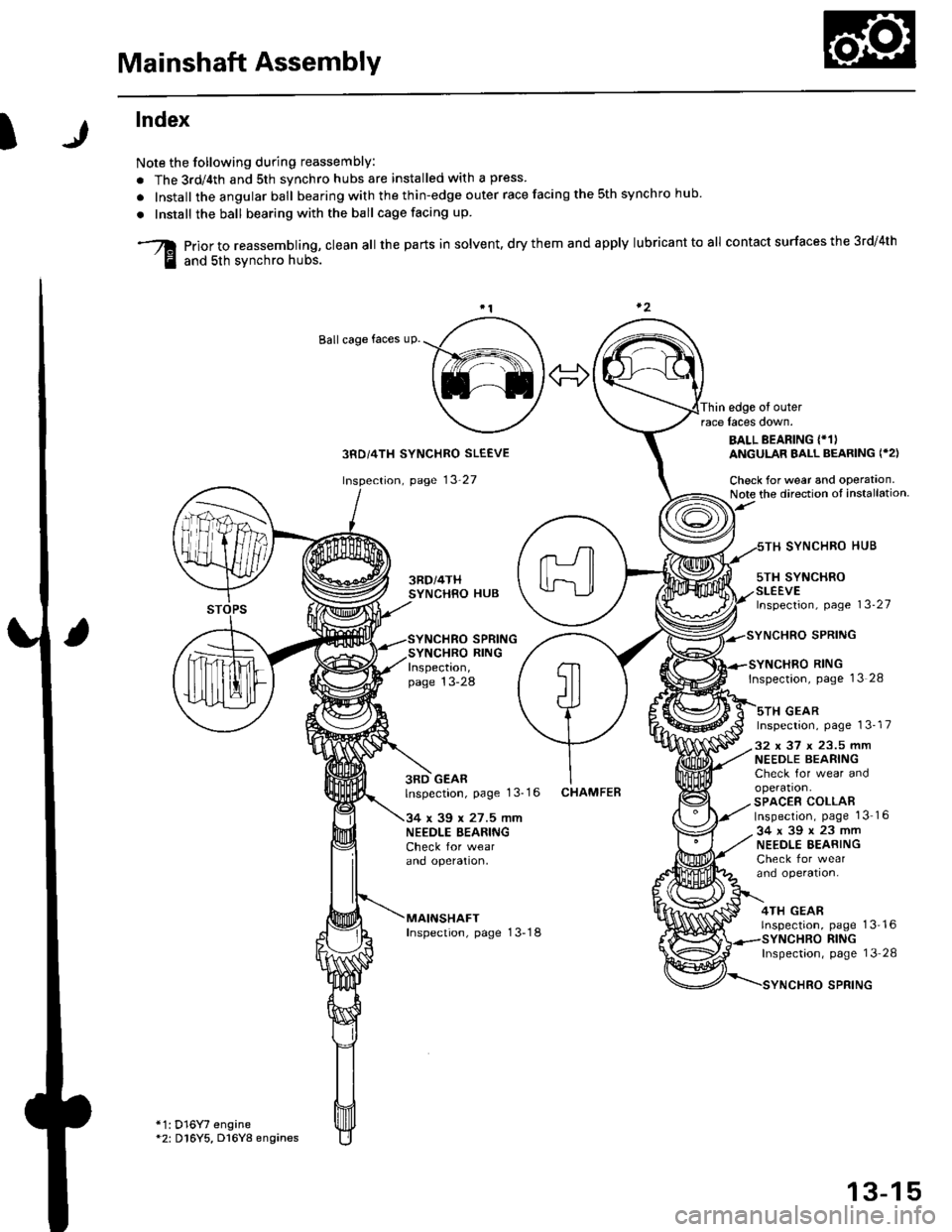

lndex

Note the following during reassembly:

. The 3rd/4th and sth svnchro hubs are installed with a press

. Install the angular ball bearing with the thin-edge outer race facing the sth synchro hub

. Install the ball bearing with the ball cage facing up

prior to reassembling, clean all the parts in solvent, dry them and apply lubricant to all contact surfaces the 3rd/4th

and sth svnchro hubs.

Ballcage faces uP.

Thin edge of outerrace laces down.

3RD/4TH SYNCHRO SLEEVE

page 13'27

SYNCHRO SPRINGSYNCHRO RINGInspection,page 13-28

BALL BEARING {*1)ANGULAR BALL BEARING ('2)

Check for wear and operataon.Note the direction ot installation

5TH SYNCHROSLEEVElnspection, page 13-27

SYNCHRO HUB

SYNCHRO RINGInspection, pase 13 28

sTH GEARInspection, page 13-17

3RD GEARlnspection, page 1 3-1 6

34 x 39 x 27.5 mmNEEDLE BEARINGCheck for wearano opetaflon,

MAINSHAFTInspection, page 13-18

CHAMFEB

32 x 37 x 23.5 mmNEEDLE BEARINGCheck for wear andoperation.SPACER COLLABInspection, page 1316

34x39x23mmNEEDLE EEARINGCheck for wearand operation,

4TH GEARrnspeclron,

*1: D16Y7 engine*2: D16Y5, D16Y8 engines

page 13'16RINGInspectaon, page 13 28

SPRING

13-15

Page 598 of 2189

Mainshaft Assembly

Disassembly (cont'd)

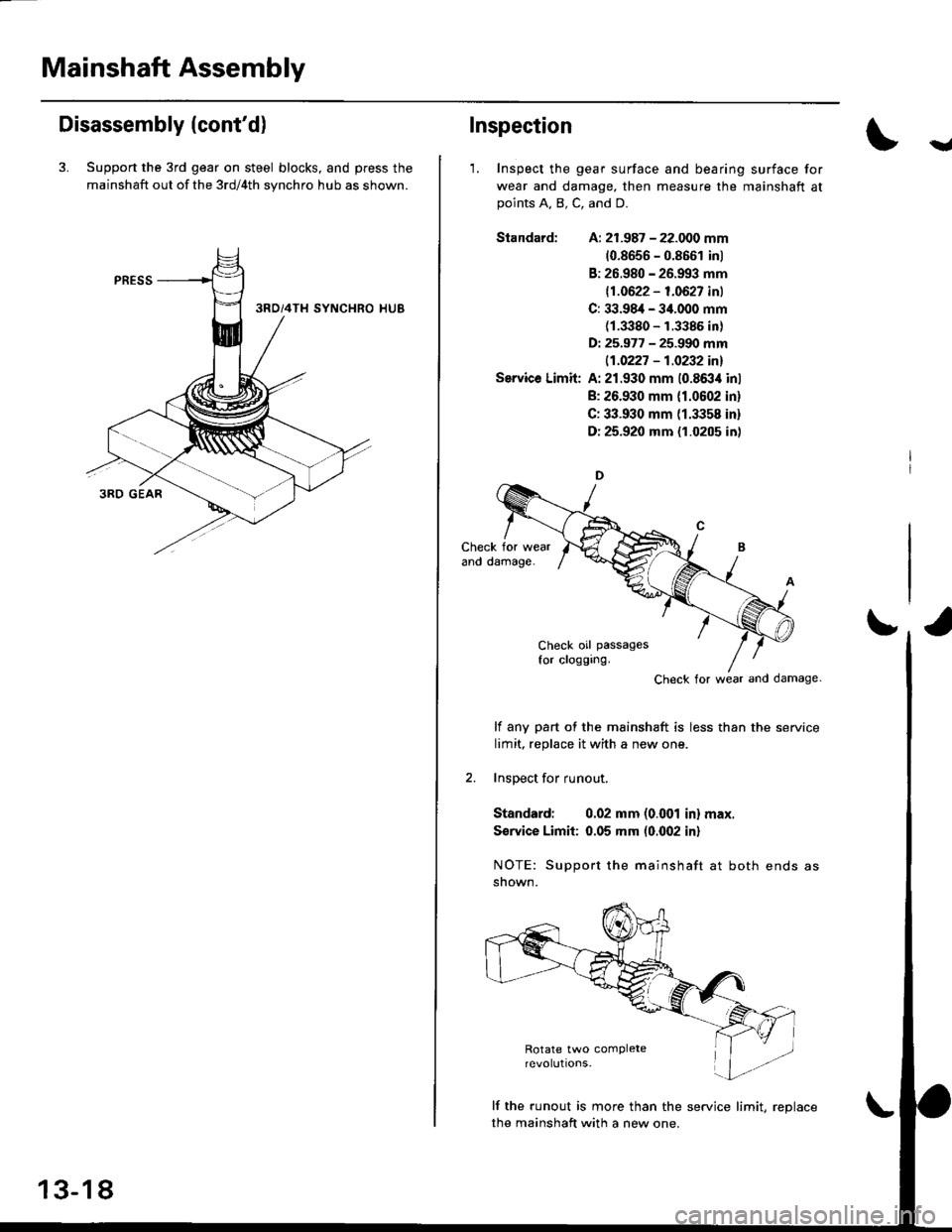

3. Support the 3rd gear on steel blocks, and press the

mainshaft out of the 3rd/4th synchro hub as shown.

13-18

Inspection

'1. Inspect the gear surface and bearing surface for

wear and damage. then measure the mainshaft atpoints A, B, C, and D.

Siandard: A: 21.987 - 22.000 mm

10.8656 - 0.8661 inl

B: 26.980 - 26.993 mm

11.0622 - 1.0627 inl

C: 33.98,1- 34.000 mm(1.3380 - 1.3385 in)

D: 25.977 - 25.990 mm

|.1.0227 - 1.0232 inl

Service Limit: A: 21.930 mm 10.8634 inl

B: 26.930 mm {1.0602 in}

C: 33.930 mm (1.3358 in)

D: 25.920 mm (1.0205 in)

Check for wear and damage

lf any part of the mainshaft is less than the service

limit, replace it with a new one.

2. Inspect for runout.

Standardi 0.02 mm (o.(Xtl in) max.

S€rvice Limii: 0.05 mm (0.002 in)

NOTE: Support the mainshaft at both ends as

snown.

lf the runout is more than the service lirnit, reolace

the mainshaft with a new one.

Y

Page 599 of 2189

I

)r'

Reassembly

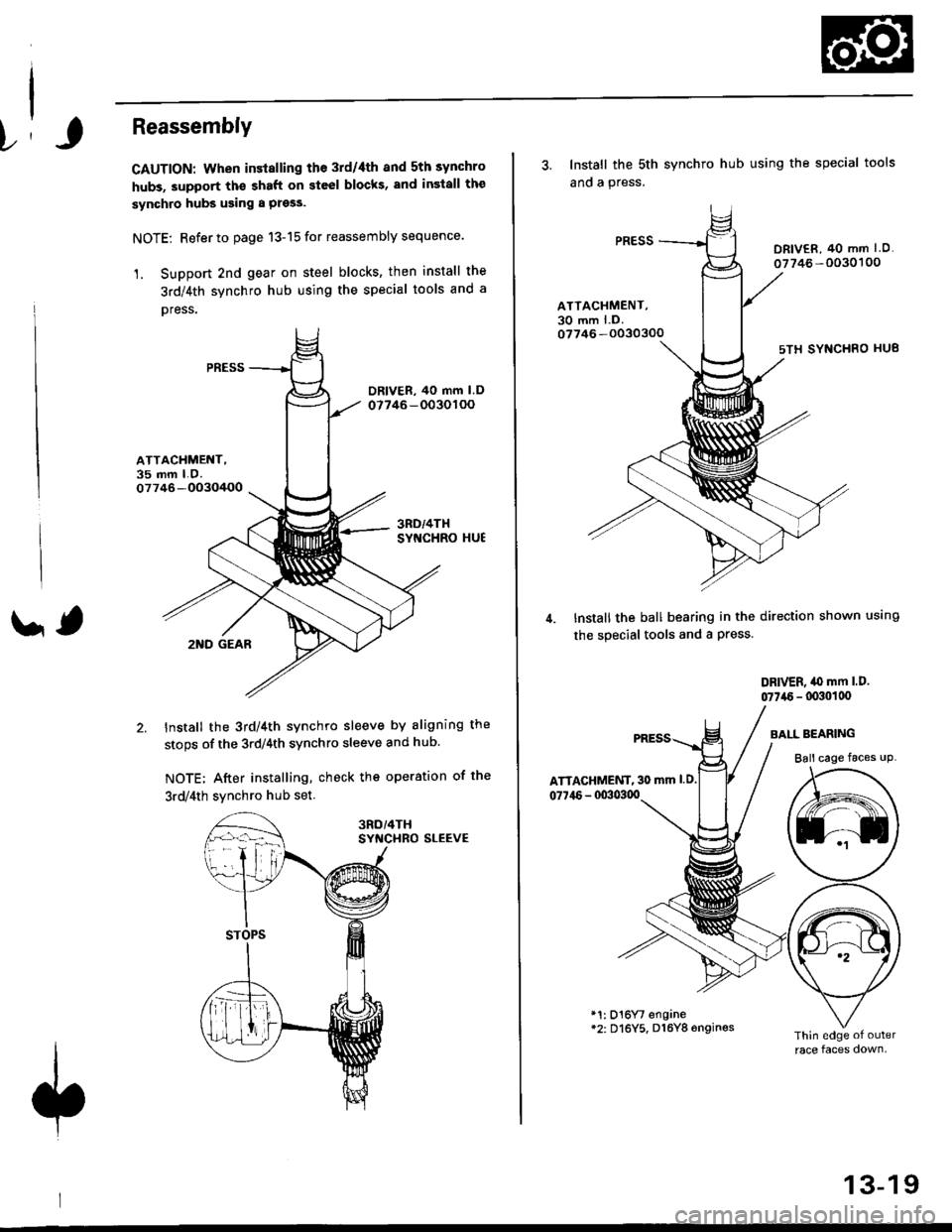

CAUTION: When installing the 3rd/4th and 5th synchro

hubs, support th€ shaft on steel blocks, and insiall the

synchro hubs using a press.

NOTE: Refer to page 13-15 for reassembly sequence.

1. Support 2nd gear on steel blocks' then install the

3rd/4th synchro hub using the special tools and a

oress.

ATTACHMENT,35 mm LO.07746-OO3O/+OO

' ,2I{D GEAR

Install the 3rd/4th synchro sleeve by aligning the

stops of the 3rdl4th synchro sleeve and hub.

NOTE; After installing, check the operation of the

3rd/4th svnchro hub set

SYf{CHRO SLEEVE

3. Install the sth

ano a press.

synchro hub using the special tools

DRIV€R, 40 mm I O.

07746 -0030'�100

ATTACHMENT,30 mm l.D.07746 -O030300

sTH SYNCHRO HU8

Install the ball bearing in the direction shown using

the special tools and a Press.

DRIVER, iO mm l.D.

07746 - lxxlollx'

ATTAGHMENT, 30 mm l.D.

077i16 - 00303qt

BAI-L BEARING

Ball cage faces uP

*1: D16Yt engane*2: Dl6Y5, D16Y8 6ngines

13-19

Page 600 of 2189

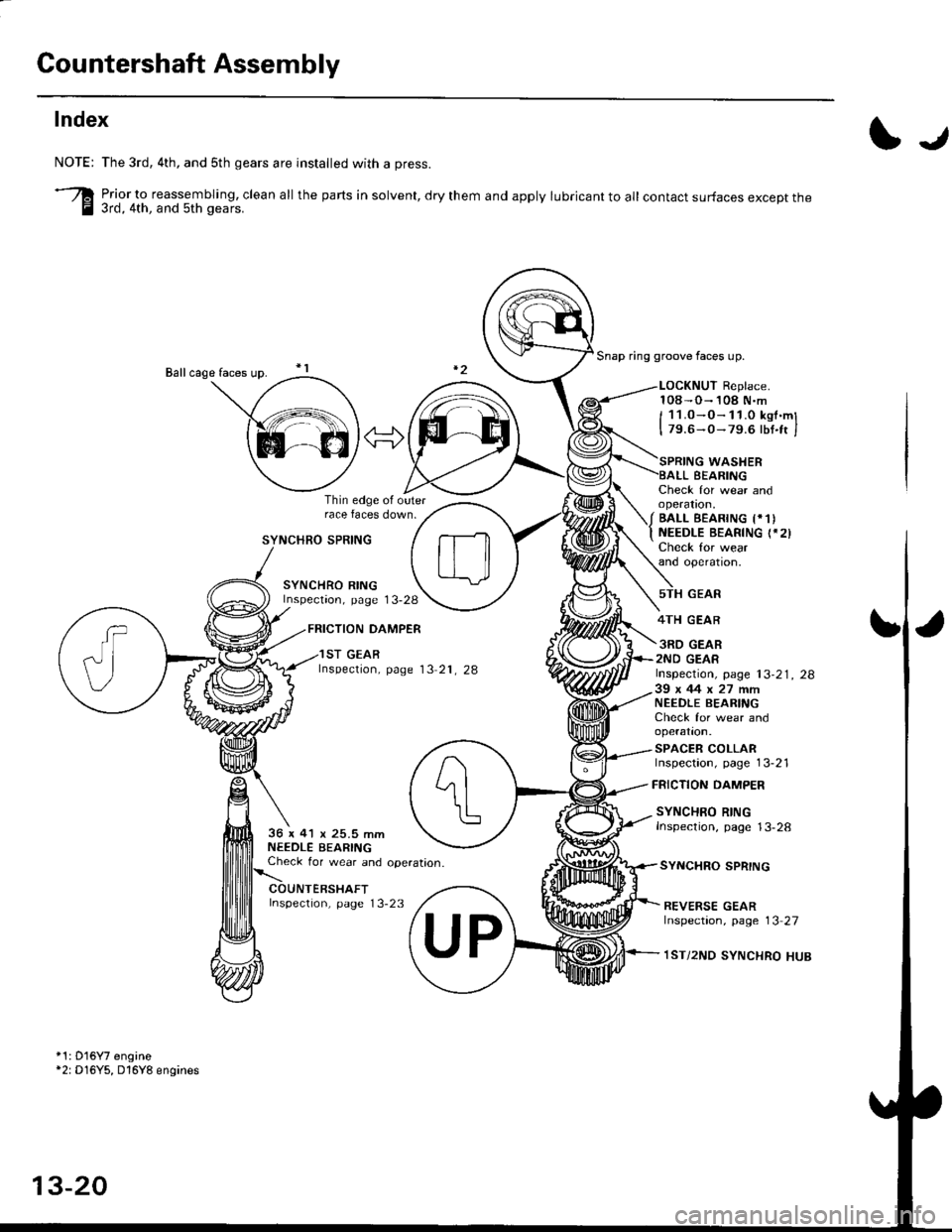

Countershaft Assembly

Index

I.r

NOTE:

-re

The 3rd, 4th, and sth gears are installed with a press.

Prior_to reassembling, clean all the parts in solvent, dry them and apply lubricant to all contact surfaces except the3rd, 4th, and 5th gears.

Snap ring groove faces up.

LOCKNUT Replace.108-O- 108 N.m

I 11.0-O-11.0 kst.ml

I 79.6-0- 79.6 lbt.ft I

SYNCHRO SPRING

SYNCHRO RINGInspectaon, page 13-28

FRICTION DAMPER

Thin edge ol outerrace faces down.

Check for wear andoperatron,

/ BALL EEAR|NG t*1)

t NEEDLE BEARTNG (.2)

Check for wearand operatron,

WASHERBEARING

GEAR

4TH GEAR

3RD GEAR2ND GEAR

FRICTION DAMPER

SYNCHRO SPRING

SYNCHRO RINGInspection, page 13-2836 x 41 x 25.5 mmNEEDLE BEARINGCheck for wear and operataon.

Inspection, page 13-23

1ST GEARlnspection, page 13 21, 28lnspection, page 13-21, 2839x44x27m�mNEEDLE BEARIfI'GCheck for wear andoperation.

SPACER COLLARInspection, page 13-21

REVERSE GEARlnspection, page 13 27

1ST/2ND SYNCHRO HUB

*1: D'16Y7 engine*2: D16Y5, D16Y8 engines

13-20