engine removal HONDA CIVIC 1997 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1175 of 2189

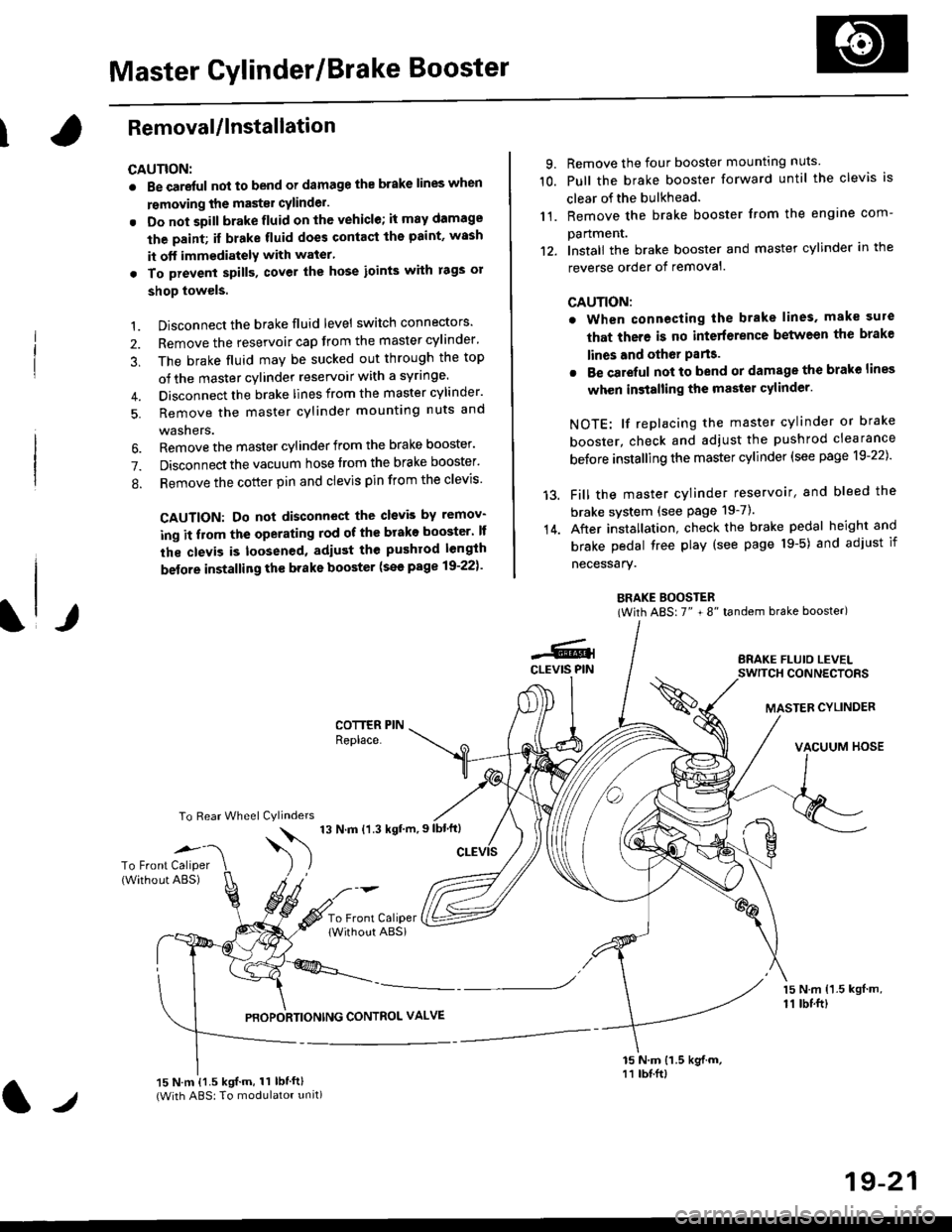

Master Cylinder/Brake Booster

IRemovaUlnstallation

CAUTION:

. Be care{ul nol to bend or damage the brake lines when

rsmoving the mastsr cYlinder.

. Do not soill brakefluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wssh

it off immediatelY with water'

. To prevent spill3, cover the hose ioints with rags or

shop towels.

9. Remove the four booster mountlng nuts

10. Pull the brake booster forward until the clevis is

clear of the bulkhead.

11. Remove the brake booster from the engine com-

panmenr.'12. Install the brake booster and master cylinder in the

reverse order of removal.

CAUTION:

. When connecting the brake lines. make sure

that there is no inte erence between the brake

lines and oth6r Parts.

r Be careful not to bend or damage the brake lines

when installing the master cylinder.

NOTE: lf replacing the master cylinder or brake

booster, check and adiust the pushrod clearance

be{ore installing the master cylinder (see page 19-221'

Fill the master cylinder reservoir, and bleed the

brake svstem (see Page 19-7).

After installation. check the brake pedal height and

brake pedal tree play (see page l9-5) and adjust if

necessary.

BRAKE BOOSTER(With ABS: 7" + 8" tandem brake booster)

BRAKE FLUIO LEVELSWITCH CONNECTORS

MASTER CYLINDER

VACUUM HOSE

1.

2.

3,

5.

Disconnect the brake fluid level switch connectors'

Remove the reservoir cap from the master cylinder'

The brake fluid may be sucked out through the top

of the master cylinder reservoir with a syrlnge.

Disconnect the brake lines from the master cylinder'

Remove the master cylinder mounting nuts and

washers.

\l/

6. Remove the master cylinder from the brake booster'

7. Disconnect the vacuum hose trom the brake booster'

8. Remove the cotter pin and clevis pin from the clevis'

CAUTION: Do not disconnect the clevb by remov-

ing it from the operating rod of the brako booster' lf

the clevis is loosened, adiust the pushrod length

before installing th€ brake booster (see page 19-221'

COTTER PINReplace.

To Rear Wheel Cylinders

14.

-6.4CLEVIS PIN

To Front Caliper(Without ABS)$

t'N't'ttrnt'-''

To Front CaliperlWithout ABSi

PBOPORTIONING CONTROL VALVE

15 N.m {1.5 kgl m,11 tbtft)

15 N.m {1.5 kgif.m, 11 lbtft}(With ABS: To modulator unit)lr

19-21

Page 1228 of 2189

\il

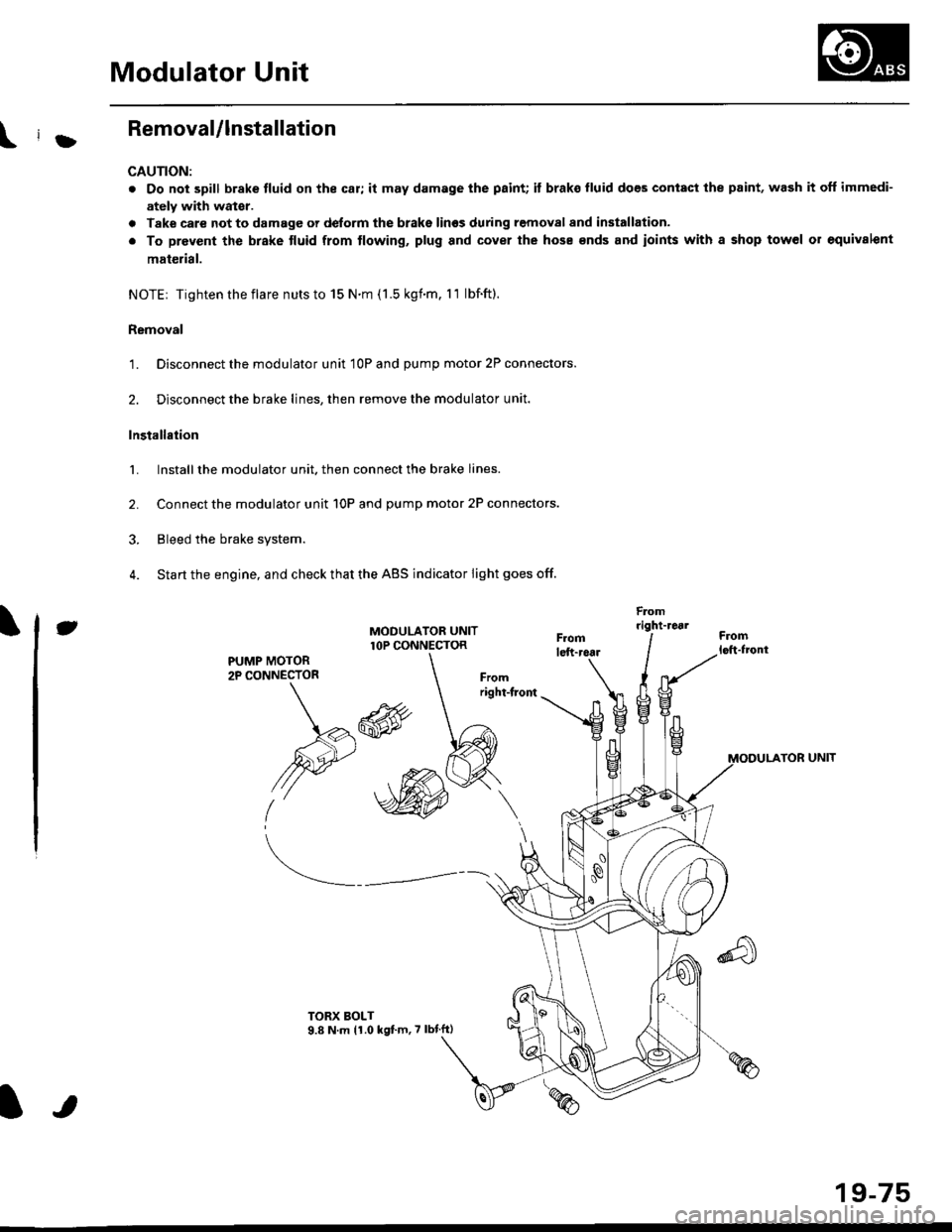

Modulator Unit

RemovaUlnstallation

CAUTION:

. Do not spill brake tluid on the car; it may damage the paint; it brako lluid does contact the paint, wash it off immedi-

ately with wator.

a Take care not to damage or delorm the brake lin€s during removal and installation.

. To prevent the brake tluid from tlowing, plug and cover the hose €nds and ioints with a shop tow6l or equivalent

mat€rial.

NOTE| Tightentheflare nutsto 15 N.m (1.5 kgnm. l1 lbf.ft).

Removal

'1. Disconnect the modulator unit 10P and Dump motor 2P connectors.

2. Disconnect the brake lines, then remove the modulator unit.

Installaiion

1. Install the modulator unit. then connect the brake lines.

2. Connect the modulator unit 10P and oumD motor 2P connectors.

3. Bleed the brake system.

4. Start the engine, and check that the ABS indicator light goes off.

Fomright-1461

PUMP MOTOR2P CONNECTOR

J

-R

/2e'

t'

TOR UNIT

tt

19-75

Page 1414 of 2189

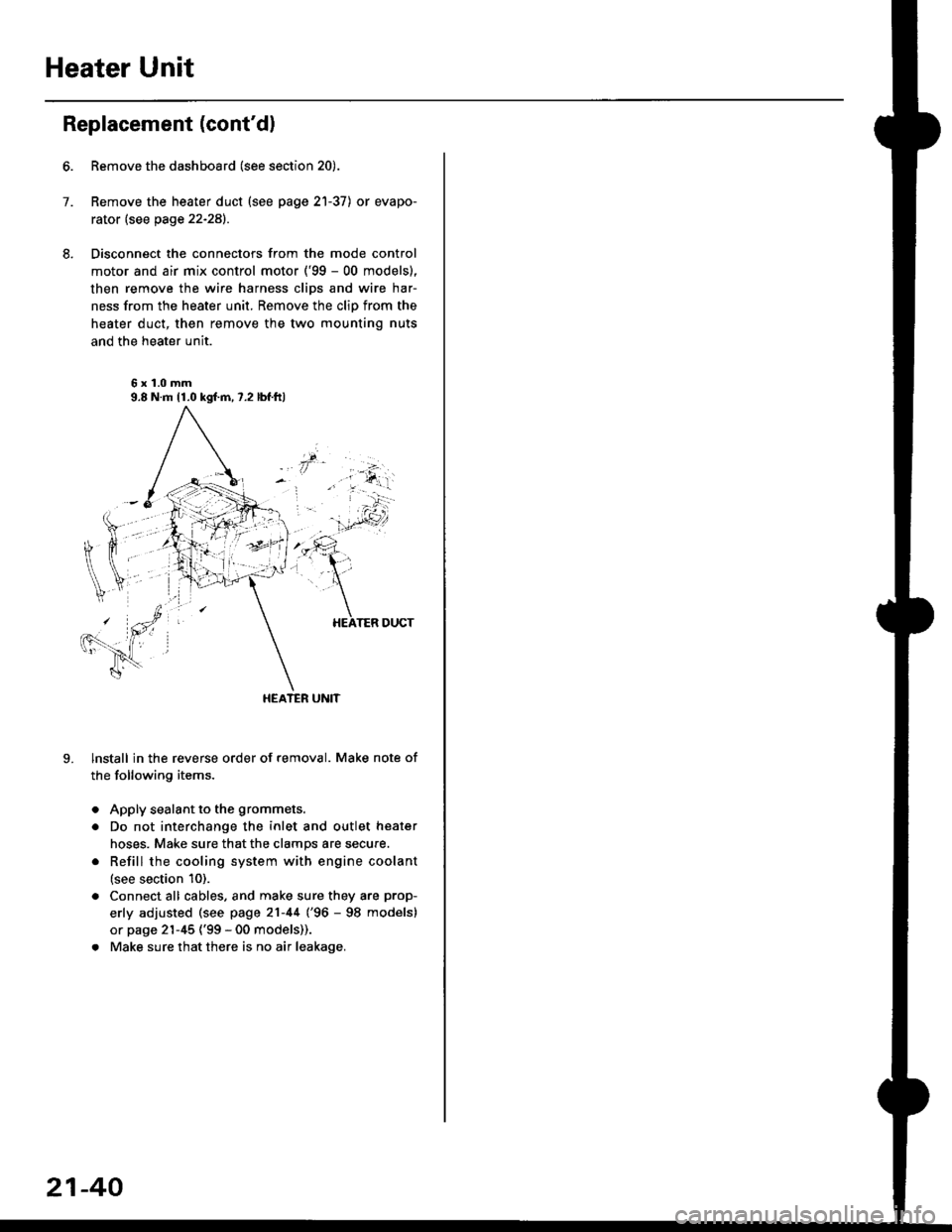

Heater Unit

Replacement (cont'dl

6.

7.

8.

9.

Remove the dashboard (see section 20).

Remove the heater duct (see page 21-37) or evapo-

rator (see page 22-28).

Disconnect the connectors from the mode control

motor and air mix control motor ('99 - 00 models),

then remove the wire harness clips and wire har-

ness from the heater unit. Remove the clip from the

heater duct, then remove the two mounting nuts

and the heater unit.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 lbf.ftl

HEATER UNIT

lnstall in the reverse order of removal. Make note of

the following items.

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

(see section 10).

Connect all cables, and make sure they are prop-

erly adjusted (see page 21-44 (96 - 98 models)

or page 21-45 ('99 - 00 models)).

Make sure that there is no air leakage.

21-40

Page 1455 of 2189

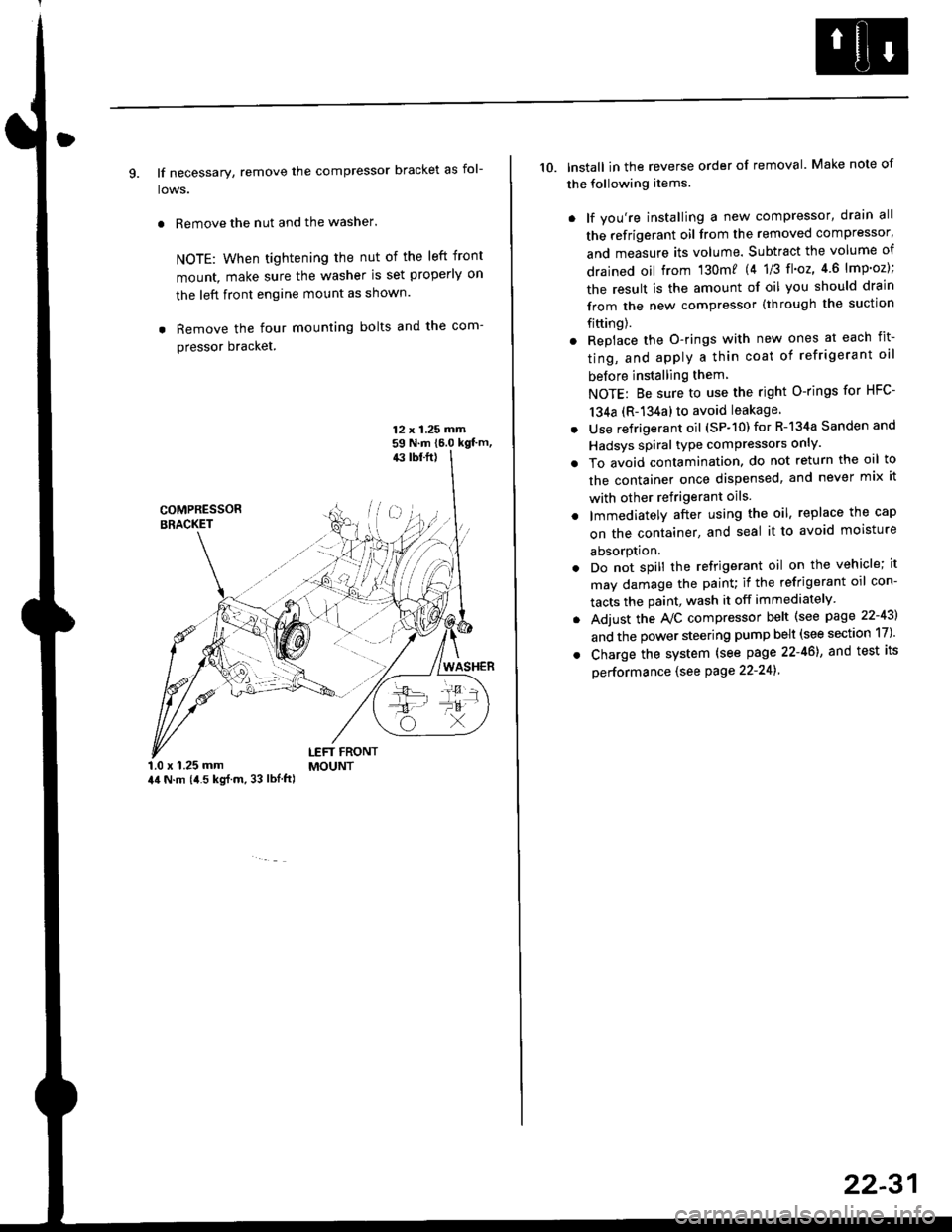

9. lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer.

NOTE: When tightening the nut of the left front

mount, make sure the washer is set properly on

the left front engine mount as shown.

. Remove the four mounting bolts and the com-

pressor bracket.

12 x 1.25 rrirn59 N.m 16.0 kgt'm,43 tbf.ft)

COMPRESSORBRACKET

WASHER

1.0 x 1.25 mm44 N.m (i1.5 kg{.m, 33 lbl.ft)

LEFT FRONTMOUNT

10. lnstall in the reverse order of removal. Make note of

the following items.

. lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume. Subtract the volume of

drained oil from '130m? 14 1/3 tl'o2,4 6 lmp'oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

fifting).

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage

. Use refrigerant oil (SP-10) for R-134a Sanden and

Hadsys spiral type compressors only'

o To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediatelY after using the oil, replace the cap

on the container, and seal it to avoid moisture

absorption.

. Do not spill the refrigerant oil on the vehicle; it

may damage the painu if the refrigerant oil con-

tacts the paint, wash it off immediately

. Adjust the Ay'C compressor belt (see page 22-43)

and the power steering pump belt (see section 17)'

. Charge the system (see page 22-46), and test its

oerformance (see Page 22-241

22-31

Page 1576 of 2189

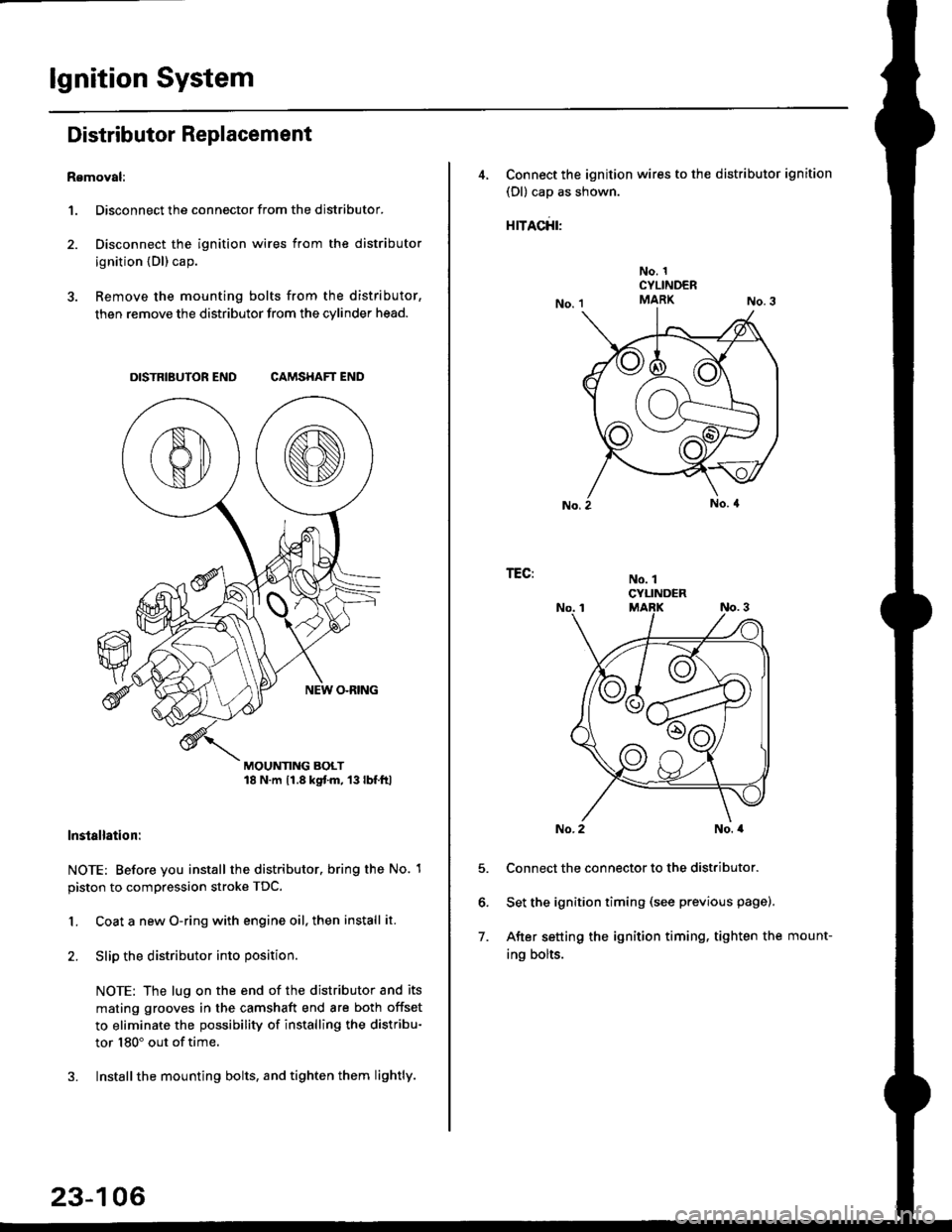

lgnition System

Distributor Replacement

Removal:

1. Disconnect the connector from the distributor.

2. Disconnect the ignition wires from the distributor

ignition {Dl) cap.

3. Remove the mounting bolts from the distributor,

then remove the distributor from the cylinder head.

DISTRIBUTOR END CAMSHAFT END

MOUNTING BOLT18 N.m 11.8 kgtm, 13lbf.ltl

lnstallation:

NOTE: Before you install the distributor. bring the No. 1

piston to compression stroke TDC.

1. Coat a new O-ring with engine oil, then install it.

2. Slip the distributor into position

NOTE: The lug on the end of the distributor and its

mating grooves in the camshaft end are both offset

to eliminate the possibility of installing the distribu-

tor 180" out of time.

3. Installthe mounting bolts, and tighten them lightly.

23-106

4, Connect the ignition wires to the distributor ignition

(Dl) cap as shown.

rracfit'

No. 1CYLINDERMARK

No. 1CYLINDER

TEG:

5.

6.

7.

No. 2No. a

Connect the connector to the distributor.

Set the ignition timing (see previous page).

After setting the ignition timing, tighten the mount-

ing bolts.

Page 1596 of 2189

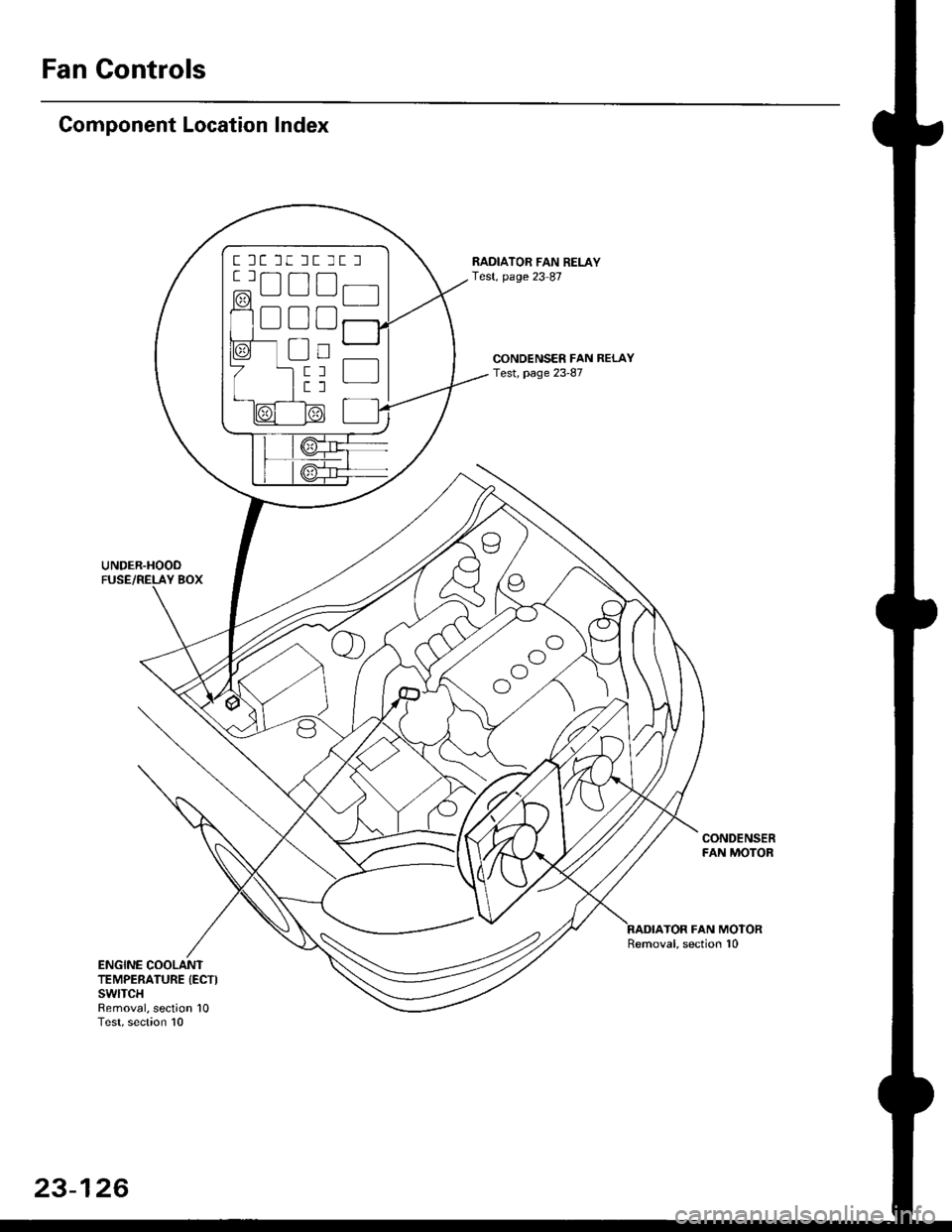

Fan Controls

Component Location Index

UNDER.HOOO

CONDENSER FAN RELAYTest, page 23-87

RADIATOR FAN RELAYTest, page 23 87

CONDENSERFAN MOTOR

TOR FAN MOTORRemoval, section 10

ENGINE COOLANTTEMPERATURE (ECTI

swtTcHRemoval, section 10Test, section l0

t lt lt lt tt l

tlTtlnr-l

mU!L-Jfl_l'1 - f-t t-_l -

I L--J L__J LJ f-----"1

o

^o

o"l

23-126

Page 1598 of 2189

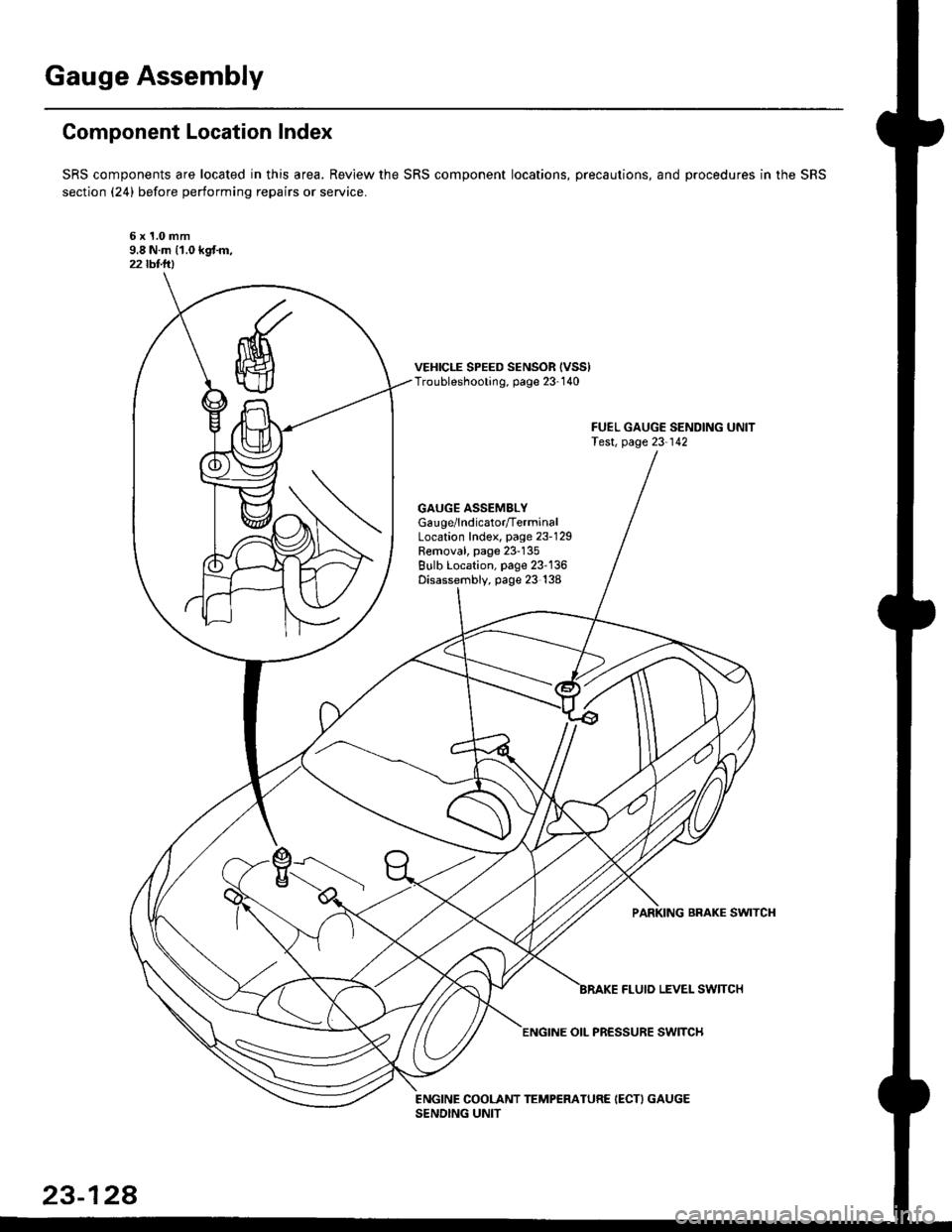

Gauge Assembly

Component Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

6x1.0mm9.8 N.m 11.0 kgf.m,22lbt.lrl

VEHICLE SPEED SENSOR {VSS)Troubleshooting, page 23-1 40

GAUGE ASSEMBLYGau ge/lndicator/TerminalLocation Index, page 23-129Removal, page 23-135Bulb Location, page 23-136Disassembly, page 23 138

PARKING BRAKE SWITCH

FLUIO LEVEL SW]TCH

23-128

ENGINE OIL PR€SSURE SWITCH

Page 1718 of 2189

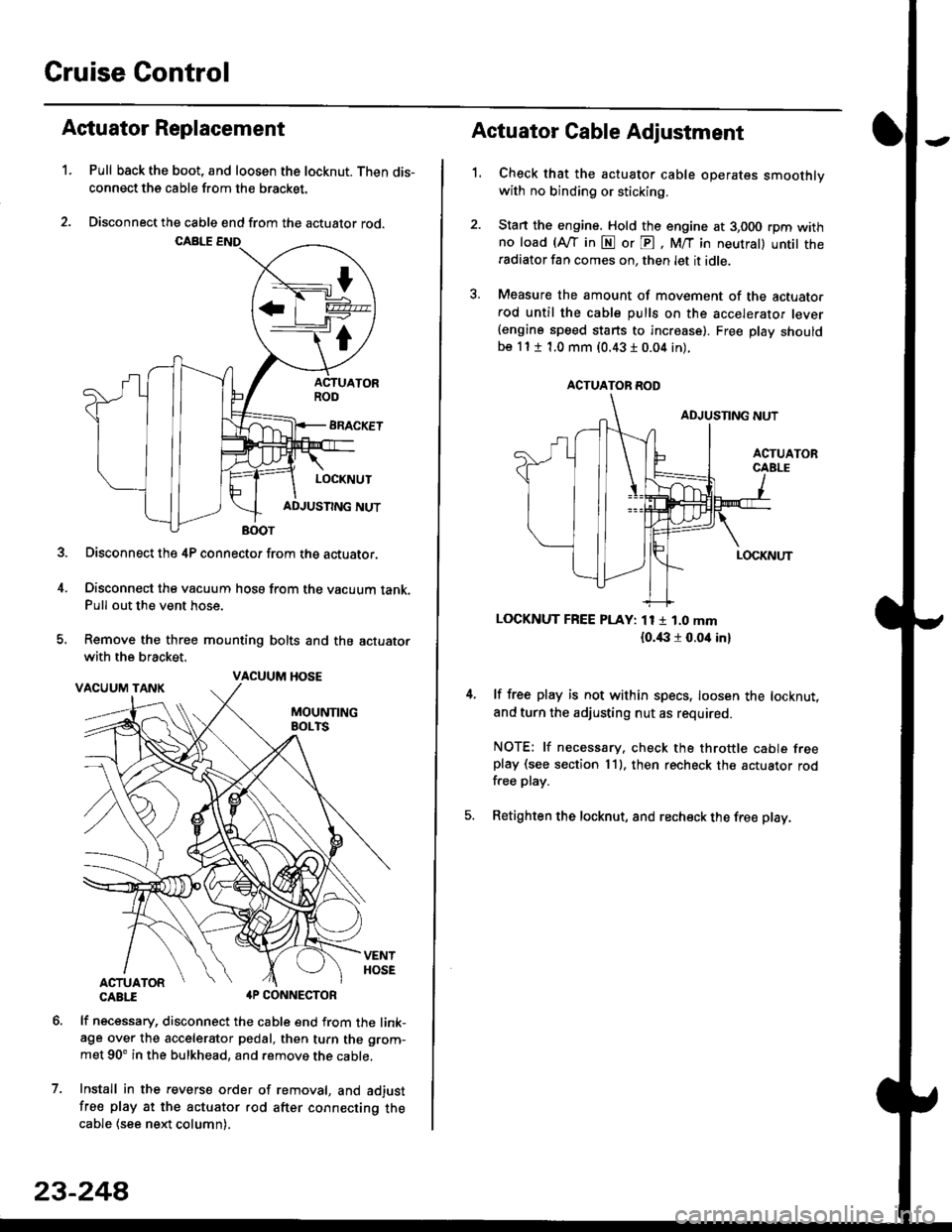

Cruise Control

t

D=

t

Astuator Replacement

1.Pull back the boot, and loosen the locknut. Then dis-

connect the cable from the bracket.

Disconnect the cable end from the actuator rod.

Disconnect the 4P connector from the actuator.

Disconnect the vacuum hosa from the vacuum tank.Pull out the vent hose.

Remove the three mounting bolts and the actuator

with the bracket.

CABTI aP CONNECTOR

lf necessary, disconnect the cable end from the link-age over the accelerator pedal, then turn the grom-

met 90' in the bulkhead, and remove the cable,

Install in the revers€ order of removal, and adjust

free play at the actuator rod after connecting thecable (see ne)d column).

7.

VACUUM HOSE

23-244

1.

Actuator Cable Adjustment

Check that the actuator cable operates smoothlywith no binding or sticking.

Stan the engine. Hold the engine at 3,000 rpm withno load (Afl'in N or E, M/T in neutral) untit theradiator fan comes on, then let it idle.

Measure the amount of movement of the actuato.rod until the cable pulls on the accelerator lever(engine speed starts to increase). Free Dlay shouldbe 11 t 1.0 mm (0.43 I 0.04 in).

LOCKNUT FREE PLAY: 11 1 1.0 mm

{o.i|:l r 0.oit in}

lf free play is not within specs, loosen the locknut,

and turn the adjusting nut as required.

NOTE: lf necessary. check the throttle cable freeplay (see section 11). then recheck the actuator rodfree play.

Retighten the locknut, and recheck the free play.

ACTUATOR ROD