Electrical troubleshooting HONDA CIVIC 1997 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 963 of 2189

Electrical Troubleshootang ('gg - 00 Models)

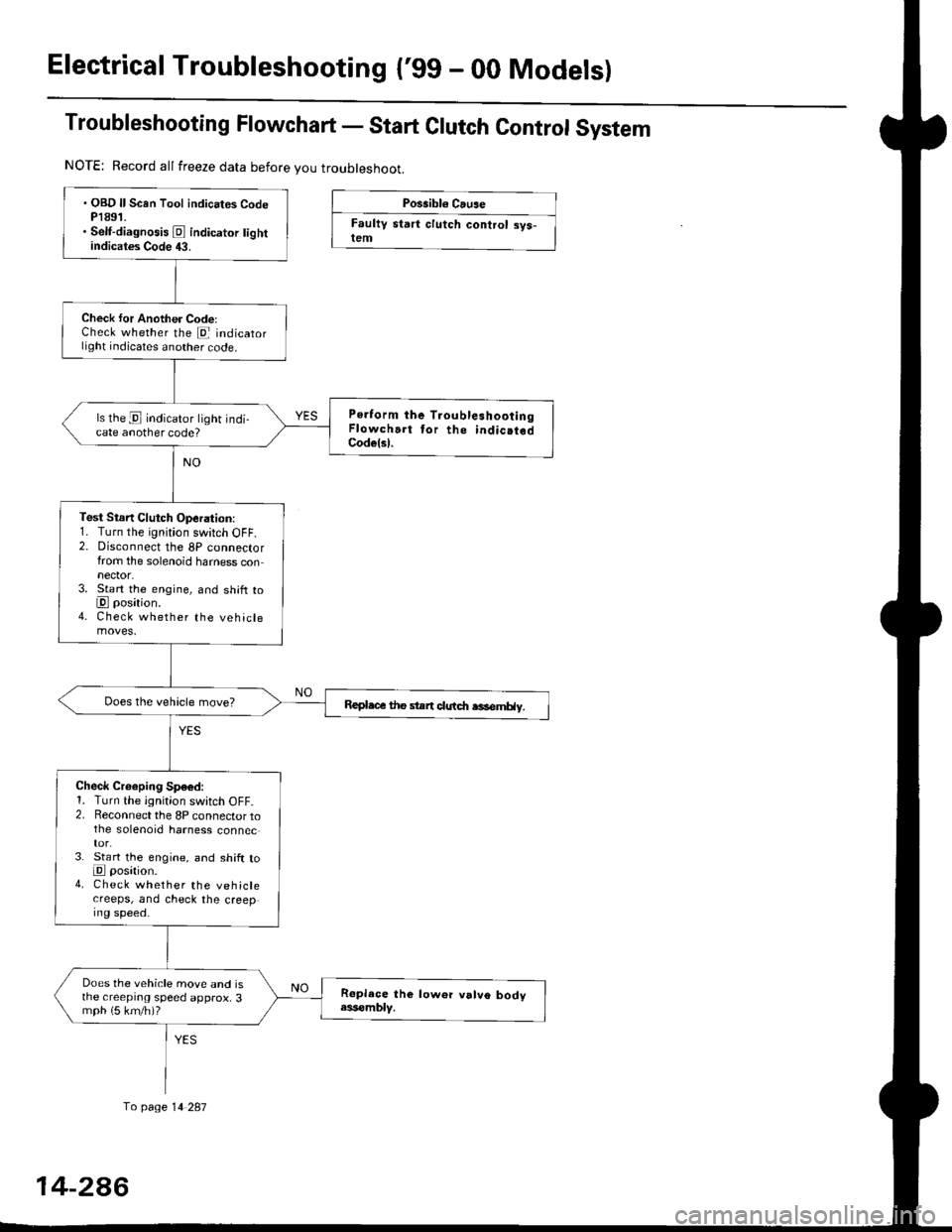

Troubleshooting Flowchart - Start Clutch Control System

Possibl€ Cause

Faultv start clutch control sys-lem

NOTE: Record allfreeze data before you troubleshoot.

fo page 14 287

. OBD ll Scan Tool indicates CodeP1891.. Self-diagnosis E indicator tightindicates Code 43.

Check for Another CodelCheck whether the E indicatorlight indicates another code.

Perform the TroubleshootingFlowchart tor the indic.tedCodelsl.

ls the E indicator light indi-cate another code?

Test Stsn Clutch Operation:1. Turn the ignition switch OFF.2. Disconnect the 8P connectorfrom the solenoid harness connector.3. Start the engine, and shift toE position.4. Check whether the vehiclemoves.

Repl.c€ the stan clutdt rasemHy.

Check Croeping Sp€6d:1. Turn the ignition switch OFF.2. Reconnect the 8P connector tothe solenoid harness connec

3. St€rt the engine, and shift toE posation.4. Check whether the vehiclecreeps, and check the creeping speed.

Does the vehicle move and isthe creeprng speed approx, 3mph (5 km/h)?

14-2A6

Page 965 of 2189

Electrical Troubleshooting ('99 - 00 Models)

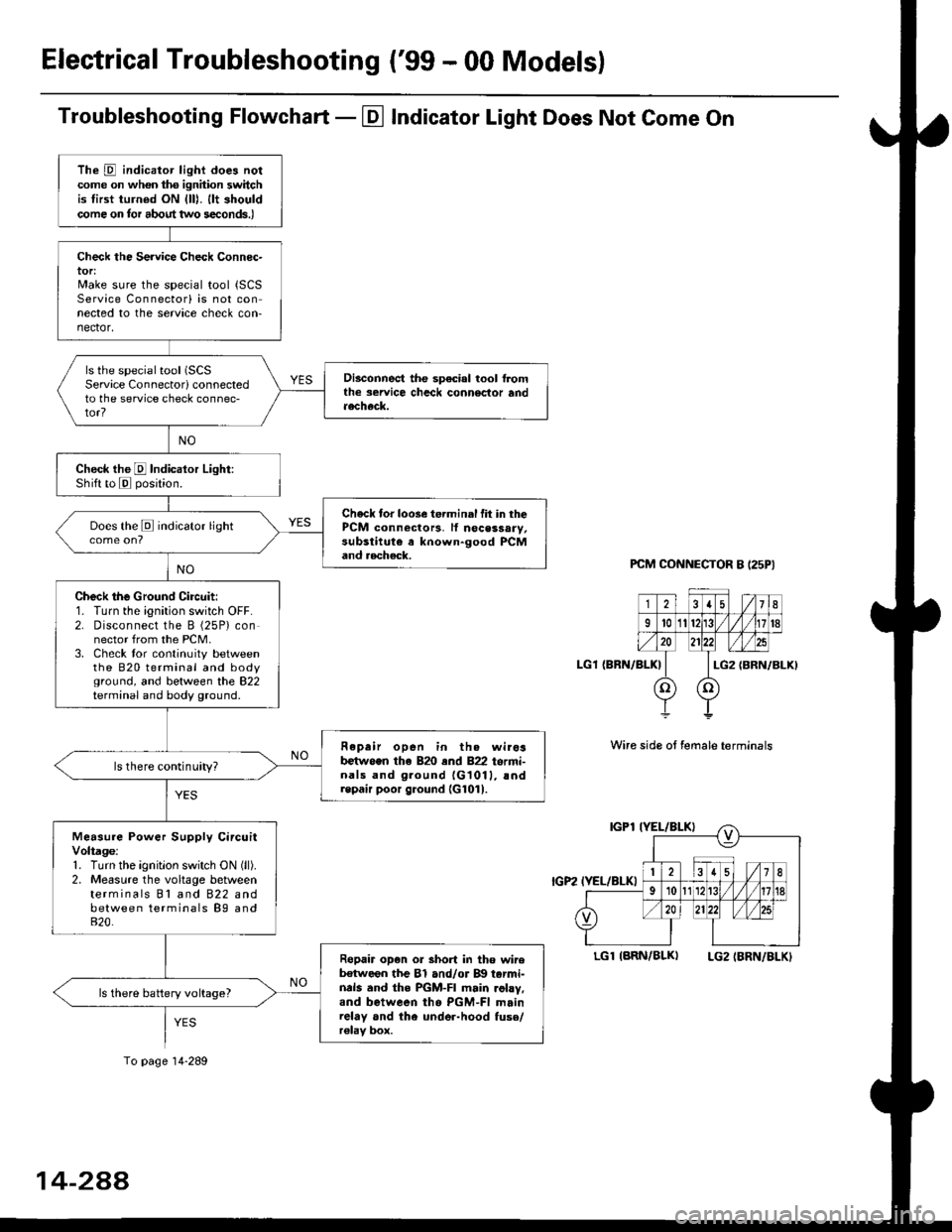

Troubleshooting Flowchart - El Indicator Light Does Not Come On

PCM CONNECTOR B I25PI

LGl {BRN/BLK)

Wire side ot female terminals

LGlIARN/BLK) LG2IBRN/BLKI

The D indicator light does notcome on whon ths ignhion switchis tirst turned ON {lll. llt shouldcome on tor about two s€conds.)

Check the Service Check Connec-tor:Make sure the special tool {SCSService Connectorl is not connected to the service check con-nector,

ls the special tool (SCS

Service Connectorl connectedto the service check connec-tor?

Disconnect the sp€cial tool f]omthe seruice chcck connoclor andaecheck.

Check the E Indicalor Light:Shift to E posjtion.

Check tor loose te.minal fit in thePCM connectors, lf nocessary,substitute a known-good PCMand aecheck.

Does the E indicator light

Check the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the B (25P) connector from the PCM.3. Check tor continuity betweenthe 820 terminal and bodyground, and between the 822terminal and body ground.

Fepair open in th. wirosb€tw.en the 820 end 822 termi-nals and ground {G1011, !ndrepair poor ground {G1011.

ls there continuity?

Measure Power Supply CircuitVoltage:1. Turn the ignitlon switch ON (ll).

2. Measure the voltage betweenterminals Bl and 822 andbetween terminals B9 and820.

Ropair op€n or short in tho wireb€tween the Bl and/or B!| tarmi-nds and the PGM-FI main .ohy,and between tho PGM-FI mainrelay and the under-hood fuso/r€lav box.

ls there battery voltage?

To page 14-289

14-2AA

Page 967 of 2189

ElectricalTroubleshooting ('gg - 00 Models)

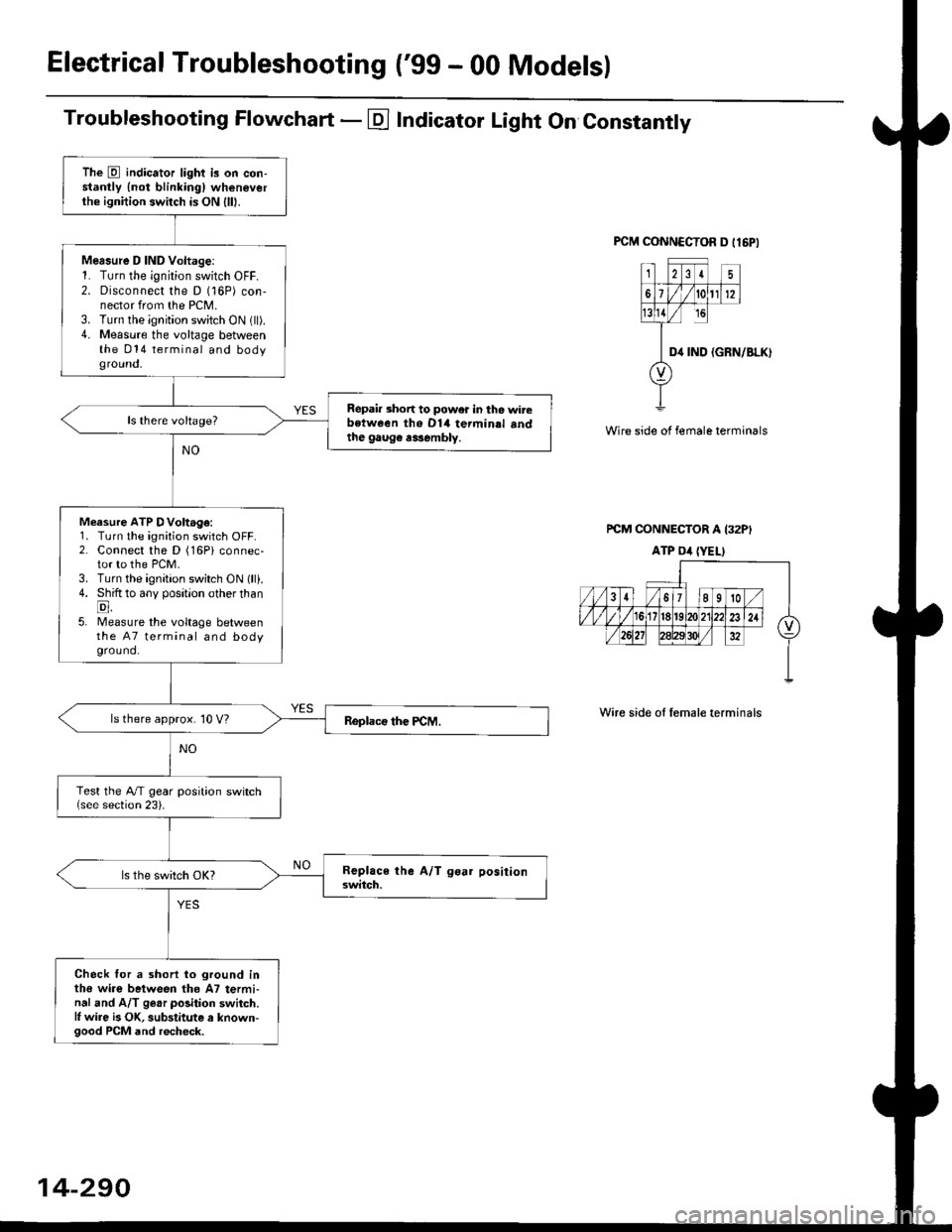

Troubleshooting Flowchart - E Indicator Light On Constantly

FCM CONNCCTOR D tl6PI

23I5

61t012

tsll / rc

II D4 rND

o

(GRN/BLK)

Wire side of female terminals

rcM CONNECTOR A I32PI

ATP Dil {YELI

Wire side of lemale terminals

The E indicator light is on con-stantly {not blinkingl wheneverthe ignition switch is ON lll|.

Mersure D IND Voltage:1. Turn the ignition switch OFF.2. Disconnect the D (16P) con-nector from the PCM.3. Turn the ignition switch ON (ll).4. Measure the voltage betweenthe 014 terminal and bodyground,

Repair short to power in tho wirebstween the Dl4 termin.l sndthe gaug€ r3sembly.

Measure ATP DVoltage:1. Turn the ignition switch OFF.2. Connect the D (16Pi connec-tor to the PCM.3. Turn the ignition switch ON lll).4. Shift to any position other thanE,5. lMeasure the voltage betweenthe 47 terminal and bodyground.

ls there approx. 10 V?

Test the A/T gear position switch{see section 23).

Check for a shorl lo ground inthe wire between tho A7 termi-nal and A/T ge.r polition switch.l, wire is OK, substitute a known-good PCM and recheck.

14-290

Page 1393 of 2189

Troubleshooting -'99 - 00 Models

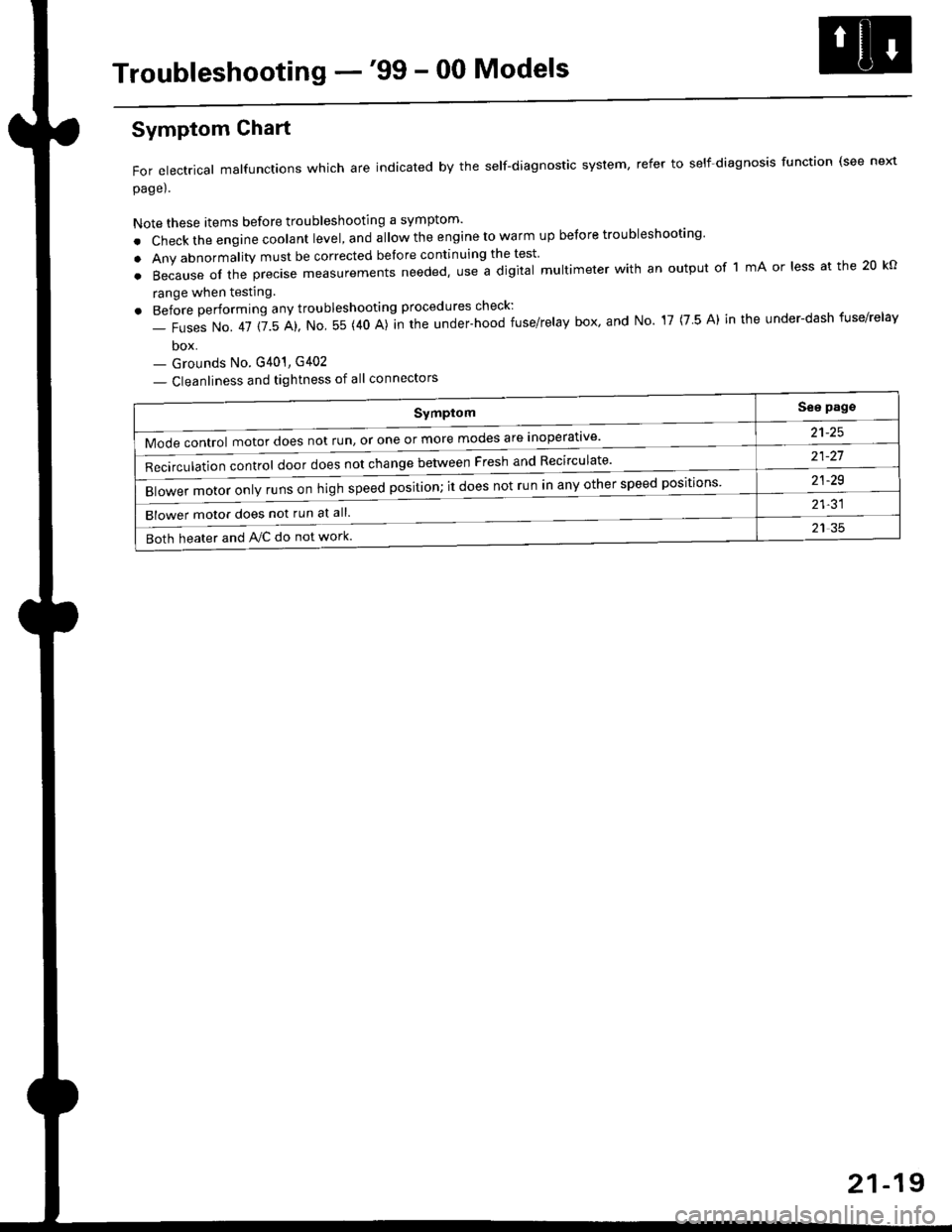

Symptom

Mode control motor does not run, or one or more modes are inoperat've'

Recirculation control door does not change between Fresh and Recirculate'

Blower motor only runs on high speed position; it does not run in any other speed positions

Blower motor does not run at all.

Both heater and Ay'C do not work

See pags

a1_tq

21-21

21-29

21-31

21 35

Symptom Chart

For electrical malfunctions which are indicated by the self-diagnostic system, refer to self-diagnosis function (see next

page).

Note these items before troubleshooting a symptom'

. Check the engine coolant level, and allow the engine to warm up before troubleshooting'

. Any abnormality must be corrected before continuing the test

.Becauseoftheprec|semeasurementsneeded,UseadigitaImu|timeterwithanoutputoflmAor|essatthe20ko

range when testing

. Before performing any troubleshooting procedures check:

- Fuses No. 41 115 Al, No 55 (40 A)]n the under-hood fuse/relay box' and No 17 (7 5 A) in the under-dash fuse/relav

box- Grounds No. G401, G402

- Cleanliness and tightness of all connectors

21-19

Page 1471 of 2189

l'f .

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.

Page 1474 of 2189

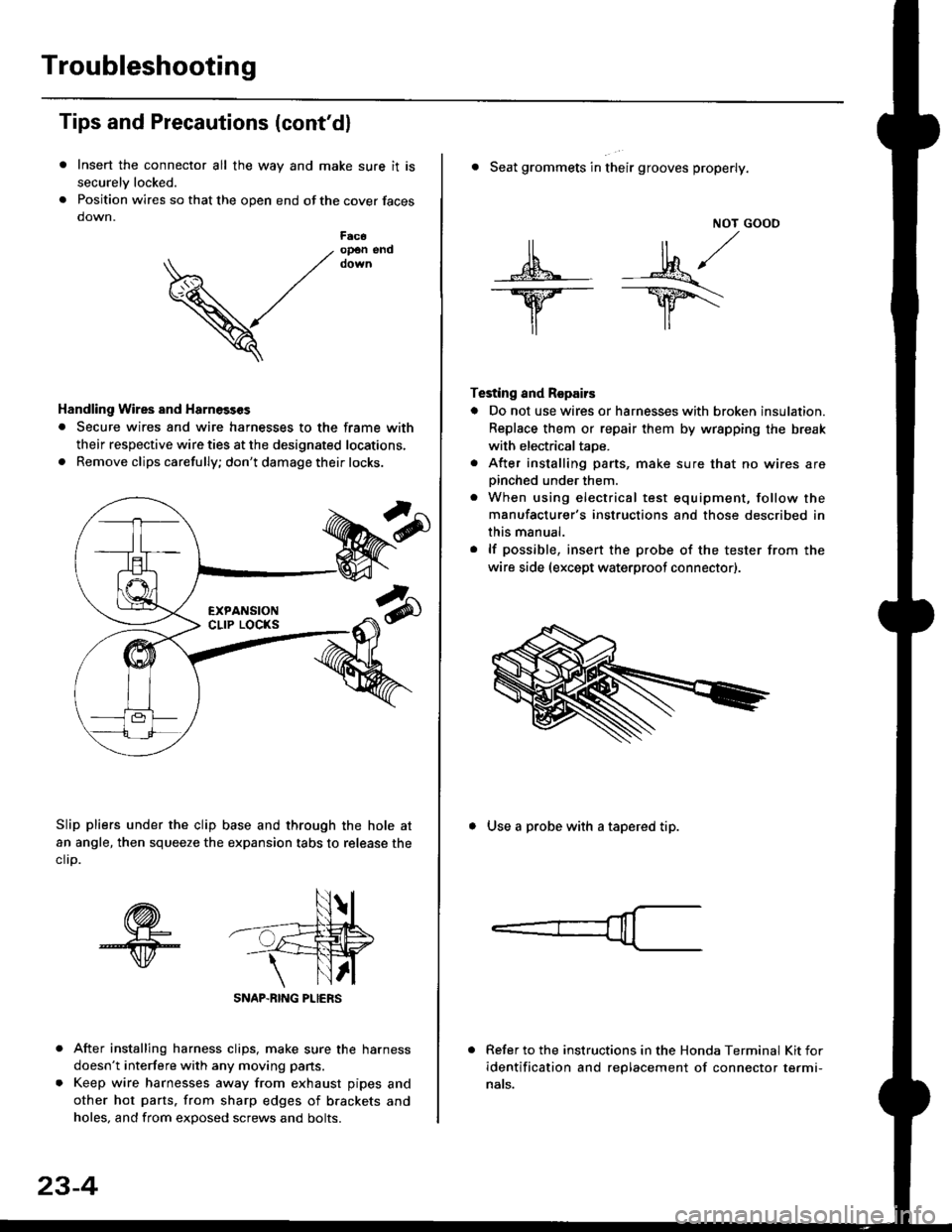

Troubleshooting

Tips and Precautions (cont'dl

Insert the connector all the way and make sure it is

securelv locked.

Position wires so that the open end of the cover faces

down.

After installing harness clips, make sure the harness

doesn't interfere with any moving pans.

Keep wire harnesses away from exhaust pipes and

other hot parts. from sharp edges of brackets and

holes, and from exDosed screws and bolts.

V

F6c6op€n end

Handling Wires and Harnosscs

. Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations,

. Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clrp.

SNAP-BING PLIERS

23-4

NOT GOOO

ll il,/

s*' -.1}8."/_Y--_Y5\

il ,,

Testing and Repairs

o Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrspping the break

with electricaltaoe.

. After installing parts, make sure that no wires arepinched under them.. When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

. lf possible, insert the probe of the tester from the

wire side (except waterproof connector).

. Seat grommets in their grooves properly.

. Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nats.

Page 1582 of 2189

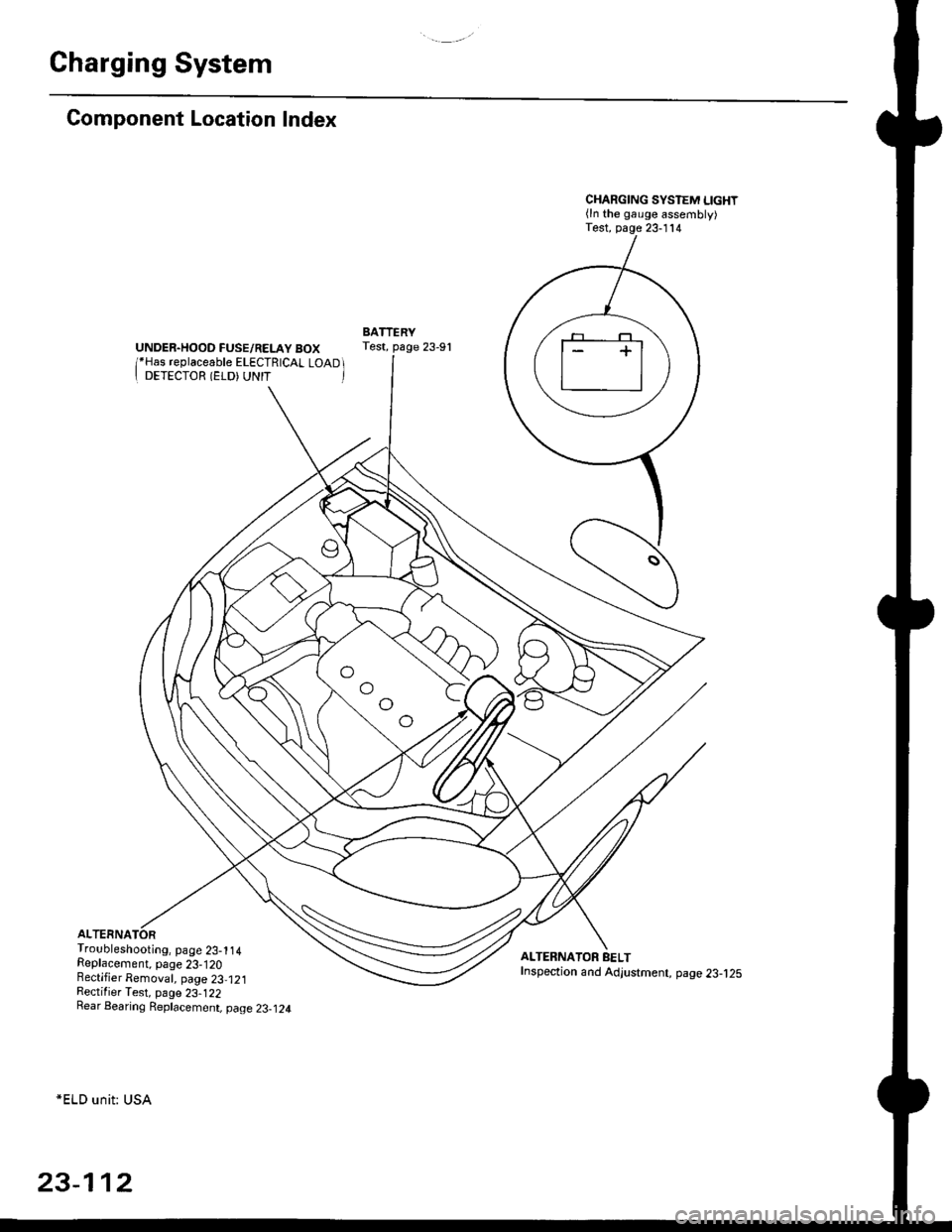

Charging System

Component Location Index

UNDER.HOOD FUSE/RELAY BOX/*Has replaceable ELECTRICAL LOAD II DETECTOR (ELD) UNIT '

Troubleshooting, page 23-1 14Replacement, page 23-120Bectifier Removal, page 23,121Rectifier Test, page 23-122Rear Bearing Replacement, page 23-j24

*ELD unit: USA

CHARGING SYSTEM LIGHT(ln the gauge assembly)Test, page 23- l14

BATTERYTest, page 23-91

ALTERNATOR BELTInspection and Adjustment, page 23-t25

[]

23-112

Page 1830 of 2189

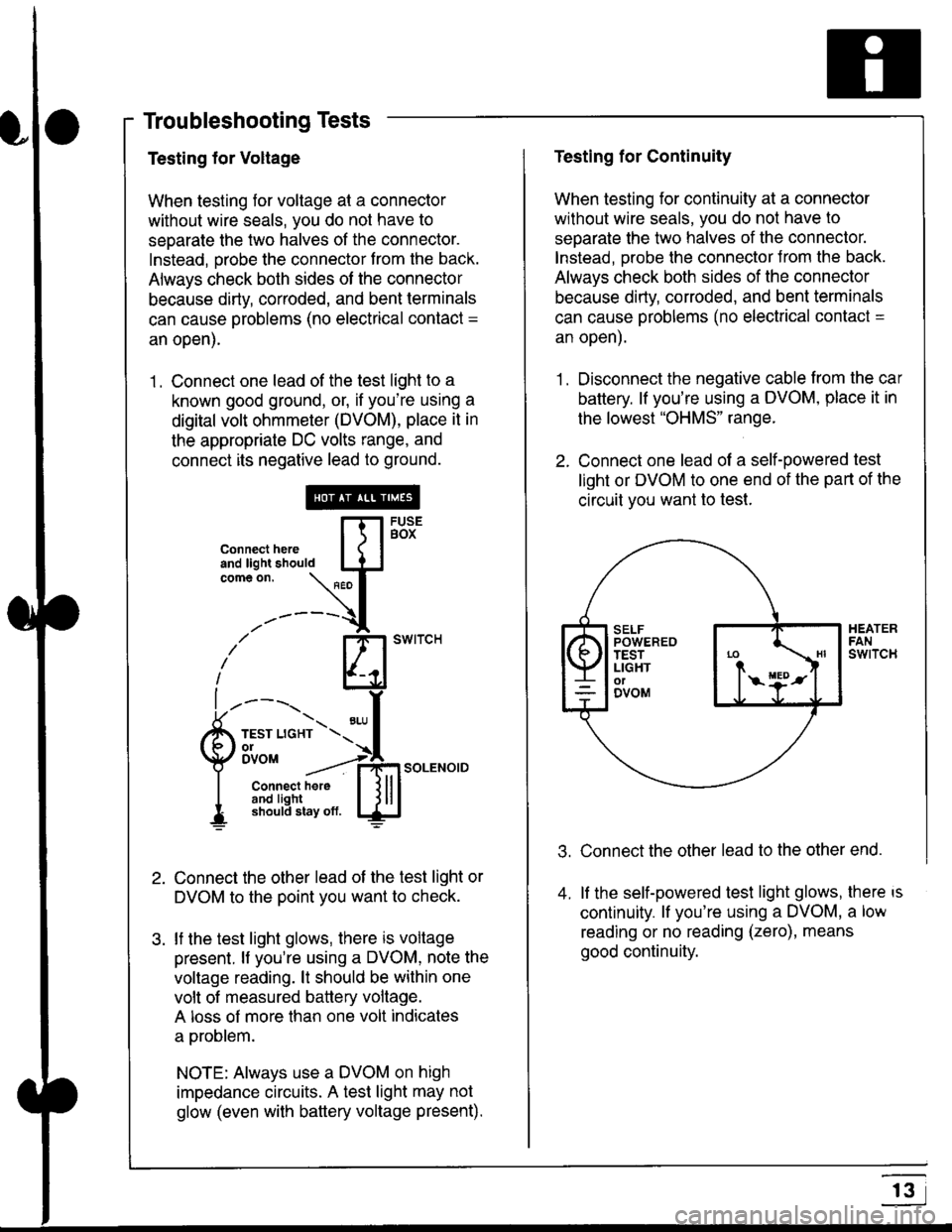

Troubleshooting Tests

Testing for Voltage

When testing for voltage at a connector

without wire seals, you do not have to

seoarate the two halves of the connector.

Instead, probe the connector from the back.

Always check both sides of the connector

because dirty, corroded, and bent terminals

can cause problems (no electrical contact =

an open).

1 . Connect one lead of the test light to a

known good ground, or, if you're using a

digital volt ohmmeter (DVOM), place it in

the appropriate DC volts range, and

connect its negative lead to ground.

Connect the other lead of the test light or

DVOM to the point you want to check.

lf the test light glows, there is voltage

present. lf you're using a DVOM, note the

voltage reading. lt should be within one

volt of measured battery voltage.

A loss of more than one volt indicates

a problem.

NOTE: Always use a DVOM on high

impedance circuits. A test light may not

glow (even with baftery voltage present).

connecthere [fl5tst-tand light should IJJcomeon.

\" I

------{

/' BT swrrcH

lhl

l ----., I

6m""*soLENo,DI connect here I { lll

I 3#Ji8iL,* lj!!J

Testing for Continuity

When testing for continuity at a connector

without wire seals, you do not have to

separate the two halves of the connector.

lnstead. Drobe the connector Jrom the back.

Always check both sides of the connector

because dirty, conoded, and bent terminals

can cause problems (no electrical contacl =

an open).

1. Disconnect the negative cable from the car

battery. lf you're using a DVOM, place it in

the lowest "OHMS" range.

2. Connect one lead of a self-powered test

light or DVOM to one end of the part of the

circuit vou want lo test.

Connect the other lead to the other end.

lf the self-powered test light glows, there is

continuity. lf you're using a DVOM, a low

reading or no reading (zero), means

good continuity.

.t.

A

r3

Page 1917 of 2189

- How the Gircuit Works

With the ignition switch in ON (ll) or START (lll),

battery voltage is supplied through fuse 15 and

the BLI(WHT and BLK/YEL wire to the vehicle

speed sensor (VSS). The sensor is grounded by

the BLK wire to G1 01 . The speedometer and

other control units in the circuit supply about 5

volts to the BLU/WHT wire. The vehicle soeed

sensor (VSS) intermittently grounds the

BLUMHT wire which generates a pulsed signal

in it. The number of pulses per minute

increases/decreasos with the soeed of the car.

Reter to th€ Service Manual (Section 23, Electrical)

tor specific tosts or troubleshooting procedures.

33-1

Page 1922 of 2189

Gruise Control (cont'd)

- How the Circuit Works

The cruise control system uses mechanical and

electrical devices to maintain the car's sDeed at a

setting selected by the driver.

System Description

The cruise control unit receives command signals

from the crurse control main switch and the cruise

control SeVResume switch. With the ignition switch

in ON (ll) or START (lll), voltage is provided to the

cruise control main switch through fuse 14. When

you push the switch to ON, power is provided to the

cruise control unit and the brake switch.

The cruise control unit receives information about

operating conditions from the brake switch, the

vehicle speed sensor (VSS), and the clutch switch

(manual transmission) or the A,/T gear position

switch (automatic transmission). The cruise control

unit then sends signals to the cruise control actuator

which regulates the throttle position to maintain the

selected speed. The conlrol unit compares the

actual speed of the car to the selected speed. The

control unit then uses the result of that comoarison

to open or close the throttle.

The brake switch releases the system's control of

the throttle at the instant you press on the brake

pedal. The switch sends a signal to the control unit

by removing power from the normally closed brake

input (GRY wire), and providing power at the

normally open brake input (GRN/vVHT wire). The

control unit responds by allowing the throttle to

close. The clutch switch or the A,/T gear position

switch sends a "disengage" signal to the control unit

that also allows the throttle to close.

The cruise control system will set and automatically

maintain any speed above 25 mph (40 km/h). To set

it, make sure the main switch is on and the switch

indicator is on. Then, after reaching the desired

speed, press the SET switch. This sends a "set"

signal to the cruise control unit which, in turn,

controls the cruise control actuator to maintain the

set speed.

When you push the SET switch and the cruise

control system is on, the "cruise control" ON

indicator lights up.

34-4

(

You can cancel the cruise control system by

turning the main switch off . This removes power to

the control unit and erases the set speed from

memory. lf the system is disengaged temporarily

by the brake switch, or clutch switch, and the car's

speed is still above 25 mph, press the resume

switch: the car will automatically return to the

previously set speed.

For gradual acceleration without pressing the

accelerator pedal, push the RESUME switch and

hold it there. This will send an "acceleration" signal

to the control unit. When you release the switch, the

system will be reprogrammed for the new speed. To

slow the car down. oush the SET switch in and hold

it there. This sends a "deceleration" signal to the

control unit, causing the car to coast. When the

desired speed is reached, release the SET switch.

This reprograms the system tor the new speed.

Refer to the Service Manual (Section 23, Electrical)

tor specific tests or troubleshooting procedures.

(

a