Water HONDA CIVIC 1997 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1330 of 2189

Trunk Lid/Hatch

WeatherstripLicense Plate Trim

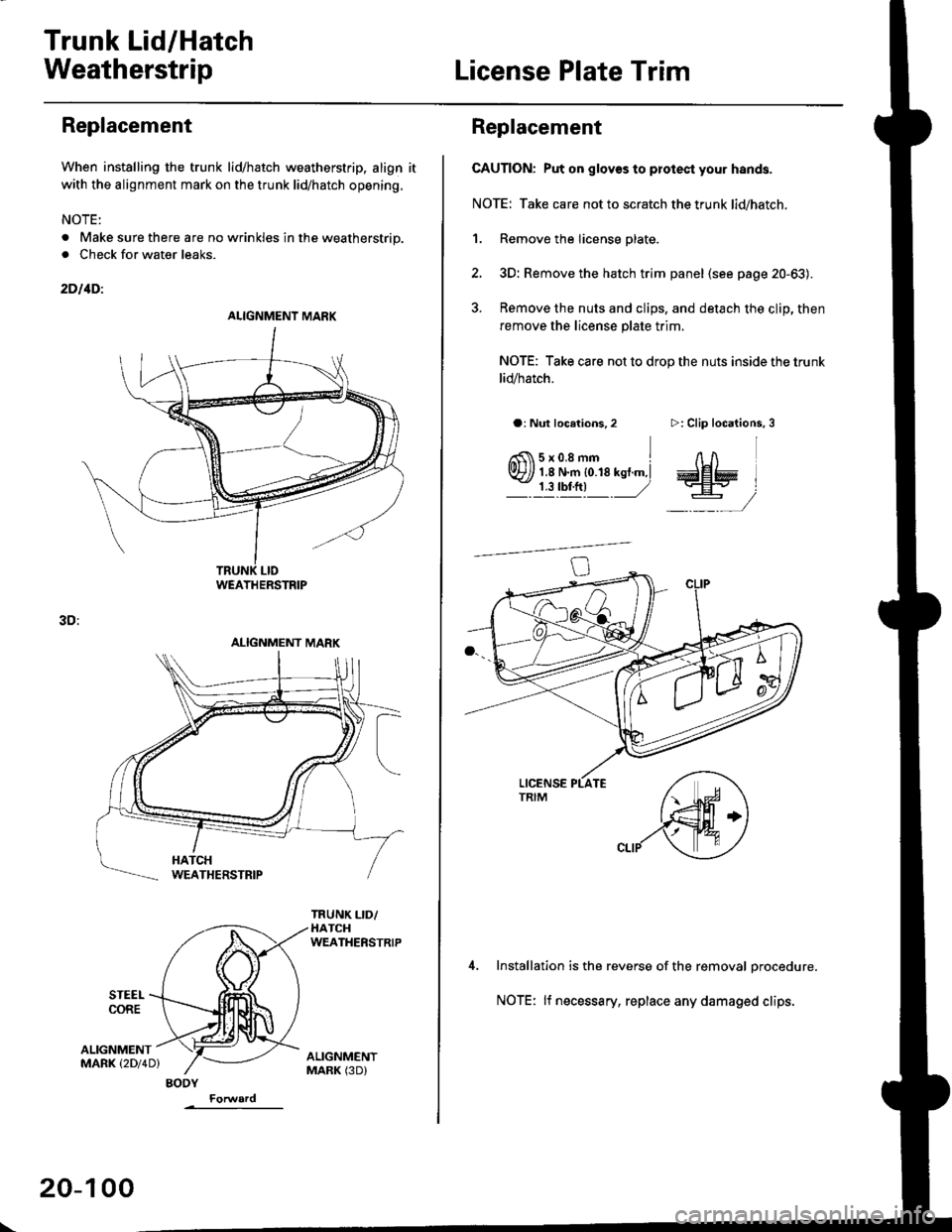

Replacement

When installing the trunk lid/hatch weatherstrip. align it

with the alignment mark on the trunk lid/hatch opening.

NOTE:

. Make sure there are no wrinkles in the weatherstrip.

. Check for water leaks.

2DllDi

STEEI.CORE

3D:

ALIGNMENTMARK (2Dl4D)

ALIGNMENT MARK

WEATHERSTRIP

ALIGNMENT MARK

BODY

\

20-100

Replacement

CAUTION: Put on glov€s to plotest your hands.

NOTE: Take care not to scratch the trunk lid/hatch.

1. Remove the license plate.

2, 3D: Remove the hatch trim panel (see page 20-63).

3. Remove the nuts and clips, and detach the clip, then

remove the license plate trim.

NOTE: Take care not to drop the nuts inside the trunk

lid/hatch.

a: Nut locations,2

6fi\5x0.8mm Irvr?// 1,8 N.m {0.18 kst.m,l- j llrftl ,/

>: Clip locations,

InA

aa# )

-,/

Installation is the reverse of the removal orocedure.

NOTE: lf necessary, replace any damaged clips.

Page 1333 of 2189

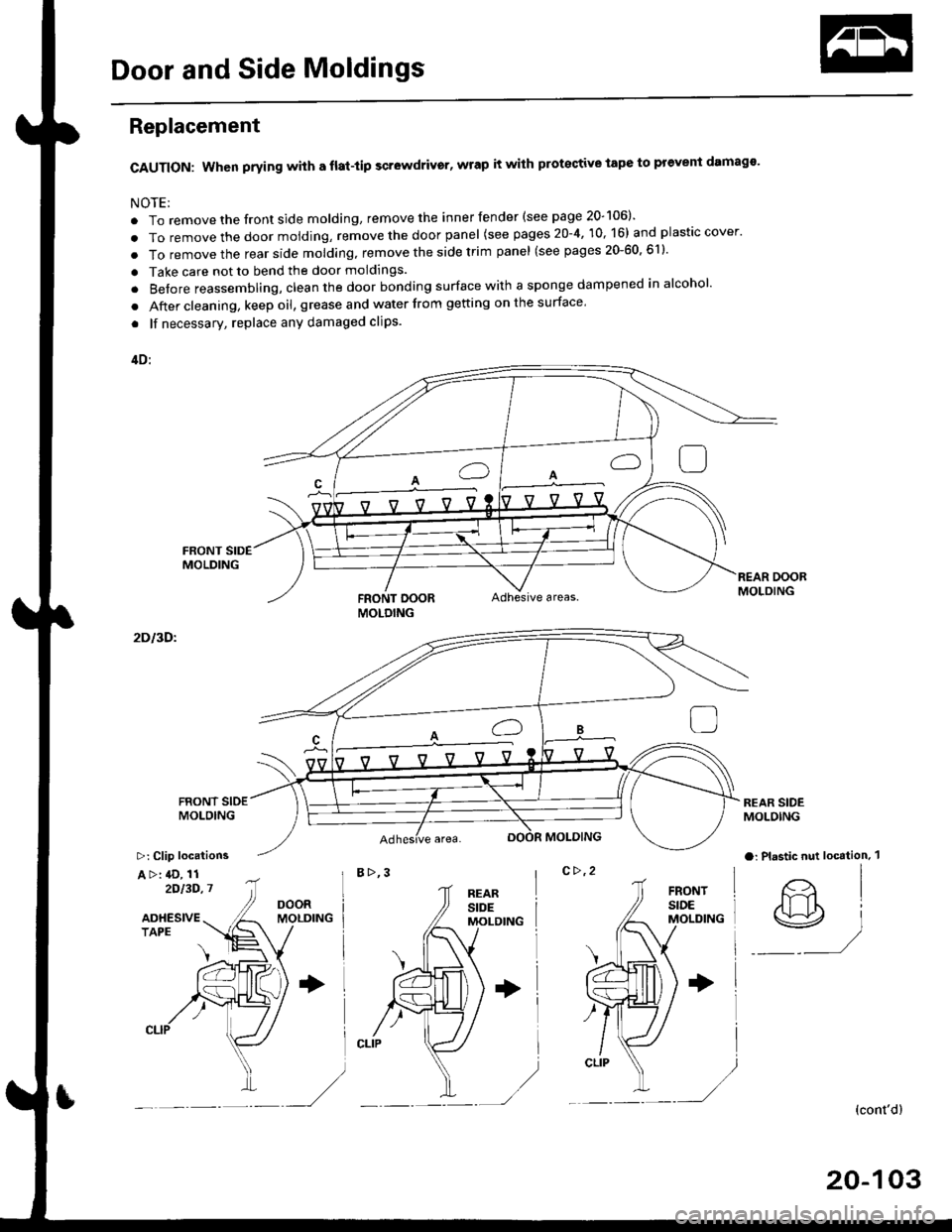

Door and Side Moldings

Replacement

CAUTION: When prying with a flat-tip scr6wdrivgr, wrap it with protective tape to prevent damags'

NOTE;

. To remove the front side molding, remove the inner fender (see page 20-106)'

. To remove the door moiding, remove the door panel (see pages 20-4, 10, 16) and plastic cover.

. To removethe rearside molding, remove the side trim panel (see pages 20-60,611'

. Take care not to bend the door moldings.

. Before reassembling, clean the door bonding surface with a sponge dampened in alcohol'

. After cleaning, keep oil, grease and water from getting on the surface'

. lf necessary, replace any damaged clips.

4D:

FRONT DOORAdhesive areas.

2Dl3Dl

B>,3c>,2

REAR SIDEMOLOING

a: Plastic nut loc€tion. 1

@)

(cont'dl

20-103

MOLDING

>: Clip locations

A >: 4D, 112')13D,7

Page 1334 of 2189

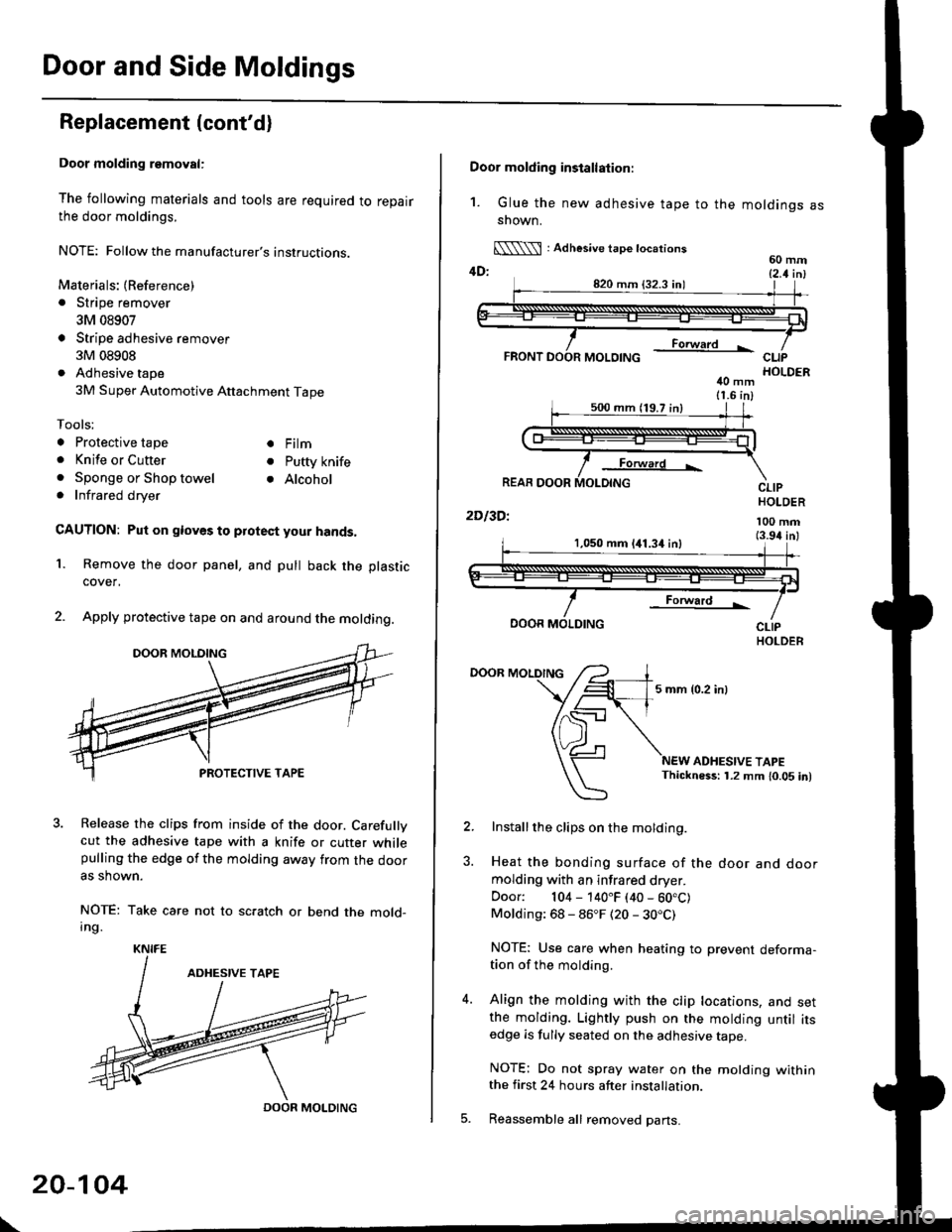

Door and Side Moldings

Replacement (cont'dl

Door molding removal:

The following materials and tools are required to repairthe door moldings.

NOTE: Followthe manufacturer's instructions.

Materials: (Reference)

. Stripe remover

3M 08907

Stripe adhesive remover

3M 08908

Adhesive tape

3M Super Automotive Attachment Tape

Tools;

a Protective tape

. Knife or Cutter

. Sponge or Shop towel. Infrared dryer

. Film

. Putty knife

. Alcohol

CAUTION: Put on gloves to protect your hands,

Remove the door panel, and pull back the plastic

cover,

Apply protective tape on and around the molding.

3. Release the clips from inside of the door. Carefullvcut the adhesive tape with a knife or cutter whilepulling the edge of the molding away trom the dooras shown.

NOTE: Take care not to scratch or bend the mold-Ing.

1.

KNIFE

DOOR MOLDING

\

20-104

Door molding installation:

1. Glue the new adhesive tape to the moldings assnown.

[\\\l : Adhesive tape tocations60 mm4D: t2 t i^l

40 mm11.6 in)

Forward L

REAR DOOR

2Dl3Dl

CLIPHOLDER

100 mm(3.94 inl1,050 mm 141.34 inl

Forward !

DOOR MOLDING

DOOR MOLDING

5 mm {0.2 inl

ADHESIVE TAPEThickness: 1.2 mm 10.05 in)

Installthe clips on the molding.

Heat the bonding surface of the door and doormolding with an infrared dryer.

Door: 104 - 140"F (40 - 60.C)Molding: 68 - 86"F (20 - 30.C)

NOTE: Use care when heating to prevent deforma-tion of the molding.

Align the molding with the clip locations, and setthe molding. Lightly push on the molding until itsedge is fully seated on the adhesive tape.

NOTE: Do not spray water on the motding withinthe first 24 hours after installation.

Reassemble all removed pans.

Page 1336 of 2189

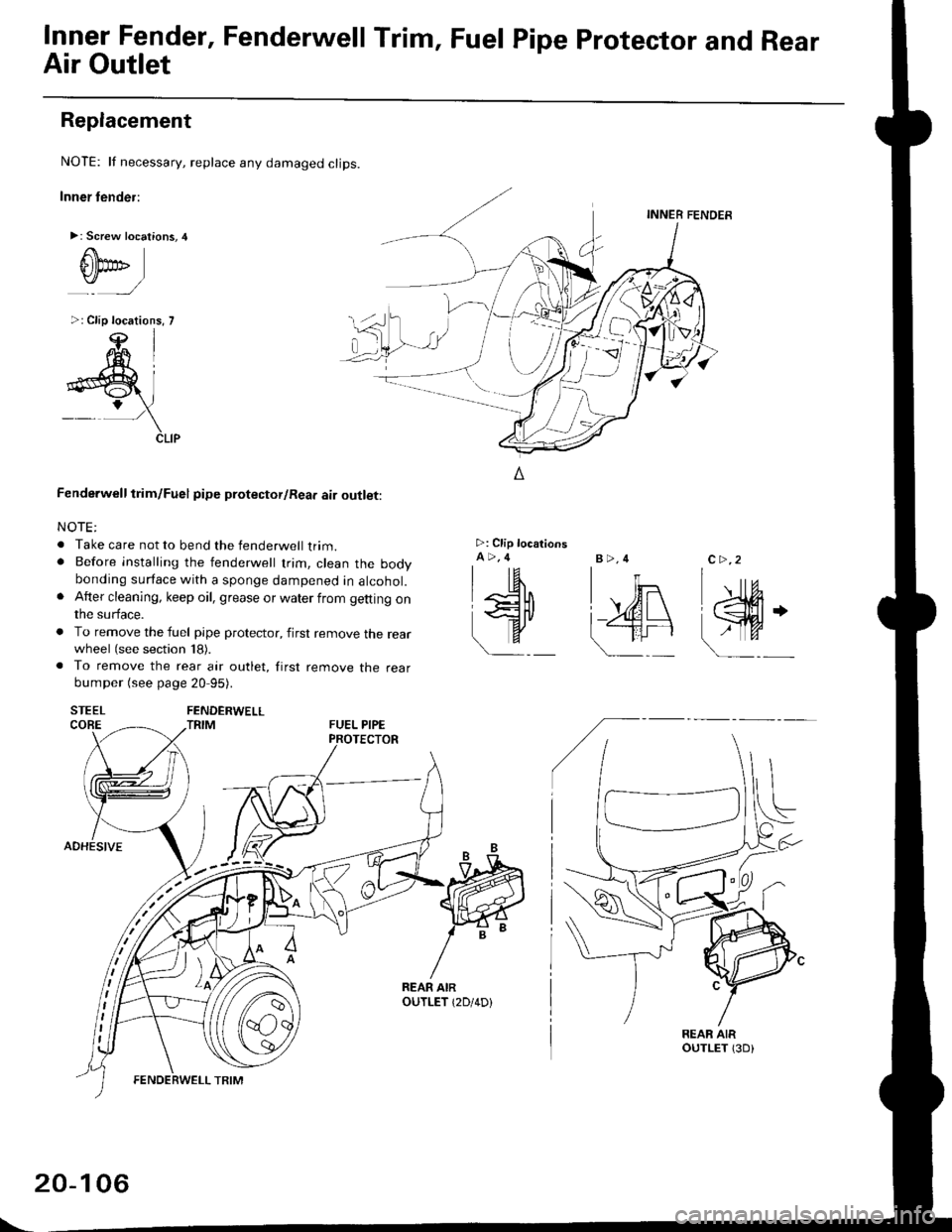

Inner Fender, Fenderwell rrim, Fuel Pipe protector and Rear

Air Outlet

Replacement

NOTE: lf necessary, replace any damaged clips.

Inner tender:

>: Screw locations,4

r\

tllpo" l:,/

>: Clip locations, 7

Fenderwell trim/Fuel pipe protector/Rea. air outlet:

NOTE:

. Take care not to bend the fenderwell trim.. Before lnstalling the fenderwell trim, clean the bodybonding surface with a sponge dampened in alcohol.. After cleaning, keep oil, grease or water from getting onthe surface.

. To remove the fuel pipe protector, first remove the rearwheel (see section 18).. To remove the rear air outlet, first remove the rearbumper (see page 20 95).

STEEL FENDERWELL

>: Clip locationsA>,4B>,4

l;1A

!--l1!

c >,2

I

tAh'frv

\:

+

\-

20-106

Page 1348 of 2189

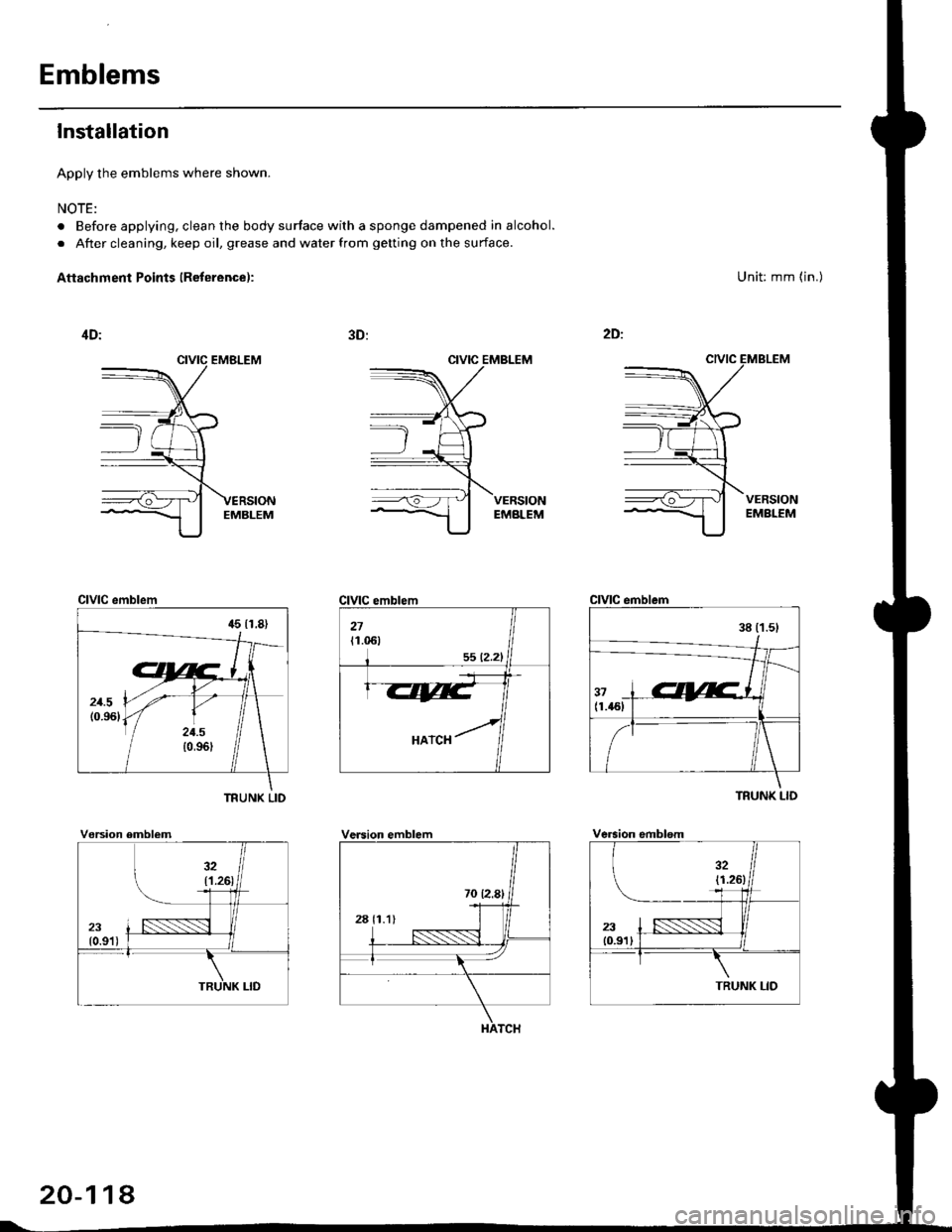

Emblems

Installation

Apply the emblems where shown.

NOTE:

. Before applying, clean the body surface with a sponge dampened in alcohol.

. After cleaning, keep oil, grease and water from getting on the surface.

Aftachment Points (Reterence):

CIVIC EMBLEM

Unit: mm (in.)

CIVIC emblem

TFUNK LID

CIVIC emblem

TRUNK LID

Vorsion emblemVersion emblemVersion emblsm

20-114

Page 1369 of 2189

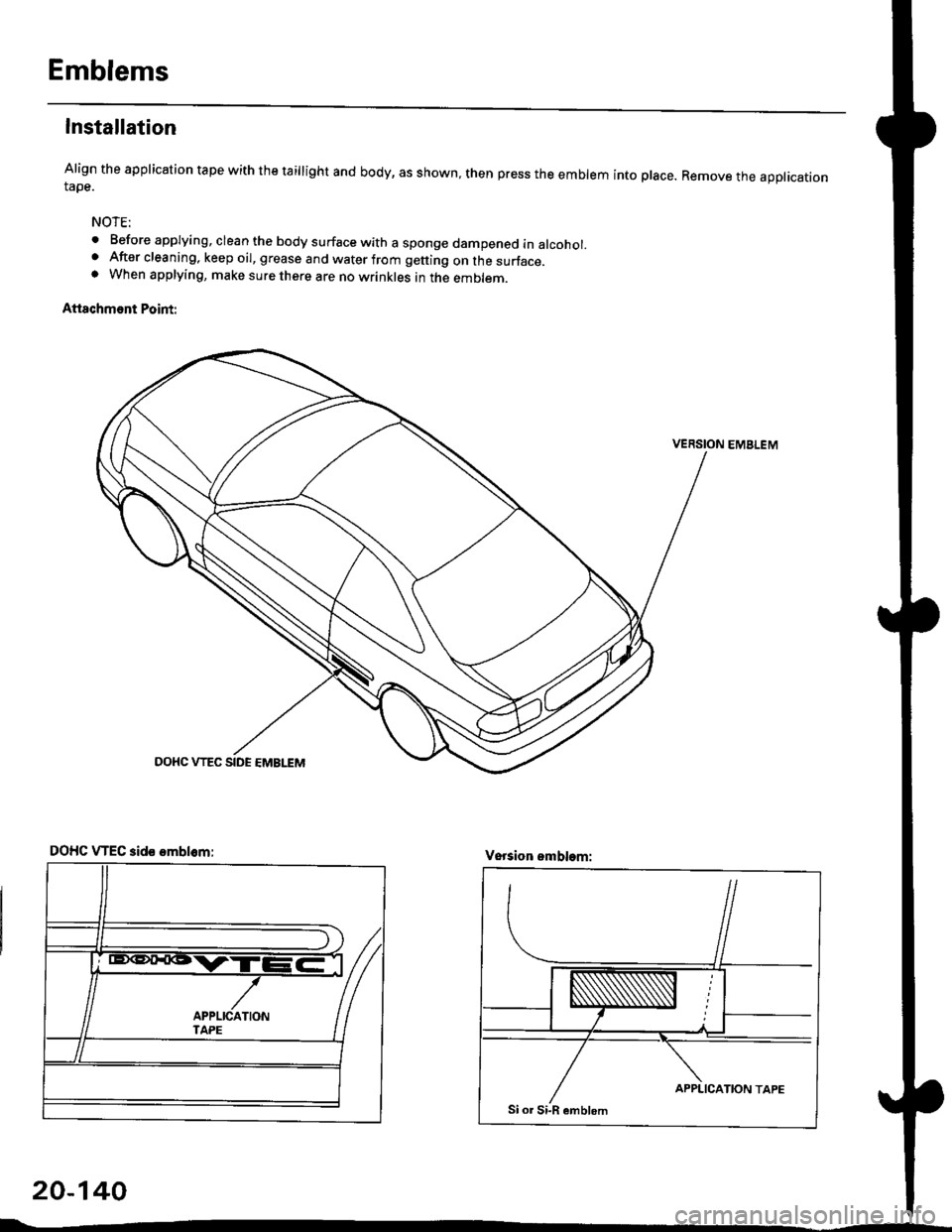

Emblems

Installation

Align the application tape with the taillight and body, as shown, then press the emblem into place. Remove the appticationtape.

NOTE:

o Before applying, clean the body surface with a sponge dampened in alcohol.. After cleaning, keep oil, grease and water from getting on the surface.. When applying, make sure there are no wrinkles in the emblem.

Attschment Point:

VERSION EMBLEM

20-140

DOHC VTEC aid€ omblom:Vsrsion emblem:

Page 1373 of 2189

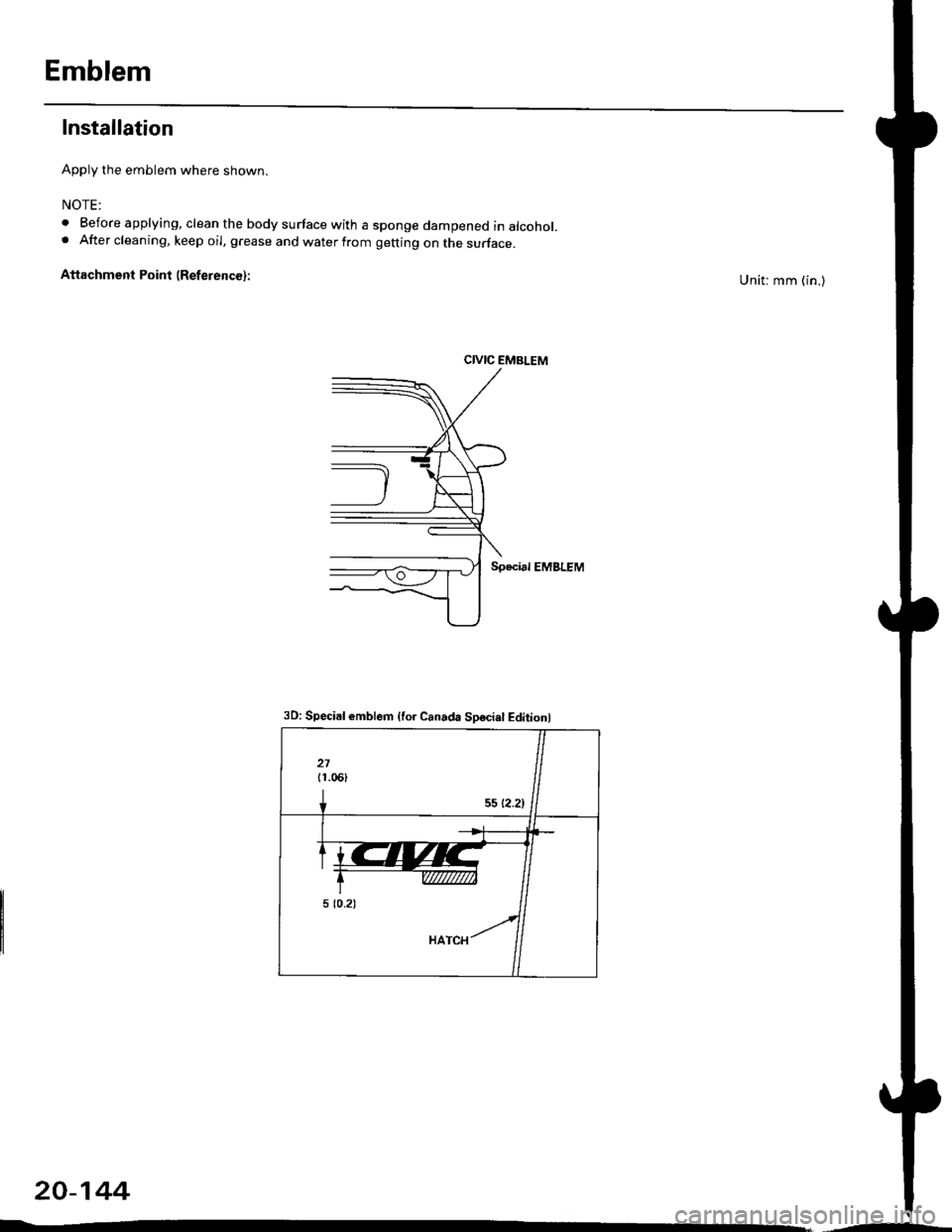

Emblem

Installation

Apply the emblem where shown.

NOTE:

. Before applying, clean the body surface with a sponge dampened in alcohol.. After cleaning, keep oil, grease and water from getting on the surface.

Attachment Point (ReferencG):Unit: mm (in,)

CIVIC EMBLEM

Special EMBLEM

20-144

3D: Special emblem {for Canada Sosciel Editionl

Page 1445 of 2189

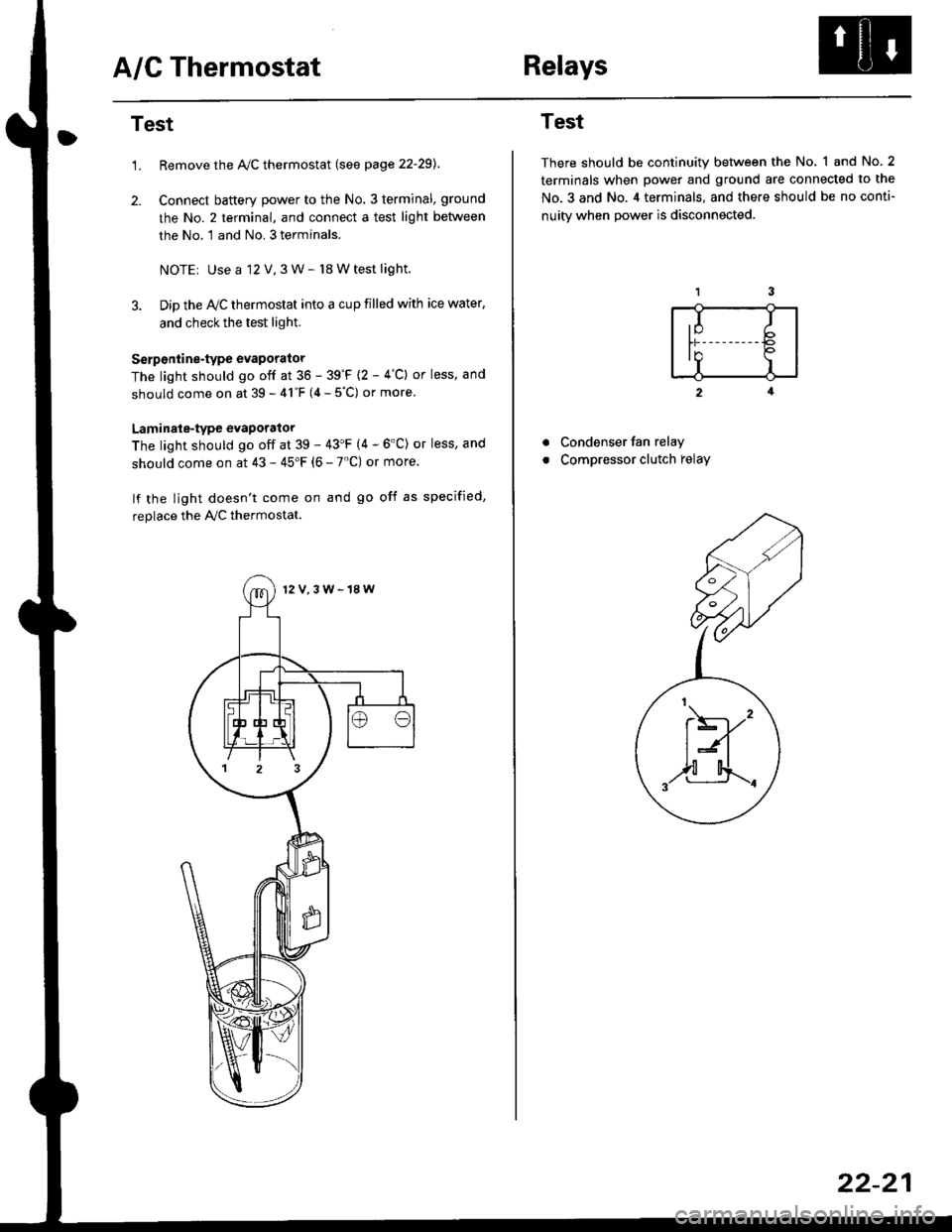

A/C ThermostatRelays

Test

1.Remove the Ay'C thermostat (see page 22-29).

Connect baftery power to the No. 3 terminal, ground

the No. 2 terminal, and connect a test light between

the No. 1 and No. 3 terminals.

NOTEr Use a 12 V,3 W- l8 W test light.

Dip the IVC thermostat into a cup filled with ice water,

and check the test light.

Serp6ntine-type evaporator

The light should go off at 36 - 39'F {2 - 4"C} or less, and

should come on at 39 - 41"F (4 - 5"C) or more

Laminale-type evaporator

The light should go off at 39 - 43'F (4 - 6'C) or less, and

should come on at 43 - 45"F (6 - 7'C) or more

lf the light doesn't come on and go off as specified,

replace the PVC thermostat.

12V,3W-18W

Test

There should be continuity between the No, 1 and No.2

terminals when power and ground are connected to the

No.3 and No. 4 terminals, and there should be no conti-

nuitv when Dower is disconnected.

2

Condenser fan relay

Compressor clutch relay

a

a

,I Ib

In Io'r I

t\----,'

t:n

,,l[4..-.

22-21

Page 1450 of 2189

A/C System Service

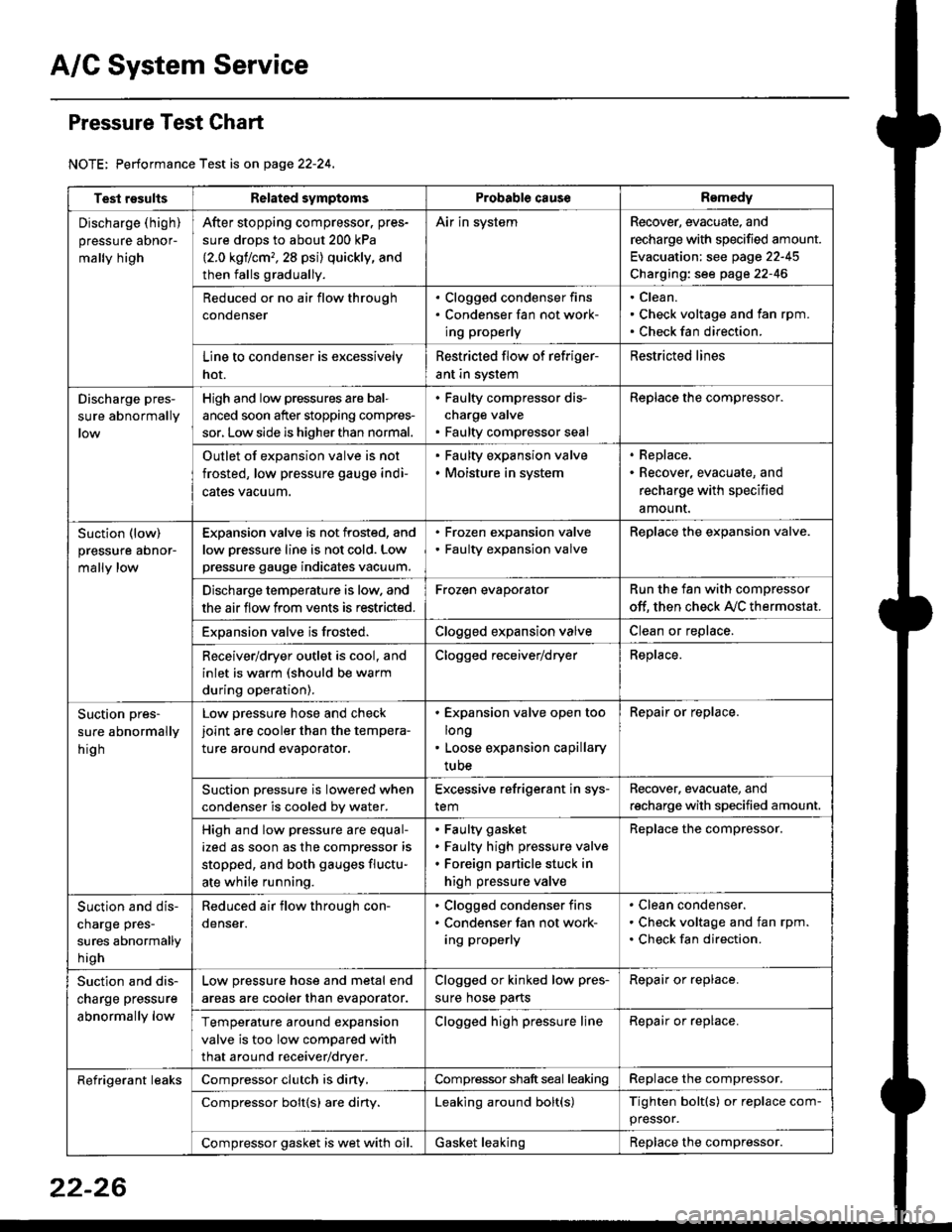

Pressure Test Chart

NOTE: Performance Test is on page 22-24,

Test resultsRelated symptomsProbabl€ causeRemedy

Discharge (high)

pressure aDnor-

mally high

After stopping compressor. pres-

sure drops to about 200 kPa

{2.0 kgflcm,,28 psi) quickly, and

then falls gradually.

Air in systemRecover, evacuate, and

recharge with specified amount.

Evacuation: see page 22-45

Charging: see page 22-46

Reduced or no air flow through

condenser

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean.

Check voltage and fan rpm.

Check fan direction.

Line to condenser is excessively

hot.

Restricted flow of refriger-

ant in system

Restricted lines

Discharge pres-

sure abnormally

High and low pressures are bal-

anced soon after stopping compres-

sor, Low side is higher than normal.

. Faulty compressor dis-

charge valve. Faulty compressor seal

Replace the compressor.

Outlet of expansion valve is not

frosted, low pressure gauge indi-

cales vacuum.

. Faulty expansion valve. Moisture in system

. Replace,. Recover, evacuate, and

recharge with specified

amount.

Suction (low)

pressure abnor-

mally low

Expansion valve is not frosted, and

low oressure line is not cold. Low

pressure gauge indicates vacuum.

. Frozen expansion valve. Faulty expansion valve

ReDlace the exoansion valve.

Discharge temperature is low. and

the air flow from vents is restricted.

Frozen evaporatorRun the fan with compressor

off. then check A,/C thermostat.

Exoansion valve is frosted.Clogged expansion valveClean or replace.

Receiver/dryer outlet is cool, and

inlet is warm (should be warm

during operation).

Clogged receiver/dryerReplace.

Suction pres-

sure abnormally

hig h

Low pressure hose and check

joint are cooler than the tempera-

ture around evaporator.

. Expansion valve open too

long. Loose expansion capillary

tube

Repair or replace.

Suction oressure is lowered when

condenser is cooled bv water.

Excessive refrigerant in sys-

tem

Recover. evacuate, and

recharge with specified amount.

High and low pressure are equal-

ized as soon as the compressor is

stopped, and both gauges fluctu-

ate while running.

Faulty gasket

Faulty high pressure valve

Foreign particle stuck in

high pressure valve

Replace the compressor.

Suction and dis-

charge pres-

sures abnormally

h igh

Reduced air flow through con-

denser.

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean condenser.

Check voltage and fan rpm.

Check fan direction.

Suction and dis-

charge pressure

abnormally low

Low pressure hose and metal end

areas are cooler than evaporator.

Clogged or kinked low pres-

sure hose parts

Repair or replace.

Temperature around expansion

valve is too low compared with

that around receiver/dryer.

Clogged high pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny,Compressor shaft seal leakingReplace the compressor.

Compressor bolt{s) are diny.Leaking around bolt(s)Tighten bolt(s) or replace com-

pressor.

Compressor gasket is wet with oil.Gasket leakingReplace the compressor.

22-26

Page 1473 of 2189

Troubleshooting

ll.

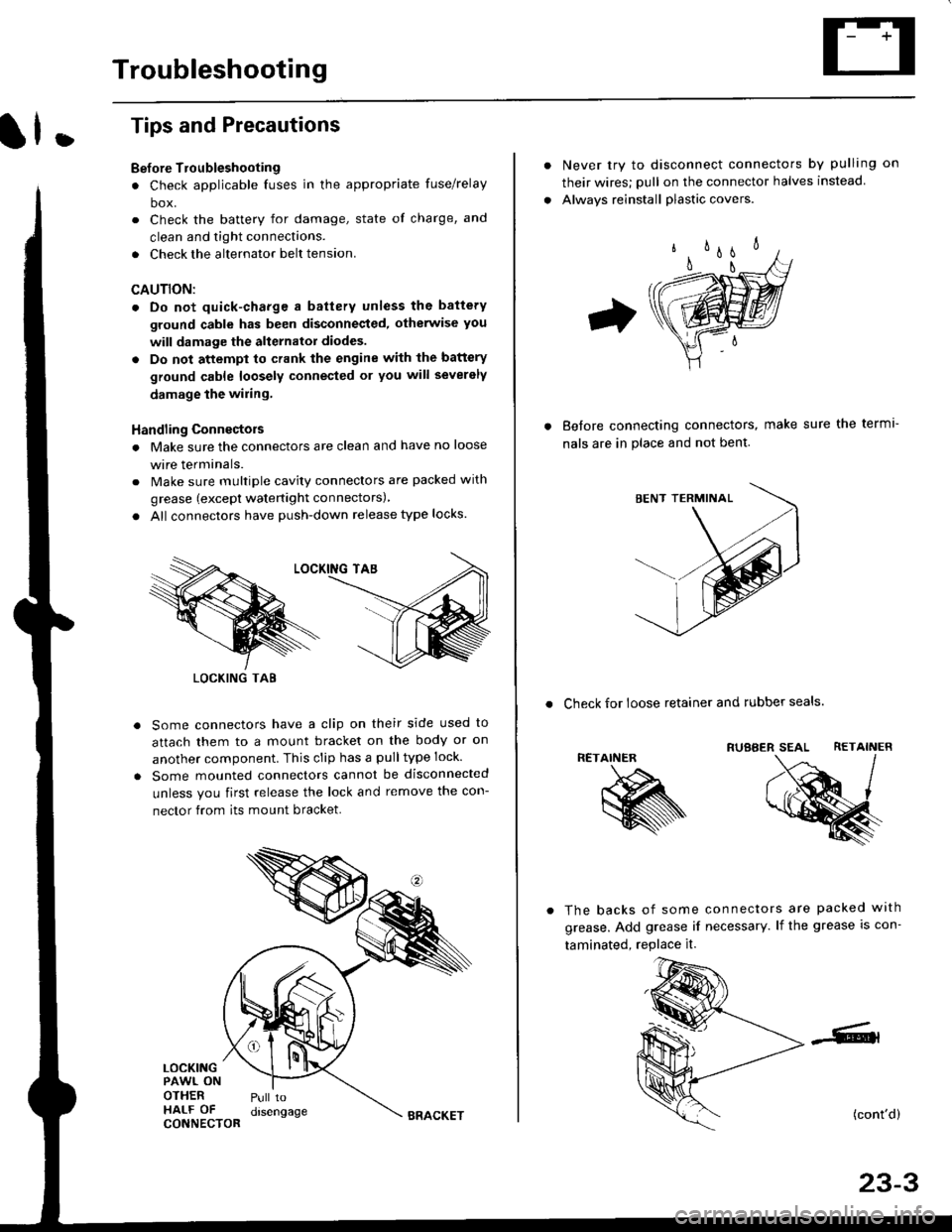

Tips and Precautions

Bef ore Troubleshooting

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconneqted, otherwise you

will damage the alternator diodes.

. Do not attempt to crank the engine with the battery

ground cable loosely connecled or you will severely

damage the wiling,

Handling Connectois

. Make sure the connectors are clean and have no loose

wire terminals.

. Make sure multiple cavity connectors are packed with

grease (except watertight connectors)

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pulltype lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFCONNECTOR

Pull todrsengage

LOCKING TAB

BRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead

Alwavs reinstall plastic covers.

Before connectang connectors,

nals are in place and not bent.

make sure the terml-

. Check for loose retainer and rubber seals.

RETAINER

The backs of some connectors are packed with

grease. Add grease if necessary. lf the grease is con-

taminated, replace it.

(cont'd)

23-3