Connectors HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 37 of 2189

Llo

CANADA model ('00 model)

CAUTIONTO AVOID SERIOUS INJURYT. FOR MAXIMUM SAFETY PROTECTION lN ALL TYPES OF

CRASHES, YOU MUST ALWAYS WEAR YOUR SAFETY

BELT.. DO NOT INSTALL REARWARD-FACING CHILD SEATS lN

ANY FRONI PASSENGER SEAT POSITION.

. DO NOT PLACE ANY OBJECTS OVER THE AIRBAG OR

BETWEEN THE AIRBAG AND YOURSELF.. SEE THE OWNER'S MANUAL FOR FURTHER

INFORMATION AND EXPLANATIONS.

Except Cx tor passenger side

F: ASSISTANT INFoRMATION: US MODEL ('96. '97 mod€l)

AIRBAG SEE OTHER SIDE,

U.S. model l'98 - 00 modell

AIRBAG WARNINGFLIP VISOR OVER

Llo

G: STEERING COLUMN NOTICE

NOTICETO PBEVENT SRS DAMAGE, REMOVE STEERING WHEEL

BEFORE REMOVING STEERING SHAFT CONNECTING

BOLT.

ll: MONITOR CAUTION

NOTICE. NO SERVICEABIf PABTS lNSlDE.. REFER TO SERVICE MANUAL FOR DETAILED INSTRUC'

TtoNs.

DANGEREXPLOSIVE/FLAMMABLECONTACT WITH ACID, WATER OR HEAVY METALS SUCH

AS COPPER, LEAD OR MERCURY MAY PRODUCE HARM.

FUL AND IRRITATING GASES OR EXPLOSIVE COM-

POUNDS, STORAGE TEMPERATURES MUST NOT EXCEED

2OO'F I1OO"C}. FOR PROPER HANOLING, STORAGE AND

DISPOSAL PNOCEDURES REFER TO SERVICE MANUAL'

SRS SUPPLEMENT.POISONCONTAINS POISONOUS SODIUM AZIDE AND POTASSIUM

NITRATE.FIRST AIDIF CONTENTS ARE SWALLOWEO, INDUCE VOMITING. FOR

EYE CONTACT, FLUSH EYES WITH WATEB FOR 15 MIN-

UTES. IF GASES IFROM ACID OB WATER CONTACT) ABE

INHALED. SEEK FRESH AIR. IN EVERY CASE, GET PROMPT

MEDICAL ATTENTION.KEEP OUT OF REACH OF CHILDREN,

WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND, IF ACCIDEN-

TALLY OEPLOYED, CAN SERIOUSLY HUBT OR KILL YOU.

. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES.TH€Y CAN CAUSE ACCIDENTAL DEPLOYMENT'

. NO SERVICEABLE PABTS lNSlDE. oO NoT

DISASSEMBLE.. PLACE AIRBAG UPRIGHT WHEN REMOVED. FOLTOW SERVICE MANUAL INSTRUCTIONS CAREFULLY

I: FRONT SEAT PASSENGER MOOULE DANGER

Jr SRS WARNING IHOOD)

' Exceot CANADA CX

K: PASSENGER AIRBAG CAUTION

u.S. model l'98 - 00 model)

WARNINGCHILDREN CAN 8E KILLED OR INJUREO BY PASSENGER

AIRBAG,THE BACK SEAT IS THE SAFEST PLACE FOR CHILDREN 12

AND UNDER. MAKE SURE ALLCHILDREN USE SEAT BELTS

OR CHILD SEATS.

(cont'd)

1-35

SUPPLEMENTAL RESTRAINT SYSTEM ISRS}

THIS VEHICLE IS EOUIPPED WITH DBIVER AND FRONT

SEAT PASSENGER AIRBAGS'.ALL SRS ELECTRICAL WIRING AND CONNECTORS ABE

COLORED YELLOW.TAMPERING WITH, DISCONNECTING OR USING

ELECTRICAL TEST EOUIPMENT ON THE SRS WIRING CAN

MAKE THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTAL

FIRING OF THE INFLATOR.

WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND, IF ACCIDEN.

TALLY DEPLOYED, CAN SERIOUSLY HURT YOU. FOLLOW

SERVICE MANUAL INSTRUCTIONS CAFEFULLY'

Page 96 of 2189

Engine RemovaUlnstallation

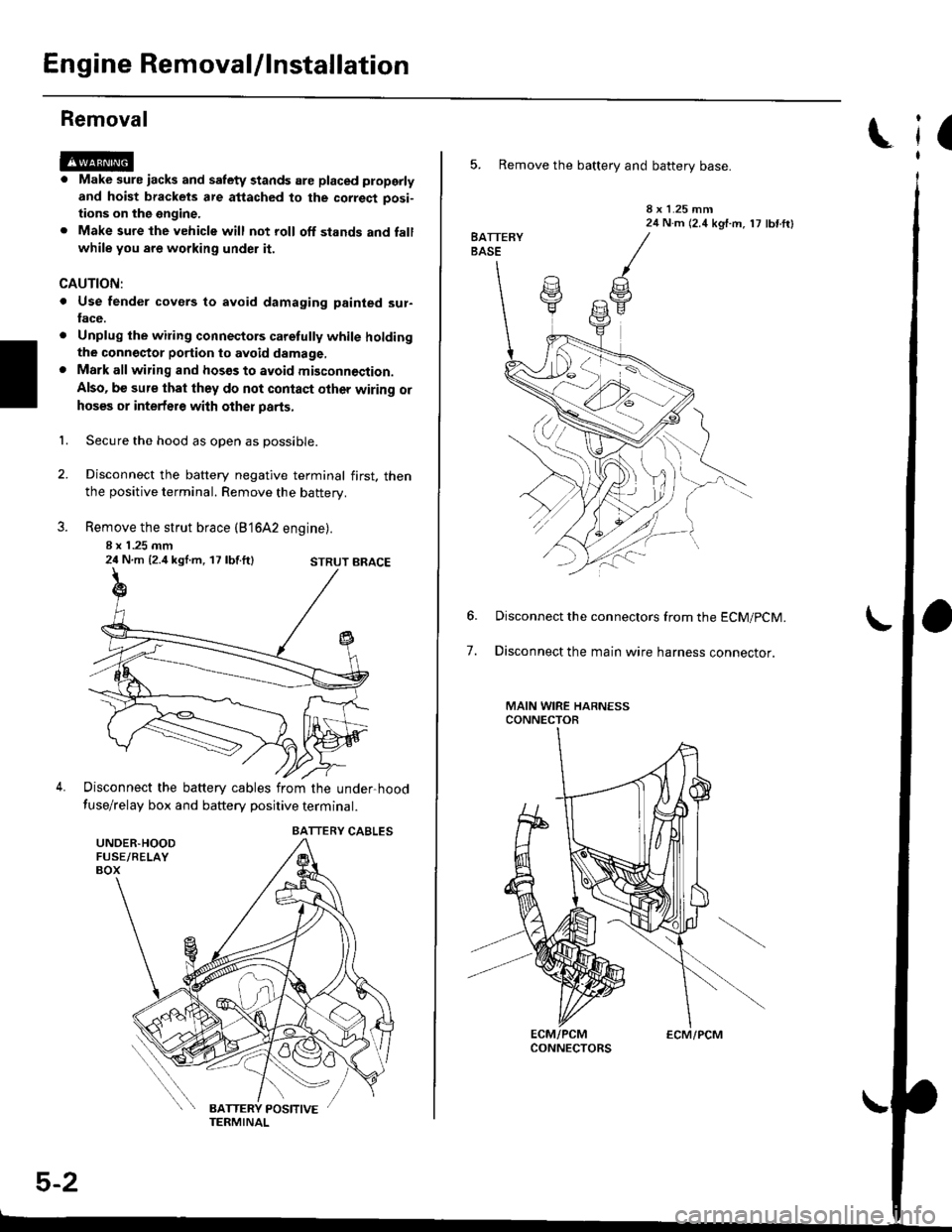

Removal

@@

1.

. Make sure iacks and salety stands are placed ploperly

and hoist brackets are attached to the correct posi-

tions on the engine.

. Make sure the vehicle will not roll off stands and fall

while you are working under it.

CAUTION:

. Use fender covers to avoid damaging painted sur-face.

. Unplug the wilin9 connectors caretully while holdingthe conngstor portion to avoid damage,. Mark all wiring and hosos to avoid misconnoction.

Also, be sure that they do not contact other wiring or

hoses or interfere with other parts,

Secure the hood as open as possible.

Disconnect the battery negative terminal first. thenthe positive terminal. Remove the battery.

Remove the strut brace (B'16A2 engine).

8 x 1 .25 mm24 N.m {2.4 kgl.m, 17 lbf.ft}

Disconnect the battery cables from the under-hood

fuse/relay box and battery positive terminal.

STRUT BRACE

UNDER.HOODFUSE/RELAYBOX

BATTERY CABLES

5-2

ECM/PCM

(

5. Remove the battery and battery base.

8 x 1.25 mm24 N.m (2.4 kgf.m, 17 lbf ftl

7.

Disconnect the connectors from the ECM/pCM.

Disconnect the main wire harness connector.

MAIN WIRE HARNESSCONNECTOR

Page 99 of 2189

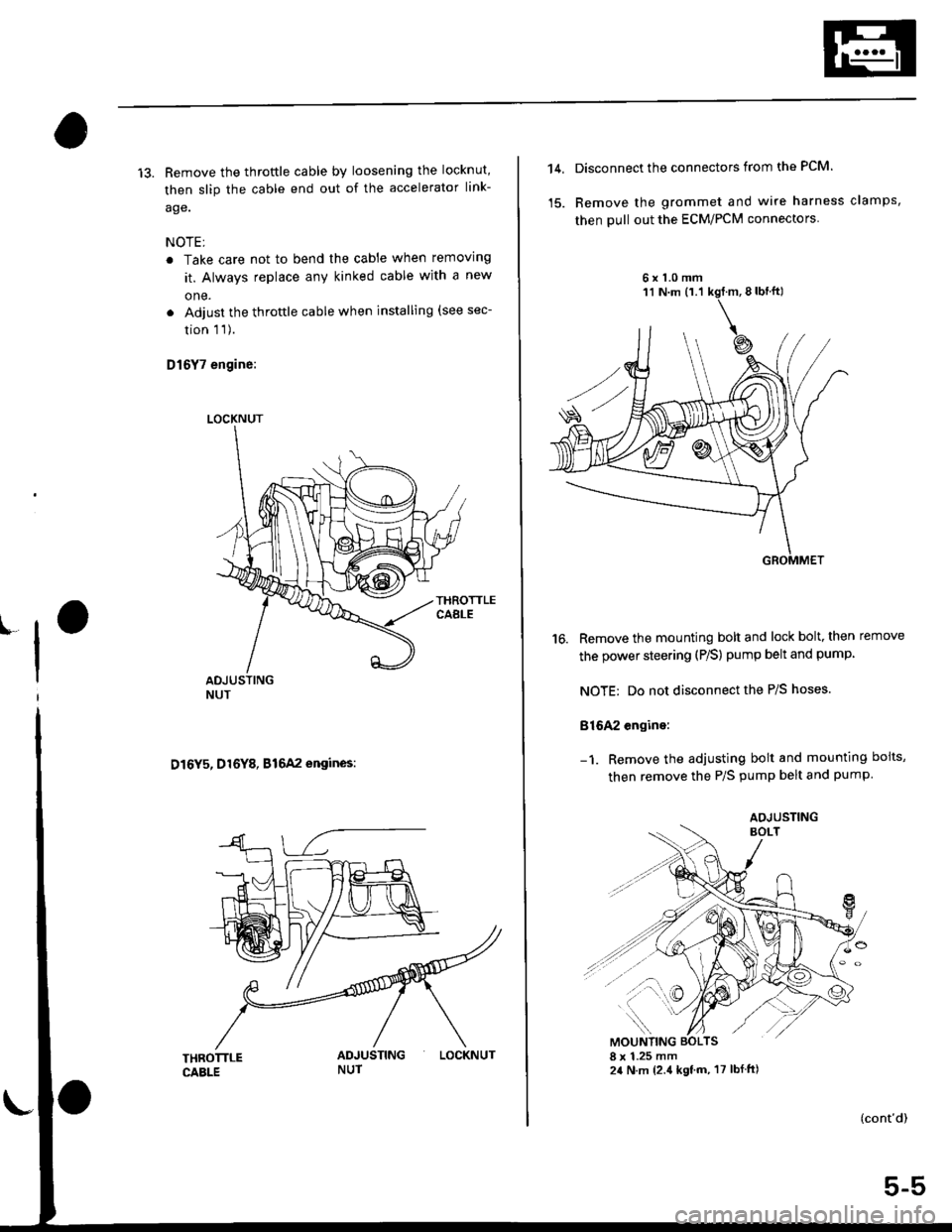

13. Remove the throftle cable by loosening the locknut,

then slip the cable end out of the accelerator link-

age.

NOTE;

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

D16Y5, D16Y8, B16A2 engines:

LOCKNUT

LOCKNUT

14,Disconnect the connectors from the PCM.

Remove the grommet and wire harness clamps,

then pull out the ECM/PCM connectors

6x1.0mm

16. Remove the mounting bolt and lock bolt, then remove

the power steering (P/S) pump belt and pump

NOTE: Do not disconnect the P/S hoses.

816A2 engine:

Remove the adjusting bolt and mounting boits,

then remove the P/S pump belt and pump

(cont'd)

5-5

AOJUSTING

Page 138 of 2189

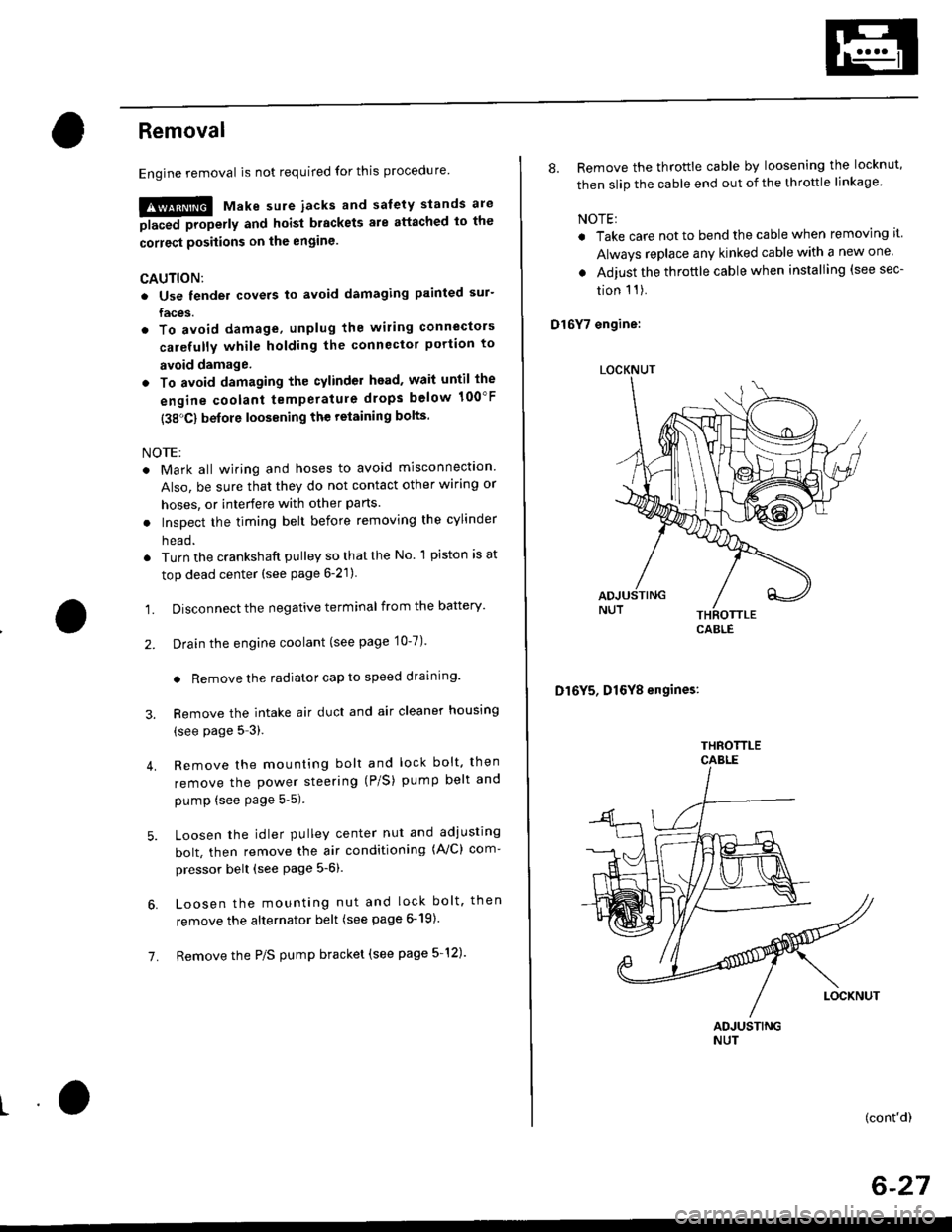

Removal

Engine removal is not required for this procedure

!!!s@ Make sure iacks and salety stands are

f ta"eata"ea propetty and hoist brackets are attached to the

correct positions on the engine.

CAUTION:

. Use tender covels to avoid damaging painted sul-

faces.

o To avoid damage, unplug the wiling connectors

carefully while holding the connector portion to

avoid damage.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F

{38"C} before loossning the tetaining bolts.

NOTE:

o Mark all wiring and hoses to avoid misconnectlon

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

. Inspect the timing belt before removing the cylinder

h ead.

. Turnthe crankshaft pu lley so that the No. lpistonisat

top dead center (see Page 6-21)

'1. Disconnect the negative terminal from the battery'

Drain the engine coolant (see page'10-7).

a Remove the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing

(see page 5 3).

Remove the mounting bolt and lock bolt. then

remove the power steering (P/S) pump belt and

pump (see page 5'5).

Loosen the idler pulley center nut and adjusting

bolt' then remove the air conditioning (A'lc) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt. then

remove the alternator belt (see page 6-19).

Remove the P/S pump bracket (see page 5-12).

3.

4.

2.

6.

1.

8. Remove the throttle cable by loosening the locknut,

then slip the cable end out of the throttle linkage

NOTE:

. Take care not to bend the cable when removing it

Always replace any kinked cable with a new one

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

Dl6Y5, Dl6Y8 engines:

THFOTTLECABLE

(cont'd)

6-27

LOCKNUT

CABLE

Page 140 of 2189

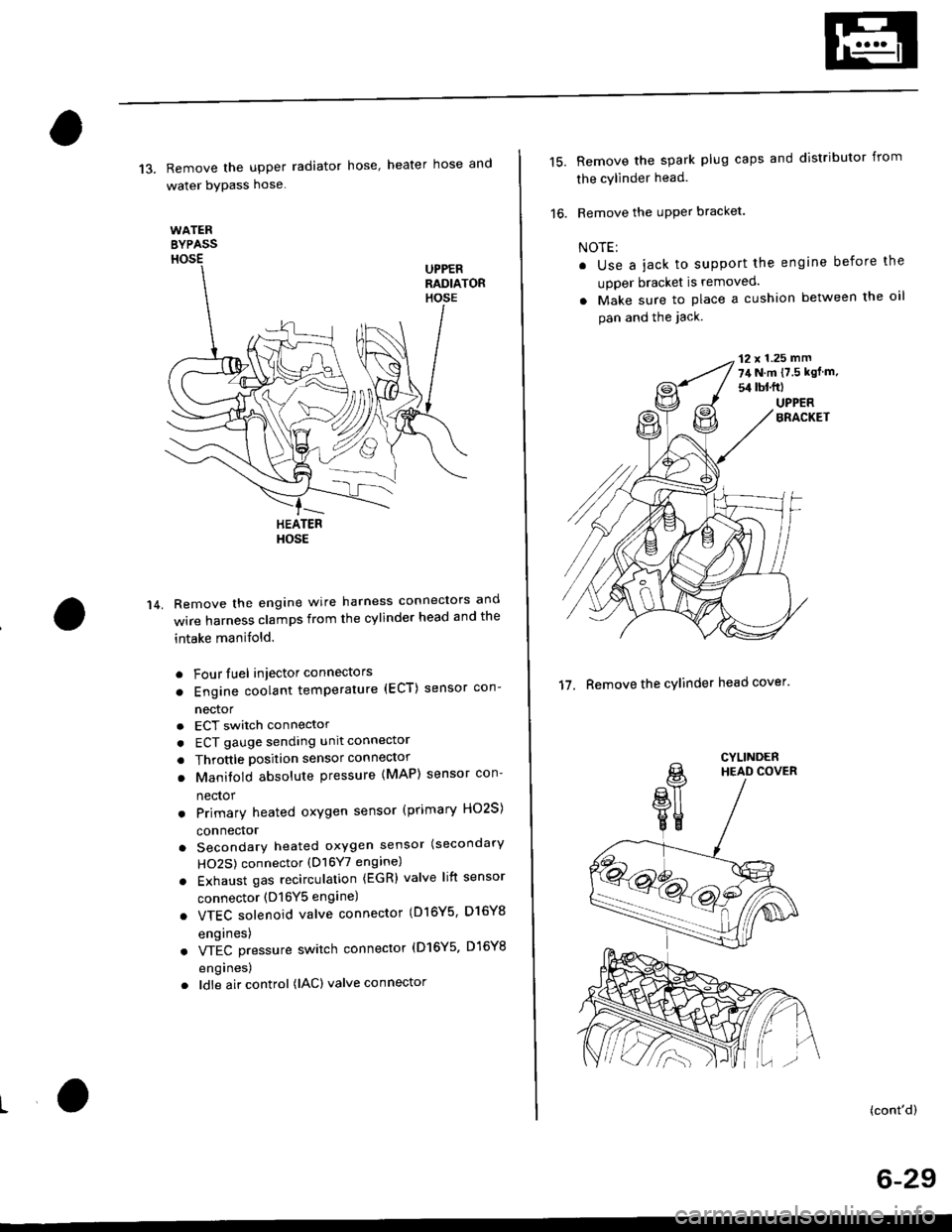

13. Remove the upper radiator hose' heater hose and

water bYPass hose

WATEREYPASSHOSEUPPERRADIATORHOSE

14.

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

nector

a

a

a

ECT switch connector

ECT gauge sending unit connector

Throttle position sensor connector

Manitold absolute pressure (MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

Secondary heated oxygen sensor (secondary

HO2S) connector (D16Y7 engine)

Exhaust gas recirculation (EGR) valve lift sensor

connector (D16Y5 engine)

. VTEC solenoid valve connector (Dl6Y5, D16Y8

engrnes)

. VTEC pressure switch connector (D16Y5. D16Y8

engrnes,

. ldle air control (lAC) valve connector

15.Remove the spark plug caps and distributor from

the cylinder head.

Remove the uPPer bracket.

NOTE:

. Use a jack to support the engine before the

upper bracket is removed.

. Make sure to place a cushion between the oil

pan and the jack.

12 x 1.25 mm

74 N.m {7.5 kgf m.

sil lbl.ftl

UPPERBRACKET

'17. Remove the cylinder head cover'

CYLINDERHEAD COVER

(cont'd)

6-29

Page 158 of 2189

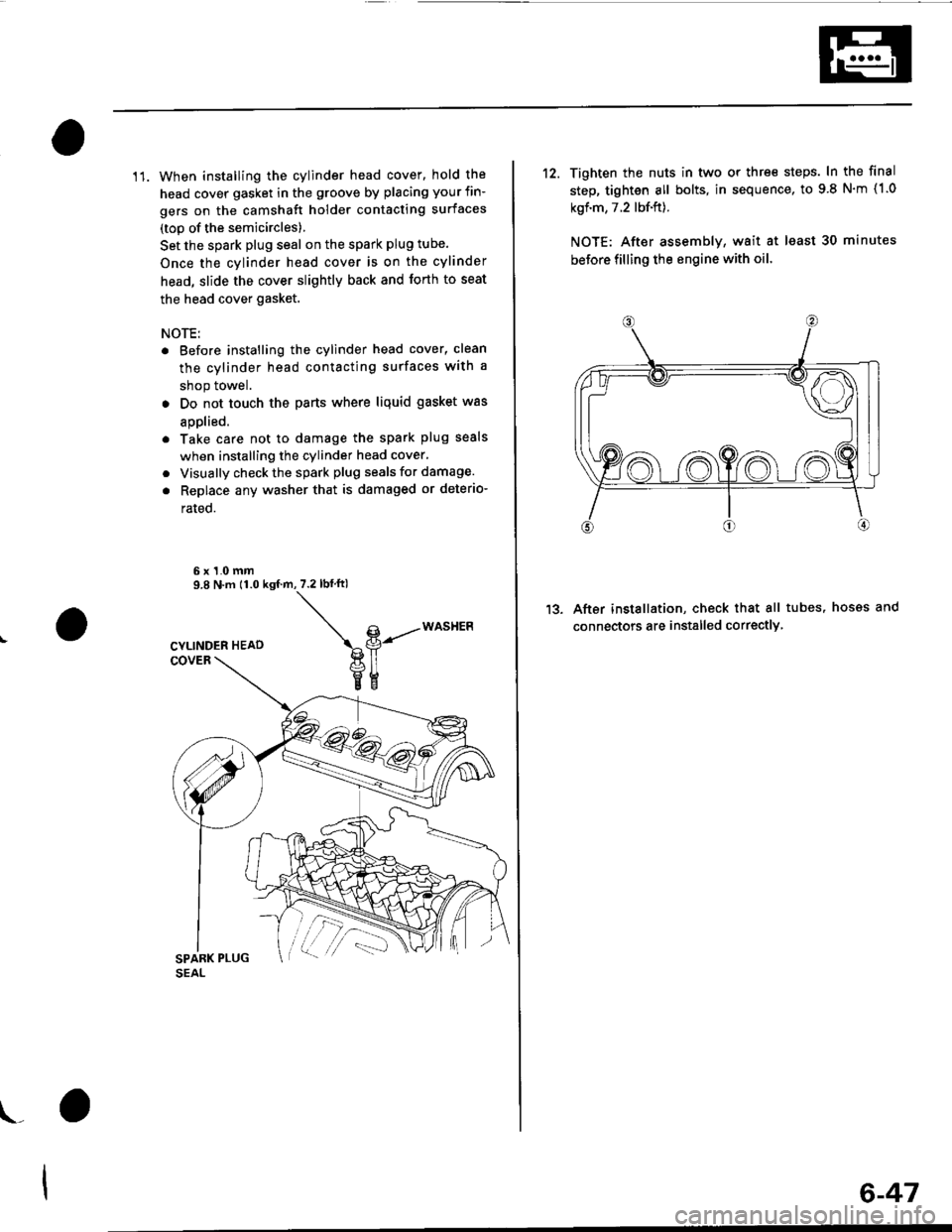

11. When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft holder contacting surfaces

(top of the semicircles)

Set the spark plug seal on the spark plug tube.

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

. Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

. Do not touch the parts where liquid gasket was

aDolied.

. Take care not to damage the spark plug seals

when installing the cylinder head cover,

. Visually check the spark plug seals for damage.

. Replace any washer that is damaged or deterio-

rated.

6x1.0mm9.8 N.m 11.0 ksf.m,7.2lbf ftl

\g-----*o""t'Ptl

veEE

\_

6-47

12. Tighten the nuts in two or thre€ steps. In the final

step, tighten all bolts, in sequence, to 9 8 N'm (1.0

kgf.m, 7.2 lbf.ft).

NOTE: After assemblv, wait at least 30 minutes

before filling the engine with oil

After installation, check that all tubes, hosss and

connectors are installed correctlY

1?

Page 177 of 2189

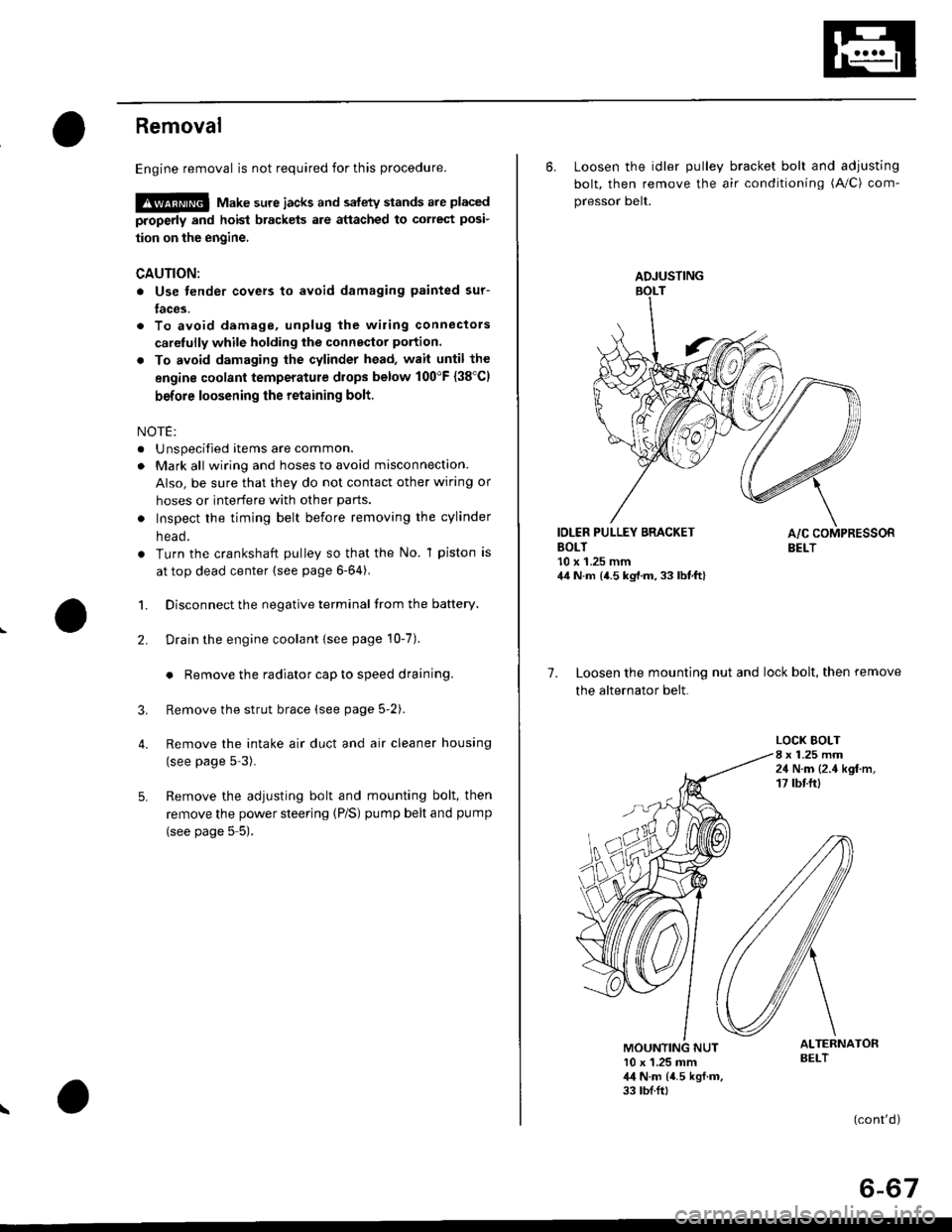

Removal

Engine removal is not required for this procedure.

!@@ Make sure jacks and safety stands are placed

properly and hoist brackels are attached to correst posi-

tion on the engine,

CAUTION:

o Use fender covers to avoid damaging painted sur-

faces.

To avoid damage, unplug the wiling connectors

carelully while holding the connector portion.

To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F {38'Cl

before loosening the retaining bolt.

NOTE:

. Unspecified items are common.

. Mark all wiring and hoses to avoid misconnection.

AIso, be sure that they do not contact other wiring or

hoses or interfere with other parts.

o Inspect the timing belt before removing the cylinder

n eao.

. Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (see page 6-64).

1. Disconnect the negative terminal from the battery.

Drain the engine coolant {see page 10-7).

. Remove the radiator cap to speed draining.

Remove the strut brace (see page 5-2).

Remove the intake air duct and air cleaner housing

(see page 5-3).

Remove the adjusting bolt and mounting bolt, then

remove the power steering (P/S) pump belt and pump

(see page 5 5).

2.

3.

4.

\

ADJUSTING

6. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A/C) com-

pressor belt.

IDLER PULLEY BRACKETBOLT10 x 1.25 mm44 N.m {4.5 kg,l.m, 33 lbt.ft}

7. Loosen the mounting nut and lock bolt, then remove

the alternator belt.

LOCK BOLT8 x 1.25 mm24 N.m {2.4 kgf.m,17 tbtftl

ALTERNATORBELT10 x 1.25 mm,l,l N.m {4.5 kgf.m,33 tbf.ft,

(cont'd)

6-67

Page 179 of 2189

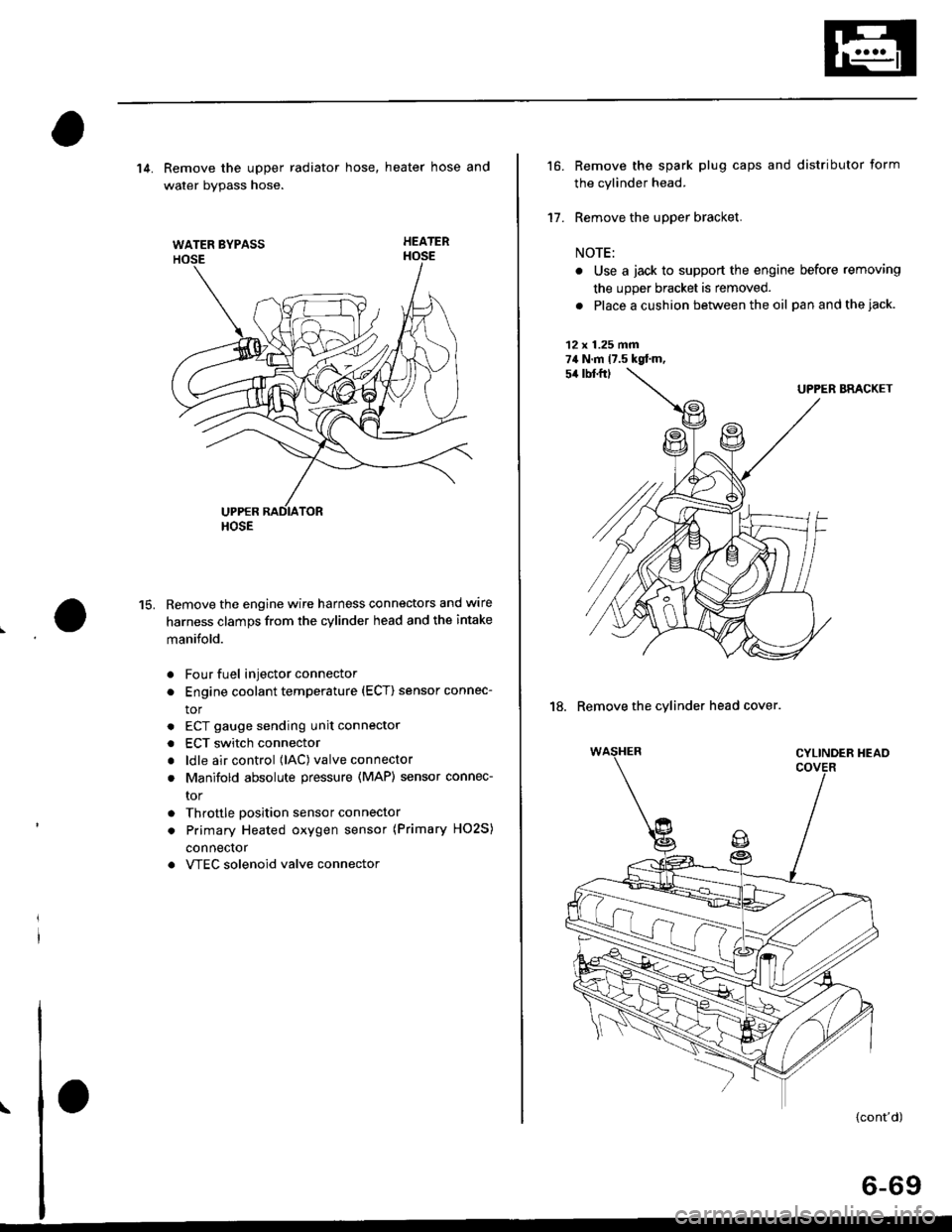

WATER BYPASS

HOSE

14. Remove the upper radiator hose, heater hose and

water bvpass hose.

HEATER

Remove the engine wire harness connectors and wlre

harness clamps from the cylinder head and the intake

manifold.

Four fuel injector connector

Engine coolant temperature (ECT) sensor connec-

tor

ECT gauge sending unit connector

ECT switch connector

ldle air control (lAC) valve connector

Manifold absolute pressure (MAP) sensor connec-

tor

Throttle position sensor connector

Primary Heated oxygen sensor (Primary HO2S)

connecror

VTEC solenoid valve connector

15.

a

a

a

a

a

\

16.

17.

Remove the spark plug caps and distributor form

the cylinder head.

Remove the upper bracket.

NOTE:

. Use a jack to support the engine before removing

the upp€r bracket is removed.

. Place a cushion between the oil panandthejack.

12 x 1.25 fin74 N.m 17.5 kgtm,

UPPER BRACKET

18. Remove the cylinder head cover.

{cont'd)

6-69

Page 270 of 2189

!

Fuel and Emrsslons

SoecialToofs .....,...."..,. 11-2

Component Locations

lndex ....................., ......... 11-3

Svstem Description

Vacuum Connections ................,,..,.. ......... 11-12

Electrical Connections ...............,.,.,... ....... 11-29

System Connectors ........,.,.,.......................... 1 1-51

Troubleshooting

Troubleshooting Procedures ................. .. 11-81

Engine Control Module/PowertrainControl Module TerminalAfiangement ....,.,..... 11-88

Diagnostic Trouble Code Chart .................,., 11.97

How to Read Flowcharts .,.......................... . 11-103

PGM-Fl System

System Description ...... 11-10,1

Troubleshooting Flowcharts

Engine Control Module/PowertrainContlol Module ........ 11-107

Manitold Absolute Pressure Sensor .....'. . ... 11-115

fntake Air Temperatuie Sensor ..... . . ., . 11'121

Engine Coolant Temperatuae Sensol ........., 11-128

Throttle Position Sensor ...................,........... 11-132

Primary Heated Orygen Sensor (Sensor 1l ... 11-139

Secondary Heated Oxygen Sensor(Sensor 21.................................................... 1 1-153

Heated Oxygen Sensor Heater ...................,. 11-157

Fuel Supply System ...... 11-164

Random Mislire ......., ..11-166

Misfire Detected in One Cylindsr ................. 11-167

Knock Sensor .,.,............ 11-170

CKP/TDC/CYP Sensor ................................... 11'172

Vehicle Speed Sensor ...........,......,...,.,........... 1t-176

Barometric Pressure Sensor ...............,......... I 1-178

Electrical Load Detector,.,,............................ 1 1-179

CKF Sensor .................... 11-183

ECM/PCM Internal Circuit ............................. I 1-188

A/T Signal {TMA/TMBI .................................. I 1-189

ldle Control System

System Doscriplion ............ 11-190

Troubleshooting Flowcharts

ldle Control System ...... 11-192

ldle Air Control Va1ve .................................... I 1-19i1

Starter Switch Signal .................................... 1 1'202

Air Conditioning Signal ................................. 11'201

Ahernator FR Signal .................................... . 1 1-208

BrakeSwitch Signal ..................................... f 1"210

Power Sleering Prossure Switch Signal ......11-212

A/T Gear Position Signal ............................... 11-216

Clutch Swiich Signal ................................-.... 11-214

ldte Speed Setting . .............11-220

Fuel Supply System

Fuel Lines .,...................,.,.,.,11-221

Fuef Tube/Ouick-Connect Fittings ..........,.,........ 11 -227

System Description ....'.... 11-230

Fuel Pressure .......,.,,........... 11-230

Fuef fniectors ......................11-232

Fu€f Pressure Regulator .....,.......................'...,. 11-231

Fuef Fifter ............................11-235

Fuel Pump .............'.......'.... 11-236

PGM-FI Main Relay .............11'237

Fuel Tank ................ ....,...'.'.' 11'211

Intake Air System

System Description ....-.-.....11-243

Air Cfeaner ...........,......."". .11-211

Throttle Cable .....................11-211

Throttfe Body ........ ..'... . . .,.11-211

Fuel Iniestion Air Control System ,.,.,....-........... 11-250

Emission Control System

System Description .-..........11-252

Taifpip€ Emission ...............11-252

Three Way Catafytic Convert€r ............,.,,.,.,.,.... 11 -252

Exhaust Gas Racirculaiion System ...,.,,,,.,.,.,.,,. 11'254

Positive Crankcas€ Ventilation System .... . . .. 11-266

Evaoorative Emission Controls ..................,,..,.,. 11 -267

Page 320 of 2189

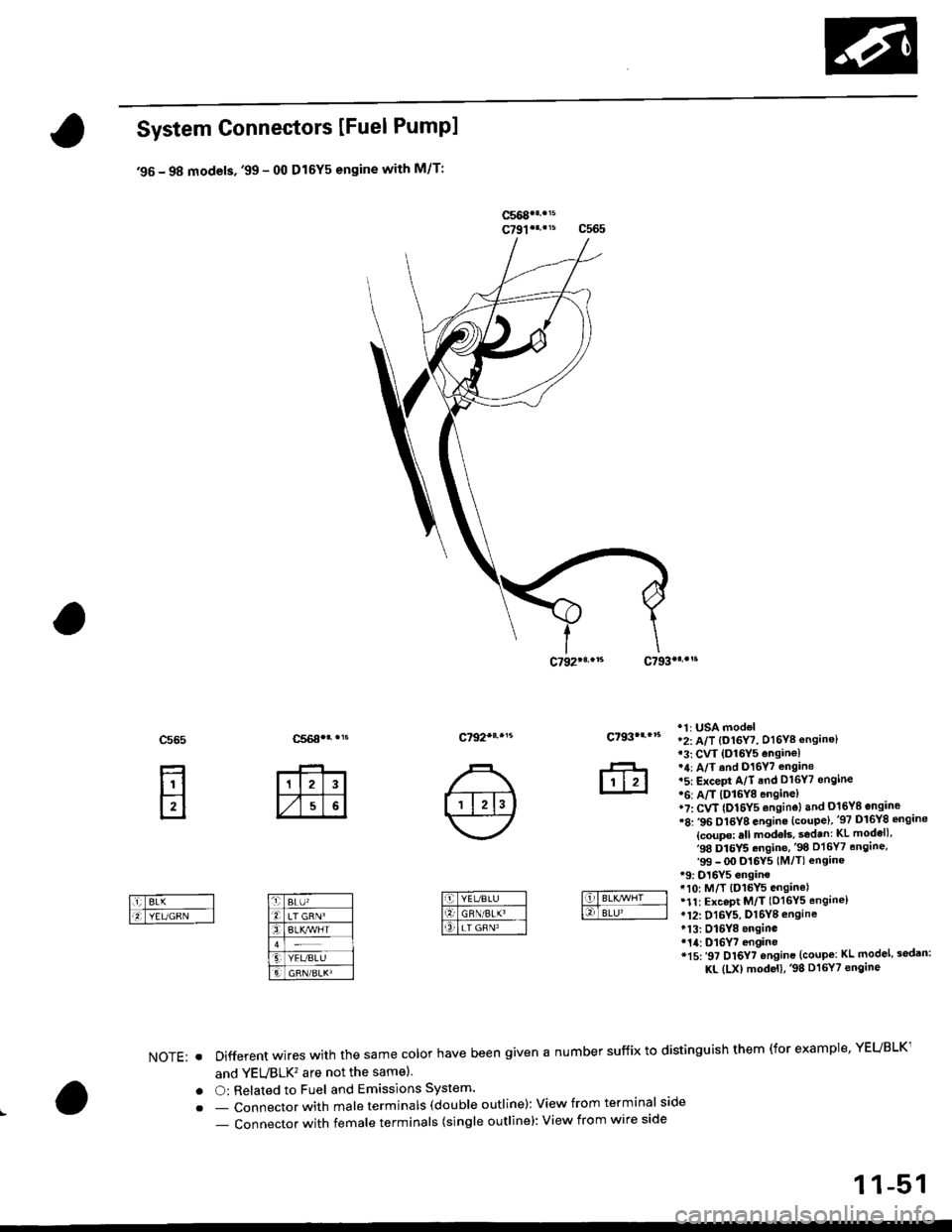

System Connectors [Fuel Pumpl

'95 - 98 models, '99 - 00 Dl6Y5 engine with M/T:

ffi

c565

E

c792*r,.'5c793|.,.s

*1r USA mod€l'2: A/T {O16Y7, D16Y8 ensine}13: CVT {O16Y5 ensin€l*4: A/T ind D16Y7 .ngane*5: ExceFt A/T end D16Y7 engine'6: A/T lDl6Y8 enginel*7: CvT (Dl6Y5 enginoland 016Yg engine'8: ,96 Dl6YB engine {coupe),'97 Dl6Y8 sngine

{coupe: sll models, s€d.nr KL modell,'98 Dl5Y5.ngine,'98 D16Y7 engine,'99 - OO Dl6Y5 (M/Tl enginer9: D16Y5 onginet10: M/T {D15Y5 ensinelr1t: ExceDt M/T (D16Y5 engine)tl2: D16Y5, Dl6Yg engine*13: Dl6Y8 enginer14: D16Y7 engine*15:'97 Dl6Y7 ensine {coupe: KL model, sodan:

KL (LX) modeu,'98 Dt6Y7 engine

NOTE: . Different wires with the same color have been given a number suffix to distinguish them (for example' YEUBLK1

and YEVBLK'� are not the samel.

. O: Related to Fuel and Emissions System'

. - Connector with male terminals (dou ble outline): View f rom term inal side

- Connector with female terminals (single outline): View from wire side

c7931...15

ffi

1 1-51